Dolby Laboratories CP500-D, CP500-300, CP500-SR, CP500-70, CP500 Installation And Alignment Manual

Page 1

Film-Tech

The information contained in this Adobe Acrobat pdf

file is provided at your own risk and good judgment.

These manuals are designed to facilitate the

exchange of information related to cinema

projection and film handling, with no warranties nor

obligations from the authors, for qualified field

service engineers.

If you are not a qualified technician, please make no

adjustments to anything you may read about in these

Adobe manual downloads.

www.film-tech.com

Page 2

Model CP500

Digital Cinema Sound

Processor

Installation and Alignment

Issue 5 Part No. 91371

Page 3

Installation and Alignment Manual

For

Model CP500

Digital Cinema Sound Processor

Dolby Laboratories Incorporated

U.S.A. 100 Potrero Avenue, San Francisco, CA 94103

Tel: 415-558-0200; Fax: 415-863-1373, www.dolby.com

U.K. Wootton Bassett, Wiltshire SN4 8QJ

Tel: (44) 1793-842100; Fax: (44) 1793-842101

Equipment manufactured by Dolby Laboratories is warranted against defects in materials and

DISCLAIMER OF WARRANTIES:

workmanship for a period of one year from the date of purchase.

merchantability or fitness for a particular purpose.

LIMITATION OF LIABILITY:

negligence or otherwise shall not exceed the cost of repair or replacement of the defective components and under no circumstances shall

Dolby Laboratories be liable for incidental, special, direct, indirect or consequential damages (including but not limited to damage to software

or recorded audio or visual material), or loss of use, revenue or profit even if Dolby Laboratories or its agents have been advised, orally or in

writing, of the possibility of such damages.

Dolby and the double-D symbol are registered trademarks of Dolby Laboratories.

Windows 95 is a trademark of Microsoft Corporation

Digital decoding covered by the following U.S. patents: 4,790,016, 4,914,701, 4,799,260 4,941,177, 5,109,417, 5,142,656, 5,230,038,

5,274,740, 5,297,236, 5,357,594, 5,463,424, 5,583,962, 5,608,805, and other worldwide patents granted and pending.

There are no other express or implied warranties and no warranty of

It is understood and agreed that Dolby Laboratories’ liability whether in contract, in tort, under any warranty, in

©1998 Dolby Laboratories Inc.

ISSUE 5

Software v 1.30

S98/11507/12003

Dolby Part No. 91371

Page 4

SECTION 1 INTRODUCTION

1.1 About the Dolby CP500......................................................................1-1

1.2 Hardware Configurations Available....................................................1-1

CP500-D........................................................................................1-1

CP500-300.....................................................................................1-1

CP500-SR......................................................................................1-2

CP500-70.......................................................................................1-2

1.3 About This Manual..............................................................................1-2

1.4 Specifications ......................................................................................1-3

1.5 Regulatory Notices..............................................................................1-5

FCC ...............................................................................................1-5

UL..................................................................................................1-5

UK .................................................................................................1-5

IEC.................................................................................................1-5

SECTION 2 EQUIPMENT REQUIRED

TABLE OF CONTENTS

SECTION 3 INSTALLATION AND JUMPERS

3.1 Replacing an Existing Sound System..................................................3-1

3.1.1 Before playing the film:........................................................3-1

3.1.2 While playing the film:.........................................................3-1

3.1.3 Disconnect the old system....................................................3-1

3.2 Mount the CP500.................................................................................3-2

3.3 Connect the CP500..............................................................................3-2

3.3.1 Connect Motor Start Relays ................................................3-3

3.3.2 Connect Remote Controls ...................................................3-3

3.3.3 Connection of Solar Cell Boards.........................................3-4

3.4 Check and Set Jumpers........................................................................3-6

Cat. No. 661 Optical Pre-amplifier Card (Analog

Soundtracks)......................................................................3-6

Cat. No. 681 Analog Switch Card.....................................3-6

Cat. No. 682 Analog Output Card.....................................3-7

Cat. No. 683 Crossover Card (Optional)...........................3-8

3.5 Install Circuit Cards - Card Descriptions ..........................................3-10

Model CP500-D ..........................................................................3-10

Cat. No. 222SR/A Module..............................................3-10

Cat. No. 661 Optical Preamplifier Card..........................3-10

Cat. No. 681 Input Switch Card ......................................3-10

Cat. No. 675A Digital Signal Processing Cards (2)........3-10

Cat. No. 685 6-Channel Analog to Digital Converter

Card .................................................................................3-10

Cat. No. 662 6-Channel Digital to Analog Converter

and Voltage Controlled Amplifier Card..........................3-10

Cat. No. 682 Analog Output Card...................................3-10

Cat. No. 684 System Controller Card..............................3-10

Cat. No. 683 Crossover Card (Optional).........................3-11

Page 5

ii

Dolby Digital Soundtrack Processing System............................. 3-11

Cat. No. 670 Video Front-end Card............................................ 3-11

Cat. No. 671 DSP Cards (2)........................................................ 3-11

Cat. No. 673 System Services Card ............................................ 3-11

Cat. No. 675A Digital Signal Processing Card........................... 3-11

Cat. No. 680 Bit Rate Converter Card ........................................ 3-11

Model CP500-D/300............................................................................... 3-11

Model CP500-SR ....................................................................................3-11

Model CP500-70..................................................................................... 3-11

Cat. No. 222A Modules (2)......................................................... 3-11

Cat. No. 669 Adapter Card..........................................................3-11

Cat. No. 685 6-Channel Analog to Digital Converter

Card............................................................................................. 3-11

3.6 Bypass Power Wiring....................................................................................3-12

3.7 Power On.......................................................................................................3-13

3.7.1 Hum and Other Noise Problems.....................................................3-14

Fold-Out Drawings:

Card Locations

CP500 Wiring

SECTION 4 FRONT PANEL and ALIGNMENT OVERVIEW

4.1 The CP500 Front Panel................................................................................. 4-1

4.1.1 Soft Keys: SK1 to SK8..................................................................4-1

4.1.2 Hard Keys....................................................................................... 4-1

Formats........................................................................................ 4-1

Menu............................................................................................4-1

Cancel..........................................................................................4-3

OK............................................................................................... 4-3

Exit.............................................................................................. 4-3

4.1.3 Other Controls and Indicators:....................................................... 4-3

4.2 System Password........................................................................................... 4-4

4.3 Aligning the B-Chain.................................................................................... 4-5

SECTION 5 B-CHAIN ALIGNMENT

5.1 Check Theater Equipment............................................................................. 5-1

Amplifiers....................................................................................5-1

Air-conditioning.......................................................................... 5-2

5.2 Preparing for Room Equalization.................................................................. 5-2

Using a Microphone Multiplexer with the CP500...................... 5-2

5.2.1 Configure the Cat. No. 682 for Use with the Optional

Cat. No. 683 Electronic Crossover Card................................................. 5-2

5.2.2 Screen Channels............................................................................. 5-2

5.2.3 Surround Channel Bass Drivers (Optional)....................................5-3

5.3 Room Equalization........................................................................................ 5-4

5.4 Bypass Crossover Adjustment......................................................................5-15

Page 6

iii

SECTION 6 A-CHAIN ALIGNMENT

6.1 Aligning the A-Chain....................................................................................6-1

6.2 Analog Optical Alignment - Projector...........................................................6-2

SECTION 7 Cat. No. 700 DIGITAL SOUNDHEAD

7.1 Mechanical Alignment ....................................................................................7-1

7.2 Adjustment Setup with Oscilloscope ..............................................................7-1

7.3 Focus Adjustment............................................................................................7-2

7.4 Exciter Lamp Level Confirmation and Adjustment........................................7-3

7.5 Film Path Alignment.......................................................................................7-3

7.6 Optical Alignment...........................................................................................7-4

7.7 How to Identify Types of Soundtracks............................................................7-6

7.8 Film Threading................................................................................................7-6

7.9 Cat. No. 673.....................................................................................................7-7

7.10 Projector Changeover / Motor Run Indicators ..............................................7-7

7.11 Format Control ..............................................................................................7-7

7.12 Automatic Selection of the Dolby Digital Format.........................................7-7

7.12.1 A Quick Look at Operation With Standard Set-up........................7-7

7.12.2 Operation with Custom Setup ........................................................7-9

Allowable Source Formats..........................................................7-10

Allowable Target Formats...........................................................7-10

How It Works..............................................................................7-10

Disabling the Auto-Digital Feature.............................................7-10

7.12.3 Setting Up the Auto-Digital System.............................................7-11

Assigning Source Formats...........................................................7-11

Assigning Target Formats ...........................................................7-12

7.13 Maintenance and Adjustments ....................................................................7-13

7.13.1 Replacing the Exciter Lamp.........................................................7-13

7.13.2 Print Cleanliness...........................................................................7-13

7.13.3 Adjustments..................................................................................7-13

SECTION 8 FINAL ADJUSTMENTS

8.1 Setting Optical Surround Delay.......................................................................8-1

8.2 Setting Digital Soundhead Delay ....................................................................8-3

8.2.1 Static.................................................................................................8-3

8.2.2 Dynamic............................................................................................8-4

8.2.3 Typical Settings................................................................................8-4

8.3 Setting Digital Surround Delay.......................................................................8-5

Page 7

8.4 Bypass Adjustments........................................................................................8-6

8.4.1 Before you Adjust ............................................................................8-6

8.4.2 Bypass Level Adjustment (No Cat. No. 683 Electronic

Crossover Card Installed)..........................................................................8-7

8.4.3 Output HF/LF Balance and Level Adjustments(With

Cat. No. 683 Electronic Crossover Card)..................................................8-8

8.4.4 Bypass Level Adjustment for Early Cat. No. 682 (No

Cat. No. 683 Electronic Crossover Card Installed)........................ 8-10

8.4.5 Early Cat. No. 682 Output HF/LF Balance and Level

Adjustments (With Cat. No. 683 Electronic Crossover

Card)...............................................................................................8-11

8.5 About Non-sync ............................................................................................ 8-12

8.6 Mute Speed Adjustment................................................................................ 8-13

SECTION 9 ACCESSORIES

9.1 CP500 Operation with Remote Controls.........................................................9-1

9.1.1 Cat. No. 689 CP500 Remote Control...............................................9-1

9.1.2 Cat. No. 734 CP500 Remote Fader..................................................9-2

9.1.3 Auditorium Fader.............................................................................9-3

9.2 Operation with Cat. No. 580 Microphone Multiplexer...................................9-4

9.2.1 Operation..........................................................................................9-4

9.2.2 Components......................................................................................9-6

iv

SECTION 10 TROUBLESHOOTING

10.1 During the Show..........................................................................................10-1

10.1.1 If Film Sound Is Lost.................................................................... 10-1

10.1.2 If One Channel Fails or is Distorted.............................................10-2

10.1.3 If Switching to Bypass Does Not Restore Sound......................... 10-2

10.1.4 If You Hear Extraneous Noises When Playing a

Digital Film............................................................................................. 10-2

10.1.5 Excessive or Inappropriate Sound From Surround

Speakers .................................................................................................. 10-3

10.1.6 On CP500s Equipped with Cat. No. 683 Electronic

Crossover:................................................................................................10-3

