DR TIRES/WHEELS 22 - 1

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT ......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE ROTATION . 2

STANDARD PROCEDURE - MATCH

MOUNTING ...........................3

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE ......................4

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE /

TEMPORARY .........................5

DESCRIPTION - TIRES ..................5

DESCRIPTION - RADIAL – PLY TIRES ......6

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEEDS.........................6

DESCRIPTION - REPLACEMENT TIRES .....6

DESCRIPTION - TIRE INFLATION

PRESSURES ..........................6

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES .............................7

DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION ........................7

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS ..........................7

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS ...........................8

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD................................8

STANDARD PROCEDURE - REPAIRING

LEAKS ..............................10

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE ..........10

WHEELS

DESCRIPTION .........................11

OPERATION ...........................11

DIAGNOSIS AND TESTING

WHEEL INSPECTION ..................11

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................12

STANDARD PROCEDURE - DUAL REAR

WHEEL INSTALLATION .................12

SPECIFICATIONS

TORQUE CHART ......................13

STUDS

REMOVAL .............................14

INSTALLATION .........................14

WHEEL COVER

REMOVAL .............................14

INSTALLATION

INSTALLATION - REAR .................14

INSTALLATION - FRONT ................15

SPARE TIRE

DESCRIPTION

DESCRIPTION - SPARE / TEMPORARY

TIRE ...............................15

DESCRIPTION - FULL SIZE, SPARE WHEEL

WITH MATCHING TIRE .................15

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is the wobble of the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

