Dometic 641515.30, 641416.30, 641432.30, 641435.30, 641516.30 Installation Instructions Manual

...Page 1

USA

SERVICE OFFICE

Dometic Corporation

1120 North Main Street

Elkhart, IN 46514

CANADA

Dometic Corporation

46 Zatonski, Unit 3

Brantford, Ontario

CANADA N3T 5L8

RECORD THIS UNIT INFORMATION

FOR FUTURE REFERENCE:

Model Number

Serial Number

ADB Number

ADB Serial Number

Date Purchased

Roof Top Unit

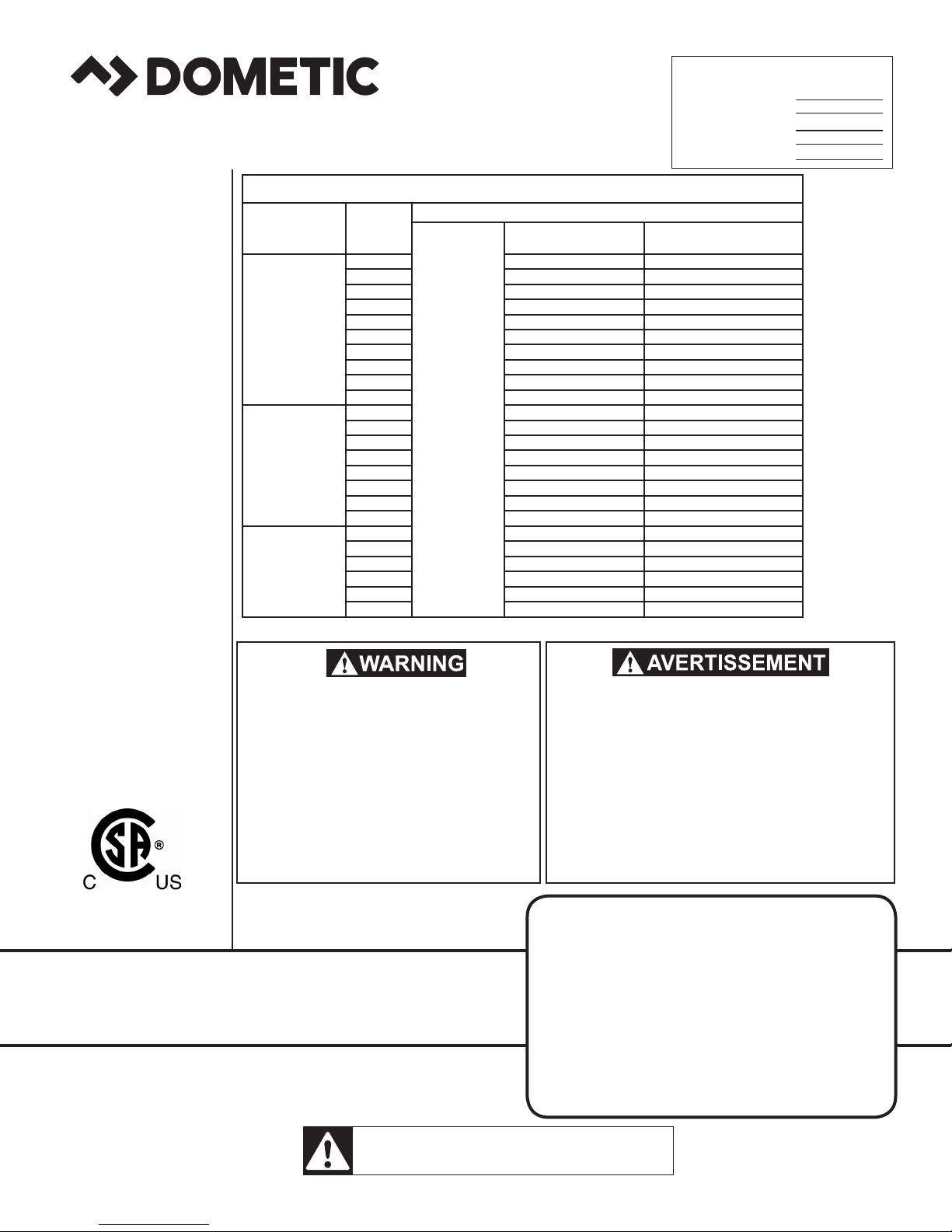

Description Model Use With Air Distribution Box

3310742.XXX Control Indoor Temperature

641415 Analog Board Built In N/A

641416 Analog Board Built In N/A

641515 CCC Board Built In Optional 3106486.XXX

641516 CCC Board Built In Optional 3106486.XXX

Air Conditioner

Air Conditioner

W/Electric Heat

Heat Pump

Note: Installation requires a #2 phillips screwdriver with 9/32" maximum diameter x 1-1/4" minimum length.

641715 Digital Board Built In N/A

641716 Digital Board Built In N/A

641815 CCC 2 Board Built In Optional 3311931.XXX

641816 CCC 2 Board Built In Optional 3311931.XXX

641915 LCD Board Built In N/A

641916 LCD Board Built In N/A

641432 Analog Board Built In N/A

641435 Analog Board Built In N/A

641535 CCC Board Built In Optional 3106486.XXX

641732 Digital Board Built In N/A

641735 Digital Board Built In N/A

641835 CCC 2 Board Built In Optional 3311931.XXX

641932 LCD Board Built In N/A

641935 LCD Board Built In N/A

651515 CCC Board Built In Optional 3106486.XXX

651516 CCC Board Built In Optional 3106486.XXX

651815 CCC 2 Board Built In Optional 3311931.XXX

651816 CCC 2 Board Built In Optional 3311931.XXX

651915 LCD Board Built In N/A

651916 LCD Board Built In N/A

Sensor

This manual must be read and

SERVICE CENTER &

DEALER LOCATIONS

Please Visit:

www.eDometic.com

understood before installation,

adjustment, service, or maintenance is performed. This unit must

be installed by a qualied service

technician. Modification of this

product can be extremely hazardous and could result in personal

injury or property damage.

INSTALLATION INSTRUCTIONS

REVISION A

Form No. 3312500.030 09/16

(French 3312709.037_A)

©2016 Dometic Corporation

LaGrange, IN 46761

Read these instructions carefully. These

instructions MUST stay with this product.

Lire et comprendre ce manuel avant de

procéder à l’installation, à des réglages,

de l’entretien ou des réparations.

L’installation de ce produit doit être

effectuée par un réparateur qualié.

Toute modication de ce produit peut

être extrêmement dangereuse et

entraîner des blessures ou dommages

matériels.

MODELS

641415.30X

641416.30X

641432.30X

641435.30X

641515.30X

641516.30X

641535.30X

641715.30X

641716.30X

641732.30X

641735.30X

641815.30X

641815C35X

1

641815.80X

641815C85X

641816.30X

641816C35X

641816.80X

641816C85X

641835.30X

641835C35X

641835.80X

641835C85X

641915.30X

641915C35X

641915.80X

641915C85X

641916.30X

641916C35X

641916.80X

641916C85X

641932.30X

641935.30X

641935C35X

641935.80X

641935C85X

651515.30X

651516.30X

651815.30X

651815C35X

651815.80X

651815C85X

651816.30X

651816C35X

651816.80X

651816C85X

651915.30X

651916.30X

651916C35X

651916.80X

651916C85X

Page 2

IMPORTANT SAFETY INSTRUCTIONS

This manual has safety information and instructions to help users eliminate or reduce the risk

of accidents and injuries.

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. It is used to alert

you to personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

UNDERSTAND SIGNAL WORDS

A signal word, when used with the safety alert

symbol, will identify a safety hazard and its level

of risk for personal injury. A signal word, without

the safety alert symbol, will be used for property

damage messages only.

