Page 1

Chrysler / DoDge Minivan

Service Manual

2011-2014 Model Year

Main: (800) 956-6668

Local: (952) 890-7851

Fax: (952) 808-2775

TM

Your Life. Your Ride.

6591 W. Hwy 13

Savage, MN 55378

www.rollxvans.com

Page 2

Page 3

chrYSler / dodge Minivan

2011-2014 Model Year

Service Manual

#13315-004

June 2014

Page 4

TaBle of conTenTS

Important Item Locations ...................................................................................................................... 1

Battery Information - General ............................................................................................................... 6

Battery Information - Draw Test Procedure .......................................................................................... 8

Rollx Vans Door (Motor Bar) - Troubleshooting .................................................................................... 9

Rollx Vans Door (Motor Bar) - Replacement Parts ............................................................................. 10

OEM Power Door - Troubleshooting....................................................................................................11

Door Modifications .............................................................................................................................. 12

Exhaust System.................................................................................................................................. 14

Exterior / Van Dimensions .................................................................................................................. 16

Fuel System........................................................................................................................................ 17

Front Suspension (Struts)................................................................................................................... 23

Rear Suspension ................................................................................................................................ 24

Engine Mounting (Cradle Drop) .......................................................................................................... 25

Torque Specifications (Suspension) ................................................................................................... 26

Interior..................................................................................................................................................27

Kneeler - Troubleshooting....................................................................................................................29

Kneeler - Replacement Parts...............................................................................................................30

One Touch System - Troubleshooting..................................................................................................31

One Touch System - Overview.............................................................................................................32

One Touch System - v8.0 Basic Interface............................................................................................34

One Touch System - v8.0 Advanced Interface - Setup ....................................................................... 35

One Touch System - v8.0 Advanced Interface - Debugger ................................................................ 36

One Touch System - v8.0 Error Codes ............................................................................................... 38

One Touch System - Relay Board Troubleshooting ........................................................................... 41

In The Floor - Troubleshooting ........................................................................................................... 43

In The Floor - Replacement Parts ...................................................................................................... 44

Folding Ramp - Troubleshooting ........................................................................................................ 45

Page 5

TaBle of conTenTS

Folding Ramp - Replacement Parts ................................................................................................... 46

Folding Ramp - Motor Install / Removal and Adjustment ................................................................... 49

Rear Heat & Air................................................................................................................................... 51

Remote System - Troubleshooting ..................................................................................................... 52

Remote System - Location & Wiring .................................................................................................. 53

Seat Detector - Location & Description .............................................................................................. 54

Seat Wiring - Driver’s Side (2011-2014)..............................................................................................55

Seat Wiring - Passenger’s Side (2011-2012) ..................................................................................... 63

Seat Wiring - Passenger’s Side (2013-2014) ..................................................................................... 69

One Touch - Wiring (With Door Open Limit Switch)............................................................................73

One Touch - Wiring (With Door Detector)............................................................................................75

One Touch - Wiring (No Can Bus).......................................................................................................77

One Touch - Wiring (With Wing Window Interface).............................................................................79

Rollx Vans Power Door (Motor Bar) - Wiring ..................................................................................... 81

Maintenance Information .................................................................................................................... 83

Warranty ............................................................................................................................................. 84

Page 6

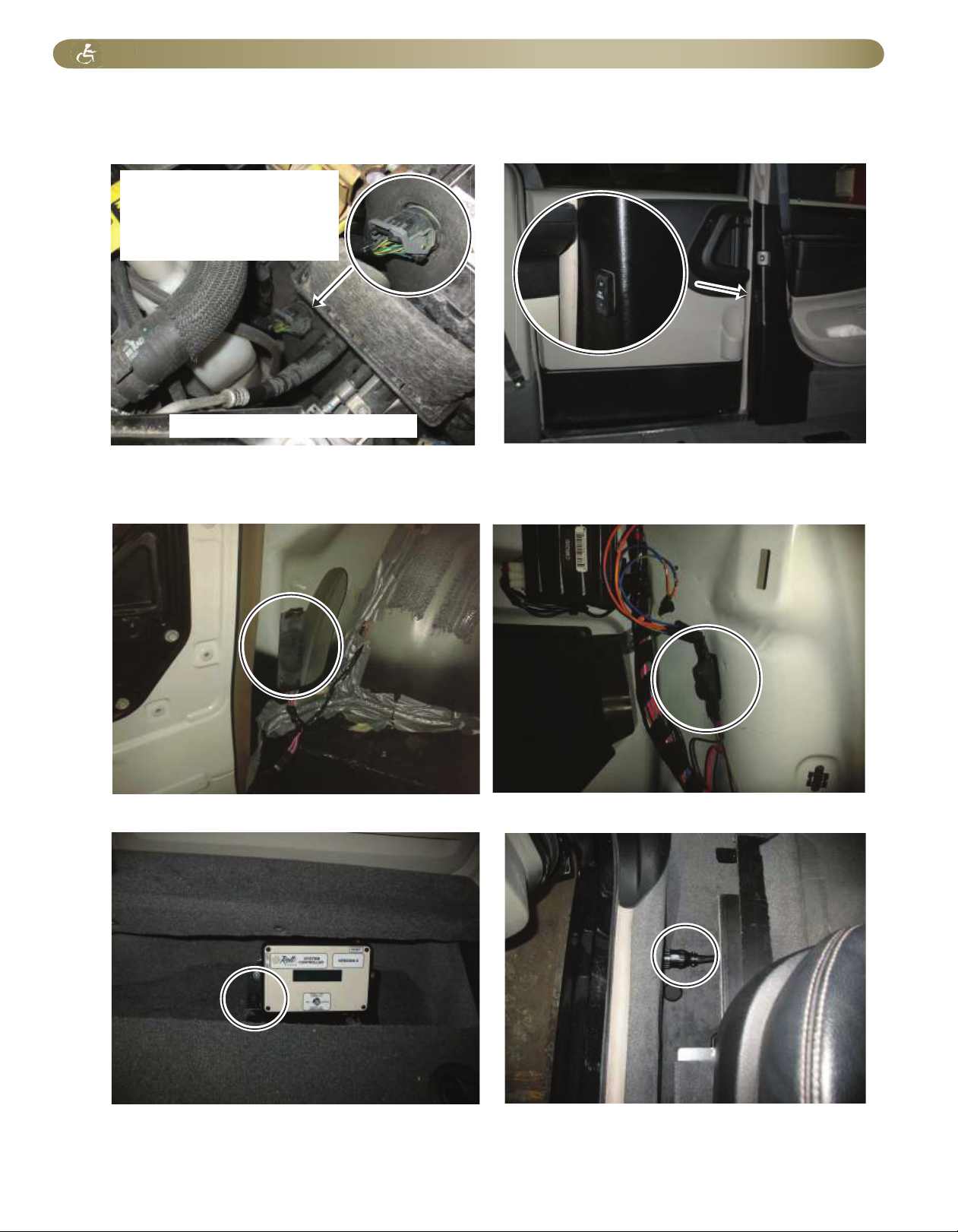

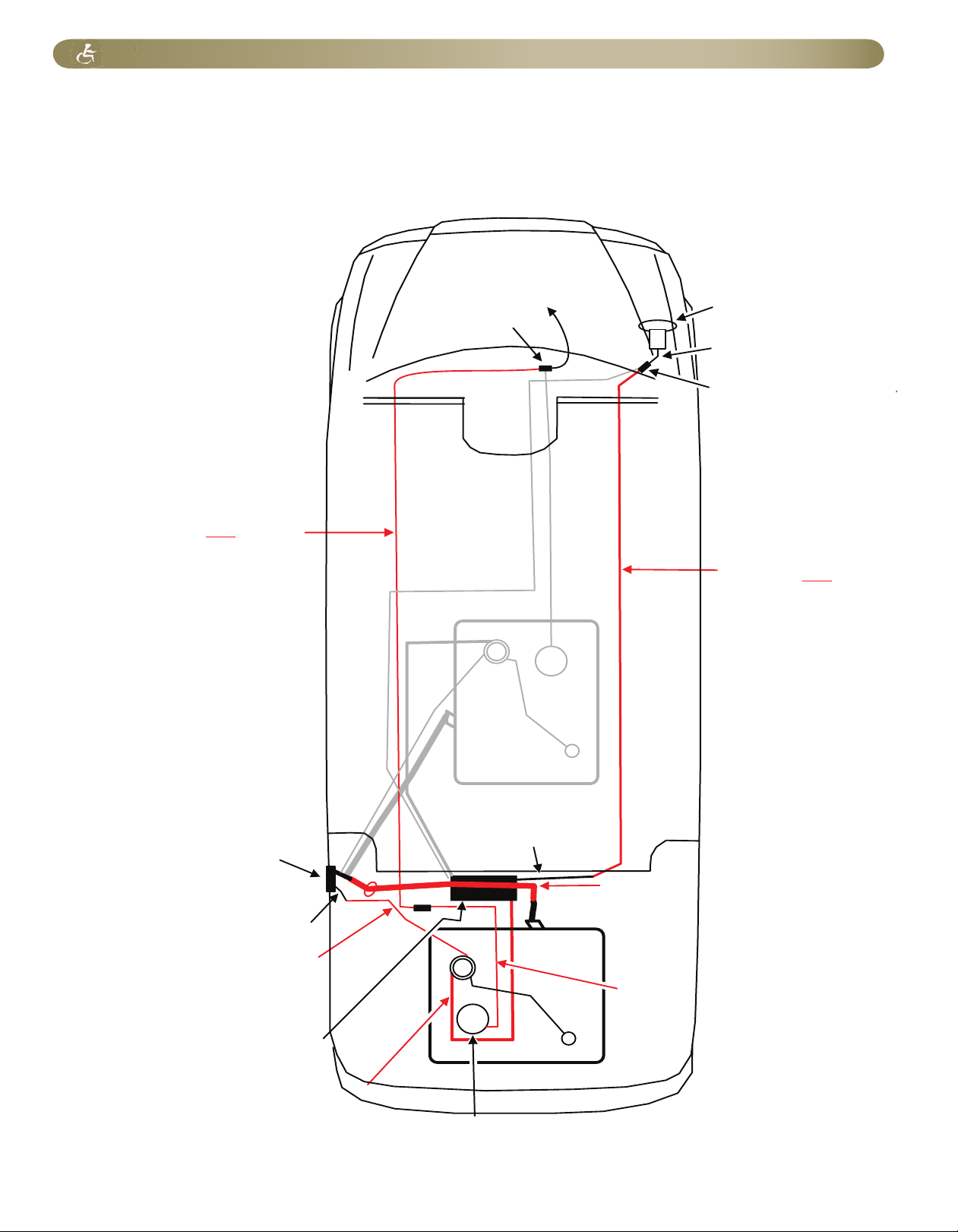

Kneeler

Passenger Sliding

Door Open Switch

(Before 8/26/2013)

Rear Heat Connections

Rear A/C Connections

OTC Remote

Receiver

OTC fuse panel

(Under Glove Box)

Passenger

Seat

Detetector

Rear Heat

and Air Unit

Driver Seat

Detector

OTC

Main Fuse

Rollx Vans Main Wire Harness

(Ceiling Along Passenger’s Side)

ITF Ramp Access

Panel

Power Seat

Connector(s)

Power Seat

Connector

OEM Main Wire Harness

(Floor Along Driver’s

Side)

Neutral Safety

Signal Splice

ITF Ramp Override

Switch

OTC Remote

Programming

Switch

Rear Heat & A/C Front

Connections

Door Detector

(

after 4/15/2014

)

(

after 8/26/2013

)

Wing Window Interface

(

after 4/15/2014

)

