Page 1

DR STEERING 19 - 1

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION ..........................1

OPERATION ............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM ....................2

DIAGNOSIS AND TESTING - POWER

STEERING FLOW AND PRESSURE ........4

SPECIAL TOOLS

STEERING ...........................5

STEERING

DESCRIPTION

CAUTION: MOPART ATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

Power steering systems consist of:

• Steering column

• Rack and pinion steering gear

• Belt driven hydraulic steering pump

• Pump pressure and return hoses

• Oil Cooler

OPERATION

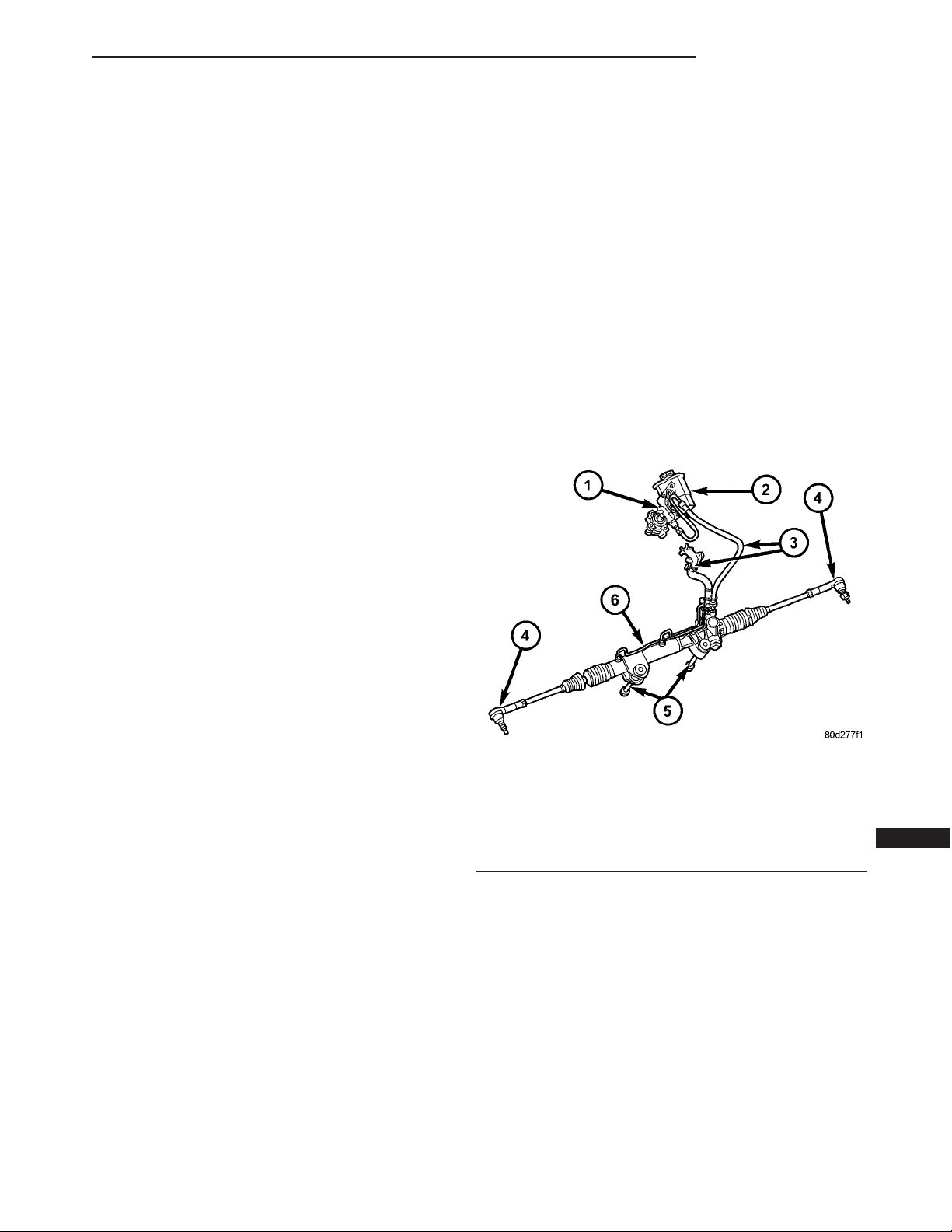

The steering column shaft is attached to the gear

pinion. The rotation of the pinion moves the gear

rack from side-to-side. This lateral action of the rack

pushes and pulls the tie rods to change the direction

of the front wheels (Fig. 1).

Power assist is provided by an engine mounted

hydraulic pump which supplies hydraulic fluid pressure to the steering gear.

COLUMN ...............................6

GEAR - INDEPENDENT FRONT SUSPENSION ..16

GEAR - LINK/COIL .......................19

LINKAGE - INDEPENDENT FRONT

SUSPENSION ...........................31

LINKAGE - LINK/COIL ....................33

PUMP .................................38

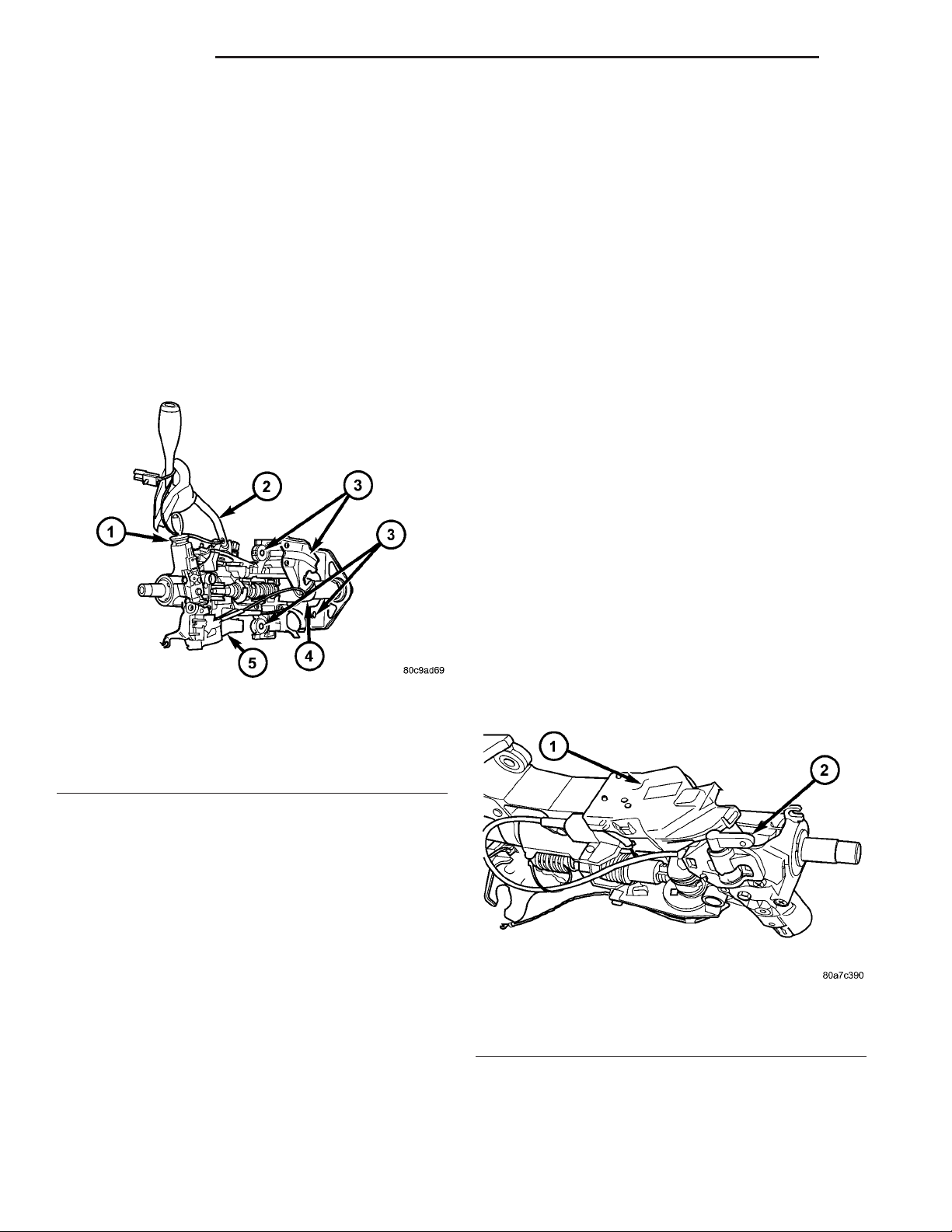

Fig. 1 STEERING COMPONENTS

1 - POWER STEERING PUMPASSEMBLY

2 - RESERVOIR

3 - HOSES

4 - TIE ROD ENDS

5 - MOUNTING BOLTS

6 - RACK & PINION

Page 2

19 - 2 STEERING DR

STEERING (Continued)

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM

There is some noise in all power steering systems. One of the most common is a hissing sound evident at a

standstill parking. Or when the steering wheel is at the end of it’s travel. Hiss is a high frequency noise similar

to that of a water tap being closed slowly. The noise is present in all valves that have a high velocity fluid passing

through an orifice. There is no relationship between this noise and steering performance.

STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONAL HISS OR

WHISTLE

RATTLE OR CLUNK 1. Gear mounting bolts loose. 1. Tighten bolts to specification.

CHIRP OR SQUEAL 1. Loose belt. 1. Adjust or replace.

WHINE OR GROWL 1. Low fluid level. 1. Fill to proper level.

1. Steering intermediate shaft to dash panel

seal.

2. Noisy valve in power steering gear. 2. Replace steering gear.

2. Loose or damaged suspension

components.

3. Internal gear noise. 3. Replace steering gear.

4. Pressure hose in contact with other

components.

5. Loose or damaged intermediate shaft or

column.

2. Pressure hose in contact with other

components.

3. Internal pump noise. 3. Replace pump.

4. Air in fluid 4. Check for lekas, Evacuate air

1. Check and repair seal at dash

panel.

2. Inspect and repair suspension.

4. Reposition hose.

5. Inspect and repair or replace.

2. Reposition hose.

from P/S system.

SUCKING AIR SOUND 1. Loose return line clamp. 1. Replace clamp.

SCRUBBING OR

KNOCKING

2. O-ring missing or damaged on hose

fitting.

3. Low fluid level. 3. Fill to proper level.

4. Air leak between pump and reservoir. 4. Repair as necessary.

5. Reservoir cap not installed correctly. 5. Install reservoir cap correctly.

1. Wrong tire size. 1. Verify tire size.

2. Replace o-ring.

Page 3

DR STEERING 19 - 3

STEERING (Continued)

BINDING AND STICKING

CONDITION POSSIBLE CAUSE CORRECTION

DIFFICULT TO TURN WHEEL

STICKS OR BINDS

INSUFFICIENT ASST. OR POOR RETURN TO CENTER

CONDITION POSSIBLE CAUSE CORRECTION

HARD TURNING OR MOMENTARY

INCREASE IN TURNING EFFORT

1. Low fluid level. 1. Fill to proper level.

2. Tire pressure. 2. Adjust tire pressure.

3. Steering components (ball

joints/tie rod ends).

4. Loose belt. 4. Adjust or replace.

5. Low pump pressure. 5. Pressure test and replace if

6. Column shaft coupler binding. 6. Replace coupler.

7. Steering gear worn. 7. Replace gear.

8. Pump seized / Stuck valve 8. Replace pump.

1. Tire pressure. 1. Adjust tire pressure.

2. Low fluid level. 2. Fill to proper level.

3. Loose belt. 3. Adjust or replace.

4. Low pump pressure. 4. Pressure test and repair as

5. Internal gear leak. 5. Replace gear.

3 Inspect and repair as necessary.

necessary.

necessary.

STEERING WHEEL DOES NOT

WANT TO RETURN TO CENTER

POSITION

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE PLAY IN STEERING

WHEEL

VEHICLE PULLS OR LEADS TO

ONE SIDE.

1. Tire pressure. 1. Adjust tire pressure.

2. Wheel alignment. 2. Align front end.

3. Lack of lubrication. 3. Inspect and lubricate suspension

compnents.

4. High friction in steering gear. 4. Replace gear.

LOOSE STEERING AND VEHICLE LEAD

1. Worn or loose suspension or

steering components.

2. Worn or loose wheel bearings. 2. Inspect and repair or adjust

3. Steering gear mounting. 3. Tighten gear mounting bolts to

4. Gear out of adjustment. 4. Replace gear.

5. Worn or loose steering coupler. 5. Inspect and replace as

1. Tire Pressure. 1. Adjust tire pressure.

2. Radial tire lead. 2. Rotate tires.

3. Brakes dragging. 3. Repair as necessary.

4. Wheel alignment. 4. Align front end.

1. Inspect and repair as necessary.

bearings.

specification.

necessary.

