Page 1

DR/DH TIRES/WHEELS 22 - 1

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT ..............2

STANDARD PROCEDURE

MATCH MOUNTING ....................4

TIRE AND WHEEL BALANCE .............5

TIRE ROTATION .......................6

TIRES

DESCRIPTION

TIRES ...............................7

SPARE / TEMPORARY TIRE ..............8

RADIAL – PLY TIRES ...................8

TIRE PRESSURE FOR HIGH SPEEDS ......8

REPLACEMENT TIRES ..................8

TIRE INFLATION PRESSURES ............9

DIAGNOSIS AND TESTING

PRESSURE GAUGES ...................9

TIRE NOISE OR VIBRATION ..............9

TREAD WEAR INDICATORS .............10

TIRE WEAR PATTERNS ................10

TIRE/VEHICLE LEAD ...................10

STANDARD PROCEDURE

TIRE REPAIR AREA ....................12

CLEANING

TIRES ..............................12

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE ..........12

WHEELS

DESCRIPTION

DESCRIPTION ........................13

WHEEL DESIGN ......................14

DIAGNOSIS AND TESTING

WHEEL INSPECTION ..................15

STANDARD PROCEDURE

WHEEL REPLACEMENT ................15

DUAL REAR WHEEL INSTALLATION .......17

SPECIFICATIONS

TORQUE CHART ......................18

STUDS

REMOVAL .............................18

INSTALLATION .........................19

WHEEL COVER

REMOVAL .............................19

INSTALLATION

REAR ..............................19

FRONT .............................20

SPARE TIRE

DESCRIPTION

SPARE / TEMPORARY TIRE .............20

FULL SIZE, SPARE WHEEL WITH

MATCHING TIRE ......................20

Page 2

22 - 2 TIRES/WHEELS DR/DH

TIRES/WHEELS

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT

Radial runout is the difference between the high and

low points on the tire or wheel.

Lateral runout is the wobble of the tire or wheel.

Lateral runout of more than 2.0 mm (.080 inch) mea-

sured near the shoulder of the tire may cause the

vehicle to shake.

Page 3

DR/DH TIRES/WHEELS 22 - 3

Radial runout of more than 1.5 mm (.060 inch) measured at the center line of the tread may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate the

