Page 1

Pub. Nr.: 599363886 --- REV.:A

Service Manual

MF 20-60 60-litre refrigerator with freezer compartment

Models : A552, EA0600 RH057 D3

A552E EA0601 RH060

A552EM EA0602 RH060 D

A552ESZ EA3200 RH060 D2

WA3200 RH060 DF

Page 2

2

Table of Contents:

1. The appliance .................................................................................... 3

1.1. Specifications ....................................................................................3

1.2. Important notes.................................................................................. 3

1.3. Spare parts, electrical wiring diagram................................................ 3

2. Installation and repair operations....................................................... 4

2.1. Tools.................................................................................................. 4

2.2. Cabinet, door .....................................................................................5

2.2.1. Adjusting right and left-hand swing door............................................ 5

2.2.2. Replacing legs ...................................................................................6

2.2.3. Replacing cowl ..................................................................................7

2.2.4. Replacing lock ................................................................................. ..7

2.2.5. Replacing door panel.........................................................................8

2.2.6. Replacing freezer door ......................................................................9

2.3. Electrical components......................................................................10

2.3.1. Replacing lighting device and bulb ..................................................10

2.3.2. Replacing bulb without dismounting lighting device......................... 12

2.3.3. Replacing heating element (Cylindrical heating element)................ 13

2.3.4. Replacing heating element [”Half-moon” heating element (as of May 2003)]15

2.3.5. Replacing temperature sensor......................................................... 16

2.3.6. Replacing thermostat.......................................................................17

2.3.7. Replacing timer................................................................................ 20

2.3.8. Appliance with semi-automatic defrosting........................................21

2.3.9. Temperature controller ....................................................................21

2.4. Cooling aggregate ...........................................................................22

2.4.1. Replacing cooling aggregate ........................................................... 22

Page 3

3

1. The appliance

1.1. Specifications

The appliance is a 60-litre upright refrigerator, operating with a wet absorption cooling

system.

At ambient temperatures between +16°C and +32°C, the cooling compartment

temperature can be adjusted between 0°C and +6°C using the thermostat. The

minimum temperature of the freezer compartment is - 12°C.

You can make ice cubes using the ice tray placed in the freezer compartment.

Defrosting of the appliance is either automatic, where the appliance is switched off for

1,5 to 2 hours every 24 hour by the installed control, or it is semi-automatic and can

be initiated by pressing the defrost switch. Restart is done automatically in both

cases.

1.2. Important Notes

- Do not repair or clean the appliance with the power supply cord plugged in!

- The appliance may only be operated by adults!

- All instructions in the operating manual must be followed when operating

the appliance!

- Any repair or service of the appliance that involves disassembling electrical

parts may be carried out by authorized service technicians only!

- Certain parts of the aggregate remain hot for a while after shutdown;

service must be carried out with caution!

- After any repair that involves disrupting the electrical circuit or the

replacement of aggregate, an electrical insulation resistance test must be

carried out at all times! (see 2.3.3.)

- Only appliances with compliance qualifications may be connected to the

mains!

- It is recommended to wear protective gloves for operations with possible

hand injuries!

1.3. Spare parts, electrical wiring diagram

The lists of spare parts and electrical wiring diagrams by Product numbers can be

found on the web page http://www.electrolux-ti.com.

Attention!

Any functional parts that need to be replaced during repair may only be

replaced by parts identical to the originals and which were chosen based

on the list of spare parts!

Page 4

4

2. Installation and repair operations

2.1. Tools

Recommended tools:

- Universal pliers 160-mm, 2 pc.