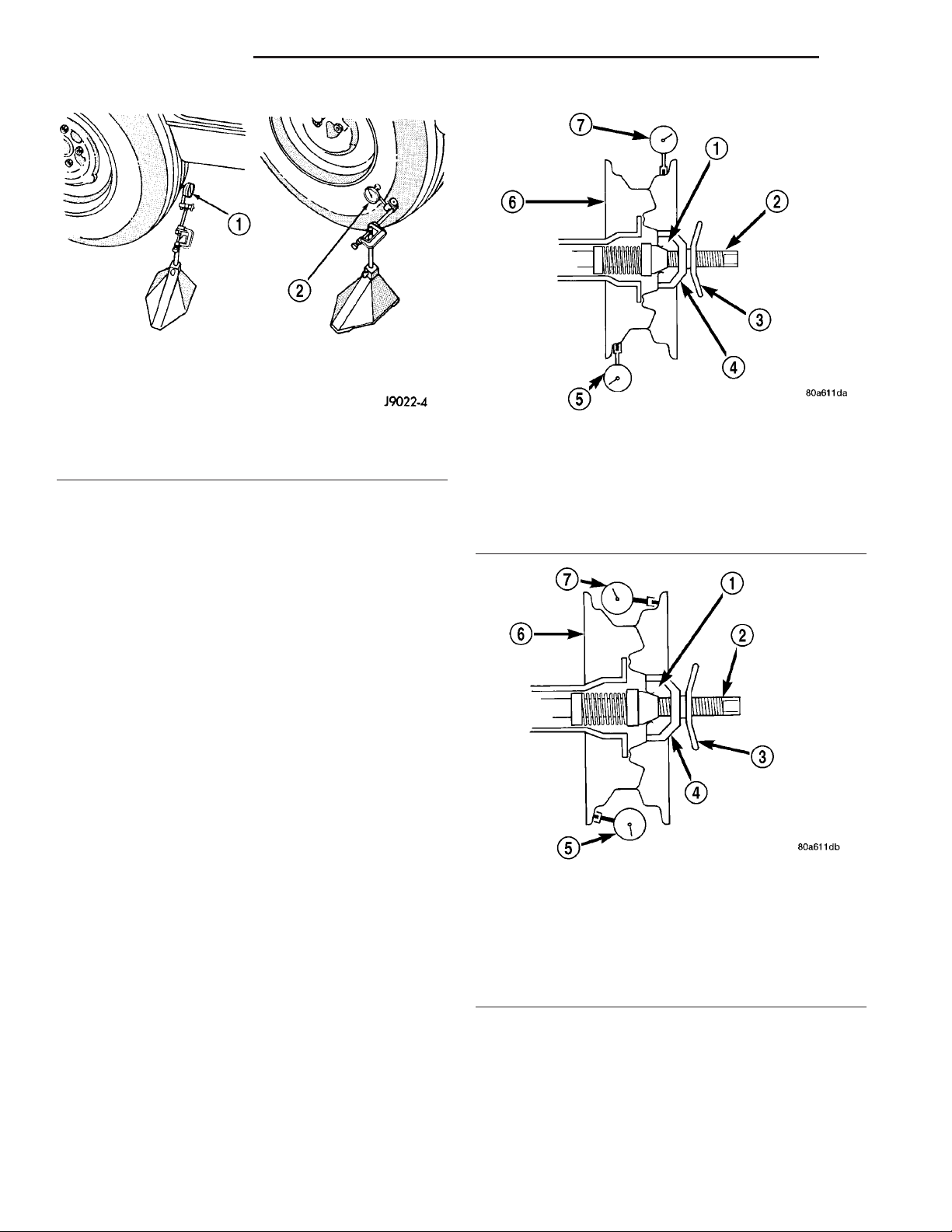

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

22 - 2 TIRES/WHEELS DR

TIRES/WHEELS (Continued)

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

• STEEL WHEELS: Radial runout 0.031 in., Lat-

eral runout 0.031 in. (maximum)

• ALUMINUM WHEELS: Radial runout 0.020 in.,

Lateral runout 0.025 in. (maximum)

(3) If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees.

Recheck runout, Refer to match mounting procedure.

