Page 1

INSTALLATION INSTRUCTIONS

RECORD THIS INFORMATION FOR FUTURE REFERENCE

BEFORE INSTALLING THE UNIT:

Model Number

Serial Number

Date Purchased

Place of Purchase

SELF-CONTAINED

AIR CONDITIONER & HEA T PUMP

FOR

USA

SERVICE OFFICE

Dometic Corporation

2320 Industrial Parkway

Elkhart, IN 46516

574-294-2511

CANADA

Dometic Corporation

46 Zatonski, Unit 3

Brantford, ON N3T 5L8

CANADA

519-720-9578

For Service Center

Assistance Call:

800-544-4881

US

RECREATIONAL VEHICLES

ROT ARY COMPRESSOR

SYSTEM MODELS

Air Conditioners

39626.501 & 39626.506

Heat Pumps

39726.501 & 39726.506

THIS UNIT IS DESIGNED FOR OEM INSTALLATION

ALL INITIAL INSTALLATIONS MUST BE APPROVED BY THE SALES DEPT.

AVERTISSEMENT

WARNING

!

This manual must be read and understood before installation, adjustment, service, or maintenance is

performed. This unit must be installed by a qualified service technician. Modification of this product

can be extremely hazardous and

could result in personal injury or

property damage

Lire et comprendre ce manuel avant de

procéder à l'installation, à des réglages,

de l'entretien ou des réparations.

L'installation de cet appareil doit être

effectuée par un réparateur qualifié.

T oute modification de cet appareil peut

être extrêmement dangereuse et

entraîner des blessures ou dommages

matériels.

!

APPLICATION MANUAL

INSTALLATION INSTRUCTIONS

REVISION:

Form No. 3308463.011 5/06

(Replaces 3308463.003

(French 3308477.011)

©2003 Dometic Corporation

LaGrange, IN 46761

AND

SYSTEM

MODELS

39626.501

39626.506

Important: Instructions must stay with unit.

Owner read carefully

1

39726.501

39726.506

Page 2

INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS:

1.0 SAFETY INSTRUCTIONS ...........................................................................PAGE 3

2.0 APPLICATION MANUAL ............................................................................. PAGE 4

2.1 AIR DISTRIBUTION...........................................................................PAGE 4

2.2 HOW ROOM AIR IS RELATED TO OUTLET PERFORMANCE .....PAGE 7

2.3 SPECIFICATION AND REQUIREMENTS.........................................PAGE 7

2.4 HIGH-POT REQUIREMENTS............................................................PAGE 8

2.5 MOUNTING IN COACH......................................................................PAGE 9

2.6 WIRING DIAGRAM 39726.501 & 39726.506 ..................................... PAGE 10

2.7 SPECIFICATIONS-HEAT PUMP ....................................................... PAGE 10

2.8 WIRING DIAGRAM 39626.501 & 39626.506 ..................................... PAGE 11

2.9 SPECIFICATIONS - AIR CONDITIONER ......................................... PAGE 11

3.0 INSTALLATION MANUAL ........................................................................... PAGE 12

3.1 GENERAL INSTRUCTIONS.............................................................. PAGE 12

3.2 PROCEDURE ....................................................................................PAGE 12

3.3 ELECTRICAL WIRING ......................................................................PAGE 14

3.4 CONTROL SYSTEM WIRING............................................................PAGE 14

3.5 SYSTEM CONFIGURATION AND CHECK OUT ..............................PAGE 16

2

Page 3

INSTALLATION INSTRUCTIONS

1.0 SAFETY INSTRUCTIONS

This manual has safety information and instructions to help users eliminate or reduce the risk of

accidents and injuries.

RECOGNIZE SAFETY INFORMATION

!

This is the safety-alert symbol. When you see this

symbol in this manual, be alert to the potential for

personal injury .

Follow recommended precautions and safe operating instructions.

UNDERSTAND, SIGNAL WORDS

A signal word , WARNING OR CAUTION is used

with the safety-alert symbol. They give the level of

risk for potential injury .

WARNING

!

ous situation which, if not avoided, could result in

death or serious injury .

CAUTION

!

ous situation which, if not avoided may result in

minor or moderate injury .

CAUTION

symbol indicates, a potentially hazardous situation which, if not avoided may result in property

damage.

indicates a potentially hazard-

indicates a potentially hazard-

used without the safety alert

Read and follow all safety information and instructions.

3

Page 4

INSTALLATION INSTRUCTIONS

2.0.0 APPLICATION MANUAL

2.1 AIR DISTRIBUTION

2.1.1 GENERAL INFORMATION

The purpose of an air conditioning system is to provide

environmental conditions in a space to keep its occupants

comfortable.

The basic elements of a simple forced circulation air system

consists of a cooling unit, a centrifugal blower, a temperature

sensing device controlling operation of the compressor and

blower, suitable air filters, and a duct system.

Air is filtered, cooled, and distributed to various areas of the

vehicle. Duct work should deliver this conditioned air as

directly, quietly, and economically as possible. If the

distribution is not properly sized and balanced, flow of air will

not be as calculated and the system will not function properly

or efficiently.