WARNING indicates a hazard-

ous situation which, if not avoided, could result

in death or serious injury.

CAUTION, used with the safe-

ty alert symbol, indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

GENERAL INFORMATION

A. Product features or specications as described or il-

lustrated are subject to change without notice.

B. This air conditioner/heat pump (hereinafter referred to

as the "unit") is designed for:

1. Installation on a recreational vehicle during the

time the vehicle is manufactured.

2. Mounting on the roof of a recreational vehicle.

3. Roof construction with rafters/joists on minimum

of 16 inch centers.

4. Minimum of 1.00 inch and maximum of 5.5 inches

distance between roof to ceiling of recreational

vehicle.

C. The ability of the air conditioner to maintain the de-

sired inside temperature depends on the heat gain of

the RV.

Some preventative measures taken by the occupants

of the RV can reduce the heat gain and improve the

performance of the air conditioner. During extremely

high outdoor temperatures, the heat gain of the ve-

hicle may be reduced by:

1. Parking the RV in a shaded area

2. Using window shades (blinds and/or curtains)

3. Keeping windows and doors shut or minimizing

usage

4. Avoiding the use of heat producing appliances

Operation on High Fan/Cooling mode will give opti-

mum or maximum efciency in high humidity or high

outside temperature.

Starting the air conditioner early in the morning and giving

it a "head start" on the expected high outdoor ambient will

greatly improve its ability to maintain the desired indoor

temperature.

For a more permanent solution to a high heat gain, accessories like Dometic outdoor patio and window awnings

will reduce heat gain by removing the direct exposure to

the sun. They also add a nice area to enjoy company dur-

ing the cool of the evening.

D. Condensation

NOTICE is used to address

practices not related to personal injury.

Read and follow all safety information and

instructions to avoid personal injury.

Note: The manufacturer of this unit will not be responsible

for damage caused by condensed moisture on ceilings or

other surfaces. Air contains moisture and this moisture

tends to condense on cold surfaces. When air enters the

RV, condensed moisture may appear on the ceiling, windows, metal parts, etc. During normal operation this unit

removes moisture from the air. Keeping doors and windows closed when this air conditioner is in operation will

minimize condensed moisture on cold surfaces.

2

Page 3

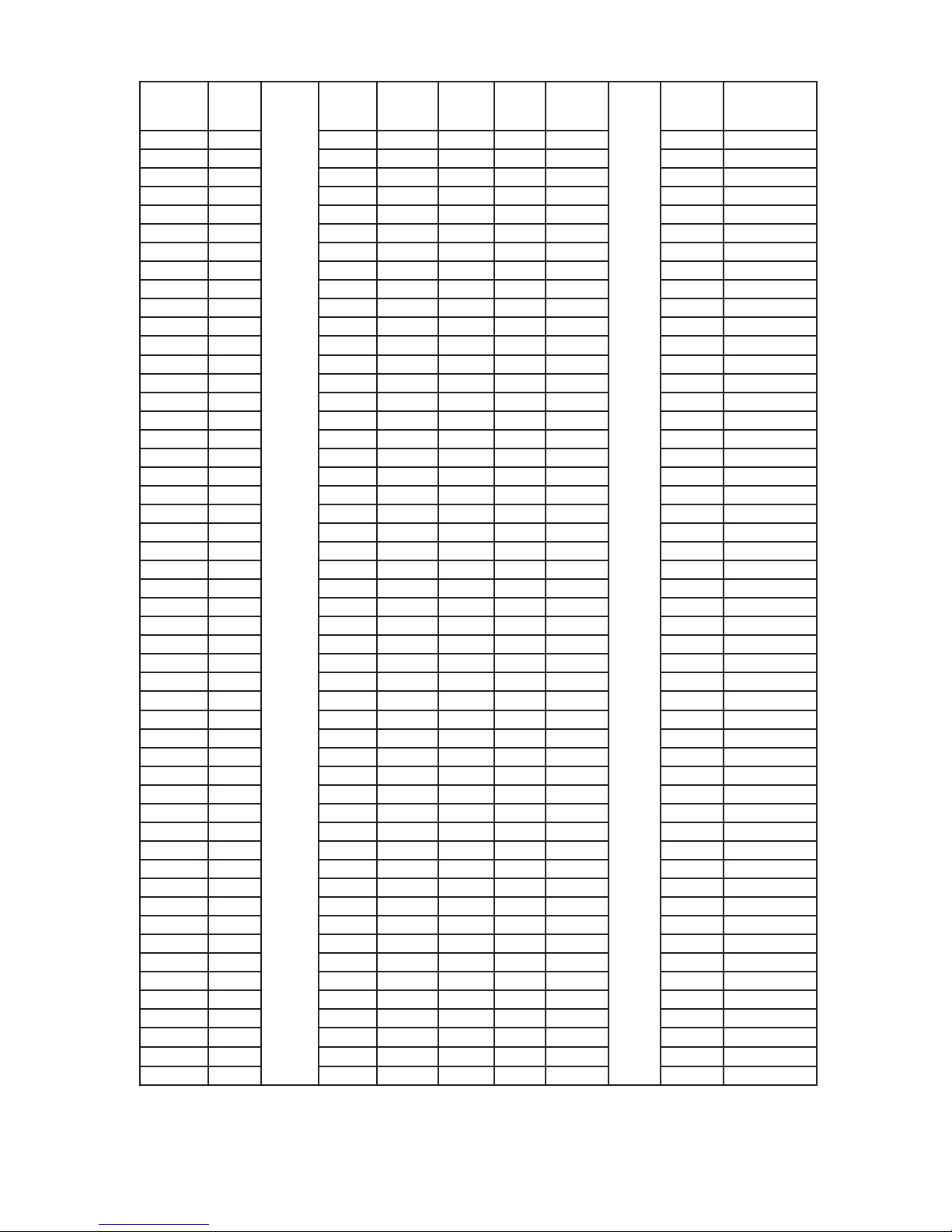

SPECIFICATIONS

Model No. Nominal

641415.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641416.30X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641432.30X 11,000 10.5 63.0 3.5 10.0 19.0 20 Amp 3.5 KW / 5.0 KW

641435.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641515.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641516.30X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641535.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641715.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641716.30X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641732.30X 11,000 10.5 53.0 3.5 10.0 19.0 20 Amp 3.5 KW / 5.0 KW

641735.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641815.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641815C35X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641815.80X 13,500 12.6 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641815C85X 13,500 12.6 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641816.30X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641816C35X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641816.80X Hi Cap 13.4 63.0 2.6 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641816C85X Hi Cap 13.4 63.0 2.6 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641835.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641835C35X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641835.80X 13,500 12.6 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641835C85X 13,500 12.6 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641915.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641915C35X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641915.80X 13,500 12.6 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641915C85X 13,500 12.6 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641916.30X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641916C35X Hi Cap 12.3 61.0 3.3 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641916.80X Hi Cap 13.4 63.0 2.6 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641916C85X Hi Cap 13.4 63.0 2.6 8.5 23.0 20 Amp 3.5 KW / 5.0 KW

641932.30X 11,000 10.5 53.0 3.5 10.0 19.0 20 Amp 3.5 KW / 5.0 KW

641935.30X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641935C35X 13,500 12.5 61.0 3.5 10.0 17.5 20 Amp 3.5 KW / 5.0 KW

641935.80X 13,500 12.5 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

641935C85X 13,500 12.5 63.0 2.6 8.5 19.0 20 Amp 3.5 KW / 5.0 KW

651515.30X 13,500 12.5 61.0 3.5 10.0 25.0 20 Amp 3.5 KW / 5.0 KW

651516.30X Hi Cap 12.3 61.0 3.3 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651815.30X 13,500 12.5 61.0 3.5 10.0 25.0 20 Amp 3.5 KW / 5.0 KW

