Page 1

DOMETIC GMBH

TECHNICAL DOCUMENTATION

SERVICE MANUAL

DOMETIC ABSORTIONREFRIGERATOR

for LEISURE VEHICLES –

the new 8 series

SIEGEN

RM 8XXX

TD MBA 2007-10 EN

Page 2

Content

Page

MODELS

OPERATING

COMPONENTS

INSTALLATION

SERVICE + MAINTENANCE

TD S3

TD S21

TD S32

TD S39

TD S46

TD S2

Page 3

MODELS

TD S3

Page 4

MODELS

Description of models

RM(S)(T) 8400 L

RM

Refrigerator Mobile

L = with interior light

0 = manual ignition (battery

igniter)

S = housing with

step

T = TecTower

D = large

L = extra Large

O = single-door

fridge with oven

TD S4

series

4 = width 486 mm

5 = width 525 mm

1 = Automatic ignition

5 = Automatic ignition and

automatic energy selection

0 = Standard Depth

5 = Depth + 55 mm

6 = Depth + 65 mm

Page 5

MODELS

Model Description

RM(S)8xx1 MES 85-122 l

RM(S)8xx5 AES 85-122 l

Width of Housing: 486 mm or 525 mm

Height: 821 mm

Depth: 568mm, 623mm or 633mm

Fridges of the 8-series are only available

with curved door

TD S5

Page 6

MODELS

Model Description

RM(S)8xx0 Battery Igniter 85-122 l

Width of Housing: 486 mm or 525 mm

Height: 821 mm,

Depth: 568 mm, 623 mm or 633 mm

Fridges of the 8-series with manual ignition

are provided with a battery igniter and a

Gas-Operation-Indicator (Galvanometer)

TD S6

Page 7

MODELS

Special Features RM 8xxx

The housing of the fridge RM 8xxx consists of

absolute plastic material (Polystyrene) and is

equipped with carrying handles on the side. Due

to this a decrease of weight of ca. 1.5 kg is

achieved compared to similar models like

RM 7401 or RM 7405.

There is a continuous groove on the outsides

and bottom part. A flexible sealing has to be

fitted into this groove, in order to enable an

TD S7

airtight assembly.

Page 8

MODELS

Special Features RM 8xxx

Building in the fridge,

please note, that the

feet are not screwed

onto the housing

anymore, but are

injected directly onto it.

Thus, when building in

the fridge, it is not

possible anymore to

TD S8

save 8mm height by

taking off the feet.

Page 9

MODELS

Special Features RM 8xxx

The color of the inner liner is not papyrus

white anymore, but white. The shelves

and the vegetable bin are ice-blue.

An innovative shelf system enables

individual usage of the cooling

compartment. The shelves and the bin

are dishwasher-suitable. The vegetable

bin is available with and without lid.

TD S9

The rubber sealing is exchangeable.

Page 10

MODELS

Special Features RM 8xxx

In all single-door RM

8xxx fridges, the

freezing compartment

can be taken out if

needed. This

increases the capacity

as well as the cooling

performance in the

TD S10

cooling compartment.

Page 11

MODELS

Special Features RM 8xxx

RM 8xxx with

removable

freezer

compartment

TD S11

Locking of freezing compartment

Page 12

MODELS

Special Features RM 8xxx

All RM 8xxx fridges have a new door

lock. By pushing the locking button the

door is opened.

Closing the door the locking bar snaps

in and the door is locked. For using the

locking button, the panel is formed

asymmetric (recess on one side). I.e.

changing the door rabbet is not

possible anymore. The rabbet has to

be determined before the fridge is

TD S12

installed.

The product number controls the side

of the door rabbet. Please notify this, if

the door or the fridge is exchanged!

Page 13

MODELS

Special Features RM 8xxx

The locking bar inside the door is fixed with two screws, which are behind a plastic cover. The

gear rods inside the door are not exchangeable. The lock in the fridge is exchangeable. It also

contains the fridge lighting, which was converted into a long-living LED-lighting. The door is

brought into winter position by moving the red hook.