- magnetic screwdriver handle

- Pz 1 fitting-strip

- Pz 2 fitting-strip

- Phillips screwdriver Ph 1

- Standard screwdriver 120 * 5

- Standard screwdriver 100 * 4

- 14-mm wrench

- Electric hand drill whit φ 3,2 mm drill

Figure 1

Page 5

5

2.2. Cabinet, door

2.2.1. Adjusting right and left-hand swing door

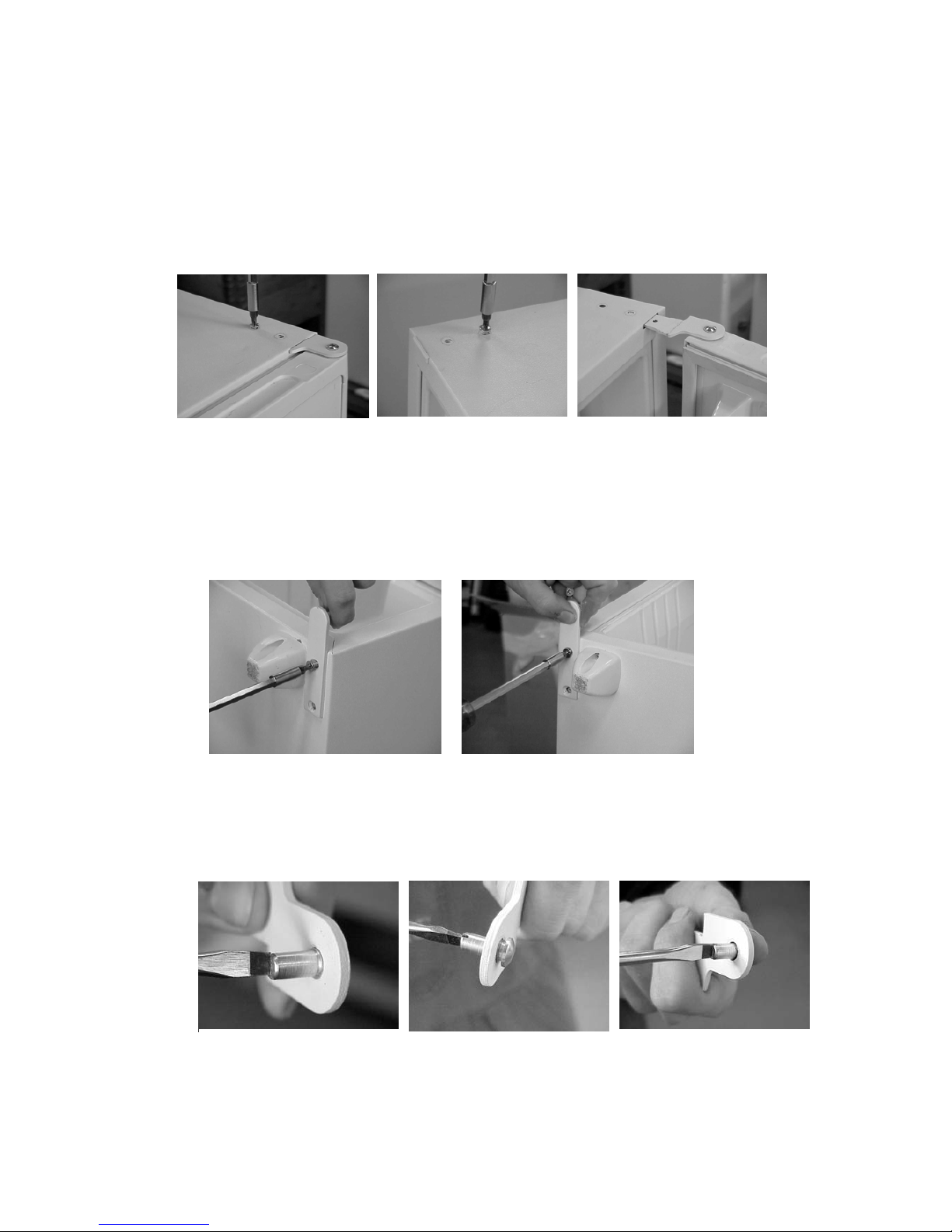

- Unscrew top door mount screws. (Fig. 2)

- Unscrew door mount hole cover screws. (Fig. 3)

- Open door.

- Pull top door mount by tilting door. (Fig. 4)

- Set aside door mount, unhinge door from bottom door mount pin.

- Pull door mount hole cover. Help with standard screwdriver when pulling.

- Place cabinet on its back carefully so that the hinge is not damaged.

- Install bottom door mount on opposite side. (Fig. 5, 6)

- Unscrew door mount pin from top door mount, then screw from opposite

direction and tighten. (Fig. 7, 8, 9)