651815C35X 13,500 12.5 61.0 3.5 10.0 25.0 20 Amp 3.5 KW / 5.0 KW

651815.80X 13,500 13.1 63.0 2.6 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651815C85X 13,500 13.1 63.0 2.6 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651816.30X Hi Cap 12.3 61.0 3.3 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651816C35X Hi Cap 12.3 61.0 3.3 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651816.80X Hi Cap 13.4 63.0 2.6 8.5 27.0 20 Amp 3.5 KW / 5.0 KW

651816C85X Hi Cap 13.4 63.0 2.6 8.5 27.0 20 Amp 3.5 KW / 5.0 KW

651915.30X 13,500 12.5 61.0 3.5 10.0 25.0 20 Amp 3.5 KW / 5.0 KW

651916.30X Hi Cap 12.3 61.0 3.3 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651916C35X Hi Cap 12.3 61.0 3.3 8.5 24.0 20 Amp 3.5 KW / 5.0 KW

651916.80X Hi Cap 13.4 63.0 2.6 8.5 27.0 20 Amp 3.5 KW / 5.0 KW

651916C85X Hi Cap 13.4 63.0 2.6 8.5 27.0 20 Amp 3.5 KW / 5.0 KW

Capacity

(BTU HR)

Cooling

* For wire length over 24 ft., consult the National Electric Code for proper sizing.

** Dometic Corporation gives GENERAL guidelines for generator requirements. These guidelines come from experiences

people have had in actual applications. When sizing the generator, the total power usage of your recreational vehicle

must be considered. Keep in mind generators lose power at high altitudes and from lack of maintenance.

*** CIRCUIT PROTECTION: Time Delay Fuse or Circuit Breaker Required.

Electrical

Rating

120 VAC

60Hz. 1PH

Compressor

Rated Load

Amps

Compressor

Locked Rotor

Amps

Fan Motor

Rated Load

Amps

3

Fan Motor

Locked

Rotor

Amps

Refrigerant

R-410A

(Oz.)

Minimum

Wire Size*

12 AWG

Copper

Up to 24'

AC Circuit

Protection

***Installer

Supplied

Minimum

Generator

Size**

1 Unit / 2 Units

Page 4

INSTALLATION INSTRUCTIONS

FIG. 1

A. Precautions

PERSONAL INJURY HAZARD. Failure to obey

these installation instructions may cause serious personal injury and/or property damage.

1. Read installation and operating instructions carefully before attempting to start this unit installation.

2. Dometic Corporation will not be liable for any

damages or injury incurred due to failure in fol-

lowing these instructions.

3. Installation MUST comply with the National Elec-

trical Code ANSI/NFPA-70 and CSA Standard

C22.1 (latest edition) and any State or Local

Codes or regulations.

4. Do NOT add any devices or accessories to this

unit except those specically authorized in writing

by Dometic Corporation.

5. This equipment MUST be serviced by qualied

personnel and some states require these people

to be licensed.

B. Choosing Proper Location For The Unit

This unit is specically designed for installation on the

roof of a recreational vehicle (RV). When determining

your cooling requirements, the following should be

considered:

• Size of RV;

• Window area (increases heat gain);

• Amount of insulation in walls and roof;

• Geographical location where the RV will be used;

• Personal comfort level required.

1. For one unit installation: The unit should be

mounted slightly forward of center (front to back)

and centered from side to side.

2. For two unit installations: Install one unit 1/3 and

one unit 2/3's from front of RV and centered from

side to side.

It is preferred that the unit be installed on a relatively at

and level roof section with the RV parked on a level sur-

face, but up to a 8° tilt is acceptable.

3. After Location Has Been Selected

a. Check for obstructions in the area where unit

will be installed. See FIG. 1.

9-1/2"

40"

29"

Dimensions Are Nominal

Keep These Areas

12"

4"

Dimensions Are Nominal

Free Of Obstructions

14-1/4" x 14-1/4"

(± 1/8") Opening

Front

4"

b. The roof must be designed to support 130

pounds when the RV is in motion. Normally a

200 lb. static load design will meet this require-

ment.

PROPERTY DAMAGE HAZARD. It is the responsibility of the installer of this system

to ensure structural integrity of the RV roof.

Never create a low spot on the roof where

water will collect. Failure to obey this warning may cause water damage to the product

and the RV.

c. Check inside the RV for air distribution box

obstructions. (i.e. door openings, room dividers, curtains, ceiling xtures, etc.) See FIG. 2.

FIG. 2

4-15/16"

5-1/8"

Air Distribution Box

25"

20"

Dimensions Are Nominal

3"

9-3/16"

Air

5-29/64"

Duct

2-15/16"

3"

Front

2-3/4"

(overall

depth)

Front

6"

View From Above

Dimensions Are Nominal

4

14-1/4" x 14-1/4" (±1/8")

Opening

Page 5

C. Roof Preparation

1. Opening Requirements - Before preparing the

ceiling opening, the type of system options must

be decided upon. Read all of the following instructions before beginning the installation.

SHOCK HAZARD. There may be electrical

wiring between the roof and the ceiling. Disconnect 120 VAC power supply and the positive (+) 12 VDC terminal at the supply battery.

Failure to obey this warning may cause death

or severe personal injury.

2. Mark a 14-1/4" x 14-1/4" (±1/8") square on the

roof and carefully cut the opening. The 14-1/4"

x 14-1/4" (±1/8") opening is part of the return air

system of the unit and MUST be nished in accordance with ANSI A 119.2.

3. Using the roof opening as a guide, cut the matching hole in the ceiling.

4. The opening created must be framed to provide

adequate support and prevent air from being

drawn from the roof cavity. Framing stock 3/4"

thick or more must be used. Remember to pro-

vide an entrance hole at the front of the opening

for power supplies, indoor temperature sensor (if

applicable), communication cable, and furnace

wiring (if applicable). See FIG. 3.

D. Wiring Requirements

1. Route a copper, with ground, 120 VAC supply

wire from the time delay fuse or circuit breaker

box to the roof opening. The proper size wire can

be determined from the chart on page 3.

a. This supply wire must be located in the front

portion of the 14-1/4" x 14-1/4" (±1/8") opening.

b. The power MUST be on an appropriately

sized separate time delay fuse or circuit

breaker. The proper size protection can be

determined from the chart on page 3.

c. Make sure at least 15" of supply wire extends

into the roof opening. This insures an easy

connection at the junction box.

d. Wiring MUST comply with National Electri-

cal Code ANSI/NFPA-70 and CSA Standard

C22.1 (latest edition) and any State or Local

Codes or regulations.

e. Protect the wire where it passes into the

opening with approved method. See para-

graph "d" above.

2. Route a dedicated 12 VDC supply wire (18-22

AWG) from the RV's converter (ltered side) or

battery to the roof opening.

Note: When a Comfort Control Center (hereinafter re-

ferred to as CCC) thermostat is being installed with multiple zones, this 12 VDC supply wire needs to be supplied

to the unit designated zone 1 only.

FIG. 3

Do Not Cut Roof

Structure Or

Rafters

3/4" Min.

Leave Access For Power

Supply Wiring

Good-Rafters

Supported By

Cross Beams

Good LocationBetween Roof

Rafters

Frame Opening So It

Won't Collapse When

Bolting Down Unit

15" Min. At

Front Of

Opening

PROPERTY DAMAGE HAZARD. It is the responsibility of the installer of this system to

ensure structural integrity of the RV roof. Never

create a low spot on the roof where water will

collect. Failure to obey this warning may cause

water damage to the product and the RV.

