Bedienungsanleitung

Operating Instructions

ExOn3A, DX306

ExOn3A-5, DX314

Dohle Extrusionstechnik GmbH

Eitorfer Strasse 1

D – 53809 Ruppichteroth

www.dohle-extruder.de

Operating Instructions

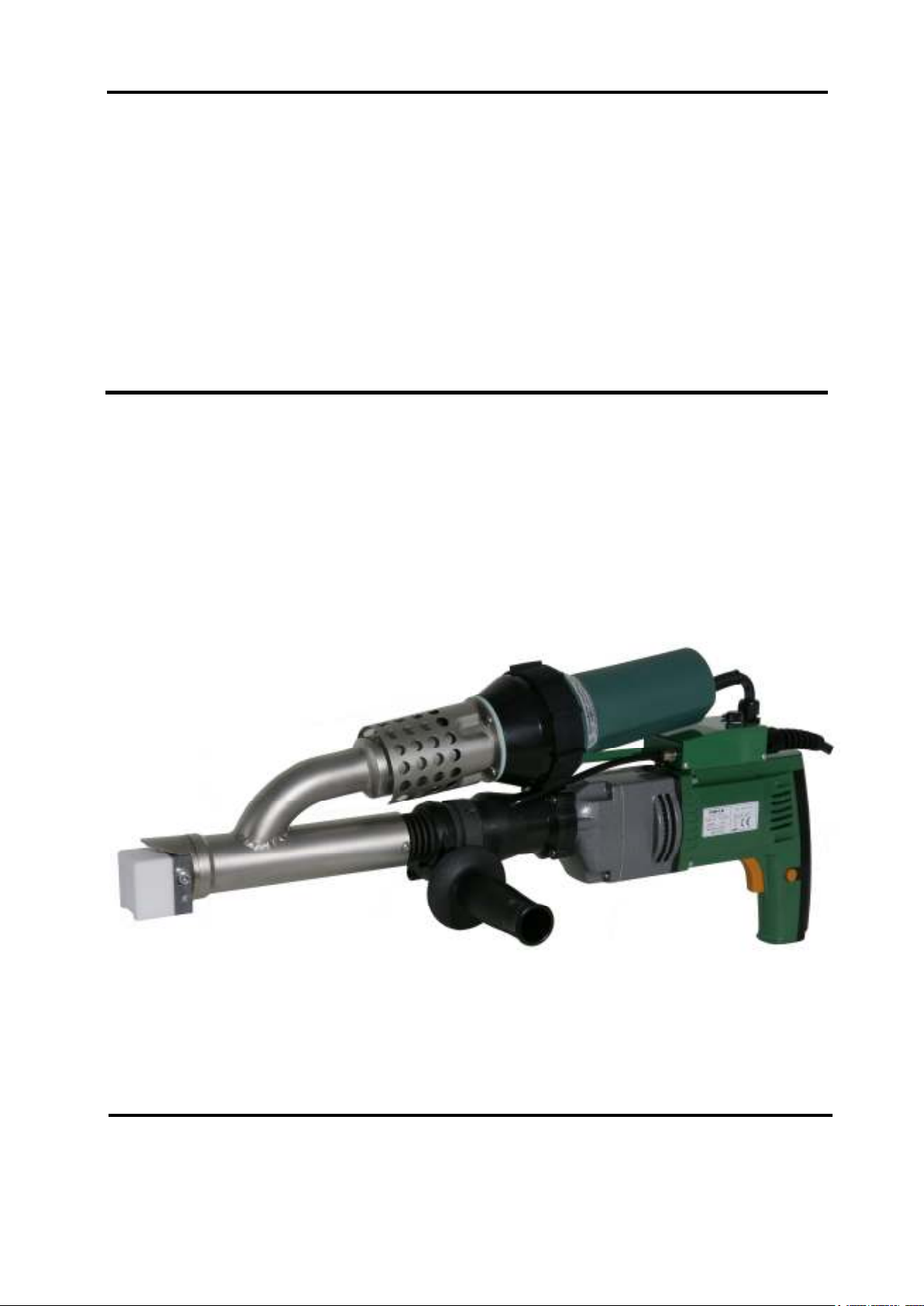

DOHLE Hand Welding Extruder ExOn3A

We retain all copyrights of all descriptions, drawings and schedules contained in these

operating instructions which may not be reproduced nor be made accessible by third parties

or by competitors, neither in whole nor in part, unless we have expressly consented thereto.