Page 4

19 - 4 STEERING DR

STEERING (Continued)

DIAGNOSIS AND TESTING - POWER STEERING

FLOW AND PRESSURE

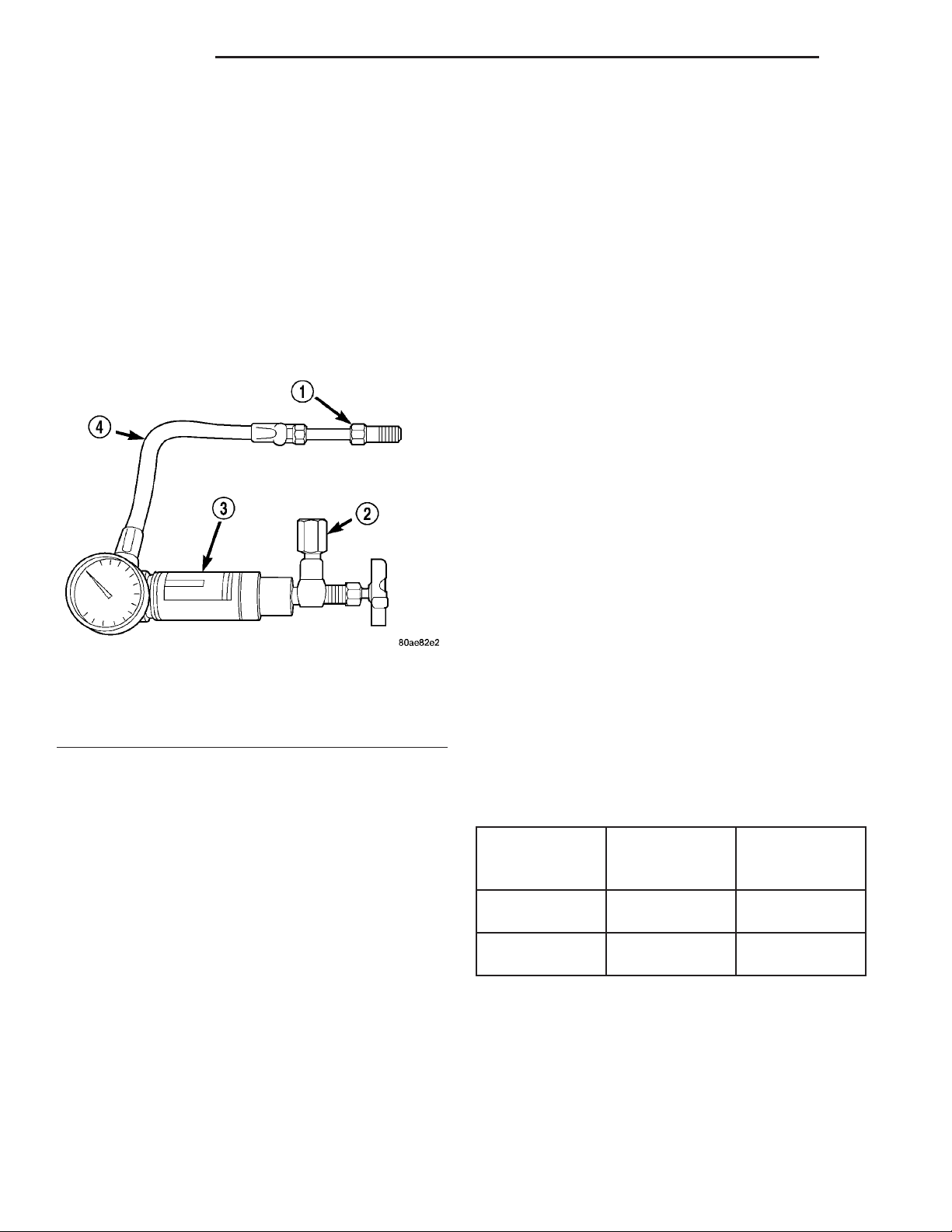

The following procedure is used to test the operation of the power steering system on the vehicle. This

test will provide the gallons per minute (GPM) or

flow rate of the power steering pump along with the

maximum relief pressure. Perform test any time a

power steering system problem is present. This test

will determine if the power steering pump or power

steering gear is not functioning properly. The following pressure and flow test is performed using Power

Steering Analyzer Tool kit 6815 and (Fig. 2) Adapter

Kit 6893.

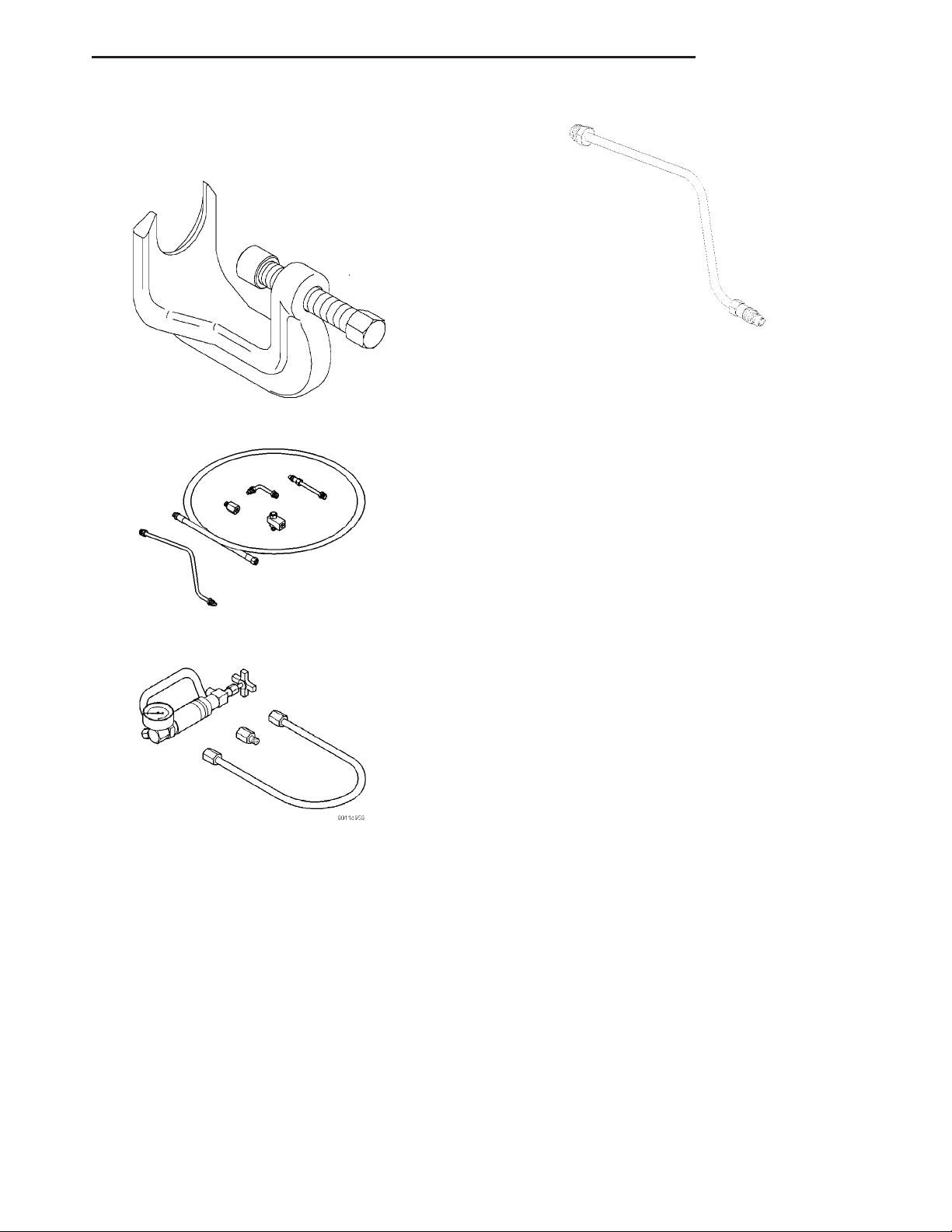

Fig. 2 Analyzer With Tube and Adapter

1 - TUBE

2 - ADAPTER FITTINGS

3 - ANALYZER

4 - GAUGE HOSE

FLOW AND PRESSURE TEST

(1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect pressure gauge hose from the Power

Steering Analyzer to adapter 6826.

(3) Connect tube 6825A to Power Steering Analyzer test valve end.

(4) Disconnect the high pressure hose from the

power steering pump.

(5) Connect the tube 6825A to the pump fitting.

(6) Connect the power steering hose from the

steering gear to the adapter 6826.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circulate power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.

(9) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(10) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

(11) Increase the engine speed to 1500 RPM and

read the flow meter. If the flow rate (GPM) is below

specification, (refer to pump specification chart for

GPM) the pump should be replaced.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than three seconds as the pump could be

damaged.

(12) Close valve fully three times and record highest pressure indicated each time. All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

• Pressures above specifications but not within

345 kPa (50 psi) of each other, replace pump.

• Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

(13) Open the test valve and turn the steering

wheel to the extreme left and right positions three

times against the stops. Record the highest pressure

reading at each position. Compare readings to the

pump specifications chart. If pressures readings are

not within 50 psi of each other, the gear is leaking

internally and must be replaced.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 3 seconds at a time

because, pump damage will result.

PUMP SPECIFICATION

ENGINE

1500 series

2500 & 3500

series

RELIEF

PRESSURE ±

65

11032 kPa

(1615 ± 65 psi)

12400 kPa

(1800 ± 50 psi)

FLOW RATE

(GPM) AT 1500

RPM

3.1 - 3.5

3.5 - 4.0

Page 5

DR STEERING 19 - 5

STEERING (Continued)

SPECIAL TOOLS

STEERING

ADAPTER, POWER STEERING FLOW/PRESSURE -

6825A

PULLER - 8677

ADAPTERS, POWER STEERING FLOW/PRESSURE

TESTER - 6893

ANALYZER SET, POWER STEERING FLOW/

PRESSURE 6815

Page 6

19 - 6 COLUMN DR

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION ..........................6

DIAGNOSIS AND TESTING - STEERING

COLUMN .............................7

REMOVAL .............................7

INSTALLATION ..........................9

IGNITION SWITCH

DESCRIPTION ..........................9

OPERATION ............................9

DIAGNOSIS AND TESTING - IGNITION

SWITCH .............................9

REMOVAL .............................10

INSTALLATION .........................11

KEY-IN IGNITION SWITCH

DESCRIPTION .........................11

DIAGNOSIS AND TESTING - IGNITION

SWITCH AND KEY LOCK CYLINDER .......11

KEY CYLINDER

REMOVAL .............................12

COLUMN

DESCRIPTION

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will

have to be used.

INSTALLATION .........................12

GEAR SHIFT LEVER

REMOVAL .............................12

INSTALLATION .........................12

UPPER STEERING COUPLING

REMOVAL .............................13

INSTALLATION .........................14

LOWER STEERING COUPLING

REMOVAL

REMOVAL - ALL LD & HD EXCEPT 4X4 HD . 14

REMOVAL - 4X4 HD ...................14

INSTALLATION

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD.................................15

INSTALLATION - 4X4 HD ................15

STEERING WHEEL

REMOVAL .............................15

INSTALLATION .........................15

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COATINGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

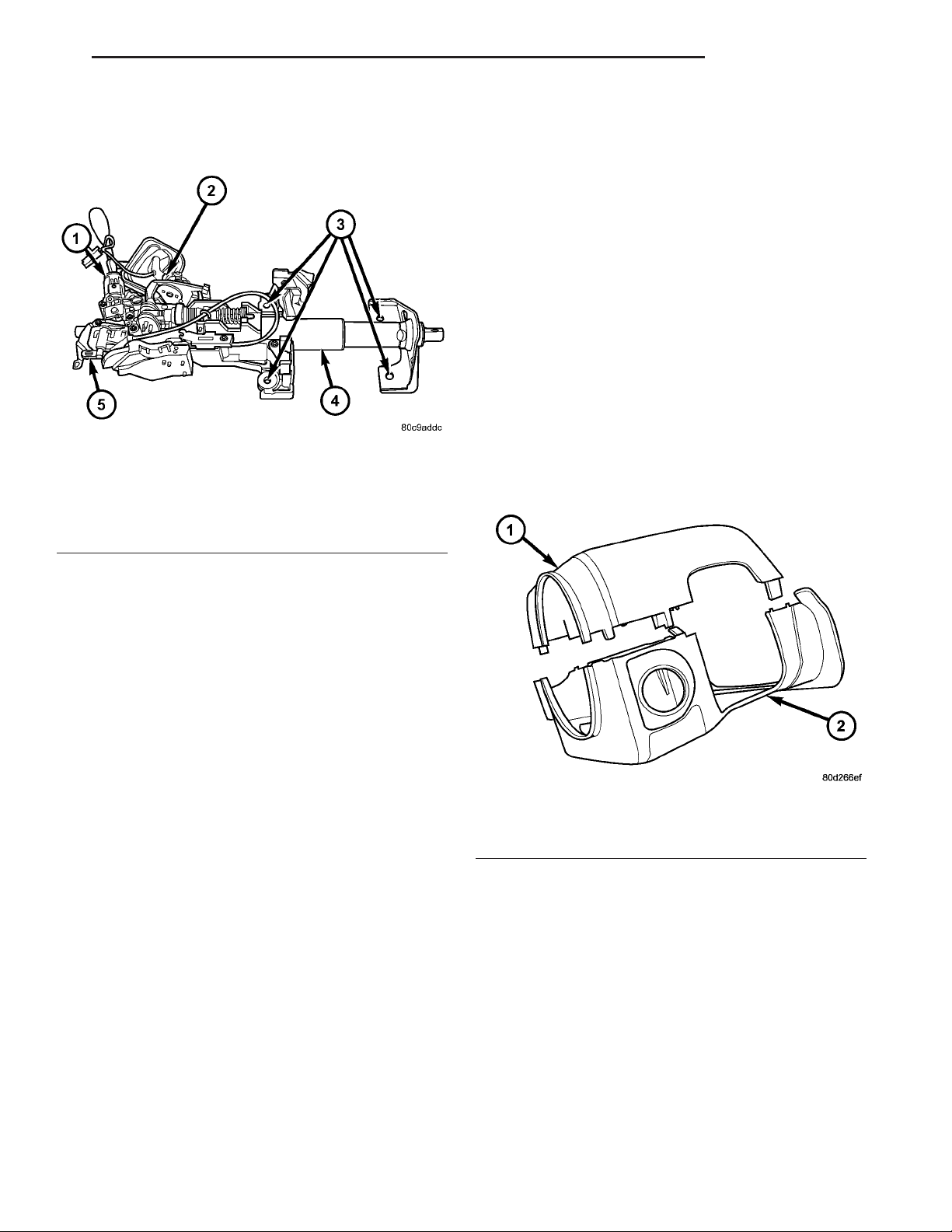

The tilt and standard column (Fig. 1) has been

designed to be serviced as an assembly; less wiring,

switches, shrouds, steering wheel, etc. Most steering

column components can be serviced without removing the steering column from the vehicle.