wheel and tire assembly on the mounting studs (See

Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

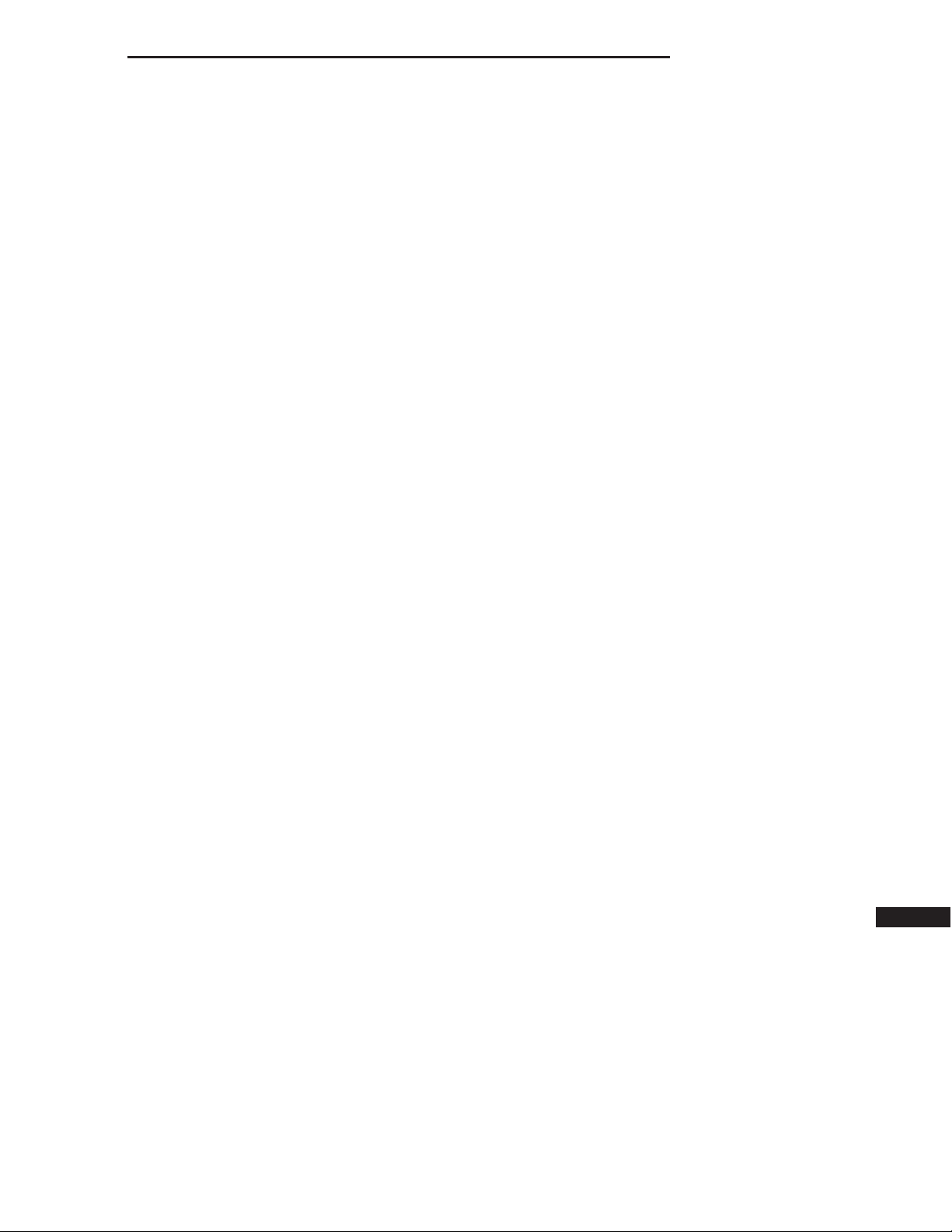

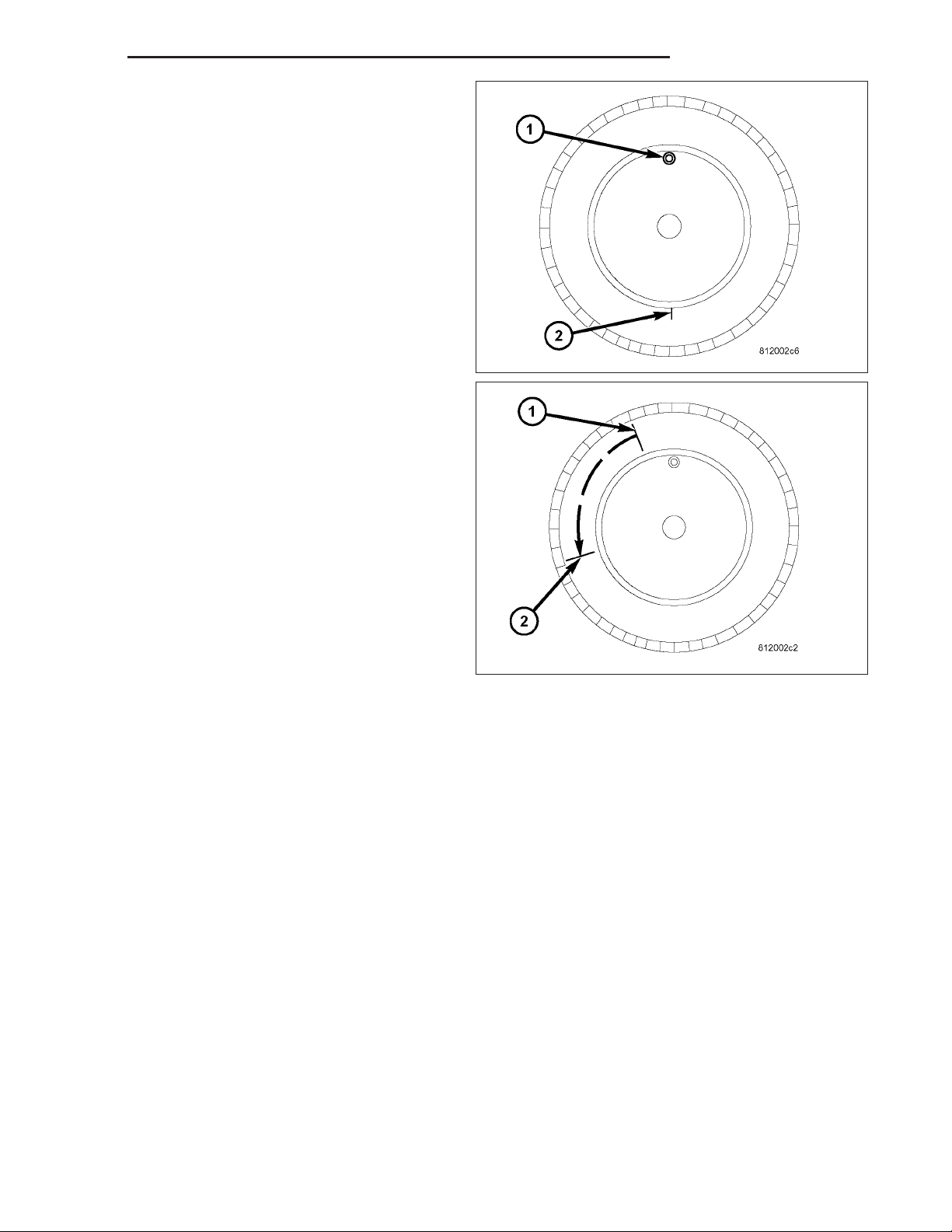

METHOD 1 (RELOCATE WHEEL ON HUB)

1. Drive vehicle a short distance to eliminate tire flat spotting from a parked position.

2. Check wheel bearings and adjust if adjustable or replace if necessary.

3. Check the wheel mounting surface.

4. Relocate wheel on the mounting, two studs over from the original position.

5. Tighten wheel nuts until all are properly torqued, to eliminate brake distortion.

6. Check radial runout. If still excessive, mark tire sidewall, wheel, and stud at point of maximum runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly effective when there is runout in both tire and wheel.

1. Remove tire from wheel and mount wheel on service dynamic balance machine.

2. Check the wheel radial runout.

Page 4

22 - 4 TIRES/WHEELS DR/DH

3. Check the wheel lateral runout.

• STEEL WHEELS: Radial runout 0.031 in., Lateral

runout 0.031 in. (maximum)

• ALUMINUM WHEELS: Radial runout 0.02 in.,

Lateral runout 0.025 in. (maximum)

4. If point of greatest wheel lateral runout is near original chalk mark, remount tire 180 degrees.

Recheck runout.

STANDARD PROCEDURE

MATCH MOUNTING

Wheels and tires are match mounted at the factory. This means that the high spot of the tire is matched to the low

spot on the wheel rim. Each are marked with a bright colored temporary label on the outboard surface for alignment.

The wheel is also marked permanently on the inside of the rim in the tire well. This permanent mark may be a paint

dot or line, a permanent label or a stamped impression such as an X. An optional location mark is a small spherical

indentation on the vertical face of the outboard flange on some non styled base steel wheels. The tire must be

removed to locate the permanent mark on the inside of the wheel.

Before dismounting a tire from its wheel, a reference mark should be placed on the tire at the valve stem location.

This reference will ensure that it is remounted in the original position on the wheel.

1. Remove the tire and wheel assembly from the

vehicle and mount on a service dynamic balance

machine.