STANDARD PROCEDURE

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

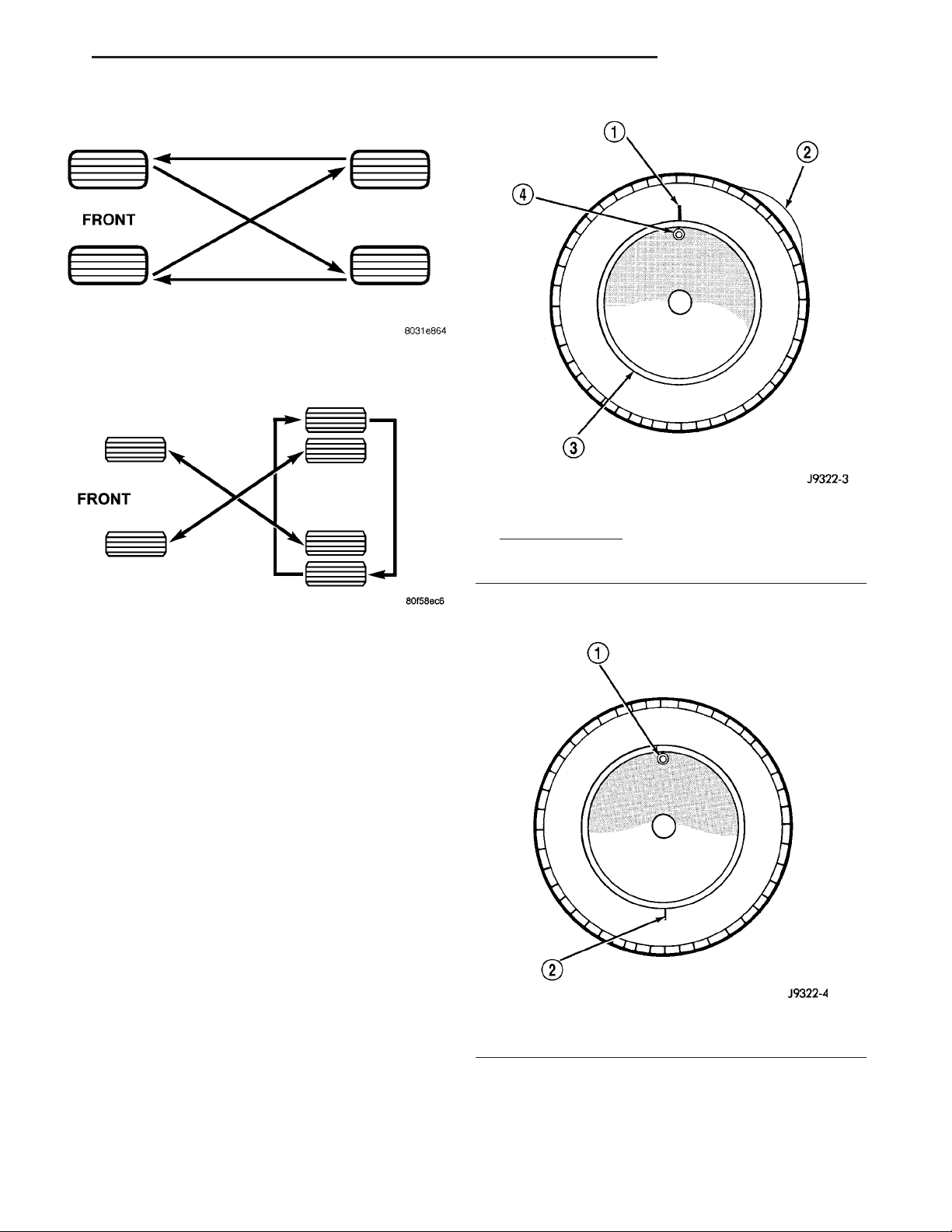

STANDARD PROCEDURE - TIRE ROTATION

Tires on the front and rear axles operate at different loads and perform different steering, driving, and

braking functions. For these reasons, the tires wear

at unequal rates. They may also develop irregular

wear patterns. These effects can be reduced by rotating the tires according to the maintenance schedule

in the Owners Manual. This will improve tread life,

traction and maintain a smooth quiet ride.

The recommended method of tire rotation is (Fig.

4) & (Fig. 5). Other methods can be used, but may

not provide the same tire longevity benefits.

CAUTION: 3500 Dual rear tires have a new tire rotation pattern. This is to accommodate the asymmet-

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

rical design of the ON/OFF road tires and the use of

the outlined white letter (OWL) tires. When replacing a flat, the spare tire may have to be remounted

on the rim or installed at a different location to

maintain the correct placement of the asymmetrical

design or the (OWL).

DR TIRES/WHEELS 22 - 3

TIRES/WHEELS (Continued)

Fig. 4 TIRE ROTATION PATTERN - SINGLE REAR

WHEEL (SRW)

Fig. 6 First Measurement On Tire

1 - REFERENCE MARK

2 - 1ST MEASUREMENT

HIGH SPOT MARK TIRE AND RIM

3 - WHEEL

4 - VALVE STEM

Fig. 5 TIRE ROTATION PATTERN - DUAL REAR

WHEELS (DRW)

STANDARD PROCEDURE - MATCH MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. Each are marked

with a bright colored temporary label on the outboard surface for alignment. The wheel is also

marked permanently on the inside of the rim in the

tire well. This permanent mark may be a paint dot

or line, a permanent label or a stamped impression

such as an X. An optional location mark is a small

spherical indentation on the vertical face of the outboard flange on some non styled base steel wheels.

The tire must be removed to locate the permanent

mark on the inside of the wheel.

Before dismounting a tire from its wheel, a reference mark should be placed on the tire at the valve

stem location. This reference will ensure that it is

remounted in the original position on the wheel.

(1) Remove the tire and wheel assembly from the

vehicle and mount on a service dynamic balance

machine.

(2) Measure the total runout on the center of the

tire tread rib with a dial indicator. Record the indicator reading. Mark the tire to indicate the high spot.

