Dometic RM24A, RM36C, RM46, RM47, RM66 Service Manual

...

-.B)pzGGq

Diagnostic Service Manuals

SERVICE

United States

SALES OFFICES

DOMETIC SALES CORP.

Zone 1

2320 Industrial Parkway

Elkhart. IN 46515

(219)

295.5226

DOMETIC

SALE S

Zone II

2920 Avenue

Arlington, TX 76011

(81 7)

649.5726

DOMETIC

Zone III

14441 Bonelli St.

City of Industry, CA 91746

(818 ) 968-9431

Canada

CORP .

“E”

East

SALES CORP.

DOMETIC DISTRIBUTION INC

866 Langs Drive

CambrIdge. Ontario

N3H

2N7

Canada

(519 ) 653-4390

SERVICE MANUAL

c

REFRIGERATOR

for

recreat ional vehicles

RM24A RM36C

RM46 RM4

7

Edition

Publication No

4528-E/Service

May

DSC #

1

1973

648

When

orderi ng

MODEL. QUANTITY. PART NUMBER. DESCRIPTION

For

electric details

VOLTAGE. WATTAGE

SPARE PARTS

also:

always

state:

RM66 RM67

1

RM76 RM77

1

2

Service Instructions for Domtic Absorption Refrigerators

The absorption refrigerators described in this manual are

in recreational vehicles.

Since the vehicles in

camp sites

designed co operate by means of bottle propane or butane gas as

electricity

These Service Instructions cover the Dometic

RM46,

Description

ECHNIGU

Cabinet es,

INSTALLATION

General

Ventilation___

Gas connections ____ ____

Electrical connections___________..______ 5

Approved installations

Measurements...

FEATURES

equipment .

INSTRUCTIONS

instructions . ____ .

....

where

12/110V.

RM47, RM66, RM67,

.._ .... ..... ......... .....

...................

........... ....

____

............ ........

which

electrical power is not available,

..........

the refrigerators are

RM76,

RM77.

LIST OF CONTENTS

Pag

3

10

primarily

located

may be driven to remote

the refrigerator5 have been

Models RM24, RM36C,

Description

ELECTRIC OPERATION -

Re place ment

Wiring diagrams................................

4

5

5

7

PRESSURE

OPERATING RECOMMENDATIONS

Gas operation

Electric

MAINTENANCE

Levelling

of heater_______________.__.

MEASURING

_______ _____ _______ _____

operation

_________

for installation

well as

by

FUNCTIONAL

DEVICES

.................

..................

PARTS

........ .......

Page

37

38

39

40

41

42

Cabinet

THE

GAS/ELECTRIC EQUIPMENT

AS

Adjustments

To change the door panel _ . _ ____ _____

Replacement of door gasket___.________.. 15

Replacement of evaporator door and gasket. 16

Reversing outer door__

ABSORPTION REFRIGRATOR SYSTEM

Sealed system constructions .. _ _ _ _ .

Operating analysis for cooling unit ......

Cooling unit replacement

Gas

equipment for

Dual electric equipment for

Car/electric

RM46,

RM47,

OPERATION Termostat -

The gas burner ...... .

Flue system .......................

Thermo flame

equipment

RM66, RM67, RM76,

FUNCTIONAL

replacment

failure device ........ .......

.... . ...... ......

.............. ...

RM24

..... . .....

RM24 . .......

for

RM36C,

RM77... ____

PARTS

___

......

.

..... ..

.............. ..........

....

___

......

........

32

.........

20

22

23

29

30

33

34

13

18

28

35

Temperature Control (thermostat).... 42

The

themostat capillary

Storing food in the refrigerator_______.

Cleaning _____

Ice cubes___________ ____ ______________

Travel latch ____ ____ _____

Door seal_

Odors inside the refrigerator

Odors from

Flame blows out

Flint lighter_______

Piezo

lighter ____________ _ ____ _________

DIAGNOSIS

Trouble

refrigerators _____ __

Trouble

refrigerators_______ .... .

Failed refrigerating unit_____..._____._

Operation analysis for electric

operated

shooting - electric operated

.... .

......

___ ______ ______ ____ ___

fumes .......... .......

..... ........ .

shooting -

refrigerators

tube

..........

______

gas

......... ......

.............. .

....... .....

____ ________

...... ........ ....

...... .............

operated

. ......... ......

............. .......

42

43

43

43

43

43

44

44

44

44

45

47

48

49

50

Operation

operated

Periodic

analysis for LP gas

refrigerators

maintenance

....... ...........

................ ..

51

52

1..

TECHNICAL FEATURES

RM24

3

The cabinet has a so called “Full Finish Casing”

built-in. RM24 is a compact refrigerator, ideal for campers, fitted with

and seals.

This refrigerator is fitted with right-hand door with change over facility to

hand door and exchangeable front door panel in an aluminium framed door.

Exchange can be made without the removal of the door.

available operated from the rear of the cabinet.

fitted as standard to assist in maintaining flame stability under adverse wind

conditions.A sealing frame is fitted around the cabinet for building-in purposes,

The refrigerator has one basic casing which is Foamed in place with a lining.

Insulation material polyurethane.

The construction of the door,

foamed in place with the door pan and magnetic gasket.

Equipment

Fool-proof electric/gas interlock system.

Flint lighting system. The electric and the gas thermostats are of the English

complete, is an aluminium extruded door frame

Thermo-electric flame failure device.

and can be used freestanding or

front

frame

left-

A full range of equipment is

A blow-out protection flue is

Ranco-make .

The

gas/e1

through the service door in the wall, when installed in a

controls are located at the rear of the refrigerator and are acccssiole

vehicle.

Version

Gas/110

RM36C, RM46, RM47, RM66,

Cabinet

Thin wall polyurethane insulation.

place insulation.

Lining of vacuum-foamed

moulded SB plastic.

Distinct stop for evaporator door at

Cabinet shelf with hinge for big bottles,

The shelves run in grooves and will not move during transport of the vehicle.

Freezer compartments are, of aluminiurn sheet,except

moulded part of the lining.

Accessible control panel inside the fresh food compartment.

volts A.C. and 12 volts D.C.

RM67, RM76, RI.177

RM76

and RM77 are foamed against mould.

ABS

plastic, except

All models except

RM36C,

90’

opening,

RM76

and RM77 have foamed in

which has a lining of injection

RM46, RM47, RM66

RM36C,

where it is an

and RM67

injectior

4

Door

All models will be delivered with right hand door hinging, but it is possible for

the customer to change the door hinging from right to left hand.

Replacement

profile of the door frame has to be removed.

Equipment

All models incorporate a thermo-electric flame failure safety device and a

lighting system.

The equipment for electric and gas operation is located at the rear of the cabinet

and manipulated from inside the cabinet.

The gas shut-off valve and the electric voltage-change switch are interlocked so

that both methods of operation cannot be inadvertently used at the same time.

The electric and gas thermostats are of the Ranco-make.

Version

All models will be available with

A.C. or LP

2.

INSTALLATION INSTRUCTIONS

For LP-gas and electric operation

General instructions

of door panel is possible without removing the door. Only the side

combination equipments for LP gas and 110 volts

gas/110

volts A.C. and

12 volts

in Motor Homes and Recreational Vehicles.

D.C.

piezo

The refrigerators outlined herein

Refrigerators by the American Gas

recreational vehicle and are approved by the Canadian Gas Association.

The certifications are, however,

accordance with the following instructions,

The installation must conform with:

In U.S.A.:

Installation of Gas Appliance and Gas Piping, 221.30

1.

Mobile Homes

2.

Recreational Vehicles A 119.2

3.

accordance with the National Electrical Code ANSI CI

an external alternating current electrical source is utilized.

Any applicable local code,

4.

In

Canada:

C S A Standard B 149.“Installation Code for Gas Burning Appliances and Equipment”

1.

C S A Standard B

2.

homes”

A 119.1

-

1969.

210.1/Z

240.4.“Gas equipped recreational vehicles and mobile

have been design certified under ANS 221.19

Association for installation in a mobile home or

contingent on the installation being made in

-

1964.

1970. The unit must be electrically grounded in

-

-

1968, when installed if

Ventilation

The installation shall be made in such a manner as to separate the combustion system

from the living space of the recreational vehicle. Openings for air supply or for

venting of combustion products shall have a minimum dimension of not less than

l/4

inch.