10.2 Between Shows........................................................................................... 10-4

10.2.1 Analog Film Sound Signal Path LEDs......................................... 10-4

10.2.2 Digital Film Sound Signal Path LEDs......................................... 10-5

10.2.3 Bypass Signal Path LEDs............................................................. 10-7

10.3 Troubleshooting Chart.................................................................................10-7

APPENDIX A ADVANCED OPERATIONS

A.1 Customizing the Format Display Screen........................................................A-1

Page 8

v

A.2 Saving System Settings...................................................................................A-5

A.2.1 Using the Terminal Program in Windows®.....................................A-5

Equipment Needed ........................................................................A-5

Transferring Data From the CP500 to the Computer....................A-5

Transferring Data From the Computer to the CP500..................A-9

A.2.2 Using Load500 Software...............................................................A-11

Equipment Needed ......................................................................A-11

Transferring Data From the CP500 to the Computer..................A-11

Transferring Data from the Computer the to the

CP500..........................................................................................A-13

A.3 Transferring Data Between Two CP500s.....................................................A-15

APPENDIX B CAT. NO. 683 ELECTRONIC CROSSOVER

B.1 Description and Features.................................................................................B-1

B.2 Installation ......................................................................................................B-1

B.3 Alignment .......................................................................................................B-2

B.3.1 Screen Channels...............................................................................B-2

B.3.2 Surround Channel Bass Drivers.......................................................B-3

B.3.3 Bypass Crossover Subsystem...........................................................B-3

B.4 Special Applications.......................................................................................B-4

B.4.1 Time Delay.......................................................................................B-4

B.4.2 Crossover Frequency........................................................................B-5

B.5 Headers Available...........................................................................................B-5

B.6 Jumpers and Headers ......................................................................................B-6

APPENDIX C BACKPLANE CONNECTOR ASSIGNMENTS

1. Automation Connector:............................................................C-1

2. Serial Data Connector: .............................................................C-1

3. Motor Start Connector:.............................................................C-1

4. Bypass / Remote Connector:....................................................C-2

5. Main / LF Output Connector:...................................................C-2

6. Crossover Output Connector:...................................................C-2

7. Optical 1 Input Connector:.......................................................C-3

8. Optical 2 Input Connector:.......................................................C-3

9. Mic. Input Connector: ..............................................................C-3

10. Accessory Rack Analog Connector:.......................................C-4

11. Accessory Rack Digital Connector:........................................C-5

12. 6 Channel Input Connector:....................................................C-6

13. Reader 1 and Reader 2 Input Connector:................................C-7

FOLD-OUT DRAWINGS:

System Setup Menu Tree

Alignment and Diagnostics Menu Tree

Signal Block Diagram

Backplane Interconnections

Page 9

vi

APPENDIX D THE DOLBY DIGITAL SUBSYSTEM

D.1 Basic Functions ..............................................................................................D-1

D.2 Discussion of Changeover Technique............................................................D-3

D.3 Auxiliary Data Channel..................................................................................D-3

APPENDIX E THE EVOLUTION OF DOLBY FILM SOUND

Optical Sound.......................................................................................... E-1

Magnetic Sound.......................................................................................E-2

Dolby Gets Involved................................................................................E-3

The Next Step: Dolby SR........................................................................ E-4

And Now - Dolby Digital........................................................................E-4

About Dolby AC-3.................................................................................. E-5

Making Films Sound Better....................................................................E-5

Page 10

1.1 About the Dolby CP500

Do lby Labora tories ha s continuously established ne w benchmarks fo r motion

picture sound. The CP500 Digital Cinema Processor maintains that tr adition, setting

new standa rds for p er f orma nce, va lue , flexibility, a nd conv enienc e. E ntirely selfcontained, the CP500 provides both Dolby Digital and Dolby analog processing

built in. An easy-to-read LCD screen and uncomplicated front panel soft keys

makes it easy to install, operate, and maintain. Software that can be readily

prog ra mmed, controls any exis ting or future format. Bu ilt-in test instru mentation

that includes a real time analyzer make the CP500 easier to align and calibrate than

conventional processors. No external PC is required for setup. Once aligned,

calibration settings can be password protected to pr event mis-adjustment.

Built-in diagnostic software enables theater st aff to verify performance of the

complete theater so und system. Calibration settings for a given theater can be

stor ed on a PC, and should the need ever arise, they can be transferred directly to

another CP500 or other modules, thereby reducing or eliminating the ne ed for

further calibration after repairs. As improvements to the CP500 digital control and

processing software are developed, the latest r evisions can be downloaded from a

PC to t he CP500 hardware. Mor eover, updates to the audio coding used for Dolby

Digital soundtracks, whic h are includ ed from time to time on Dolby Digital release

prints, download automatically into the CP500 t he first time such a print is played in

the cinema.

SECTION 1

INTRODUCTION

Options available for the CP500 include internal Linkwitz-Riley crossover networks

(Cat. No . 683) for bi-amplified screen speakers, and 6 channel A/D converter (Cat.

No. 685) for use with Dolby models DA10 or DA20 processors, 70mm magnetic

systems, or other cinema sound systems.

1.2 Hardware Configurations Available

The CP500 is available in four versions:

CP500-D

• Dolby Digital de cod ing ca pa bility

• Dolby A- type and S R a nalog soundtrack de coding ca pability

CP500-D/300

• Primarily used in preview theaters and studios

• Dolby A- type and S R a nalog soundtrack de coding ca pability

• Dolby Digital de cod ing ca pa bility

Page 11

CP500-SR

• Dolby A- type and S R a nalog soundtrack de coding ca pability

• Upgradable to Dolby Digital decoding by means of plug-in circuit cards

CP500-70

• Dolby Digital de cod ing ca pa bility

• Dolby A- type and S R a nalog soundtrack de coding ca pability

• 70mm magnetic soundtrack c ap ability (inclu de s a 6 c han nel A /D module

and 4 additional channels of Dolby A-Type noise reduction for use with

an external magnetic pre-amp); can play Formats 42 and 43

Any CP500 configuration also interfaces readily with other film sound eq uip ment.

1.3 About This Manual

Th is ma n ual is intende d to be use d by in dividu als who ar e q ua lified in the area of

cinema sound equipment installation and service. The basic day-to-day operation of

the CP500 is covered in the CP500 Users' Manual, Dolby part number 91372.

1-2

This installation and alignment manual covers the procedures necessary to ensure

that t he t heat er sound system is accurately aligned to standards that have been

es tablished by Dolb y Laboratories. Follow ing these proced ures will ensure that the

t heater so und s ystem will accurat ely reproduce the soundt r ack as the director and

sou nd mixers inten de d.

The Dolby CP500 is the central element of the theater sound system. The projector,

the Dolby Processor, t he po wer amplifiers and the loudspeakers, as well as the

auditoriu m itse lf, must all be consider ed wh en aligning the system fo r optimum

performance.

The system alignment pro cedur e is divided into t w o parts. T he B-chain alignment

includes the equalization, loudspeaker crossover, and o u tput level adjustments, in

addition to the regulation of miscellaneous functions, such as fade-out time

adjustment. The A-chain alignment involves adjustments made to the pro jector

soundhead optics, solar cell, and optical preamplifier card.

Page 12

1.4 Specifications

Construction

Rack-m ount chassis fra me construction with p lug-in m od u les accessible behi nd hinged fr ont

panel.

Signal Connect ions

a. Standard 9 pin D-type connectors for Mic., Optical 1, Optical 2, Seria l Data , a nd Motor Start

signals.

b. Standard 25 pin female D-type connectors for Digital Readers 1 and 2, Accessory Unit,

Automation connections, and 6 Channel Analog Inputs.

c. RCA type phono jacks for Non-sync 1 and 2.

d. Phoenix screw terminal connectors for processor outputs, bypass power, and remote control

connections.

Signal Inputs

a. 6 Channel: Six analog inputs for use with external magnetic preamplifier or external

processor, 300 mV operatin g level. (Requires optional Cat. No. 685.)

1-3

b. Optical: Two pairs of balanced inputs for two projectors with stereo solar cells (available from

Dolby Laboratories mounted on brackets for most projector types). Inputs compatible with LED

illuminated reverse-scan analog readers.

c. Non-sync: Two stereo inputs for non-sync sources. 50 kOhm input impedance, 50 mV to 2.5 V

sensitivity. 2:4 decoder may be used to decode Dolby Surround program sources.

d. Microphone: One balanced input for B-chain equalization P.A. mic. or multiplexer and one

unba lan ced inp u t for h ou s e announcement mic.

e. Dolby Digital Film Reader (CP500-D): Two inputs for connection to penthouse or inboard

readers.

Signal Outputs

47 ohms output impedance will drive any load greater than 600 ohms. Maximum output level, +20

dBu. Typical operating l evel, -10 dBu.

Operating levels from 25 mV to 0.7 V may be accommodated.

Output For Hearing-impaired System

Center-weighted sum of L, R, C for connection to auxiliary system for the hearing impaired.

Output impedance is 47 ohms with a fixed output level of 200 mV.

Optical Preamplifier

A Cat. No. 661 Optical Preamplifier accepts signals from two projectors with stereo solar cell s .

Gain and slit loss adjustments are digitally controlled.

Noise Reduction

Two channels of Dolby A-type noise reduction and two channels of Dolby SR are provided as

standard. Up to six channels of A-type (CP500-70) and two additional channels of studio SR

(CP500-300) can be accommodated.

Four Channel Decoder

Cat. No. 675A DSP Module decodes left, center, right , a nd surround channels from the two optical

tracks on Dolby analog optical prints. Adjustable delay to optimize front to surround separation.

Page 13

1-4

Loudspeaker Equalization

L,C,R: 27 band digital 1/3 octave EQ; digitally controlled bass and treble

LsRs: digital 9-band, full octave EQ

SW: Digital parametric EQ with 12dB cut capability

Remote Connections

Connections for up to two Dolby Cat. No. 689 remote fader, format selectors and/or Cat. No. 734

fader-only remotes are provided. A provision is also made for a temporary auditorium fader

consisting of a 100k potentiometer.

Automation

Direct mode allows eight contact closures to ground for selecting formats.

Sequential mode allows a single contact closure to ground for sequencing pre-programmed

formats.

Distortion

Typically 0.05% in Dolby SR mode (Format 05, with output operating level set to -10 dBu and

input 10dB over Dolby level ).

Dynamic Range

Typically 92 dB with fader set to 7.0.

Dimensions

Four units high rack mount chassis. Standard 178 mm high by 493 mm wide faceplate (7 x 9").

Maximum projection behind mounting sur face is 360 mm (14.17"). Maxim um projection in front

of mounting plate is 32 mm (1.23").

Weight

11.7 kgs (26 lb.) Max.

Power Requirements

100 - 240 VAC, 50-60 Hz Auto Sensing. 2 A max. i nput current . Single phase. 120 Watts max.

Fuse Requirements

Single 1 1/4" or 5 X 20 mm slow blow fuse according to local safety requirements.

Operating Conditions

0 - 40 oC, 20-80 % humidity, non-condensing.

Page 14

1.5 Regulatory Notices

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his or her own

expense.

UL

The CP500 is UL listed. This installa ti on m anual is for use by qualified personnel only. To avoid

electric shock do not open the unit or perform any servicing unless you are qualified to do so.

1-5

WARNING

fuse only with the same type and rating.

