Page 1

MANUAL FL180/170

®

Fiber-Lite

HIGH INTENSITY FIBER OPTIC ILLUMINATORS

INSTRUCTION

MANUAL

for Models 180 & 170-D

Illuminators

Your purchase of the Dolan-Jenner

Fiber-Optic Illumination System will

provide you with many years of service

in a large variety of applications which

require high intensity, yet cool

illumination. Please read the following

instructions to ensure that maximum

performance is obtained from your system.

Model 180 and 170-D Illuminators are readily interchangeable within the systems. The

exceptions are with System 181, 181A and 181B which require the Model 180

Illuminator for the support of the self-supporting fiber optic light pipes EEG 2823, EEG

3922 and BG 2820. In addition the Model 180 has the lowest noise and vibration

characteristics that can be incorporated into any unit, which makes it especially suitable

for high magnification stereo-microscope usage.

Fiber-Lite Illuminators achieve maximum reliability and lamp life due to certain design

considerations incorporating air flow parameters that result in long lamp life and cool

housing temperatures as well as component reliability.

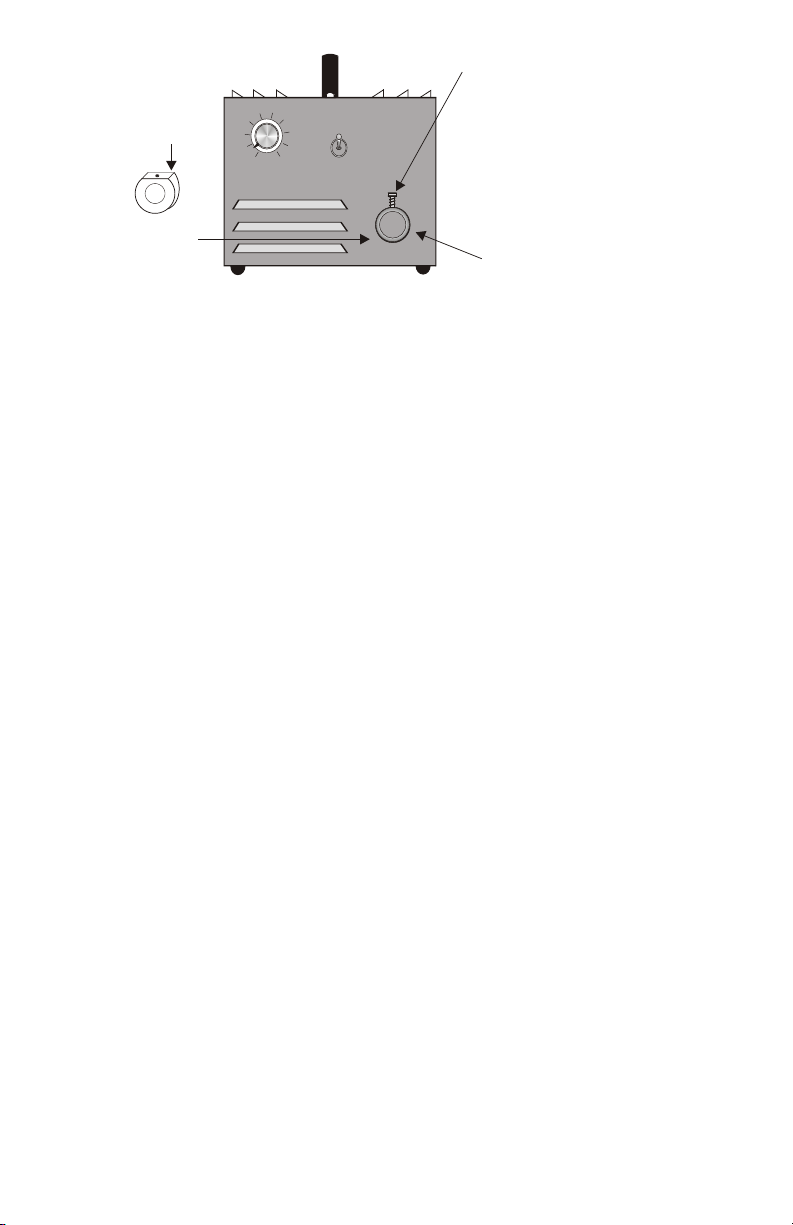

ADAPTERS (SX TYPE)

The Adapters fit into the Illuminator nosepiece with the flat area facing up. The idler

hole on the flat area is off center, and the shortest dimension faces the illuminator when

inserted.