TD S13

Page 14

MODELS

Special Features RM 8xxx

Purchasing an RM 7xxx or

an RM 8xxx, there is the

option of an electrical doorlock. When the fridge door is

closed, it is kept shut by a

magnetic sealing, but not

locked. Starting the engine,

the electronics will

automatically lock the fridge

door, due to the recognition

of the D+ signal. Also with

this kind of door lock,

changing the door rabbet is

TD S14

not possible.

Page 15

MODELS

Special Features RM 8xxx

All RM 8xxx fridges are equipped

with new door hinges made of

metal with a plastic casing

(polystyrene). This hinges are not

screwed onto the housing

anymore, but snap in. Thus it is

not necessary anymore to adjust

the height. Building in the fridge,

please note, that the door hinges

have to be supported. Minimum

TD S15

requirement for the supporting

surface of the lower hinges is the

distance from the housing edge

to the outer edges of the hinges

with 40mm.

Page 16

MODELLE

Special Features RM 8xxx

Changing the decor plate, the door has

not to be demounted anymore. It can be

changed easily:

Loosen the plastic ledge on the locking

side carefully. This ledge is only

snapped in, but not screwed onto the

housing. Then pull out the decor plate

and put in the new one. After this

reattach the plastic ledge.

TD S16

Page 17

MODELS

Special Features RM 8xxx

The operation panel can be loosened with

two screws, when the door is opened. The

electronics at the RM 8xx1 and RM 8xx5 is

screwed into the panel from the inside.

If the fridge is demounted, the operation

panel including the holding device can be

loosened very easily. It is only attached to

TD S17

the housing.

Page 18

MODELS

Special Features RM 8xxx

If the fridge is equipped with a battery igniter, as with the 7xxx – generation, a V85 Gas /

electro fitting and the known energy-selection switch are used. Also, the RM 8xxx fridges are

equipped with a galvanometer, which indicates if the flame is burning. At all single-door fridges

of the 8-series, the main connecting block is positioned on the top of the housing. The

electronics is screwed into the panel.

TD S18

Page 19

MODELS

Special Features RM 8xxx

On the backside of the 8-series

fridges the same components

are used as with the 7xxxGeneration. Cooling unit, gas

valve GV 100, burner control

device P810, burner and

heating elements are identical.

The cooling unit and the

TD S19

components are screwed onto

a metal sheet plate, which is

fixed onto the back side of the

plastic housing.

Page 20

MODELS

Special Features RM 8xxx

The electronics were

completely renewed.

MES AES

Electronics Electronics

Optical differentiation:

a “BEEPER“

Instead of using a

semiconductor, as with

AES III or MES, the new

generation uses a

microprocessor. The AESmodels are equipped with

a 7-segment-display. If an

error occurs, there is an

acoustic signal. There is

no acoustic signal for the

MES-models. All optical

indications are shown with

LED.

TD S20

Page 21

OPERATION

TD S21

Page 22

OPERATION

Interior light

If the door is left opened, the lighting switches off automatically after 2 minutes.

Dimming function of the indications on the operation panel

10 seconds after the button has been pushed for the last time, the indication (LED) switches

into the dim-mode. The dim-mode is reversed by pushing a button. The desired function is

activated by pushing the button again.

TD S22

Page 23

OPERATION

1 2 3 4

Mode on/off

MES

5 6 7

Description of the Display:

1. Pushing the button ON/OFF and modeselection-button longer than 2 seconds

= ON/OFF

Pushing the button <2 Seconds =

Selection next Mode (120V, 12V, GAS,

Auto)

2. LED Fault indication

3. LED Mode-Indication

120 V

12 V

GAS

Temp door

4. 5-step LED-Indication for inner temperature

selection (5 LEDs = max. Setting)

5. LED-Indication for „Door locked“ (only for

electrical lock)

6. Button for temperature selection

7. Button for unlocking the door while driving

(only for electrical lock)

TD S23

Page 24

OPERATION

120V-Operation mode (AC-Mode)

The 120V-operation mode is selected by pushing the button 1 (see TD S23). The button has

to be pushed several times, until the LED next to the Symbol of the power plug lights up.