Before start-up these operating instructions must be examined carefully because we will not

assume any liability for any failures resulting from improper use. No warranty claims will be

accepted if the hand-held welding and extruding machine has been modified unless this has

been done in consultation with the manufacturer/ supplier.

The appliance is not to be used by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction.

Children must be supervised not to play with the appliance.

The extruder shall be used for extrusion weld works only !

These operating instructions should always be accessible by the operator.

For after-sales service and orders please contact:

DOHLE Extrusionstechnik GmbH

Eitorfer Strasse 1

D-53809 Ruppichteroth

Telephone: (+49) 02295 – 902960

Telefax: (+49) 02295 – 902961

E-Mail: info@dohle-extruder.de

www.dohle-extruder.de

english

Content

1. Description of Type 16

2. Safety 16

3. Start-up 19

4. Drawings, Informations 21

DOHLE Extrusionstechnik GmbH 16

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

1. Type

Article-no. / Type of machine : DX306 ExOn3A / DX314 ExOn3A-5

Machine no. : .........

Required voltage : 230 V / 50 – 60 Hz

Heating unit : 3500W/15A

Processing of : PE, PP

2. Safety

Pursuant to section 55 of VDE 0 100 (Regulations of the Association of German

Electrotechnical Engineers), the extruder must be operated using a protective switch or an

isolation transformer. Always keep extruder dry!

Operating hand-held welding and extruding machines is subject to applicable national

regulations. Observe applicable regulations for the prevention of accidents as well as

technical rules for safe and professional operation.

Directive 92/ 57/ EWG dated June 24, 1992, shall be applicable by analogy.

Utilisation:

Hand-held welding and extruding machines are manufactured according to the latest state of

the art and in compliance with safety requirements.

Any improper use may result in dangers for the operator or third parties or may adversely

affect machines and assets.

Only use hand-held welding and extruding machines if in technically perfect condition and for

the purposes for which they are intended while observing the operating instructions.

The manufacturer / supplier will not accept any liability for any failure to comply with the

above or for damages resulting there from.

Any utilisation of the hand-held welding and extruding machine for other purposes than those

for which it is intended is subject to the consent of the manufacturer / supplier.

Work on electrical parts of the hand-held welding and extruding machines may only be

performed by an electrical engineer in compliance with electro-technical rules.

Special risks:

All hand-held welding and extruding machines may only be held and operated using the

handles provided for this purpose.

A risk of burning exists on all uncovered metal parts. Avoid contact with these parts

because they may achieve temperatures of up to 350 °C.

Caution: Heat can reach combustible materials!

Safety area:

The hot air stream of the hand-held welding and extruding machine may not be directed to

temperature-sensitive objects or living things. Ensure that a safety distance of 2m is

observed in all directions.

Don’t concentrate the heat stream long time on the same area.

DOHLE Extrusionstechnik GmbH 17

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

Operation:

Never use hand-held welding and extruding machines without air supply.

In case of external air supply ensure that the feed line is of sufficient size.

The pressurised air that is supplied must be free of oil and water.

Overhead work:

When working overhead always wear appropriate safety devices (such as helmet,

savety glasses, etc.).

Safety:

Check for correct nominal voltage before connecting the hand-held welding and extruding

machine to the mains voltage.

Mains voltage must be identical to the nominal voltage shown on the type plate of the handheld welding and extruding machine.

Pursuant to sec. 55 of VDE 0 100 the hand-held welding and extruding machine must be

operated using a protective switch or an isolation transformer.

Extension cords:

When using extension cords the minimum diameter of cables must be observed.

Length up to 18 m: diameter 2.5 mm²

Length up to 50 m: diameter 4.0 mm²

Extension cords must be approved and marked for their place of utilisation.

Stop operating the hand-held welding and extruding machine if:

- connecting line or plug have been damaged

- safety installations have been damaged

- foreign objects or liquids have entered the hand-held welding and extruding machine

- changes occur in the operating state

Never spray water on hand-held welding and extruding machines

(risk of short circuit)

Never use hand-held welding and extruding machines in hazardous or inflammable

areas.