Figure 2 Figure 3 Figure 4

Figure 5 Figure 6

Figure 7

Figure 8

Figure 9

Page 6

6

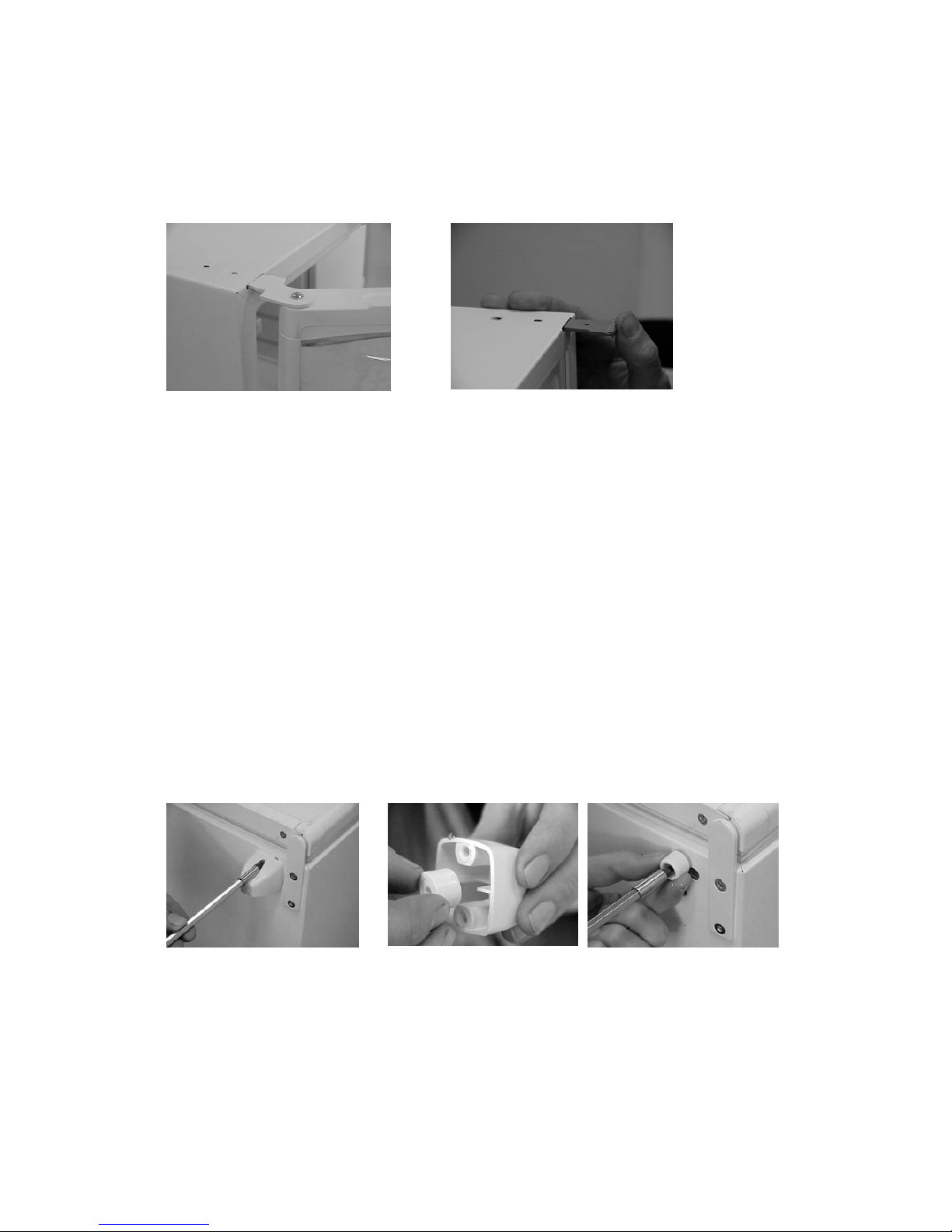

- Stand cabinet on its legs.

- Place door on bottom door mount.

- Place the replaced top door mount pin into top door mount bore of door,

then push door mount into left-hand-side opening of cabinet and secure

with 2 screws. (Fig. 10)

- Push door mount hole cover into upper right-hand-side opening, then

secure with a screw. (Fig. 11)

Make sure of unhindered opening and appropriate secure sealing of the door.

If needed, make corrections after loosening the screws that secure the door.

Re-fasten the screws.

- When only replacing the door, dismounting of the door mount hole cover

and door stop or the switching of the door mounts is not necessary.

2.2.2. Replacing legs

- Place unit on its back carefully so that the hinge is not damaged.

- Dismount outer legs by unscrewing 2-2 screws. (Fig. 12)

- Take out inner legs from outer legs. (Fig. 13)

- Mount inner legs by securing them using bores further apart from each

other. (Fig. 14)

- Screw remaining screws into appropriate bores, fasten.

- Set aside the outer legs (possible re-mounting).

- Place the refrigerator on its legs.

Figure 10 Figure 11

Figure 12 Figure 13

Figure 14

Page 7

7

2.2.3. Replacing cowl

- Turn cabinet onto door using appropriate protection support.

- In case of curved door use support on both sides to avoid oscillation

(cardboard support).

- Unscrew the screw that secures cowl, while keeping the end of cowl from

folding down. (Fig. 15, 16)

- Lastly, remove screw next to boiler insulation.

(mounting ease) (Fig. 17)

- Lift up cowl, then put replacement part in place.

- Fasten screws starting with the screw next to boiler insulation, while

holding the unfastened end of cowl with your hand.

- Tighten screws. While fastening, check the leveling of cowl and plate.

Adjust as necessary.

2.2.4. Replacing lock

”Snap lock” model

- Open door.

- Pull down rosette using 2 standard screwdrivers. (Fig. 18)

- Pop up lock cover:

With the bolt in locked position, pull the rim of lock cover onto the bolt

using a standard screwdriver to keep it from snapping back. (Fig. 19)

Snap off lock cover lid using 2 standard screwdrivers. (Fig. 20)

Figure 15

Figure 16 Figure 17

Figure 18

Figure 19 Figure 20

Page 8

8

- Unscrew securing screws. (Fig. 21)

- Pull out lock. (Fig. 22)

- Reassembly is done in reverse order.

- Rosette and lock cover lid should be snapped in place applying slight

pressure.

When popping the lock cover lid open, the bolt must be in locked position.

”Turn lock” model

- Open door.

- Pull down rosette using 2 standard screwdrivers.

- Unscrew securing screws.

- Pull out lock toward door lining.

- Push new lock in lock bore of door.

- Reinsert and tighten securing screws.

- Push rosette in place applying slight pressure.

2.2.5. Replacing door panel

- Replacement of the door panel should be done with the door detached and

the lock dismounted.

- Remove door shelves. They can be removed by lifting the shelves.

- Place door – with door lining down – on protective support.