Detection of undervoltage while operating with 120V

The controlling electronics is equipped with a detection of undervoltage.

Conditions:

- limit value: 103 V AC (min. 101

- The 120V-Relais switches off after

- Switches back from undervoltage mode to normal mode after ca. 20 seconds

- Undervoltage

TD S24

V, max. 105V)

ca. 5 seconds “observation”

fault indication by flashing of display 2 +

3 (see TD

S23)

Page 25

OPERATION

12V-operation mode (DC-Mode)

The 12V-operation mode is selected by pushing the button 1 (see TD S23). The button has

to be pushed several times, until the LED next to the Symbol of the battery lights up

Detection of undervoltage while operating with 12V

The controlling electronics is equipped with a detection of undervoltage.

Conditions:

- Limit value: 10.5 V AC (min. 10.2 V, max. 10.8 V)

- The 12V-Relais switches of after ca 10 minutes „observation“

- Switches back from undervoltage mode to normal mode after ca. 25 minutes

- Undervoltage fault indication by flashing of Display 2 + 3 (see TD S23)

.

TD S25

Page 26

OPERATION

Gas-operation mode

The 12V-operation mode is selected by pushing the button 1 (see TD S23). The button has

to be pushed several times, until the LED next to the Symbol of the Gas lights up or the

(AES-) display indicates GAS.

Ignition while operating with gas.

The controlling electronics initiates max. 3 ignition attempts in the following cycle:

25 sec. ignition, if not ok, 2 min. ventilation break

25 sec. ignition, if not ok, 2 min. ventilation break

25 sec. Ignition, if not ok, FAULT INDICATION by flashing of the fault-LED and the

gas operation LED (see TD S23).

TD S26

Page 27

OPERATION

1 2 3 4

Mode ON/OFF

AES

5

Description of the Display:

1. Pushing the button ON/OFF and Mode-selection-button

longer than 2 seconds = ON/OFF

Pushing the button <2 Seconds = Selection next mode

(120V, 12V, GAS, Auto)

2. LED Fault indication

3. Segment Mode-Indication:

GAS = Gas mode

12 = 12 V DC Mode

120=120 V AC Mode

Selecting the automatic mode, the display shows

AU alternating Gas, 12 or 120 (AU = automatic mode)

Temp door

6 7

4. 5-step LED-Indication for inner temperature

selection (5 LEDs =max. Setting)

5. LED-Indication for „Door locked“ (only for

electrical lock)

6. Button for temperature selection

7. Button for unlocking the door while driving

(only for electrical lock)

TD S27

Page 28

OPERATION

120V-operation mode (manual)

The 12V-operation mode is selected by pushing the button 1 (see TD S27). The button has

to be pushed several times, until the 7-segment-display indicates 120.

Detection of undervoltage while operating with 120V

The controlling electronics is equipped with a detection of undervoltage.

Conditions:

- Limit value: 103 V AC (min. 101 V, max. 105 V)

-120V-Relais switches off after ca. 5 seconds “observation”

- Switches back from undervoltage mode to normal mode after ca. 20 seconds

- Undervoltage fault indication by flashing of display 2 + 3 and acoustic signal (see TD S27).

TD S28

Page 29

OPERATION

12V- operation mode (manual)

The 12V-operation mode is selected by pushing the button 1 (see TD S27). The button has

to be pushed several times, until the 7-segment-display indicates 12V. D+ or S+ is not taken

into account in the manual mode.

Detection of undervoltage while operating with 12V

The controlling electronics is equipped with a detection of undervoltage.