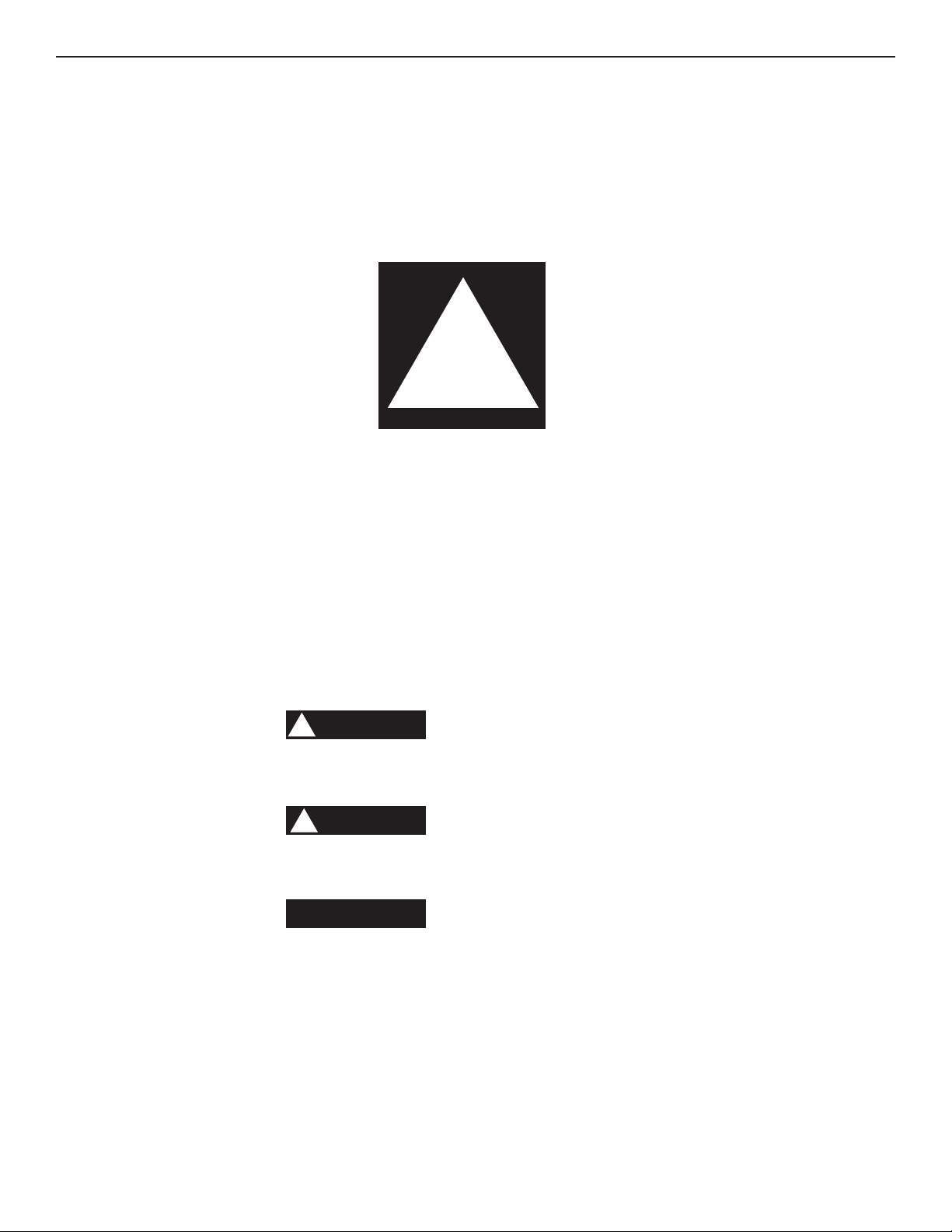

2.1.2 THE BASIC AIR CONDITIONING

CYCLE

The components which are basic to air conditioning systems

are illustrated by Figure 2.1. Air is treated at the conditioning

unit, transferred to the conditioned space through the supply

duct system and returned to the conditioning unit through the

return system. The duct systems are also referred to as the

distribution system.

2.1.3 FUNCTION OF A DUCT SYSTEM

A duct is a tube, or pipe, that carries air between two points.

Strictly speaking, in air conditioning terms, a duct system is

the arrangement of ducts between air conditioning equipment and rooms to be cooled, not including such items as

filters, cooling coils, etc. However, we shall include in our use

of the term “duct system”, every item in the air-passage

network that offers resistance to air flow. From the standpoint

of the blower it makes no difference whether a resistance is

caused by filters or by the use of a small duct; effect will be

the same. Resistance tends to restrict flow of air through the

entire system.

of the greatest heat loss and/or heat gain. The effects of the

gain or loss can then be offset by the supply air. It is

important that the selection of the diffusers and grills for the

supply and return systems receive careful attention to enable

them to accomplish their purpose.

Consideration must be given to all aspects of the supply air

distribution patterns: throw, spread, drop, etc. Also, the

outlet and return grille velocities must be held within reasonable limits. Any noise generated at the grille is equal to or

greater in importance than duct noise.

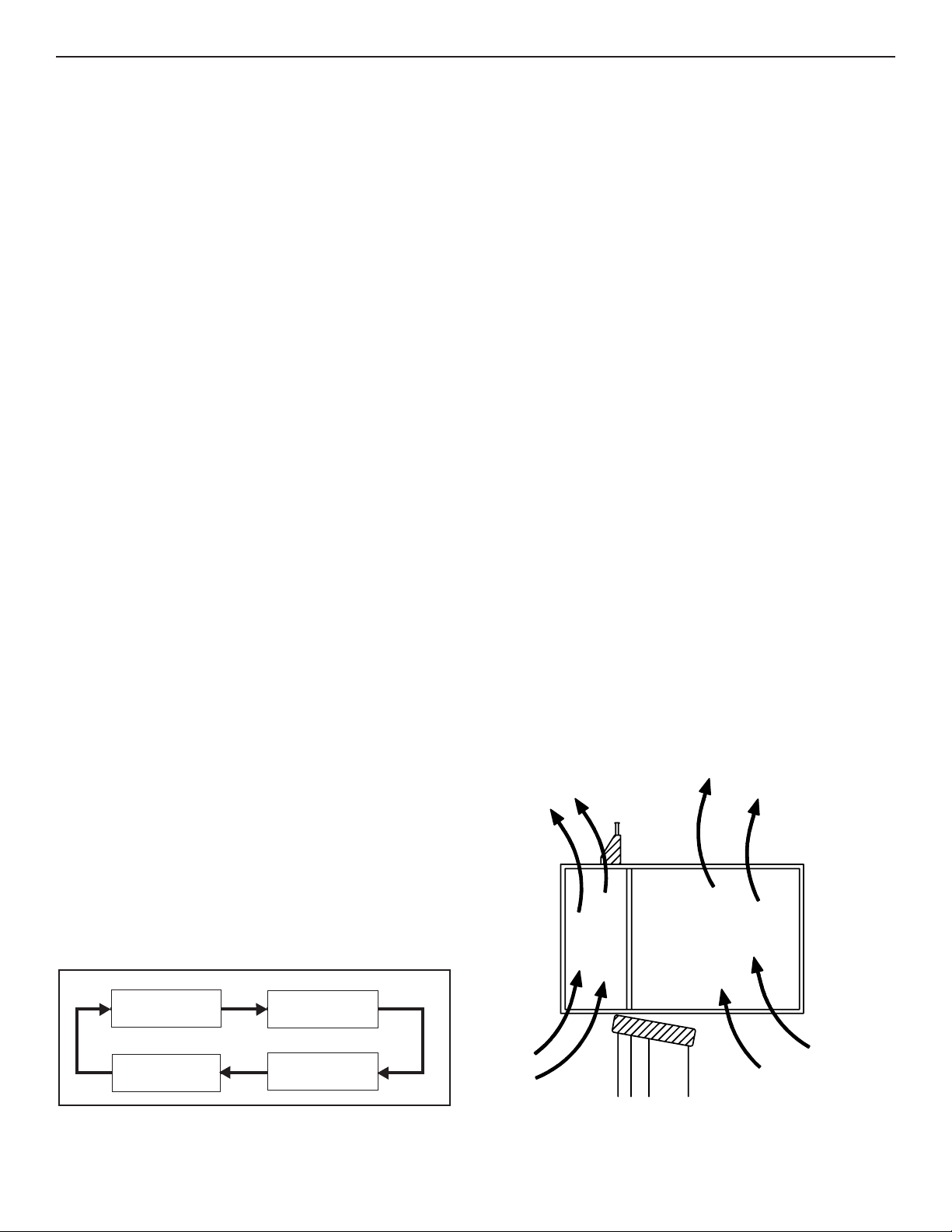

A window air conditioner (Figure 2.2) is essentially a device

with a minimum duct system, since the only items that offer

resistance to air flow are built into the cabinet.

2.1.4 FACTORS AFFECTING RESISTANCE TO AIR

FLOW

Common observations of daily events tell us something

about factors affecting resistance to air flow. We know, for

example, that more pressure is required to force a given rate

of air flow through a small duct than through a large duct. We

also know that streamlining of ducts means less resistance

to air flow, and that sharp angled turns must be avoided.