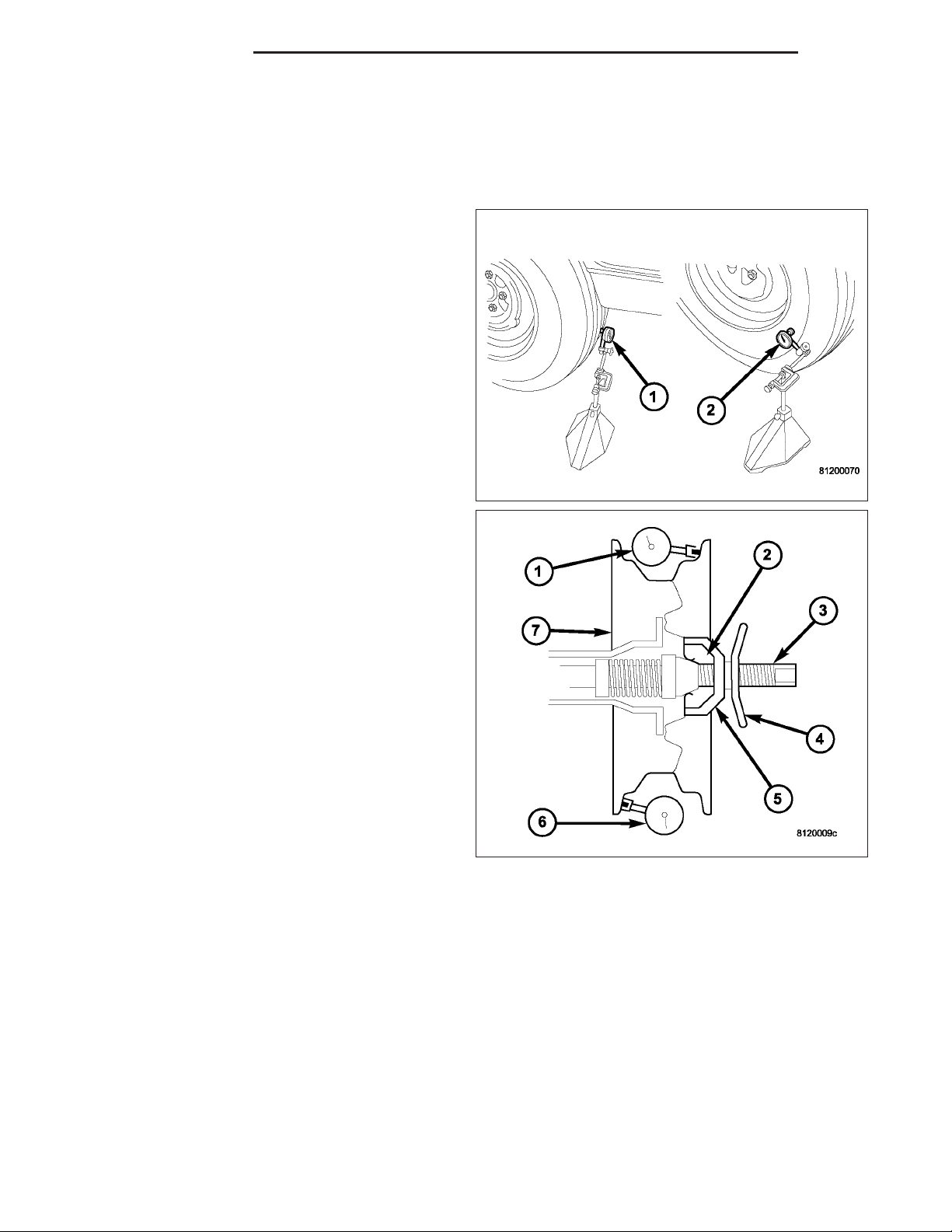

2. Measure the total runout on the center of the tire

tread rib (3) with a dial indicator. Record the indicator reading. Mark the tire to indicate the high

spot (2). Place a mark on the tire at the valve stem

(4) location (1).

Page 5

DR/DH TIRES/WHEELS 22 - 5

3. Break down the tire and remount it 180 degrees

on the rim (1)(2).

4. Measure the total indicator runout again. Mark the

tire to indicate the high spot.

5. If runout is still excessive, the following procedures

must be done.

• If the high spot is within 101.6 mm (4.0 in.) of the

first spot and is still excessive, replace the tire.

• If the high spot is within 101.6 mm (4.0 in.) of the

first spot on the wheel, the wheel may be out of

specifications. Refer to Wheel and Tire Runout.

• If the high spot is NOT within 101.6 mm (4.0 in.)

of either high spot, draw an arrow on the tread

from second high spot (1) to first (2). Break down

the tire and remount it 90 degrees on rim in that

direction. This procedure will normally reduce the

runout to an acceptable amount, if not replace

the rim.