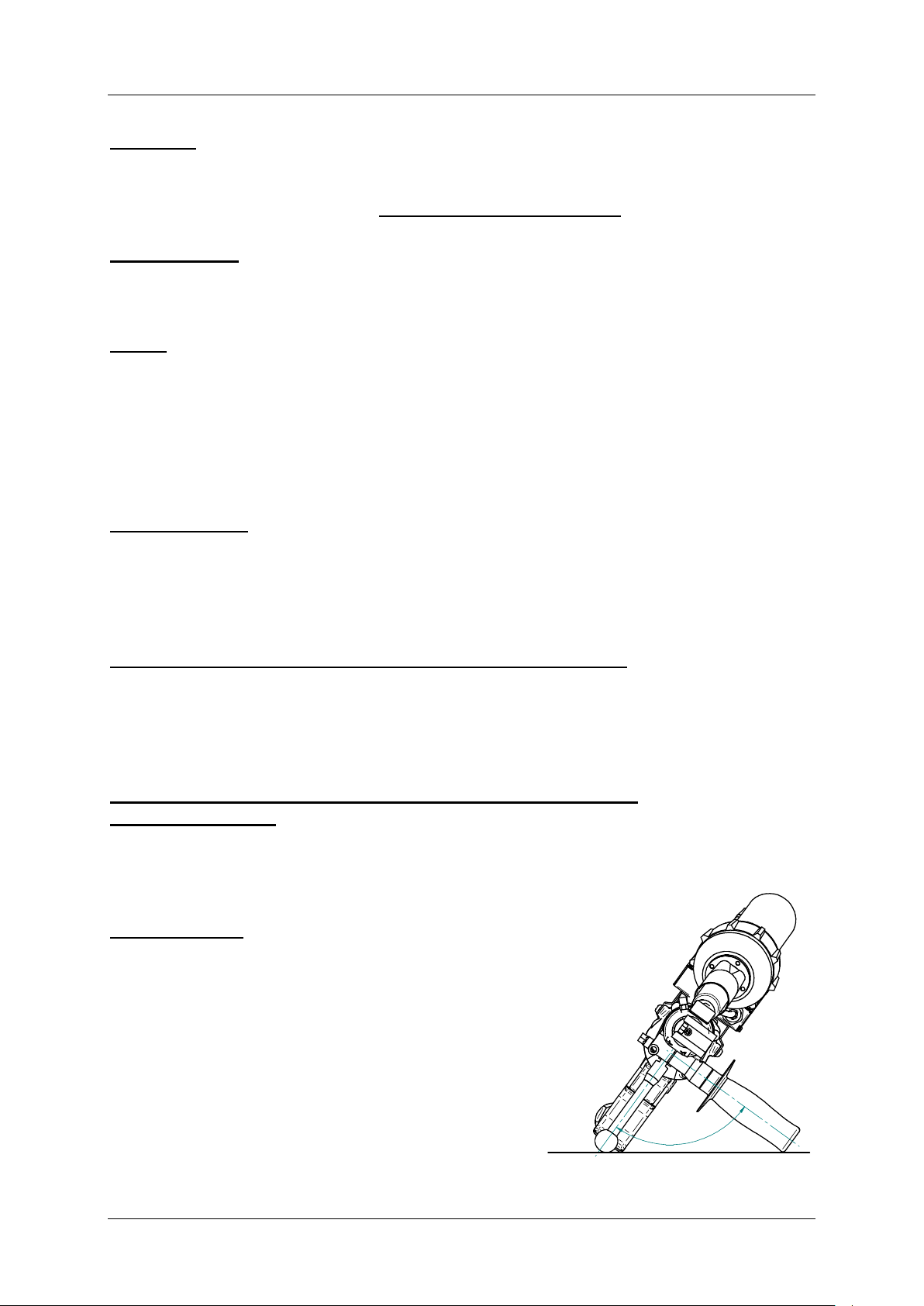

To park the tool:

To save the stand, click the machine base out and put the

tool on the three points (machine base – handle drive unit –

pivoted handle).

Make sure that the machine base to the pivoted handle is in

angle of 90°.

°

0

9

.

a

c

DOHLE Extrusionstechnik GmbH 18

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

3. Start-up

General:

Observe the notes on safety contained in these operating instructions. In addition, the

regulations on the prevention of accidents and the national regulations shall apply.

Assembling the hand-held welding and extruding machine

Our hand extruders are largely fully assembled ready for accommodated.