The ground terminal of the power plug is connected directly to the chassis of the unit. For

conti nued protection agai nst electr ic shock , a thr ee- p in, correctly wir ed and eart hed power ou tlet

must be used. Do not use a ground-lifting adapter and never cut the ground pin on the three-prong

plug.

: Check that the correct fuse has been installed. To reduce the risk of fire, replace the

FUSE - 2 Amp, time-lag (T2A), 20 mm long, 250 Volt

Dolby part no. 56027

UK

WARNING

As the colours of the cores in the mains lead may not correspond with the coloured markings

iden tifying th e term ina ls in your pl u g , pr oceed as follows:

: THIS APPARATUS MUST BE EARTHED.

• The core that is coloured green and yellow must be connected to the terminal in

the plug that is marked with the letter E or by the earth symbol

green or g reen and yell ow.

• The core that is coloured blue must be connected to the terminal that is marked

with the letter N or coloured black.

• The core that is coloured brown must be connected to the terminal that is marked

with the letter L or coloured red.

or coloured

IEC

This unit complies with the EMC r equir ement s of EN50081-1 and EN 50082-1 when insta l led in

an E2 environment in accordance with this manual.

Page 15

1-6

IMPORTANT SAFETY NOTICE

This unit complies w ith th e safety standard IEC65. To ensure safe op eration and to guard

against potential shock hazard or risk of fire, the following must be observed:

o If the unit has a volta ge s e lector, ensure that it is s e t to the correct mains voltage for your supply. If there is n o voltage

selector, en sure that your supply is in the correct range for the input requirement of the unit

oEnsure fuses fitted are the correct rating and type as marked on the unit.

o The unit must be earthed by connecting to a correctly wired and earthed power outlet.

oThe pow er cord supplied with th is unit must be wired as follows:

Live—Brown Neutral—Blue Earth—Green/Yellow

IMPORTANT – NOTE DE SECURITE

Ce materiel est conforme à la norme IEC65. Pour vous assurer d'un fonctionnement sans danger et de prévenir

tout choc électrique ou tout risque d'incendie, veillez à observer les recommandations suivantes.

o Le selecteur de tension doit être placé sur la valeur correspondante à votre alimentation réseau.

o Les fusibles doivent correspondre à la valeur indiquée sur le materiel.

o Le materiel doit être correctement relié à la terre.

o Le cordon secteur livré avec le materiel doit être cablé de la manière suivante:

Phase—Brun Neutre—Bleu Terre—Vert/Jaune

WICHTIGER SICHERHEITSHINWE IS

Dieses Gerät entspricht der Sicherheitsnorm IEC65. Für das sichere Funktionieren des Gerätes und zur

Unfallverhütung (elektrischer Schlag, Feuer) sind die folgenden Regeln unbedingt einzuhalten:

o Der Spannungswähler muß auf Ihre Netzspannung ein gestellt se in .

o Die Sicherungen müssen in Typ und Stromwert mit den Angaben auf dem Gerät übereinstimmen.

o Die Erdung des Gerätes muß über eine geerdete Steckdose gewährleistet sein.

o Das mitgeliefe rte Netzkabel muß wie folgt verdrahtet w erden:

Phase—braun Nulleiter—blau Erde—grün/gelb

NORME DI SICUREZZA – IMPORTANTE

Questa apparecchiatura è stata costruita in accordo alle norme di sicurezza IEC 65. Per una perfetta

sicurezza ed al fine di evitare eventuali rischi di scossa êlettrica o d'incendio vanno osservate le

seguenti misure di sicurezza:

o Assicurarsi che il selettore di camb io tensione s ia po sizionato sul valore corretto.

o Assicurarsi che la portata ed il tipo d i fusibili siano quelli pres critti dalla casa costruttrice.

o L'apparecchiatura deve avere un collegamento di messa a terra ben eseguito; anche la connessione rete deve

avere un collegamento a terra.

o Il cavo di alimentazione a corredo dell'apparecchiatura deve essere collegato come segue:

Filo tensione—Marrone Neutro—Blu Massa—Verde/Giallo

AVISO IMPORTANTE DE SEGURIDAD

Esta unidad cumple con la norma de seguridad IEC65. Para asegurarse un funcionamiento

seguro y prevenir cualquier posible peligro de descarga o riesgo de incendio, se han de observar

las siguientes precauciones:

o Asegúrese que el selector de tensión esté ajustado a la tensión correcta para su alimentación.

o Asegúrese q ue lo s fusibles c o lo cados son de l tip o y valor correctos, tal com o se marca en la unidad.

o La unidad debe ser puesta a tierra, conectándola a un conector de red correctamente cableado y puesto a tierra.

o El cable de red suministrado con esta unidad, debe ser cableado como sigue:

Vivo—Marrón Neutro—Azul Tierra—Verde/Amarillo

VIKTIGA SÄKERHETSÅTGÄRDER!

Denna enhet uppfyller säkerhetsstandard IEC65. För att garantera säkerheten och gardera mot

eventuell elcho ck eller brandrisk, måste följande observeras:

o Kontrollera att spänningsväljaren är inställd på korrekt nätspänning.

o Konrollera att säkringarna är av rätt typ och för rätt strömstyrka så som anvisningarna på enheten föreskriver.

o Enheten måste vara jordad genom anslutning till ett korrekt kopplat och jordat el-uttag.

o El-sladden som medföljer denna enhet måste kopplas enligt foljande:

Fas—Brun Neutral—Blå Jord—Grön/Gul

BELANGRIJK VEILIGHEIDS-VOORSCHRIFT:

Deze unit voldoet aan de IEC65 veiligheids-standaards. Voor een ve ilig gebruik en om het gevaar van electris che

schokken en het risico van brand te vermijden, dienen de volgende regels in acht te worden genomen:

o Controleer of de spanningscaroussel op het juiste Voltage staat.

o Gebruik alleen zekeringen van de aangegeven typen en waarden.

o Aansluiting van de unit alleen aan een geaarde wandcontactdoos.

o De netkabel die met de unit wordt geleverd, moet als volgt worden aangesloten:

Fase—Bruin Nul—Blauw Aarde—Groen/Geel

GB

F

D

I

E

S

NL

Page 16

SECTION 2

EQUIPMENT REQUIRED

The following equipment is required for proper installation and alignment of the

CP500 Digital Cinema Processor.

• Dual-trace oscillos cop e w ith X-Y fac ilities (minimum bandw idth 20 MHz, 50

MHz recommended).

• Ca libr ate d mic rophone ( preferab ly multiple micr ophon es and a multip lexer ).

• Sound pressure lev el me ter with slow time-con stant an d C we ighting scale .

• Voltmeter for measuring the exciter lamp power supply.

• Test Films, a vailable from Dolby Lab ora tories or equipment deale rs (Figures 2-1

through 2-7). We r ec ommend that you mak e loop s of these test films, lon g

enoug h to go th rough the entire projector film pa th so that a zimu th an d la teral

film pos ition adju stments can be made accurat ely.

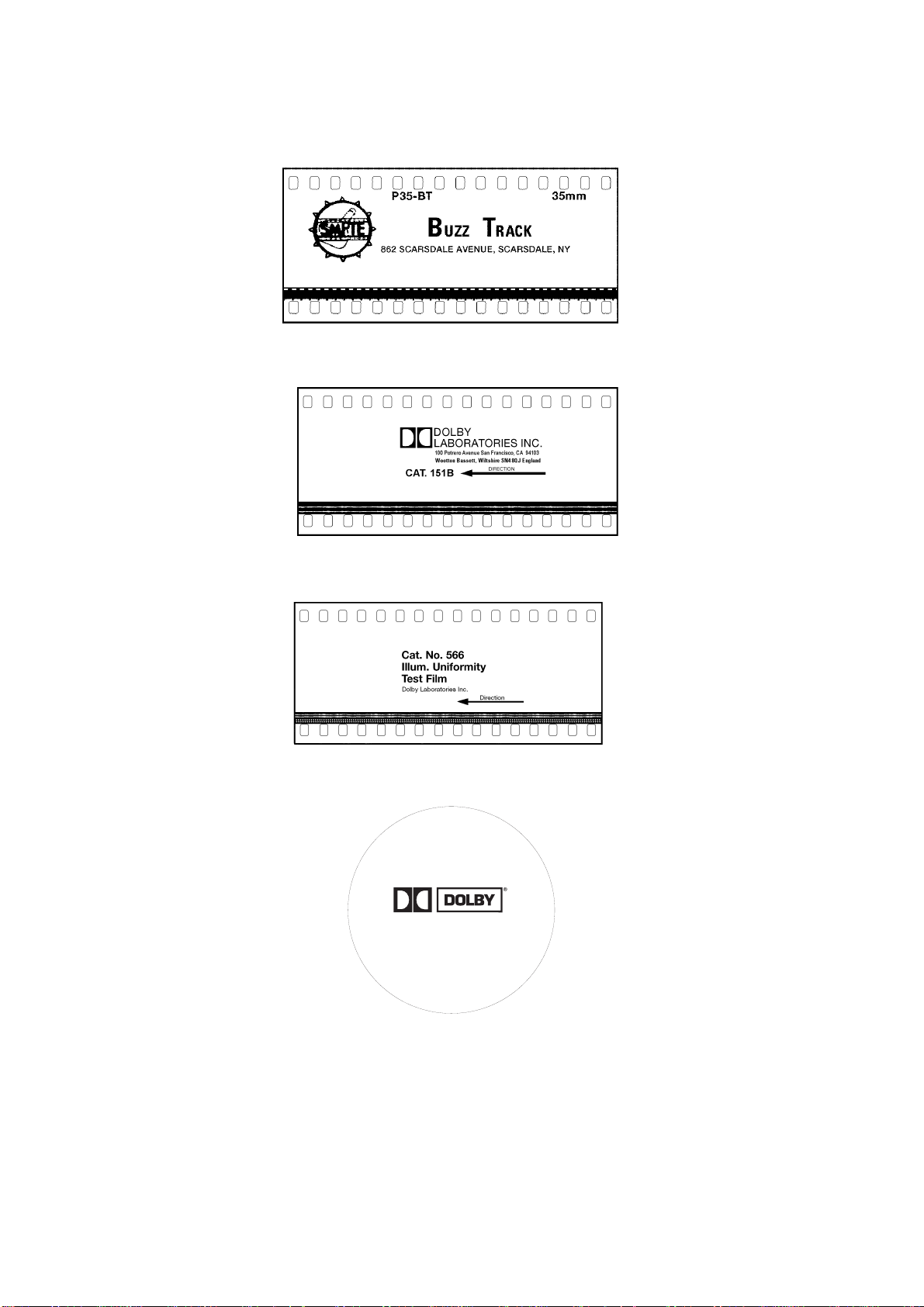

Figure 2 - 1.

Figure 2 - 2.

Dolby Tone – Cat. No. 69T.

Pink Noise – Cat. No. 69P.

Figure 2 - 3.

1kHz, Crosstalk/Cell Alignment – Cat. No. 97.

Page 17

2-2

Figure 2 - 5.

Figure 2 - 6.

Figure 2 - 4.

SMPTE Buzz Track.

Stereo Optical Surround Level – Cat. No. 151B.

Illumination Uniformi t y – Cat. No. 566.

JIFFY

TEST FILM

Cat. No. 251 SR•D—A subjective film for testing theatre sound

Figure 2 - 7.