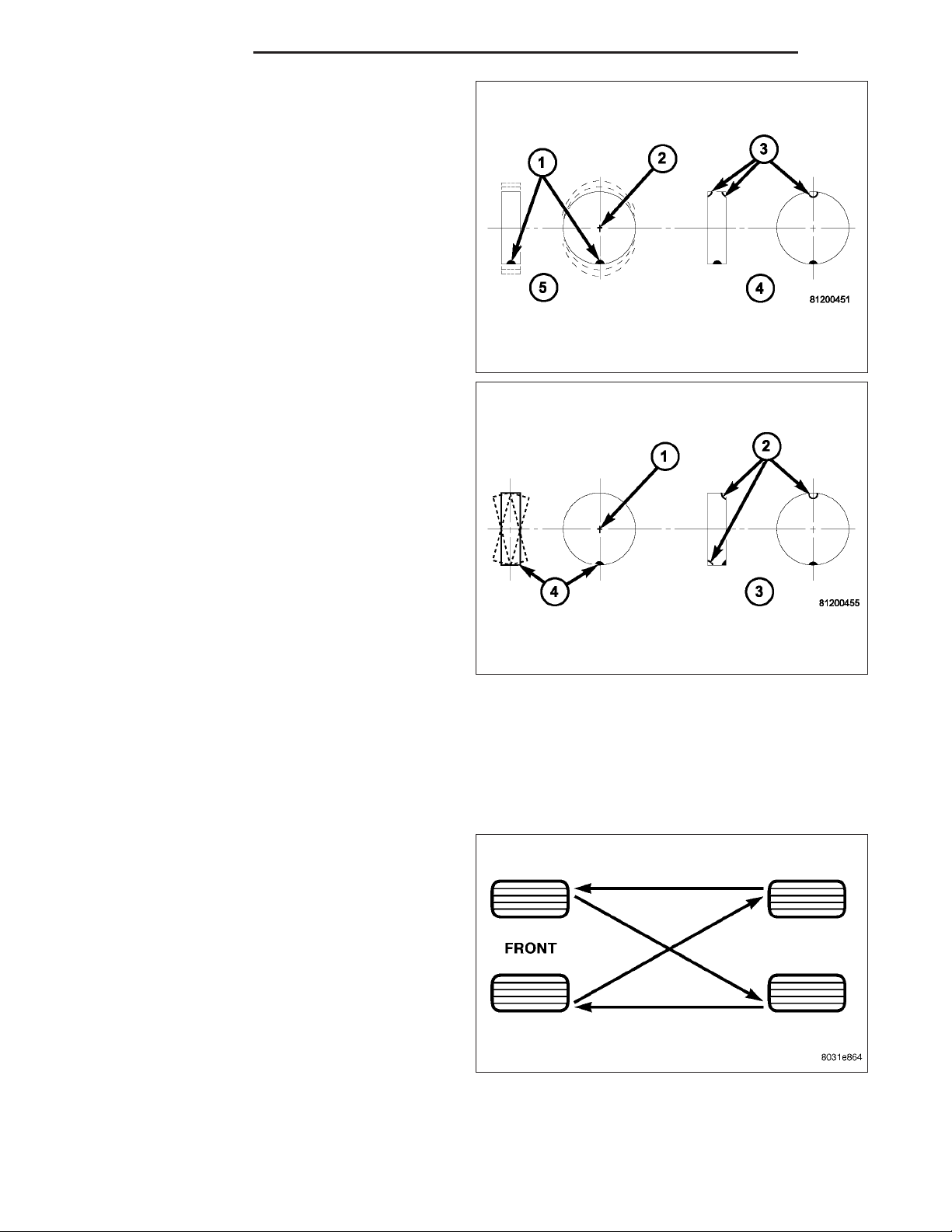

TIRE AND WHEEL BALANCE

It is recommended that a two plane service dynamic balancer be used when a tire and wheel assembly require

balancing. Refer to balancer operation instructions for proper cone mounting procedures. Typically use front cone

mounting method for steel wheels. For aluminum wheel use back cone mounting method without cone spring.

NOTE: Static should be used only when a two plane balancer is not available.

NOTE: Cast aluminum and forged aluminum wheels require coated balance weights and special alignment

equipment.

Wheel balancing can be accomplished with either on or off vehicle equipment. When using on-vehicle balancing

equipment, remove the opposite wheel/tire. Off-vehicle balancing is recommended.