To service the steering wheel, switches or airbag,

refer to Restraints and follow all WARNINGS and

CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DISCHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bearing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism. Do not

remove shaft lock plate or plate retainer. This will

damage the column.

CAUTION: Do not attempt to remove or modify the

park lock slider or link.

NOTE: When servicing the steering wheel after

removing the old bolt a new bolt must be used

when installing.

Page 7

DR COLUMN 19 - 7

COLUMN (Continued)

NOTE: When servicing the coupler a new bolt must

be used when installing.

Fig. 1 STEERING COLUMN

1 - LOCK CYLINDER

2 - GEAR SHIFT LEVER

3 - MOUNTING HOLES

4 - STEERING COLUMN

5 - TILT LEVER

(1) Position the front wheels straight ahead.

(2) Disconnect the negative (ground) cable from

the battery.

(3) Remove the two switches from the steering

wheel.

(4) Remove the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(5) Remove the steering wheel with special tool

CJ98–1 or an appropriate steering wheel puller.

CAUTION: Ensure the puller bolts are fully engaged

into the steering wheel and not into the clockspring, before attempting to remove the wheel. Failure to do so may damage the steering wheel/

clockspring.

(6) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEERING COLUMN OPENING COVER - REMOVAL).

(7) Remove the tilt lever.

(8) Remove the column shrouds (Fig. 2).

DIAGNOSIS AND TESTING - STEERING

COLUMN

If the vehicle is involved in a front end collision/the

air bag has deployed the column must be inspected.

This inspection will determine if the Column has collapsed. Inspect the column mounting capsules visually and manually push and pull them to check for

separation or fractures. If capsules are fractured or

have moved the column MUST be replaced.

REMOVAL

WARNING: BEFORE SERVICING THE STEERING

COLUMN THE AIRBAG SYSTEM MUST BE DISARMED. REFER TO ELECTRICAL RESTRAINT SYSTEM FOR SERVICE PROCEDURES. FAILURE TO DO

SO MAY RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIRBAG AND POSSIBLE PERSONAL INJURY.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering

column.

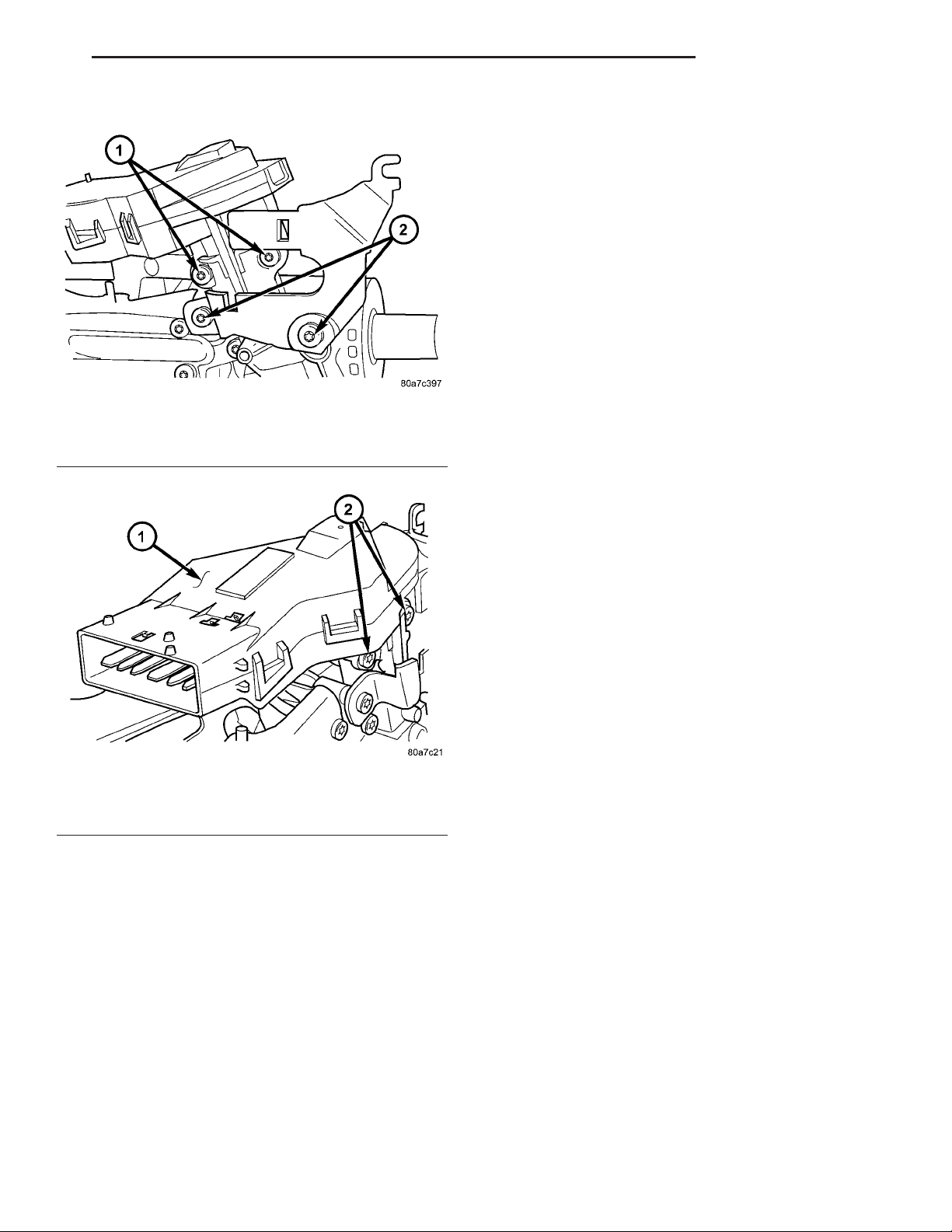

Fig. 2 UPPER & LOWER SHROUDS

1 - UPPER SHROUD

2 - LOWER SHROUD

(9) Remove the clock spring, (Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

(10) Disconnect the wiring harness to the column.

(11) Remove the shift cable from the column shift

lever actuator (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 32RH/GEAR SHIFT

CABLE - REMOVAL). (Fig. 3).

Page 8

19 - 8 COLUMN DR

COLUMN (Continued)

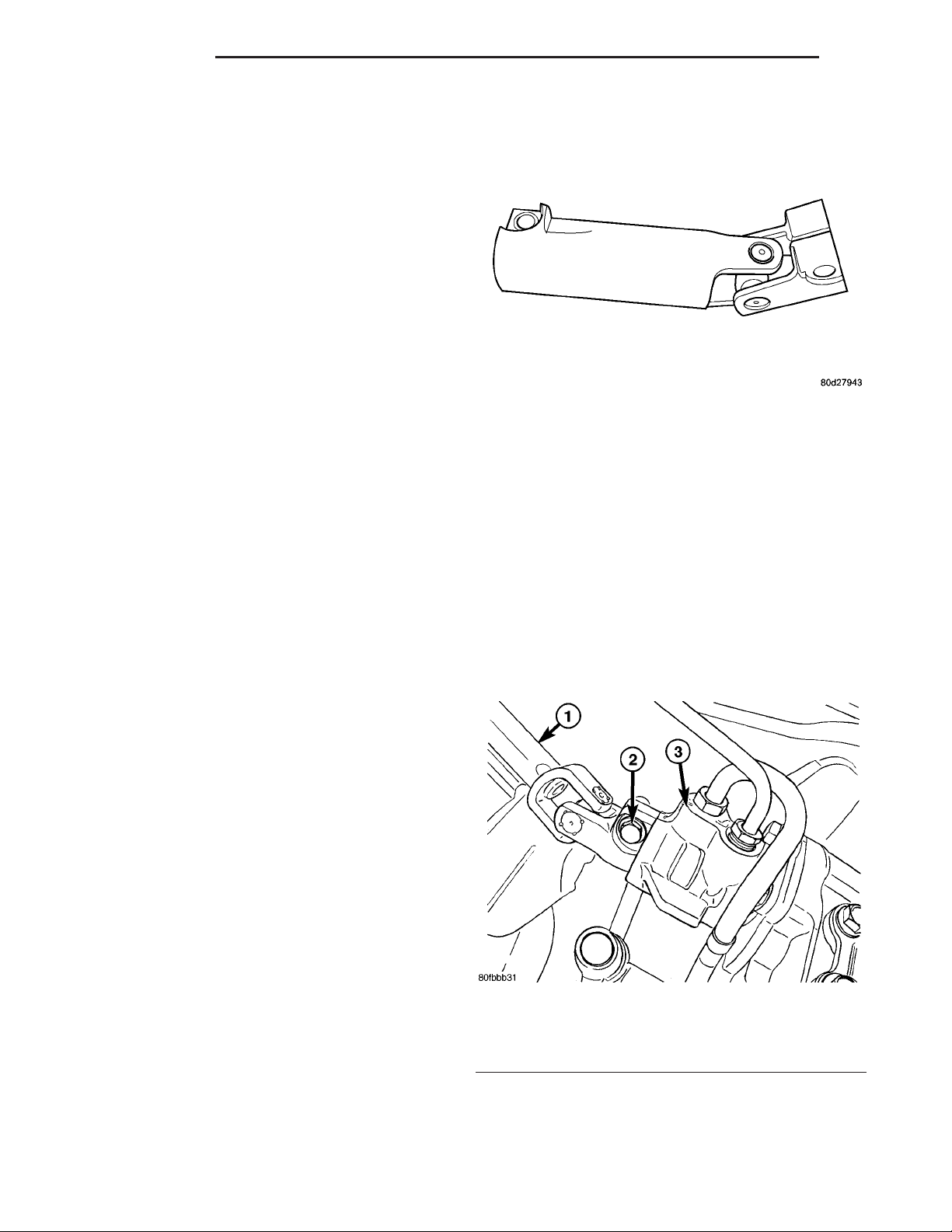

Fig. 3 SHIFT CABLE CONNECTOR

1 - Shift lever

2 - Cable Connection

3 - Overdrive Electrical Wiring

4 - Mounting Screws

(12) Release the shift cable from the column

bracket and remove it from the bracket.

(13) Remove the SKIM module in order to discon-

nect the electrical connector.