- Unscrew screws that secure locking-panel. (Fig. 23)

- Lift locking-panel from its nest. (Fig. 24)

- Pull out door panel. (Fig. 25)

Figure 21 Figure 22

Figure 23

Figure 24

Figure 25

Page 9

9

- Adjust foil lining.

- Place the the door panel up to the handle lath into groove on one side of

door.

- Slightly bend door panel. (Fig. 26)

- Snap door panel into place in groove on other side of door.

- Push door panel until cylindrical bores on the plate and on the door are

concentric. (Fig. 27)

- Insert locking-panel, secure with screws.

- Reinstall lock.

- Reinstall door.

2.2.6. Replacing freezer door

- Open refrigerator door.

- While the freezer door is shut, insert a standard 4*100 screwdriver

between the freezer’s top door mount and the freezer door, with slight

pressure lift the top door mount pin out from its bore. (Fig. 28)

- Tilt and remove the freezer door by a quick pull on the upper edge of the

freezer door. (Fig. 29)

- Lift out the freezer door from the bottom door mount bore, then remove the

bottom hinge pin from the freezer door bore. (Fig. 30)

- Insert the hinge pin into the bottom bore of the new freezer door. (Fig. 31)

- Insert the freezer door with the pin into the freezer’s door mount bore so

that the bolt secures the freezer door. (Fig. 32)

- Inserting a standard 4*100 screwdriver between the freezer door and the

upper freezer door mount, bend the freezer door mount upwards.

- Applying slight pressure on the upper part of the freezer door, snap the top

door mount pin in place. (Fig. 33)

Figure 26 Figure 27

Figure 28 Figure 29 Figure 30

Page 10

10

- Check the unhindered operation and closing of the freezer door.

2.3. Electrical components

2.3.1. Replacing lighting device and bulb

- Remove screws securing lighting device. (Fig. 34)

- Detach blocking tab on reflector from the lighting device by pressing the

reflector plate. At the same time, push the light shield off of the casing.

(Fig. 35, 36)

- Unscrew bulb. (Fig. 37)

- Snap the lighting device open by detaching the tab behind the threaded

part of the casing with a screwdriver. (Fig. 38)

Figure 31

Figure 32

Figure 33

Figure 34

Figure 35

Figure 36

Figure 37 Figure 38

Page 11

11

- Disconnecting electrical wires, removing defective lighting device.

- Reconnecting electrical wires in new casing. Prior to wiring, wires must be

threaded in the appropriate bore of the reflector holder. (Fig. 39)

- Placement of the socket in the casing so that its securing rib fits in the

groove of casing. Screws securing the wires must stand outwards from

lighting device. (Fig. 40)

- Insert control switch while holding socket in place with your finger. Screw in

bulb while constantly holding down the socket. (Fig. 41)

The bulb holds the socket elements in place, then the reflector mount can

be popped open. When snapping shut, the blocking tab should be slightly

pressed with a screwdriver. (Fig. 42, 43)

- After snapping shut, fitting should be tested.

- Replacing light shield. Make sure that the groove fits correctly on the light

shield.

While pushing aside the blocking tab of the reflector plate with a

screwdriver, the casing can be pushed in place. (Fig. 44)

Figure 40

Figure 39

Figure 41

Figure 42 Figure 43

Page 12

12

- Prior to installing the lighting device, the securing screws must be

reinserted into the lighting device so that the tips of the screws overhang

by 1-2 mm. These help positioning. (Fig. 45)

- Install lighting device, with attention to the placement of electrical wires.

- Tightening securing screws. Make sure it fits correctly. Then must be no

gap between the lighting device and the inner compartment.

2.3.2. Replacing bulb without dismounting the lighting device

- By pushing the reflector plate unhinge blocking tab on reflector from the

light shield. At the same time, push the light shield off of the casing with a

screwdriver. (Fig. 46)

- Unscrew defective bulb and replace with a new one; pay attention to

appropriate back-up power. Bulb needs to be tightened to an extent that

loose connection does not cause contact failure. (Fig. 47)

- Replacing the light shield. Make sure the groove fits correctly on the light

shield. (Fig. 48)

The light shield can be slid in place by slightly pressing the blocking tab

with a screwdriver.

Figure 44 Figure 45

Figure 46 Figure 47

Figure 48

Page 13

13

2.3.3. Replacing heating element (cylindrical heating element) :

- Remove screws of electrical cover. (Fig. 49, 50)

- Remove electrical cover.

- Disconnect electrical wires of heating element. (Fig. 51, 52, 53)

- Unscrew and remove the wire clamp. (Fig. 54)

Figure 49

Figure 50

Figure 51

Figure 52

Figure 53 Figure 54

Page 14

14

- Turn metal casing of boiler-insulation so that the joint rim becomes visible.

- While slightly pressing the metal casing of the boiler-insulation, detach the

rims. (Fig. 55)

- Turn out insulation – metal casing and rock wool together – from under the

boiler. (Fig. 56)

- Loosen screw securing the element, pull out heating element upwards. If

the heating element is jammed in the heating tube, then push it out from

below with a screwdriver. (Fig. 57, 58)

- Installing the new heating element is done in reverse order. The

heating element must be securely fixed. (It must not slide out at 100 N

axially tractive effort.)