Approved installation requires one lower fresh air intake and one upper exhaust

vent. The accessory ventilation kits shown in these instructions have been tested

and approved for use with the refrigerator models identified. Their use is

ded, and when employed,

the ventilation kits must be installed and used without

recommen

modification,

An opening to the outside at floor level of the refrigerator compartment must be

provided for ventilation of heavier-than-air fuel gases, The lower vent in the

Dometic kits is provided with proper size openings.

Gas connect ion

Hook-up to the gas supply line is accomplished at the manual gas valve, which is

furnished with a

3/8”

(SAE)

male flare connection.

All completed connections should

be checked for leaks with soapy water.

5

CAUTION: When connecting the gas line to the gas valve on the

the rear of the refrigerator,

use a back-up wrench to prevent undue

gas/e1

equipment at

rotation of the gas cock,

For hook-up and servicing purpose the

lower vent is constructed as a lift out panel.

The gas supply system must incorporate a pressure regulator to maintain a supply

pressure of not more nor less than 11 inches water gage.

Electrical connections

110 V A.C.

The 110 V electric cord should be plugged into an approved receptacle in the

refrigerator compartment. The cord should be routed to avoid coming in contact witn

the burner cover, flue cover or other hot components.

12 V D.C.

On “Tri-Power”units there is an additional terminal block marked “12 V”. The refrigerator must be connected

to the battery circuit with two wires of adequate capacity

to avoid voltage drop.

Do not use the body or chassis as a substitute for either of these wires (possibly

only in motor homes). No other electrical equipment or lighting should be connected

to the refrigerator circuit.

When estimating length and

area of conductor cable, see table, page 6.

CAUTION :

Do not operate the refrigerator on 12 Volt when the vehicle is parked. You will run

the battery dead

in

a rather short time.

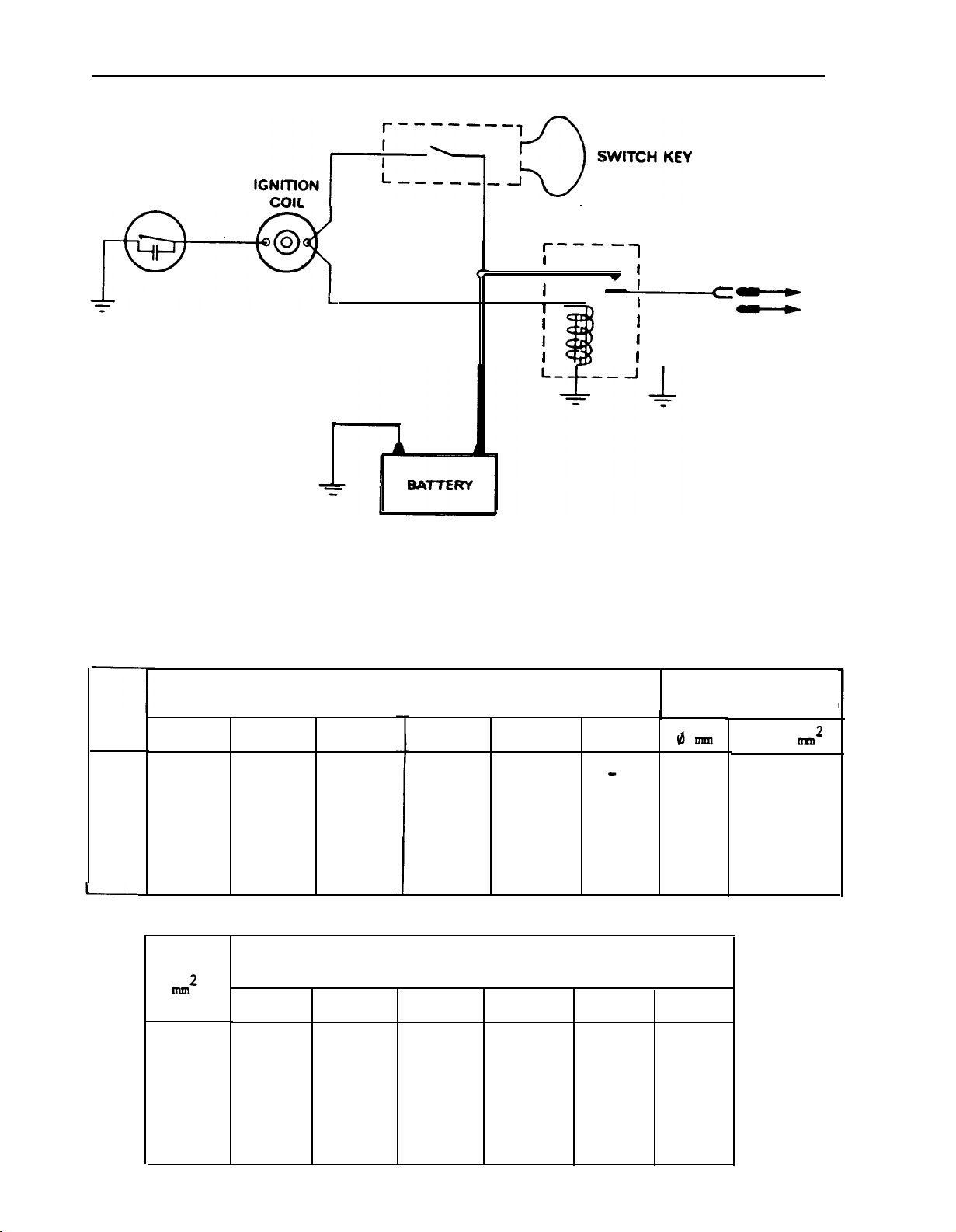

If possible the installation of a 12 Volt operated refrigerator should be completed

with a relay mounted either in the car or in the vehicle (see diagram). This relay

will automatically cut out the refrigerator when the car motor is stopped.

6

BREAKER

POINT

CAUTION

Do not operate therefrigerator on 12 Volt

when the vehicle is

out of battery in a rather short time.

If possible the installation of a 12Volt ope-

rated

refrigator should be completedwith

a relay mounted either in the car or in the

vehicle (see diagram). This

tomaticallycut out the refrigeratorwhen

the

car

motor is stopped.

parked.You

realy

will run

will au-

The figures below are guiding valuer calculated in consideration of

0.5

V voltage drop (about 7

without taking into account the losses at the terminals,

I

<-

r

I

I

1

I

I

I

RELAY

----

1

I

>

-

I

REFR.

I

I

I

I--

’

z

Fig.

1

%

input loss) in the connection cables

AWG

14

12

10

8

6

Maximum length of two conductor cable in feet from

power supply

95

w

28

45

72

125 W

150 w

21

34

54 45

87 72

17

28

175 w

15

24

38

62

225

11

18

30

48

W

99 77

Maximum length of two conductor cable in meter from

power supply

175 w

9.0

13.5

22.5

2.5

4

6

10

1.5

150

95 w

6.0

125 W

4.5

w

10.5 7.5 6.5 5.5 4.0

16.5

25.0

12.5

18.5

32.0

10.5

15.5

26.5

(solid cooper wire)