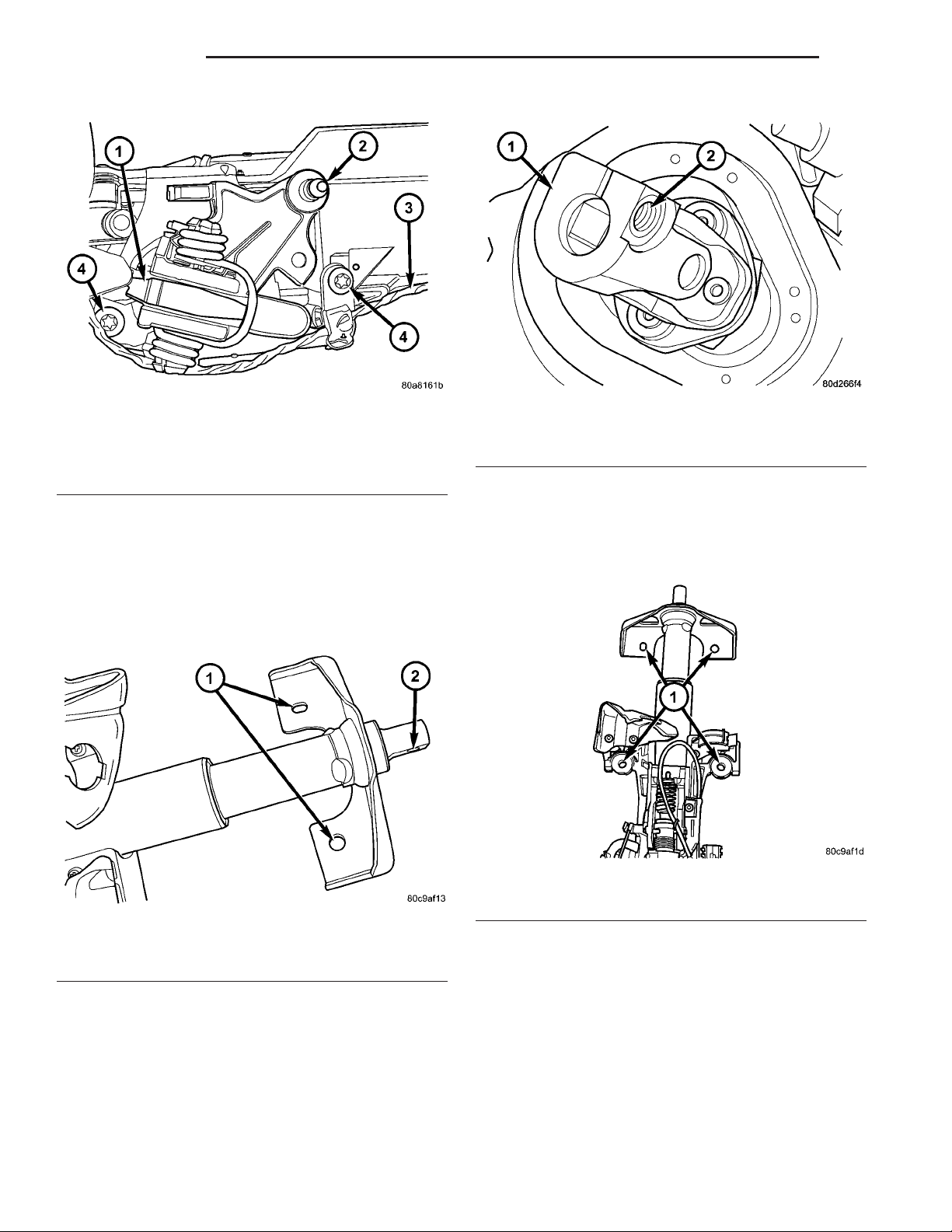

(14) Remove the upper steering shaft coupler bolt

and slide the shaft down (Fig. 4) & (Fig. 5)

Fig. 5 UPPER STEERING COUPLER

1 - STEERING COUPLER

2 - PINCH BOLT HOLE

(15) Remove the brake light switch and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

(16) Remove the four steering column mounting

nuts (Fig. 6).

Fig. 4 COUPLER SHAFT

1 - MOUNTING HOLES

2 - COUPLER BOLT HOLE

Fig. 6 MOUNTING HOLES

1 - MOUNTING HOLES

(17) Remove the steering column assembly from

the vehicle. (Fig. 7)

Page 9

DR COLUMN 19 - 9

COLUMN (Continued)

(7) Install the shifter cable. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 32RH/GEAR

SHIFT CABLE - INSTALLATION)

(8) Connect the wiring harness to the column.

(9) Install the SKIM module.

(10) Install the clockspring(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

(11) Install the shrouds.

(12) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEERING COLUMN OPENING COVER - INSTALLATION).

(13) Align the spline on the wheel hub to shaft.

(14) Then install the steering wheel and install a

new bolt. Tighten the bolt to 61 N·m (45 ft. lbs.).

(15) Install the airbag (Refer to 8 - ELECTRICAL/

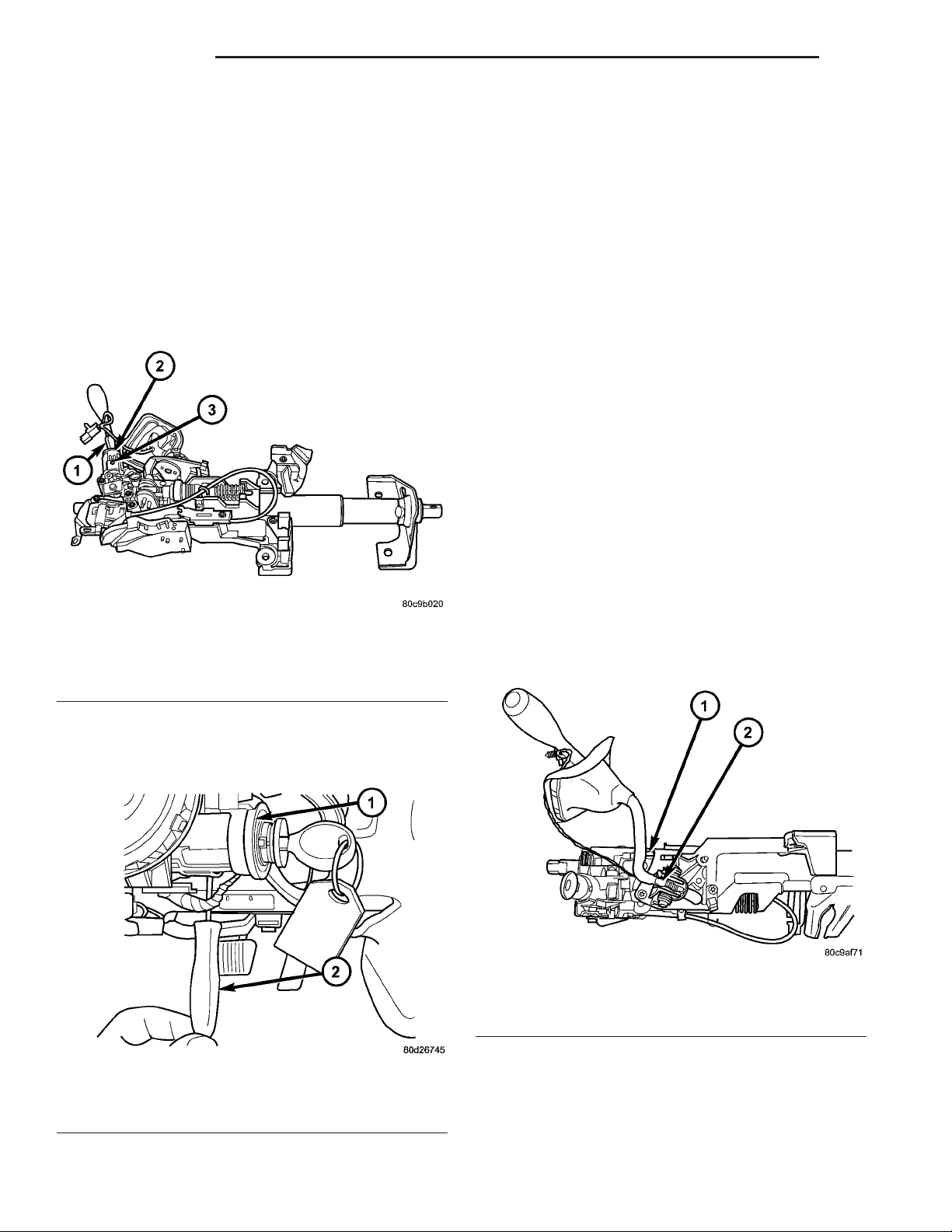

Fig. 7 STEERING COLUMN

1 - Steering Wheel

2 - Key Cylinder

3 - Gear Shift Lever

4 - Steering Column

5 - Tilt Lever Cable

INSTALLATION

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(16) Install the two steering wheel switches.

(17) Install the tilt lever handle.

(18) Install the negative battery terminal.

(19) Test the operation of the horn, Electronic

PRNDL Indicator, lights and any other functions that

are steering column operated.

WARNING: BEFORE SERVICING THE STEERING

COLUMN THE AIRBAG SYSTEM MUST BE DISARMED. REFER TO ELECTRICAL RESTRAINT SYSTEM FOR SERVICE PROCEDURES. FAILURE TO DO

SO MAY RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIRBAG AND POSSIBLE PERSONAL INJURY.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering

column.

(1) Position the steering column on the dash panel

support and loosely install the mounting nuts.

(2) Firmly slide the steering column upward

against the studs in dash panel and hand tighten the

nuts.

(3) Install the steering shaft coupler on the steering shaft and loosely install a new bolt.

(4) Center steering column in dash opening and

tighten mounting nuts to 28 N·m (250 in. lbs.).

NOTE: Torque the upper left nut first then the lower

right nut. Then torque the lower left nut then the

upper right nut.

NOTE: A new bolt must be used for reinstallation.

(5) Tighten the coupler bolt to 57 N·m (42 ft. lbs.).

(6) Install a new brake light switch (Refer to 8 ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

IGNITION SWITCH

DESCRIPTION

The ignition switch is located on the steering column. It is used as the main on/off switching device

for most electrical components. The mechanical key

cylinder is used to engage/disengage the electrical

ignition switch.

OPERATION

Vehicles equipped with an automatic transmission and a steering column mounted shifter:

an interlock device is located within the shift cable.

This interlock device is used to lock the transmission

shifter in the PARK position when the key cylinder is

in any position and the brake pedal is not depressed.

DIAGNOSIS AND TESTING - IGNITION SWITCH

TEST AND REPAIR

If the key removal effort is excessive on a vehicle

with a automatic transmission first adjust the shift

linkage, (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 46RE/GEAR SHIFT CABLE ADJUSTMENTS).

If the ignition switch effort is excessive remove the

ignition key cylinder from the steering column. (Refer

to 19 - STEERING/COLUMN/LOCK CYLINDER

HOUSING - REMOVAL). Check the turning effort of

the key cylinder. If the ignition key cylinder effort is

excessive replace the key cylinder.

Page 10

19 - 10 COLUMN DR

IGNITION SWITCH (Continued)

REMOVAL

SERVICE PRECAUTIONS

NOTE: The steering column on vehicles equipped

with an automatic transmission is not equipped

with an internal locking shaft with the ignition cylinder. Alternative methods of locking the steering

wheel for service will have to be used.

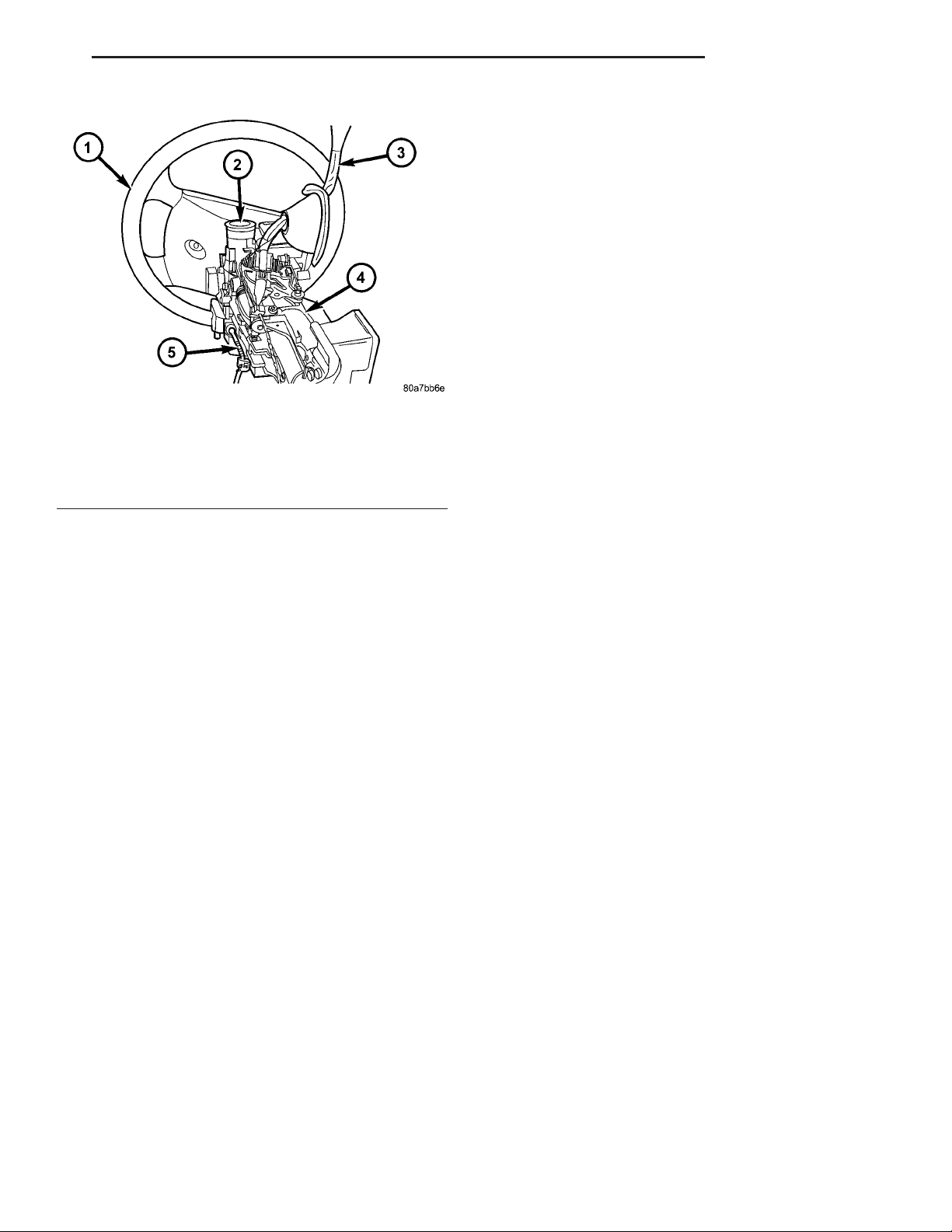

The tilt and standard column (Fig. 8) have been

designed to be serviced as an assembly; without wiring, switches, shrouds, steering wheel, etc. Most

steering column components can be serviced without

removing the steering column from the vehicle.