- Attention ! The electrical power of a heating element with ”fuzzy logic”

control is different from those with electromechanical control!

- The boiler-insulation can be reinserted by turning it in. The rims must be

snapped together by slightly pressing the metal casing.

- Turn in boiler-insulation so that the securing bore is in the correct position.

- Attach boiler-insulation to back panel with securing screw.

- Adjust wires.

- Connect electrical connections at the appropriate points.

- In appliances with ”fuzzy logic” control, snap back the printed circuit board

into the base board. When replacing, make sure that the driving shaft

jointing fits in the potentiometer’s bore.

- Secure wire clamp.

- Reinsert electrical cover, secure with screws.

Figure 55 Figure 56

Figure 57 Figure 58

Page 15

15

- Place refrigerator in upright position. Check that the thermostat switch

turns freely in the entire control range.

- Check electrical insulation resistance (with 1000-V electrical insulation

resistance metering device.)

The insulation resistance R

INS

> 2Mohm

2.3.4. Replacing heating element (”Half-moon” shaped, as of May 2003):

- Unscrew hinge screw on boiler side, slightly bend out side wall of hinge.

(Fig. 59)

- Remove temperature controller from boiler

- Bend out tabs of boiler casing.

- Lift off boiler’s cover. (Fig. 60, 61)

- Remove boiler insulation.

- Mark securing position of the heating element on the boiler to help

reassembly. (marker)

- Push down clamp securing element wire. (Fig. 62)

- Rotate back heater element in the direction of back panel. (Fig. 63)

- Push down securing clamp of heater element using 2 universal pliers.

(Fig.64)

- Replace the heating element. Electronically, this operation is identical to

those described for cylindrical element.

- Attention! The electrical power of a heating element with ”fuzzy logic”

control is different from those with electromechanical control!

- Positioning the heating element. Place securing clamp in the middle of the

element.

Place upper edge of heating element at the marking of position.

- By applying firm pressure to the clamp, snap the heating element onto the

boiler.

Figure 59 Figure 60 Figure 61

Figure 62 Figure 63 Figure 64

Page 16

16

- Position element, adjust its position. The element must be positioned in the

direction of hinge. (Fig. 65)

- Reinsert boiler-insulation, secure.

- Reinsert boiler-insulation cover, bend back blocking tabs. (Fig. 66)

- Reinsert temperature controller

- Snap back wire clamp of heating element. (Fig. 67)

- Reassemble loosened end of hinge

- Check electrical insulation resistance according to 2.3.3.

2.3.5 Replacing temperature sensor

- Remove electrical cover. (See 2.3.3)

- Push off flat sockets of temperature sensor from the flat connectors of

printed circuit board. (Sensor)

- Open refrigerator door, remove plugs from two bores of sensor cover in the

inner compartment, set aside. (Fig. 68)

- Unscrew screws of sensor cover, lift out sensor from cover. (Fig. 69, 70)

- Pull out sensor wire towards inner compartment carefully, so that the flat

sockets do not get jammed in the lead rubber gasket. (Fig. 71, 72)

Figure 65 Figure 66 Figure 67

Figure 68 Figure 69 Figure 70

Figure 71 Figure 72

Page 17

17

- Thread back new sensor wire.

Practical way to do it:

From the back panel side, insert a 4x100 standard screwdriver through

the lead bore. Slightly push the flat connector of sensor insulation

socket onto the edge of the screwdriver, secure with insulating tape.

Fold back the end of wire with insulation socket by 180°. Using the

screwdriver, pull the wire through the bore, then using that pull through

the other end of the wire as well. (Fig 73, 74)

When pulling through, pay attention to the position of the lead rubber

gasket. If it falls out, it must be put back in the bore by all means.

- Place the sensor head in the nest of the sensor cover, screw the cover

back in place.

- Place the 2 plugs back in the bores of cover.

- Push back the sensor wires onto the flat connectors of the printed circuit

board (Sensor). The sensor is not sensible to the two wires reversed.

- Screw electrical cover back on.

- Check electrical insulation resistance according to section 2.3.3.

2.3.6 Replacing thermostat

- Dismount cooling flange by unscrewing its 4 securing screws. (Fig. 75)

- Pull out thermostat capillary from cooling flange bore, straighten.

(Fig. 76, 77)

Figure 73 Figure 74

Figure 75 Figure 76 Figure 77

Page 18

18

- Pop out wire plug from thermostat switch, pull off thermostat switch from

the thermostat switch’s axis with a universal plier with protective coating.

(Fig. 78, 79)

- If the gasket slips off of the thermostat switch, remove it from the bore with

a magnetic screwdriver, detach it to the driving bolt. Reinsert the plug into

the bore, set aside switch. (Fig. 80, 81)

- Lay refrigerator onto door, support if necessary.

- Remove thermostat cover. (Fig. 82, 83)

- Remove electrical wire from thermostat.