Note: When a Comfort Control Center 2 (hereinafter

referred to as CCC 2) thermostat is being installed with

more than 2 zones, route a dedicated 12 VDC supply wire

(18-22 AWG) to zone 1 and zone 3 roof opening.

a. This supply wire must be located in the front

portion of the 14-1/4" x 14-1/4" (±1/8") opening.

b. Make sure that at least 15" of supply wire ex-

tends into the roof opening.

3. Route an indoor temperature sensor (Optional)

from the roof opening to the indoor temperature

sensor location. The 2 pin connector end goes to

the roof opening. See indoor temperature sensor

installation instructions for proper sensor location.

4. Thermostat Control Cable

a. CCC, CCC 2 & Digital thermostat.

i. Route a 4 conductor communication ca-

ble from the 14-1/4" x 14-1/4" (±1/8") roof

opening to the thermostat mounting location. Review section E "Choosing Ther-

mostat Location" before routing communication cable. Choose the shortest

most direct route. Make sure that at least

15" of wire extends into the roof opening

and 6" extends from the wall at the thermostat mounting location.

5

Page 6

Important: When more than one unit is being in-

stalled (additional zones) with the CCC and CCC 2

thermostat, an additional 4 conductor communication cable must be routed to each additional unit 141/4" x 14-1/4" (±1/8") roof opening. Make sure at least

15" of wire extends into the roof opening. See FIG. 25.

b. Analog Thermostat

i. Route a 7 conductor cable, 18 to 22 AWG,

from the 14-1/4" x 14-1/4" (±1/8") to the

thermostat mounting location. Review sec-

tion E "Choosing Thermostat Location"

before routing cable. Make sure 15" of

the wire extends into the roof opening and

6" of wire extends from the wall at the thermostat mounting location.

c. LCD Thermostat

i. Route a 3 conductor cable, 18 to 22 AWG,

from the 14-1/4" x 14-1/4" (±1/8") roof opening to the Single Zone LCD (hereinafter referred to as SZLCD) thermostat mounting

location. Review section E "Choosing

Thermostat Location" before routing

cable. Make sure that at least 15" of the

wire extends into the roof opening and 6"

extends from the wall at the thermostat

mounting location.

5. If system includes a gas furnace, route two 18

gauge thermostat wires from the furnace to the

roof opening of the unit that will control it. If more

than one furnace is to be used, route the second

set of thermostat wires to the second unit. Make

sure that 6" of wire extends into the opening.

6. Energy Management System (CCC and CCC 2

Only)

a. If an Energy Management System (load shed

feature) is to be used with the control, two

wires must be routed to the roof opening of

the zone to be managed. The signal required

for this function is normally an open relay

contact. When the EMS calls for the com-

pressor to shut off, the relay contacts should

close. Make sure at least 15" of the EMS wire

extends into the roof opening.

7. Automatic Generator Start Kit (CCC and CCC 2

Only)

a. If an Automatic Generator Start (AGS) kit will

be installed, an additional 4 conductor communication cable must be routed from the

last unit to the location of the AGS kit. Follow

AGS kit instructions for installation.

a. Locate the thermostat 54" above the oor.

b. Install the thermostat on a partition, not on an

outside wall.

c. NEVER expose the thermostat to direct heat

from lamps, sun or other heat producing

items.

d. Avoid locations close to doors that lead out-

side, windows or adjoining outside walls.

e. Avoid locations close to supply registers and

the air from them.

Note: On CCC and CCC 2 System installations WITH op-

tional indoor temperature sensor, the thermostat may be

mounted anywhere that is convenient in the RV. Try to

avoid hard to reach and hard to see areas.

F. Thermostat, Indoor Temperature Sensor,

And Thermostat Cable Installation

Note: A 2" hole in the wall is required at the CCC 2 ther-

mostat location. A 3/8" hole in the wall is required at the

CCC, Digital, Analog, and LCD thermostat location.

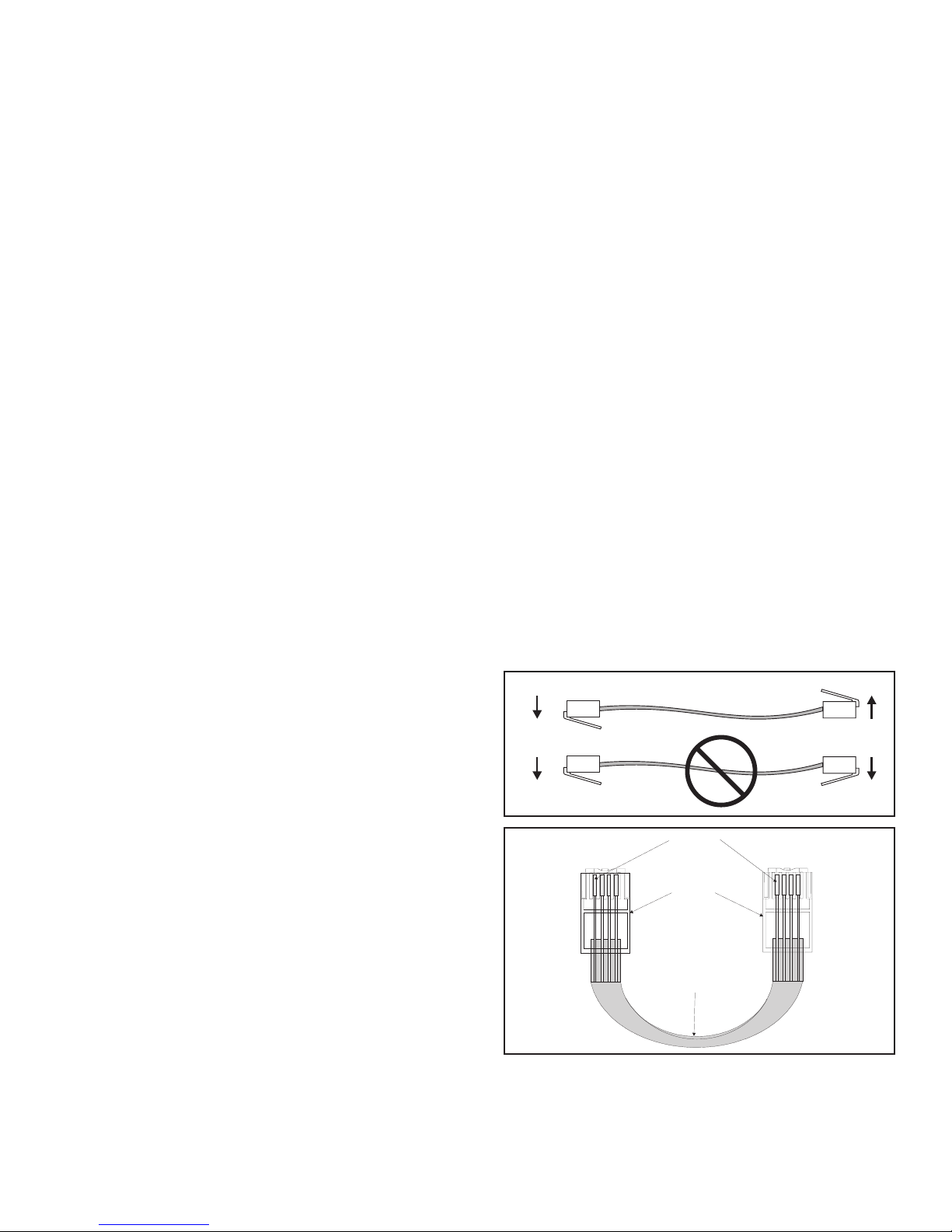

1. CCC Thermostat.

a. The previously run communication cable (4

conductor telephone cable) must be termi-

nated with two (2) RJ-11-6C4P telephone

connectors. Refer to the crimp tool manufacturer for crimping instructions. See FIGS.