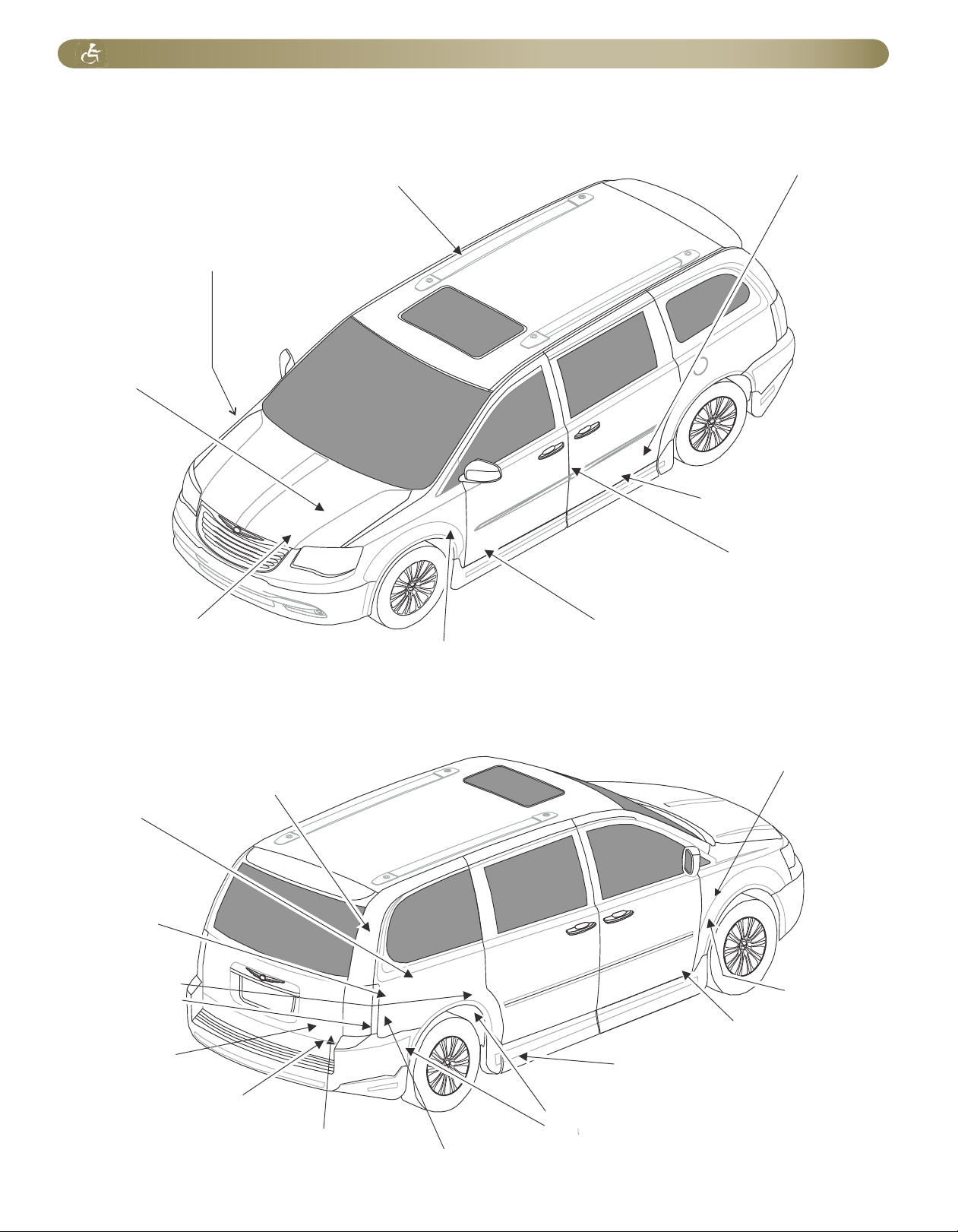

iMPorTanT iTeM locaTionS

Page 1

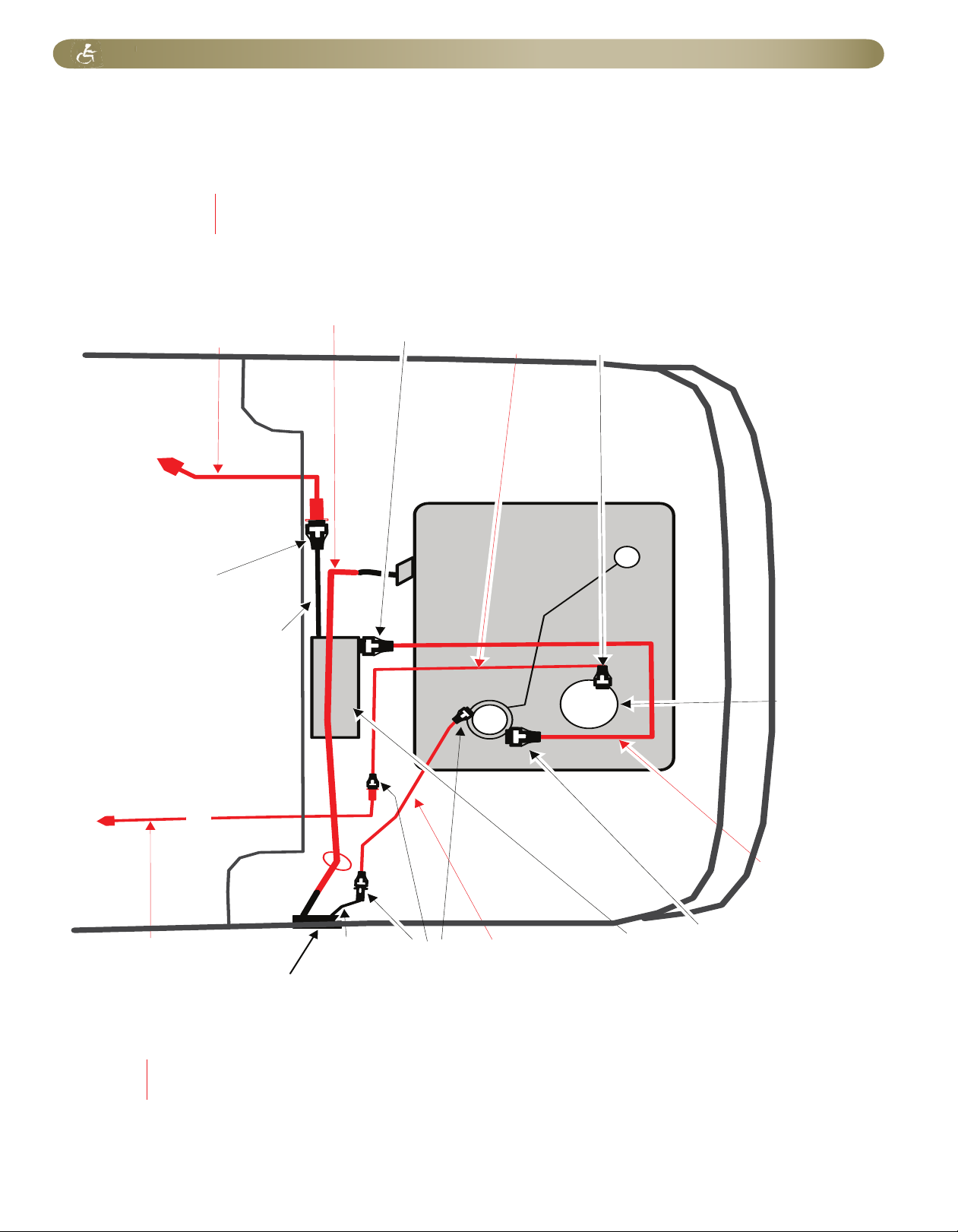

Page 7

OTC Remote Receiver

Rollx Vans Main Wire HarnessOEM Wire Harness

Main Fuse

(Engine Compartment)

OTC Fuse Panel

(Under Glove Box - Must Pull Back Fabric)

Passenger Sliding Door Open Switch

Rollx Vans Remote

Power Tie Down

(If Equipped)

Ignition Hot

Vans are equipped with a Ignition Hot and

Neutral Safety Panel to allow for quick

connection. See OTC Wiring for more

information.

6way controller

(If Equipped)

Neutral Safety

Used Before 8/26/2013

6way Seat Fuse

(40 Amp)

(If Equipped)

Main OTC Fuse

(40 Amp)