Fig. 8 STEERING COLUMN

1 - KEY CYLINDER

2 - GEAR SHIFT LEVER

3 - MOUNTING HOLES

4 - STEERING COLUMN

5 - IGNITION SWITCH

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bearing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism.

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Remove the negative (ground) cable from the

battery.

(2) Disable the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(3) Remove the lower and upper shrouds.

(4) Remove key cylinder. (Refer to 19 - STEERING/COLUMN/LOCK CYLINDER HOUSING REMOVAL).

(5) Disconnect the lower clockspring connectors.

(6) Remove the wire retainer from the tilt lever

bracket.

(7) Remove the tilt lever mounting screws to gain

access to the ignition switch mounting screws. (Fig.

9)

Safety goggles should be worn at all times when

working on steering columns.

To service the steering wheel, switches or airbag,

Refer to Electrical Restraints and follow all WARNINGS and CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DISCHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COATINGS AND ARE SPECIFICALLY DESIGNED FOR THE

Fig. 9 IGNITION SWITCH WITH TILT

1 - IGNITION SWITCH

2 - TILT LEVER MECHANISM

(8) For columns without tilt remove the bracket to

gain access to the ignition switch mounting screws.

(Fig. 10)

(9) Disconnect the electrical connector at rear of

ignition switch (Fig. 11).

Page 11

DR COLUMN 19 - 11

IGNITION SWITCH (Continued)

(3) Position switch to column and install the

mounting screw. Tighten screw to 3 N·m (26 in. lbs.).

(4) Install the tilt lever bracket mounting screws.

Tighten screws to 4.5 N·m (40 in. lbs.).

(5) If the column is non-tilt install the bracket.

Tighten screws to 4.5 N·m (40 in. lbs.) (Fig. 10)

(6) Position the wire retainer into the tilt lever

bracket.

(7) Reconnect the lower clockspring connectors.

(8) Install the key cylinder.

(9) Install steering column upper and lower

shrouds.

(10) Enable the airbag system. (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

Fig. 10 IGNITION SWITCH WITHOUT TILT

1 - Ignition Switch Mounting Screws

2 - Non-Tilt Mounitng Bracket Screws

Fig. 11 IGNITION SWITCH

1 - Ignition Switch

2 - Ignition Switch Mounting Screws

(10) Remove ignition switch mounting screw.

(11) Using a small screwdriver, push on locking

tab and remove switch from steering column.

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the ignition switch, which is mounted on the left side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition key cylinder and the driver

door ajar switch is closed (driver door is open). The

key-in ignition switch opens the ground path when

the key is removed from the ignition key cylinder.

The ground path is also opened when the driver door

ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced, (Refer to 19 - STEERING/COLUMN/IGNITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

AND KEY LOCK CYLINDER

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in the appropriate section of Electrical Wiring Diagrams.

INSTALLATION

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before installing ignition switch.

(1) Before installing ignition switch, rotate the slot

in the switch to the ON position.

(2) Connect the electrical connector to rear of the

ignition switch. Make sure that locking tabs are fully

seated into wiring connector.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

(Refer to 19 - STEERING/COLUMN/IGNITION

SWITCH - DIAGNOSIS AND TESTING).

Page 12

19 - 12 COLUMN DR

KEY CYLINDER

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal.

(1) Disconnect negative cable from battery.

(2) Remove upper and lower covers (shrouds) from

steering column.

(3) Place shifter in PARK position.

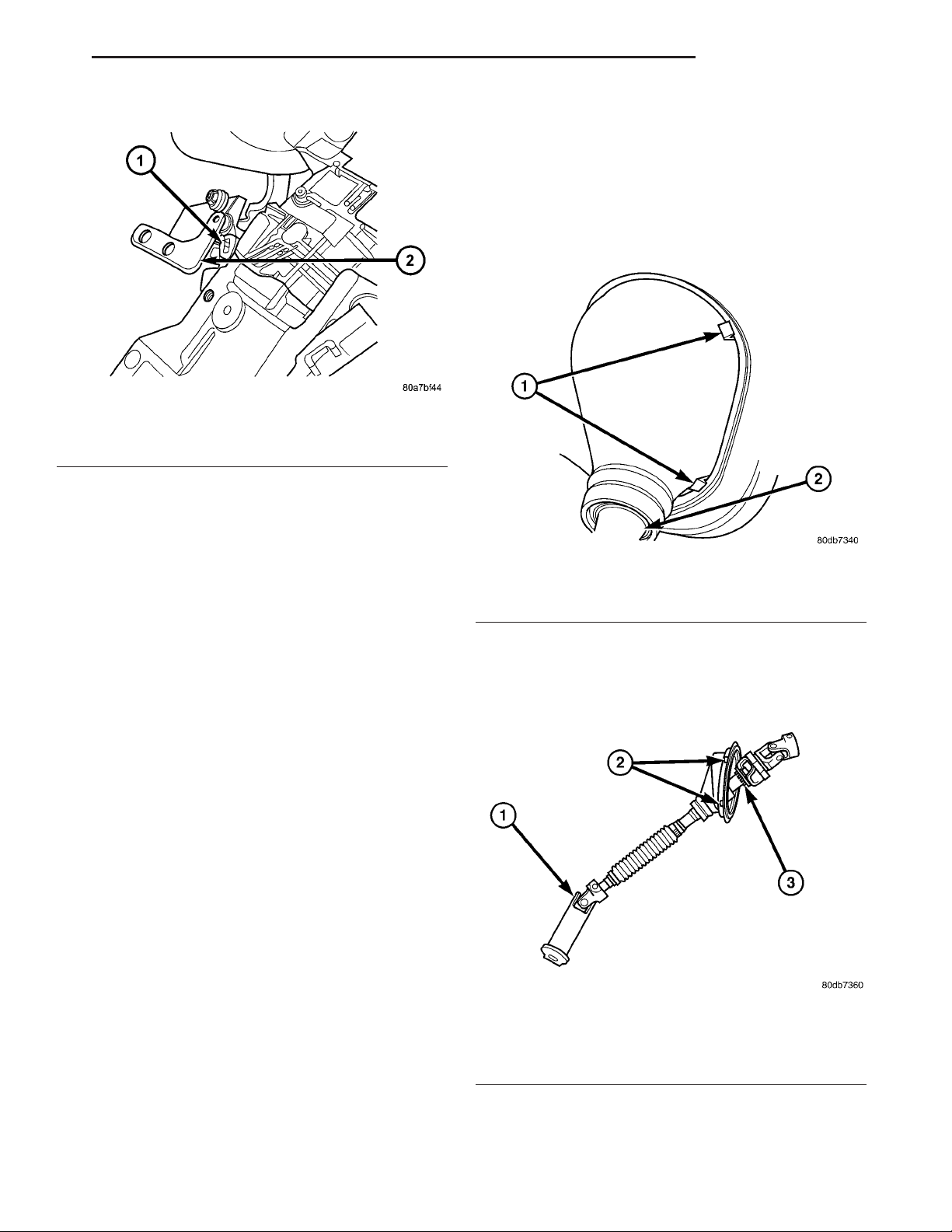

(4) A retaining pin (Fig. 12) is located at side of

key cylinder assembly.

Fig. 12 KEY CYLINDER

1 - KEY

2 - KEY CYLINDER

3 - RETAINING PIN HOLE

INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation.

(1) Install the key cylinder into the housing using

care to align the end of the key cylinder with the

ignition switch.

(2) Push the key cylinder in until it clicks.

(3) Replace the upper and lower shrouds.

(4) Reconnect the battery.

GEAR SHIFT LEVER

REMOVAL

(1) Remove the kneeblocker. (Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - REMOVAL).

(2) Remove the upper and lower column shroud.

(3) Remove and discard the brake light switch.

(4) Loosen the column bolts and lower the column

enough to allow clearance for the gear shift lever

removal.

(5) Disconnect the overdrive switch harness (if

equipped).

(6) Disconnect the shift cable from the shift lever.

(7) Remove the SKIM.

(8) Remove the gear shift lever mounting screws

and remove the lever. (Fig. 14)

(9) Remove the blocker pin from the inhibit link

slot (Fig. 14).

(a) Rotate key to RUN position.

(b) Press in on retaining pin while pulling key

cylinder from ignition switch (Fig. 13).

Fig. 13 KEY CYLINDER

1 - KEY CYLINDER

2 - PUNCH

Fig. 14 GEAR SHIFT LEVER

1 - PARK INHIBIT BLOCKER SPRING

2 - GEAR SHIFT LEVER

INSTALLATION

(1) Install the lever assembly using care to install

the pin in the blocker to slider slot (Fig. 15) and

install the mounting screws and tighten to 12 N·m

(105 in. lbs.).

Page 13

DR COLUMN 19 - 13

GEAR SHIFT LEVER (Continued)

(2) Lock the steering wheel with the tire in the

straight position.

(3) Remove and discard the lower pinch bolt.

(4) Lower the steering coupler shaft from the column.

(5) Remove the upper steering coupling shaft seal

by pushing in the four tags securing it to the panel

(Fig. 16).

Fig. 15 GEAR SHIFT LEVER SPRING

1 - BLOCKER TO INHIBIT LINK SLOT

2 - GEAR SHIFT LEVER

(2) Cycle the key from ACC to RUN and ensure

that the blocker does not stick or bind.

(3) Turn the key to the OFF position and ensure

that the shifter will not pull from the PARK position.

(4) Connect the over drive switch harness (if

equipped).

NOTE: Route and tie off harness to original location.

(5) Connect the shift cable to the lever.

(6) Ensure the gear shift lever and transmission

are in the PARK position and snap the cable adjust

clip in place.

(7) Install a new brake light switch (Refer to 8 ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION).

(8) Install the SKIM and halo.

(9) Install the upper and lower column shroud.

(10) Install the column back into place and

tighten.

(11) Install the kneeblocker. (Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTALLATION).

1 - RELEASE TANGS (4)

2 - UPPER STEERING COUPLER SHAFT

(6) Remove and discard the lower coupler pinch

bolt from the lower steering coupling shaft (Fig. 17).

(7) Remove the upper steering coupling shaft from

the vehicle (Fig. 17).

Fig. 16 RELEASE TANGS

UPPER STEERING COUPLING

REMOVAL

(1) Disconnect the negative battery cable.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will

have to be used.

Fig. 17 UPPER STEERING COUPLER SHAFT

1 - LOWER STEERING COUPLER

2 - RELEASE TANGS (4)

3 - UPPER STEERING COUPLER SHAFT

Page 14

19 - 14 COLUMN DR

UPPER STEERING COUPLING (Continued)

INSTALLATION

(1) Install the upper steering coupling shaft to the

vehicle (Fig. 17).

(2) Install the upper steering coupling shaft seal

by pushing it in securing the four tangs to the panel

(Fig. 16).

NOTE: Note: A new steering coupling shaft pinch

bolt for the upper and lower shafts must be used.

(3) Install the steering coupler shaft to the column

(Fig. 17).

(4) Install the upper pinch bolt use new bolt and

tighten to 57 N.m (42 ft.lbs).

(5) Install the shaft to the lower coupler (Fig. 17).

(6) Install the lower pinch bolt use new bolt and

tighten to 57 N.m (42 ft.lbs).

(7) Unlock the steering wheel.

(8) Reconnect the negative battery cable.

LOWER STEERING COUPLING

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will

have to be used.

Fig. 18 LOWER STEERING COUPLER

REMOVAL

(3) Lock the steering wheel with the tire in the

REMOVAL - ALL LD & HD EXCEPT 4X4 HD

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will

have to be used.

straight position.

(4) Remove the left front tire and wheel assembly.

(5) Remove and discard the upper coupler pinch

bolt (Fig. 20).

(6) Remove and discard the lower coupler pinch

bolt (Fig. 19).

(3) Lock the steering wheel with the tire in the

straight position.

(4) Remove the left front tire and wheel assembly.

(5) Mark both coupler connections for proper

installation.

(6) Remove and discard the upper coupler pinch

bolt.

(7) Remove and discard the lower coupler pinch

bolt.

(8) Remove the lower steering shaft coupler (Fig.

18).

REMOVAL - 4X4 HD

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

Fig. 19 LOWER COUPLER PINCH BOLT

1 - INTERMEDIATE STEERING SHAFT

2 - LOWER COUPLING BOLT

3 - STEERING GEAR

Page 15

DR COLUMN 19 - 15

LOWER STEERING COUPLING (Continued)

(7) Remove the lower steering shaft coupler (Fig.