Place a mark on the tire at the valve stem location

(Fig. 6).

(3) Break down the tire and remount it 180

degrees on the rim (Fig. 7).

Fig. 7 Remount Tire 180 Degrees

1 - VALVE STEM

2 - REFERENCE MARK

(4) Measure the total indicator runout again. Mark

the tire to indicate the high spot.

(5) If runout is still excessive, the following proce-

dures must be done.

22 - 4 TIRES/WHEELS DR

TIRES/WHEELS (Continued)

This procedure will normally reduce the runout to an

acceptable amount, if not replace the rim.

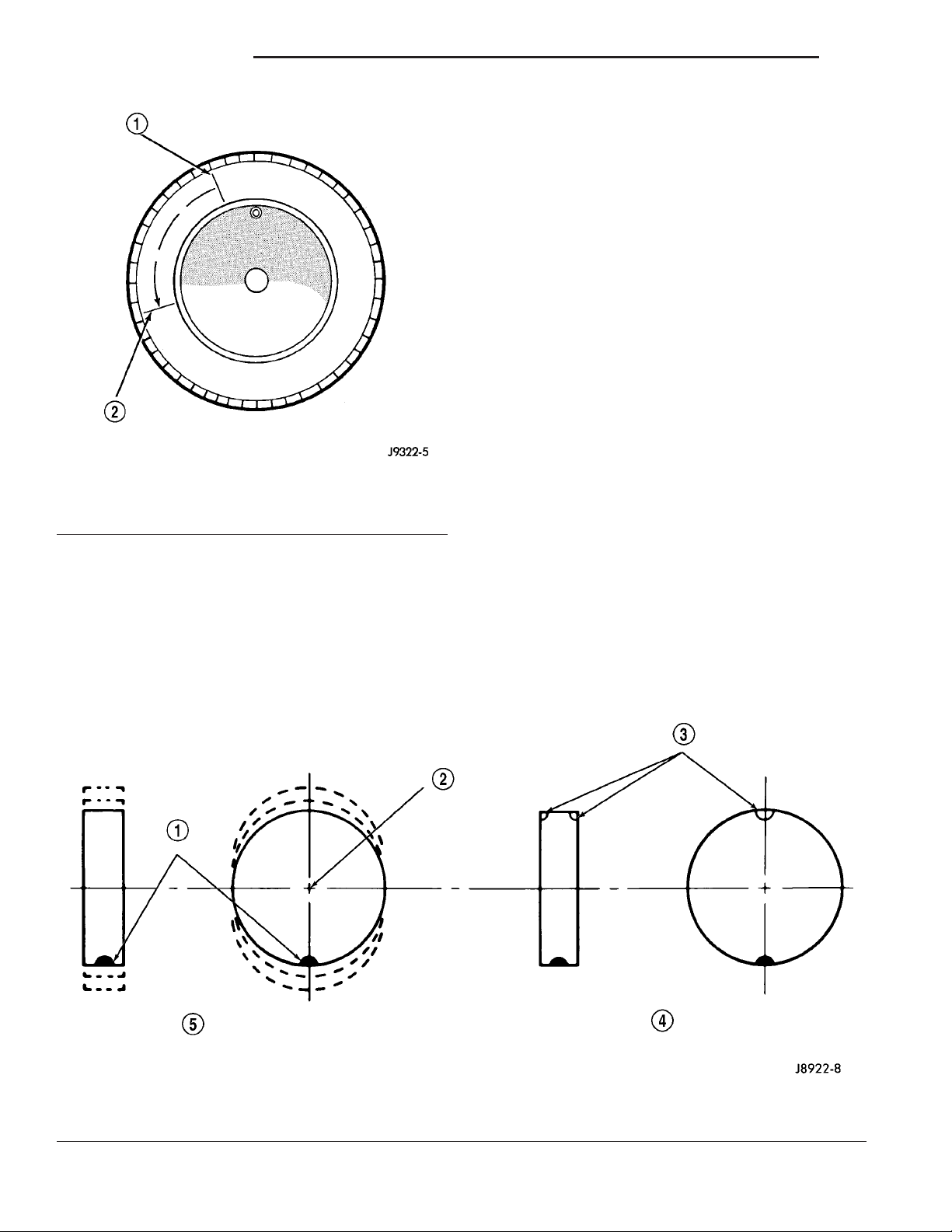

STANDARD PROCEDURE - TIRE AND WHEEL

BALANCE

It is recommended that a two plane service

dynamic balancer be used when a tire and wheel

assembly require balancing. Refer to balancer operation instructions for proper cone mounting procedures. Typically use front cone mounting method for

steel wheels. For aluminum wheel use back cone

mounting method without cone spring.

NOTE: Static should be used only when a two plane

balancer is not available.

NOTE: Cast aluminum and forged aluminum wheels

require coated balance weights and special align-

Fig. 8 Remount Tire 90 Degrees In Direction of

Arrow

1 - 2ND HIGH SPOT ON TIRE

2 - 1ST HIGH SPOT ON TIRE