Conditions:

- Limit value: 10.5 V AC (min. 10.2 V, max. 10.8 V)

- 12V-Relais switches off after ca. 10 minutes „observation“

- Switches back from undervoltage mode to normal mode after ca. 25 minutes

- undervoltage fault indication by flashing of display 2 + 3 and acoustic signal (see TD S27).

TD S29

Page 30

OPERATION

Gas-operation mode (manual)

The gas operation mode is selected by pushing the button 1 (see TD S27). The button has

to be pushed several times, until the 7-Segment display indicates GAS.

Ignition while operating with gas

The controlling electronics initiates max. 3 ignition attempts in the following cycle:

25 sec. ignition, if not ok, 2 min. ventilation break,

25 sec. ignition, if not ok, 2 min. ventilation break,

25 sec. ignition, if not ok, FAULT INDICATION by flashing of the Fault-LED and the

7-segment-display (see TD S27).

TD S30

Page 31

OPERATION

Automatic Mode

The automatic mode is selected by pushing the button 1 (see TD S27). The button has to be

pushed several times, until the 7-segment display indicates AU. The display switches from

AU to the current energy mode every 10 seconds.

-Priority

12V-Solar 120V 12V (D+) Gas

- Refueling stop of 15 minutes while operating in Auto-12V-Mode (i.e. the electronics system

switches into gas mode only after 15 minutes). During this time the appliances is in

- Recognition of undervoltage as in 120V-mode (also active while D + signal is available)

TD S31

stand-by-operation mode and only the AU-LED lights up.

Page 32

COMPONENTS

TD S32

Page 33

COMPONENTS

Electronics POWER MODULE MES Contacts

X 105 X 114 X 108 X 110 X 111 X 109 X 102 X 101

X105 = 12 V Supply / - Wiring Recognition of heating element

X114 = Reed switch or alt. electr. lock

Fuse 1A

(250V)

Fuse for

burner

control

device

Connection

to Display

X108 = Temperature sensor (NTC)

X110 = Connection burner control device (+/-, failure)

X111 = alt. 2. electr. Lock or reed switch

X109 = Lighting

J4/J5 = Frame heating

J1 = +12 V IN for heating element

J2 = +12 V Heating element

X102 = Heating element mains power

X101 = mains power inlet

J1/ J2J4 / J5

TD S33

Page 34

COMPONENTS

Electronics POWER MODULE AES Contacts

X 105 X 114 X 108 X 110 X 111 X 109X 106

Fuse 1A

(250V)

X105 = 12 V Supply / - Wiring

Recognition of heating element

X114 = Reed switch or alt. electr. lock

X108 = Temperature sensor (NTC)

X110 = Connection to burner control device (+/-, failure)

X111 = alt. 2. electr. Locks or reed switch

RF Module for RMCD

remote control

Connection to

Display

X106 = D+/Solar

X109 = Interior light

J4/J5 = Frame heating

J1 = +12 V IN for heating element

J2 = +12 V Heating element

X102 = Heating element mains power

X101 = Mains power inlet

J4 / J5 J1/ J2

X 102 X 101

Beeper

TD S34

Page 35

COMPONENTS

Burner Control Device P810

includes

Igniter ( 20-30 sec.)

Flame control and

Flame failure device

Gas valve control

(stops ignition and gas input in

case of gas fault)

Power supply : approx. 1.3V

TD S35

Page 36

COMPONENTS

Gas (Safety)-Valve GV100

includes

2 serial mounted gas valves

Power supply: approx. 1.3V - 1.5V per

valve (if switched on approx. 0,7V -09V)

TD S36

Page 37

COMPONENTS

Gas Burner Device

Already installed

Igniting electrode (1)

Ionization electrode (2)

and ground contact (3) on

burner chassis

2

3

1

TD S37

Page 38

COMPONENTS

Temperature sensor (NTC)

Installed at lower reevaporator

All operation modes (DC/AC/GAS)

are controlled thermostatically.