Rear Heat & A/C

Unit

Runs Along Driver’s

Side Floor

Runs Along Passenger’s

Side Ceiling

iMPorTanT iTeM locaTionS

Page 2

Page 8

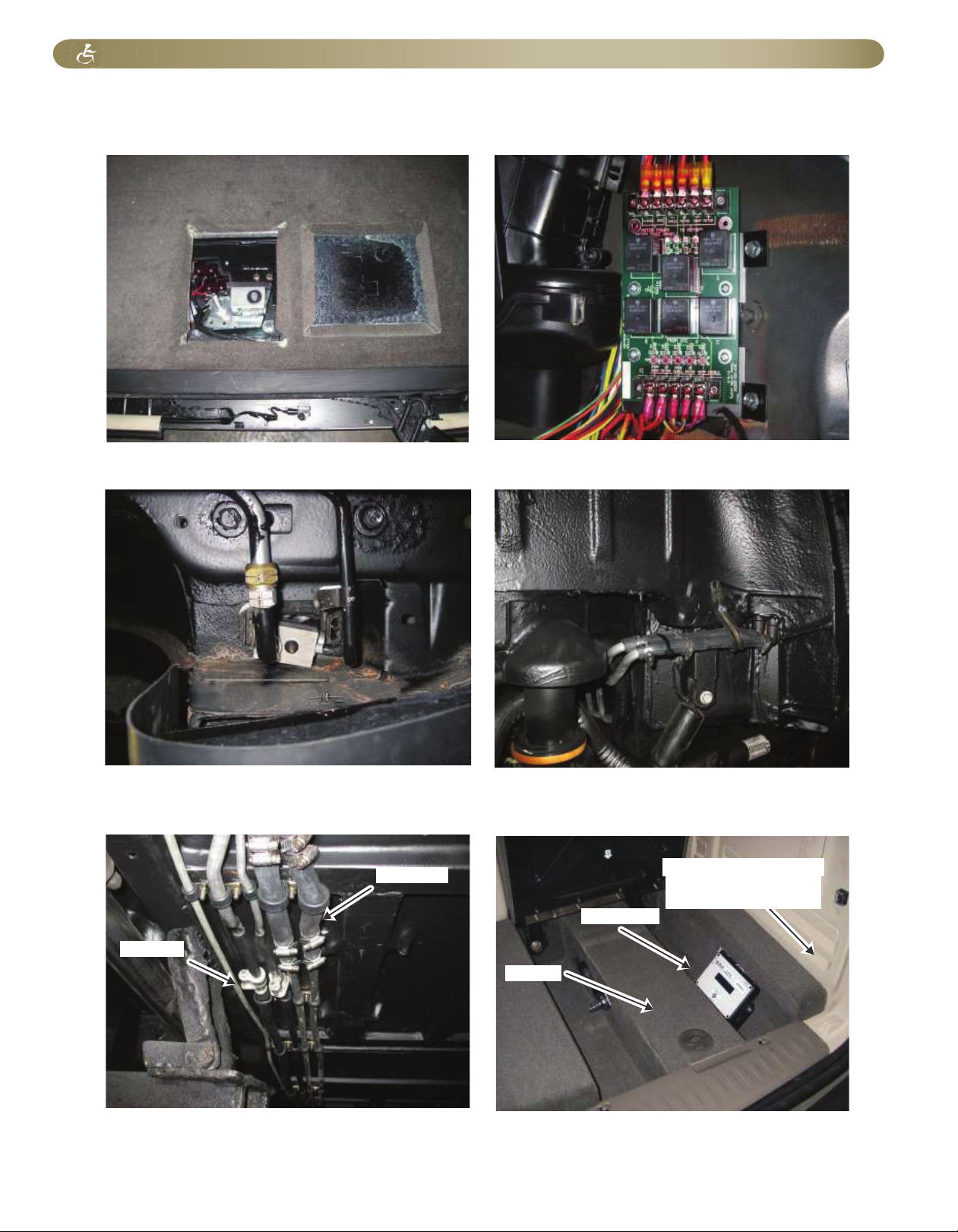

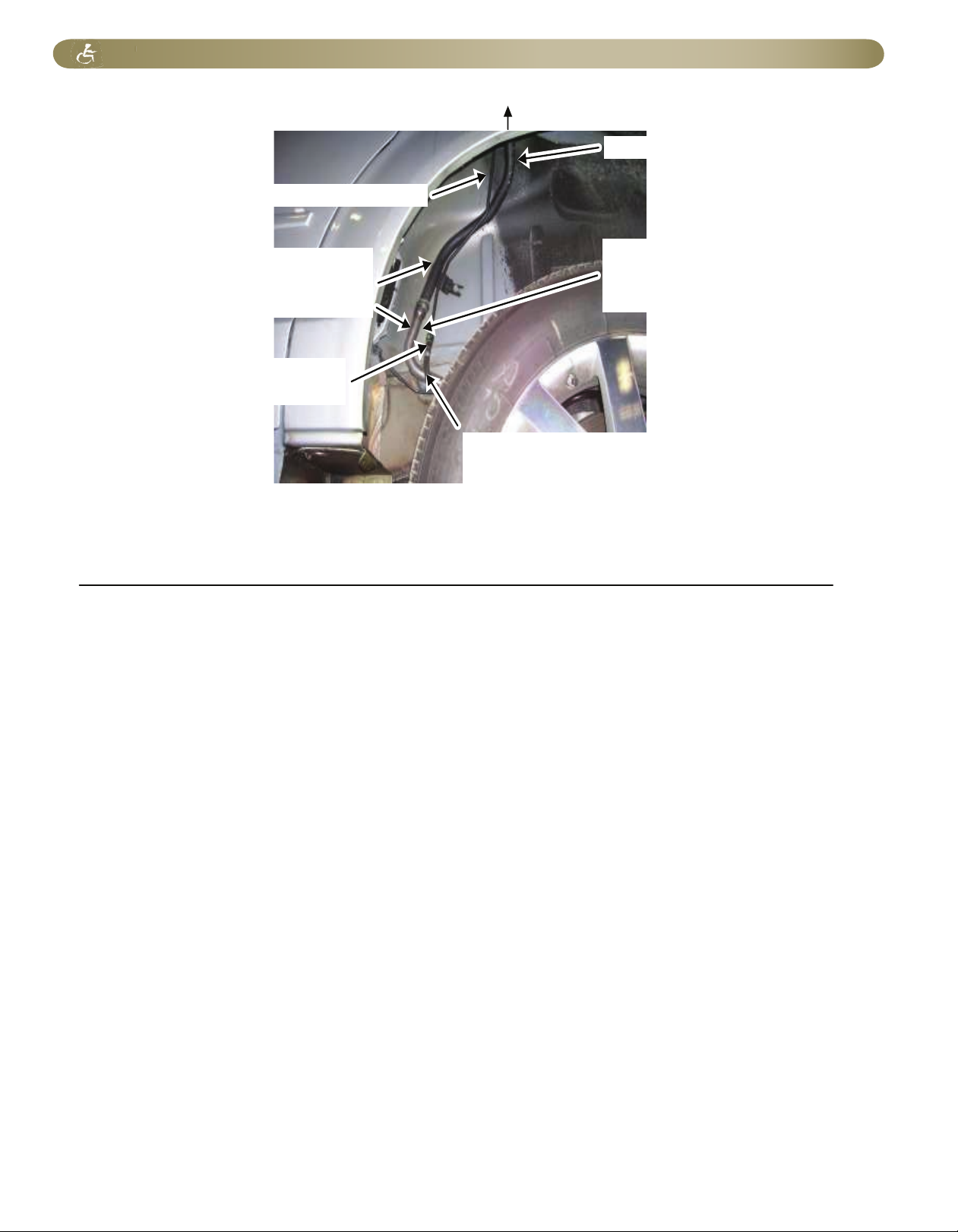

iMPorTanT iTeM locaTionS

Kneeler

OTC Board

Rear AC (Rear Connections)

(Behind Rear Right Tire)

Rear Heat (Rear Connections)

(Right Rear Tire)

ITF Ramp Access Plate

OTC Relay Board

(Behind Rear Passenger Quarter Panel)

Rear Heat & A/C (Front Connections)

(Under Passenger’s Side Front Seat Area)

Kneeler and One Touch Controller

Rear Heat

Rear A/C

Universal Door Detector

Used After 8/26/2013

(behind panel)

Page 3

Page 9

iMPorTanT iTeM locaTionS

Passenger’s Door Detector (Built After 4/15/2014)

(On Passenger’s C-Pillar)

Wing Window Interface (Built After 4/14/2014)

(Behind Rear Heat & Air Unit)

Neutral Safety Signal

ITF Ramp Override Switch

OTC Remote Programming Switch

*See OTC WIRING for diagram

NOTE:

Rollx V

ans taps into the

“TRS T3 SIGNAL” at the

“TRANSMISSION SOLENOID

PRESSURE SWITCH” to pick up

the Neutral Safety signal

Driver’s Power Seat Connector

(Passenger’s Same)

Page 4

Page 10

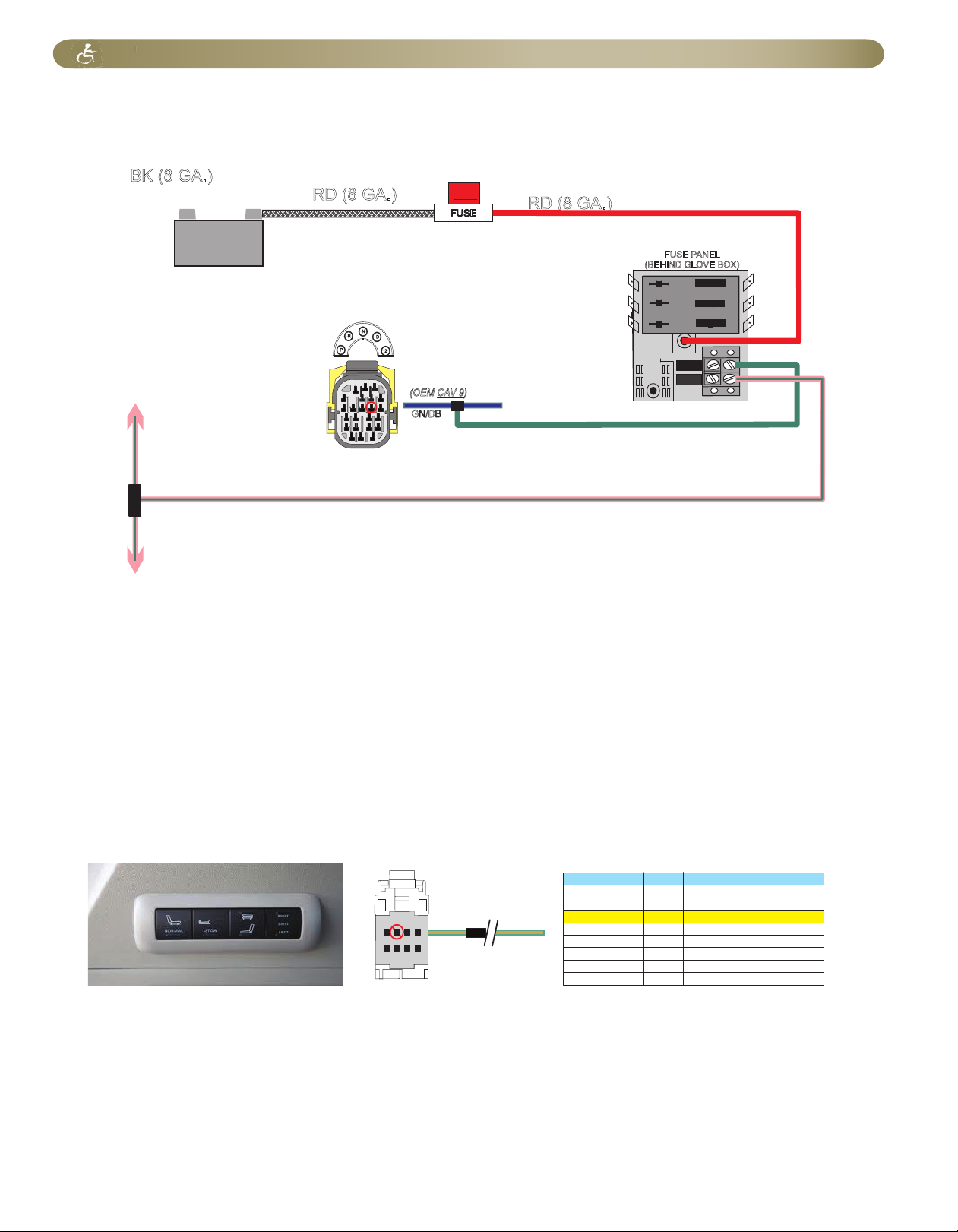

iMPorTanT iTeM locaTionS

RED (12V CONSTANT)

PK / YL

(OEM IGNITION HOT)

PK / GN (12V IGNITION HOT)

Rollx Vans Ignition Hot & Neutral Safety Board Wiring

2008-2013 Chrysler Minivans (built after 5/28/2009)

TAPS INTO OEM IGNITION

HOT (PK/GN WIRE) THAT IS

LOCATED BEHIND THE CENTER

BEZEL GOING INTO THE RADIO

Power Folding Rear Sofa

If the van is equipped with a Power Folding Rear Sofa, Rollx Vans disables the FOLD/TAILGATE

SWITCH MUX which would allow the seat to be stowed into the floor. Rollx Vans cuts the LG/TN wire

at the switch.

Pin Wire Color Gauge Function

1 NO CONNECTION

2 LG/YL 22 SEAT SWITCH SELECTOR SIG

3 LG/TN 22 SEAT FOLD SIGNAL

4 LG/DB 22 SEAT STOW SWITCH SIGNAL

5 LG/VT 22 FOLDING SEAT SWITCH RET

6 NO CONNECTION

7 NO CONNECTION

8 NO CONNECTION

1 AMP

REMOTE

DOOR DETECTOR

CONTROLLER PWR

1 AMP

1 AMP

Nuetral

Safety

Ignition

Hot

FUSE PANEL

(BEHIND GLOVE BOX)

*

2

D

N

R

P

GN/DB

Neutral Safety

1

4

8

13

17

21

3

7

23

20

16

(OEM CAV 9)

*(To Inition Hot)

located under

steering column

12

RD (8 GA.)

BK (8 GA.)

FUSE

40A

-

+

RD (8 GA.)