• If the high spot is within 101.6 mm (4.0 in.) of

the first spot and is still excessive, replace the tire.

• If the high spot is within 101.6 mm (4.0 in.) of

the first spot on the wheel, the wheel may be out of

specifications. Refer to Wheel and Tire Runout.

•

If the high spot is NOT within 101.6 mm (4.0 in.)

of either high spot, draw an arrow on the tread from

second high spot to first. Break down the tire and

remount it 90 degrees on rim in that direction (Fig. 8).

ment equipment.

Wheel balancing can be accomplished with either

on or off vehicle equipment. When using on-vehicle

balancing equipment, remove the opposite wheel/tire.

Off-vehicle balancing is recommended.

For static balancing, find the location of the heavy

spot causing the imbalance. Counter balance wheel

directly opposite the heavy spot. Determine weight

required to counter balance the area of imbalance.

Place half of this weight on the inner rim flange and

the other half on the outer rim flange (Fig. 9).

1 - HEAVY SPOT

2 - CENTER LINE OF SPINDLE

3 - ADD BALANCE WEIGHTS HERE

Fig. 9 Static Unbalance & Balance

4 - CORRECTIVE WEIGHT LOCATION

5 - TIRE OR WHEEL TRAMP, OR WHEEL HOP

DR TIRES/WHEELS 22 - 5

TIRES/WHEELS (Continued)