As air passes through ducts, cooling coils, grilles, diffusers,

and dampers, the static pressure is reduced by friction and

turbulence losses. Good duct design minimizes the need to

balance the duct system by sizing the ducts such that the

designed pressure drop allows the desired airflow rate to be

delivered to each room. An improperly sized duct system will

require extensive balancing. Balancing is a procedure by

which the air flow allotment is adjusted to supply the correct

quantity of conditioned air to each room.

COOL AIR DISCHARGE

INTO ROOM

HEATED AIR FROM

CONDENSER DISCHARGED

OUTDOORS

A forced air system is only as good as its air delivery

system. Comfort levels are affected by the quantity and

velocity of air movement within the space and the proper

mixing of the supply air with the room air. Supply air should

be furnished in a manner that will direct the air to the sources

CONDITIONED

SPACE

SUPPLY DUCT

SYSTEM

Block diagram of comfort air conditioning cycle.

Arrows indicate direction of air flow.

FIG. 2.1

RETURN DUCT

SYSTEM

CONDITIONING

UNIT

ROOM

WARM ROOM AIR

TO BE COOLED

The Window Air Conditioner represents a minimum duct system, since air to and from the cooler is handled without external

ducts.

4

EVAP

AND

FAN

COMPRESSOR,

CONDENSER

AND FAN

FIG. 2.2

OUTDOORS

OUTDOOR AIR TO

CONDENSER

Page 5

INSTALLATION INSTRUCTIONS

2.1.5 AIR FLOW AND FRICTION

Air flows in a duct system from a region of high pressure to

a region of lower pressure. The blower creates the pressure

differential which causes the air flow through the duct

system. The point of highest pressure in the system is at the

outlet of the blower. The point of lowest pressure in the

system is at the return opening of the blower. The air pressure

constantly decreases as the air flows through the system.

The pressure ultimately diminishes to zero as it passes

through the register and is diffused into the conditioned

space. As air moves through a duct, a pressure drop occurs

due to the friction between the air and the walls of the duct.

Another factor in pressure drop is the turbulence within the

air stream itself. Air moving within a duct does not flow in a

placid stream. Rather it moves in a churning and mixing path,

or “turbulent flow.” The cumulative effect of rubbing friction

and turbulence friction is friction loss. Air turbulence in a duct

system becomes substantial whenever there is a change in

the direction of air flow.

2.1.6 ECONOMICS OF DUCT DESIGN

In order to match to the system air delivery capacity, elbows

for turning the air must be kept as large as allowed by the unit

construction. Duct depth for Dometic air conditioners

may vary with each model series. Confirm the system

to be installed and refer to Figure 3.4, for specific duct

configurations required. High loss elbows must have their

resistance lowered by the use of splitters or turning vanes.

Refer to Figure 2.3 through 2.7.

Another factor in duct losses is air leakage. Although

leakage is not considered in duct design it should be an

installation consideration. Cold air leaking into the surrounding cavity will cause condensation to form under high

humidity conditions. Sealing all joints will assure moisture

free cavities and maximum distribution of air to the outlets.

In most cases of high resistance encountered in duct

systems, one or more of the following points have been

overlooked by the installer:

A. Small Diameter

Pressure losses increase as diameter of a duct is

reduced. Good design practice is that which enables the

installer to put in the smallest size duct that will do the

job of delivering required airflow rate with pressure

available. No single size of duct will prove to be ideal for

all jobs.

B. Length of Duct

Pressure loss increases as duct length is increased.

This is almost obvious; a duct which is 6 ft. long has twice

the pressure loss of one that is 3 ft. long, provided that

both ducts are the same size and both are carrying the

same airflow rate.

C. Changes in Direction (Figure 2.7)

Pressure losses increase when direction of air flow is

changed. When air is forced to make a 90° turn in a duct

system, pressure loss is much greater than for a straight

run of the same length. (Refer to FIG. 2.7)

Item 1. This sharp-angled bend causes a large pressure

loss. A simple way of visualizing such pressure loss is

to imagine that these diagrams represent highways on

which you are driving a car. As you approach a bend you

are forced to slow the car speed to 15 mph. In so doing,

a considerable part of energy of the fast-moving car has

had to be absorbed by the brakes. The analogy holds for

air particles flowing around a sharp bend.

Item 2. This sharp-angled bend on the inside corner

causes great pressure loss. The rounded corner on the

outside does not help as much as might be anticipated.

Item 3. This is a common form of 90° bend that has

relatively low resistance.

Item 4. If minimum resistance is desired, this extreme

example of a smooth, streamlined fitting can be used,

although space requirements will be prohibitive in many

installations.

Item 5. Occasionally, a beam or rafter prevents the use

of a smooth bend and a right angle bend is necessary.

In such cases the use of turning vanes (splitters) will be

effective in reducing resistance.

Item 6. Another way to reduce resistance is to change

item (3) to a modified version of item (4) by inserting

splitters in the sharper bend.

D. Sudden Contraction

When air is suddenly contracted from a large duct to a

small duct, a pressure loss occurs See Figure 2.8.

E. Sudden Expansions

The pressure loss resulting from the sudden expansion

of air from a small duct to a large duct, are much larger

than losses due to sudden contraction. As with sudden

contraction, much can be done by making air expansion

gradual, rather than abrupt. See Figure 2.9.

To summarize Section 2.1.6, the following items contribute to higher pressure losses in a duct system:

1. Smaller diameter ducts

2. Longer duct lengths

3. Changes in direction of air flow

5

Page 6

INSTALLATION INSTRUCTIONS

PREFERRED

(Standard)

POOR

Various Elbows Showing Radius Ratios

FAIR

NOT ACCEPTABLE

FIG. 2.3

D

R

W

W

R

RR =

Radius Ratio (RR)

or RR = 1.5

EDDIES

ITEM 1

Sharp Angle

EDDIES

ITEM 2

Rounded

Outer

Corner

ITEM 3

Rounded

Corners

ITEM 4

Long Radius Bend

ITEM 5

Splitters, or turning vanes

installed in sharp angle

bend

ITEM 6

Splitters in rounded

corner bend

W

Rb

Rb

FIG. 2.6

FIG. 2.4

Rb

D

Ra

Curve Ration (CR)

Optimum Reading CR = .05

CR =

Ra

Rb

FIG. 2.5

Ra

CR =

Rb

R

1

R1 = 2 Ra

CR = .25

Ra

Ra

CR =

Rb

R1 = 2 Ra

R

1

R

2

(Rb - R1)

R2 =

CR = .15

2

Ra

Using Splitters to reduce resistance.

+ Ra

FIG. 2.7

Different ways of making a 90 degree bend. Some

involve greater pressure losses than others.

LARGE DUCT

FIG. 2.8

Pressure losses occur with abrupt reducing fittings.

ABRUPT EXPANSION

SMALL

DUCT

EDDY

LOSSES

FIG. 2.9

Abrupt expansion results in excessive pressure losses.

6

ABRUPT

CONTRACTION

EDDY

LOSSES

LARGE

DUCT

SMALL

DUCT

Page 7

INSTALLATION INSTRUCTIONS

WARNING

!