“Jiffy” Test Fi l m – Cat. No. 251 SR/Digital.

Additional te st films used dur in g Dolby D igita l system installation:

•••• Cat. No. 1010 Sync Test

•••• Cat. No. 1011 Channel ID

•••• Cat. No. 1012 Dolby Level

RECORDED IN

Running Time:

Picture format:

Dolby, the Double-D symbol and Dolby Stereo are trademarks

6 minutes

1.85:1 widescreen or

2.35:1 anamorphic

Sound formats:

10

05

digital

analog

Dolby Laboratories Inc. • 100 Potrero Avenue

San Francisco, CA 94103-4813

Telephone 415-558-0200 • Facsimile 415-863-1373

of Dolby Laboratories Licensing Corporation

S96/10117/11146

Page 18

INSTALLATION AND JUMPERS

Do NOT connect the CP500 to mains power until all connections have been made

and all jumpers have been checked or set.

If air-conditioning noise is audible in the theater, arrange for lubrication of the

motor, fan bearings, adjustment of belts and drives, and cleaning of filters t o reduce

the ambient noise to a minimum. If the air-conditioning cannot be repaired switch it

off while the CP500 is being aligned.

3.1 Replacing an Existing Sound System

If the CP500 replaces an existing cinema sound system, play a typical film before

yo u remov e the old system so you w ill hav e a ben chmar k for compa ris on to the new

system. It can also serve as a check of the positioning of the exciter lamp, the

focusing of the soundtr ack lens, and the condition of the solar cell.

SECTION 3

3.1.1 Before playing the film:

• Verify that the existing power amplifiers are in good working order.

• Verify that the existing speakers are in good wo r king order, and that

there is no loose or missing hardware, stru ctural parts, or damaged

drivers in the enclosures.

• Verify that all wiring is present and properly connected and that

crosso vers are operating and are correctly adjusted.

• Check the polarity of the speaker connections.

• Verify that there are adequate earth (gr ound) connections.

• Verify that radio interference problems are adequately resolved.

3.1.2 While playing the film:

While you run the film, listen ca refully in va rious parts of th e theater for audio

system problems:

• Hum.

• Noise, clicks, pops.

• Distorted so und.

• Poor to nal balance ( lack of high-frequency or bass content).

These problems must be resolved before you can proceed with the new installation.

3.1.3 Disconnect the old system

• Disconnect power from the existing cinema sound equipment.

• Disconnect all cabling from the existing sound processor. Leave the

cables connected to the power amplifiers, booth monitor, etc.

Page 19

3.2 Mount the CP500

To avoid heat problems, do not mount t he Do lby CP500 immedia tely a bove or

below the power amplifiers. Locate the power amplifiers away from the CP500 to

avoid hum pickup problems. Always leave a 1U (43 mm, 1.75") space above and

below the CP500 t o provide adequate ventilation. Install an air guide or baffle to

deflect hot air from equipment below the CP500.

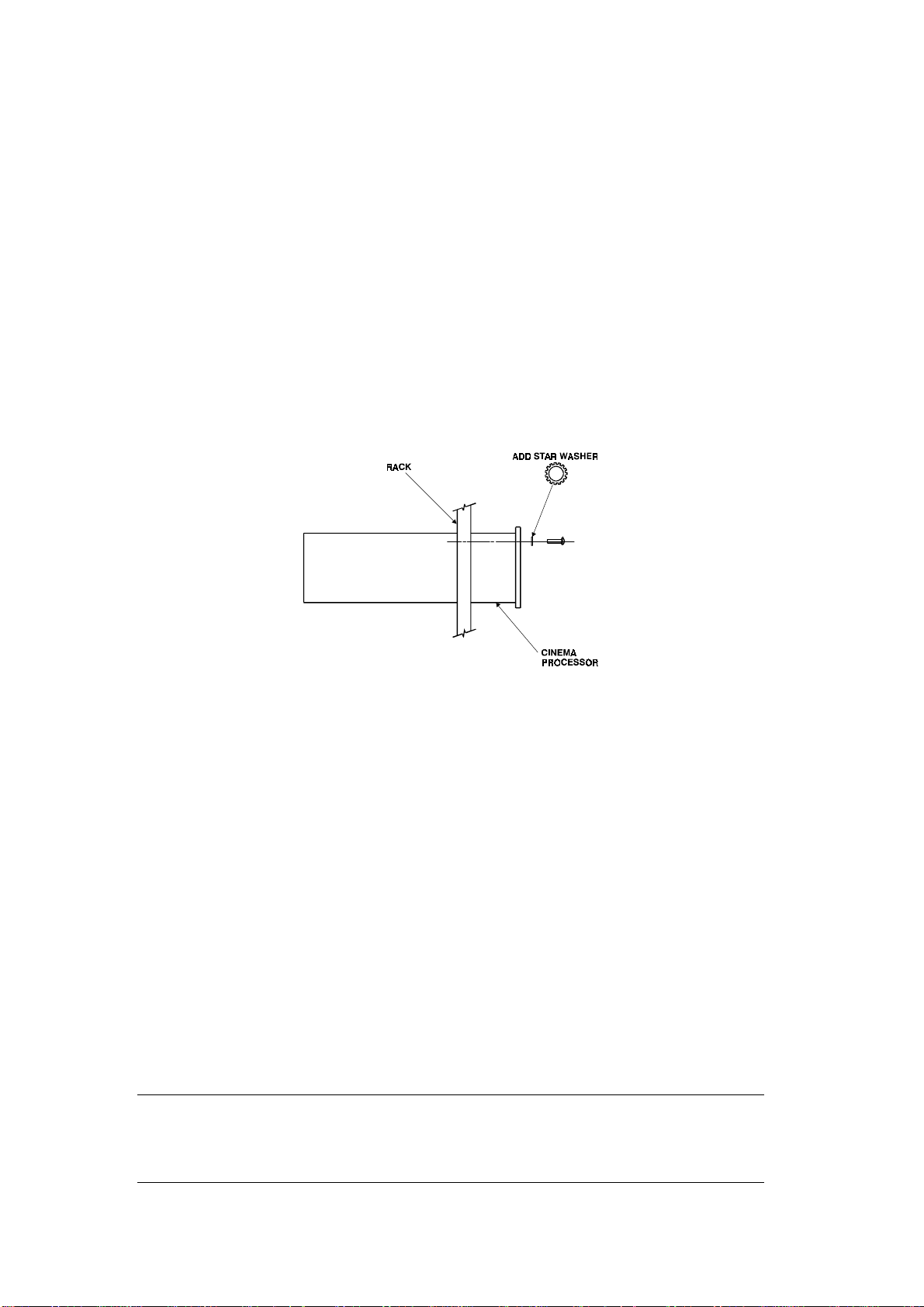

To ensure go od gro und contact, install star washers on all or at least one rack

mounting screw per piece of equipment (Figure 3-1). Th is will als o aid in the

prevention of electrical noise problems.

3-2

Figure 3 - 1.

Install star washers to rack mounting screws

Proper shielding and termination of cables and cable assemblies are also very

important. Be su re to follow the meth ods shown in th e w iring d iag rams.

If you a re ins talling a Dolby Cat. No. 700 Digital Soundtrack Reader, refer to its

installation man ua l for mou nting an d a lignment.

3.3 Connect the CP500

Refer to the approp r iate fold-out page ( at the end of this section) showing

connections to the various CP500 model configurations.

Make output signal connections by inserting stripped and tinned leads into the

supplied cable connectors and tightening each lead in place by means of the integral

set screw. The cable connectors are then plugged into place at the cor r esponding

locations shown on the fold-out wiring diagram. Shields must be connected as

shown in the fold out page to avoid radio frequency interference.

NOTE

:

Follow all local codes and regulations covering electrical wiring. It is recommended that conduit be

used for wiring runs.

.

Green plastic connector shells have been included in your installation kit for use in countries which are

governed by the E MC directi ves.

The shells

must

be used as noted on the fold-out pages.

Page 20

3-3

3.3.1 Connect Motor Start Relays

For two-pro jecto r installations, motor st ar t relays are required for projecto r

changeover. Digital data on the soundtrack is read in advance of the picture,

therefore an advanced changeover signal is required (see Appendix C). Projector

motor st ar t contact closures provide this signal to the CP500. Isolat e d contact

closures from mechanical or opto - isolated relays wired across projector motors

must be used. Refer to the Installat i o n Wi ri n g Power and Control diagram at the

end of this section.

Signal lev els :

Motor St ar t Less than 1 Vdc with respect to signal ground.

Moto r Off: Greater than 3.5Vdc, less than 18Vdc.

Re fer to the unit c onnections fo ld-out diagram for d etails ( located at the end of this

manual). For single projector installations, a prewire connector is supplied.

(Models CP500-D, and - 70)

3.3.2 Connect Remote Controls

The CP500 is equipped for use with three types of remote controls: the Cat. No .

689, and Cat. No. 734, which are offered by Dolby Laborator ies, and an auditorium

fader, which can be made from parts purchased at an any electronics store.

The Cat. No. 689 CP500 Remote Control duplicates the front panel format

selection, fader, and mute controls of the CP500.

The Cat. No. 734 CP500 Remote Fader consists of a shaft encoder with LEDs to

indicate the fader setting.

The auditorium fader is a 100k linear pot wired as a variable resistor, with

minimum resistan ce corresponding to fade r 10.

Details on how to connect any of these remotes t o the CP500 are shown in the

Installa t i o n Wi ri n g Power and Control drawing located at t he end of this section.

Page 21

3-4

3.3. 3 Connec t ion of Sola r Cell Boa rds

In contrast to t r aditional solar cells, the Cat. No . 655 and other solar cell circuit

boards used by several projector manufacturers are act ive devices with their own

power supply. Some care needs to be given to the wiring between the board and the

CP500 in order t o avoid grounding problems and to provide immunity to RF

interference. In principle, this means separating the audio ground connections and

the RF shielding screen connections.

The 0V point (audio ground) must be connected from the basement reader card to

the CP500 by a separate wire (or wires) along with the audio signal wires. The

cable shield (screen) must be kept separate from the audio ground connections. It

must be connected only to the chassis or enclosure of the equipment at each end.