275 W

24

39

62

dmm

1.628

2.052

2.588

3

.264

6.115

225 w 275 W

-

6.5

10.0

5.5

8.0

17.0 14.0

AWG

in mm

Area

2.082

3.307

5.260

8.367

13.299

mn2

Special hints

7

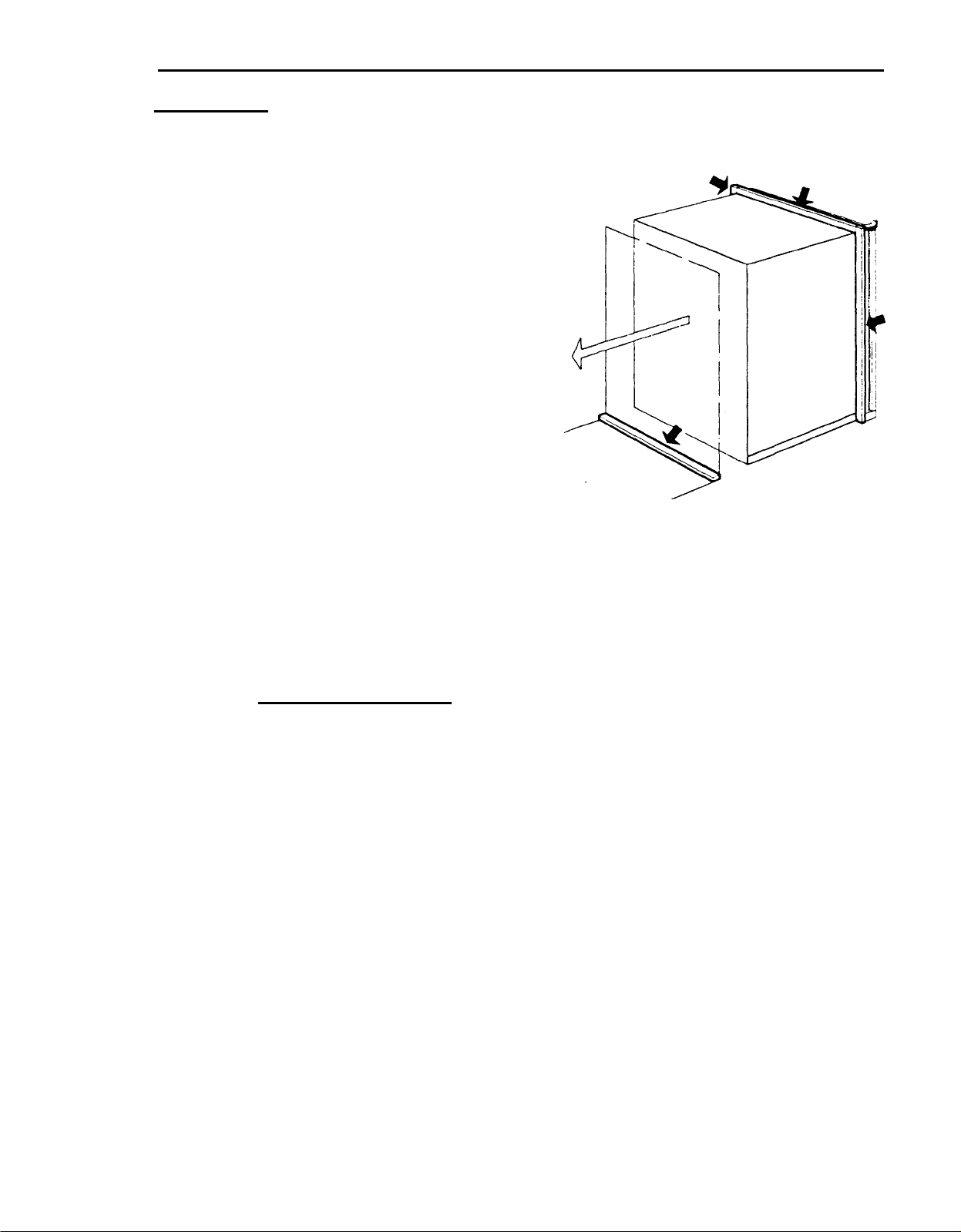

The refrigerator must be installed in a

stantial enclosure and

must

be level. A

sub-

spirit Level is supplied with each refrigerator and by placing it in the freezer compartment,

the refrigerator can be leveled

both ways front to back and side to side.

When installing the refrigerator in the

enclosure,

care should be taken to ensure a

complete sealing between the front frame of

the refrigerator and the top, sides and

bottom of the enclosure, For this purpose a

length of sealing strip is delivered with

each refrigerator. The sealing strips should

be applied to the rear surfaces of the front

frame of the refrigerator. See fig, 2.

(RM24

is supplied with this sealing already

fitted on the front frame of the refrigerator).

Be careful not to damage the sealing strip

applied to the bottom of the enclosure when

the refrigerator is put in place.

Any space between the counter or storage

area and the top of the refrigerator must

be blocked. The heat produced at the rear

of the refrigerator will otherwise become

trapped in this space making the top of

the refrigerator hot and reducing the

efficiency of the refrigerator,

r

Fig.