Cut

1

4

8

5

Page 5

Page 11

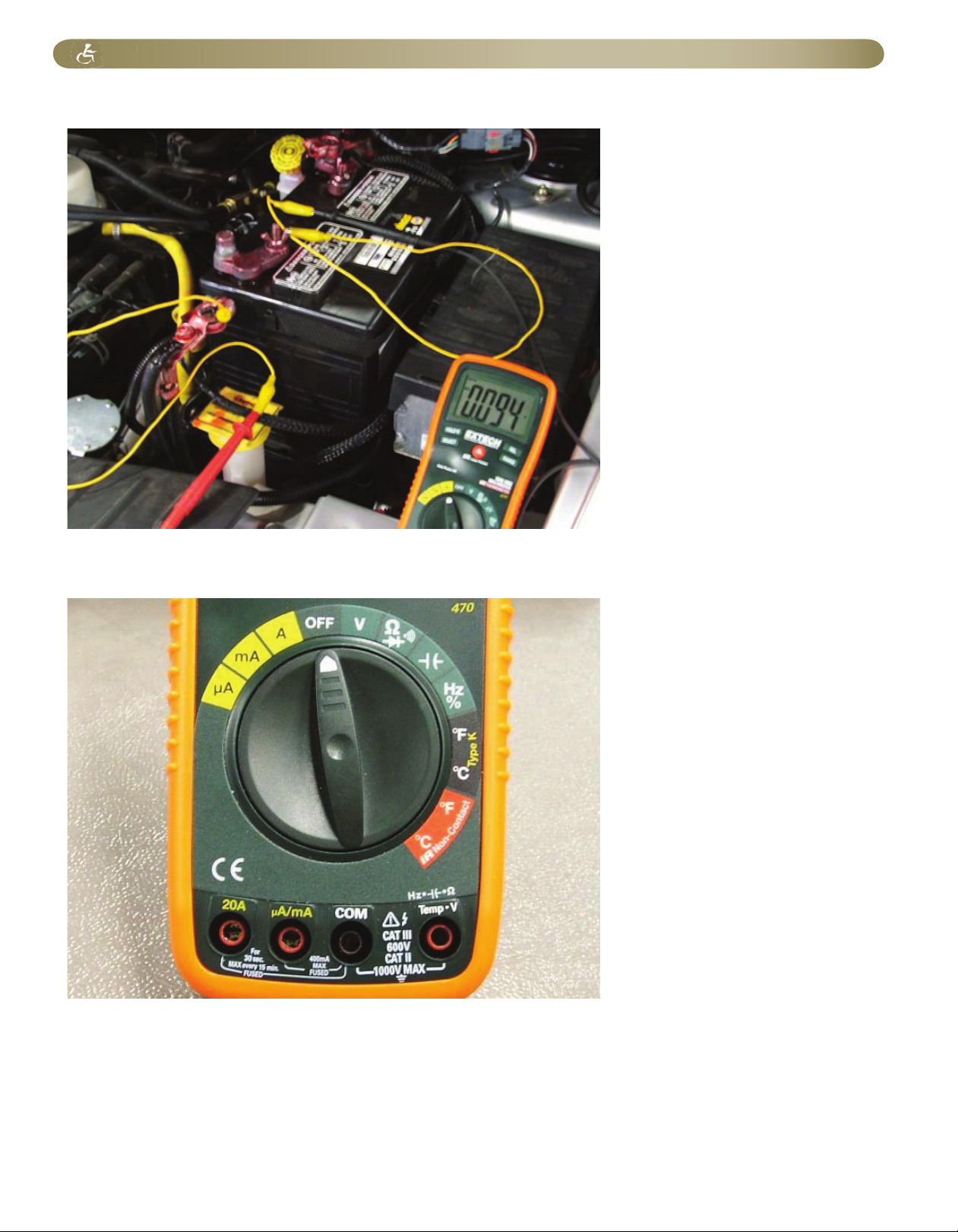

BaTTerY inforMaTion - general

The following procedure should be used to test the current draw from any battery

used in our vans.

1) Insure the battery is fully charged.

2) Remove the key from the ignition switch.

3) Close all the doors including the sliding doors and the rear tailgate.

4) Close all the windows including the rear vent windows.

5) Remove the negative (Black) cable from the battery and move it to a safe location

away from both the positive (Red) and negative terminals of the battery.

6) Acquire a Digital Multimeter with a 20 Amp current range function. NOTE: A

standard van can draw between 15 and 17 amps of current when it is first powered

up (When the battery is reconnected). You must use a multimeter with a 20 Amp

range. Using a Multimeter with a lower current range function will damage the

meter if it does not have an internal fuse. If it has an internal fuse, it will be blown.

NOTE: DO NOT RUN THE ROLLX VANS OTC OR TRY TO START THE VAN WHEN

YOU HAVE THE METER CONNECTED! YOU WILL DAMAGE THE METER!

7) Place the function switch of the Multimeter in the 20 Amp Current Measurement

position.

8) Connect the negative (black) probe (wire lead) to the black jack on the multimeter.

9) Most multimeters have more than one red jack for the positive (red) probe. They

usually have one jack for measuring AC & DC voltage and resistance, along with a

second Jack for measuring AC & DC Current. Some multimeters have more than

one red jack for measuring current (three red jacks total). As an example a meter

might have two red jacks, one rated for 200 Milliamps and a second for 20 Amps.

You should use the 20 Amp plug (or the one with the largest rating).

10) Acquire two test jumpers with alligator clips (Radio Shack # 278-002). Attach one

jumper to the positive (Red) probe and the other to the negative( Black) probe.

11) Turn the multimeter on.

12) Attach the other end of the jumper clipped on the positive (red) meter probe to the

disconnected battery cable.

NOTE: Polarity does not matter much when measuring current. A positive current

is the same as negative current. Disregard the polarity indicator on the multimeter

during these tests.

13) Attach the jumper on the negative (black) meter probe to the negative terminal of

the battery.

NOTE: YOU MAY GET A SPARK WHEN YOU ATTACH THE JUMPER. THIS IS

NORMAL. ALL THE CURRENT BEING USED BY THE VAN IS NOW RUNNING

THROUGH THE METER. AS MUCH AS 15-17 AMPS).

Page 6

Page 12

BaTTerY inforMaTion - general

14) The Multimeter should now show a reading. Keep your eye on the meter and

watch the draw. A typical van can have from 18 to 28 computer modules in it.

They are all woke up when power was applied to the van by attaching your meter

probes. As you watch the current reading you will note that it will start to fall. This

happens as the computers in the van decide they are not needed and put

themselves to sleep. Chrysler says it can take up to thirty minutes for everything

to go into sleep mode.

The current should drop in stages similar to the sequence below:

a. The reading will start as high as 15-17 amps for a short period of time.

b. It then fall to 6-8 amps for a short time.

c. Then 1 to 1.5 amps for a period of time.

d. It will then settle on around .800 amps (800 Milliamps) for a while.

e. Then it may drop to .100 to .200 amps (100 to 200 Milliamps) for period of

time.

f. Finally it will drop all the way into sleep mode, .040 to .100 amps (40 to 100

Milliamps) and will stay there until the van is woke up.

g. Note: The values you will see will vary from van to van, from van type to

type and by the number and type of accessories installed on the van. The

important thing is that it drops to a value less the 100 Milliamps (.100

Amps) for a standard van when it goes into sleep mode.

15) You can wake the van simply by opening the driver’s side door for a few seconds,

then closing it.

16) Watch the meter again to see the van go into sleep mode again. You should repeat

this test until you are satisfied the van’s “Sleep Mode” is functioning correctly.

Page 7

Page 13

BaTTerY inforMaTion - draW TeST Procedure

This picture shows a complete setup for a Draw Test:

Note the black probe attached to the negative terminal and the red probe attached to the

negative battery cable.

This picture shows a typical multimeter. Note the current range switch settings and

current probe jack markings are all in yellow for uA (Microamps), mA (Milliamps and A

(Amps).

Also note that the meter has two Jacks for current measurement, “20A” and “uA/mA”. On

this meter, for our Draw Test, we would place the Function Switch in the “A” (for Amps)

position and plug the Red Probe into the “20A” Jack. The Black Probe always goes in the

Black Jack.

Page 8

Page 14

rollX vanS door (MoTor Bar) TrouBle ShooTing

Symptom Possible Cause Remedy

Front passenger door is locked.

Unlock front passenger door.

Switch is stuck.

Make sure all user switches are not stuck.

Blown fuse.

Replace 30 or 15 amp blade fuse located

underneath hood near battery.

Manual release handle is not engaged. Turn handle all the way counter-clockwise.

Door will open, but ramp will not

deploy.

Door open limit switch needs adjustment.

Adjust the door open limit swtich (#7 on next

page). The switch can be accessed by the

passenger side rear speaker area (remove the

speaker first).

Door will open, but not close or

door will "jump" closed.

Ramp up limit switch is not engaged. Adjust the cam for up limit.

Gear on motor is stripped.

Replace motor.

Gear on bar is stripped. Replace gear rack (bar).

Door does not operate.

Door "ratchets" when operating

(make sure kneeler is off).

Page 9

Page 15

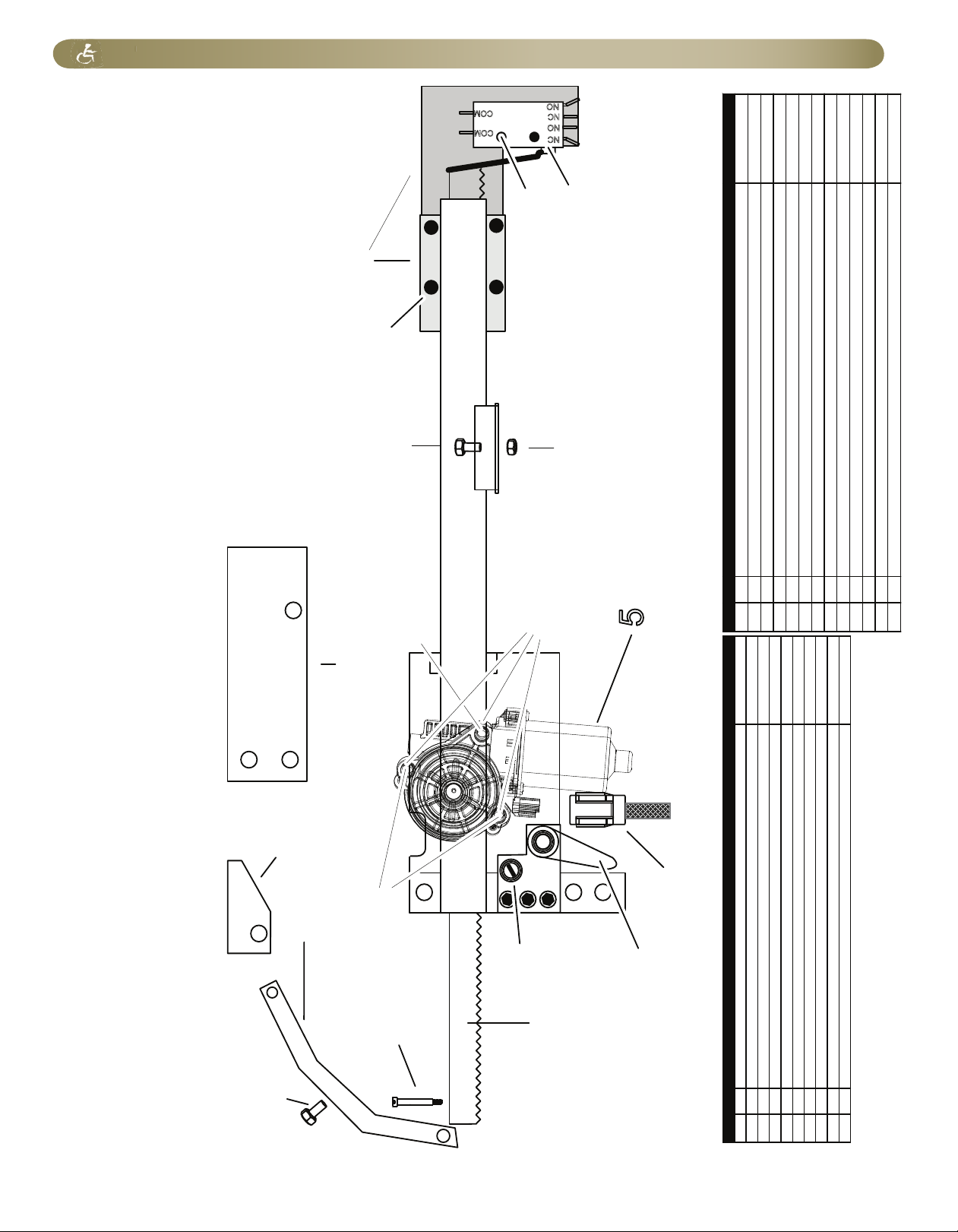

rollX vanS door (MoTor Bar) rePlaceMenT ParTS

COM

COM

NC

NC

NO

NO

1

2

3

4

5

6

7

8

9

10

11

15

12

12

13

14

Rollx Vans Power Door Exploded View

Item Qty. Description Part #

1 DOOR BAR ASM (INCLUDES THE 3 FOLLOW ING) 10026ASM

1 MTR BAR DOOR OPENER (RACK AND ASSEMBLY) 10026

1 WIRE HARNESS 5.5" FOR 310-1059

1 MTR 12V 10NM 10MM DOUBLE 210-1011

1 1 GEAR RACK (SPECIFY LONG OR SHORT)* 10026-4

LONG BAR

2 1 3/8 X 1 STRIP

1126318

3 1 ARM BAR (FOR MOTOR BAR) 10026-22

4 1 WIRE HARNESS 5.5" FOR 310-1059

5 1 MOTOR ONLY W /GEAR ASM (INCLUDES WIRE HARNESS AND SHIMS**)

10026-15ASM

* LONG USED BEFORE ~2001 IF NO REAR HEAT & AIR

** SHIMS ONLY NEEDED IF BEFORE ~2003 BUT ALWAYS SENT WIT H MOTOR

Item Qty. Description Part #

6 1 B RKT MTR BAR LIMIT SW ITCH MB1006

7 1 S WITCH DPDT (CHERRY) E19-50H

8 1 HANDLE CHROME INSIDE 6022

9 1 DOOR BRACKET A (DOOR BRACKET B - ) MB1001 (MB1002)

10 2 DOOR ARM PLATE MB1005

11 N/A MANUAL RELEA SE TENSION ADJUSTMENT NA

12 N/A 1/4-20 NYLOCK NUT SHOP SUPPLY

13 2 #6 NYLOCK NUT SHOP SUPPLY

14 1 1/4-20X3/4 HEX HEAD SCREW SHOP SUPPLY

15 1 5/8-20X1 HEX HEAD SCREW (ADJUSTMENT) SHOP SUPPLY

16 1 SHIM KIT FOR DOOR OPENERS (INCLUDES ALL 3 - VARYING SIZES) 10026-12

17 2 #10-32X2 HEX HEAD (5/32) PARTIALLY THREADED SCREW SHOP SUPPLY

18 1 #10-32X2-1/2 HEX HEAD (5/32) PARTIALLY THREADED SCREW (NUT ON BACK) SHOP SUPPLY

17

18

16

Page 10

Page 16

oeM PoWer door TrouBleShooTing

Symptom Possible Cause Remedy

Van is NOT in park. Place van into park.