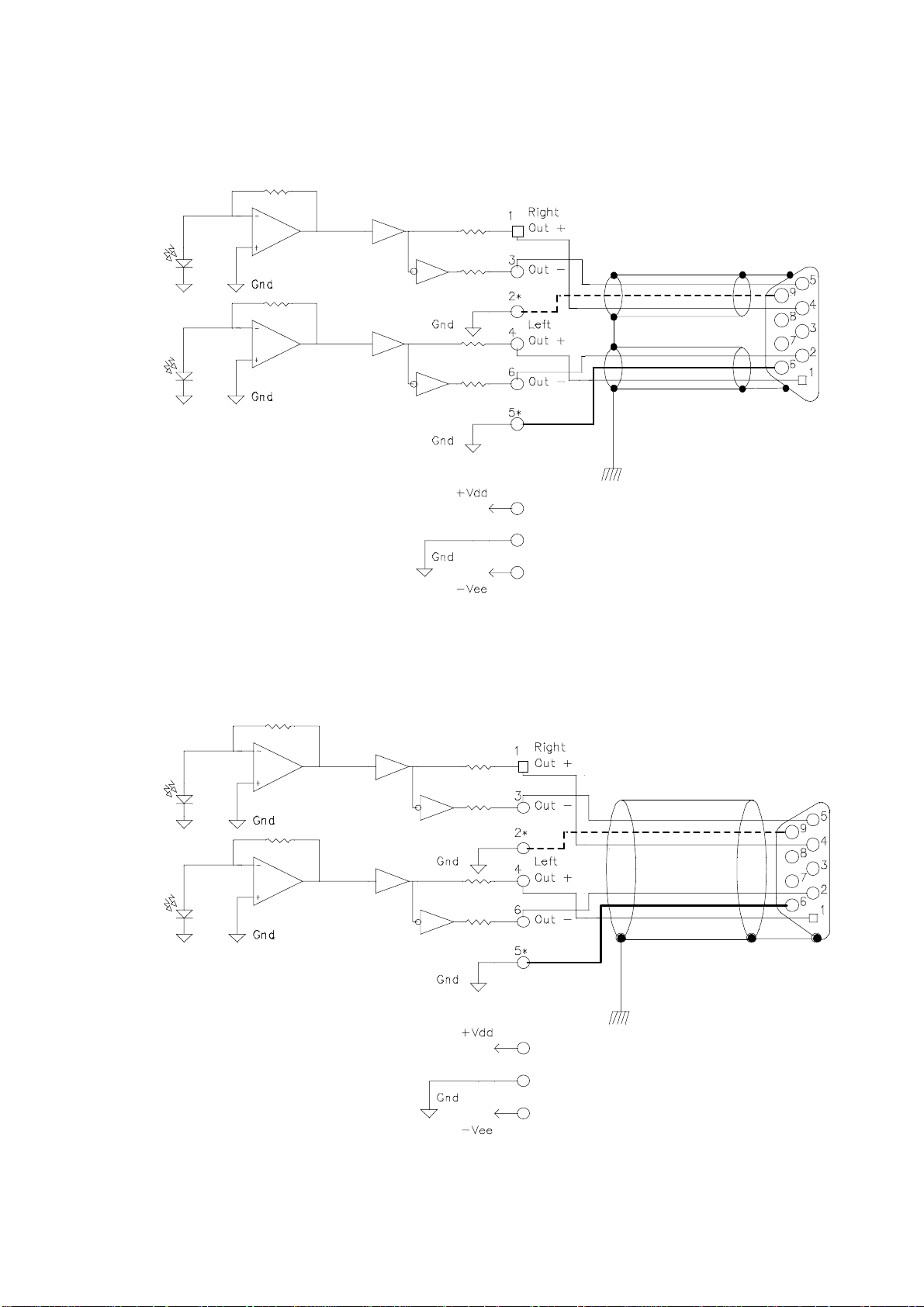

Th e following diagrams ( Figures 3-2 and 3-3) sho w two connectors on the board.

The three pin connector, J1 is used for the power supply. The signal output

connector J2 pr ovides six output pins; two each for the "balanced" left and right cell

outputs, and two 0V audio gro und connections.

NOTE:

The following tables show the Right channel appearing on pins 1, 2, and 3 of the 6-pin connector J2.

The physical orientation of the board mounting in the projector and the orientation of the connector body

mounting on the board affect which channel appears on which pins of the connector.

allocations for the channels will vary depending on mounting arrangements of the board and

connector

. The J2 connector pin solder hole with a square outline is pin 1.

J2 Pin Number Signal

1

2 Signal Ground 2 Signal Ground

3

4

5 Signal Ground 5 Signal Ground

6

Right

Right –

Left

+

Left

–

+

OR:

J2 Pin Number Signal

1

3

4

6

Be aware that pin

Left

-

Left

+

Right

-

Right

+

There must be a connection between the ground pins at the Cat. No . 655 solar cell

circuit board and the audio common in the CP500. This connection must

not

use

the shield of the optical input cable, otherwise RF energy can be imposed on the

CP500 ground system.

Pin numbers 6 and 9 of each 9-pin D connector ("Pro jecto r ") on the CP500 allow

these connections to be made. The wire that connects either of these pins to t he

Cat. No. 655 audio ground should pass inside the same shield as the optical input

cables and not connect with the shield at any point.

Page 22

* Ground Wire on J2 Pin 2 is Optional

* Ground Wire on J2 Pin 5 is Required

3-5

J2

Cinema Processor

Chassis Ground

J1

Figure 3 - 2.

Wi r i ng using two 3-wire shielded (screened) cables.

* Ground Wire on J2 Pin 2 is Optional

* Ground Wire on J2 Pin 5 is Required

J2

Cinema Processor

Chassis Ground

J1

Figure 3 - 3.

Wi r i ng using one 5 or 6-wire shielded (screened) cable.

Page 23

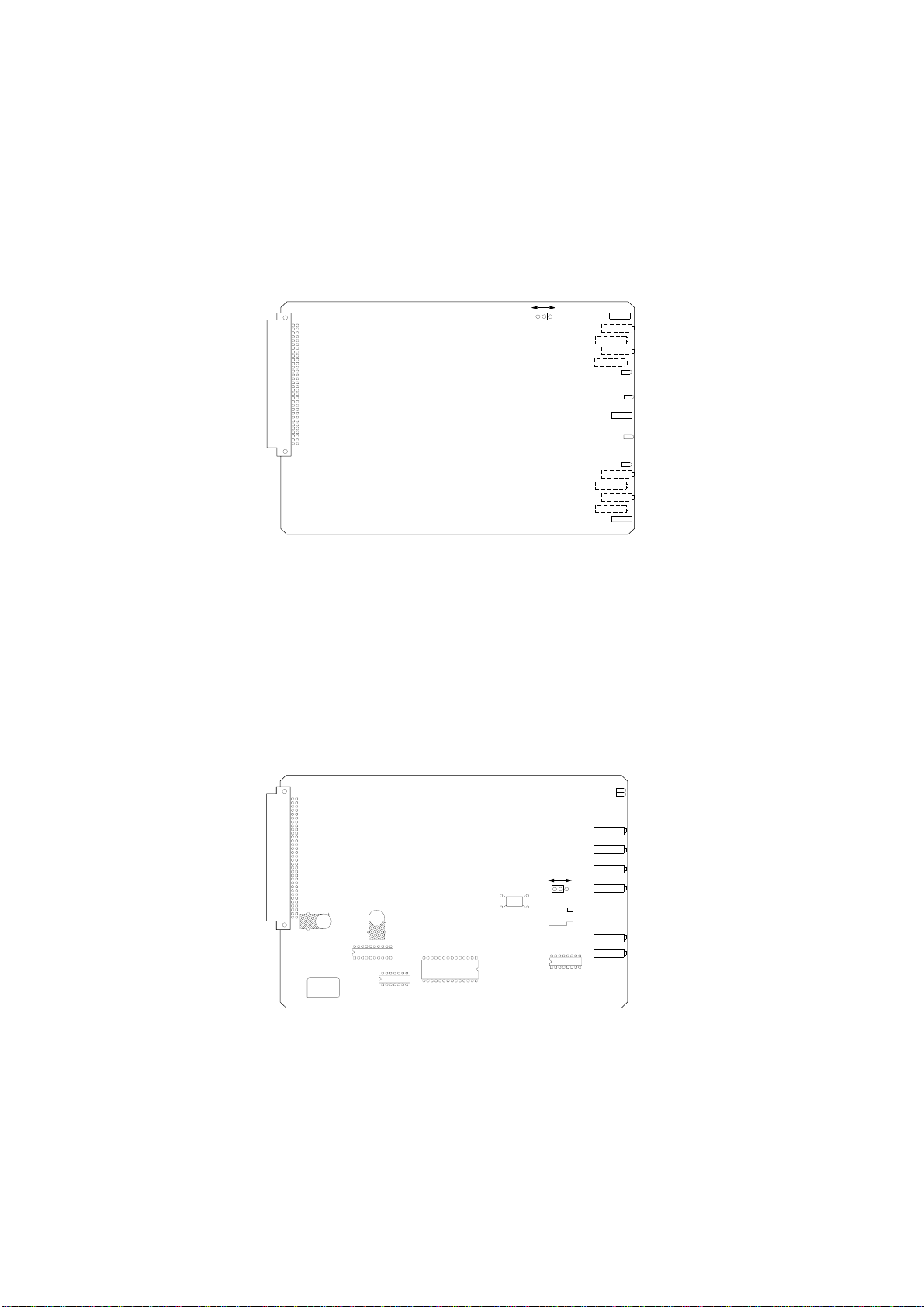

3.4 Check and Set Jumpers

Next, check the following jumpers located on each circuit card. T he factory settings

for each jumper are shown in [brackets].

3-6

Cat. No. 661 Optical Pre-amplifier Card

POWER-UP PROJECTOR

SELECT JUMPER

CAT.NO. 661

Figure 3 - 4.

(Analog Soundtracks)

PROJECTOR 1

J2

Cat. No. 661.

J2 Power-up Projector Select (Wake-up state) [P 1]

Th is ju mpe r determine s which projector is s ele cte d w hen pow er is firs t

applied to the CP500. When J2 is set to “P1”, Projector 1 is selected at

power up. When J2 is set to “P2”, Projector 2 is selected at power up. The

jumper is set to "P 1" at the facto r y.

PROJECTOR 2

DS503

PROJ 1

SIG1

DS501

GND

SIG 2

PROJ 2

Cat. No. 681 Analog Switch Card

PHANTOM MIC POWER

FOR EQ MIC

J3

C63

C64

IC9

IC6

IC8

IC7

Figure 3 - 5.

CAT.NO. 681

Cat. No. 681.

L1100

J3 Equalization Microphone Phantom Power [OFF]

This jumper enables a phantom power sour ce for theater equalization

microphones which require phantom power t o operate. When the jumper is

set to the “ON” position, phantom power (15V) is supplied to the EQ

microphone jack and the rear panel microphone connector.