Weld shoe

The machine is supplied with one weld shoe blank which can be machined to suit your

requirements.

Note: please observe guideline DVS 2207 part 4.

If you indicate your required form of seam and thickness of plates we will supply one weld

shoe machined ready for use.

Start-up of hand-held welding extruder

Observe the Safety chapter of this manual.

Before plugging in the power cord, please check that

- The heating is switched off at the air heater

- The engine is not set for continuous adjustment

- Plug in the power cord

Enter the power cord into an AC outlet (230V, 16A), use only easily accessible electrical

outlets, you represent now the on - off

the heater switch on the ON position.

The machine heats now on to the last selected setpoint temperature.

To change the temperature, they change the setting of

Potentiometer on the heat gun.

The hand extruders exon 3A has a bi-metal cold start protection, the

Device only partially protects against major damage. Always observe the longer

Heat-up times and minimum temperatures of the materials to be processed.

Incorrect operation has a fraction of the screw or the transmission of

Follow.

Warranty claims that are due to incorrect operation cannot be claimed

Caution: Observe minimal heat time of 20min.

Let the appliance unattended while it is operating.

DOHLE Extrusionstechnik GmbH 19

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

Change of the welding shoe

In order to be sure that no more old welding rod is in the hand welding extrusion, heat up the

machine on operating temperature, remove the welding shoe and change the nozzle (note:

left hand thread!).

Changing the welding filler

Heat up the hand-held welding and extruding machine until operating temperature is

reached to ensure that no welding filler is present in the machine, remove the weld

shoe and exchange the die (caution, left-handed thread) by a new one or by a die

used with the material to be applied now.

Note: with work on heated machine burn danger.

When the nozzle is changed drive for approx. 1 min. the new welding rod in the hand welding

extrusion.

Interruption of the welding

Do not leave the hand welding extruder unsupervised.

The air supply must remain maintained

Switch off the hand welding extruder

Bring the potentiometer of the air heater in position 0 and pull after ca.2 minutes

the power supply plug.

Note: Even after 15 minutes still exists burn danger on bright metal parts.

No water or other materials for accelerating the cooling procedure must be used.

Maintenance

Before maintenance work on the equipment, pull power supply plug!

Maintenance work may be accomplished only by electrical specialists.

Consider the security chapter!

After approximately 300 operation hours the hand welding extruder, including the drive unit

must be cleaned, greased and controlled. These work may be implemented only by electrical

specialists.

Drive

The carbon brushes conductors of the drive must be examined approx. every 120 operation

hours and renewed if necessary.

Deep groove ball thrust bearing /barrel extruder

The deep groove thrust bearing and the barrel extruder should be cleaned approx. every

120 operation hours and again be greased. (Note: Only high temperature grease can be

used.)