CAUTION

4. Sudden contractions in air stream

5. Sudden expansions in air stream

2.1.7 REGISTERS, DIFFUSERS, AND GRILLE SELECTION

One of the most important considerations in designing a

conditioning system is the selection of the registers, diffusers and grills. Even though a system delivers the required

amount of conditioned air to the room, discomfort results if

the air is not satisfactorily distributed. Achieving good air

distribution is as much an art as it is a science. Careful

consideration must be given to the design of the air distribution system. A forced air system is only as efficient as its

air delivery components.

Whenever a jet of conditioned air is admitted into a room it

affects all the air within that room. Movement of the supply air

induces adjacent room air to move along with it. This process

of the supply air dragging along the room air and setting it in

motion is called “entrainment” of the room air. As the room

air mixes with the supply air, the temperature difference

between them is reduced. This effect is even more pronounced with a spreading jet than with a non—spreading jet

because of the greater surface area.

2.1.8 ROOM AIR DISTRIBUTION

The final evaluation of air distribution in a space is determined

by the occupants’ comfort level. In general, a person is

thermally comfortable when their body heat loss just equals

their heat production.

During cooling, currents carry warm air up the wall to ceiling

level, and stratification forms from the ceiling down. The

solution is to project cool air into this region near the ceiling.

Performance of any supply outlet is related to initial velocity

and area. As it leaves the outlet, an air jet becomes a mixture

of supply and room air, expanding due to the induction of

room air.

most effectively, the high velocity portions of the air stream

have less tendency to enter the occupied zone of the space.

2.2 HOW ROOM AIR MOTION IS RELATED TO

OUTLET PERFORMANCE

The room air near the supply air stream is entrained by the

air stream and, in turn, is replaced by other room air. The

room air always moves toward the supply air. The only

general statement that can be made regarding room air

motion and the number of air changes is that 8 to 10 air

changes per hour are required to prevent formation of stagnant regions.

For most applications, a better approach is to supply air in

such a way that the high velocity air stream from the outlet

does not enter the occupied zone. It is practical to consider

the region within 12 inches of the walls as outside the

occupied zone as well as the region above the heads of the

occupants.

Supply air should be spread in a thin layer over the surfaces,

to surround the occupied zone with conditioned air. Air within

the occupied zone will then move toward the total air stream,

the mixture of primary and room air. The room air carries the

load with it into the air stream and room conditions are

maintained by constant mixing of room and supply air.

Improper installation may damage equipment,

could endanger life, cause serious injury and/

or property damage.

2.3 SPECIFICATIONS & REQUIREMENTS

Since it is necessary to install all or part of the duct work in

the ceiling, sidewall or floor.

The buoyant forces with non-isothermal jets cause the jet to

rise during heating and drop during cooling. If the jet is

projected parallel to and within a few inches of a surface, the

jet performance will be affected by the surface, which limits

the induction on the surface side of the jet. This creates a low

pressure region between the jet and the surface, which draws

the jet toward the surface. In fact, this effect will prevail if the

angle of discharge between the jet and surface is less than

40°. The surface effect will draw the jet from a ceiling outlet

to the ceiling. Surface effect increases the throw for all types

of outlets and decreases the drop for horizontally projected

air streams.

The air stream from the outlet tends to “hug” the surface. As

a matter of fact, this characteristic is almost essential for

good comfort air conditioning. Therefore, rather than trying to

direct the air away from surfaces, the surfaces should be

used intentionally. Note that where the surfaces are used

It is the responsibility of the R.V. manufacturer to assure that structural integrity is maintained throughout the coach.

The manufacturer should review each floor plan to determine

proper duct design and register location.

The Dometic Product Engineering and Application departments are available for recommendations and suggestions.

If the conditioned air is to be discharged from the

ceiling area, the minimum roof cavity thickness for

proper installation measured between the roof and

ceiling structure is 4 inches. This does not include

space required for insulation of the ductwork.

The air conditioner was designed to allow flexibility for layout

of duct work and the types of registers employed. To ensure

air conditioner maximum performance, certain parameters

must be adhered to. Refer to Figures 3.4 for duct sizing and

grill placement

7

Page 8

INSTALLATION INSTRUCTIONS

CAUTION

2.3.1 COOLING REQUIREMENTS

When determining the cooling requirements of each vehicle,

the following should be considered:

A. The size of the vehicle will determine the number of

air conditioning units that are required, or the need

to pre-wire for additional air conditioners depending

on the geographical location of use.

B. Amount of insulation in walls, floor and roof of the

vehicle.

C. Identify possible heat sources and plan accordingly:

1. Skylights - location should not be within 4 feet of

the air conditioner return system.

2. Skylights - should be tinted and double pane.

3. Roof vents should be a tinted type, and quantity kept to minimum.

4. Increased use of slide-outs and/or glass square

footage will require tinting with additional

insulation in wall and ceiling cavities.

5. Calculation of heat producing appliances.

2.3.2 AIR DISTRIBUTION SYSTEM SIZING

Basement systems are designed exclusively with external

ductwork for the cold air discharge. There are not provisions for an electric heater to be installed as part of the

unit. The central furnace will supply heating of the

vehicle, if installed.

The condenser section must be installed so as to have direct

access to the outside ambient. Removal of the heated

condenser air is critical for proper operation.

The installer of this air conditioner must design the air

distribution system for his particular application by following

the guidelines specified within this application manual and

unit installation instructions. Several specific requirements

MUST BE met for the air conditioner to operate correctly:

1. Unit Total Static Pressure See Figure 2.10.

2. Duct Area Requirement. See Figure 2.10.

3. Return air to the system must be filtered to prevent

dirt accumulation on the evaporator cooling surface.

4. Return air opening must be within minimums specified in the system installation instructions. This

figure must include the filter material selected.

5. Since duct work is located within a cavity, it is

necessary that all duct work must be wrapped with

a minimum R7 insulating blanket with a vapor

barrier. This will help prevent heat gain within the

duct and possible condensation.

CAUTION

Dometic Corporation will not be held liable

for roof structural or ceiling damage if the

duct work is not adequately wrapped in an

insulation blanket.

It is the responsibility of the installer to ensure the duct work will not collapse or bend

during and after installation. Dometic Corporation will not be liable for any structural damage due to improperly insulated, sealed or

collapsed duct work.

FIG. 2.10

System Duct Condenser Evap. Static

P/N Size Inlet Req. Inlet Req. Press

39626 3x15" 648 in

39726 min.

5x16"

max.

2.3.3 AIR DISTRIBUTION DUCT PREPARATION

Depending on the distribution configuration, ensure that the

air entry points have the minimum square inches required for

the series of system installed. See Figure 3.4 for permissible

duct layout. Duct elbows and/or restrictions must be kept to

a minimum. The duct must be pre-built within the structure

and sealed along its entire length. If joints or bends leak

conditioned air within the cavity, condensation will form.

When the duct is installed within the structure, care must be

taken to insure that the duct will not collapse or bend during

or after installation of the system to the vehicle.

2.3.4 LOCATION OF DISTRIBUTION DUCT

The vehicle itself and the placement of interior components

will dictate the location of the duct. One must be sure that the

registers will not fall near the thermostat or the return filters.