The SX 5, 6, & 7 adapters are made with an idler which provides quick disconnect

features that require only a few turns of the thumbscrew on the Illuminator nosepiece to

attach or disengage the fiber optic light pipe.

SYSTEM 181 ASSEMBLY INSTRUCTIONS

Due to the self-supporting features of the fiber optic light pipes (BG 2820, EEG 2823,

EEG 3922) it is necessary to remove the thumbscrew on the Illuminator and replace it

with a 7/64 socket head cap screw provided. The SX-11 adapter is then inserted as above

followed by the fiber optic pipe with the flat surface facing up. . Then insert the fiber

optic pipe with the flat surface facing up. Use an Allen Wrench to sufficiently secure the

fiber optic so that there is no rotation.

Page 2

THUMBSCREW

FLAT with

IDLER HOLE

INSERT ADAPTER

3

4

2

5 6

1

INTENSITY

7

ON

8

9

10

OFF

(For system 181,

181A and 181B see

System 181 Assembly

instructions.)

NOSEPIECE

FIBER OPTIC LIGHT PIPE INSERTION

Insert the Fiber Optic Light Pipe into the adapter and tighten the thumbscrew to secure

the fiber optic in the Illuminator.

MOUNTING STANDS

For some applications a mounting stand is required to secure the fiber optic gooseneck

in an operating position. The EEG 3736 fiber optic has a hole in the transition to accept

the securing knob on the MS-7 Mounting stand. The MS-8 Mounting stand requires that a

portion of the gooseneck be clamped directly.

LENSES

The LH755 lens is threaded on the fiber optic light pipe after the locking nut. The

LH759 lens is quickly attached or removed from the fiber optic with a turn of the

thumbscrew. Both lenses are capable of focusing the light to provide higher levels of

illumination and obtaining focused light spot diameters of .16" (.4cm) to 2.87" (7.3cm).

ANNULAR ILLUMINATION SYSTEMS

Annular Illumination Systems provide 360 degrees oblique crosslighting for detail

delineation and a crisp visual or photographic image at working distances of 1.5" (3.8

cm) to 9.5" (24.1 cm). As is the case with most non-self-supporting fiber optics and

especially with this system, a capability for electronic flash photography is acquired by

simply approximating the fiber optic to the flash source. This system has numerous

adapters for attaching the fiber optic to various models and makes of microscopes. These

adapters necessarily vary and a separate instruction sheet is provided for each.

A WORD ABOUT FIBER OPTIC LIGHT PIPES

The light pipe contains a bundle of individual glass fibers about the size of a human

hair. Each fiber consists of a central optical glass core and is cladded with a different

refractive index which allows for the transmission of light through total internal

reflection, a phenomenon in which light rays are reflected at the core/clad interface and

travel to the distant end of the fiber by a zigzag path of successive reflections. To assure

maximum light input/output each fiber bundle has an optical polish at each termination.

These bundles are then constructed in a protective sheathing to limit a bend radius

which, if exceeded, could cause the fibers to fracture. The fiber optic light pipe should be

treated as a laboratory instrument and considerate, common sense usage will assure an

unlimited lifetime. Avoid sudden forceful pressures on bends and excessive

configurations that strain the flexibility of the fiber optic.

Periodically the ends of the fiber optic and lenses should be cleaned with a lens cleaner

and lens paper.

Page 3

BK

G

LINE

BK

G

LINE

XFMR

W

LAMP

FAN MOTOR

R

W

SCHEMATIC

180

BK

BK BK

FAN MOTOR

LAMP

XFMR

W

BK

W

R

W

SCHEMATIC

170 - D

BK BK

CHANGING THE ILLUMINATOR LAMP

Should the need arise to replace the EKE type lamp the following procedure should be

used:

1. Unplug the illuminator from the wall socket.

2. Wait until the illuminator nosepiece is cool to touch.

3. Raise the cover of the illuminator.

4. Pull up on the EKE lamp to remove it from the lamp holder.

5. Remove the lamp from the socket.

6. Replace with a new EKE lamp.

CAUTION: Do not touch either the inner quartz lamp envelope or the lamp pins with

your fingers. This will result in a significant shortening of lamp life. Handle the EKE

lamp only by the dichroic reflector when attaching the lamp socket.