DOHLE Extrusionstechnik GmbH 20

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

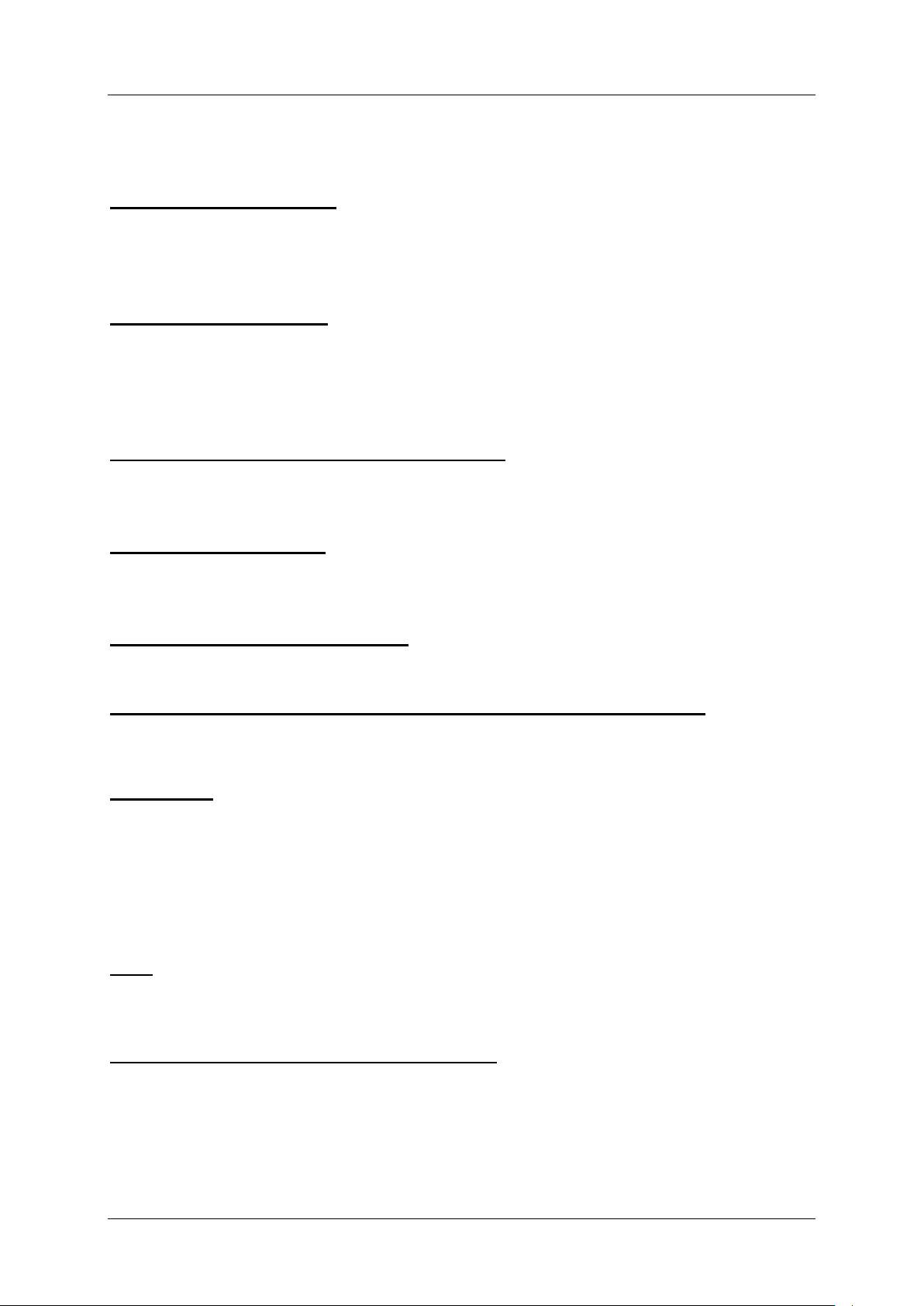

4. Drawings, Informations

DX306 ExOn3A, DX314 ExOn3A-5

D - 1728

D - 2014

D - 1729

D - 2063

D - 1630

D - 0864

D - 1630

D - 1771

D - 0632

D - 1771

D - 1319

D - 0567

DV 131

D - 1320

DB 044

D - 1748

D - 1749

D - 1769

D - 1793

D - 1513

D - 1512

D - 0688

D - 0690

D - 1778

D - 0854

D - 1744

D - 1742

D - 1772

D - 1768

D - 0042

D - 1636

DOHLE Extrusionstechnik GmbH 21

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

article-no description qty

D - 0012 feather key 1

D - 0042 air die multi fix 32mm 1

D - 0632 screw M5x65 4

D - 0680 compression spring handle 1

D - 0687 link 1

D - 0688 link joint 1502- 3002 1

D - 0690 ball button 1502 - 6002 1

D - 0726 ball 1

D - 0727 press sleeve 3x16 1

D - 0845 screw M5x6 2

D - 0854 handle 1

D - 0864 screw 2.9x6.5 DIN 7981 4

D - 1302 Potentiometer scale Micro 1

D - 1319 temperature switch T10B 1

D - 1320 Eron Extruder ExOn3A 1

D - 1512 worm ExOn3 1

D - 1513 worm ExOn3-5mm 1

D - 1630 control box ExOn3A 1

D - 1636 die ExOn3A 1

D - 1728 angle screwed cable M16x1,5 1

D - 1729 phase angle control 1

D - 1742 cylinder ExOn3A 4mm 1

D - 1744 cylinder ExOn3A 5mm 1

D - 1748 flange ExOn2-4 1

D - 1749 indentation1 ExOn2-4 1

D - 1768 burner pipe ExOn3A 1