DS100

DS200

CW

RV101

NONSYNC1 L

CW

RV201

R135

NONSYNC1 R

CW

RV100

R235

NONSYNC2 L

ONOFF

CW

RV200

NONSYNC2 R

J2

CW

RV1100

EQ MIC

CW

RV2100

SIG MIC

Page 24

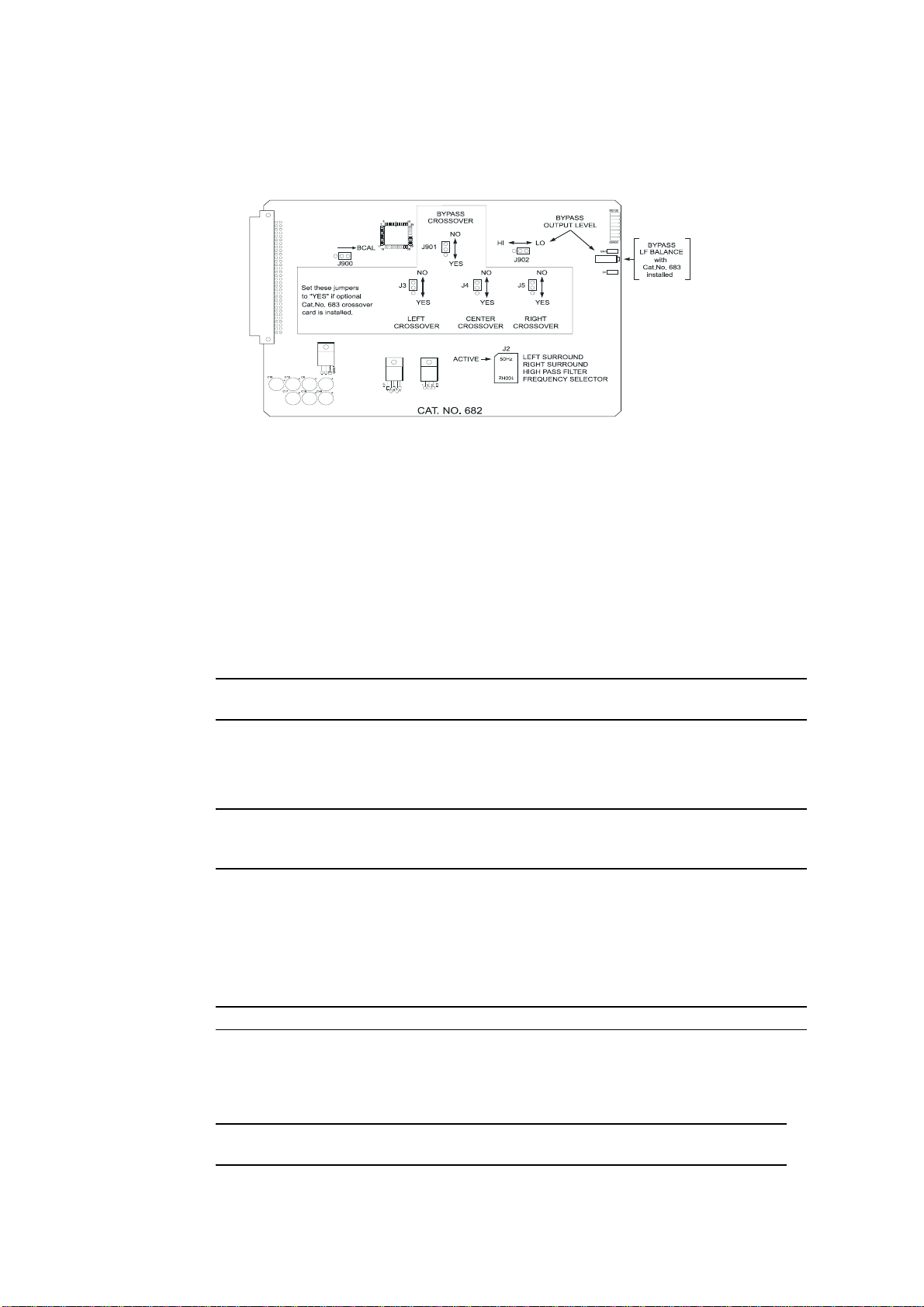

Cat. No. 682 Analog Output Card

3-7

Figure 3 - 6.

Crossover Select Jumpers [NO]

J3 Left Channel

J4 Center Channel

J5 Right Channel

J901 Bypass Audio Channel

These jumpers rout e the designated signals through an optional Cat. No. 683

crosso ver car d. If the Cat. No. 683 car d is installed, these jumpers should be

set to the “YES” position. If the optional Cat. No. 683 is not present, these

jumpers should be set to the “NO” position. The jumpers are set to the “NO”

position at the factor y.

NOTE

:

If bypass audio is routed to the optional Cat. No. 683 crossover card, the bypass portion of the

crossover circuitry must be functioning in order to produce a bypass audio output.

J900 Bypass Calibration

Th is ju mpe r inse rts a c alibrated pin k noise signal in to th e bypass system for

level a nd (optiona l) crossover a djustments . The calibra tion signal is enable d

when the jumper is in the “BCAL” position and is disabled otherwise.

NOTE

: It is important to move the jumper to the disabled position after calibration is complete so that

the bypass signal path remains completely isolated from any possible erroneous signals in the signal

path.

Cat. No. 682.

J902 Bypass Channel Output Level Select [LO]

This jumper, along with the bypass gain adjustment pot ent iometer (RV901),

adjusts the level of the bypass channel. The jumper provides a “coarse” gain

se tting and the potentiometer pr ovides a “fin e” ga in adju stment. The “HI”

jumper position can be used to produce a higher output level range on the

bypass channel. This ju mpe r is factor y set to the “ LO” p osition.

NOTE

:

If Cat. No. 683 Crossover card is installed, t he preferred se tting for this jumper is HI.

J2 L and R Surround High-Pass Filter Frequency Select [50Hz]

This header sets filter circuits to t he indicated high-pass frequency. Signals

below this frequency are attenuated in order t o prevent distort ion or damage to

surround speakers t hat ar e unable to handle extreme low frequency energy.

NOTE

:

The function of the Bypass Output Level control changes to Bypass Low Frequency

Balance Control if a Cat No. 683 Crossover Card is installed.

Page 25

3-8

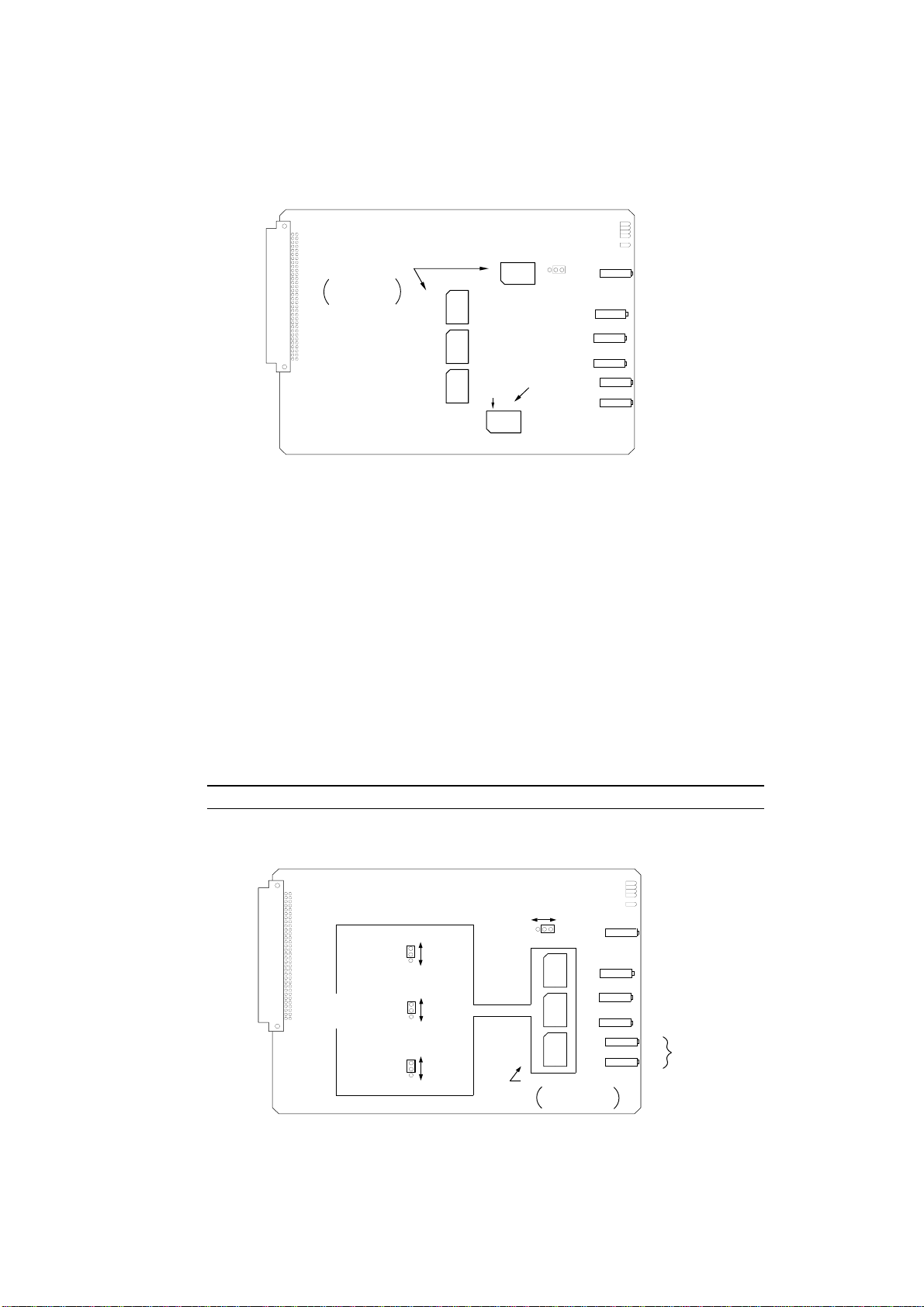

Cat. No. 683 Crossover Card (Optional)

500 Hz500 Hz500 Hz

BYPASS

RN600

LEFT SURROUND

RIGHT SURROUND

CROSSOVER FREQ

ACTIVE

50 Hz

RN400

500 Hz

BASS SPEAKER

SELECTOR

100 Hz

CROSSOVER FREQUENCY

SETTING HEADERS

Freq setting for large

horn is shown.

LEFT

CENTER

RIGHT

RN102RN202RN302

CAT. NO. 683

Figure 3 - 7.

Cat. No. 683 – Crossover Frequency Setting Headers.

Crossover Frequency Setting Headers- Screen Channels

RN102 Left Channel

RN202 Center Channel

RN302 Right Channel

RN600 Bypass

These headers select the desired crossover frequency. For large horns, the

correct setting is usually 500 Hz. For small horns, 800 Hz is usually

correct. Check the loudspeaker manufacturer’s specifications for details.

Be sure to select the same Bypass crosso ver frequency header as the

screen channels use. The headers are shipped with each card.

NOTE

: Custom settings are possible. See

LOW

FREQUENCY

DELAY

CAT. NO. 683

Figure 3 - 8.

Cat. No. 683 – Low Frequency Time Delay Enable Jumpers

J100

J200

J300

DELAY

NO DELAY

DELAY

NO DELAY

DELAY

NO DELAY

Appendix B, Cat. No. 683

BYPASS CHANNEL

HIGH FREQUENCY GAIN

J600

LEFT

CENTER

RIGHT

DELAY SETTING HEADERS

LOHI

RN101RN201RN301

1.9 mSEC 1.9 mSEC 1.9 mSEC

Delay setting for large

horn is shown.

.

BYPASS LEVEL

L

HF BALANCE

HF BALANCE

C

R

HF BALANCE

L

S

LF BALANCE

R

S

Page 26

3-9

Low Frequency Time Delay Enable Jumpers [DELAY]

J100 Left Channel

J200 Center Channel

J300 Right Channel

These jumpers allow the low frequency port ion of the designated channels

to be delayed when the jumper is placed in the “DELAY” position. This

compensates for the time offset caused by high frequency drivers being

behind the low frequency drivers in contemporary stage speakers. With the

jumper in the "DELAY" position, sound produced by the low frequency

speakers is delayed to cause the low and high frequency energy to reach

t he listen er at the same time. T here is no low frequency delay when the

jumper is set to “NO DELAY”. The factory sett ing is “DELAY”.

Low Frequency Time Delay Setting Headers

RN101 Left Channel

RN201 Center Channel

RN301 Right Channel

For large h orns, the correct d ela y setting is u su ally 1.9 ms . For s mall

horns, 0.8 ms is usually correct. The headers are shipped with each card.