4 & 5.

Important: RJ-11-6C4P connectors must be in-

stalled as shown in FIGS. 4 & 5.

FIG. 4

FIG. 5

Red

Black

Yellow

Green

Pin 1

RJ-11-6C4P

Flat Four Conductor Cable

Red

Black

Green

Yellow

E. Choosing Thermostat Location

1. CCC and CCC 2 (WITHOUT Indoor Temperature

Sensor), Analog, Digital, and Single Zone LCD

Thermostat.

The proper location of the thermostat is very im-

portant to ensure that it will provide a comfort-

able RV temperature. Observe the following rules

when selecting a location.

b. Carefully remove the base plate from the

CCC thermostat. This may be accomplished

by inserting a small screwdriver under the

tab on the bottom edge of the front cover and

gently prying. See FIG. 6

6

Page 7

FIG. 6

c. Insert the control cable through the hole in

the base plate and mount the plate to the wall

with the two (2) screws provided.

d. Install the control cable RJ-11-6C4P connec-

tor into the back of the CCC thermostat and

snap on the base plate.

e. Optional Indoor Temperature Sensor

i. Refer to the instructions provided with

the indoor temperature sensor for details

of installation.

2. CCC 2 Thermostat.

a. The previously run communication cable (4

conductor telephone cable) must be termi-

nated with two (2) RJ-11-6C4P telephone

connectors. Refer to the crimp tool manufacturer for crimping instructions. See FIGS.

4 & 5.

CCC Thermostat

Insert Screwdriver

Under Tab

Important: RJ-11-6C4P connectors must be in-

stalled as shown in FIGS. 4 & 5.

b. Choose the shortest, most direct route from

the 14-1/4" x 14-1/4" (±1/8") opening to the

selected CCC 2 thermostat location. Leave

6" of cable extending through the wall.

c. Route the communication cable through the

2" diameter hole in the wall required for the

thermostat. See FIG. 7.

FIG. 7

CCC 2 Thermostat

(Rear View)

Wall

FIG. 8

ii. Insert the 4 conductor communication

iii. Insert the 4 conductor communication

FIG. 9

iv. Align the thermostat with the back plate

3. Digital thermostat

a. The previously run communication cable (4

CCC 2 Thermostat

Disengage Tab

cable through the hole in base plate.

Align thermostat base plate with hole in

wall. Make sure base plate is level and

attach base plate to wall using the 4 sup-

plied screws.

cable connector (RJ-11-6C4P) into the

connector on the back of the thermostat.

See FIG. 9.

CCC 2 Thermostat

4 Conductor Communication Cable

and snap into position.

conductor telephone cable) must be terminated with two (2) RJ-11-6C4P telephone

connectors. Refer to the crimp to manufacturer for crimping instructions. See FIGS.

4 & 5.

d. Optional Indoor Temperature Sensor

i. Refer to the instructions provided with

the indoor temperature sensor for details

of installation.

e. CCC 2 Thermostat Installation

i. Carefully separate the thermostat base

plate from the thermostat cover. Insert

a small screw driver into the slot on bottom of thermostat and disengage the tab.

See FIG. 8.

Important: RJ-11-6C4P connectors must be in-

stalled as shown in FIGS. 4 & 5.

b. Carefully remove the base plate from the

digital thermostat. This may be accomplished

by lifting the top cover and inserting a small

screwdriver into the slot on the bottom edge

of the thermostat and base plate. Push the

small screwdriver into the slot to release

catch. See FIG. 10.

7

Page 8

FIG. 10

c. Install the communication cable through the

hole in the base plate and mount the plate

to the wall with the two (2) screws provided.

Check the alignment to ensure level installation.

d. Install the communication cable RJ-11-6C4P

connector into the back of the thermostat and

snap on the base plate.

4. Analog Thermostat

e. Make the following connections to the ther-

mostat. See FIG 11.

• Red/white wire to the +7.5 terminal

• Green wire to the "GND" terminal

• Yellow wire to "COOL" terminal

• Tan wire to the "FAN" terminal

• Blue wire to the "HI FAN" terminal

• Orange wire to the "HS/HP" terminal

• White wire to the "FUR" terminal if appli-

cable

f. Inspect all connections to make sure they are

tight and not touching any other terminals or

wires.

g. Push the wires back through the base into

the wall. Place cover on the thermostat and

push until an audible click is heard.

5. SZLCD Thermostat

Note: The wire colors listed for the three conductor cable

match the wire colors in the harness at the unit. Available

wire colors may vary.

Note: Wire colors listed for the seven conductor cable are

the most common used in the RV industry. Wire colors

may vary.

FIG. 11

a. Remove the cover from the analog thermo-

stat by starting at one corner and gently lifting

it from the base.

b. Insert the previously run seven (7) conductor

cable through the hole in the base assembly.

c. Cut back the outer cable shield approximate-

ly 3 inches and strip 1/4" insulation from each

wire.

d. Mount the thermostat level on the wall using

the screws provided.

8

FIG. 12

12V-

12V+

COMMS

a. Remove the cover from the SZLCD thermo-

stat. Depress tab on bottom of thermostat

and separate it from the base.

b. Insert the previously run three (3) conductor

cable through the hole in the base assembly.

c. Cut back the outer cable shield approximate-

ly 3 inches and strip 1/4" insulation from each

wire.

d. Mount the thermostat level on the wall using

the screws provided.

e. Make the following connections to the ther-

mostat. See FIG 12.

• Red/white wire to the 12V+ terminal

• Black wire to the 12V– terminal

• Orange wire to the "COMMS" terminal

f. Inspect all connections to make sure they are

tight and not touching any other terminals or

wires.

g. Push the wires back through the base into

the wall. Place cover on the thermostat and

push until an audible click is heard.