TD S38

Page 39

INSTALLATION

TD S39

Page 40

INSTALLATIONINSTALLATION

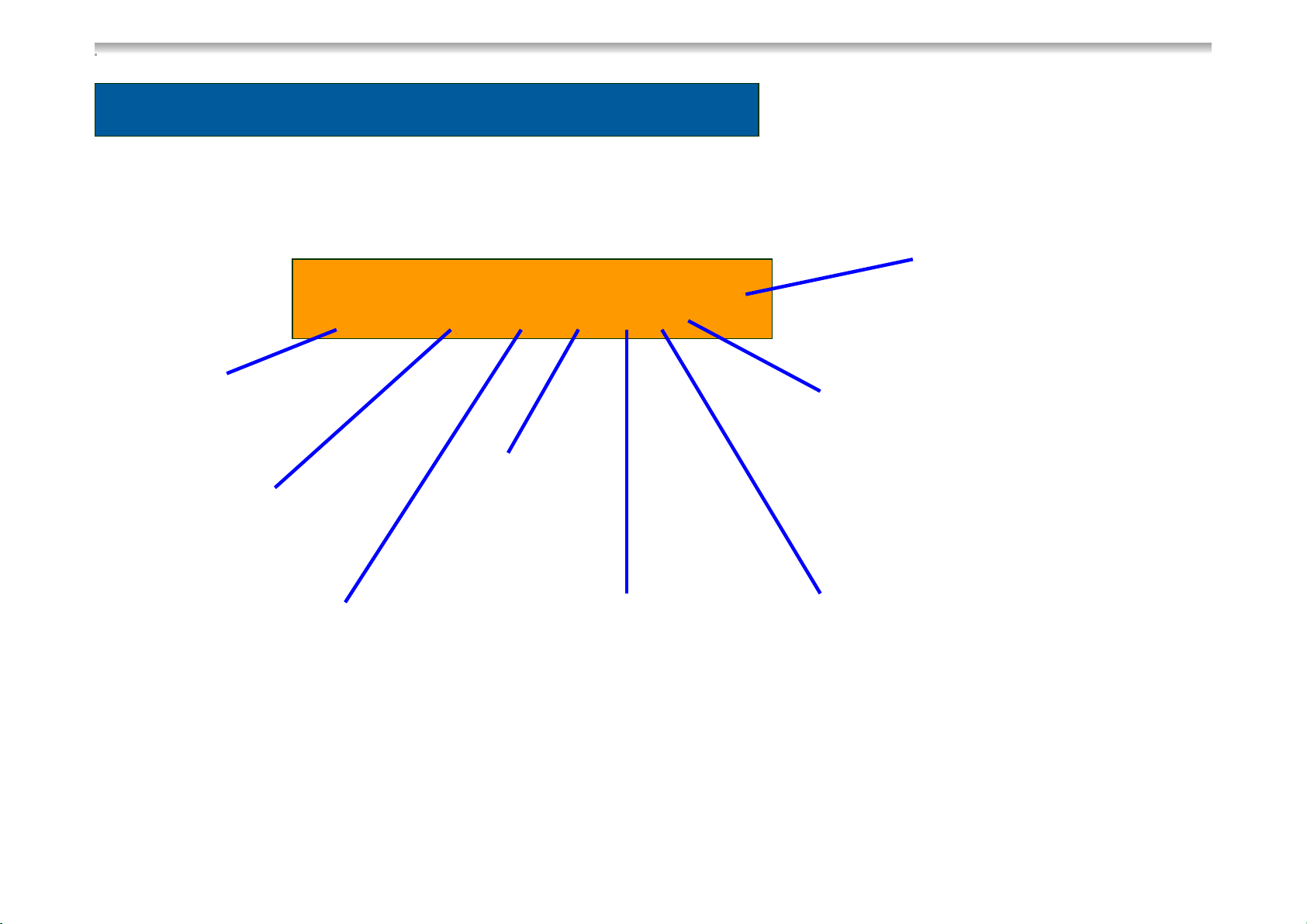

Scheme of connecting points

120V-wire – connection

to electronics

Connection power supply 12VDC

D+ and S+ Signal

12VDC Power supply

Heating element

Gas supply

TD S40

Page 41

INSTALLATION

Electrical Installation

First of all, please note the INSTALLATION INSTRUCTIONS.