2

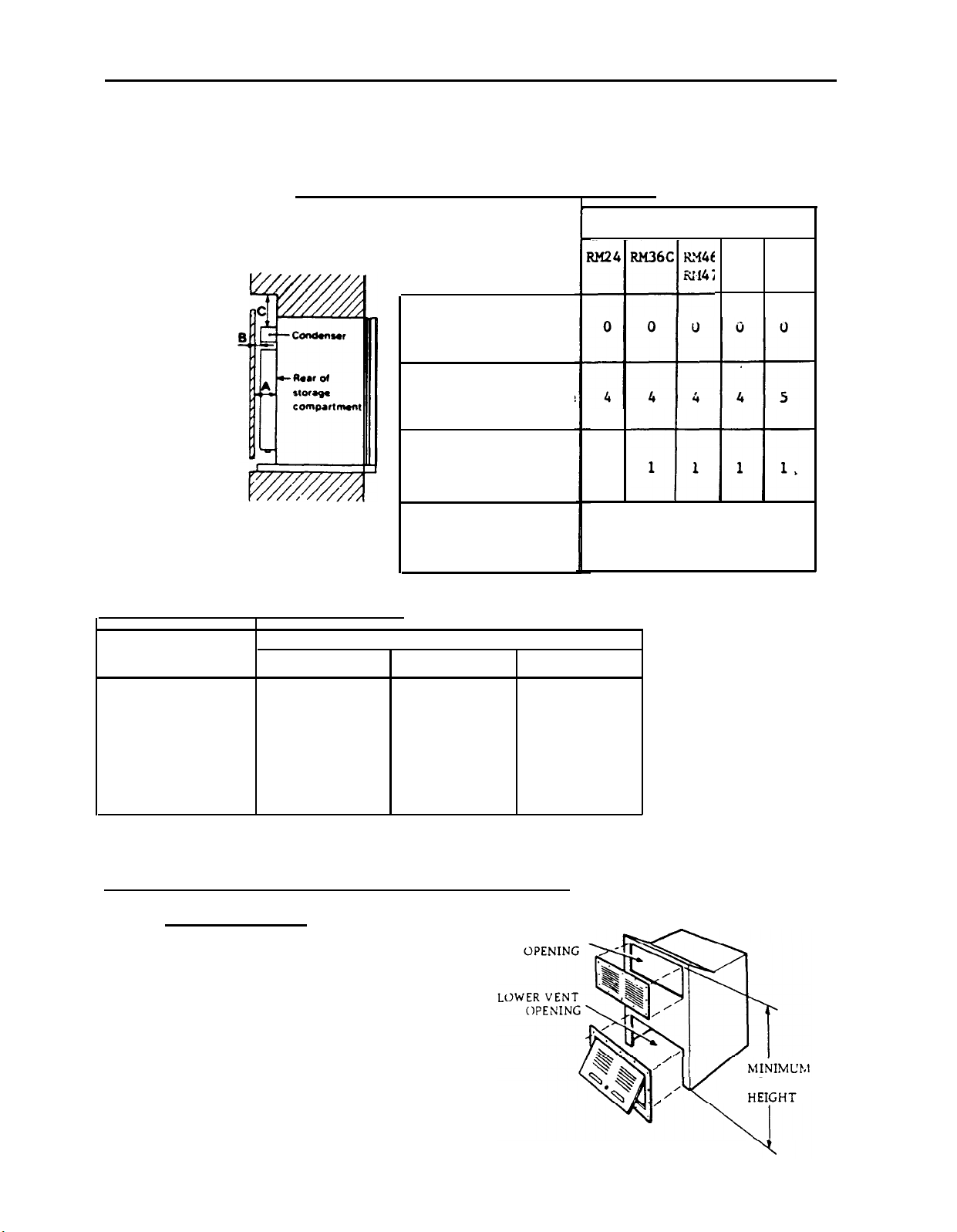

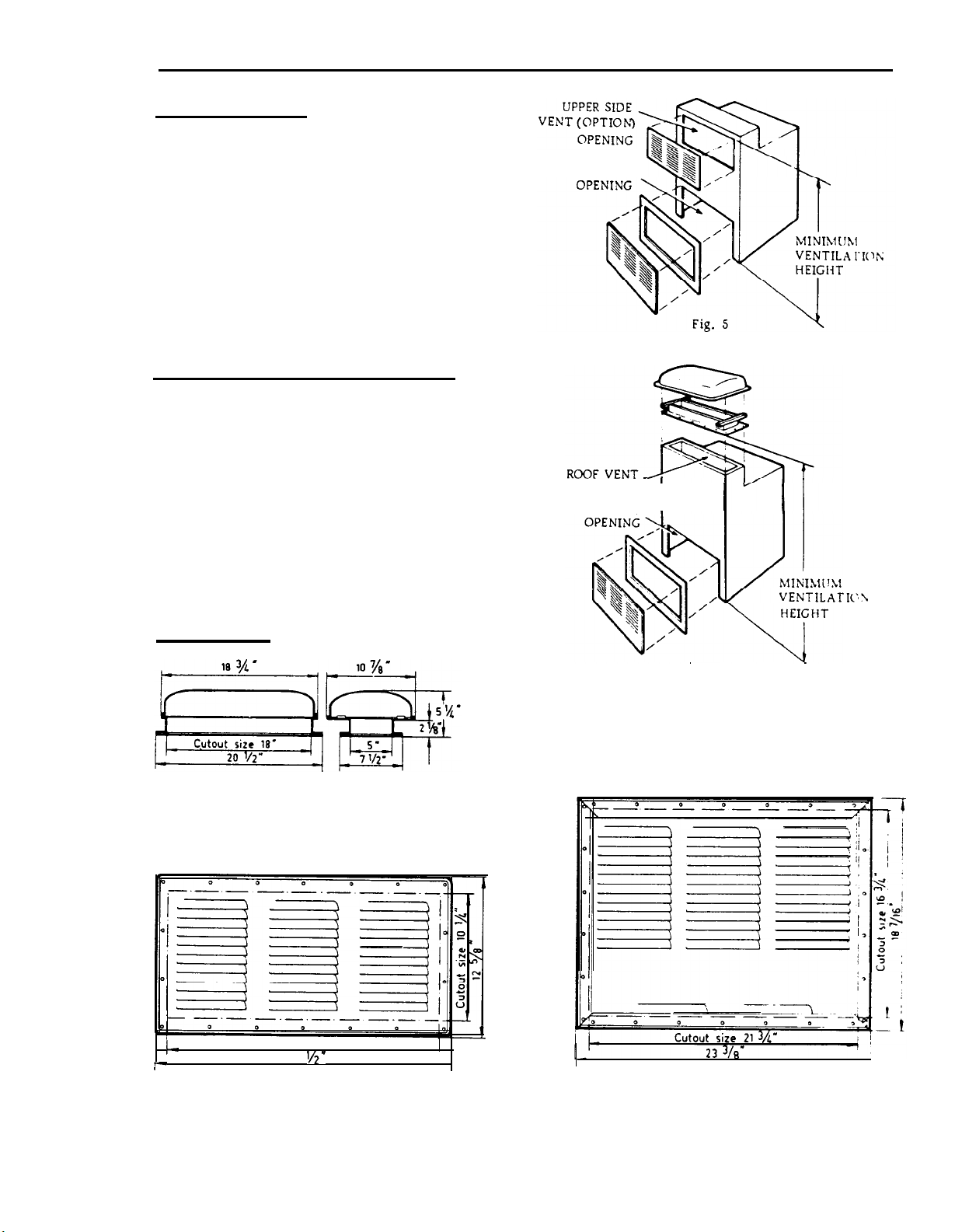

Approved

installations

Approved installations require one roof vent and one lower side vent

as optional,one upper side vent and one lower side vent, as shown in

the figures 4,

Kit No. 1

5

and 6.

comprising:

Upper side vent

(Dometic

123)

Lower side vent (Dometic 183)

Kit No. 2

Kit No. 3

comprising:

comprising:

Upper side vent

Lower side vent (Dometic

Roof vent

(Dometic

Lower side vent

(Dometic RM122)

RM2217)

V 2019)

(Dometic

RM2217)

8

When installing the refrigerators full consideration should be taken to the sealing

instructions and the specified minimum clearances and ventilation heights tabled

below:

MINIMUM INSTALLATION CLEARANCES IN INCHES

Refrigerator model

RM66

RM76

RM67

RM77

Clearances on

sides,

bottom

top and

Figure showing

location of the

clearances

the

Clearance A from

the rear of storage

compartment

Clearance B from

rear of

condenser

Fig.

3

MINIMUM

Refrigerator

model

KM24

VENTILATION

HEIGHT

FIGURES

Kit No, 1

22

9/16”

RM36C

RM46,

RM47

RM66, RM67

RM76, RM77

Clearance C on

top of

condenser

Installation type

Kit No. 2

37

l/16”

39

5/8”

47

l/2”

70

l/4”

1

See minimum ventilation

height figures

Kit No. 3

29”

32”

41”

59”

PROPER VENTING IS REQUIRED TO ENSURE BEST PERFORMANCE

Kit No. 1

comprising:

Upper side vent

Lower side vent

(see Fig. 4)

-

RM24

(Dometic

(Dometic 183)

123)

UPPER VENT

I

I

Fig.

/

VENTILATIOX

/

4

9

Kit No. 2 -

RM36C

comprising:

Upper side vent

Lover side vent

(see Fig.

Kit No. 3

5)

- RM36C,

(Dometic RM122)

(Dometic RM2217)

RM46, RM47

RM66, RM67,

RM76,

comprising:

Roof vent

Lover side vent

(see Fig.

(Dometic

V 2019)

(Dometic RM2217)

6)

Dimensions pertaining to

the installation are shown

under measurements.

RM77

LOWER VENT

OPENING

LOWER VENT

-

I

VENTILATK:\

VENTING MEANS

Fig. 1

Roof vent for Kit No. 3

Dometic

I-

c-

V 2019

Cutout size 21”

23

Fig.

‘/2’