The placement must be such that the air distribution from the

registers will provide the best possible movement within the

living area. Calculations should be made as to the strength

of the cavity, to insure structural integrity if notched for

location of the duct runs.

2.3.5 RETURN REQUIREMENTS

The return air system must be considered when layout of the

duct system is in process. This should be located as near to

the system as possible to insure adequate return back to the

evaporator coil.

2.4 HI-POT REQUIREMENTS

Each system that is built by Dometic is completely checked

electrically and hi-pot tested on our production line. Additional hi-pot testing of the system must not be done.

Disconnect the system from the power circuit prior to any

vehicle high potential test operations.

2

135 in

2

0.40 - 1.20

8

Page 9

INSTALLATION INSTRUCTIONS

2.5.0 MOUNTING IN COACH

The dual basement air conditioner and heat pump are

designed for under the floor installation. It is the vehicle

manufacturer's responsibility to provide an installation space

which will allow for cutouts and mounting of the unit without

cutting vital frame structures. The frame and structural

sections in the installation space will not cause restriction of

air movement required by the dual basement air conditioner

or heat pump. See Figures 2.11, 2.12 and 2.13.

FIG. 2.11

18"

Condenser

Coil Drain

4 Holes

22 "

9.5"

11.75"

46"

Evaporator

Coil

Condenser

Discharge

18"

2.75"

9.5"

4.56"

9.31"

Evaporator

Drain Tube

FIG. 2.12

39626.501

39726.501

Top

Discharge

18"

6.5"

39626.506

39726.506

Side

Discharge

FIG. 2.13

5.5"

Condenser

Coil

6.5"

7.5"

5.75"

2"

36"

7.5"

Electrical Box

Wiring Access

Suggested Placement

Of Supports

Important Notice

All information contained within is for the installation of Dometic Ducted Air Conditioners.

These guidelines give minimum requirements for duct sizing, duct arrangement and register location so that you receive maximum performance from the system.

These instructions DO NOT cover or warrant the

final installation of the duct work that carries

conditioned air within the ceiling cavity .

The installer is responsible for the integrity of the insulated duct within the structure to

insure that moisture laden air does not condense on duct surfaces. If proper practices

are not adhered to, condensation will collect during high ambient conditions. Damage

caused by condensation will not be covered by Dometic Corporation warranties.

9

Page 10

INSTALLATION INSTRUCTIONS

USE COPPER CONDUCTORS

115 VAC 60 Hz 1O

NATIONALELECTRIC CODE

USE COPPER CONDUCTORS

COMPLYWITH THE

FIELD WIRING MUST

115 VAC 60 Hz 1O

G-Y

COND. BLOWER

= WIRE NUT

FIELD WIRING

3108345.095

EVAP. COIL

EVAP. BLOWER

WHT

REV.

WHT

CIR.#1

115 VAC60 Hz 1O

USE COPPER CONDUCTORS

ONLY

FIELD WIRING MUST

COMPLYWITH THE

NATIONALELECTRIC CODE

PASSED

DIELECTRIC

CIR.#2

115 VAC60 Hz 1O

USE COPPER CONDUCTORS

ONLY

WHT

2.6 WIRING DIAGRAM 39726.501 & 39726.506

EVAP. BLOWER

BRN

BLK

EVAP. COIL

MOTOR

BRN

VIO

VIO

GRY

BRN

BRN

FIELD WIRING

FACTORYWIRING

COMPRESSOR

WHT

COMPRESSOR

= WIRE NUT

R

OL

C

S

RED

BLK

BLK

BLK

BLK

BLK

REV.

VALVE

ASM

REV.

VALVE

ASM

ORN

R

OL

C

S

3108345.095

WHT

WHT

MOTOR

CAP

COMP

STARTER

START

CAP

HERM

FAN

VIO

BLK

VIO

BLK

START

COMP

STARTER

RED

WHT

RED

WHT

WHT

WHT

BRN

WHT

BRN

COND. BLOWER

MOTOR

RED

WHT

C

RUN

WHT

CAP

BRN

RUN

C

HERM

CAP

BLK

CAP

BRN

RED

WHT

DIP SWITCHES

ON

2

3

1

FREEZE

CONTROL

P5P4

RED

BLK

BLU

BLU

YEL

YEL

WHT

G-Y

BLK

CIRCUIT

BOARD

K1

COM

7

8

4

5

6

NO

NC

ORN

P6

ELEC.

BOX

BLKHD

ORN

G-Y

GRY

T1

T4

T2

T3

COM

RED

NO

NC

BLK

ELEC.

BOX

BLKHD

BLK

WHT

ORN

GRY

GRY

K6

ORN

G-Y

BLK

P1

P2

P3

AMB.

SENSOR

F1

3 AMP FUSE

BLK

G-Y

2.7 SPECIFICATIONS - HEAT PUMP

System Model 39726.501 & 39726.506*

Nominal BTU Capacity 26,000

Volts/Phase/Hertz (each circuit) 115 AC / 1 / 60

Run Amps Comp (Circuit 1 =10.0) (Circuit 2 = 9.8)

LRA Compressor (Circuit 1 = 59.0) (Circuit 2 = 59.0)

Total Blwr/Fan Motor Run Amps 8.5 (Circuit 1)

Total Blwr/Fan Motor LRA Amps 18.0 (Circuit 1)

Duct Static - Min. ( In. Water Column) 0.40

Duct Static - Max. ( In. Water Column) 1.20

Generator Size Per/Unit - Min. *** 7.5K

Wire Size (Up to 24 ft.)** (Circuit 1) No. 10 AWG Copper Conductors)

(Suggested) (Circuit 2) No. 12 AWG Copper Conductors)

Circuit Protection (Circuit 1) 25Amp

Time Delay Fuse or (Circuit 2) 15Amp

HACR Circuit Breaker

Control Voltage 12V DC

Refrigerant R-22

System Refrigerant Charge (Circuit 1 = 46.5) (Circuit 2 = 38.5)

Size (In Inches) Width Height Depth

46 18 22

Installed 205 Pounds

Weight

*

Models ending with .506 suffix and manufactured with "SIDE AIR DISCHARGE".

For wire lengths over 24 ft. consult the National Electric Code for proper sizing.

**

The Manufacturer gives only general guidelines for generator requirements. These generator

***

requirements come from experiences consumers have with our equipment in field applications.

When sizing the generator, the total electrical power must be taken into consideration. Keep in

mind that generators lose power because of altitude increases above sea level , high outdoor

temperatures and lack of maintenance.

10

Page 11

INSTALLATION INSTRUCTIONS

C

HERM

HERM

C

3108345.061

FIELD WIRINGFIELD

WIRING

FACTORYWIRINGFACTORY

WIRING

P4P3 P5

NC

P6

COM

K6

COM

NO

K1

F1

P1

P2

NO

T3

NC

T1

3 AMP FUSE3AMP FUSE

CIRCUITCIRCUIT

MOTOR

COND.BLOWERCOND.