Page 9

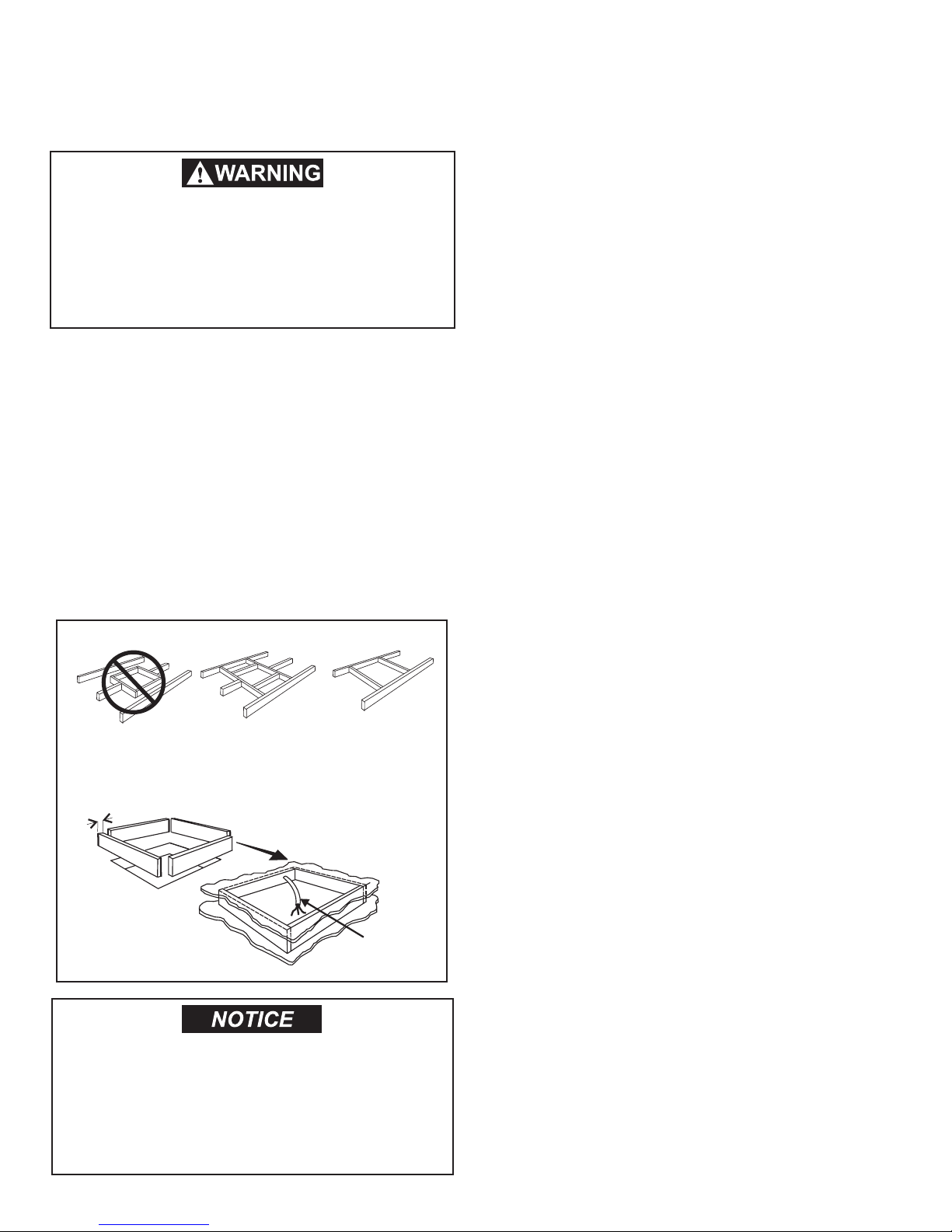

G. Placing The Unit On The Roof

1. Remove the unit from the carton and discard

carton.

PERSONAL INJURY HAZARD. This unit weighs

approximately 100 pounds. To prevent back

injury, use a mechanical hoist to place unit

on roof. Failure to obey this warning could

cause severe personal injury.

2. Remove air distribution box and mounting hardware from the air distribution box kit carton.

3. Remove wire tie holding center of rear aluminum

bracket to plastic template.

4. Reach up into the return air opening and pull the

unit electrical wires down for later connection.

5. Mount the junction box with screws to the framing

in front of the 14-1/4" x 14-1/4" (±1/8") opening.

See FIG. 15.

FIG. 15

2. Place the unit on the roof.

3. Lift and place the unit over the prepared opening using the gasket on the unit as a guide. See

FIG. 13.

PROPERTY DAMAGE HAZARD. Do not slide

the unit. Failure to obey this warning may

damage the neoprene gasket attached to the

bottom and create a leaky installation.

FIG. 13

Lift And Place

FRONT

Do Not Slide

4. Place the air distribution box kit inside the RV.

This box contains mounting hardware for the unit

and will be used inside the RV.

This completes the outside work. Minor adjustments can

be done from inside the RV if required.

Low

Voltage

Wires

AC

Power

Supply

Fasten Junction Box To

Front Of Opening

6. Base Pan Duct Adapter.

a. Remove the liner from the foam tape and posi-

tion on the base so screw hole and air openings

are aligned. See FIG. 16.

FIG. 16

Discharge

Opening Place

Flange Of Duct

On RH Side When

Facing Front

Screw

b. Install screw to help hold duct adapter to base

pan if desired.

7. 120 VAC Power Supply Connection

Front

Return Air

Opening

Base Pan

Duct Adapter

H. Installing The Unit

1. Check gasket alignment of the unit over the roof

opening and adjust if necessary. Unit may be

moved from below by slightly lifting. See FIG. 14.

FIG. 14

Center Unit From Below

Roof Gasket

SHOCK HAZARD. Disconnect 120 VAC at

the source. Failure to obey this warning may

cause death or severe personal injury.

Note: Wiring MUST comply with National Electrical Code

ANSI/NFPA-70 and CSA Standard C22.1 (latest edition)

and any State or Local Codes or regulations.

a. Install the strain relief in the junction box.

b. Route the previously run 120 VAC power

supply wire through the strain relief into the

junction box. Tighten connector making sure

not to damage wire.

Note: Connect wiring per schematic with UL listed wire

connectors for size of wire being connected.

9

Page 10

SHOCK HAZARD. This product is equipped

with a 2 wire plus ground system for protection against shock hazard. Make sure that the

unit is wired into a properly grounded 120 VAC

circuit and the polarity is correct. Failure to

obey this warning may cause death, severe

personal injury or damage to the equipment.

c. Connect white to white; black to black; and

green to green or bare wire using appropriate

size wire connector.

d. Tape the connectors to the supply wires to

assure they don't vibrate off.

e. Push the wires into the box.

f. Install the junction box cover with screws pro-

vided.

8. Ceiling template installation.

Note: The large center hole in the ceiling template goes

to the rear.

a. Start each mounting bolt by hand before

tightening any of them. The threaded inserts

in the base pan can be seen to aid in starting

the bolts.

i. This installation uses a 3 bolt pattern,

one in the rear center and two in the front

corners. See Fig. 17.

PROPERTY DAMAGE HAZARD. If bolts are

left loose there may not be an adequate roof

seal or if over tightened, damage may occur

to the unit base or ceiling template. Tighten

to torque specications listed in this manual.

9. Template/Duct connector

a. Pull duct down through template opening.

b. Cut the duct 1/2"-1" below template opening.

See Fig. 17.

c. Align the template duct adapter with the tem-

plate duct hole making sure the screw holes

line up (if not rotate 1/2 turn). Insert template

duct adapter into duct. Leave one loop of

duct wire below the duct adapter groove. Do

not insert tabs inside of the duct.

d. Snap duct adapter into template and install 2

screws through the duct adapter tabs into the

ceiling template. See Fig. 18.

FIG. 18

Fit Duct

Adapter

Inside Duct

FIG. 17

Ceiling

Template

Trim Duct 1/2" to

1 " Below Ceiling

Template

Mounting Bolt

Front

Do Not Disturb

Thermostat Bulb

Mounting

Bolt

Start 3 Mounting

Bolts By Hand

• Evenly tighten the bolts to a torque

of 40 to 50 inch pounds. This will

compress the roof gasket to approximately 1/2". The bolts are self

locking so further tightening is not

necessary. See FIG. 17.

Install 2 Screws In Tabs

Duct Adapter

Screw Holes

Must Line Up

If Necessary

Rotate 1/2 Turn

10

Page 11

I. Wiring The System (Low Voltage Connec-

tions)

1. CCC, CCC 2 & Digital Thermostat

PROPERTY DAMAGE HAZARD. Disconnect

the positive (+) 12 VDC terminal at the supply battery. Failure to obey this warning may

cause damage to equipment.

Note: If optional solar panel is to be installed, do so at this

time. Follow installation instructions packaged with solar

panel.

a. Connect the previously run 12 VDC supply

wire to the red and black wires protruding

from the 14-1/4" x 14-1/4" (±1/8") roof open-

ing.

b. Connect the previously run furnace thermo-

stat wires (if applicable) to the blue wires pro-

truding from the 14-1/4" x 14-1/4" (±1/8") roof

opening. The polarity of these connections

does not matter.

c. Terminate the previously run 4 conductor

communication cable(s) protruding into the

14-1/4" x 14-1/4" (±1/8") roof opening. The

cable(s) must be terminated with a telephone

RJ-11-6C4P connector. Refer to the crimp

tool manufacturer for crimping instructions.

