Page 1

doepfer

1. Introduction

System A - 100

Module A152 is a useful switching and Track&Hold module. It combines three sub-units within one module:

• 1-to-8 multiplexer

• 8-fold Track&Hold

• 8-fold digital outputs unit

The active step of the three sub-units can be controlled

by an external control voltage (CV addressed mode)

or via a Clock/Reset controlled binary counter

(clocked mode). In this case the rising edge of each

clock signal causes an advance to the next step. The

rising edge of the reset signal resets to step 1.

The currently active step is displayed by a LED.

For the CV addressed mode a manual control and a

control voltage input with attenuator is available.

The module can be used for a lot of switching and

controlling functions in the A-100 system. Among other

things the T&H section of the A-152 allows the emulation

of the "toggling T&H" function of the Buchla module

266 "Source of Uncertainty".

Voltage Addressed T&H/Switch A-152

1

Page 2

Voltage Addressed T&H/Switch A-152

System A - 100

doepfer

2. Basic principles

The sum of the voltages coming from the manual

address control and the CV input define the currently

addressed step of the 3 sub-devices. An address in the

range 1...8 is generated by an internal analog-to-digital

converter. Three address signals (A0, A1 and A2) are

used to address the sub-units multiplexer, T&H and the

digital output section with LED display.

Alternatively the address signals A0, A1 and A2 can be

generated by an internal 3 bit binary counter that is

controlled by the signals clock and reset. For this the

the analog voltage applied to the analog-to-digital converter mentioned above has to remain unchanged as the

CV control has priority over the clock/reset control.

Sub-device #1 is the bidirectional 8-fold multiplexer

(nothing but an electronical 8-fold rotary switch). Bidirectional means that it works into both directions like a

mechanical rotary switch. The common socket may

work as an output that is connected to one of the 8

inputs that are e.g. connected to modulation or audio

sources. But the common socket may even function as

input. In this case the signal applied to the common

socket is output to the currently addressed single socket.

Sub-device #2 is the addressed 8-fold T&H. The signal

at the common T&H input is connected to the addressed

T&H output. The addressed output follows the voltage

applied to the common T&H input (track phase). As

soon as another output is addressed the last voltage is

stored (hold phase).

Remark:

A-148) the output voltage follows (i.e. tracks) to the input

voltage as long as the corresponding stage (1...8) is

active. Just when the stage is deselected the last voltage

is held. The S&H has only a very short track phase and

picks out a sample of the input voltage within a very

short time.

Sub-device #3 is the digital output section. The digital

output of the currently addressed step turns to "high". All

other digital outputs are low.

The digital output section also drives the LEDs.

In contrast to the Sample&Hold (see S&H

2

Page 3

doepfer

3. Overview

!

System A - 100

a

"

a

Controls:

Voltage Addressed T&H/Switch A-152

§

1 Address manual address control

2 CV attenuator for address CV input $

3

3 1...8 LED display (8x)

1

2

$

%

&

"

!

Inputs / Outputs:

!a SW I/O single multiplexer inputs/outputs (8x)

!b Common Switches In/Out

common multiplexer output/input

"a T&H Outs track&hold outputs (8x)

"b Common T&H Input

common track&hold input

§ Digital Outs digital outputs (8x)

$ CV In address control voltage input

% Clock In Clock input for the binary counter

% Reset In Reset input for the binary counter

b

b

3

Page 4

Voltage Addressed T&H/Switch A-152

System A - 100

doepfer

3. Controls / Inputs / Outputs

1 Address (control)

2 CV (control) / $ CV In (socket)

This group of elements is responsible for the address

generation in the voltage controlled mode. Control 1

Adress is used to adjust the address manually. The

control voltage input $ CV In with the corresponding

attenuator 2 CV can be used to modulate the address

by means of an external control voltage (e.g. ribbon

controller A-198, Theremin A-178, joy stick A-174,

ADSR, LFO, random voltage, sequencer and so on).

The required control voltage difference at socket $ is

about 5V to reach all available addresses with attenuator

2 set to it's maximum position.

% Clock In (socket) / & Reset In (socket)

This group of elements is responsible for the address

generation in the clocked mode with the internal binary

counter. In this mode each positive transition (rising

edge) of the signal applied to the Clock input % triggers

an advance to the next step. Any positive transition of

the signal applied to the Reset input & resets the

counter to step 1.

Attention! If the module is be controlled by clock and

reset signals the analog control voltage has to remain

unchanged as the CV control has priority over the

clock/reset control. E.g. simply turn the CV control 2

fully counterclockwise (or make sure that no control

voltage is applied to socket $) and do not touch the

address control knob 1. But of course this overwriting

behaviour can be used intentionally for special effects.

3 1...8 (LEDs, 8x)

The currently addressed step of all sub-units is displayed

with one of the LEDs.