Some important points:

Power line connection

protection with a 2A fuse

Battery connection

protection with a 16A fuse

The electric circuit of the 12V-heating element has to be switched via an appropriate relay,

so the heating element is not supplied anymore, after the engine has been turned off.

The electronics has to be permanently attached to 12V, which is not interrupted, turning off

the engine.

TD S41

Page 42

INSTALLATIONINSTALLATION

Electrical Installation

Terminal block AES-Model

1 black: - cable

12V-permantent connection for electronics

2 violet: + cable

12V-permanent connection for electronics

3 bl: D+ cable to contact X106 on the

electronics

4 wt: S+ cable to contact X106 on the

electronics

123456

5 white: -cable for 12V heating element

6 red: + cable for 12V heating element via starter

lock and 16A fuse

At the terminal strip of the MES-models, the terminals

3 + 4 are not used.

TD S42

Page 43

INSTALLATIONINSTALLATION

Electrical Installation

TD S43

Page 44

INSTALLATIONINSTALLATION

Electrical Installation

TD S44

Page 45

INSTALLATION

Gas installation

First of all, please note the information of the INSTALLATION INSTRUCTIONS.

2

The gas connection to the appliance has to be done with a

cutting ring connection L8, DIN 2353-ST acc. to EN 1949

(e.g.. Ermeto).

Burner control device (1)

Gas valve (2)

1

Gas connection (3)

TD S45

AB

3

4

Gas tube to the burner (4)

A (max. torque 10Nm ) and B (max. torque 20 Nm) are

preinstalled pipes

Page 46

SERVICE + MAINTENANCE

TD S46

Page 47

INSTALLATIONSERVICE + MAINTENANCE

Some information

Gas Valve GV100

Masse

This component includes two serial mounted gas

valves (as part of flame failure device).

Power supply : approx. 1.3V - 1.5V per valve

Power supply : approx. 0,7V - 0,9V per valve

(switched on gas mode)

Inductive resistance : per valve ca. 28,5 Ohm

Measuring points: Voltage and Resistance

Valve 1 : Pin 1 - Ground (Housing)

Valve 2 : Pin 2 - Ground (Housing)

1

2

TD S47

Page 48

INSTALLATIONSERVICE + MAINTENANCE

Some information

Burner Control Device P810

Power Supply: ca. 1.3V

Measuring points: Flat plug connection

between Pin 2 and Pin 3.

1

2

Cable to Ignition plug : 1

Cable to ionization plug : 2

Exchanging the cables is not possible, as they have different dimensions.

TD S48

Page 49

INSTALLATIONSERVICE + MAINTENANCE

Some information

Temperature Sensor (NTC)

Table of resistance

°

Temperature

0/32 27.7

5/41 22.29

10/50 18.07

15/59 14.74

20/68 12.11

25/77 10.00

C/F Resistance kOhm

Measuring Point: Electronics

loosen contact X108

Cable white / brown

When the sensor is defect, the fridge will operate permanently.

TD S49

Page 50

INSTALLATIONSERVICE + MAINTENANCE

Some information

Interior light and door lock

The Interior light and the door lock are

unit, which is exchanged completely in

case of a defect.

The transparent cover is not included,

but a separate part.

After removing the cover, the lighting

housing can be dismantled.

TD S50

Page 51

INSTALLATIONSERVICE + MAINTENANCE

Some information

Cleaning of burner

The burner and the chimney must be

cleaned regularly, at least one time a

year.

If auto gas is used, Dometic

recommends a maintenance every half

year, as the contamination risk of the

burner is higher, due to the burning of

the auto gas.