D - 1769 deep groove ball bearing 61904 2Z ISB 1

D - 1771 screw M5x16 8

D - 1772 screw M4x6 T20 DIN7985 2

D - 1778 axis ExOn2-6 1

D - 1793 indentation2 ExOn2A+3A 1

D - 2014 potenziometer 100k 1

D - 2050 screwed cable buckelproofed PG11 1

D - 2063 main cable 8m 1

DB 044 drive unit BSM 275, 230V, 1400W 1

DV 131 screw M4x8 T20 DIN7985 1

DOHLE Extrusionstechnik GmbH 22

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

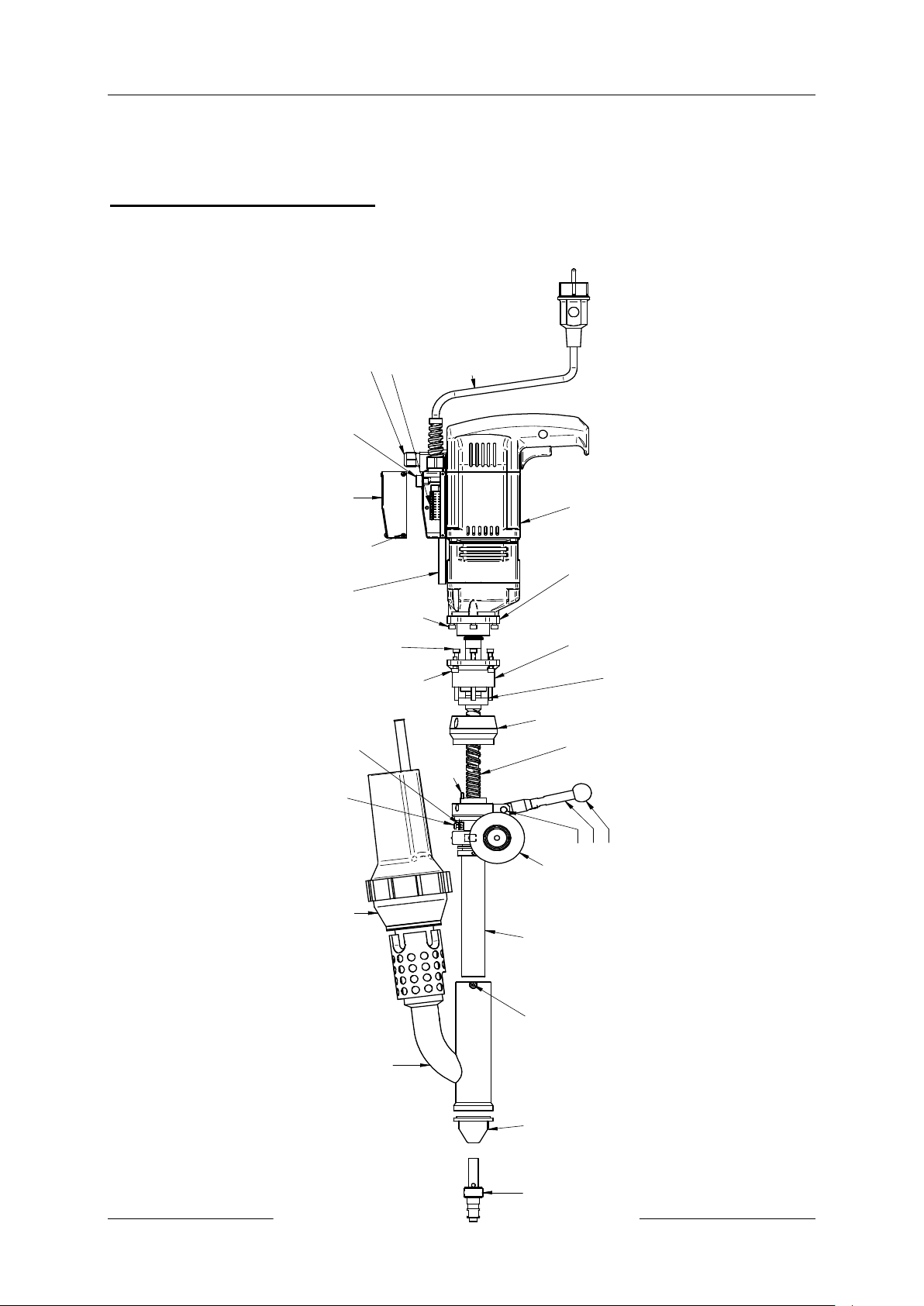

D-1320 Eron 230V/2300W

6600602

6101242

6600611

66006166113695

6106186

6100263

6600608

6100268 6100444

6600622

6600609

6600606

66006366600638

6100284

6600614

6600637

66006126101760

6100287

6600616

5101270 6600613

5113268

DOHLE Extrusionstechnik GmbH 23

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

article-No description qty

5101270 gasket 70x48x4 1

5113268 heating element 230V/2200W 1

6100263 potentiometer knob red 1

6100268 strain relief 1

6100284 countersunk screw M4x12 TX 3

6100287 hexagon nut M5 1

6100444 cord guard 9,6x75 1

6101242 connecting shackle 1

6101760 mica tube 47,6x95 1

6106186 rocker switch 1

6113695 temperatur limit switch 135°C 1

6600601 air filter 1

6600602 handle 1

6600606 motor 230V SL 1

6600607 carbon brush 2

6600608 potenziometer 10KOhm 1

6600609 electronic circuit board 230V 1

6600610 triac 25A/800V 2

6600611 PT fillister head screw M3x8 TX 8