Page 6

22 - 6 TIRES/WHEELS DR/DH

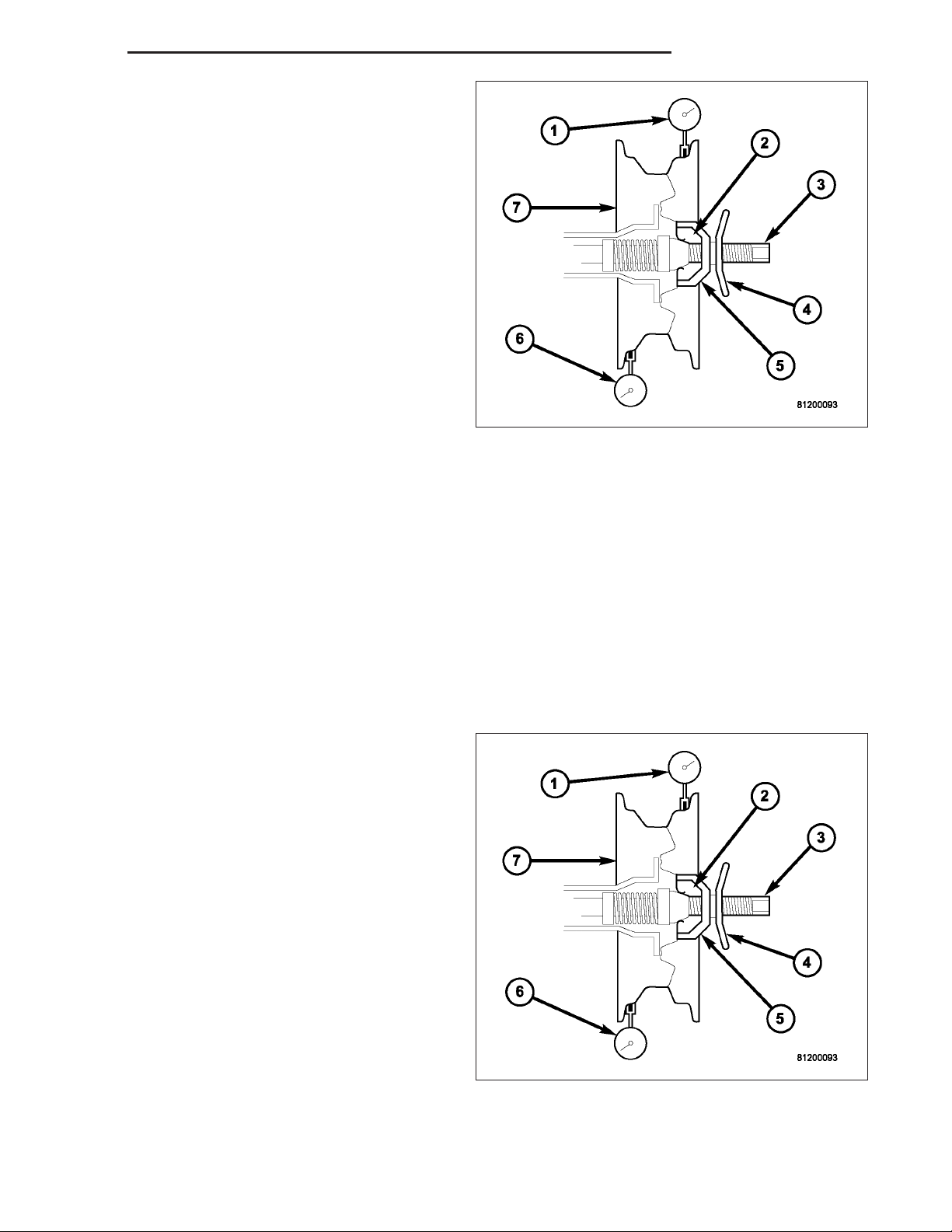

For static balancing, find the location of the heavy

spot (1) causing the imbalance (5). Counter balance

wheel directly opposite the heavy spot. Determine

weight required to counter balance the area of imbalance (4). Place half of this weight on the inner rim

flange (3) and the other half on the outer rim flange

(3).

For dynamic balancing (3), the balancing equipment is

designed to locate the amount of weight to be applied

to both the inner and outer rim flange (2).

TIRE ROTATION

Tires on the front and rear axles operate at different loads and perform different steering, driving, and braking functions. For these reasons, the tires wear at unequal rates. They may also develop irregular wear patterns. These

effects can be reduced by rotating the tires according to the maintenance schedule in the Owners Manual. This will

improve tread life, traction and maintain a smooth quiet ride.

The recommended method of tire rotation for single

rear wheel is. Other methods can be used, but may

not provide the same tire longevity benefits.

Page 7

DR/DH TIRES/WHEELS 22 - 7

CAUTION: 3500 Dual rear tires have a new tire

rotation pattern. This is to accommodate the outlined white letter (OWL) tires. When replacing a

flat, the spare tire may have to be remounted on

the rim or installed at a different location to maintain the correct placement of the outlined white

letter (OWL) tires.

The recommended method of tire rotation for dual rear

wheel is. Other methods can be used, but may not

provide the same tire longevity benefits.

TIRES

DESCRIPTION

TIRES

Tires are designed and engineered for each specific vehicle. They provide the best overall performance for normal

operation. The ride and handling characteristics match the vehicle’s requirements. With proper care they will give

excellent reliability, traction, skid resistance, and tread life.

Driving habits have more effect on tire life than any other factor. Careful drivers will obtain in most cases, much

greater mileage than severe use or careless drivers. A few of the driving habits which will shorten the life of any tire

are:

• Rapid acceleration

• Severe brake applications

• High speed driving

• Excessive speeds on turns

• Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread wear. It is important to follow the tire rotation interval (Refer to 22

- TIRES/WHEELS - STANDARD PROCEDURE). This will help to achieve a greater tread life.

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher the

tire identification code.

Performance tires have a speed rating letter after the

aspect ratio number. The speed rating is not always

printed on the tire sidewall. These ratings are:

• Q up to 100 mph

• S up to 112 mph

• T up to 118 mph

• U up to 124 mph

• H up to 130 mph

• V up to 149 mph

• Z more than 149 mph (consult the tire manufac-

turer for the specific speed rating)

An All Season type tire will have either M+S,M&SorM–S(indicating mud and snow traction) imprinted on the

side wall.

Page 8

22 - 8 TIRES/WHEELS DR/DH

TIRE CHAINS

Tire snow chains may be used on certain models. Refer to the Owner’s Manual for more information.

SPARE / TEMPORARY TIRE

The temporary spare tire is designed for emergency use only. The original tire should be repaired or replaced at the

first opportunity, then reinstalled. Do not exceed speeds of 50 M.P.H. when using the temporary spare tire. Refer to

Owner’s Manual for complete details.

RADIAL – PLY TIRES

Radial-ply tires improve handling, tread life and ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of four. Under no circumstances should they be used on the front only.

They may be mixed with temporary spare tires when necessary. A maximum speed of 50 MPH is recommended

while a temporary spare is in use.

Radial-ply tires have the same load-carrying capacity as other types of tires of the same size. They also use the

same recommended inflation pressures.

The use of oversized tires, either in the front or rear of the vehicle, can cause vehicle drive train failure. This could

also cause inaccurate wheel speed signals when the vehicle is equipped with Anti-Lock Brakes.

The use of tires from different manufactures on the same vehicle is NOT recommended. The proper tire pressure

should be maintained on all four tires.

TIRE PRESSURE FOR HIGH SPEEDS

For proper tire pressure specification refer to the Owners Manual.

REPLACEMENT TIRES

The original equipment tires provide a proper balance of many characteristics such as:

• Ride

• Noise

• Handling

• Durability

• Tread life

• Traction

• Rolling resistance

• Speed capability

It is recommended that tires equivalent to the original equipment tires be used when replacement is needed.

Failure to use equivalent replacement tires may adversely affect the safety and handling of the vehicle.

The use of oversize tires may cause interference with vehicle components. Under extremes of suspension and

steering travel, interference with vehicle components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH TIRES HAVING ADEQUATE SPEED CAPABILITY CAN

RESULT IN SUDDEN TIRE FAILURE.