TD S51

Page 52

SERVICE + MAINTENANCE

Service Mode AES

The Service Mode is activated by keeping pressed down the temperature button

and switching on the main button.

After this the 7-Segment-Display shows „1“. By pushing the temperature button,

the different test-steps can be activated:

1 = activates 120 V heating element (120V must be available)

2 = activates 120V relay (120V has not to be necessarily available)

3 = activates 12 V heating element (D+ and 12V supply has to be available)

4 = Intern test step (is not indicated)

5 = activates burner control device – output (Gas operation)

6 = activates frame heating

7 = activates interior lights (Except for electrical lock)

TD S52

52

Page 53

SERVICE + MAINTENANCE

Service Mode AES

8 = Intern test step (is not indicated)

9 = Recognizing electrical lock or reed switch

10 = activates all 7 segment-components one after the other

11 = activates all LED´s

Exiting the diagnosis mode: Push „mode“ button or wait for 10 minutes.

TD S53

53

Page 54

SERVICE + MAINTENANCE

Controlling the interior light via reed switch

The AES-Electronics uses the X114 and X111 as well for controlling the reed

switch as well as the electrical lock.

The electronics will recognize the application of a reed switch, following the

below steps:

1. Choose step 9 in the service mode

2. Open the door

3. Close the door (reed switch will be recognized)

4. Continue service mode (push button 6)

The interior light will now be controlled via the reed switch.

Basically the electronics are defined with “recognizing Reed switch”.

TD S54

54

Page 55

SERVICE + MAINTENANCE

Electrical door lock

Optionally, 2 electrical door locks can be controlled.

They are connected to X111 and X114 (it does not matter in which order; X111 and X114 are

equivalent)

In the service mode the electronics will recognize the locks, following the below steps:

1. Open the door(s)

2. Choose step 9 in the service mode

3. Close door(s) (Door locks will be recognized)

4. Activate D+

5. Continue Service mode (push button 6)

The locked door is indicated with LED 5 and can be unlocked by pushing the button 7.

If you have 2 electrical door locks, LED 5 will flash, if one lock is not locked.

TD S55

55

Page 56

SERVICE + MAINTENANCE

AESFailureNo.

No 120V, respective under 195V (AC Mode)1

No 12V, respective under 10,5V (DC Mode)2

Ignition without success (Gas Mode)3

NTC sensor defect4

120V heating element defect*5

12V heating element defect*6

Failure LED 2 and „120“ (3) flash

Acoustic Signal

Failure LED 2 and „12“ (3) flash

Acoustic Signal

Failure LED 2 and „GAS“ (3) flash

Acoustic Signal

Failure LED 2 and Temp.-LEDs (4) flash

Acoustic Signal

Failure LED 2 and Indicator 4 „HE 1“ flash

Acoustic Signal

Failure LED 2 and Indicator 4 „HE 2“ flash

Acoustic Signal

TD S56

Acoustic SignalDoor opened (longer than 2min.)7

56

Page 57

SERVICE + MAINTENANCE

*Sequence for recognizing „Heating element defect“:

Conditions: Interior temperature >18/64°C/F, corresponding relay is switched on

(120V or 12V), door has to be closed for longer than 5 minutes.

Temperature of reevaporater (a) is recorded

After 2 hours, the temperature (b) is recorded again, if the fridge is in the

same mode

If the temperature difference a-b < 3 °K, the corresponding heating element

error will be indicated

TD S57

57

Page 58

SERVICE + MAINTENANCE

Service Mode MES

The Service Mode is activated by keeping pressed down the temperature button

and switching on the main button.

After this all 3 mode-LEDs (3) light up.