- Unscrew securing screws from thermostat. (Fig. 84)

- Dismount thermostat case by loosening the locking nut. (Fig. 85)

- Pull out thermostat capillary from refrigerator cabinet, remove defective

thermostat.

Figure 78 Figure 79

Figure 80

Figure 81

Figure 82

Figure 83

Page 19

19

- Reinstall thermostat case onto the new thermostat, secure with nut. During

assembly make sure that the navigation-securing pin of thermostat fits into

the bore of plate. (Fig. 86)

- Reinsert thermostat onto panel, secure with screws.

- Reassemble thermostat wires.

- Reinsert thermostat cover, secure.

- Insert thermostat capillary into cabinet approx. 200 mm deep. (Fig. 87)

- Place refrigerator in upright position.

- Insert thermostat capillary into cooling flange approx. 200 mm deep.

- Reinsert cooling flange, carefully positioning thermostat capillary, then

secure with 4 plate screws (the original corrosion-proof screws should be

used).

- Push thermostat switch back onto the shaft of thermostat. When

positioning, make sure that the shaft jointing fits with the switch bore

jointing. (Fig. 88)

Figure 84 Figure 85

Figure 86

Figure 87

Figure 88

Page 20

20

- Make sure that the thermostat can be turned within the entire control

range.

- Adjust the capillary spiral that remains outside of thermostat so that it does

not overhang from the outline of the cabinet.

- Seal the point of exit of capillary from the cabinet with rubber sealing.

- Check electrical insulation resistance according to 2.3.3.

2.3.7 Replacing timer

Paragon-type timer

- Remove timer cover. (Fig. 89)

- Remove wire clamp, push down electrical wire. (Fig. 90)

- Unscrew screws securing timer. (Fig. 91)

- Replace timer, set: turn defrost marking clockwise by 90º compared to

marking on the casing. Meanwhile, you should hear 2 clicks. This way the

timer is definitely turned on. (Fig. 92, 93)

- Reinsert timer, making sure that the rotating part sits in the bore of the

textile-bakelite housing. (Fig. 94)

- Secure timer with screws.

- Push back electrical wires according to the wiring diagram.

- Reinsert timer cover, secure.

- Check electrical insulation resistance according to 2.3.3.

Figure 89 Figure 90 Figure 91

Figure 92 Figure 93

Figure 94

Page 21

21

Diehl-type timer

The Diehl-type timer is not equipped with a separate cover, the control switch

is covered with a transparent cover. Its electrical wiring is exactly identical to

that of Paragon timer connection.

Setting the new timer after replacement:

- On the 24-hour control switch, on which one notch means 15 minutes,

push out 6 pins radially (1,5 hour period). All the other switch pins must be

in pushed-in position.

- The first pushed out pin on the control switch must be rotated to 0.00 hour.

This way the switch-on is set to 1.30 hour. The control switch may only be

rotated clockwise.

- Reinsert control switch cover.

2.3.8 Appliance with semi-automatic defrosting

In some models defrosting is not controlled by automatic controls but the user

needs to initiate it by pressing the defrost switch located at the center of the

thermostat switch. Restarting is done automatically by the thermostat. Its

assembly is almost identical to electromechanical thermostats with timers.

- The defrost switch is located in the place of the plug, in the middle of the

thermostat switch.

- It is pulled of together with the thermostat switch.

- It can be reassembled after pushing up the thermostat switch. The defrost

switch should be inserted in the bore of the thermostat switch and should

be pushed up onto the defrost pin in the middle of the thermostat shaft with

an approx. Ø5 cylinder pin.

Naturally, there is no defrost timer in these devices.

2.3.9 Temperature controller (as of April 2002)

The temperature controller – in the event of a circuit break – may not be

replaced as a service component. If switched off, the cooling appliance may

only be repaired by replacing the aggregate.

The aggregate for servicing purposes is only available as a set.

Beside the aggregate, the set includes:

- 1 temperature controller with the necessary maximum length wire, without

the connection element on the ends of the wire.

- 1 set of all available electrical connection elements, also the screws

needed for installation.

The description of the application can be found in section 2.4.1 (Replacing

cooling aggregate).

Page 22

22

2.4. Cooling aggregate

2.4.1. Replacing cooling aggregate

Attention! The cooling aggregate of refrigerators that are equipped

with a temerature controller (as of April 2002) must only be replaced

when also replacing the temperature controller or, in the event of a circuit

break in the temperature controller, the cooling aggregate must also be

replaced at all times.

In appliances with no temerature controller only the aggregate needs to be

replaced. The assembly instructions must be applied accordingly.

In case of electrical circuits of appliances with ”Fuzzy logic” and with

electromechanical thermostats the procedures should be followed

accordingly.

- Open refrigerator door.

- Unscrew 4 screws of cooling flange, remove cooling flange. (Fig. 95)

- Open freezer door, unscrew 2 screws securing freezer. (Fig. 96)

- Turn refrigerator onto its door, secure. (see: 2.3.3)

- Disassemble heating element from boiler (see: 2.3.3, 2.3.4)

- Remove electrical cover or thermostat cover.

- Disconnect electrical wire of temperature controller.