Overhead on/off switch is turned to the OFF

position.

Turn switch to ON position.

OTC program failure. Press OTC reset button.

OTC reads low voltage.

Start van's engine and press OTC reset button.

If door still does not open review OTC board

display and contact customer service.

Bad OTC board.

Press the OTC reset button and while in Idle

Mode press a user button and watch the LED.

Notice if OTC appears to be working properly.

Review error codes stored and call customer

service.

Main OTC fuse (40 amp) is blown. Replace fuse under hood by battery.

OEM overhead ON / OFF switch is OFF.

Turn switch to ON position. This switch enables /

disables the OEM buttons located on the B

pillars that Rollx Vans uses to trigger the sliding

door to open or close.

Defective OEM door opener.

Operate door manually and contact customer

service.

Ramp sliding door does NOT

attempt to CLOSE after ramp

stows.

Ramp up limit switch is not being activated

properly.

Close door manually, press OTC reset button,

and press Rollx Vans user button to operate

system again. If door still does not attempt to

close after ramp is stowed, review OTC board

display and contact customer service.

Defective door open bracket. Adjust the bracket and contact customer service.

Defective OEM door opener.

Press OTC reset button, press interior OEM

push button to see if door will close

automatically. If door still does not respond,

review OTC board display and contact customer

service.

Obstruction. Check door track for any debris and remove.

Ramp needs adjustment (Foldout only). Adjust folding ramp to stow more.

OEM door sensitivity set low. Contact local Chrysler Dealership.

Ramp sliding door opens and van

kneels, but when door is all the way

open, van unkneels and cycle

ends.

OEM Door Ajar Pin Switch (Rollx Vans Door

Close signal) is never deactivated when door

begins to open.

If the OTC thinks the door is open and closed it

will end the cycle. Examine switch / wiring.

Ramp needs adjustment (Foldout only). Adjust folding ramp to stow more.

Defective OEM cinch motor.

Operate door manually and contact customer

service.

Ramp sliding door does NOT

OPEN manually.

Door is locked.

Unlock door. When pulling door handle, pull

handle out and then slide door to open.

Ramp sliding door does NOT

OPEN manually from interior

handle, but does from exterior

handle.

Child safety lock is activated.

See OEM owner manual to deactivate child

safety lock.

Ramp sliding door closes half way

and then moves back and forth.

Stuck door open limit swith, or CAN BUSS door

opener Module.

Adjust swtich located in rear of lower door track,

or unplug module & wait 2 seconds.

Door handle is not releasing.

Pull handle to disengage latch and slide to

close.

Obstruction. Check door track for any debris and remove.

Ramp sliding door will NOT CLOSE

manually.

Ramp sliding door does NOT

OPEN with interior OEM push

buttons after pressing OTC reset

button.

Ramp sliding door attempts to

close (door motor runs) after ramp

stows, but door does not move.

Ramp sliding door kicks back when

opening or closing.

Ramp sliding door does not seal

when almost closed.

Passenger sliding door does NOT

OPEN with interior Rollx Vans user

button.

Note: In order to disable the OEM door from closing when the ramp is out, Rollx Vans interupts

Chryler’s CAN BUS circuit to prevent the door from getting any signal to close. The Scan tool will read

a “No Communication with the Right Rear Door Module” everytime the system deploys

the ramp. This is a normal trouble code and is to be excpected.

Page 11

Page 17

door ModificaTionS

#10277 - Rivets (9 per Door)

Inner Door Skin (Extension)

Driver Side - #B08180-D5

Passenger Side - #B08180-P5

DOOR TRACK EXT BKT UPPR 08

#B08030ASM

Needs to be painted to match van

Outer Sliding Door

#10277 - Rivets (6 per Door)

Door extension kits

part numbers and

descriptions

-B08180-D5-KIT-ITF

Door skin svc kit itf dr

-B08180-D5-KIT-FO

door skin svc kit fo dr

-B08180-P5-KIT-ITF

Door skin svs kit itf pass

-B08180-P5-KIT-FO

Door skin svs kit fo pass

OEM BOLT (3)

A#6505 480A

#B08033

‘08 LOWER DOOR ARM

(Spaceship bracket)

OEM LOWER DOOR ROLLER ARM

Passenger Side - #5020 920AB

Driver Side - #5020 921AB

Current

#B08180-DP6 - L BRKT DOOR SKIN DR/PASS 08

Before 10/20/2008

#10503 - 1”X 1” 14GA ROLLED ANGLE

CABLE POWER DOOR 2008

#AR-2008

BOLT (3) - #0115007

WASHER (3) - #1133004

Page 12

Page 18

door ModificaTionS

DOOR TRACK EXT BKT LOWR 08 ASM

#B08032ASM

(#B08032-1ASM Vans Started after 7/21/2010)

(Includes Switch, Wire Harness, and Bracket)

SNAKE CONNECT BLOCK SLIDE ARM

#B08050 (Not Shown)

BUMPER, MIDDLE TRACK

#9306K14

Passenger Sliding Door Middle Track

ZOOM +

Door track kits and descriptions include OEM track and door open switch bracket

B08059asm-dr - Door track asm 08-09 dr

B08059asm-dr-2010 - Door track asm 10-13 dr

B08059asm-ps - Door track asm 08-09 ps

B08059asm-ps-2010 - Door track asm 10-13 ps

DOOR OPEN SWITCH

ASSEMBLY - #05089-003

Built Before 8/26/2013

DOOR TRACK EXT BKT LOWR 08

#B08032

(#B08032-1 Vans Started after 7/21/2010)