BLOWER

EVAP.BLOWEREVAP. BLOWER

MOTOR

COMPRESSOR

R

C

S

OL

COMPRESSOR

S

C

OL

R

= WIRE NUT=WIRE NUT

ELEC.

BOX

BLKHD

SENSORSENSOR

AMB.

COMP

RED

WHT

START

CAP

STARTERSTARTER

STARTER

COMP

START

CAP

RUN

CAP

CAP

RUN

T2

DIP SWITCHESDIPSWITCHES

1

2

3

4

5

6

7

8

ON

BOARD

GRY

GRY

BRN

BLK

ORN

G-Y

GRY

ORN

YEL

YEL

BLU

BLU

BLK

ORN

WHT

G-Y

BLK

RED

BLK

BLK

BLK

WHT

WHT

RED

WHT

BLK

BLK

WHT

REDRED

WHT

GRY

WHT

BRN

ORN

BLK

CONTROL

FREEZE

EVAP.COILEVAP.COIL

WHT

FAN

BRN

CAP

MOTOR

BRN

BRN

BRN

BRN

WHT

BRN

RED

RED

WHT

WHT

ORN

RED

USE COPPER CONDUCTORSUSE COPPER CONDUCTORS

WHT

G-Y

BLK

ONLY

CIR.#2

115 VAC60 Hz 1 PHA SE115 VAC 60 Hz 1 PHASE

NATIONALELECTRIC CODENATIONALELECTRIC CODE

USE COPPER CONDUCTORSUSE

COPPER CONDUCTORS

ONLY

FIELD WIRING MUSTFIELD

WIRING MUST

COMPLYWITH THECOMPLY

WITH THE

CIR.#1

115 VAC60 Hz 1 PHA SE115 VAC 60 Hz 1 PHASE

BLK

G-Y

WHT

DIELECTRIC

PASSED

2. 8 WIRING DIAGRAM 39626.501 & 39626.506

2.9 SPECIFICATIONS - AIR CONDITIONER

System Model 39626.501 & 39626.506*

Nominal BTU Capacity 26,000

Volts/Phase/Hertz (each circuit) 115 AC / 1 / 60

Run Amps Comp (Circuit 1 = 10.1) (Circuit 2 = 9.8)

LRA Compressor (Circuit 1 = 59.0) (Circuit 2 = 59.0)

Total Blwr/Fan Motor Run Amps 8.5 (Circuit 1)

Total Blwr/Fan Motor LRA Amps 18.0 (Circuit 1)

Duct Static - Min. ( In. Water Column) 0.40

Duct Static - Max. ( In. Water Column) 1.20

Generator Size Per/Unit - Min. *** 7.5K

Wire Size (Up to 24 ft.) ** (Circuit 1) No. 10 AWG Copper Conductors)

(Suggested) (Circuit 2) No. 12 AWG Copper Conductors)

*

**

***

Circuit Protection (Circuit 1) 25Amp

Time Delay Fuse or (Circuit 2) 15Amp

HACR Circuit Breaker

Control Voltage 12V DC

Refrigerant R-22

System Refrigerant Charge (Circuit 1 = 46.5) (Circuit 2 = 38.5)

Size (In Inches) Width Height Depth

Installed 205 Pounds

Weight

Models ending with .506 suffix and manufactured with "SIDE AIR DISCHARGE".

For wire lengths over 24 ft. consult the National Electric Code for proper sizing.

The Manufacturer gives only general guidelines for generator requirements. These generator

requirements come from experiences consumers have with our equipment in field applications.

When sizing the generator, the total electrical power must be taken into consideration. Keep in

mind that generators lose power because of altitude increases above sea level , high outdoor

temperatures and lack of maintenance.

46 18 22

11

Page 12

INSTALLATION INSTRUCTIONS

3.0.0 INSTALLATION INSTRUCTIONS

3.1 GENERAL INFORMATION

3.1.1 THIS UNIT IS DESIGNED FOR:

A. Installation in a recreational vehicle at the time the

vehicle is manufactured.

B. Heating operation in a MILD GEOGRAPHICAL

AREA where the heat loss is minimal.

C. Turning "OFF" the heat pump and switching to

furnace (aux. heat) when the outside temperature is below 30 degrees Fahrenheit.

D. Returning to heat pump when the temperature

returns to 38 degrees Fahrenheit.

3.1.2 HEAT GAIN/LOSS

The ability of the heat pump/air conditioner to maintain

the desired inside temperature depends on the heat

gain/loss of the RV. Some preventative measures

taken by the occupants of the RV can reduce the heat

gain and improve the performance of the unit. During

extremely high outdoor temperatures, the heat gain of

the vehicle may be reduced by:

A. Parking the RV in a shaded area.

B. Using window shade (blinds and/or curtains)

C. Keeping windows and doors shut or minimizing us-

age.

C. Avoiding the use of heat producing appliances.

Starting the unit early in the morning and giving it a

"head start" on the expected high outdoor ambient

will greatly improve its ability to maintain the desired indoor temperature.

3.1.3 CONDENSATION:

Dometic Corporation will not be responsible for damage caused by condensed moisture on ceilings, walls

or other surfaces. Air contains moisture and this

moisture tends to condense on cold surfaces. When

air enters the RV, condensed moisture may appear on

the ceiling, windows, metal parts, etc.. The unit removes this moisture from the air during normal operation. Keeping doors and windows closed when the unit

is in operation will minimize condensed moisture on

cold surfaces.

3.2.0 PROCEDURE

3.2.1 LOCATION

This system is intended for installation in a recreational vehicle

where the interior is essentially one undivided space. (See FIG.

3.1)

FIG. 3.1

POSSIBLE LOCATIONS

A. The unit is to be installed below the floor with DIRECT

access to outside air for the outside coil.

B. The thermostat cable maximum length is twenty-five (25)

feet. Total length of cable used (including thermostat)

for the control system is seventy-five (75) feet maxi-

mum.

C. The unit should be protected as much as possible from

the elements. Do not locate unit where road spray,

rocks, etc. will hit the unit.

Note: The fins of the outside coil should face the exterior

of the vehicle.

3.2.2 OUTSIDE COIL

A. Supply Air

The inlet of the outside coil should be positioned so that

it draws air from outside the vehicle. Special care must

be taken to prevent the discharge air from recirculating to the inlet of the outside coil. If unit is

installed in a compartment, the discharge air must

be open to the outside. The recirculation of condenser air within the compartment will cause high

internal operation pressures and tripping of breakers will occur. Compartment cannot be sealed.

Shields should be added to ensure fresh air supply. See

FIG. 3.2

3.1.4 PRECAUTIONS:

A. Read Installation Instructions carefully before

attempting to start your unit installation.

B. Dometic Corporation will not be liable for any

damages or injury incurred due to failure in the

following of these instructions.

C. Installation must comply with the National Elec-

tric Code ANSI/NFPA-70 and CSA Standard

C22.1 (latest edition) and any State or Local

Codes or regulations.

D. DO NOT add any devices or accessories to the

unit except those specifically authorized by

Dometic Corporation.

E. This equipment must be serviced by qualified

personnel and some states require these people

to be licensed.

Shields Installed To Prevent

Recirculation Of Outside Air.