See FIGS. 4 & 5.

Important: RJ-11-6C4P connectors must be installed

with the same polarity on each end. Standard telephone

cables will not operate the controls.

d. Plug the communication cable(s) into the

telephone coupler(s) in the 14-1/4" x 14-1/4"

(±1/8") roof opening. If more than one zone

is used on the CCC and CCC 2 models, the

second coupler will be used to join each ad-

ditional zone.

e. Plug the indoor temperature sensor cable (if

applicable) into the matching connector pro-

truding from the return air opening.

f. Energy Management System (CCC an CCC

2 Only). If applicable, connect the previously

run Energy Management System wires to the

yellow wires protruding from the 14-1/4" x 14-

1/4" (±1/8") roof opening. The polarity of this

connection does not matter.

2. Analog Thermostat

a. Connect the previously run 12 VDC supply

wire to the red and black wires protruding

from the units return air opening. Connect

+12 VDC to the red wire; –12 VDC to the

black wire.

b. Connect the previously run furnace thermo-

stat wires (if applicable) to the blue/white

wires protruding from the units return air

opening. The polarity of these connections

does not matter.

c. Connect red/white wire protruding from the

units return air opening to the seven wire

cable thermostat +7.5 terminal.

d. Connect the green wire protruding from the

units return air opening to the seven wire ca-

ble thermostat “GND” terminal.

e. Connect the yellow wire protruding from the

units return air opening to the seven wire ca-

ble thermostat “COOL” Terminal.

f. Connect the tan wire protruding from the

units return air opening to the seven wire

cable thermostat “FAN” terminal.

g. Connect the blue wire protruding from the

units return air opening to the seven wire

cable thermostat “HI FAN” terminal.

h. Connect the orange wire protruding from the

units return air opening to the seven wire

cable thermostat “HS/HP” terminal (if applicable).

i. Connect the white wire protruding from the

units return air opening to the seven wire ca-

ble thermostat “FUR” terminal (if applicable).

3. LCD Thermostat

a. Connect the previously run +12 VDC supply

wire to the red wire protruding from the units

return air opening.

b. Connect the previously run –12 VDC supply

wire to both the black wire protruding from

the units return air opening and to the wire of

the three wire cable that goes to the thermostat 12V– terminal.

c. Connect the previously run furnace thermo-

stat wires (if applicable) to the blue wires pro-

truding from the units return air opening.

d. Connect the red/white wire protruding from

the units return air opening to wire of the

three wire cable that goes to thermostat 12V+

terminal.

e. Connect the orange wire protruding from the

units return air opening to wire of the three

wire cable that goes to thermostat COMMS

terminal.

J. Air Distribution Box Installation

Important: The inner walls of the ADB go inside the

walls of the ceiling template during installation.

1. Working from the rear looking forward with the

rear tipped down, place the air distribution box inner walls against the inside of the ceiling template

walls. Slide the air distribution box backwards until it touches the template. Raise the air distribution box to the ceiling. See FIG. 19.

11

Page 12

2. Push up on the ADB at the locations indicated by

the paper labels to engage the snap locks. There

will be a quiet click heard when each latch en-

gages. See FIG. 19.

FIG. 19

Position

ADB Walls

Inside And

Against End

Of Template

Walls

5. Filter installation. Slide lters into slots in air distribution box. The outward curved side of the lter

handle faces the ceiling. See FIG. 20.

This completes the digital, analog, and LCD thermostat

unit installation. (Proceed to section K to complete the CCC

and CCC 2 thermostat installation)

Verify that all features of the system work. See digital,

analog, or LCD thermostat Operating Instructions or User's

Guide. Reconnect the 12 VDC and 120 VAC power supplies. Check fan speeds, cooling mode, heat pump mode,

and furnace mode (if connected). If features do not work,

disconnect the 12 VDC and 120 VAC power supplies and

verify that all wiring is correct.

Raise Back

End Of ADB

To Ceiling

Push Here To Engage

Latches, Then Remove Labels

3. Hold the air distribution box to the ceiling with one

hand and install two coarse threaded 3.5 mm X 19

mm sharp pointed screws in the location shown in

FIG. 20.

4. Auxiliary screws may be installed at the locations

shown. These are NOT required to secure the ADB

to the template, but may be desired for aesthetic

purposes in some ceiling geometries. See FIG. 20.

FIG. 20

Auxiliary Screw Locations

K. System Conguration, Reset & Check Out

(CCC and CCC 2 Thermostat Only)

Now that the system is installed, it is necessary to do a

system conguration, reset and check out.

1. Electronic Control Conguration

Depending on the equipment options installed by the

recreational vehicle manufacturer, the appropriate

dip switches will need to be switched to the "ON"

position. Placing the switch in the "ON" position

selects that option. See FIGS. 21, 22 & 23.

FIG. 21

CCC

Dip Switches

Note: Dip switches are in the "OFF" position when shipped

from the factory except on heat strip and (heat pump CCC 2

only) models. On these models the appropriate dip switch,

heat strip or (heat pump CCC 2 only), is in the "ON" position from the factory. To gain access to the dip switches,

the outside plastic shroud must be removed from the unit.

Next remove the electrical box cover. The electrical box

will be on the curb side of the RV after installation. See

FIGS. 21, 22 & 23.

CCC 2

Dip Switches

Install 2 Primary

Mount Screw First

Auxiliary Screw

Locations

12

FIG. 22

CCC

Dip Switches

Heat Strip

Zone 2

Zone 3

Zone 4

Furnace

Differential

Stage

Gen Start

CCC 2

Ext. Stage

Zone 2

Zone 3

Zone 4

Stage

Heat Strip

Heat Pump

Furnace

Dehumidify

Gen Start

Page 13

CCC Dip Switch Selection

a. Each CCC thermostat can have up to 4 zones.

When only one unit is installed it becomes

Zone 1 and no dip switch setting is required.

Each additional unit must be assigned a zone

(2 through 4). Each unit must have a different

zone setting.

b. Heat strip selection - On heat strip models

the #1 dip switch is in the "ON" position from

the factory. Non heat strip models leave in

the "OFF" position.

c. Furnace selection - when a furnace has been

connected to a zone, place the furnace dip

switch “ON” for that zone.

d. Differential - differential is the temperature

difference between the “ON/OFF” cycle of

the thermostat in the furnace mode. The nor-

mal differential is preset in the circuit board

with the dip switch set to the “OFF” position.

In some situations, it may be necessary to

decrease the differential. The location of the

thermostat may create a condition where the

normal differential will not maintain your com-

fort zone. If this occurs, the differential can

be shortened by placing the differential dip

switch to the “ON” position.

Note: Setting the differential dip switch should only be required when installation conditions are less than desirable

and is not covered under the limited warranty.

e. Stage selection - stage is not used on these

units. Leave in the “OFF” position.

f. Gen start selection - leave in the “OFF” posi-

tion.

g. Replace the unit electrical box cover.

h. Repeat this procedure for each additional

zone

FIG. 23

On Position

Off Position

CCC 2 Dip Switch Selection

a. Ext. Stage - Ext. Stage is not used on this unit.

Leave in the “OFF” position.

b. Zone selection - Each CCC 2 thermostat can

have up to 4 zones. When only one unit is

installed it becomes Zone 1 and no dip switch

setting is required. Each additional unit must

be assigned a zone (2 through 4). Each unit

must have a different zone setting.

c. Stage selection - Stage is not used on this unit.

Leave in the “OFF” position.

d. Heat Strip - On heat strip models the #6 dip

switch is in the "ON" position from the factory.