1/4-20X1/2” Hex Bolt

#0115001

FHSCS 1/4-20X1/2 ZB

#94222

Page 13

Page 19

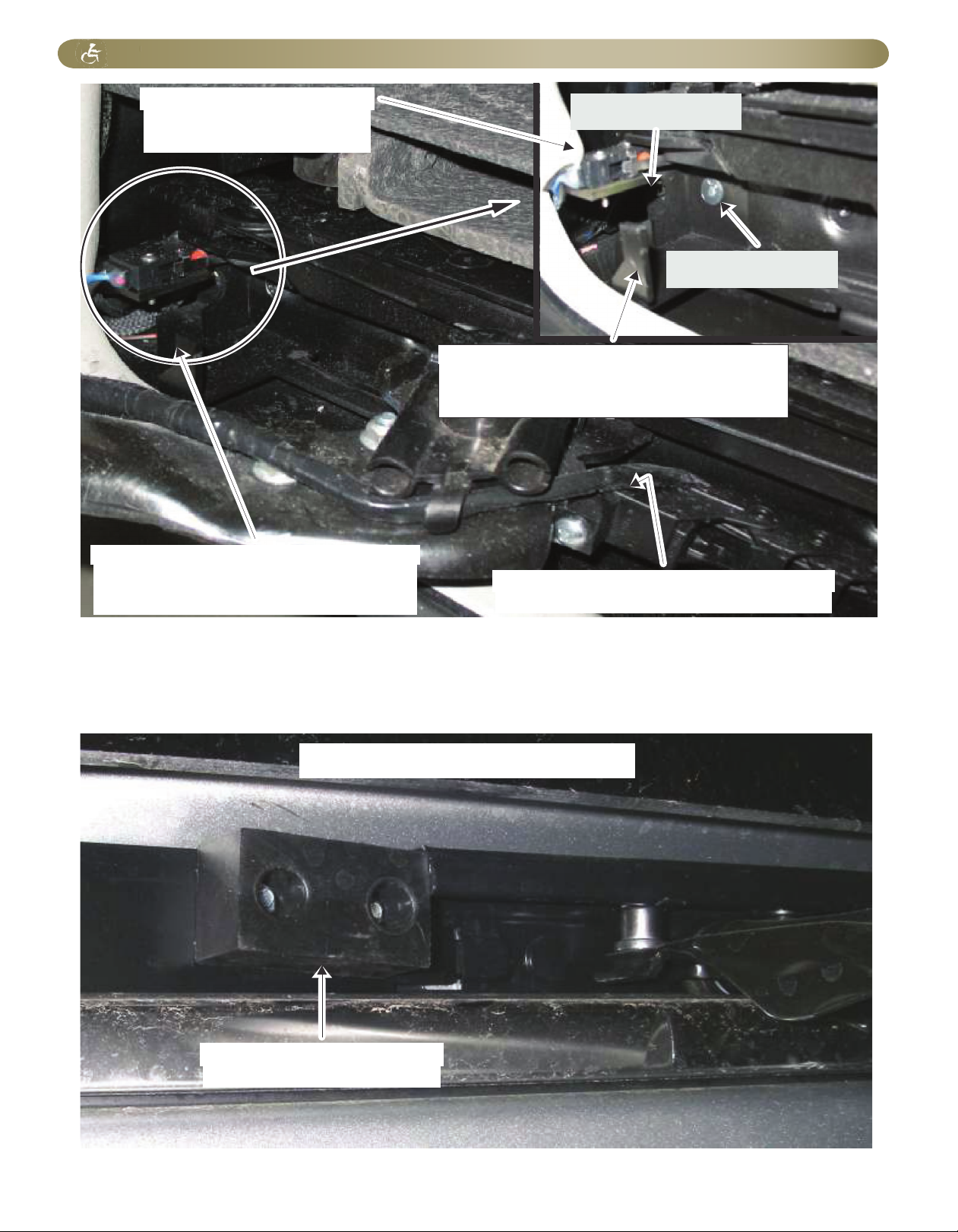

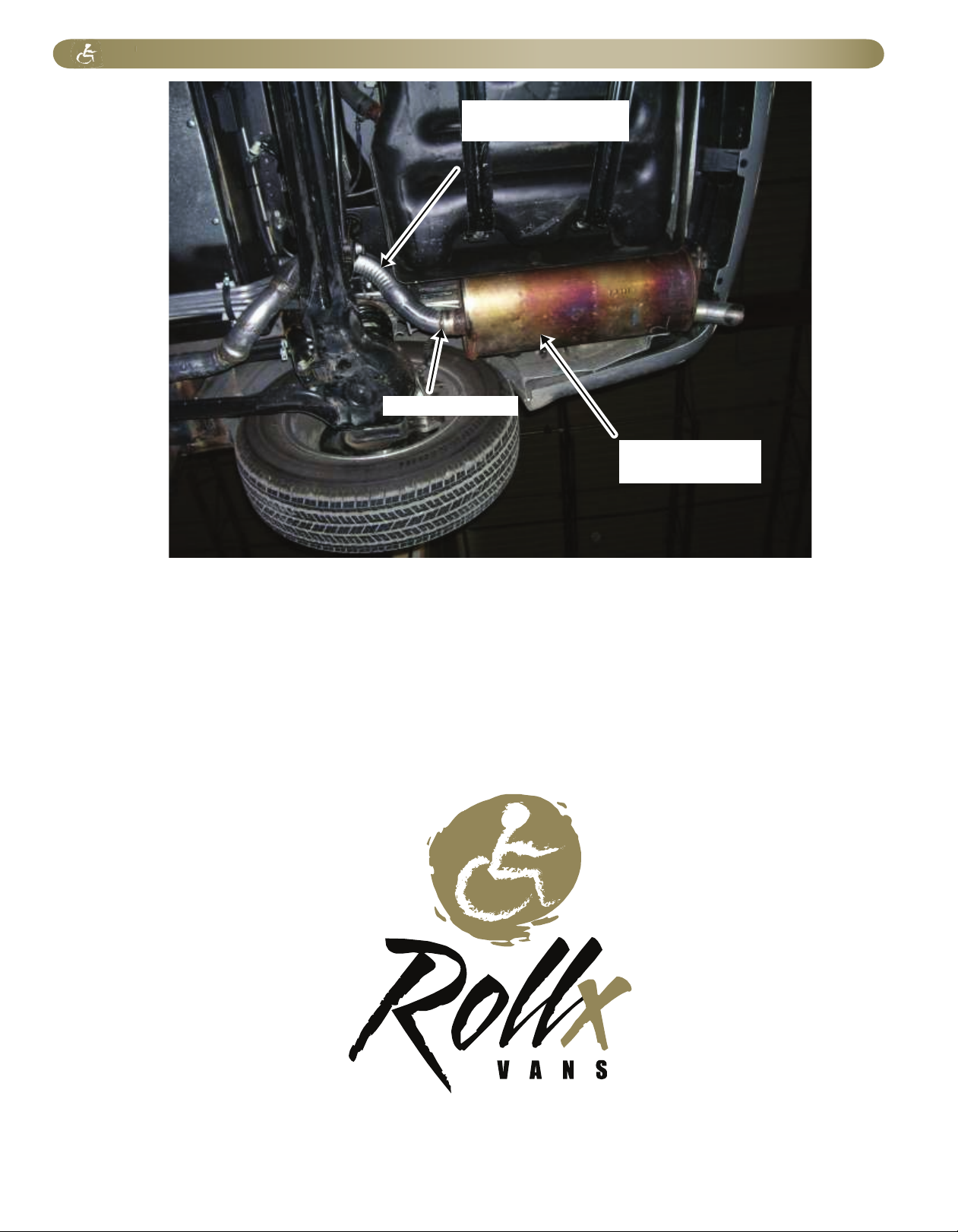

Rollx Vans Exhaust

#B08201-SS

Rollx Vans begins their exhaust from the OEM Catalytic Converter (Rollx Vans does not modify the OEM

Catalytic Converter or OEM 02 Sensor). Rollx Vans Exhaust is welded to the OEM Catalytic Converter

and runs down the passenger side of the van.

Rollx Vans reuses the OEM Hangers to support the exhaust. Rollx Vans Exhuast is 2-1/4 inch diameter

aluminized tubing and replaces the OEM 2-1/2 exhaust.

OEM Hanger

Rollx Vans Weld

OEM Catalytic Converter /

O2 Sensor

Rollx Vans Exhaust

3.3L & 3.8L #B08200-SS

4.0L #B08202

3.6L #B11200-SS

Rollx Vans Weld

eXhauST SYSTeM

Page 14 Page 14

Page 20

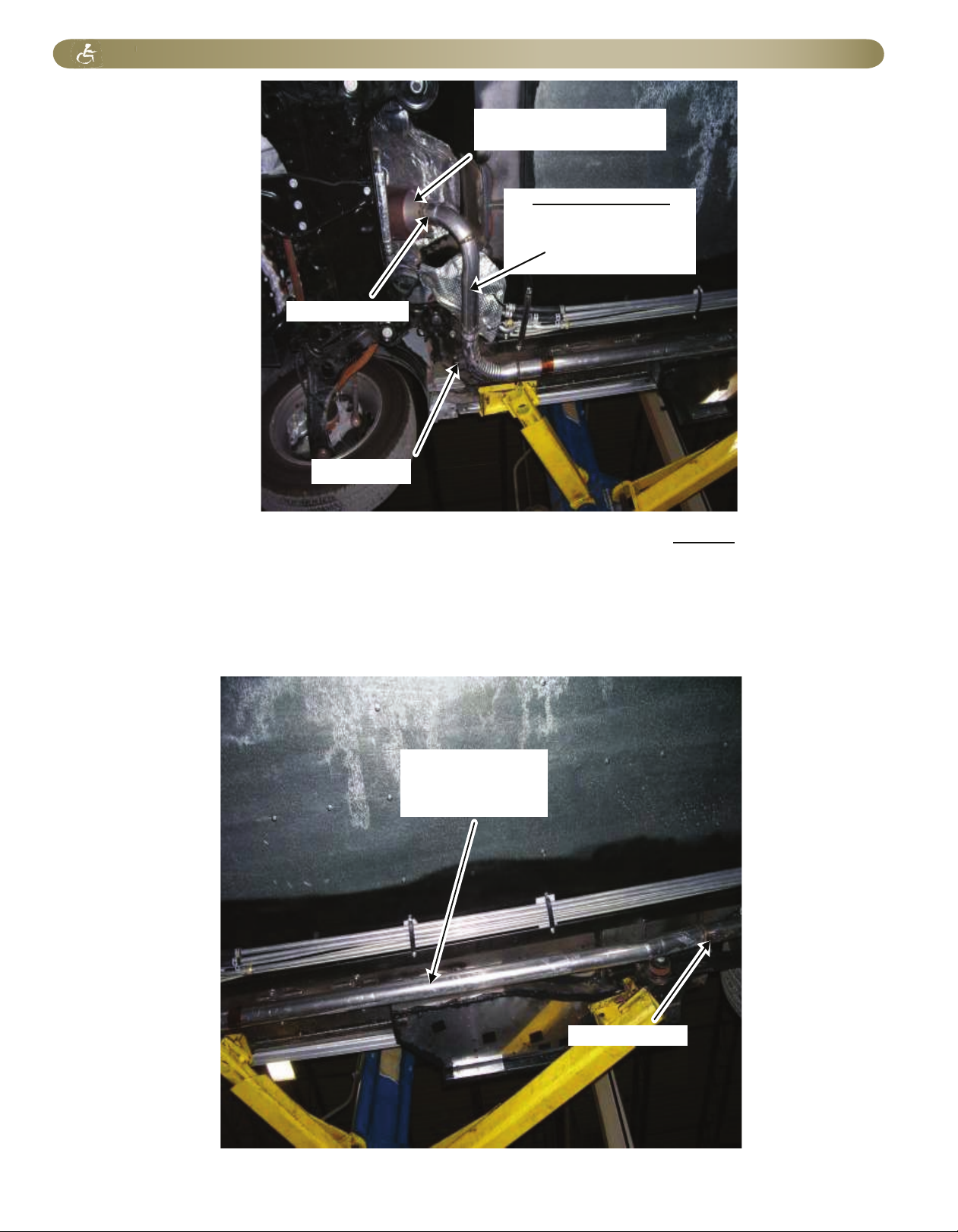

Rollx Vans Exhaust continues over the rear axle and is welded to the OEM Muffler and Tailpipe.

Rollx Vans eliminates the OEM Resonator.

Rollx Vans Exhaust

#B08201-SS

OEM Muffler and

Tailpipe

Rollx Vans Weld

eXhauST SYSTeM

Page 15

Page 21

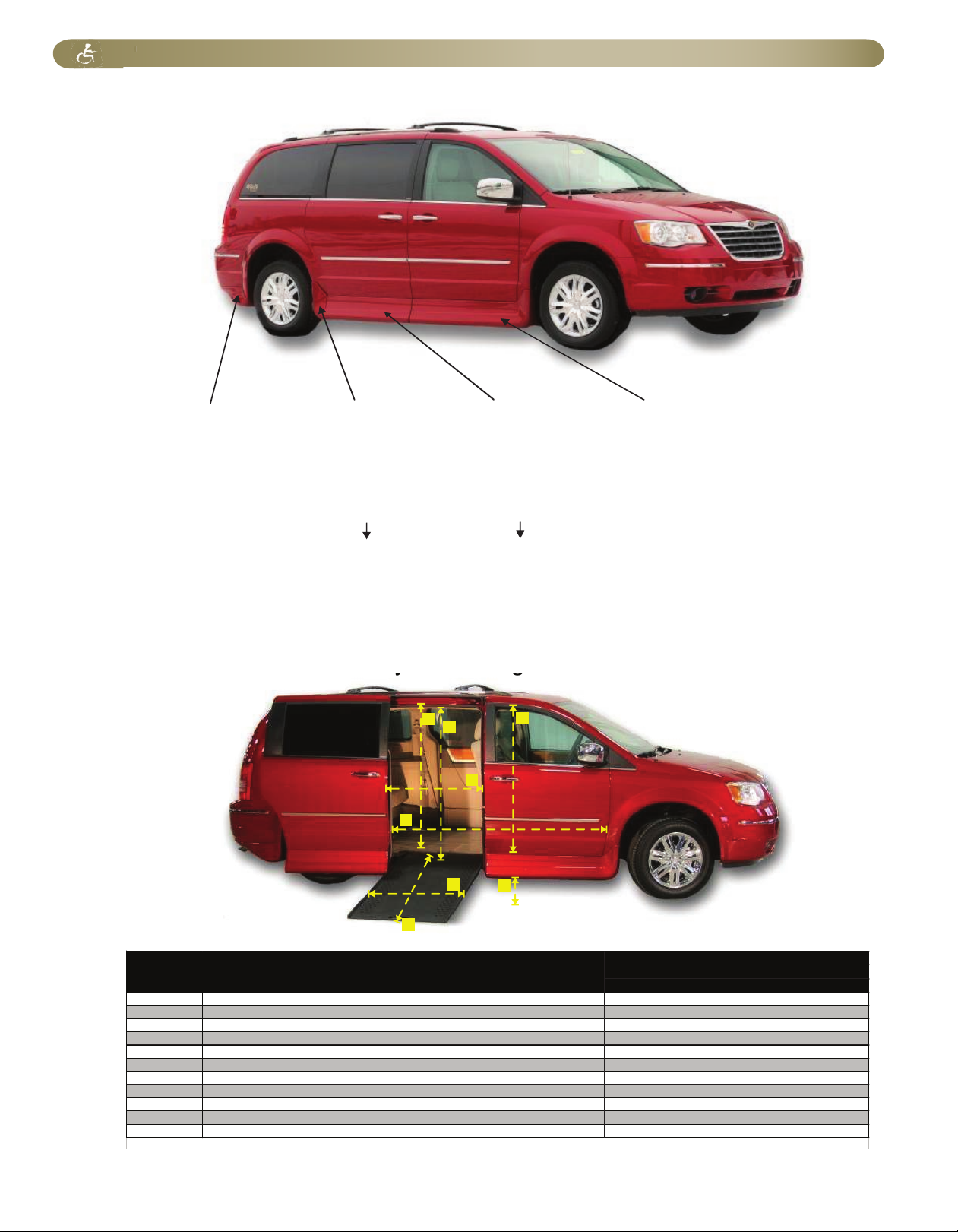

eXTerior / van diMenSionS

AAAAA21AAAAA2AAAA2

3

4

5

7

6

68

2011-2013 Chrysler / Dodge Minivan Dimension Sheet

Rollx Vans Chrysler/Dodge Rollx Vans Chrysler/Dodge

In The Floor Ramp Folding Ramp

11 Inch Drop 11 Inch Drop

1 Floor to Ceiling Height 58 58

2 Passenger Sliding Door Opening Height 54.5 54

3 Floor to Overhead Console 57 57

4 Passenger Sliding Door Opening Width 31.5 31.5

5 Cargo Area Length (Rear "z" to Firewall Along Floor) 84 84

6 Ground Clearance - Ground Effect 7 7

7 Ramp Length 50 55.5

8 Ramp Width (Inside Wall to Inside Wall) 30 29

Cargo Area Width When Closed (Door to Door / Door to Ramp) 66.5 61.5

Ground Clearance - Lowest Point (Exhaust) 5.5 5.5

Cargo Area Length (Rear Sofa to Clip-in Base) 54.5 54.5

* All measurements are subject to change depending on various van configurations and should be used as approximation

s.