FIG. 3.2

12

Page 13

INSTALLATION INSTRUCTIONS

CAUTION

The outside coil is a "draw-through" type. When the

face of the coil is positioned behind a louvered or other

type of restrictive opening, the FREE AREA of the

opening must be at least 648 square inches.

CAUTION

Do not install the unit where the fan will draw

air from the exhaust of the vehicle, a motor

generator set, transmission, road heat or

any other heat producing source.

B. Free Area

Free area is the opening that remains in a grill or

louvered panel after the restrictions are taken away.

For example, an opening of 10 x 20 inches has 200

square inches. When this opening is covered with a

grill that is 56 percent open the FREE AREA is (200

x .56), 112 square inches. See FIG. 3.3.

Expanded and perforated metal grills in general vary

from 30 percent to 60 percent open. Be certain that

648 square inches of FREE AREA is available to the

face of the outside coil.

Note: Service access must always be supplied either

as clearance or as a defined access panel.

FIG. 3.3

8

3.2.3 MOUNTING

The Model 39626 Air conditioner and 39726 Heat Pump units

design are for installation below the floor. This unit should be

mounted in an angle-iron frame, designed and built for the

Model 39626 and 39726. Frame rails should not restrict the

condenser air discharge opening.

Important: Do not mount the Units in a sealed com-

partment. Recirculation of hot condenser discharge air

will cause high system pressure and trip breakers.

3.2.4 CLEARANCES

8

EXAMPLE OF HOW TO DETERMINE FREE

1/2

AREA OR % OPEN AREA:

2

1/2

TOTAL AREA = 8 X 8 = 64

2

FREE AREA = 2 X 2 X 9 openings

1/2

2

% OPEN AREA = = 56 %

1/2

A. The unit clearances depend on:

1. Inlet air access used;

2. Discharge air duct arrangement;

3. Return air duct;

=36

36

64

Where the return air must be provided through louvers

or mesh screen, the FREE AREA percentage of the

material used shall be taken into consideration when

making this determination. An example of how to

determine FREE AREA is included in "3.2.2. Outside

Coil".

B. Grills (See FIG. 3.4)

Note: The return air grill must have the same square

surface as the return air duct.

1. For each system, there must be a return grill to

bring vehicle air back into the unit. There must also

be at least four discharge grills per unit.

2. Return grills must be mounted in front of the inside

coil. If this is not possible, make sure there is

nothing blocking the air flow from the grill to the

inside coil.

3. The unit must have a return filter between the grill

and the unit. This filter must be accessible for

periodic cleaning.

C. Discharge Air (See FIG. 3.4)

The air diffusion system, supplied by the installer,

must be sized to maintain a static pressure at the

blower outlet between 0.40 (minimum) and 1.20 (maximum) inches water column.

The installer has the options of side discharge or top

discharge and side return. The unit can be ordered

originally with the inside blower mounted to discharge

the air as required. If the installer needs to change the

direction of the discharge it is necessary to rotate the

inside blower housing 90 degrees.

All air handling ducts must be properly insulated to

prevent condensation forming on their surface during

operation. A vapor barrier must also be supplied on the

outer surface of the insulation to prevent moisture from

traveling through the insulation and condensing on the

cold duct work.

D. Condensate Drain

A condensate drain tube is located on bottom of the

base pan, under the return air opening.

1. The installer needs to install the condensate drain

into the base pan and ensure a snug fit.

2. A 3" diameter hole must be provided for installation

of the tube and clearance. See Figure 2.11.

Note: Condensate will not drain properly if drain

tube is not installed or missing.

Allow a minimum of eight (8) inches for the return air

duct. Access to the electrical connections must be

provided when making the installation.

3.2.5 INSIDE COIL SECTION

A. Return Air

The inside coil must have free access to room air. A

minimum of 135 square inches of FREE AREA

opening is required.

It is the responsibility of the installer to ensure that the drain tube is installed properly

and that it will not leak. Dometic Corporation

will not be liable for any structural damage

due to improperly installed, sealed or restricted drain tube.

13

Page 14

INSTALLATION INSTRUCTIONS

RETURN SYSTEM

Return to be 6 ft. minimun from floor.

Use wall structure for delivery to basement area.

Return grille must be filtered.

Minimun return required per duct sizing for unit to perform

within Engineer specifications. See Chart below.

MINIMUM MAXIMUM

SIDE RETURN 135IN.

REGISTER REQUIREMENTS

REQ. SIZE MIN. QTY.

4 X 6 8

4 X 8 6

4 X 10 5

4 X 12 4

2

291 IN.

INSULATED DUCT

Minimum Maximum

2

45 IN.

(3 " depth Min.)

2

80 IN.

2

FIG. 3.4

ADDITIONAL REQUIREMENTS:

Damper required in furnace.

Vibration isolators should be

used at each mounting point.

12 VDC required for thermostat

operation.

Condenser air inlet.

Condenser air outlet

(bottom)

Must be isolated from

condenser inlet air.

Supply Duct must be insulated.

Supply Duct from air conditioner

must be equal to or greater

in IN.2 as the floor ductwork.

Use 45 degree angle on inlets

& outlets

3.3 ELECTRICAL WIRING

WARNING

!

This product is equipped with a 3-wire

(grounded) system for protection against

shock hazard. Make sure that the appliance

is wired into a properly grounded 1volt AC

circuit and the polarity is correct. Failure to

do so could result in death, personal injury

or damage to the equipment.

3.3.1 SUPPLY WIRE INSTALLATION

A. Locate the unit electrical box. Remove the cover from

the electrical box.

B. Each electrical circuit are grouped together with a wire

tie.

CIR. #1: Black, White and Green w/yellow

CIR. #2: Orange, Gray and Green w/yellow

C. Route two independent supply circuits of properly

sized copper conductors to the air conditioner electrical box.

1. Circuit #1 should carry a 25 Amp load.

2. Circuit #2 a 15 Amp load.

D. Circuit #1 should be wired directly from the coach's

main breaker panel.

Electric box access required.

Circuit #1 - 25 Amp

Circuit #2 - 15Amp

E. Circuit #2 should be wired through the on-board

generator or a separate power cord dedicated to

Circuit #2.

Note: A standard 30 amp hookup will not power both

Circuit 1 and Circuit 2 and the coach's other major

appliances.

3.3.2 SUPPLY WIRE CONNECTION

A. Connect main power supply Cir. #1 to unit electrical

box with approved Romex connectors.

B. Using wire nuts attach the main power supply black

"Hot" to the units black wire, and white to the white

wire. Attach the main power supply ground wire to the

Green w/yellow wire.

C. Connect the secondary power supply Cir. #2 to unit

electrical box with approved Romex connectors. Use

wire nuts to attach black "Hot" to orange wire of circuit

#2. and power supply white to the gray wire. Attach

the ground wire of circuit #2 to the green w/yellow wire.

3.4.0 CONTROL SYSTEM WIRING

3.4.1 CONNECTION OF LOW VOLTAGE WIRES

A. Route Remote Temperature Sensor Cable, (required

for additional units or if used), through the low voltage

port on the electrical box and attach it the "white (P4)"

plug on main board.