6600612 rubber ring 1

6600613 turbine housing lower part 1

6600614 stripper 1

6600615 phototransistor 1

6600616 countersunk screw M3x10 TX 4

6600622 fillister head screw M4x10 TX 2

6600636 turbine 1

6600637 turbine 1

6600638 turbine housing upper part 1

DOHLE Extrusionstechnik GmbH 24

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

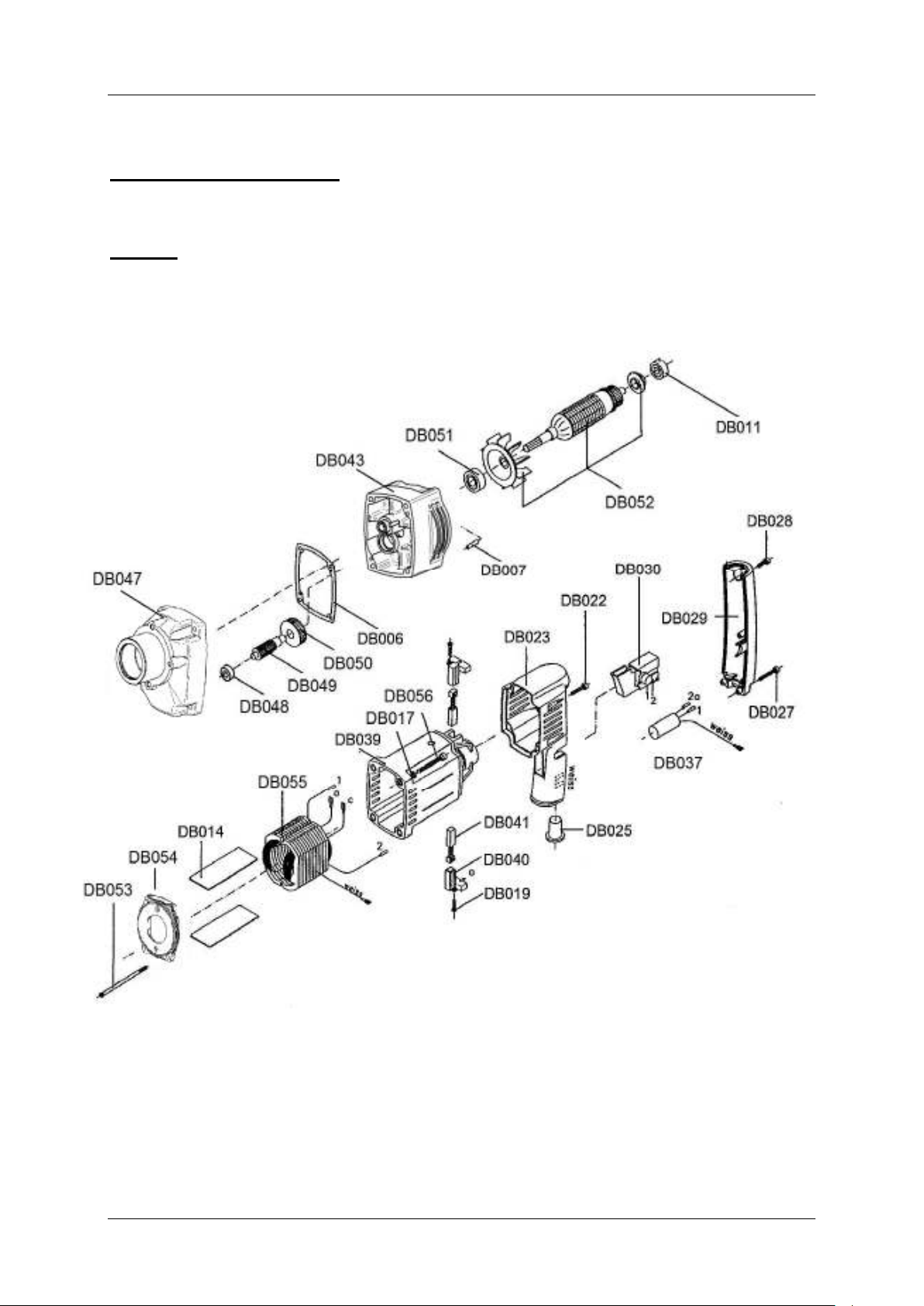

Spare Parts Drive Unit

DB044

DOHLE Extrusionstechnik GmbH 25

Operating Instructions

DB047

1

Gear BSM 275

DB049

1 Idler 8Z

DB050

1

Gearwheel 26

Z

DB006

1

Flat Gasket

DB007

2

Cylinder Pin 4m6, 6x16 DIN7

DB0

43 1 Engine Flap

DB0

51 1 Ball Bearing 6201 2

RS

DB0

52 1 Armature Winding BSM 275

DB011

1

Ball Bearing 608

-2Z

DB0

53 2 Raised Head Screw

M4x100 DIN84

DB0

54 1 A

ir Ring

DB014

2

Insulating Plate

DB017

4

Spring Washer M5 DIN 7980

DB0

56 1 Cheese Heat Screw M5 x 8

5 DIN 912

DB019

2

Cheese Heat Screw 2,9 x 9,5 DIN 7971

DB022

1

Raised Head Screw 3,9 x 19 DIN 7981 G

DB023

1

Handle BSM 270 green

DB025

1

Stopper

DB027

1

Raised Head Screw 3,9 x 25 DIN 7981 G

DB028

1

Raised Head Screw 3,9 x 13 DIN 7981 G

DB029

1

Handgrip Black

DB030

1

Switch ON

-

OFF

DB0

48 1 Ball Bearing 626

-2Z

DB034

1

Shaft BSM 270

– 280

DB036

1

Drive Unit BSM 270, 230 V, 800 W, green

DB03

7 1 Capacitor 2007 BSM 270

DB0