Page 9

DR/DH TIRES/WHEELS 22 - 9

TIRE INFLATION PRESSURES

WARNING: OVER OR UNDER INFLATED TIRES

CAN AFFECT VEHICLE HANDLING AND TREAD

WEAR. THIS MAY CAUSE THE TIRE TO FAIL SUDDENLY, RESULTING IN LOSS OF VEHICLE CONTROL.

Under inflation will cause rapid shoulder wear (1), tire

flexing, and possible tire failure.

Over inflation will cause rapid center wear (1) reduction in the tire’s ability to cushion shocks.

Improper inflation can cause:

• Uneven wear patterns

• Reduced tread life

• Reduced fuel economy

• Unsatisfactory ride

• Vehicle drift

For proper tire pressure specification refer to the vehicles Owners Manual.

DIAGNOSIS AND TESTING

PRESSURE GAUGES

A quality air pressure gauge is recommended to check tire pressure. After checking the air pressure, replace valve

cap finger tight.

TIRE NOISE OR VIBRATION

Radial-ply tires are sensitive to force impulses caused by improper mounting, vibration, wheel defects, or possibly

tire imbalance.

To find out if tires are causing the noise or vibration, drive the vehicle over a smooth road at varying speeds. Note

the noise level during acceleration and deceleration. The engine, differential and exhaust noises will change as

speed varies, while the tire noise will usually remain constant.

Page 10

22 - 10 TIRES/WHEELS DR/DH

TREAD WEAR INDICATORS

Tread wear indicators (3) are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators (3) will appear as

a 13 mm (1/2 in.) band.

Tire replacement is necessary when indicators appear

in two or more grooves or if localized balding occurs.

TIRE WEAR PATTERNS

Under inflation will cause wear on the shoulders of tire. Over inflation will cause wear at the center of tire.

Excessive camber causes the tire to run at an angle to the road. One side of tread is then worn more than the

other.

Excessive toe-in or toe-out causes wear on the tread edges and a feathered effect across the tread.

TIRE/VEHICLE LEAD

Use the following Vehicle Lead Diagnosis And Correction Chart to diagnose and correct a vehicle lead or drift

problem.

Page 11

DR/DH TIRES/WHEELS 22 - 11

Page 12

22 - 12 TIRES/WHEELS DR/DH

STANDARD PROCEDURE

TIRE REPAIR AREA

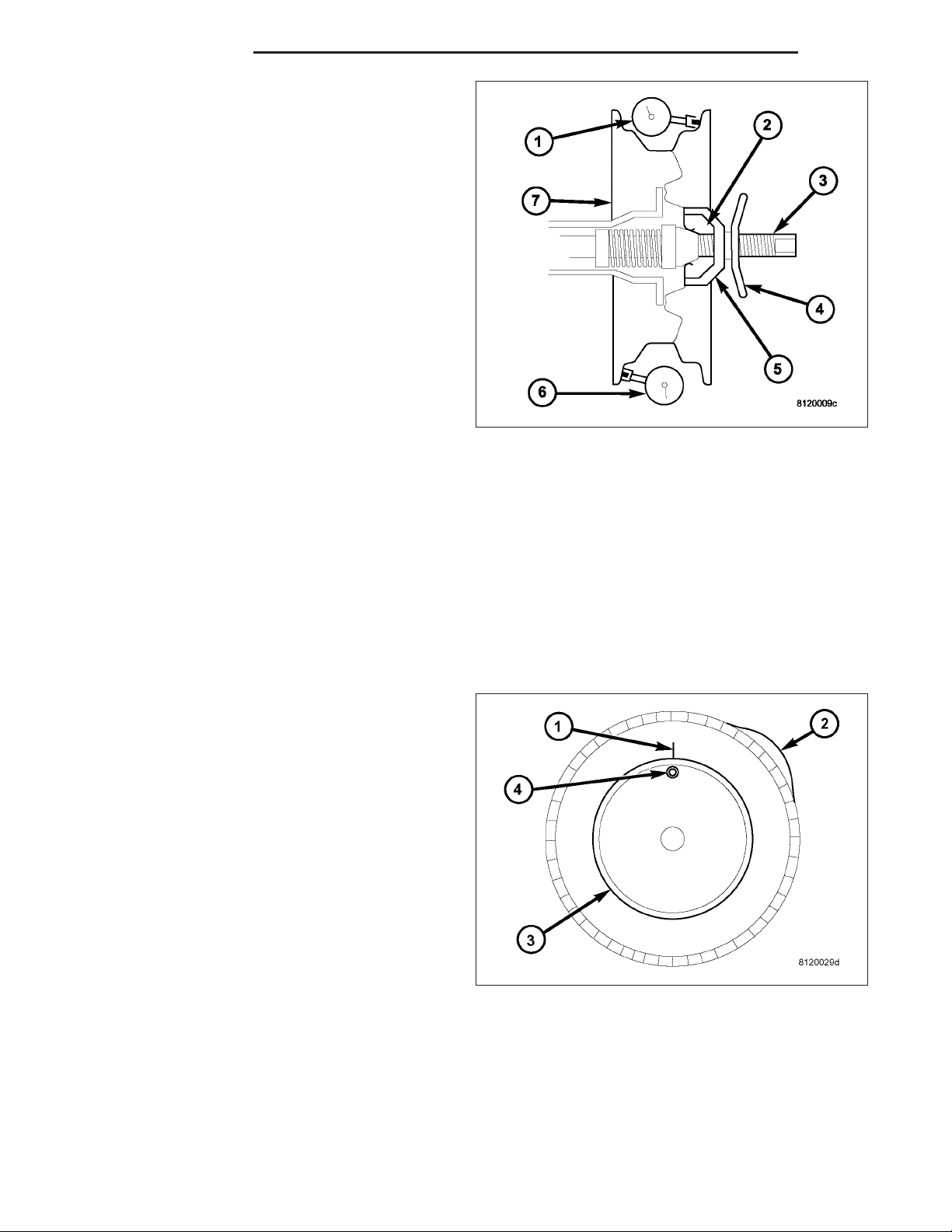

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (1). The tire

should be replaced if the puncture is located in the

sidewall.