20).

Fig. 20 INTERMEDIATE STEERING SHAFT

1 - UPPER COUPLING BOOTAND BOLT

2 - INTERMEDIATE STEERING SHAFT

3 - LOWER COUPLING BOLT

4 - STEERING GEAR

INSTALLATION

(5) Install the left front tire and wheel assembly

(Refer to 22 - TIRES/WHEELS/WHEELS - STANDARD PROCEDURE).

(6) Lower the vehicle.

(7) Reconnect the negative battery cable.

(8) Unlock the steering wheel.

STEERING WHEEL

REMOVAL

(1) Disable and remove the driver’s side airbag.(Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(2) Partially remove the steering wheel bolt and

leave the bolt in the column.

(3) Install puller CJ98-1 or equivalent using the

top of the bolt to push on. (Fig. 21)

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD

(1) Install the coupler to the steering rack & pin-

ion using the marks made in the removal process.

(2) Install the coupler to the intermediate shaft

using the marks made in the removal process.

NOTE: New pinch bolts must be used for reinstallation.

(3) Install the lower pinch bolt and tighten to 57

N·m (42 ft. lbs.).

(4) Install the upper pinch bolt and tighten to 57

N·m (42 ft. lbs.).

(5) Install the left front tire and wheel assembly

(Refer to 22 - TIRES/WHEELS/WHEELS - STANDARD PROCEDURE).

(6) Lower the vehicle.

(7) Reconnect the negative battery cable.

(8) Unlock the steering wheel.

INSTALLATION - 4X4 HD

(1) Install the coupler to the steering gear.

(2) Install the coupler to the intermediate shaft.

NOTE: New pinch bolts must be used for reinstallation.

(3) Install the lower pinch bolt and tighten to 28

N·m (250 in. lbs.).

(4) Install the upper pinch bolt and tighten to 57

N·m (42 ft. lbs.).

Fig. 21 STEERING WHEEL PULLER

1 - STEERING WHEEL

2 - SPECIAL TOOL CJ98-1

(4) Remove and discard the steering wheel bolt.

(5) Remove the steering wheel.

INSTALLATION

NOTE: Do not reuse the old steering wheel bolt (a

new bolt must be used)

(1) Install steering wheel to the column

NOTE: Be certain that the steering wheel mounting

bolt is tightened to the proper torque specification

to ensure proper clockspring operation.

(2) Install the new steering wheel bolt. Tighten the

bolt to 61 N·m (45 ft. lbs.).

(3) Install the driver’s side air bag. (Refer to 8 ELECTRICAL/RESTRAINTS/DRIVER AIRBAG INSTALLATION).

Page 16

19 - 16 GEAR - INDEPENDENT FRONT SUSPENSION DR

GEAR - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

GEAR - INDEPENDENT FRONT SUSPENSION

DESCRIPTION .........................16

REMOVAL .............................16

INSTALLATION .........................17

SPECIFICATIONS

TORQUE CHART ......................18

GEAR - INDEPENDENT FRONT

SUSPENSION

DESCRIPTION

A rack and pinion steering gears (Fig. 1) is made

up of two main components, the pinon shaft and the

rack. The gear cannot be adjusted or internally serviced. If a malfunction or a fluid leak occurs, the gear

must be replaced as an assembly.

BUSHING

REMOVAL .............................18

INSTALLATION .........................18

(2) Drain and siphon the power steering fluid from

the reservoir.

(3) Raise the vehicle.

(4) Remove and discard the steering coupler pinch

bolt.

(5) Remove the power steering hoses from the rack

& pinion.

(6) Remove the tire and wheel assembly.

(7) Remove the tie rod end nuts and separate tie

rod ends from the knuckles with Special tool 8677

(Refer to 19 - STEERING/LINKAGE/TIE ROD END REMOVAL).

(8) Remove the skid plate (Refer to 13 - FRAME &

BUMPERS/FRAME/FRONT SKID PLATE - REMOVAL).

(9) Remove the rack & pinion mounting bolts. (Fig.

2) & (Fig. 3)

(10) Remove the rack & pinion from the vehicle.

Fig. 1 STEERING GEAR

1 - OUTER TIE ROD ENDS

2 - MOUNTING BUSHINGS

3 - BELLOWS

REMOVAL

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will

have to be used.

(1) Lock the steering wheel.

Fig. 2 STEERING GEAR MOUNTING BOLTS

1 - STEERING GEAR MOUNTING BOLTS 4X4

Page 17

DR GEAR - INDEPENDENT FRONT SUSPENSION 19 - 17

GEAR - INDEPENDENT FRONT SUSPENSION (Continued)

an additional 90°. (Refer to 19 - STEERING/LINKAGE/TIE ROD END - INSTALLATION).

(5) Install the pressure power steering hose to the

steering gear and tighten to 32 N·m (23 ft. lbs.).

(Refer to 19 - STEERING/PUMP/HOSES - INSTALLATION).

(6) Install the return power steering hose to the

steering gear and tighten to 71 N·m (52 ft. lbs.).

(Refer to 19 - STEERING/PUMP/HOSES - INSTALLATION).

(7) Install the front skid plate (Refer to 13 FRAME & BUMPERS/FRAME/FRONT SKID PLATE

- INSTALLATION).

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCEDURE).

Fig. 3 STEERING GEAR 4X2

1-SWAYBAR

2 - STEERING GEAR

3 - LEFT OUTER TIE ROD END

4 - LOWER CONTROLARMS

5 - LEFT INNER & RIGHT OUTER (TIE ROD ENDS)

(9) Remove the support and lower the vehicle.

(10) Fill the system with fluid, (Refer to 19 STEERING/PUMP - STANDARD PROCEDURE).

(11) Adjust the toe position. (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION

NOTE: Before installing gear inspect bushings and

replace if worn or damaged.

NOTE: In the frame there is two holes for the

mounting of the steering gear one is slotted and

one is round, When tightening the gear to specifications make sure to tighten the mounting bolt with

the hole first to avoided movement of the steering

gear.

(1) Install the gear on the front crossmember and

tighten the mounting bolts to 319 N·m (235 ft. lbs.).

(Fig. 4) & (Fig. 3).

(2) Slide the shaft coupler onto the gear. Install

new pinch bolt and tighten to 49 N·m (36 ft. lbs.).

(3) Clean and dry the tie rod end studs and the

knuckle tapers.

(4) Install the tie rod ends into the steering knuckles and tighten the nuts to 61 N·m (45 ft. lbs.) then

Fig. 4 STEERING GEAR 4X4

1 - FRONT AXLE

2 - STEERING GEAR MOUNTING NUTS & BUSHINGS

Page 18

19 - 18 GEAR - INDEPENDENT FRONT SUSPENSION DR

GEAR - INDEPENDENT FRONT SUSPENSION (Continued)

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Rack and Pinion Steering

Gear

Gear to Frame Bolts

Rack and Pinion Steering

Gear

Coupler Bolt

Tie Rod End

Knuckle Nut

Tie Rod End

Jam Nut

Power Steering Line

Pressure Line

Power Steering Line

Return Line

Power Steering Line

Pressure Line To Pump

Then tighten an additional

319 235 —

49 36 —

61

Then tighten an additional

90°

75 55 —

32 23 —

71 52 —

37 27 —

45

90°

—

BUSHING

REMOVAL

(1) Remove the steering gear (Refer to 19 STEERING/GEAR - REMOVAL).

CAUTION: Do not overtighten the vise on the gear

case.

(2) Mount the steering gear in a soft jawed vise.

NOTE: If the bushings are seized a brass punch can

be used to remove the bushings from the gear

using care not to strike the gear.

(3) Remove the front mounting bushings.

(4) Remove the rear mounting bushings.

(5) Remove the steering gear from the vise and

place it on the bench.

INSTALLATION

NOTE: Coat all bushings with a thin rubber lubricate oil prior to installation.

NOTE: A rubber mallet can be used to assist in the

installation of the bushings once lubricated.

(1) Coat the rear bushings with a thin rubber

lubricate oil then install the rear bushings using a

rubber mallet to seat the bushings in the gear.

(2) Coat the front bushings with a thin rubber

lubricate oil then install the front bushings using a

rubber mallet to seat the bushings in the gear.

(3) Install the steering gear (Refer to 19 - STEERING/GEAR - INSTALLATION).

(4) Adjust the toe position (if necessary) (Refer to 2

- SUSPENSION/WHEEL ALIGNMENT - STANDARD PROCEDURE).

Page 19

DR GEAR - LINK/COIL 19 - 19

GEAR - LINK/COIL

TABLE OF CONTENTS

page page

GEAR - LINK/COIL

DESCRIPTION .........................19

OPERATION ...........................19

REMOVAL .............................19

INSTALLATION .........................20

ADJUSTMENTS

ADJUSTMENT ........................20

SPECIFICATIONS

POWER STEERING GEAR ..............21

TORQUE CHART ......................22

SPECIAL TOOLS

POWER STEERING GEAR ..............22

PITMAN SHAFT SEAL

REMOVAL

REMOVAL - GAS ENGINE ...............23

GEAR - LINK/COIL

DESCRIPTION

The power steering gear is a recirculating ball type

gear (Fig. 1). The gear ratio’s used are 12.5:1.

OPERATION

The gear acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is supported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned from input from the steering column

the rack piston moves. The rack piston teeth mesh

with the pitman shaft. Turning the worm shaft, turns

the pitman shaft, which turns the steering linkage.

REMOVAL - DIESEL ...................24

INSTALLATION

INSTALLATION - GAS ENGINE ...........24

INSTALLATION - DIESEL ................25

STEERING GEAR INPUT SHAFT SEAL

REMOVAL .............................25

INSTALLATION .........................28

PITMAN SHAFT

REMOVAL

REMOVAL - GAS ......................29

REMOVAL - DIESEL ...................30

INSTALLATION

INSTALLATION - GAS ..................30

INSTALLATION - DIESEL ................30

REMOVAL

(1) Place the front wheels in a straight-ahead position.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will

have to be used.

(2) Lock the steering wheel.

(3) Siphon out as much power steering fluid as

possible.

Fig. 1 STEERING GEAR

1 - INPUT SHAFT

2 - OUTLET

3 - INLET

4 - VALVE ASSEMBLY HOUSING

5 - PITMAN SHAFT COVER BOLTS

6 - STEERING GEAR

7 - MESHLOAD ADJUSTER NUT

8 - PITMAN SHAFT

Page 20

19 - 20 GEAR - LINK/COIL DR

GEAR - LINK/COIL (Continued)

(4) Disconnect and cap the fluid hoses from steering gear (Refer to 19 - STEERING/PUMP/HOSES REMOVAL).

(5) Remove coupler pinch bolt at the steering gear

and slide shaft off gear (Fig. 2).

Fig. 4 STEERING GEAR REMOVAL/INSTALLATION

1 - STEERING GEAR

2 - MOUNTING BOLTS (3)

INSTALLATION

Fig. 2 COLUMN SHAFT

1 - STEERING COUPLER

2 - STEERING GEAR INPUT SHAFT

(6) Mark the pitman shaft and pitman arm for

installation reference. Remove the pitman arm from

the shaft with Puller C-4150A (Refer to 19 - STEERING/LINKAGE/PITMAN ARM - REMOVAL), (Fig. 3).

(1) Position the steering gear on the frame rail and

install the three mounting bolts (Fig. 4). Tighten the

mounting bolts to 196 N·m (145 ft. lbs.).

(2) Align steering coupler on gear shaft. Install

pinch bolt and tighten to 49 N·m (36 ft. lbs.) torque.

(3) Align and install the pitman arm (Refer to 19 STEERING/LINKAGE/PITMAN ARM - INSTALLATION).

(4) Install the washer and retaining nut on the pitman shaft. Tighten the nut to 305 N·m (225 ft. lbs.).

(5) Connect fluid hoses to steering gear (Refer to

19 - STEERING/PUMP/HOSES - INSTALLATION),

tighten to 31 N·m (23 ft. lbs.).

(6) Add fluid, (Refer to 19 - STEERING/PUMP STANDARD PROCEDURE).

(7) Reset the toe and center the steering wheel

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT STANDARD PROCEDURE).

Fig. 3 PITMAN ARM REMOVAL

1 - PITMAN ARM

2 - C-4150A PULLER

(7) Remove steering gear three mounting bolts

(Fig. 4). Remove the steering gear from the vehicle.

ADJUSTMENTS

ADJUSTMENT

CAUTION: Steering gear must be adjusted in the

proper order. If adjustments are not performed in

order, gear damage and improper steering response

may result.

NOTE: Adjusting the steering gear in the vehicle is

not recommended. Remove gear from the vehicle

and drain the fluid. Then mount gear in a vise to

perform adjustments.

Page 21

DR GEAR - LINK/COIL 19 - 21

GEAR - LINK/COIL (Continued)

(1) Remove the steering gear from the vehicle

(Refer to 19 - STEERING/GEAR - REMOVAL).

(2) Mount the gear carefully into a soft-jawed vise.