!a SW I/O (sockets, 8x)

!b Common Switches In/Out (socket)

These sockets belong to the multiplexer sub-unit. The

common socket !b is connected to the currently addressed single I/O socket !a that is displayed by the illuminated LED 3. The remaining seven single I/O sockets

are open, i.e. at this moment they have no connection

among each other or to the common socket !b.

The multiplexer works bidirectional. This means that it

works into both directions like a mechanical rotary

switch. The common socket may work as an output that

is connected to one of the 8 inputs (which are e.g.

connected to modulation or audio sources). But the

4

Page 5

doepfer

System A - 100

Voltage Addressed T&H/Switch A-152

common socket may even function as input. In this case

the signal applied to the common socket is output to the

currently addressed single I/O socket.

Both control voltages and audio signals can be pro-

cessed by the multiplexer unit. The voltage range of the

in/outputs to be switched is the full A-100 voltage

range -12V....+12V. All A-100 signals can be switched

without any restrictions.

"a T&H Outs (sockets, 8x)

"b Common T&H Input (socket)

These sockets belong to the Track&Hold sub-unit. The

common T&H input "b is connected to the currently

addressed T&H output "a that is displayed by the

illuminated LED 3. The active T&H output follows the

voltage applied to the T&H input (track phase). As soon

as another output is addressed the last voltage is stored

(hold phase).

Only control voltages can be processed by the T&H

unit due to the holding capacitors of the T&H circuits.

The T&H section is not suitable for audio signals.

The T&H section of the A-152 allows the emulation of

the "toggling T&H" function of the Buchla module 266

"Source of Uncertainty". Only the first two T&H outputs

of the A-152 are required for this application (digital

output 3 has to be connected to the reset input).

§ Digital Outputs (sockets, 8x)

These sockets belong to the digital output section. The

digital output of the currently addressed step turns to

"high" (i.e. about +12V) . It is displayed by the illuminated

LED 3. All other digital outputs remain at low level.

The digital outputs can be used to reduce the number of

addressed stages in the clocked mode. If the digital

output 5 is connected to the reset input & only steps

1...4 of the counter will be addressed.

Another application is the triggering of other A-100 modules (e.g. ADSR, LFO reset, clock divider/sequencer,

trigger delay, analog sequencer and so on). For example

the ribbon controller A-198 can be used to trigger 8

different devices one after another by moving the finger

over the ribbon manual.

For logical connection of several digital outputs the logic

module A-166 can be used (e.g. for simple rhythmic

patterns).

To generate a short trigger signal from the gate-type

digital outputs the trigger modifier A-165 is the right

choice (each digital output remains in the "high" state

while it is addressed, this is called a "gate-type" signal).

5

Page 6

Voltage Addressed T&H/Switch A-152

Normalling options

System A - 100

doepfer

The common terminals of the multiplexer and the T&H

section can be normalled in different ways, i.e. they can

be pre-connected provided that no plugs are inserted

into the corresponding sockets. For that purpose two

single row pin headers with jumpers are available:

JP8: located on the pc board of the multiplexer unit

(labelled "BOARD C SWITCHES") at the lower edge

JP7: located on the pc board of the T&H unit (labelled

"BOARD B T&H") at the lower edge as well

There are two possibilities to set the jumpers of JP7 and

JP8:

• JP8 below, JP7 towards the common T&H socket

In this case the common socket of the multiplexer unit

!b is connected to the common input of the T&H unit "b

provided that no plug is inserted into the common socket

!b of the multiplexer unit. For both units T&H and

multiplexer the same input signal is used (applied to the

common input of the T&H unit "b). The eight single

sockets of the multiplexer unit !a function as outputs in

this case.

• JP8 top, JP7 away from the common T&H

(factory setting

In this case the common input of the T&H unit "b is

connected to the common socket of the multiplexer unit

!b provided that no plug is inserted into the common

input of the T&H unit "b. This leads to two possibilities:

1. For both units T&H and multiplexer the same input

signal is used. The signal is applied to the common

socket of the multiplexer unit !b. In this case the eight

single sockets of the multiplexer unit !a function as

outputs.

2. No plug is inserted into the common socket of the

multiplexer unit !b. In this case the single sockets of the

multiplexer unit !a are used as inputs for the T&H with a

separate input for each T&H output. Each single socket

of the multiplexer !a works as input for the neighbouring

T&H stage "a. In this case the eight single sockets of

the multiplexer unit !a function as inputs.

If one or both jumpers are removed no normalling is

active. We recommend to keep the jumpers for a later

re-installation of the normalling option.