By pushing the temperature button (6), the different test-steps can be activated,

test steps 1-6 are indicated by the temperature LEDs (4)

1 = activates 120 V heating element (120V must be available)

2 = activates 120V relay (120V has not to be necessarily available)

3 = activates 12 V heating element (12V has to be available)

4 = activates burner control device – output (Gas operation)

5 = activates frame heating

6 = activates interior lights (For fridges without electrical lock)

TD S58

58

Page 59

SERVICE + MAINTENANCE

Service Mode MES

7 = Recognition sequence (Reed switch or electrical lock)

8 = activates temperature LEDs (4)

9 = activates lock and failure LED (2) + (5)

Exiting the diagnosis mode: Push the „mode“ button or wait for 10 minutes.

TD S59

59

Page 60

SERVICE + MAINTENANCE

Controlling the interior light via reed switch

The MES-Electronics uses the X114 and X111 as well for controlling the reed

switch as well as the electrical lock.

In the Service mode, the electronics will recognize the application of a reed

switch, following the below steps:

1. Choose step 7 in the service mode

2. Deactivate D+; open the door

3. Push temperature button (6)

4. Close the door (reed switch will be recognized)

5. Continue service mode (push button 6)

The interior light will now be controlled via the reed switch.

Basically the electronics are defined with “recognizing Reed switch”.

TD S60

60

Page 61

SERVICE + MAINTENANCE

Electrical door lock

Optionally, max. two electrical door locks can be controlled. They are connected to X111

and X114 (Notify, that if there is only one lock this has to be connected to X111).

In the service mode the electronics will recognize the locks following the below steps:

1. Open the door(s)

2. Choose step 7 in the service mode

3. Close the door(s)

4. Deactivate D+

5. Continue Service mode with step 6

The locked door will be indicated via LED 5, and can be unlocked by pushing button 7.

If you have 2 electrical door locks, LED 5 will flash, if one lock is not locked.

TD S61

61

Page 62

SERVICE + MAINTENANCE

Error messages

AESErrorNo.

1

Mode)

4

5

120V heating element or cooling unit

defect*

12V heating element or cooling unit

defect*

Failure LED 2 and LED 3 (DC Mode) flash No 12V, respective under 10,5V (DC

Failure LED 2 and LED 3 (Gas Mode) flashIgnition without success (Gas Mode)2

Failure LED 2 and temperature – LEDs 4 flashNTC sensor defect3

Failure LED 2, LED 3 (AC Mode) and

temperature – LEDs 4 flash

Failure LED 2, LED 3 (DC Mode) and

temperature – LEDs 4 flash

TD S62

62

Page 63

SERVICE + MAINTENANCE

*Sequence for recognizing „heating element defect“:

Conditions: Interior temperature >18/64°C/F, corresponding relay is switched on

(120V or 12V), door has to be closed for longer than 5 minutes

Temperature of reevaporator (a) is recorded

After 2 hours, the temperature (b) is recorded again, if the fridge is in the

same mode.

If the temperature difference a-b < 3 °K, the corresponding heating element

error will be indicated.

TD S63

63

Page 64

INSTALLATION

DOMETIC GMBH

DOMETIC GMBH

TECHNISCHE DOKUMENTATION

TECHNISCHE DOKUMENTATION

IN DER STEINWIESE 16

IN DER STEINWIESE 16

57074 SIEGEN

DD--57074 SIEGEN

GERMANY

GERMANY

www.dometic.com

www.dometic.com

Page 65

This manual has been provided courtesy of

DARREN KOEPP - OWNER, MY RV WORKS, INC.

www.myrvworks.com

You can find more RV service manuals here:

www.myrvworks.com/manuals

My RV Works, Inc.

Over the years of running a mobile RV repair service, having a dedicated place

to access service manuals for all the different appliances and components

found on RVs was something that I always had a desire to create.

I hope this resource makes your RV repairs easier, as it has mine, but please

be careful and follow proper safety practices when attempting to repair

your own RV.

If in doubt, please consult with a professional RV technician!

All service manuals provided on www.myrvworks.com are believed to be

released for distribution and/or in the public domain.

Loading...

Loading...