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(3) Hold the steering gear upside down over a

drain pan and rotate the input shaft back and forth

several times lock-to-lock to discharge the fluid from

the steering gear

(4) Rotate the input shaft to the left stop and then

back-off approximately 45 degrees. Using an inchpound torque wrench on the input shaft, record the

peak torque required to slowly and evenly rotate the

input shaft clockwise

from the 45 degree position. This peak torque reading is the preload torque. The preload torque must be

within2-10in-lbs.

(5) Rotate the input shaft to its center of travel

(approximately 1.5 turns from either stop). Place the

torque wrench on the input shaft with the handle in

the vertical position. Rotate the torque wrench slowly

and evenly

and record the peak torque measure on or near center. This total on-center torque reading must be5-9

in-lbs higher than the previously measured preload

torque without exceeding a total of 17 in-lbs. The

value of the total on-center minus the preload torque

is defined as the meshload torque

1

⁄4turn (90 degrees) each side of center

1

⁄2turn (180 degrees) starting

(6) If required, adjust the on-center torque by loosening the adjuster screw lock nut and turning the

adjuster screw until the total on-center and meshload

torque readings fall within the specified values. Turn

the adjuster screw clockwise to increase and counterclockwise to decrease the torque reading. While holding the adjuster screw in place, tighten the lock nut

to 31 N·m (23 ft. lbs.).

(7) Re-check the preload and on-center torque

readings.

(8) Install pitman arm on the steering gear (Refer

to 19 - STEERING/LINKAGE/PITMAN ARM INSTALLATION).

(9) Reinstall steering gear to the vehicle (Refer to

19 - STEERING/GEAR - INSTALLATION).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

Type

Gear Code & Ratio 12.5:1

Recirculating Ball

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Preload

Torque

Meshload Torque 0.56-1.02 — 5-9

0.23-1.13 — 2-10

+ Preload (17 Max)

Page 22

19 - 22 GEAR - LINK/COIL DR

GEAR - LINK/COIL (Continued)

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Steering Gear Mounting

Frame Bolts

Power Steering Line

Pressure

Power Steering Line

Return

Power Steering Line

Pressure Line To Pump

Steering Gear

Adjustment Screw Locknut

Steering Gear

Pitman Shaft Nut

Steering Gear

Pitman Shaft Cover Bolts

Steering Gear

Valve Housing to Gear

Bolts

Steering Gear

Retainer Ring Screw

Steering Gear

Retainer Ring

196 145 —

32 23 —

71 52 —

37 27 —

31 23 —

305 225 —

68 50 —

54 40 —

2.26 — 20

97 72 —

SPECIAL TOOLS

POWER STEERING GEAR

HANDLE C-4171

INPUT SHAFT SEAL INSTALLER - 8987

Page 23

DR GEAR - LINK/COIL 19 - 23

GEAR - LINK/COIL (Continued)

PULLER, SLIDE HAMMER - C-3752

PITMAN SHAFT SEAL PROTECTOR - 8993

SEAL REMOVER ADAPTER - 8990

PITMAN SHAFT SEAL INSTALLER - 8989

INPUT SHAFT SEAL PROTECTOR - 8986

PITMAN SHAFT SEAL

REMOVAL

REMOVAL - GAS ENGINE

(1) Seperate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM REMOVAL).

(2) Clean exposed end of pitman shaft and housing

with a wire brush.

(3) Rotate the steering wheel from stop to stop and

count the number of turns.

(4) Center the steering wheel by rotating it from

the stop back 1 1/2 turns to achieve center position.

(5) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

RETAINER RING WRENCH - 8988

(6) Remove the pitman shaft from the gear.

(7) Remove dust seal from the housing with a special tool (Fig. 5).

CAUTION: Use care not to score the housing bore

when prying out seals and washer.

(8) Remove retaining ring with snap ring pliers.

Page 24

19 - 24 GEAR - LINK/COIL DR

PITMAN SHAFT SEAL (Continued)

Fig. 5 SLIDE HAMMER

1 - STEERING GEAR

2 - SLIDE HAMMER C-3752 USED WITH SPECIAL TOOL

ADAPTER

8990

(9) Remove washer from the housing.

NOTE: Tighten the slide hammer adapter 8990 into

the seal using wrenches, in order to make a tight fit

to pull the seal out. If this is not performed the seal

may tear on the removal making it difficult to

remove.

(10) Remove oil seal from the housing with a spe-

cial tool 8990 with slide hammer C-3752.

REMOVAL - DIESEL

(1) Seperate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM REMOVAL).

(2) Remove the steering gear box (Refer to 19 STEERING/GEAR - REMOVAL).

(3) Install the steering gear in a soft jawed bench

vise.

(4) Clean exposed end of pitman shaft and housing

with a wire brush.

(5) Rotate the input shaft with a 12 point socket

from stop to stop and count the number of turns (Fig.

6).

(6) Center the input shaft by rotating it from the

stop 1/2 of the total amount of turns (Fig. 6).

(7) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

Fig. 6 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

CAUTION: Use care not to score the housing bore

when prying out seals.

(10) Remove retaining ring with snap ring pliers.

(11) Remove washer from the housing.

NOTE: Tighten the slide hammer adapter 8990 into

the seal using wrenches, in order to make a tight fit

to pull the seal out. If this is not performed the seal

may tear on the removal making it difficult to

remove.

(12) Remove oil seal from the housing with a spe-

cial tool 8990 with slide hammer C-3752. (Fig. 5).

INSTALLATION

INSTALLATION - GAS ENGINE

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

(1) Coat the oil seal and washer with high temp

grease.

NOTE: Install the oil seal with the lip facing inward.

Flat side of the oil seal should be against the

washer.

(8) Remove the pitman shaft from the gear.

(9) Remove dust seal from the housing with a special tool 8990 (Fig. 5).

(2) Install the oil seal with special tool 8989 driver

and C-4171 handle (Fig. 7).

(3) Install backup washer.

(4) Install the retainer ring with snap ring pliers.

Page 25

DR GEAR - LINK/COIL 19 - 25

PITMAN SHAFT SEAL (Continued)

INSTALLATION - DIESEL

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

(1) Coat the oil seal and washer with high temp

grease.

NOTE: Install the oil seal with the lip facing inward.

Flat side of the oil seal should be against the

washer.

(2) Install the oil seal with special tool 8989 driver

and C-4171 handle (Fig. 7).

Fig. 7 SEAL INSTALLATION

1 - SPECIAL TOOL

C-4171

2 - SPECIAL TOOL

8989

3 - STEERING GEAR

(5) Coat the dust seal with high temp grease.

(6) Install the dust seal with a driver and handle

(Fig. 7).

(7) Install protective seal protector 8993 over the

shaft (Fig. 8).

(3) Install backup washer.

(4) Install the retainer ring with snap ring pliers.

(5) Coat the dust seal with high temp grease.

(6) Install the dust seal with special tool 8989

driver and C-4171 handle (Fig. 7).

(7) Install protective seal protector 8993 over the

shaft (Fig. 8).

(8) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(9) Install the new cover bolts and tighten to 68

N·m (50 ft. lbs.).

(10) Install the steering gear (Refer to 19 -

STEERING/GEAR - INSTALLATION).

(11) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(12) Perform a wheel alignment (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 8 PITMAN SHAFT SEAL PROTECTOR

1 - STEERING GEAR

2 - SPECIAL TOOL

8993

(8) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(9) Install the new cover bolts and tighten to 68

N·m (50 ft. lbs.).

(10) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

STEERING GEAR INPUT

SHAFT SEAL

REMOVAL

(1) Remove the steering gear from the vehicle

(Refer to 19 - STEERING/GEAR - REMOVAL).

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(2) Mount the steering gear upside down over a

drain pan in a soft jawed vise.

(3) Place a drain pan under the gear and rotate

the input shaft back and forth several times lock-tolock to discharge the fluid from the steering gear

(4) Drain all the remaining fluid from the gear.

(5) Rotate the input shaft from stop to stop and

count the number of turns using a 12 point socket

(Fig. 9).

Page 26

19 - 26 GEAR - LINK/COIL DR

STEERING GEAR INPUT SHAFT SEAL (Continued)

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Center the input shaft by rotating it from the

stop back 1 1/2 turns to achieve center position (Fig.

9).

Fig. 9 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

(10) Remove the valve housing and wormshaft

assembly from the steering gear housing and place

the valve housing in a soft jawed vise (Fig. 11).

Fig. 11 VALVE HOUSING AND WORMSHAFT

1 - VALVE HOUSING

2 - SET SCREW

3 - RETAINER RING

(11) Remove the retainer ring set screw from the

valve housing (Fig. 12).

(7) Remove the pitman shaft (Refer to 19 -

STEERING/GEAR/PITMAN SHAFT - REMOVAL).

(8) Remove the four bolts securing the valve hous-

ing.

(9) Remove the valve housing from the steering

gear (Fig. 10).

Fig. 10 VALVE ASSEMBLY

1 - VALVE HOUSING

2 - WORMSHAFT BALLS

3 - STEERING GEAR HOUSING

Fig. 12 SET SCREW FOR THE RETAINER RING

1 - SET SCREW

2 - 3/32 ALLEN HEAD SOCKET

3 - RETAINER RING

Page 27

DR GEAR - LINK/COIL 19 - 27

STEERING GEAR INPUT SHAFT SEAL (Continued)

(12) Using special tool reatainer ring wrench to

remove the steering gear worm thrust bearing

reatainer ring (Fig. 13).

Fig. 13 REATINER RING REMOVAL

1 - SPECIAL TOOL

8988

2 - RATCHET

(13) Separate the wormshaft assembly from the

valve housing, Then remove the wormshaft assembly

from the vise (Fig. 14).

(14) Remove the dust seal with a pick (Fig. 15).

Fig. 15 DUST SEAL REMOVAL

1 - PICK

2 - VALVE HOUSING

3 - SEAL

CAUTION: Use care not to score the housing bore

when removing seals.

(15) Remove the snap ring with snap ring pliers

(Fig. 16).

Fig. 14 WORMSHAFT AND VALVE ASSEMBLY

1 - PISTON TEFLON SEALS

2 - RETAINER RING

Fig. 16 SNAP RING REMOVAL

1 - SNAP RING PLIERS

2 - SNAP RING

3 - VALVE HOUSING

Page 28

19 - 28 GEAR - LINK/COIL DR

STEERING GEAR INPUT SHAFT SEAL (Continued)

(16) Using special tool slide hammer C-3752 with

adapter 8990 remove the oil seal (Fig. 17).

Fig. 18 RETAINER RING INSTALLATION

1 - VALVE HOUSING

Fig. 17 OIL SEAL REMOVAL

1 - SPECIAL TOOL

8990

WITH SLIDE HAMMER C-3752

2 - VALVE HOUSING

2 - SPECIAL TOOL

3 - TORQUE WRENCH

INSTALLATION

(1) Inspect the piston teflon seals for damage.

Replace if needed.

NOTE: To replace the teflon seals, use a pick to

remove the teflon o-ring and the rubber o-ring

underneath. Install a new rubber o-ring in the piston

seal grove and a new teflon o-ring over the top of it.

(2) Install the valve into the valve housing.

(3) Thread the retainer ring into the valve housing

(Fig. 18). Tighten to 97 N·m (72 ft. lbs.)

NOTE: It is very important to make sure to compensate for the added length of the torque wrench

when torquing to proper specifications.

(4) Install the retainer ring set screw. Tighten to

2.26 N·m (20 in. lbs.)

(5) Clean the steering gear housing.

CAUTION: Valve assembly must be centered to the

housing (Fig. 19).

(6) Install the valve assembly into the steering

gear (Fig. 19). Tighten the new bolts to 54 N·m (40 ft.

lbs.)

(7) Install the input shaft seal protector 8986 (Fig.

20).

(8) Coat the new seal in high temp grease and

Install the new oil seal using special tool 8987 driver

and C-4171 handle (Fig. 21).

Fig. 19 CENTERED GEAR TEETH

1 - GEAR INSTALLED WITH THE CENTER TOOTH CENTERED IN

HOLE

2 - VALVE HOUSING

NOTE: Drive the oil seal into the housing until the

outer edge does not quite clear the snap ring

groove.

(9) Insert the snap ring into the housing. Using

special tool 8987 driver and C-4171 handle push the

snap ring and oil seal together until the snap ring

seats in the groove.

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

Page 29

DR GEAR - LINK/COIL 19 - 29

STEERING GEAR INPUT SHAFT SEAL (Continued)

(14) Install the steering gear to the vehicle (Refer

to 19 - STEERING/GEAR - INSTALLATION).

(15) Perform a wheel alignment (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

PITMAN SHAFT

REMOVAL

REMOVAL - GAS

(1) Separate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM REMOVAL).

Fig. 20 INPUT SHAFT SEAL PROTECTOR

1 - INPUT SHAFT

2 - SPECIAL TOOL

8986

(2) Clean exposed end of pitman shaft and housing

with a wire brush.

(3) Rotate the steering wheel from stop to stop and

count the number of turns.

(4) Center the steering wheel by rotating it from

the stop back 1 1/2 turns to achieve center position.

(5) Remove the pitman shaft cover bolts.