Deflate tire completely before removing the tire from

the wheel. Use lubrication such as a mild soap solution when dismounting or mounting tire. Use tools free

of burrs or sharp edges which could damage the tire

or wheel rim.

Before mounting tire on wheel, make sure all rust is

removed from the rim bead and repaint if necessary.

Install wheel on vehicle, and tighten to proper torque

specification.

CLEANING

TIRES

Remove the protective coating on the tires before delivery of a vehicle. This coating may cause deterioration of the

tires.

To remove the protective coating, apply warm water and let it soak for a few minutes. Afterwards, scrub the coating

away with a soft bristle brush. Steam cleaning may also be used to remove the coating.

NOTE: DO NOT use gasoline, mineral oil, oil-based solvent or a wire brush for cleaning.

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE

TIRE SIZE SUPPLIER REVOLUTIONS PER MILE

P245/70R17

WRANGLER SRA

LT245/70R17

LTX A/S

LT265/70R17E

LTX A/S

LT245/70R17

RUGGED TRAIL T/A

LT265/70R17E

RUGGED TRAIL T/A

LT285/70R17D

ALL TERRAIN T/A

P265/70R17

WRANGLER SR/A

P265/70R17

WRANGLER GS/A

LT275/70R17E

WRANGLER AT/S

GOODYEART 685

MICHELINT

MICHELINT 657

BF GOODRICHT

BF GOODRICHT

BF GOODRICHT

GOODYEART 657

GOODYEART 661

GOODYEART 649

675

684

658

632

Page 13

DR/DH TIRES/WHEELS 22 - 13

TIRE SIZE SUPPLIER REVOLUTIONS PER MILE

LT275/70R17E

TTL

P275/55R20

EAGLE LS

P275/60R20

WRANGLER HP

LT235/80R17E

WRANGLER SRA

LT235/80R17E

WRANGLER GSA

LT235/80R17E

AMERITRAC

LT235/80R17E

AMERITRAC TR

305/40ZR22

SCORPION ZERO

STANDARD CAB

SRT-10

USES A

3 SEASON TIRE

305/40ZR22

SCORPION ZERO

QUAD CAB

SRT-10

IDENTIFIED WITH A

9QC9 AT THE END OF THE DOT

CODE

IS A

4 SEASON TIRE

GOODYEART 649

GOODYEART 655

GOODYEART 636

GOODYEART

GOODYEART

GENERALT

GENERALT

PIRELLIT

PIRELLIT

649

649

649

648

654

654

WHEELS

DESCRIPTION

DESCRIPTION

Original equipment wheels are designed for the specified Maximum Vehicle Capacity.

All models use steel or aluminum drop center wheels.

Aluminum wheels require special balance weights and alignment equipment.

Page 14

22 - 14 TIRES/WHEELS DR/DH

1. On vehicles equipped with dual rear wheels, The

rim is an eight stud hole pattern wheel. The wheels

have a flat mounting surface (1).

2. The slots (1) in the wheel must be aligned to provide access to the valve stem.

WHEEL DESIGN

The rim size is on the vehicle safety certification label

located on the drivers door shut face. The size of the

rim is determined by the drivetrain package. Original

equipment wheels/rims are designed for operation up

to the specified maximum vehicle capacity.

All models use stamped steel, cast aluminum or

forged aluminum wheels. Every wheel has raised sections between the rim flanges (1) and rim drop well (3)

called safety humps.

Initial inflation of the tire forces the bead over these

raised sections. In case of rapid loss of air pressure,

the raised sections help hold the tire on the wheel.

The wheel studs and nuts are designed for specific

applications. All aluminum and some steel wheels

have wheel stud nuts with an enlarged nose. This

enlarged nose is necessary to ensure proper retention

of the wheels. Do not use replacement studs or nuts with a different design or lesser quality.

Page 15

DR/DH TIRES/WHEELS 22 - 15

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

• Excessive run out

• Dents or cracks

• Damaged wheel lug nut holes

• Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammering, heating or welding.

If a wheel is damaged an original equipment replacement wheel should be used. When obtaining replacement

wheels, they should be equivalent in load carrying capacity. The diameter, width, offset, pilot hole and bolt circle of

the wheel should be the same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT REPLACEMENT WHEELS MAY ADVERSELY AFFECT THE

SAFETY AND HANDLING OF THE VEHICLE. USED WHEELS ARE NOT RECOMMENDED. THE SERVICE HISTORY OF THE WHEEL MAY HAVE INCLUDED SEVERE TREATMENT OR VERY HIGH MILEAGE. THE RIM

COULD FAIL WITHOUT WARNING.

STANDARD PROCEDURE

WHEEL REPLACEMENT

The wheel studs and nuts are designed for specific applications. They must be replaced with equivalent parts. Do

not use replacement parts of lesser quality or a substitute design. All aluminum and some steel wheels have wheel

stud nuts which feature an enlarged nose. This enlarged nose is necessary to ensure proper retention of the aluminum wheels.

NOTE: Do not use chrome plated lug nuts with

chrome plated wheels.

NOTE: All wheel nuts should then be tightened

just snug. Gradually tighten them in sequence to

the proper torque specification.

NOTE: Never use oil or grease on studs or nuts.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening of

wheel nuts. This could affect the safety and handling

of your vehicle.

To install the wheel (3), first position it properly on the mounting surface.

Page 16

22 - 16 TIRES/WHEELS DR/DH

8–lug.

(SRT-10).

6– bolt pattern.

Wheels must be replaced if they have:

• Excessive runout

• Bent or dented

• Leak air through welds

• Have damaged bolt holes

Page 17

DR/DH TIRES/WHEELS 22 - 17

Wheel repairs employing hammering, heating, or welding are not allowed.