8

Upper side vent, Kit No. 2

Dometic RM122

Fig. 6

1

Fig. 9

Lover vent, Kits No, 2

\

and No, 3

Dometic RM2217

10

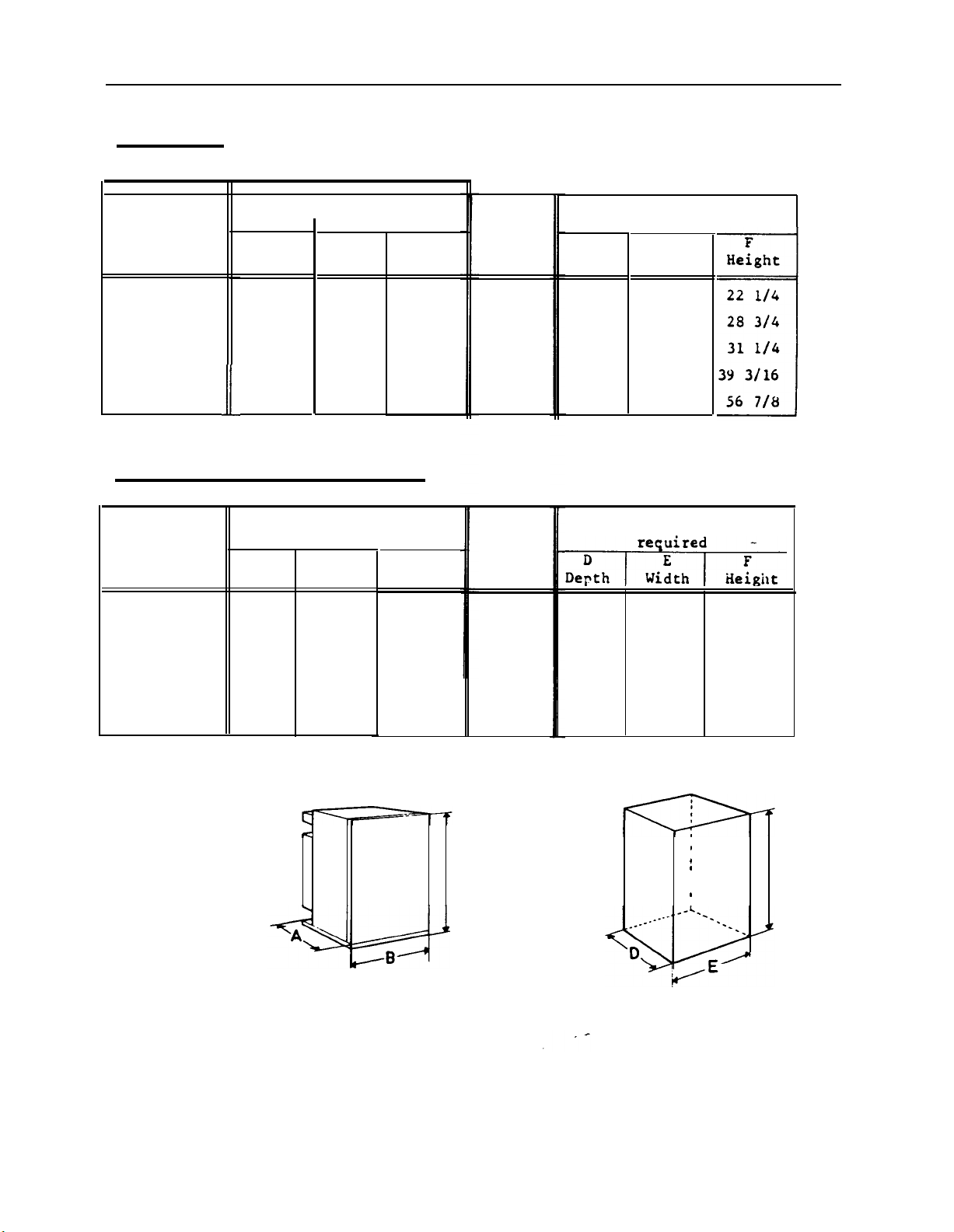

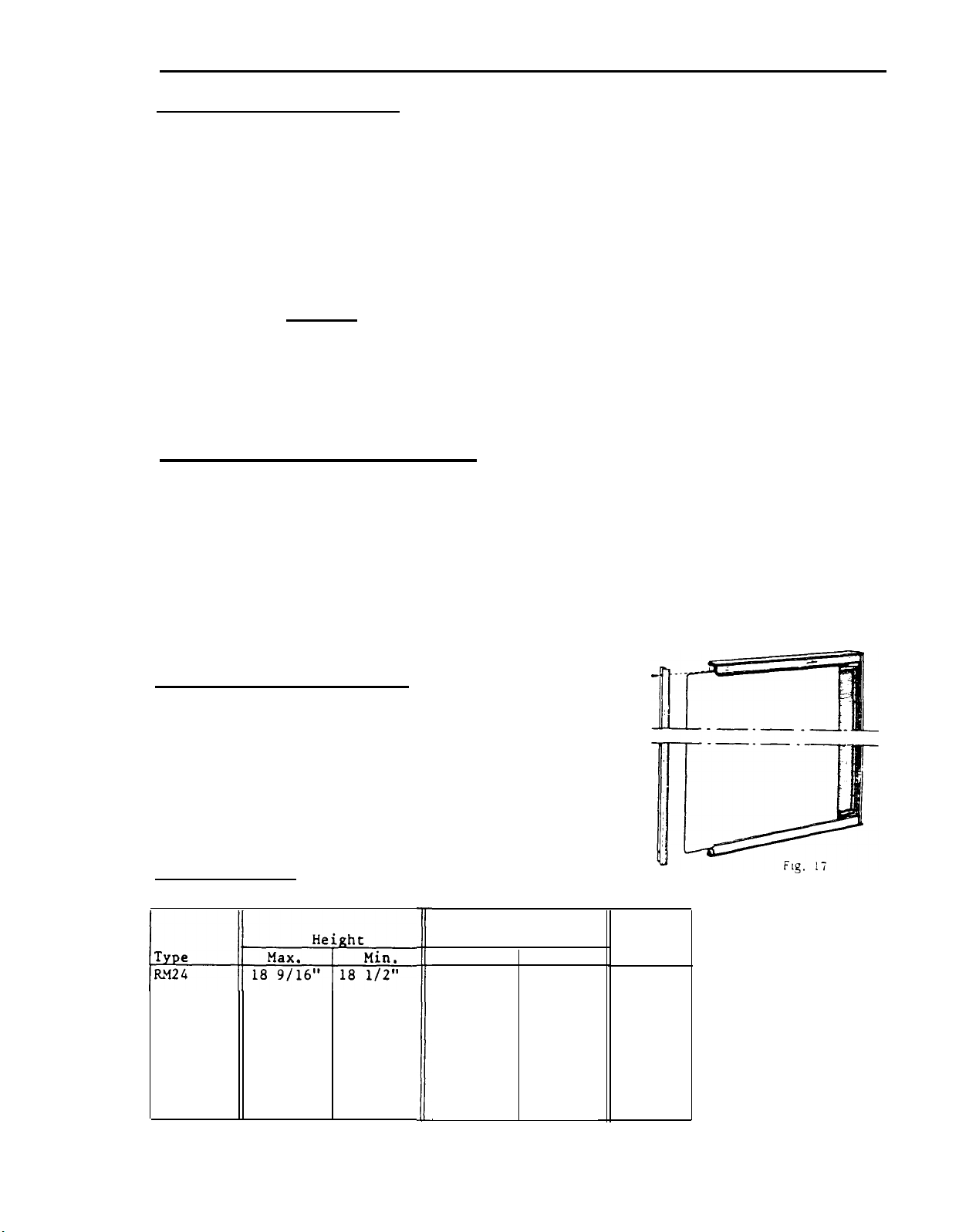

MEASUREMENTS

Cabinet and recess dimensions in inches.

r

Cabinet

Refrigerator

models

Overall

A

Depth

dimens

ons

B

Width

C

Height

Door

pro-

jection

Built-in space

required

D

Depth

Width

E

RM24

RM36C

RM46,

RM47

RM66, RM67

RM76,

RM77

18

217/8

24

24 7/8

24

ii

13/16

7/8

5/8

19

20

21

21

23

l/8

l/4

9/16

9/16

7/16

22l/8

283/8

30

7/8

13/16

38

56l/2

Cabinet and recess dimensions in mm.