- Pull apart temperature controller – heating element connection.

- Unscrew wire clamp. (See: 2.3.3)

- Unscrew screws securing aggregate. (Fig. 97)

- Pull off drain water evaporator from fluid heat-exchange pipe.

- Lift out aggregate, set aside for workmanlike destruction. (Fig. 98)

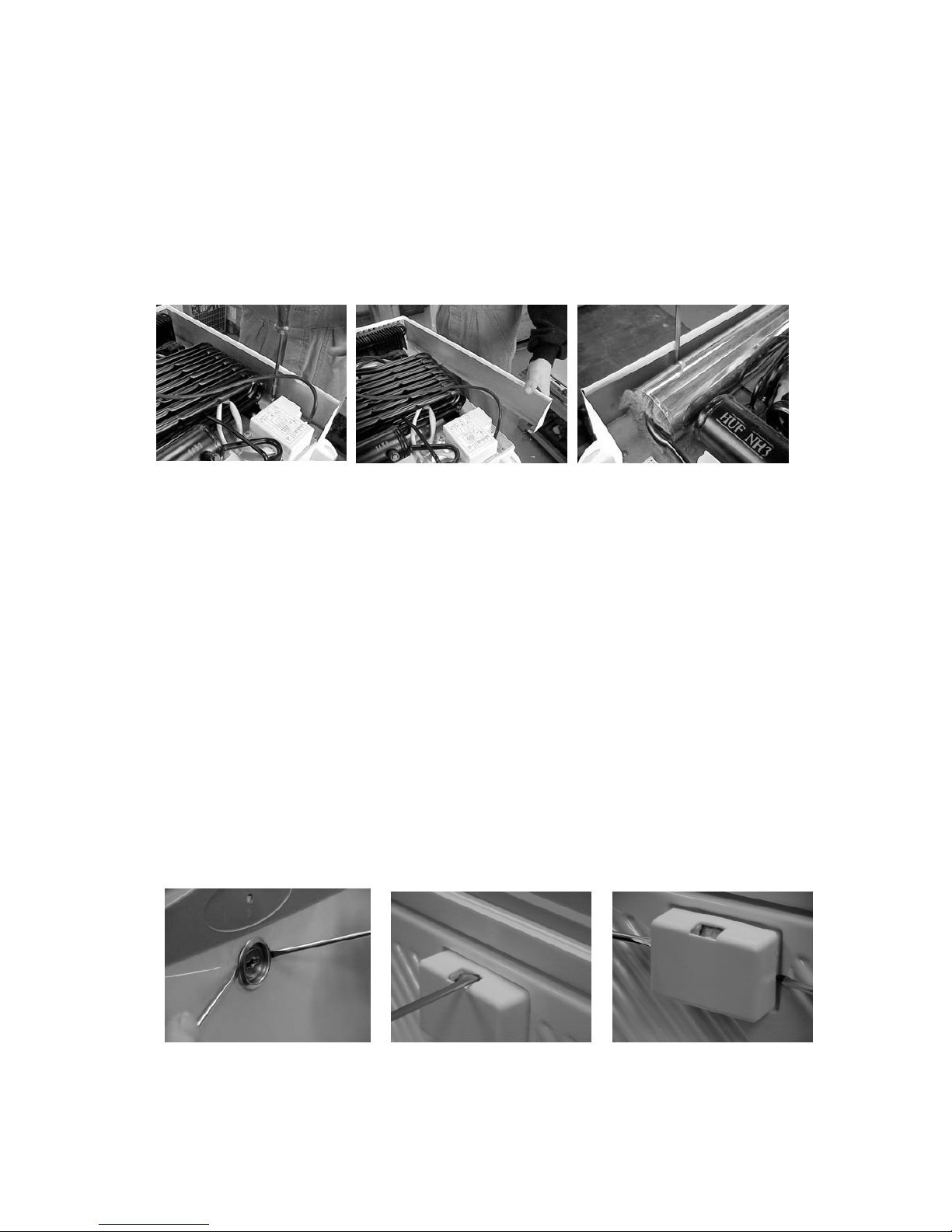

Figure 95 Figure 96

Figure 97

Figure 98

Page 23

23

Final assembly of temperature controller, mounting onto aggregate:

(This procedure is not necessary for appliances with no temperature controller)

Figure 99 presents the necessary elements and tools, for your information.

- Cut the wire of the temperature controller to size, according to the size of the wire

of the temperature controller on the replaced aggregate. (Fig. 100)

- From the connection kit, choose the connection elements that are identical to the

original temperature controllers.