Original equipment wheels are available through your dealer. Replacement wheels from any other source should be

equivalent in:

• Load carrying capacity

• Diameter

• Width

• Offset

• Mounting configuration

Failure to use equivalent replacement wheels may affect the safety and handling of your vehicle. Replacement with

used wheels is not recommended. Their service history may have included severe treatment.

DUAL REAR WHEEL INSTALLATION

Dual rear wheels use a special heavy duty lug nut wrench. It is recommended to remove and install dual rear

wheels only when the proper wrench is available. The wrench is also use to remove wheel center caps for more

information refer to Owner’s Manual.

The tires on both wheels must be completely raised off the ground when tightening the lug nuts. This will ensure

correct wheel centering and maximum wheel clamping.

A two piece flat face lug nut with right-hand threads is

used for retaining the wheels on the hubs.

The dual rear wheel lug nuts should be tightened

according to the following procedure:

NOTE: Do not use more then two drops of oil on

the nut/washer (1), since the center caps attach in

this area.

• Place two drops of oil to the interface of the nut/

washer (1) before installing on the wheel stud.

• Tighten the wheel lug nuts in the numbered sequential pattern until they are snug tight. Then tighten lug nut to

specified torque following same number sequence, (Refer to 22 - TIRES/WHEELS/WHEELS - SPECIFICATIONS).

• Tighten lug nuts in same numbered sequence a second time to the specified torque. This will ensure that the

wheels are thoroughly mated.

• Check lug nut specified torque after 100 miles (160 kilometers). Also after 500 miles (800 kilometers) of vehicle

operation.

NOTE: Wheel lug nuts should be tightened to specified torque at every maintenance interval thereafter.

Page 18

22 - 18 TIRES/WHEELS DR/DH

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

1500 Series

Lug Nut 9/16 X 18 with

60° Cone

LD

2500 Series

Lug Nut 9/16 X 18 with

60° Cone

HD SRW

3500 Series

Lug Nut 9/16 X 18 with

Flat Washer

HD DRW

129 95 —

197 145 —

210 155 —

STUDS

REMOVAL

1. Raise and support the vehicle.

2. Remove the wheel and tire assembly.

3. Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/ROTORS - REMOVAL).

4. Remove the wheel speed sensor from the hub.

5. Press the stud from the hub using special tool

C-4150A (1).

6. Remove the stud (2) from the hub (1) through the

backing plate access hole (3).

Page 19

DR/DH TIRES/WHEELS 22 - 19

INSTALLATION

1. Install the new stud (2) into the hub flange (1).

2. Install three proper sized washers onto the stud,

then install lug nut with the flat side of the nut

against the washers.

3. Tighten the lug nut until the stud is pulled into the

hub flange. Verify that the stud is properly seated

into the flange.

4. Remove the lug nut and washers.

5. Install the brake rotor, caliper adapter, and caliper,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

ROTORS - INSTALLATION).

6. Install the wheel speed sensor.

7. Install the wheel and tire assembly, use new lug nut on the stud or studs that were replaced.

8. Remove the support and lower the vehicle.

WHEEL COVER

REMOVAL

NOTE: The hub caps must be removed before raising the vehicle off the ground.

NOTE: You must use the flat end of the hub/cap remover/installer combination tool to pry off the wheel

skins. Insert the flat tip completely and using a back and forth motion, loosen the wheel skin. repeat this

procedure around the tire until the wheel skin pops off.

1. On 2500/3500 single rear wheel (SRW) models, insert a hub/cap remover/installer combination tool using the

blade on the end of the tool to pry the cap off in a back and forth motion.

2. On 3500 models with dual rear wheels (DRW), you must first remove the hub caps. The hub/cap remover/installer combination tool must be inserted in the pry off notch of the rear hub caps.

3. Position the hub/cap remover/installer combination tool and pull out on the tool firmly. The cap should come off.

4. The wheel skins can now be removed from the wheel.

5. On 3500 models front hub caps use the hub/cap remover/installer combination tool to pry off the cap in a back

and forth motion. The wheel skins can now be removed.

INSTALLATION

REAR

1. Install one 1 1/2 in. valve stem extension on each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with a 10 in. or greater extension can be used to remove the

existing valve stem cap and install the extension.

2. Install one 1 in. valve stem extension on each outer wheel.

3. Align the cooling windows of the wheel skin with the cooling windows of the wheel. Seat one side of the wheel

skin’s retainer onto the wheel. Using a rubber mallet, strike thew wheel skin on the outer circumference. Strike at

several locations around the circumference until the skin is fully seated.

Page 20

22 - 20 TIRES/WHEELS DR/DH

NOTE: The wheel skin and the hub cap are fully seated when there is a consistent gap between the skin/cap

and the wheel.

4. Tug on the hub/cap wheel skin to ensure that they are properly installed.

FRONT

1. Align the valve stem with the notch in the wheel skin.

2. Seat on side of the wheel skin’s wire retainer on to the wheel.

3. Using a rubber mallet, strike the opposite side of the wheel skin until the skin is properly seated.

NOTE: The wheel skin and the hub cap are fully seated when there is a consistant gap between the skin/

cap and the wheel.

4. Tug on the hub cap/wheel skin to ensure that they are properly installed.

SPARE TIRE

DESCRIPTION

SPARE / TEMPORARY TIRE

The temporary spare tire is designed for emergency use only. The original tire should be repaired or replaced at the

first opportunity, then reinstalled. Do not exceed speeds of 50 M.P.H. when using the temporary spare tire. Refer to

Owner’s Manual for complete details.

FULL SIZE, SPARE WHEEL WITH MATCHING TIRE

The spare is a full usage wheel with a matching tire, It can be used within the (posted legal) speed limits or distance

limitations as of the rest of the vehicles four tires. Refer to Owner’s Manual for complete details.

Loading...

Loading...