Cabinet

Refrigerator

models

RM24

RM36C

RM46,

RM47

RM66,RM67

RM76,

RM77

Overall

A

Depth

478

Width

486

556 513

631

547

631 547

625

595

dimen

B

ions

C

Height

562

720

785

985

1435

1

7/16

1

3/4

1

3/4

1

3/4

1

3/4

Door

pro-

jection

37

45

45

45

45

18

20

23

23

23

l/4

l/4

l/4

l/4

5/8

19

200

217/8

21 7/8

23

13/16

l/4

l/4

Built-in space

OIPIh

460

515

590

489

521

555

590 555

599

605

572

729

794

994

1444

Cabinet overall dimensions

-e

Built-in space

C

Fig. 10 Fig. 11

requirements

,

I

0

I

I

F

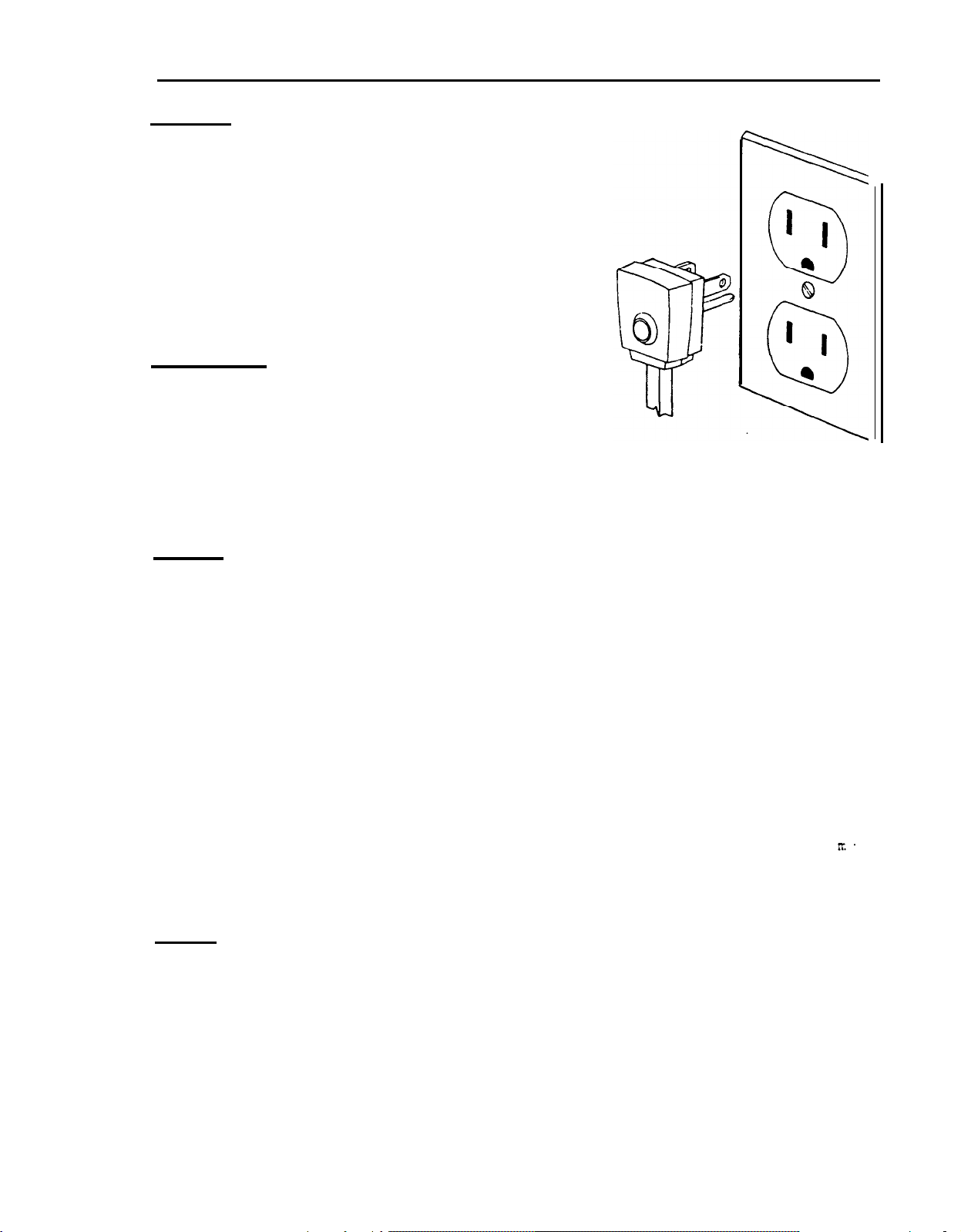

Grounding

It is imperative, for personal safety, that

all refrigerators equipped with a three-prong

(Grounding) plug be used only with properly

grounded wall receptacles, See fig. 12.

If there is any doubt as to whether the wall

receptacle is properly grounded, the customer

should have it checked by a qualified electrician. DO NOT, UNDER ANY CIRCUMSTANCES,

CUT OR REMOVE THE

THIRD

(GROUND) PRONG FROM

THE POWER CORD PLUG,

11

Proper

fusing

Fusing of any circuit should be in accordance

with local electrical code, The refrigerator

should be plugged into a separate branch

circuit, Use of extension cords should be

Fig.

avoided on refrigeration equipment. In the

12

event an extension cord is used, the cord

should not exceed six feet and be of sixteen

gauge or heavier wire.

Gas line

L.P. gas is highly inflammable and it is of extreme importance to ensure that all

joints in piping carrying the gas from the storage bottle to the burner on the

absolutely gas tight. Check at least twice a

refrigerator are

-

and will

remain

-

year.

The gas line should be free

After installation, the gas

checked for leaks up to the

of kinks and sharp ends.

should be turned on and all joints in the gas line

burner using soapy water. This check should be repeated

periodically ,

Do not fit any extension tothe top of the flue. This is not only unnecessary, but

can create draught conditions which can adversely affect correct combustion at the

burner and consequently,

the functioning of the cooling unit,

The refrigerator should be operated at an inlet gas pressure of

Incoming gas pressure is controlled by the pressure regulator on the

11” W.G. (280 IT.. W.G

propane/butane

bottle.

CAUTION

When connecting the gas line to the gas cock on the

:

gas/el

equipment

at the rear of

the refrigerator,use a back-up wrench to prevent undue rotation of the gas cock.