Measurement Description

#B08180-P1

#B08180-D1

(Before 12/2/08)

#B08180-P3

#B08180-D3

(After 12/2/08)

#B08180-P3.2

#B08180-D3.2

(Chrysler Vans Only)

(Dodge Vans Only)

#B08180-P4D

#B08180-D4D

#B08180-P4

#B08180-D4

#B08180-P = Passenger Side

#B08180-D = Driver Side

(Before 12/2/08)

#B08180-P2

#B08180-D2

(After 12/2/08)

#B08180-P2.2

#B08180-D2.2

When replacing either of these ground effects on a 2008 Chrysler van built before 12/2/08. order

as follows:

D3 or P3 = it is necessary to replace both the D2 and D3 with the new D2.2 and D3.2

(same for passenger side).

D2 or P2 = we have about 20 in stock of each so just replace that required piece until

out of stock, then follow above rule.

Ÿ

Ÿ

Page 16 Page 16

Page 22

OEM Filler Neck Top

(Gas Cap)

OEM Fuel Fill

Vent Line

Rollx Vans Fuel Fill

Vent Hose (5/16”)

OEM Fuel

Tank

Rollx Vans Charcoal

Canister Vent Hose (5/8”)

OEM Fuel Pump /

OEM Fuel Filter

Rollx Vans Main Fuel Hose (3/8”)

Rollx Vans Filler Neck Metal Tube

Rollx Vans Main Fuel Metal Line (5/16”)

Rollx Vans Charcoal

Canister Vent Metal Line (3/8”)

OEM Charcoal

Canister

To Engine

OEM Fuel Quick

Disconnect (5/16”, 0°)

Pre-modified

OEM Setup

2011-2014 Chrysler Town & Country / Dodge Grand Caravan (3.6L)

Rollx Vans Fuel / Emission System Overview

(V5)

OEM EGR Valve

OEM Plastic Line

OEM Quick Disconnect (3/8”, 45°)

OEM Charcoal

Canister Vent Line

*See page 18 for Rollx Vans part #’s

fuel SYSTeM

Page 17

Page 23

OEM Filler Neck Top

(Gas Cap)

OEM Fuel Fill

Vent Metal Line

Rollx Vans Fuel Fill

Vent Hose (5/16”)

Part #H-211

(5/16” HIGH PRESSURE

HOSE-R9) 37 inches

OEM Fuel

Tank

Rollx Vans Charcoal

Canister Vent Hose (5/8”)

Part #10929-00834

(FUEL LINE 5/8”-R7)

53 inches

OEM Fuel Pump /

OEM Fuel Filter

Rollx Vans Main Fuel Hose (3/8”)

Part #H-212

3/8” HIGH PRESSURE HOSE-R9)

40 inches

Rollx Vans Filler Neck

Part #B08103ASM

(FILLER NECK 2008 ASM)

Rollx Vans Main Fuel

Metal Line (5/16”)

Part #126299

(5/16”X028/X13' FUSION)

Rollx Vans Charcoal

Canister Vent Metal Line (3/8”)

Part #101865

(3/8”X028X13' FUSION WELD)

OEM Charcoal

Canister

OEM Charcoal

Canister Vent Line

OEM Quick Disconnect (3/8”, 90°))

OEM Quick

Disconnect (5/16”)

OEM Quick Disconnect (5/8”)

OEM Quick Disconnect (5/8”)

OEM Quick Disconnect (3/8”)

0°

OET 15

90°

90°

OET 17

45°

OET 17

90°

Clamp #10

45°

Clamp #10

90°

OET 15

fuel SYSTeM

Page 18

Page 24

fuel SYSTeM

OEM Fuel Fill Neck

OEM Fuel Fill Vent Line

Rollx Vans Fill Neck Extension

#B08103

(Aluminized Steel Tubing)

OEM Fuel Filler Neck (Gas Cap)

Rollx Vans welds a Fill Neck Extension onto OEM Fuel Fill Neck to extend the OEM Fuel Fill Neck to

the OEM Fill Neck Hose that attaches to the tank. The completed assembly is #B08103ASM that

includes the OEM Fuel Fill Neck welded to the Rollx Vans Fill Neck Extension. The modified filler neck

Is smoke tested for possible pin hole leaks.

Rollx Vans attaches a Fuel Fill Vent Hose that begins at the gas tank to the OEM Fuel Fill Vent Line

with a 9/16” clamp. This hose and the filler neck tube are routed underneath the frame.

Rollx Vans Fuel Fill Neck

Assembly

#B08103ASM

Rollx Vans Fuel Fill Vent Hose

#H-211

(5/16” Fuel Injection Hose,SAE 30R9, Goodyear)

OEM Quick Disconnect

with Rollx Vans Clamp #OET 1315 (5/16”)

Page 19

Page 25

fuel SYSTeM

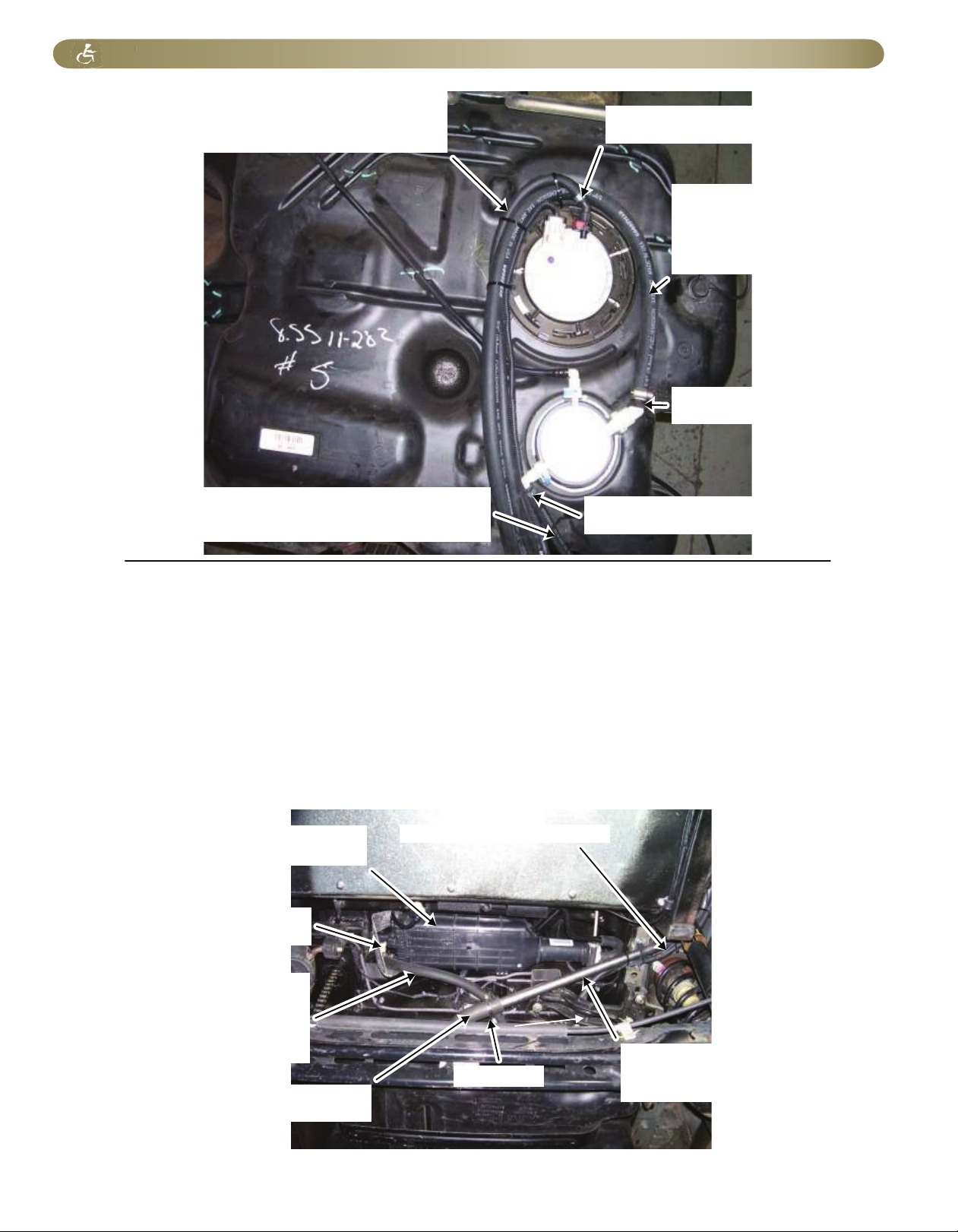

Rollx re-uses the OEM Gas Tank.

Vans

Rollx replaces OEM Fuel Fill Vent Hose with Rollx Fuel Fill Vent Hose that runs to OEM Fuel

Vans Vans

Vent Line near Filler Neck top (Gas Cap).

Rollx replaces OEM Charcoal Canister Vent Hose with Rollx Charcoal Canister Vent Hose

Vans Vans

that runs to OEM Charcoal Canister. Rollx does not modify the OEM Charcoal Canister or its mounting.

Vans

Rollx replaces OEM Main Fuel Hose with Rollx Main Fuel Hose that runs to Rollx Main

Vans Vans Vans

Fuel Metal Line where it is attached to the flared metal line with the OEM Quick Disconnect.

Rollx Vans Main Fuel Hose

Part

#H-212

(3/8” Fuel Injection Hose,SAE 30R9,180 PSI,WP,

CARB #c-u-06-002, Gates Corp.)

Rollx Charcoal Canister Vans

Vent Hose

Part #10929-00834

(5/8” Fuel/Emissions Hose,

SAE 30R7, Goodyear)

Rollx Fuel Fill Vent Hose

Vans

OEM Quick Disconnect

with #10 Hose Clamp

Rollx Fuel Fill Vent Hose Vans

Part

#H-211

(5/16” Fuel Injection Hose,SAE 30R9, Goodyear)

OEM Quick Disconnect with

Rollx Clamp #OET 1315 (5/16”) Vans

Part

OEM Fuel Fill Hose

at Tank

OEM Clamp

Rollx Fill Neck Extension

Vans

Part #B08103ASM

(Aluminized Steel Tubing)

Rollx Charcoal Vans

Canister Vent Hose

Part #10929-00834

(5/8” Fuel/Emissions Hose,

SAE 30R7, Goodyear)

OEM Charcoal Canister

(OEM mounting)