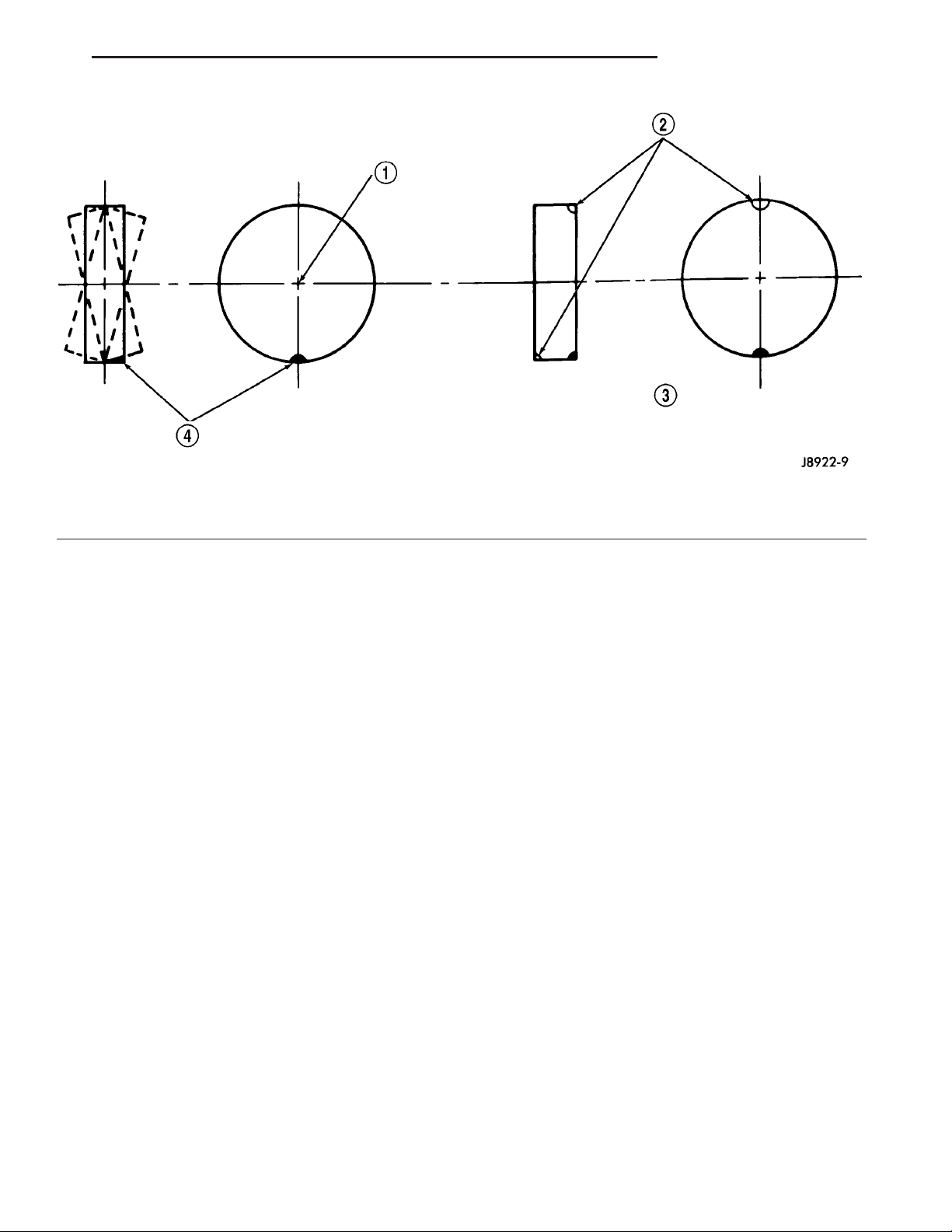

Fig. 10 Dynamic Unbalance & Balance

1 - CENTER LINE OF SPINDLE

2 - ADD BALANCE WEIGHTS HERE

3 - CORRECTIVE WEIGHT LOCATION

4 - HEAVY SPOT WHEEL SHIMMY AND VIBRATION

For dynamic balancing, the balancing equipment is

designed to locate the amount of weight to be applied

to both the inner and outer rim flange (Fig. 10).

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE / TEMPORARY

The temporary spare tire is designed for emergency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner’s Manual for

complete details.

DESCRIPTION - TIRES

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling characteristics match the vehicle’s requirements. With

proper care they will give excellent reliability, traction, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain in most

cases, much greater mileage than severe use or careless drivers. A few of the driving habits which will

shorten the life of any tire are:

• Rapid acceleration

• Severe brake applications

• High speed driving

• Excessive speeds on turns

• Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation interval shown in the section on Tire Rotation, (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE).

This will help to achieve a greater tread life.

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 11).

Performance tires have a speed rating letter after

the aspect ratio number. The speed rating is not

always printed on the tire sidewall. These ratings

are:

• Q up to 100 mph

• R up to 106 mph

• S up to 112 mph

• T up to 118 mph

• U up to 124 mph

• H up to 130 mph

• V up to 149 mph

• Z more than 149 mph (consult the tire manu-

facturer for the specific speed rating)

An All Season type tire will have either M+S,M

&SorM–S(indicating mud and snow traction)

imprinted on the side wall.

Loading...

Loading...