NOTE

: Custom settings are possible. See

Appendix B, Cat. No. 683

.

RN400 L and R Surround Low-Pass Filter Frequency Select [50Hz]

This header sets filter circuits to t he indicated low-pass frequency. Signals

below this frequency are sent to the surround channel low frequency

drivers. Both the Cat. No. 682 Output card and t he Cat. No. 683 have

reversible filter headers for the surround channels. Ensure that t he headers

on both cards are set to the same frequency, chosen to suit the low

freq ue ncy h andling cap ability of the surround sp ea ke rs in use. If you ha ve

surro u nd bass drivers, it is probably best t o set bo th headers to

100 Hz in order to improve the low frequency power handling abilit y of

the surround channel. The factory sett ing is 50Hz.

J600 Bypass Channel HF Output Level Range [LO]

This jumper selects between two gain ranges for t he bypass channel high

frequency output. The “HI” setting has approximately 12 dB higher

output level than the “LO” setting. The factory setting is “LO”.

Page 27

3-10

3.5 Install Ci rcuit Cards - Card Descriptions

If they are not already installed in the CP500 unit, install all of the cards for your

system as shown below for each CP500 version. Note that the noise reduction

modules (Cat. No . 222SR-A) are shipped uninstalled. Th is is to prev ent da mag e

during shipment due to their weight. Sho u ld it ever be necessary to ship the CP500

again, be sure to remove these from the unit and pack them separately.

NOTE

: Cat. No. 222SR-A modules are primarily intended for playback of 35mm photographic soundtracks,

and have headroom capabilities based on that medium. As a result, use of Cat. No. 222SR-A modules are not

recommended for playback of 35 mm magnetic print-masters or SR encoded 70mm magnetic film. Contact

Dolby Laboratories for further information.

Model CP500-D

Cat. No. 222SR/A Module

Provides two channels of Dolby A-type noise reduction and Dolby SR processing.

Cat. No. 661 Optical Preamplifier Card *

Must be functioning for bypass operation

*

Amplifies the outputs of the analog soundtrack solar cells in the selected projector.

Projecto r select logic.

Provide s slit loss equalization.

Cat. No. 681 Input Switch Card

Stereo analog multiplexer for selecting signal to be fed to noise reduction cards.

Audio sample rate clock.

Cat. No. 675A Digital Signal Processing Cards (2)

Matrix decoder for Dolby Pro-Logic.

No n-sync processing.

Signal generation and signal analysis functions.

Twenty-seven band 1/3 octave equalization for L, C, R channels.

Nine band octave equa lizatio n for L a nd R su rround channels.

Equalization for subwoofer channel.

Cat. No. 685 6-Channel Analog to Digital Converter Card

Used for external 6-channel analog inputs (optional).

Cat. No. 662 6-Channel Digital to Analog Converter and Voltage

Controlled Amplifier Card

Converts digital data to analog audio and includes the main fader voltage controlled

amplifier.

Cat. No. 682 Analog Output Card *

Must be functioning for bypass operation

*

Switches and routes output channels.

Contains treble and bass control circuits.

Generates hearing impaired output and mid-surround output.

Contains bypass power regulator and output amplifier.

Cat. No. 684 System Controller Card

Mu st be present for lev el c on trol in bypass mode. Bypass will fu n ction at a fix ed

level if this car d is not pre sent or ope ra tional.

Page 28

3-11

Contains Microprocessor.

Controls front pa nel displa y and controls.

Contains interface for remotes and automation equipment.

Cat. No. 683 Crossover Card (Optional)

Provides active high- an d low -pass filters on L , C, and R signals fo r bi-amplified

installa tion s.

Provides low frequency surround channel outputs.

Provides low freque n cy d ela y for time alignment of L, C, and R low fr eq ue ncy

drivers.

Contains bypa s s crossover and must be p rese nt fo r bypass operatio n in bi-a mplified

systems.

Dolby Digital Soundtrack Processing System

Cat. No. 670 Video Front-end Card

Digitizes the video data received from the film sou ndtrack r ea de r.

Cat. No. 671 DSP Cards (2)

Processes the digitized video data and extract s the AC-3 bitstr eam.

Cat. No. 673 System Services Card

Contains the operat ing software.

Cat. No. 675A Digital Signal Processing Card

This additional Cat. No. 675A provides Dolby AC3 decoding.

Cat. No. 680 Bit Rate Converter Card

Converts PCM audio from the variable projector r ate clock to a stable PCM

audio sample rate.

Model CP500-D/300

Contains the same boards as the CP500-D above, except Cat. No . 300 modules are

used in place of the Cat. No. 222SR/A modules. A Cat. No. 668 Adapter Card is

required. Used primarily in preview theaters and studios.

Model CP500-SR

Contains the same boards as the CP500-D above except without the Dolby Digital

soundtrack pr ocessing system cards.

Model CP500-70

Contains the same boards as the CP500-D, and additionally:

Cat. No. 222A Modules (2)

Provides four additional channels of Dolby A-type noise reduction bringing the total

number of noise reduced channels to six.

Cat. No. 669 Adapter Card

Us ed for installing th e tw o Cat. No. 222A cards above.

Cat. No. 685 6-Channel Analog to Digital Converter Card

Used for external 6-channel analog inputs.

Page 29

3.6 Bypass Power Wiring

For emergency operation, t he CP500 co mes equipped with an independent external

mains power module. If the main power supply or processor circuitry fails, the unit

will automatic ally switc h to byp as s operation , allowing the show to contin ue with

limit ed sound processing functions. T he unit can also be switched manually to

bypass operation by pu s hing a butt on loc ated inside the front panel and labeled

POWER/BYPASS.

In some cou ntr ies the pr imary cable for the modu le ma y n ot hav e a mains plug

fitted. These unterminated leads must be as follows:

Brown wire -- Live or hot Blue wire -- Neutral

NOTE

:

If you are uncertain about the wiring of your mains outlet do not use it. Consult a qualified

electrician.

3-12

For safety reasons, the bypass power module contains an internal fuse.

mains power until the output wires have been connected to the CP500. Otherwise, shorted secondary wires

will blow the fuse.

DO NOT

connect the module to AC

Install the ferrite clamp on the bypass power supply cable where it connects to the

back of the CP500. Open the clip and wrap the bypass power supply wire around

one side of the ferrite three times so that t he loo ps lie inside the ferrite channel.

Close the clip until it snaps firmly closed. Make sure that the bypass power supply

cable is not pinched between the halves of the ferrite clamp.

Page 30

3.7 Power On

Connect the bypass power module to the CP500 and plug it into AC mains. The

unit is shipped with the POWER/BYPASS switch set to BYPASS. The front panel

BYPASS LED should light.

Open the front panel and confirm that one of the Pro jecto r S elect LEDs is on.

Projector 1 or Projecto r 2 is selected by Jumper J2 on the Cat. No. 661 (See

manual section 3.4).

Connect the main power cable. Then, push the Bypass/Power button to turn on the

CP500.

3-13

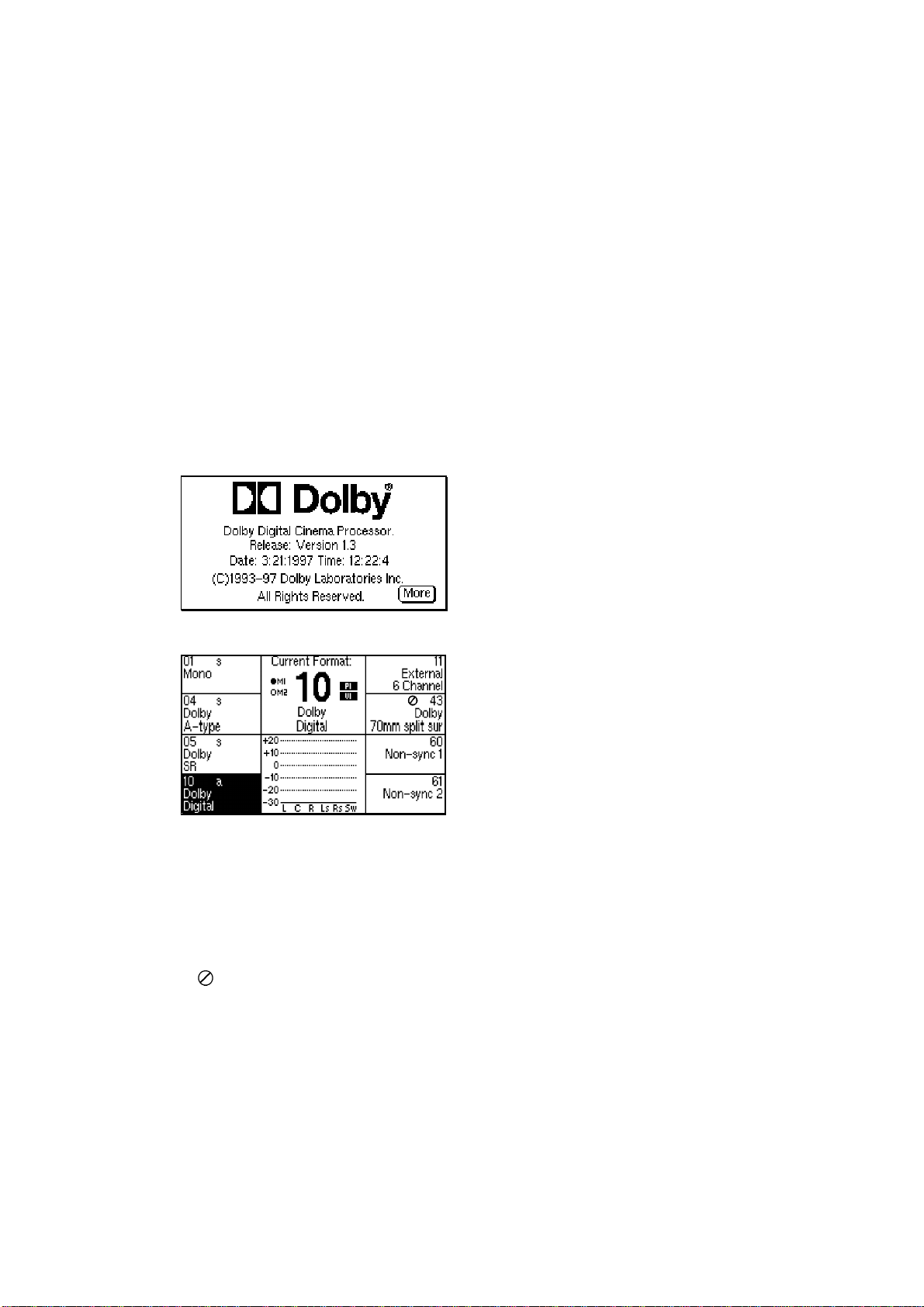

When power is first applied, the first

screen that appears displays the revision

level of t he so ftwa re. Next, a brief

"Loading System" message is displayed.

In a few seconds, the Current Forma t

screen appears. This is the normal screen

that t he projectionist or any other

operat or would see and the only screen

t h ey w ill n ee d to see for ordin ary

purposes.

Run quick checks to co nfirm that:

• Rotating the front panel knob changes the numbers displayed next to it.

• Pushing the MUTE button causes the MUTE LED to flash.