Fig. 21 INPUT SHAFT SEAL INSTALLATION

1 - VALVE HOUSING

2 - SPECIAL TOOL

8987

3 - SPECIAL TOOL

C-4171

(10) Install the new dust seal using high temp

grease, special tool C-4171 (driver) and 8987 (han-

dle).

(11) Check to make sure the gear is centered in

the middle tooth before installing the pitman shaft

(Fig. 19).

(12) Install the pitman shaft into the steering gear

(Refer to 19 - STEERING/GEAR/PITMAN SHAFT INSTALLATION).

(13) Perform over-center meshload adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Remove the pitman shaft from the gear (Fig.

22).

Fig. 22 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

(7) Remove the cover if needed by loosing the

adjuster nut, Then removing the cover from the pitman shaft.

Page 30

19 - 30 GEAR - LINK/COIL DR

PITMAN SHAFT (Continued)

REMOVAL - DIESEL

(1) Separate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM REMOVAL).

(2) Remove the steering gear box (Refer to 19 STEERING/GEAR - REMOVAL).

(3) Install the steering gear in a soft jawed bench

vise.

(4) Clean exposed end of pitman shaft and housing

with a wire brush.

(5) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns (Fig.

23).

(6) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns (Fig. 23).

Fig. 24 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

Fig. 23 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

(7) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(8) Remove the pitman shaft from the gear (Fig.

24).

(9) Remove the cover if needed by loosing the

adjuster nut, Then removing the cover from the pitman shaft.

INSTALLATION

INSTALLATION - GAS

(1) Coat the seal with power steering fluid.

(2) Install pitman shaft into the steering gear until

it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N·m (50 ft. lbs.).

(4) Perform over-center meshload adjustment,

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(6) Perform a wheel alignment (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

INSTALLATION - DIESEL

(1) Coat the seal with power steering fluid.

(2) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N·m (50 ft. lbs.).

(4) Perform over-center meshload adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the steering gear (Refer to 19 - STEERING/GEAR - INSTALLATION).

(6) Install the pitman arm (Refer to 19 - STEERING/LINKAGE/PITMAN ARM - INSTALLATION).

(7) Perform a wheel alignment (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Page 31

DR LINKAGE - INDEPENDENT FRONT SUSPENSION 19 - 31

LINKAGE - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

LINKAGE - INDEPENDENT FRONT

SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END ................................31

LINKAGE - INDEPENDENT

FRONT SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END

NOTE: If the outer tie rod end is equipped with a

lubrication fitting, grease the joint then road test

the vehicle before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.

(3) Mount a dial indicator solidly to the vehicle

steering knuckle and then zero the dial indicator.

(4) Position indicator plunger on the topside of the

outer tie rod end.

TIE ROD END

REMOVAL - OUTER TIE ROD END ..........31

INSTALLATION - OUTER TIE ROD END ......32

TIE ROD END

REMOVAL - OUTER TIE ROD END

NOTE: Do not twist the boot anytime during

removal or installation.

(1) Loosen the jam nut.

(2) Remove the outer tie rod end nut from the ball

stud.

(3) Separate the tie rod ball stud from the knuckle

with Remover 8677 (Fig. 1).

(4) Unthread the outer tie rod end from the inner

tie rod.

NOTE: The dial indicator plunger must be perpendicular to the machined surface of the outer tie rod

end.

(5) Position a pry bar in order to pry downwards

on the outer tie rod end.

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the outer tie rod end (Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL).

(7) If the outer tie rod end is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 1 TIE ROD SEPARATION

1 - TIE ROD END

2 - SPECIAL TOOL 8677

Page 32

19 - 32 LINKAGE - INDEPENDENT FRONT SUSPENSION DR

TIE ROD END (Continued)

INSTALLATION - OUTER TIE ROD END

NOTE: Do not twist the boot at anytime during

removal or installation.

(1) Thread the outer tie rod end onto the inner tie

rod, to it’s original position (Fig. 2).

(2) Install the outer tie rod end into the steering

knuckle (Fig. 2).

(3) Tighten the ball stud nut on the ball stud to 61

N·m (45 ft. lbs.) then an additional 90°.

(4) Set wheel toe pattern, (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD PROCEDURE).

(5) Tighten jam nut to 75 N·m (55 ft. lbs.) (Fig. 2).

Fig. 2 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

Page 33

DR LINKAGE - LINK/COIL 19 - 33

LINKAGE - LINK/COIL

TABLE OF CONTENTS

page page

LINKAGE - LINK/COIL

DESCRIPTION .........................33

STANDARD PROCEDURE - LUBRICATION ....34

SPECIFICATIONS

TORQUE CHART ......................34

SPECIAL TOOLS

STEERING LINKAGE ...................35

DAMPER

REMOVAL .............................35

INSTALLATION .........................35

DRAG LINK

REMOVAL .............................35

LINKAGE - LINK/COIL

DESCRIPTION

The steering linkage is comprised of a tie rod end,

tie rod, drag link, steering damper and pitman arm

(Fig. 1).

CAUTION: If any steering components are replaced

or serviced an alignment must be performed.

NOTE: To avoid damaging ball stud seals, use

Puller C-3894–A or an appropriate puller to remove

tie rod ends (Fig. 2).

INSTALLATION .........................35

PITMAN ARM

REMOVAL .............................35

INSTALLATION .........................36

TIE ROD END

REMOVAL .............................36

INSTALLATION .........................37

TRACK BAR

REMOVAL .............................37

INSTALLATION .........................37

Fig. 1 LINK/COIL FRONT SUSPENSION

1 - STABILIZER BAR

2 - PITMAN ARM

3 - STEERING GEAR

4 - STABILIZER LINK

5 - TIE ROD ENDS

6 - LOWER SUSPENSION ARMS

7 - DRAG LINK

8 - TRACK BAR

9 - DAMPER

10 - UPPER SUSPENSION ARM

Page 34

19 - 34 LINKAGE - LINK/COIL DR

LINKAGE - LINK/COIL (Continued)

STANDARD PROCEDURE - LUBRICATION

Periodic lubrication of the steering system components is required. Refer to Lubrication And Maintenance for the recommended maintenance schedule.

The following components must be lubricated:

• Tie rod

• Tie rod end

• Drag link

Fig. 2 Ball Stud Puller

1 - CLAMP

2 - ADJUSTMENT SLEEVE

3 - PULLER TOOL C-3894–A

4 - SEAL

5 - TIE-ROD END

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Pitman Arm

Gear Shaft Nut

Drag Link

Pitman Arm

Drag Link

Tie Rod

Drag Link

Adjuster Clamp

Tie Rod End

Knuckle

Tie Rod End

Adjuster Clamp

Stabilizer Bar Link to Axle 68 50 —

Steering Damper

Axle

Steering Damper

Tie Rod

300 225 —

88 65 —

108 80 —

61 45 —

108 80 —

61 45 —

95 70 —

81 60 —

Page 35

DR LINKAGE - LINK/COIL 19 - 35

LINKAGE - LINK/COIL (Continued)

SPECIAL TOOLS

STEERING LINKAGE

Remover Ball Stud MB-991113

Puller Tie Rod C-3894-A

(2) Remove the drag link nut from the knuckle

side.

(3) Remove the drag link from the right knuckle

and pitman arm with Puller C-3894A (Fig. 3).

Fig. 3 DRAGLINK REMOVAL

1 - PITMAN ARM

2 - DRAGLINK

3 - C -3894-A PULLER

Remover Ball Joint C-4150A

DAMPER

REMOVAL

(1) Remove the steering damper mounting nuts

and bolts.

(2) Slide the damper from the isolation bushing.

(3) Remove the damper.

INSTALLATION

(1) Install the steering damper on the axle and iso-

lation bushing. Tighten nut to 95 N·m (75 ft. lbs.).

(2) Install the steering damper on the tie rod.

Tighten nut to 81 N·m (60 ft. lbs.).

DRAG LINK

REMOVAL

(1) Remove the draglink nut from the pitman arm

side.

INSTALLATION

(1) Install the drag link to the pitman arm. Install

the nut and tighten to 88 N·m (65 ft. lbs.).

(2) Install the drag link to the right steering

knuckle. Install the nut and tighten to 108 N·m (80

ft. lbs.).

(3) Install tie rod to the left steering knuckle and

drag link. Install the nuts and tighten to 108 N·m

(80 ft. lbs.).

(4) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT STANDARD PROCEDURE).

(5) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N·m (45 ft. lbs.).

NOTE: Position the clamp on the sleeve so retaining bolt is located on the bottom side of the sleeve.

PITMAN ARM

REMOVAL

(1) Remove the drag link from the right knuckle

and pitman arm with Puller C-4150A (Fig. 4).

(2) Mark the pitman arm and shaft positions for

installation reference. Remove the nut and washer

from the pitman arm (Fig. 5). Remove the pitman

arm with Puller C-4150A.

Page 36

19 - 36 LINKAGE - LINK/COIL DR

PITMAN ARM (Continued)

Fig. 4 PITMAN ARM REMOVAL

1 - PITMAN ARM

2 - C-4150A PULLER

Fig. 5 PITMAN ARM REMOVAL/INSTALLATION

1 - STEERING GEAR

2 - PITMAN ARM

3 - NUT

4 - WASHER

Fig. 6 PITMAN ARM INSTALLED

1 - DRAGLINK

2 - STEERING GEAR

3 - SWAYBAR

4 - NUT/WASHER

5 - PITMAN ARM

NOTE: Position the clamp on the sleeve so retaining bolt is located on the bottom side of the sleeve.

TIE ROD END

REMOVAL

(1) Remove tie rod nuts (Fig. 7).

(2) Remove tie rod from drag link and left knuckle

with Puller C-4150A.

INSTALLATION

(1) Align reference marks and install pitman arm.

(2) Install the lock washer and retaining nut on

the pitman shaft and tighten nut to 251 N·m (185 ft.

lbs.).

(3) Install the drag link to the pitman arm (Fig. 6).

Install the nut and tighten to 108 N·m (80 ft. lbs.).

(4) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT STANDARD PROCEDURE).

(5) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N·m (45 ft. lbs.).

Fig. 7 TIE ROD ENDS

1 - NUT

2 - TIE ROD ENDS

Page 37

DR LINKAGE - LINK/COIL 19 - 37

TIE ROD END (Continued)

INSTALLATION

(1) Install tie rod to the left steering knuckle and

drag link. Install the nuts and tighten to 108 N·m

(80 ft. lbs.).

(2) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT STANDARD PROCEDURE).

(3) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N·m (45 ft. lbs.).

NOTE: Position the clamp on the sleeve so retaining bolt is located on the bottom side of the sleeve.

TRACK BAR

REMOVAL

(1) Raise and support the axle.

(2) Remove the track bar bolts and nuts (Fig. 8).

(3) Remove the track bar (Fig. 8).

INSTALLATION

(1) Install the track bar.

(2) Install the new bolts and nuts. Tighten to 203

N·m (150 ft lbs.).

Fig. 8 TRACK BAR REMOVAL/INSTALLATION

1 - TRACK BAR

2 - BOLT

3 - NUT

(3) Remove the supports under the axle and lower

the vehicle to the ground.

Page 38

19 - 38 PUMP DR

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION .........................38

OPERATION ...........................38

DIAGNOSIS AND TESTING - PUMP LEAKAGE . 39

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER

STEERING PUMP - INITIAL OPERATION....39

STANDARD PROCEDURE - FLUSHING

POWER STEERING SYSTEM ............39

REMOVAL

REMOVAL - GAS ......................40

REMOVAL - DIESEL ...................40

INSTALLATION

INSTALLATION - GAS ..................41

INSTALLATION - DIESEL ................41

SPECIFICATIONS

TORQUE CHART ......................41

FLUID

DESCRIPTION .........................42

STANDARD PROCEDURE - POWER

STEERING FLUID LEVEL CHECKING ......42

FLUID COOLER

REMOVAL .............................42

INSTALLATION .........................42

HOSES - I.F.S.

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER ............................43

REMOVAL - PRESSURE HOSE ...........43

REMOVAL - RETURN HOSE - RESERVOIR

TO COOLER .........................43

INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER ............................43

INSTALLATION - PRESSURE HOSE .......43

INSTALLATION - RETURN HOSE -

RESERVOIR TO COOLER ...............43

HOSES - LINK/COIL

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER ............................43

REMOVAL - PRESSURE HOSE ...........44

REMOVAL - RETURN HOSE - RESERVOIR

TO COOLER .........................44

INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER ............................44

INSTALLATION - PRESSURE HOSE .......44

INSTALLATION - RETURN HOSE -

RESERVOIR TO COOLER ...............44

POWER STEERING PRESSURE SWITCH

DESCRIPTION .........................45

OPERATION ...........................45

REMOVAL - 3.7L, 4.7L & 5.7L ..............45

INSTALLATION - 3.7L, 4.7L & 5.7L ..........45

PULLEY

REMOVAL .............................45

INSTALLATION .........................46

RESERVOIR

REMOVAL .............................46

INSTALLATION .........................46

PUMP

DESCRIPTION

CAUTION: MOPART ATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do