14

Page 15

INSTALLATION INSTRUCTIONS

Insert Screwdriver

under Tab

Insert Screwdriver

under

Tab

M

O

D

E

MODE

FANFAN

UPUP

D

O

W

N

DOWN

O

F

F

O

N

OFF

ON

Z

O

N

E

ZONE

TE

M

P

TEMP

B. Route a dedicated DC supply line (18-22 AWG copper

conductors) from the Converter or Battery to the

unit's electrical box. Connect with wire nuts positive

(+) DC to the red wire; Negative (-) DC to the black

wire.

C. Route thermostat wires from the furnace (if applicable)

to the electrical box and attached them to the blue

wires extending from the main board. The polarity of

these connections does not matter.

D. Route the Energy Management System 2 wires (if

applicable) to the electrical box and connect them to

the yellow wires extending from the main board. The

polarity of these wires does not matter.

Note: If yellow wires are not used and a circuit is made

between them, the unit will fail to operate.

3.4.2 CONTROL CABLE INSTALLATION

A. A 4-conductor flat control cable, must be routed be-

tween the Comfort Control Center (CCC) and the electrical box. The maximum length of all control

cables is seventy-five (75) feet.

B. Select the shortest direct route between Comfort

Control Center

TM

and the electrical box for the sys-

tem.

C. A 3/8" diameter hole will be needed to route the con-

trol cable through the wall.

D. Leave 6" of cable extending through the wall.

E. The cable that must be used is a 4-conductor flat

control cable.

F. The cable must be terminated with two RJ-11 tele-

phone connectors. Refer to the crimp tool manufacturer for crimping instructions. Be sure the cable

is installed correctly into the connector before it is

crimped. Polarity is important and a standard

pre-made telephone cable will not work.

Note: RJ-11 connectors must be wired identically

on both ends. See FIG. 3.5.

4. Avoid locations close to doors that lead outside,

windows or adjoining outside walls;

5. Avoid locations close to supply registers and the

air from them;

6. Never locate CCC in a room that is warmer or

cooler than the rest of the coach - such as the

kitchen;

7. The major living area is normally a good location.

Note: If the system is to be used with a Remote

T emperature Sensor , the Comfort Control Center

may be mounted anywhere that is convenient in

the coach.

8. Try to avoid hard to reach or hard to see areas.

9. Refer to the instructions provided with the Remote

T emperature Sensor for details of inst allation.

B. Comfort Control Center™ Installation

1. Carefully remove the base plate from the Comfort Control Center™. This may be accomplished

by inserting a small screwdriver under the tab on

the bottom edge of the front cover and gently prying. See FIG. 3.6.

FIG. 3.6

FIG. 3.5

G. Plug the communications cable(s) into one of the

telephone jack(s) on the circuit board in the electrical box. (It does not matter which one.)

3.4.3 COMFORT CONTROL CENTER MOUNTING

A. Location

The proper location of the Comfort Control Center

(CCC) is very important to ensure that it will provide a

comfortable RV temperature. Observe the following

general rules when selecting a location.

1. Locate the CCC about 54" above the floor;

2. Install CCC on a partition, not on an outside wall;

3. Direct heat from lamps, sun or other heat producing items will cause erratic operation and temperatures;

2. Insert the control cable through the hole in the

base plate and mount the plate to the wall with

the two screws provided. Check the alignment to

ensure level installation.

3. Install the control cable RJ-11 connector into the

back of the Comfort Control Center™ and gently press onto the base plate.

4. If a Remote Temperature Sensor is to be used,

the connector end must be routed to the electri

cal control box and connected to the color matching plug on the relay board.

5. If a furnace is to be controlled by the system, the

two furnace thermostat leads must be routed to

the electrical control of the air conditioner that will

control it. Make sure at least 15" of the furnace

thermostat wires extend into the electrical control box.

15

Page 16

INSTALLATION INSTRUCTIONS

6. If an Energy Management System - EMS (load

shed) is to be used with the control, two wires

must be routed to the electrical control box. The

signal required for this function is a normally open

relay contact. When the EMS calls for the compressor to shut off, the relay contacts should

close. Make sure that at least 15" of the EMS

wires extend into the electrical box.

7. In the event that other units are to be installed

(additional zones), an additional 4-conductor communications cable must be routed to the other

locations Make sure that at least 15" of the wire

extends into each of the electrical control boxes.

3.5 SYSTEM CONFIGURATION & CHECK

OUT

Now that the system is installed, it is necessary to configure the electronics, and then check all operations. If the

installation is a single zone, (Without a Furnace) no adjustment to the dip switches are necessary: however, the stage

dip switch is preset to the "ON" position.

3.5.1 ELECTRONIC CONTROL CONFIGURA TION

A. If there is more than one zone, the dip switch for

each successive zone must be set to "ON". To gain

access to the dip switches the cover on the unit's

electrical box must be removed.

B. Turn "ON" the "ZONE" dip switch on the electronic

control board to set its zone. See figure 3.7.

FIG. 3.7

ZONE 2

HEAT STRIP

ON

12 345

ZONE 4

DIFFERENTIAL

STAGE

FURNACE

ZONE 3

GEN START

678

E. Turn "ON" the furnace dip switch when a furnace is

connected to the blue wires off the control board.

F. Differential dip switch is the difference between the

"ON/OFF" cycle of the thermostat. The normal dif-

ferential is preset in the circuit board with the dip

switchset to the "OFF" positions. In some situations,

it maybe necessary to decrease the Differential.

The location of the Comfort Control Center

TM

may

create a condition where the normal differential will

not maintain the temperature at your comfort level. If

this occurs, the Differential can be shortened by placing the Differential dip switch to the "ON" position.

G. The "GEN START" dip switch - leave in the "OFF"

position.

3.5.2 SYSTEM RESET

On new installation the COMFORT CONTROL CENTER TM,

and/or any changes made to the dip switches requires the

electronic control kit to be reset.

A. Turn "ON/OFF" switch to the "OFF" position.

B. Simultaneously depress and hold the "MODE" and

"ZONE" push-buttons while turning the "ON/ OFF"

switch to "ON". The LCD Display should show "FF"

until the "MODE" and "ZONE" push-buttons are released.

3.5.3 System Checkout

A. Verify that all features of the inst alled system work.

Check fan speeds, cooling mode, furnace (if connected) and heat pump. If the features do not work,

check all wiring and confirm that the correct options

have been selected on the Electronic Control Box.

3.5.4 Service And Disposal Of Unit

A. The Clean Air Act of 1990 set guidelines in regards

to recapturing or disposition of refrigerants. Service

agents working with reclamation of refrigerants must

be certified by the Environmental Protection Agency

(EP A). Check with the EPA authorities for proper handling or evacuation of refrigerants.

NOTE: The Control Board should have the S tage Dip

Switch preset to "ON". All other dip switches are

shipped from the factory in the "OFF" position.

C. Turning "ON" of zone 2 dip switch identifies this as

zone 2: likewise zone 3 and 4.

D. Stage dip switch is to be in the "ON" position. This

will control the operation of the second compressor,

provided AC power is available to Circuit #2. The temperature differential between the first and second stage

is preset and cannot be changed.

16

Loading...

Loading...