• Pushing any of the buttons on each side of the display causes the mute LED to

go off and the LED next to the bu tto n pushe d to go on (except buttons next to

" " on the display).

Page 31

3-14

3.7. 1 Hum a nd O t he r Noise Problems

If you hear undesirable hum from the speakers when you apply power to the CP500

and other pro jection room equipment, check the following list for possible causes.

1. Equipment grounding. All equipment including the CP500 is grounded to

the rack. To ensure goo d ground cont act, install a starwasher t o one

mounting screw per piece of equipment. Installation of star washers is

stro ngly recommended because electrical contact may not be achieved since

modern powder coat paints can be very tough.

2. Ground loops caused by audio signal wiring, especially to power amplifiers.

Be sure to check t he booth monitor installation.

3. Projector power wiring. All mains wiring sh ould be proper ly grou n ded.

4. Room lighting dimmer controls (SCR-TYPE).

5. Power amplifiers. Disconnect from the CP500 and ground the inputs to

determine if the powe r a mplifie rs are ca using h um problems.

6. S olar cell w iring. (An alog film sound forma t selec ted ). Ch ec k the sh ield

connections. Cell wiring should be placed away from mains and other

wiring. Cell wires must not be co nnected to t he frame of the projector.

7. Exciter lamp power supply. Check for ripple on the DC power supply

outputs. Some old exciter lamp power supplies and emergency supplies

provide AC to th e la mp. T he re su lting hum mak es them totally u n su itable

fo r a Dolby film soun d s ystem. Such excit er supplies must be replaced.

8. Projection room lighting/solar cells. Ambient lighting, especially

florescent tubes, can leak into the so lar cell area and cause hum.

Page 32

FRONT PANEL AND ALIGNMENT OVERVIEW

This section describes the CP500 LCD display and operation of the front panel

contro ls, along with of an overview of the general principles involved in the

alignment of Dolby cinema equipment. It is useful to develop an understanding of

why the CP500 is aligned as described in this manual. If the installer is already

familia r with the CP500 and these principles, or is in a hurry to complete the

installa tion , th is sec tion may b e read late r. Continue th e installation pr oce dure

beginning wit h Section 5.

4.1 The CP500 Front Panel

4.1.2 Soft Keys: SK1 to SK8

SECTION 4

(SK1)

(SK2)

(SK3)

(SK4)

(SK5)

(SK6)

(SK7)

(SK8)

The butto ns located on each side of the LCD display are sometimes called "soft

keys"(SK) . That is, t he y do not have a sing le fixed fu nc tio n but rather their function

is software contro lled and changes based on the current screen displayed. The

purpose o f each butto n is shown on the display and can change with each different

displayed screen.

4.1.3 Hard Keys

FORMATS

The single large and four small keys along the bottom of the display are the "hard

keys" . Their function is labeled on th e p anel. The la rge key on the left,

FORMATS, is used to return to the Format Selection (Current Formats) screen

from any other menu screen. This screen is displayed during normal day-to-day

operat ion of the CP500. If any other screen or menu is displayed, this butto n ret ur ns

t he display immedia tely to this "top" of the menu tr ee .

MENU

The MENU key is used as the first step in selecting all software functions and

menus except format selection. It selects or ret ur ns t he unit to the top menu.

Page 33

SOFT KEYS 1 - 8

Used to select the function shown

next to the switch in the front panel

display.

BYPASS INDICATOR

Indicates continuous red when unit is in

bypass mode.

MUTE ON INDICATOR

Flashes when mute is activated.

MAIN FADER/MULTI-FUNCTION CONTROL

Controls sound level and also is used for

data selection in menu operations.

(SK1)

(SK2)

(SK3)

(SK4)

FRONT PANEL DISPLAY

FRONT PANEL DISPLAY

Displays format and menu

screens.

FORMATS KEY

Used to switch to format

selection screen.

(SK5)

(SK6)

(SK7)

(SK8)

FADER LEVEL DISPLAY

Displays fader setting. Ranges from 0 to 10.

Normally set to 7.0 This display shows '- -'

when in data entry mode.

4-2

MUTE KEY

Mutes output to all channels when activated.

EXIT KEY

Used to select the previous menu.

OK KEY

Used during pop-up menu operations. Selects

option currently in pop-up window selection box.

Also stores currently displayed data.

CANCEL KEY

Used during pop-up menu operations. Cancels

pop-up menu operation and restores the

previous menu or data.

MENU KEY

Used to return to the top of the menu tree.

Page 34

4-3

CANCEL

Many of the screens used during set-up, alignment, or diagnostics contain a "PopUp" screen within the main screen. The CANCEL key is used to cancel the current

pop-up oper ation being performed and restore any data that was changed during the

pop-up screen operation.

OK

This key is used to accept and store the current set ting in a po p- up scr een.

EXIT

This key is used to signal completion of an adjustment procedure o r select the

previous screen.

4.1. 3 Ot he r Control s a nd Indicators

To t he right of the display is another window showing the selected fader level. As

with previous generations of Dolby cinema processors, a fader sett ing of "7.0" is the

nominal correct operating level. This setting matches the level used during the film's

production. As the main fa der (or front panel knob) is turned, the numbers on the

dis play will mov e fro m ze ro to te n. The mai n fader rotates continuously with no

end s tops . The number dis played w ill alw ays indica te the curr ent level setting.

Bypass

Mute On

The MUTE butto n is used to fade the sound down without disturbing the current

fader setting. A green LED, MUTE O N, located above the fader level display will

flash, indicating that the CP500 out puts are muted.

A BYPASS LED is located to t he left of the MUTE ON LED. As with other

Dolby cinema processors, the CP500 utilizes a separat e back-up po wer supply

which is used during emergency operation. If the CP500 is operating in bypass

mo de , this r ed LED will c ome on (not flash in g). If th ere shou ld be a failu re, th e

system can switch into bypass mode either temporarily or permanently. The

minimum electro nics required for a bypass output signal from the CP500 is:

• Functioning bypass power transformer (external module)

• Cat. No. 661 Optical Preamplifier card

• Cat. No. 682 Analog Output card

• Cat. No. 683 ( optional) Crossover card, if used in a bi-amplified

installation.

Page 35

A manual bypass push- but ton is loca ted inside t he fro nt p a nel on the r ight hand side

of the unit.

4.2 System Password

Many of the CP500 alig nment functions can be pro tected from unauthorized access

be using a system password (any fo ur numbers). A password can be stored after the

system is aligned in o r der to block any changes to the B-chain alig nment, level

settings, or time delays. Knowledge of this password would be required to enter

these CP500 menus. The CP500 is shipped with no system password. The number

stored in CP500 memory is "0000". This allows access to all alignment functions.

The following procedure should be used to set or change the system password.

4-4

Press the MENU key.

FORMATS

FORMATS

Menu Cancel OK

MENU

Menu Cancel OK

The Menu Selections sc reen will be

displayed.

Press Alignment (SK2).

Exit

The System Alignment screen will

appear. Press S e t System Passwo rd

(SK8).

Exit

NOTE

:

If a system password has already been

stored in memory, then the screen below will

appear.

Rotate the front panel knob to select the

digit you wish to set, then press and hold

soft-key SK4, "1234", while rotating the

front panel knob to set the desired

number. Repeat this process for any of

the four password digits you wish to set.

OK

Press the OK key to store the new

password.

Page 36

4.3 Aligning the B-Chain

The B-chain is defined as those system components from the fader through the

loudspeakers. In the CP500, available adjustments include equalization, level

contro l, and digital soundhead, analog, and digital surround delay settings.

Adjus table mute fa de -out time is also provide d.

It is not practical for the entire cinema industry to standardize on a single make and

model of lo udspeaker . I n any event, the different acoustical characteristics of

individual theaters would, to some extent, negate any such standardized speakers.

Electronic equalization of each loudspeaker system achieves consistent results in a

broad spectrum of environment s, and with a broad range of speakers. Accurat e

equalization requires the use of standardized acoustic measurement pr ocedures.

A pink no ise generator pr ovides a continuous random noise signal that covers the

total bandwidt h and is used to measure and adjust the response of the loudspeakers.

Th e use of r andom nois e e liminates the pr oblems inheren t with ton es (s tanding

wave patterns in the theaters) and enables the frequency response of the entire

system to be observed. Each channel can be measured and adjusted independently

of the other channels.

4-5

A calibrated microphone or a multi-microphone setup with multiplexer is placed in

the auditorium to receive the pink noise reproduced by the loudspeaker. The output

of the selected microphone is fed to a real time analyzer (RTA) circuit built into the

CP500 cinema processor, and equalization can be performed using t he CP500 front

panel display to show the audio spectrum received by the micr ophone(s). Pure pink

noise would yield a “flat” horizontal line on the RTA. Thus, the effect of

adjustments to the equalizers is quickly and easily seen.

One of the problems inherent in equalization is the nature o f the environment. In an

open space, a perfect loudspeaker, radiating a perfectly flat response in all

directions, placed in front of a perfectly flat microphone, pro ducing perfectly flat

response to soun ds arriving from all dire ctions, will d isp lay a pe rfectly flat r es ponse

on the RTA from pink noise. In an enclo sed space such as a t heat er , the results are

different. When the pink noise generator is first turned on, all of the sound that

init ially reaches t he microphone comes directly from the loudspeaker; the response

is fla t—for a few milliseconds. The n r eflecte d sound fr om th e w alls, ceilin g, floor,

seats, etc. star ts to ar r ive at the microphone together with the direct sound from the

loudspeaker. This indirect o r r eflected sound reinforces t he direct sound. T he

sys tem soon se ttles into an eq uilibrium con dition. As mu ch ener gy is bein g a bsorbed

at the w alls, ceilin g, etc. as is fed into the room. Since h igh and mid frequency

energy is absor bed when sound is reflected, the displayed respo nse appears to have

a risin g bass an d a falling treble ch aracteris tic. At fir st g lance, ro lling off th e bass

and boosting the high frequencies may appear to be the logical approach for a flat

steady-stat e r esponse, but such an arrangement works o nly on sustained sounds.

Dialogue contains short, impuls ive sounds and will yie ld a muc h-too-b right resu lt

Page 37

4-6

because there is no time for reverberation to build and add to t he o r iginal sound.

What is required is a curve that favors such impulsive “first arrival” so und and

implies th e same ge ntly fallin g response tha t is obs erve d whe n the outp ut of an id ea l

loudspeaker is measured with a perfect microphone in the theater.

The amount of reverberation varies with frequency and the higher the frequency the

mo re the treble will be absorbed rathe r than b eing r efle cte d. A typical r ever bera tion

curve in a theater rolls off at about 3 dB per o ctave above 2 kHz. This characteristic

is used to define the standard st eady-state response curve for all dubbing theaters in

which films with Dolb y soundtracks are mix ed and for all D olby processor-equipped

cinemas.

The size of the theater affects the reverberation time and, therefore, the

measurement of frequency response. After alignment to this standard curve, so me

slig ht adjustment of high frequency slope may be found necessary for extremely

large or small theaters. T he Treble Control can be used to reduce the out put on the

response curve by approximately 1 dB at 8 kHz for very large theaters; an increase

of 1 dB at 8 kHz may be in order for a very small theater. Any such adjustment

should be b ased on an evaluation b y ear of actua l known films rathe r th an as a r ule