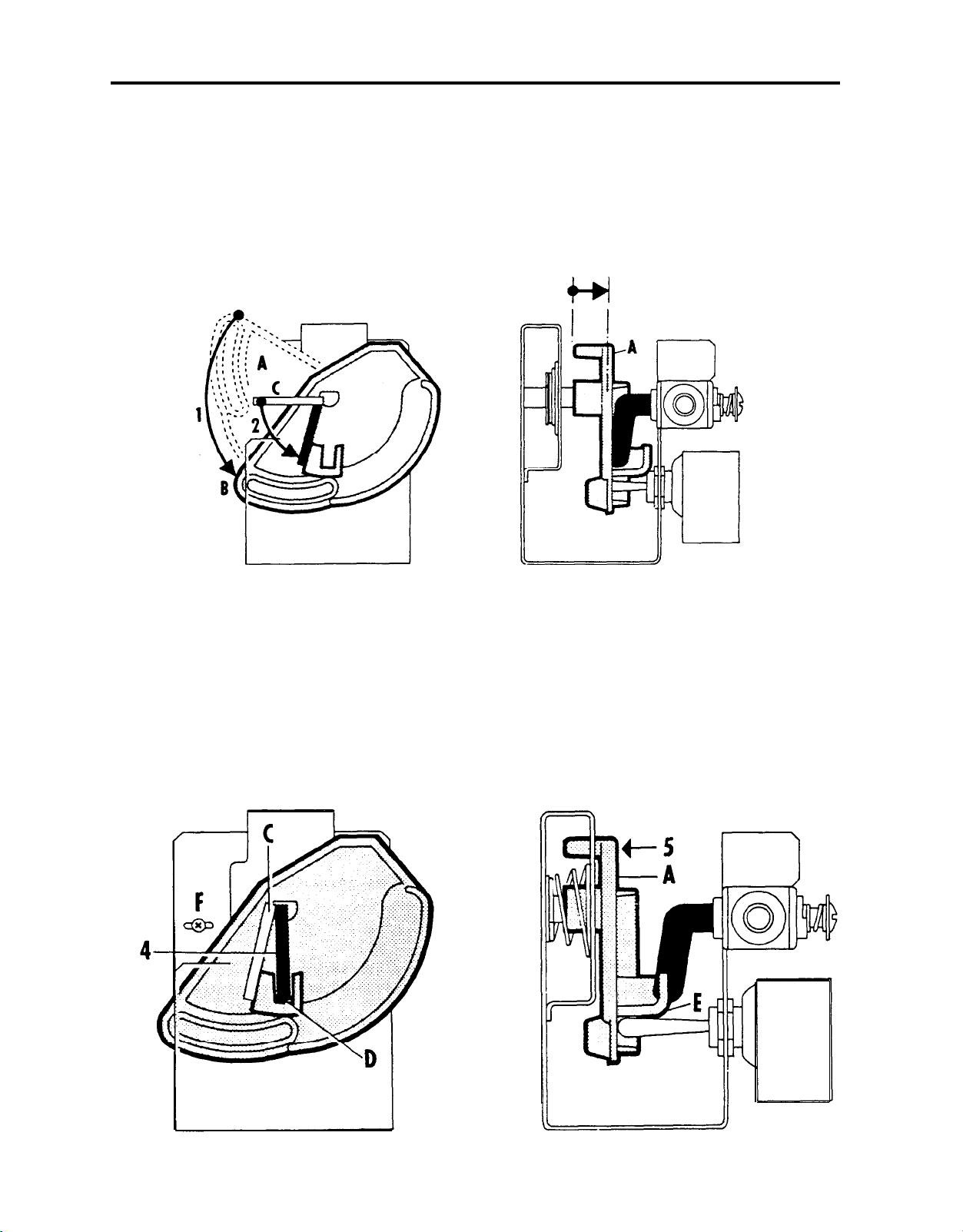

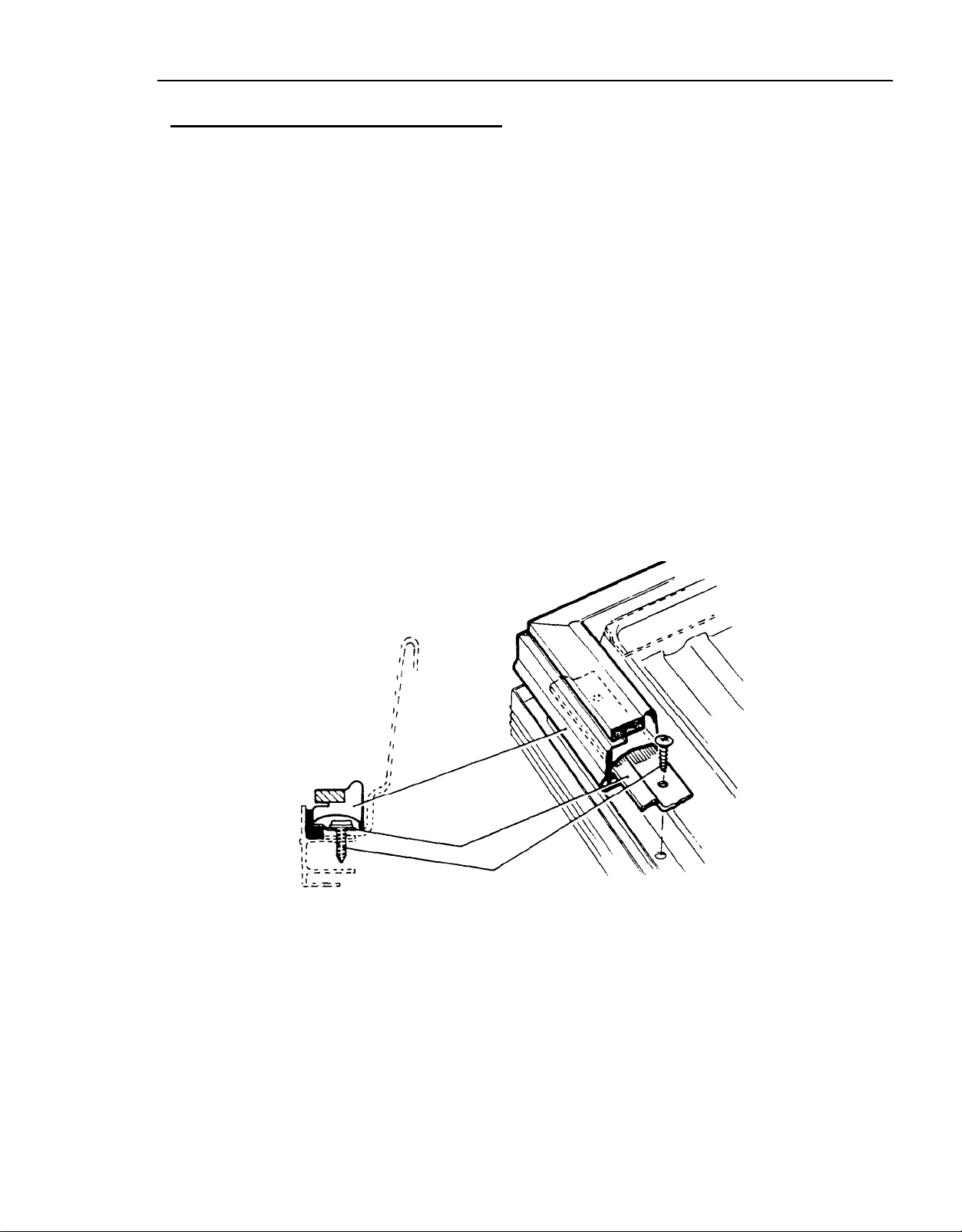

It is of utmost importance for correct functioning of the

RM46,

RM47,

RM66, RM67 and RM76, RM77, that the gas cock lever is correctly engaged

in the slot

"E"

(see Fig,

16) on the plastic driving disc “A” of the

gas/el

control on

gas/el

control

RM36C,

mechanism.

12

If for

disc,

1.

2.

3.

any reason

the gas cock lever has come off position in the driving plastic

check alignment, Proceed as follows:

Turn

Turn

downwards

downwards

the driving plastic disc "A" to stop

the lever

"C"

of the gas cock as far as possible (fig, 13).

Pull the driving disc "A" outwards (fig. 14).

.3.

WI

. .

"B"

(see fig. 13).

Fig.

13

Turn

4.

3.

the lever

Release the driving disc which is then pulled inwards by spring action, whereby

the lever of the gas cock snaps into its slot

"C"

of the gas cock into vertical position

Fig.

14

"D"

(see fig. 15).

"E"

on the driving disc

"A"

(fig. 16).

iiote:

If

the

gas cock lever

disc "A",

sluggishly

adjust the two fastening screws

snaps into its position in the driving

"F"

of the mechanism.

Fig.

Fig.

15

16

Combustible Material Storage

Combustible material such as ether, gasoline, hexane, naphtha, benzine, butane,

propane, alcohols,

stored in a refrigerator. These materials are classified as hazardous and constitute

a dangerous application of the refrigerator.

Keeping sealed system area free of litter,

acitone,

benzol, lacquer solvent,

or natural gas SHOULD NOT BE

13

Litter,including paper or rags,

not be stored in the area of the absorption system behind the refrigerator. Often

rags or paper towels (etc.) will be saturated with a combustible cleaning solvent,

Such materials must not be allowed in the space behind the refrigerator

the gas flame which

is operated on electricity,litter must not be stored in this area because of

heat given off by the refrigerating absorption system. It is also of utmost

importance that the air circulation round the unit’s parts behind the cabinet is

unrestricted.

of the refrigeration unit.

3..

UNUSED OR ABANDONED REFRIGERATORS

An unused or abandoned refrigerator or freezer in your basement or garage poses a

hazard to children.

When you discard a refrigerator or freezer . . .

COMPLETELY REMOVE THE DOOR. In many municipalities,

takes only a moment with a screwdriver.

as you can,have the old unit carted away and destroyed before it attracts a

child’s curiosity and endangers his life.

4.

TO CHANGE THE DOOR PANELS

on models

RM66,

Good refrigeration performance is dependent upon adequate ventilation

RM36C, RM46, RM47,

RM67,

RM76, RM77

is

used to power the refrigerator. Even when the refrigerator

woodshavings or other combustible material, should

this is the law. At any rate, it

Do this as soon as possible.

because

Also, as soon

of

Remove the screws holding one side

member of the aluminium door frame.

Pull out the outer door panel, re-

place panel,reassemble and refit

the door,

Panel dimensions

18

RM36C 257/

RM46,RM47 2725/32'”

RM66,RM67 35

RM76,RM77

RM76,RM77 41

11

32”

21/32"”

11/32”

l/32”

253/ 32”

27

21/32”

35

17/32”

11

l/4”

40

15/16”

i

20

21

21

23

23

Width

Max.

3/16” 18l/8”

5/32” 201/32”

l/2”

l/2”

13/16” 233/4”

13/16” 233/4”

Min.

21 3/8"

21

3/8”

Thick-

ness

Max,

l/8”

5/32”

5/

32”

5/32”

l/8”

l/8”