Non heat strip models leave in the "OFF"

position.

e. Heat Pump - On heat pump models the #7 dip

switch is in the "ON" position from the factory.

Non heat pump models leave in the "OFF"

position.

f. Furnace - If a Furnace/Aqua heat system has

been connected to this unit, the furnace dip

switch must be placed in the “ON” position.

g. Dehumidify - Dehumidify is not used on this

unit. Leave in the “OFF” position.

h. Gen start selection - Leave in the “OFF” posi-

tion.

i. Replace the unit electrical box cover and out

side plastic shroud.

j. Repeat this procedure for each additional

zone.

2. System Reset

a. CCC system

After setting the dip switches in the electronic

control, do a system reset.

i. Turn the ON/OFF switch to the “OFF”

position.

ii. Simultaneously press and hold the

MODE and ZONE push-buttons while

turning the ON/OFF switch to “ON”.

FF should appear in LCD display until the mode and zone push-buttons are

released.

iii. When a dip switch is turned on after initial

conguration, a system reset will need to

be done before the CCC thermostat will

recognize the updated selection.

b. CCC 2 system

After setting the dip switches in the electronic

control, do a system reset.

i. Reconnect the 12 VDC and 120 VAC power

supplies.

ii. Make sure the CCC 2 thermostat is in the

“OFF” mode.

iii. Simultaneously press the MODE and

ZONE buttons. The LCD will display “IniT”

and all available zones.

iv. Release the MODE and ZONE buttons.

v. Press the ON/OFF button to exit system

set up.

vi. When a dip switch is turned on after initial

conguration, a system reset will need to

be done before the CCC 2 thermostat will

recognize the updated selection.

3. System Checkout

Verify that all features of the installed system work.

See CCC and CCC 2 thermostat Operating Instructions or User’s Guide. Reconnect the 12 VDC and

120 VAC power supplies. Check fan speeds, cooling mode, heat pump mode, and furnace mode (if

connected). If the features do not work disconnect

the 12 VDC and 120 VAC power supplies and

verify that all wiring is correct and that the correct

dip switches have been turned on.

13

Page 14

L. Furnace/Aqua Temperature Differential

Setting (CCC 2 Only)

This system can be congured to operate using an ON/OFF

differential of either 1 degree F. or 2 degree F. See FIG. 24.

1. To set the differential, simultaneously press the

PROGRAM button and the up button on the

CCC 2 thermostat. "diF1" will appear in the display

while the buttons are pressed. See FIG. 24. To

set the 2 degree differential, simultaneously press

the PROGRAM button and the down button.

"diF2 will appear in the display while the buttons

are pressed.

FIG. 24

MAINTENANCE

A. Air Filters

1. Periodically (a minimum of every 2 weeks of op-

eration) slide out the return air lters located on

the end of the air distribution box. Wash the lters

with soap and warm water, let dry and then rein-

stall.

Note: To insure easy future removal the lters need to be

replaced with the domed side of their handle positioned

towards the ceiling.

Note: Never run the unit without both return air lters in

place. This will plug the unit evaporator coil with dirt and

may substantially degrade the performance of the unit

over time.

D. Frost Formation On Cooling Coil

1. Frost on a small portion of the coil is not unusual.

Under certain conditions, ice may form on the

evaporator coil. This is indicated by very cold output at very low air speed and the icing can be

seen through the hole network with the lters removed. If this should occur, inspect the lter and

clean if dirty. Make sure air vents are open and

not obstructed. Units have a greater tendency to

frost when the outside temperature is relatively

low. This may be prevented by adjusting the thermostat control knob to a warmer setting (counter

clockwise). Should frosting continue, operate on

any fan ONLY setting until the cooling coil is free

of frost; then resume normal operation. If frost

condition persist, contact your local service center for assistance.

SERVICE-UNIT DOES NOT OPERATE

If your unit fails to operate or operates improperly, check

the following before calling your service center.

A. If RV connected to motor generator, check to be sure

motor generator is running and producing power.

B. If RV connected to power supply by a land line, check

to be sure line is sized properly to run unit load and it

is plugged into power supply.

C. Check your fuse or circuit breaker to see if it is open.

Insure fuse is not burnt, or circuit breaker is "ON"

and not activated.

D. After the above checks, call your local service center

for further help. This unit must be serviced by qualied service personnel only.

E. When calling for service, always give the following:

1. Unit model and serial number found on identication

label located on base pan of unit bottom. (Remove

lter and view through network of holes)

2. Air distribution box model and serial number found

on rating plate located on ceiling template. Observe

this rating plate through the air distribution box right

side vent opening.

B. Air Distribution Box Housing

1. Clean air distribution box housing with a soft cloth

dampened with a mild detergent. Never use furniture polish or scouring powders.

C. Fan Motor

1. The blower motor is factory lubricated and requires no service.

14

Page 15

FIG. 25

(OPTIONAL)

WIRING DIAGRAM

6414 Series

15

Page 16

WIRING DIAGRAM

6(1625

)5((=(

9

9

/2$'6+('

)851$&(

/2$'6+('

)851$&(

,1'225

6(1625

287'225

6(1625

6415 Series

6417 Series

77

7

.

5(/$<

&20

12

$&32:(502'8/(%2$5'

5('

%/.

3

%/8

3

3

%/.

%/.

5-&$%/(

72767$7

),(/':,5,1*

)$&725<:,5,1*

7

%/.

7

<(/

<(/

%/8

.

5(/$<

&20

6418 Series

%/.

<(/

5('

12

7

7

333

7(03

7(03

16

02725

*51<(/

*51<(/

%/.

:+7

%/8

*5<

*51<(/

:+7

&2035(6625

2/

5

6

&

:+7

+($7(5(/(0(17

:+7

/,0,76:,7&+

3$66('

',(/(&75,&

%51

:+7

9$&

+]

86(&233(5

&21'8&7256

21/<

5('

%/.

:+7

12786('

21620(

02'(/6

67$57

237

&$3

5('

37&5

)$1

&

+(50

5('

Page 17

3$66('',(/(&75,&

<

:+7

%5

:+7

67$57

&$3

37&5

237

5('

:+7

WIRING DIAGRAM

641915 & 641916 Series

%/8

6

5&2/

5('

%5

02725

641932 & 641935 Series

</

%/8

%/.

5('

.5(/$<

12

&20

<

<

<

<

%/./,1(

*51<(/($57+

:+71(87

%/.

-

5('

5(':+7

-

%/.

25*

)851$&(

)851$&(

<

<

9$&

+=2

86(&233(5

&21'8&7256

21/<

)5((=(

6(1625

9

9

9

&200

%/8

%/8

62/$525

',57<),/7(5

,1',&$725

,)86('

9

`

72

767$7

),(/':,5,1*

)$&725<:,5,1*

6833/

72

`

767$7

6515 Series

17

Page 18

WIRING DIAGRAM

<

6518 Series

6519 Series

3$66('',(/(&75,&

:+7

%5

:+7

67$57

&$3

37&5

237

5('

:+7

5(9(56,1*9$/9(

%5

5('

%/8

2/&5

6

02725

</

%/8

%/.

5('

%/.

.5(/$<

12

&20

<

<

<

<

%/./,1(

*51<(/($57+

:+71(87

%/.

-

)851$&(

)851$&(

-

-

5('

5(':+7

%/.

25*

<

<

9$&

+=2

86(&233(5

&21'8&7256

21/<

287'225

7(03

6(1625

)5((=(

6(1625

9

9

9

&200

%/8

%/8

62/$525

',57<),/7(5

,1',&$725

,)86('

9

`

72

767$7

),(/':,5,1*

)$&725<:,5,1*

6833/

72

`

767$7

18

Loading...

Loading...