55 1 Field 230 V

DB039

1

Motor Case Green

DB040

2

Carbon Holder BSM 270

DB041

2

Carbon Brush BSM 270

DOHLE Hand Welding Extruder ExOn3A

Art.No Qty Description

DOHLE Extrusionstechnik GmbH 26

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

DOHLE Extrusionstechnik GmbH 27

Operating Instructions

DOHLE Hand Welding Extruder ExOn3A

s = thickness of material

illet weld

f

s

Welding Shoes

corner weld

s

a = s x 0,7

thickness of material order - no.

5-8

10-12

15

20

25

30

35

40

a

D-0174

D-0175

D-0177

D-0178

D-0179

D-0180

D-0181

D-0182

V-seam

s

thickness of material

5-8

10

12

15

20

25

30

35

40

order - no.

D-0183

D-0184

D-0185

D-0186

D-0187

D-0188

D-0189

D-0190

D-0191

overlap weld

thickness of material order - no.

5-8

10-12

15

D-0195

D-0196

D-0197

X - weld

s

thickness of material order - no.

10

15

20

25

30

35

40

D-0198

D-0199

D-0200

D-0201

D-0202

D-0203

D-0204

welding shoe, round

15

Ø

20

Ø

25

Ø

order - no.

D-0600

D-0366

D-0337

B

width of weld B

25

30

35

40

please require for shoes for special application

order - no.

D-0192

D-0193

D-0194

D-0599

D

OHLE Extrusionstechnik GmbH 28

welding shoe - unshaped

size

30 x 30 x 45

30 x 40 x 50

30 x 45 x 45

50 x 60 x 80

50 x 70 x 80

35

Ø

order - no.

D-0223

D-0224

D-0225

D-0247

D-0248

D-0598

Loading...

Loading...