14

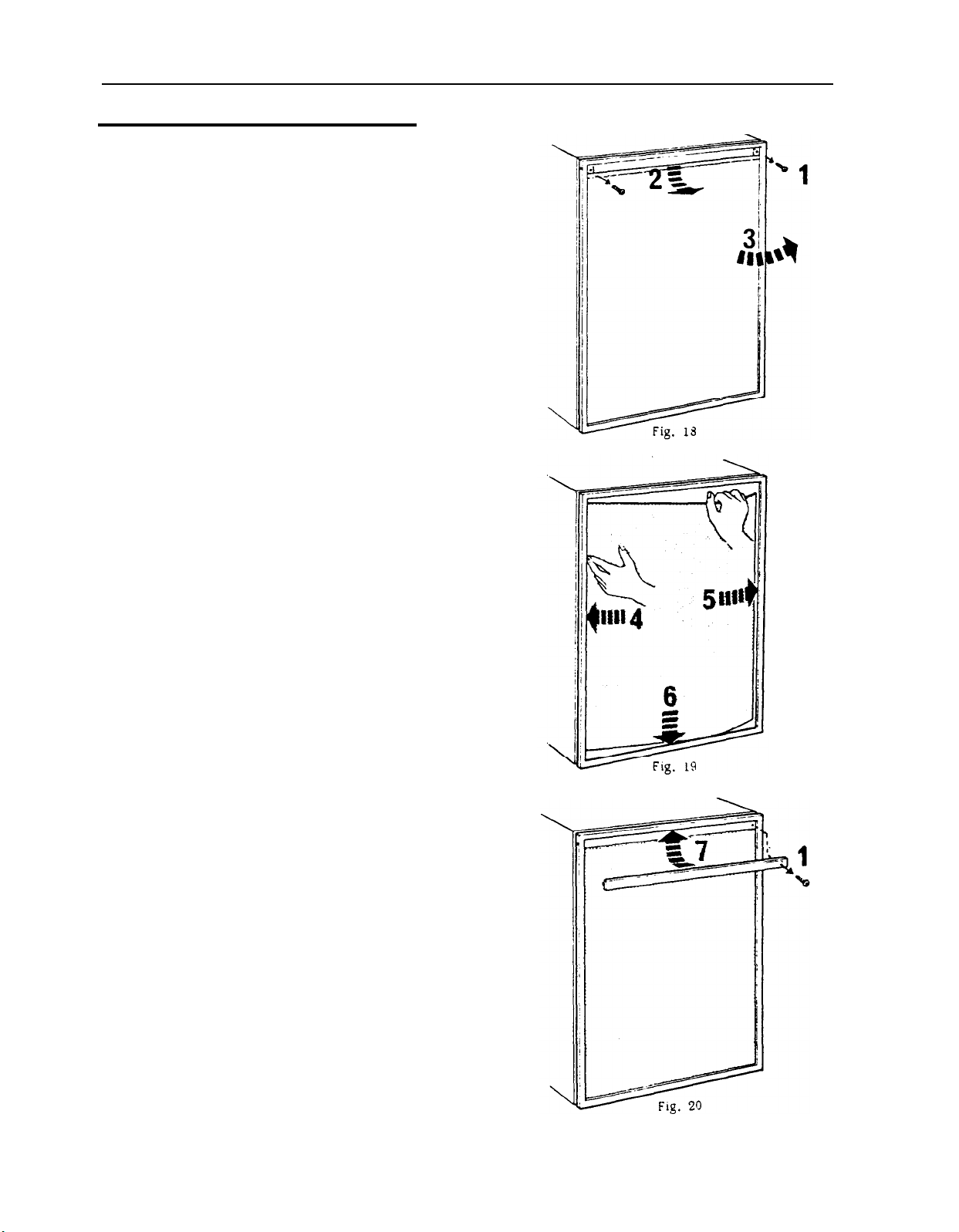

To change the door panel. Model RM24.

Remove the top decoration strip

A.

with its two screws

(1).

pull outward

on the top of the door panel and lift

slightly

to free the panel from the

bottom groove.

If a new panel is being installed,

B.

assure

that

it is the same size as

the old panel,

Install the new panel by inserting

c.

one of the vertical sides of the

panel into the groove of the door

frame (4).

Bend the panel gently so that the free

D.

side of the panel can be slipped into

corresponding groove of the door

frame (5).

Push the panel downwards so that the

E.

lower horizontal edge of the panel

is fitted in the bottom groove (6).

Between the upper edge of the panel

F.

and the door frame there is now

a gap which should be covered by the

decoration strip,

(2)

Put the strip across the door so that

G.

the gap is covered and push it up-

wards (7). The tabs on the inside of

the strip should fit in behind the

flange of the door frame.

When put in place, secure the deco-

H.

ration strip by means of the two

screws (1).

The panel is then locked

in proper position.

5.

REPLACEMENT OF DOOR GASKET ON

The construction of the door complete is an aluminium extruded door frame foamed

in place with the door pan and magnetic door gasket, i.e. the door pan cannot be

removed,

RM24

15

Therefore,

the above model. The gasket is delivered in a set consisting of the gasket and of

necessary fastening strips and

The replacement is made as follows:

Remove the door and place it with its front downwards on a soft surface.

1.

Cut off the defective door sealing gasket,

2.

possible).

Drill

3.

door pan as pattern.

Fit the sealing gasket as shown in the figure 21.

4.

Fit the door and adjust it so that it seals properly.

5,

a special door sealing gasket for service purposes has been produced for

screws and is ordered under part No.

(Cut as near to the door pan as

7/64”

holes for the screws of the fastening strips. Use the holes of the

290 07 33-00/3.

Fig. 21

16

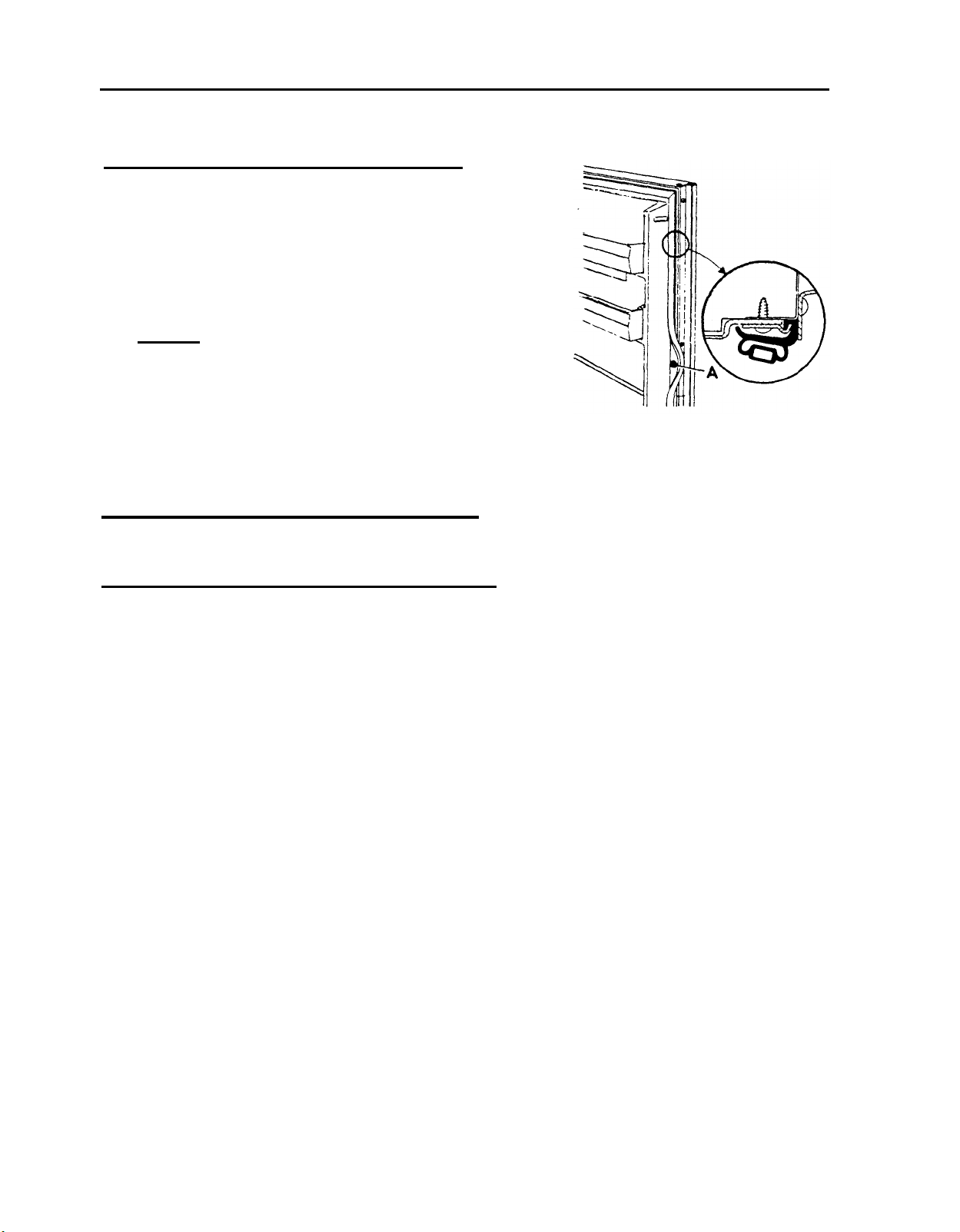

Replacement of door gasket on models

RM36C, RM46, RM47, RM66, RM67, RM76, RM77

Remove the door shelves.

1.

Unscrew the upper hinge bolt, incline the door

2.

outwards and lift off the door.

Lay door on flat surface with door pan facing

3.

up.

CAUTION:

The

4.

6.

REPLACEMENT OF EVAPORATOR DOOR CASKET -

1.

2.

screws

hidden by the door gasket. Pull the door

gasket to one side and remove all screws "A"

(see fig.

REPLACEMENT OF EVAPORATOR DOOR ON

Unscrew the retainer (fig. 25) and remove the door.

Put evaporator door on a flat surface vith the sealing gasket up,

Pry the door front away from the inner pan by means of a screwdriver (fig.

Be sure to protect door panel

prevent scratches and dents.

holding the door pan in place are

24)

from the door plate.

RM36C

to

RM36C

Fig. 24

26).

Loading...

Loading...