- Press connection elements with press tool. (Fig. 101)

- Pull insulation sockets onto connectors. (Fig. 102)

Figure 99

Figure 100 Figure 101 Figure 102

Page 24

24

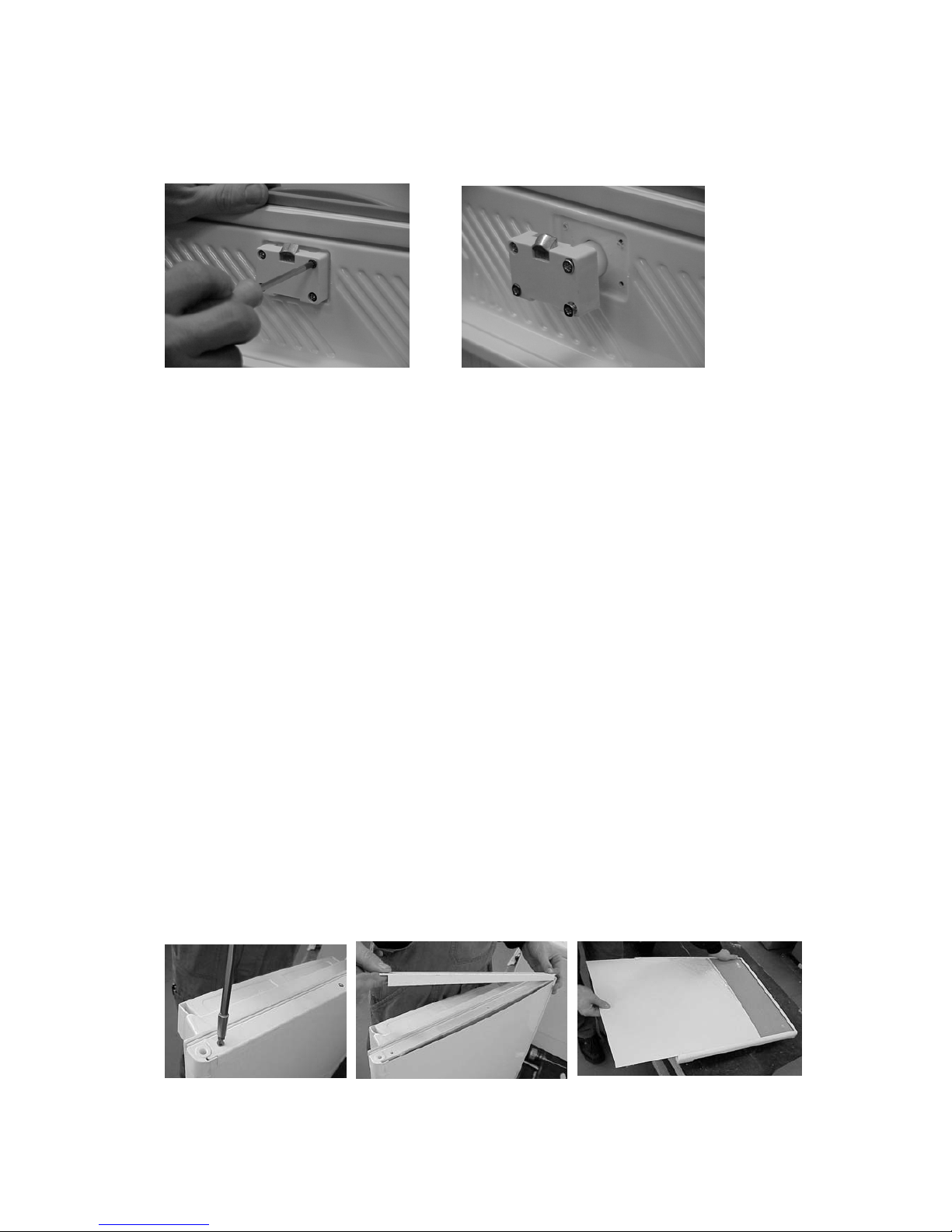

- Secure temperature controller on boiler-tube of aggregate with 2 screws.

- Pull protecting socket onto the end of outer securing screw of temperature

controller, because the sharp end of screw can cause an accident.

(Fig. 103, 104)

Installation :

- Reassemble aggregate and heating element in opposite order of

disassembly.

- Reinsert electrical connections of temperature controller according to the

status prior to disassembly.

- Screw wire clamp back on.

- Reinsert electrical cover or thermostat cover, secure with screw.

- Push drain water evaporator onto fluid heat-exchange pipe.

Make sure the drain water outlet pipe’s outlet portion reaches in the drain

water evaporator. (Fig. 105)

- Lay refrigerator on its back.

- Drill 2, 3.2mm diameter bores on the freezer mount (where the cooling

aggregate is attached to the freezer compartment) according to the

positioning of bores on the freezer compartment. (Fig. 106)

During this procedure, you must wear protective goggles !

Figure 103 Figure 104

Figure 105

Figure 106

Page 25

25

- Secure freezer compartment with 2 plate screws. Only the original

corrosion-proof screws or screws of identical quality may be used.

(Fig. 107)

- Place cooling flange back, secure with 4 plate screws. Again, only

corrosion-proof screws may be used. (Fig. 108)

- Place refrigerator in upright position, remove any metal shavings from

internal areas.

- Check electrical insulation resistance according to section 2.3.3.

Information:

Certain devices do not include all of the elements (lock, lamp, hinge).

Parts of the instructions describing this do not apply to such devices.

Jászberény, 12/12/2003 Compiled by: László Kaszab

Technologist engineer

Rev. : A

Figure 107 Figure 108

Loading...

Loading...