)

6

Page 7

doepfer

System A - 100

5. User Examples

Graphic VCO

The right picture shows the principle patch for a socalled graphic VCO. For a graphic VCO the waveform is

determined by a sequence of voltage levels. Normally

the levels are adjusted with faders and the fader positions represent the waveform. In the A-100 such a VCO is

not available as we believe that the expenditure and

costs do not correspond to the result. From our point of

view the features of a graphic VCO are overestimated

very often. But with the A-152 one has the tool to built a

graphic VCO with a few additional modules only. And

that's how it works:

Voltage Addressed T&H/Switch A-152

The CV address input of the A-152 is connected to the

output of a VCO (e.g. sawtooth or triangle output of an

A-110 or A-111). The manual address control and the

CV attenuator are adjusted so that just all 8 LEDs of the

A-152 light up, i.e. that all 8 stages of the A-152 are

addressed while the VCO passes through it's waveform

(this is why only sawtooth/triangle/sine are suitable waveforms but not rectangle). The CV controlled address

generator of the A-152 is able to work up to moderate

audio frequencies. If different voltages are applied to the

eight multiplexer inputs of the A-152 one obtains a

graphic VCO signal at the common multiplexer output

that has the same frequency as the VCO.

Here are some examples how to generate the eight

voltages:

• 8 fixed voltages (e.g. from the CV source module

A-176): This is the "classic" graphic VCO with manually adjustable values (for DIY's: 8 faders connected

between GND and +12V could be used too)

• 8 automatically varying voltages (e.g. 8 LFO outputs

from two A-143-3)

• 8 random analog voltages (e.g. random voltages

from A-118 or A-149-1 or S&H A-148)

• 8 random digital voltages (e.g. A-149-2)

• or any combination of the above suggestions

7

Page 8

Voltage Addressed T&H/Switch A-152

System A - 100

doepfer

For the last 3 examples the waveform changes more or

less accidentally. If the A-149-1 resp. A-149-2 is used

the waveform changes can be synced as for these

modules the random voltages are triggered by a clock

signal. Especially in combination with an A-155 a lot of

interesting applications may result. E.g. the clock inputs

of the A-149-1 can be controlled by the sequencer clock

or a A-155 trigger row. In both cases the change to the

next waveform is in sync with the sequencer.

If the triangle output of a VCO is used to control the

A-152 only odd harmonics will occur as the graphic

waveform is passed through symmetrically in both directions.