7. Reinsert the lamp holder.

8. Close cover.

9. Insert plug in wall socket and, if necessary, check the alignment of the lamp.

10. The lamp holder is precision aligned at the factory on the angle for optimum lamp

input into the fiber optic. Occasionally there are dimensional variations of replacement

lamps that may result in a reduction of illumination. The reduction is apparent when

illuminating a piece of white paper at a distance of three inches with an unlensed fiber

optic. Should there be visible a central area of less intensity than the periphery, the lamp

should be aligned. This condition is due to the physical positioning of the quartz

envelope within the reflector and can be eliminated by the following:

W

ALIGNMENT:

1. Illuminate a piece of paper with the distal end of the fiber optic about 3" away. Do not

use a lens. Check for a darker central area.

2. Place the illuminator on its side and loosen the two lamp holder adjustment screws on

the base. With the screws loose, rotate the lamp holder until the darker central area

changes to a brighter intensity than the periphery.

3. Secure the screws at the best position obtainable.

Page 4

PERFORMANCE STATEMENT

Dolan-Jenner Industries, Inc. (DJI) recognizes that its illuminator products may be used

under an almost unlimited variety of conditions. As such, we are prepared to assist the

customer in the selection and application of any of these products. This includes application

engineering, sample testing and other means as determined by DJI.

Where DJI has made specific recommendation for its products, systems or detection

techniques (based on complete and detailed information furnished by the customer), we will

extend every effort to assure that the customer is satisfied with the performance of our

products. Continual development and improvement of DJI products may require changes in

details that do not coincide with descriptions or illustrations shown. All fiber optic bundle

diameters are nominal.

TWO YEAR WARRANTY ON LIGHT SOURCES

Dolan-Jenner Industries, Inc. (DJI) warrants its products to be free from defective material

and workmanship. Any light source or parts thereof which are determined by DJI to be

defective within two years from date of shipment will be replaced or repaired at our option.

This policy is effective August 1, 2005 and is not retroactive. All fiber optics are warranted for

one year. This warranty specifically excludes both incandescent and quartz-halogen lamps,

sockets, fuses and optical filters.

Any products which, in our opinion, have been subjected to misuse, neglect, incorrect

wiring, or where installation procedures are not in accordance with the instruction manual, are

excluded from the warranty. Nor does this warranty extend to products on which repair or

alterations have been made outside the factory, or on which the identification or serial number

has been altered, or to accessories not of our manufacture.

Our obligation with respect to products or parts covered by this warranty shall be limited to

repair or replacement, F.O.B., Boxborough, Massachusetts. In no event shall DJI be held liable

for consequential or special damages, or for transportation, installation, adjustment, or other

expenses which may arise in connection with such products or parts. This warranty is in lieu

of all other statements or warranties or guarantees, written or implied, by DJI or its authorized

representatives.

Important: All merchandise returned to the factory for repair must be accompanied by a completed return form available

on http://www.setra.com/tra/repairs/pdf. Please contact factory for a return authorization number prior to shipping

merchandise to factory

REPLACEMENT PARTS

MODEL 170D MODEL 180

PART NO. DESCRIPTION PART NO. DESCRIPTION

02-015002-0000 Transformer 02-015004-0000 Transformer

02-015904-0000 Lamp Holder-QEZ-10M 02-015904-0000 Lamp Holder-QEZ-10M

02-023301-0001 Lamp Socket-QCZ-34 02-023301-0001 Lamp Socket-QCZ-34

02-013800-5001 Rheostat-50 ohms, 25W 02-015302-1250 Fuse, 2.5A 250V 3AG Slo-Blo

02-015850-0000 Lamp EKE, 150W, 21V 02-013801-5001 Rheostat-50ohms, 50W

02-001054-0000 Fan 02-015850-0000 Lamp EKE, 150W, 21V

02-018201-0002 Switch 02-001003-0000 Fan

02-001500-0000 Fan Guard 02-018201-0001 Switch

® Dolan-Jenner Industries All Right Reserved Printed in U.S.A. Rev. D 05-000007-0000

Dolan-Jenner Industries, Inc. • 159 Swanson Road. • Boxborough, MA 01719

For 115V, 50/60 Cycle Version

02-001502-0000 Fan Guard

Components for 220V, 50/60Hz

02-015004-0001 Transformer

02-015302-1125 Fuse, 1.25A 250V 3AG Slo-Blo

02-013801-1502 Rheostat

02-001007-0000 Fan

(978) 263-1400 • FAX: (978) 264-0292

E-Mail sales@dolan-jenner.com

Loading...

Loading...