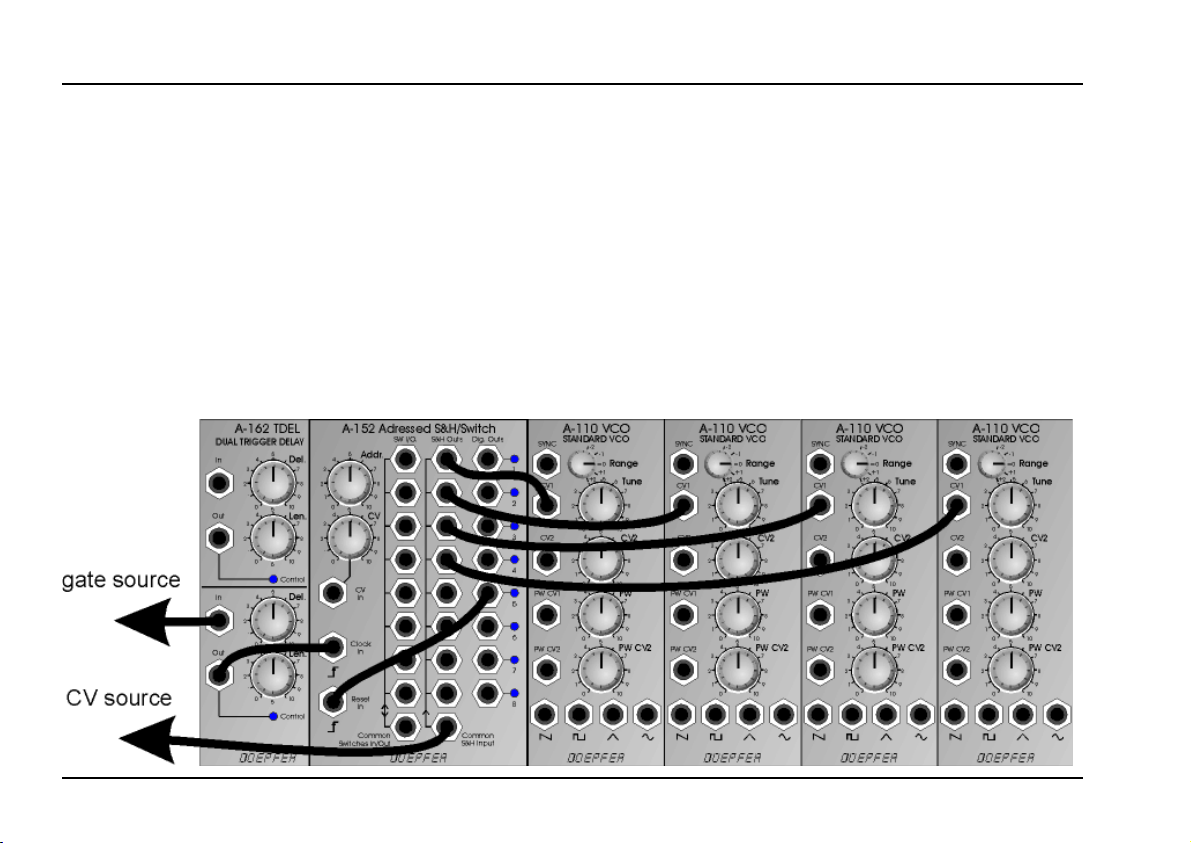

Mono-Poly-Konverter

The picture below shows an application of the A-152 that

distributes a monophonic pitch control voltage (e.g. the

CV of a sequencer, a MIDI-to-CV interface or a monophonic keyboard) into several polyphonic control voltages that are used to control several VCOs. And that's

how it works:

The pitch CV is connected to the common input of the

T&H unit. The positive transition of the corresponding

gate signal indicates that a new CV is generated (e.g. by

pressing a key on the keyboard or during the advance to

the next sequencer step). The gate signal is used to

8

Page 9

doepfer

System A - 100

Voltage Addressed T&H/Switch A-152

trigger the advance to the next address of the A-152.

The trigger delay connected between the gate source

and the clock input of the A-152 is required because of

the timing between the positive transition of the gate

signal and the CV change. The T&H has to take over

and store the CV not before the CV is stable. Otherwise

the result will not meet the expectations. As the time

correlation between the gate transition and the CV

change may vary the A-162 is used to solve problems

that may arise from this. Ideally the gate transition and

CV change happens exactly simultaneously, but "simultaneously" is a problem in the real world as there are

always some delays in the micro/millisecond range that

may cause problems (e.g. the MIDI-to-CV interface or

sequencer of manufacturer #1 generates the gate transition 200us before the CV change but for manufacturer

#2 the behaviour is reverse and the delay is 500 us). To

avoid such problems the A-162 is used. First the trigger

length is adjusted so that the A-152 triggers correctly. If

the width is too short the A-152 may not trigger or the

step advances are uneven. After that the delay time is

adjusted so that the CV values appear sequentially at

the T&H outputs of the A-152 as expected. Usually the

A-162 settings will be close to the left-most positions of

the controls for delay and length.

The four VCO outputs can be mixed in an A-138 before

the subsequent signal processing (VCF,VCA,ADSR ...).

But even each VCO outputs can be processed separately. In this case the digital outputs of the A-152 may be

used to trigger the envelope generators that are assigned to the corresponding VCO.

The number of outputs can be decreased or increased

by connecting the reset input to another digital output.

A special case is the limitation to two outputs. This leads

to the function of the toggling S&H unit of the Buchla

module 266 Source of Uncertainty. The only difference

is that the Buchla module contains two S&H instead of

two T&H. If an A-148 S&H is connected between the CV

source and the A-152 the functions are identically.

Another solution is to modify the A-152 so that the T&H

section works as S&H. For details please refer to the

DIY page on our web site www.doepfer.com.

In the example the digital output five is connected to the

reset input of the A-152 to limit the number of outputs to

four.

9

Page 10

Voltage Addressed T&H/Switch A-152

System A - 100

7-fold Manual Ribbon Gate

The right picture shows an application of the A-152 in

combination with the ribbon controller A-198. The position control voltage of the A-198 is used to address the

A-152. If the manual address control and the CV attenuator are adjusted in the right way the position sensor

of the A-198 covers the complete address range of the

A-152 and a small share of the position range is assigned to one of the eight addresses of the A-152.

If the hold switch of the A-198 is set "off" the A-152

jumps to address 1 as soon as the finger is removed

from the position sensor. As soon as the sensor is

touched, one of the stages in the range 2...8 is addressed and the corresponding digital output turns to "high" displayed by the corresponding LED. This leads to a

7-fold manual gate generator that can be operated like a

percussion set. According to the position of the finger,

that touches the position sensor of the A-198 one of the

gate outputs of the A-152 is active. The gate outputs

may be used to trigger percussive sounds stored in an

A-112 sampler module or percussive patches based on

other A-100 modules.

doepfer

are available that follow the position CV of the A-198 in a

certain range. As soon as the finger leaves the corresponding range the last voltage is stored.

In principle the gate outputs can be used for any gate/

trigger/clock function in the A-100.

In the example the position CV is also patched to the

common T&H input. At the T&H outputs control voltages

10

The multiplexer unit can be used for additional switching

functions (e.g. to connect different modulation or audio

sources to a module).

Loading...

Loading...