OEM Quick Disconnect with

Rollx Clamp #OET 1317 (3/8”)Vans

Part

OEM Quick Disconnect

with #10 Hose Clamp

Page 20

Page 26

fuel SYSTeM

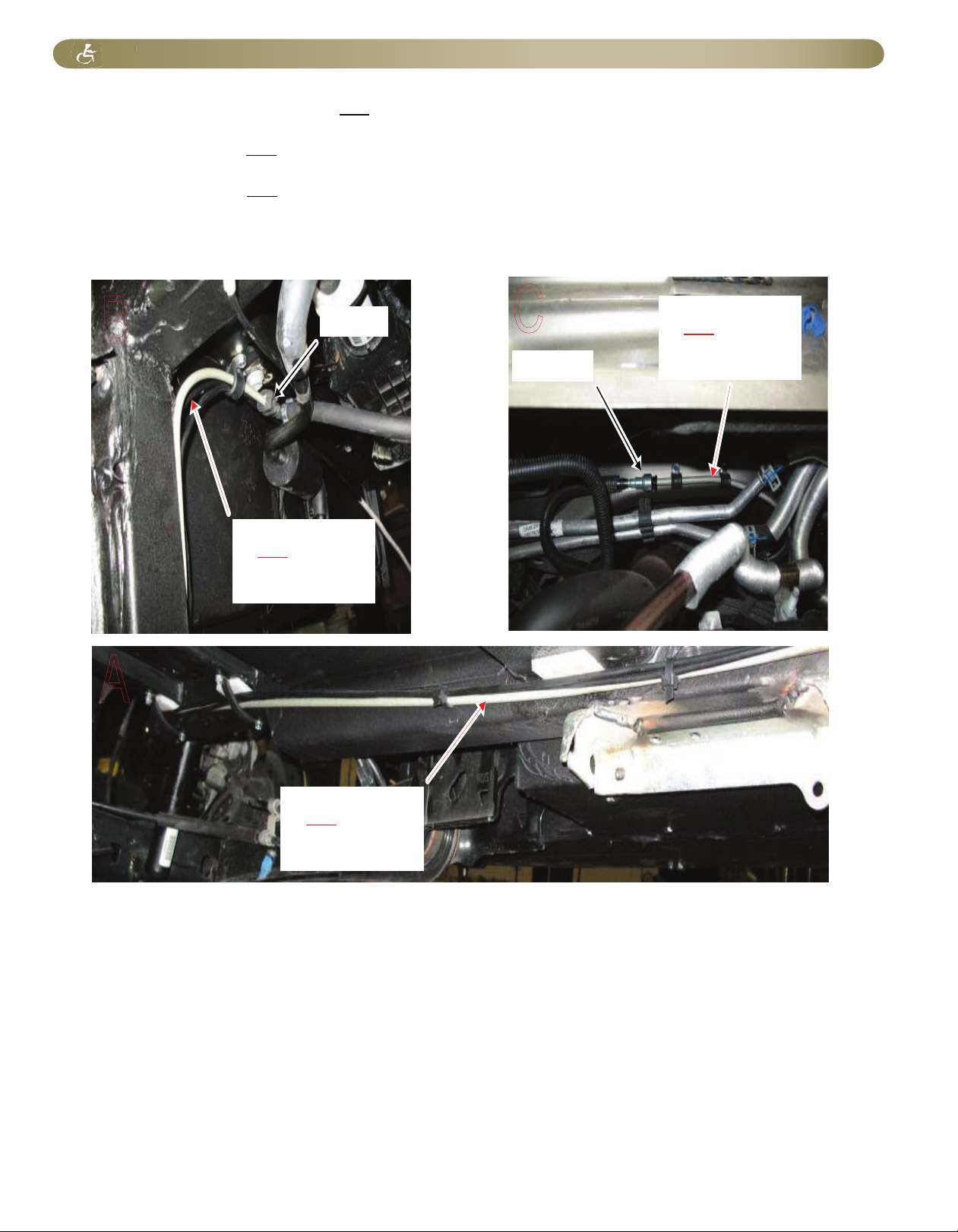

A) Rollx routes the Rollx Main Fuel Metal Line (5/16”) under the driver’s side of the van using P-Clamps to secure.

Vans Vans

B) The Rollx Main Fuel Metal Line (5/16”) is routed up the rear z, flared and attached to OEM Quick Disconnect.

Vans

C) The Rollx Main Fuel Metal Line (5/16”) is routed up under the engine compartment, flared and attached to OEM Quick Disconnect.

Vans

Rollx Vans Main Fuel

Metal Line (5/16”)

Part #126299

(5/16”X028/X13' FUSION)

Rollx Vans Main Fuel

Metal Line (5/16”)

Part #126299

(5/16”X028/X13' FUSION)

Rollx Vans Main Fuel

Metal Line (5/16”)

Part #126299

(5/16”X028/X13' FUSION)

OEM Fuel Quick

Disconnect (5/16”, 0°)

A

B

C

OEM Fuel Quick

Disconnect (5/16”)

Engine Compartment

Page 21

Page 27

fuel SYSTeM

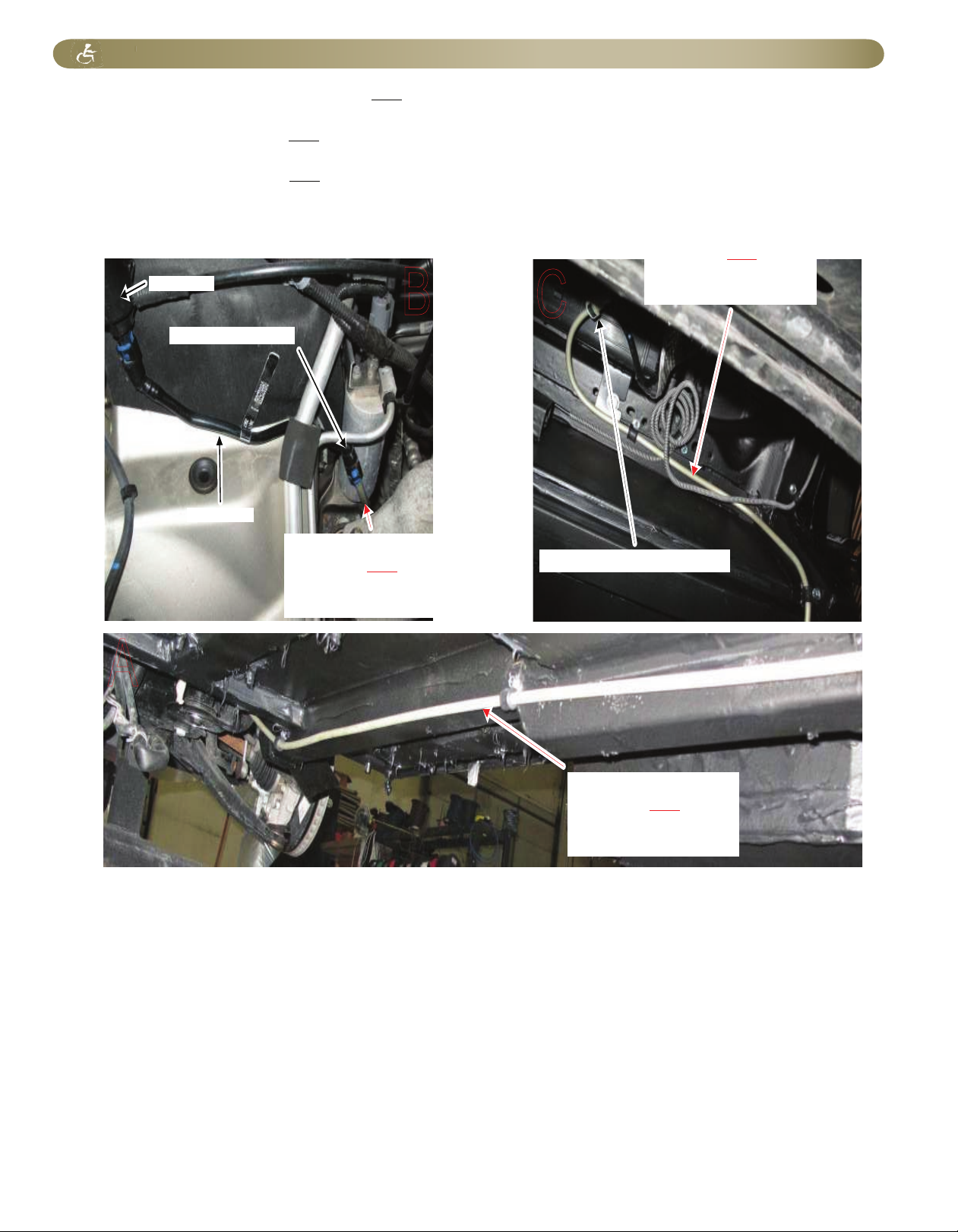

A) Rollx runs the Rollx Canister Vent Metal Line (3/8”) under the passenger side of the van using P-Clamps to secure.

Vans Vans

B) The Rollx Canister Vent Metal Line (3/8”) is routed up under the engine compartment, flared and attached to OEM Quick Disconnect.

Vans

C) The Rollx Canister Vent Metal Line (3/8”) is routed up the rear z, flared and attached to OEM Quick Disconnect.

Vans

A

B

C

Engine Compartment

Rollx Vans Charcoal

Canister Vent Metal Line (3/8”)

Part #101865

(3/8”X028X13' FUSION WELD)

Rollx Vans Charcoal

Canister Vent Metal Line (3/8”)

Part #101865

(3/8”X028X13' FUSION WELD)

OEM Quick Disconnect (3/8”, 90°))

Rollx Vans Charcoal

Canister Vent Metal Line (3/8”)

Part #101865

(3/8X028X13' FUSION WELD)

OEM Quick Disconnect (3/8”, 45°)

OEM Plastic Line

OEM EGR Valve

Page 22

Page 28

Strut Collar Assembly #B08001ASM

Adjustable

Camber Bolt #41-214

Front Strut Mounting Bolts #B08001ASM

BOLTS:

5/16” -18 x 1” (QTY 6)

#0115055

WASHERS:

1/4” ZINC FLAT(QTY 6)

#1133004

LOCK WASHERS:

5

/16” (QTY 6)

#1133892

*Reuse OEM strut collar nuts

to fasten collar to strut.

OEM

Camber Bolt

Stabilizer Bar Link

Strut Assembly

fronT SuSPenSion

Page 23

Page 29

Snubber Extension Assembly

p.n. B08055ASM

Vans Built Prior to 1-2-2013

SERVICE KIT #R0046

COIL SPACER ON BOTTOM

Vans Built After 1-2-2013

SNUBBER EXTENSION ON TOP

Kneel Axel Mount B08022

Brake line bracket B08068ASM-DR

Brake line bracket B08068ASM-PS

Traction Bar Spacers B08065

BOLTS:

(QTY 4)

M10-1.50 x 100mm

#0153998

WASHERS: (QTY 4)

1/2” ZINC FLAT

#1133012

Traction Bar

Trailing Arm

Shock Absorber

Coil Spacer

Coil Spacer

rear SuSPenSion

Page 24

Page 30

engine MounTing (cradle droP)

Front Engine Mount

Right Side Engine Mount

Left Side Engine Mount

1” Motor Mount

N05010 (QTY 4)

2.5” Motor Mount

N05011 (QTY 5)

BOLTS:

M10-1.50 x 70mm (QTY 3)

#0153994

WASHERS:

3/8” ZINC FLAT(QTY 3)

#1133008

BOLTS:

M12-1.50 x 70mm (QTY 2)

#38503

WASHERS:

1/2” ZINC FLAT(QTY 2)

#1133012

BOLTS:

M14-2.0 x 190mm (QTY 4)

#0122055

Left Cradle Mount

(Right side same)

Left Crossmember Bracket

(Right side same)

WASHERS:

3/8” ZINC FLAT(QTY 4)

#1133012

BOLTS:

M12-1.75 x 50mm (QTY 4)

#0122055

WASHERS:

3/8” ZINC FLAT(QTY 4)

#1133012

OEM Isolator bolt

#4721 746AB (QTY 1)

1” Motor Mounts

N05010 (QTY 5)

Page 25

Page 31

TorQue SPecificaTionS

Torque Specifications

Location Torque

100 Ft. Lbs.

116 Ft. Lbs.

65 Ft. Lbs.

21 Ft. Lbs.

21 Ft. Lbs.

100 Ft. Lbs.

40 Ft. Lbs.

129 Ft. Lbs.

60 Ft. Lbs.

55 Ft. Lbs.

55 Ft. Lbs.

Engine & Cradle Front Engine Mount 83 Ft. Lbs.

Mounting

40 Ft. Lbs.

70 Ft. Lbs.

Left & Right Cradle Mounts 120 Ft. Lbs.

Left & Right Cross Member Brackets (M14 Bolts) 120 Ft. Lbs.

Left & Right Cross Member Brackets (M12 Bolts) 40 Ft. Lbs.

Right Side Engine Mount

Left Side Engine Mount

Front Suspension Wheel nuts

Camber Bolts

Stabilizer Bar Link Nuts

Rear Suspension

Trailing Arm Pivot Thru-Bolts

Item

Shock Absorber Upper Mounting Bolts

Shock Absorber Lower Mounting Bolts

Strut Collar-to-Strut

Traction Bar To Axle Bolts

Strut Collar-to-Body

Trailing Arm Bracket-to Body Bolts

Wheel nuts

Page 26

Page 32

L-TRACK 12 HOLE #10015-1

L TRACK 5 HOLE - #10006

L TRACK 3 HOLE (FRONT) #10016

L-TRACK 4-(FRONT) #Fe200763

END CAP FOR SERIES L

#8663 END CAP

L-TRACK 6 HOLE #10007-1

CLIP IN SEAT BASE COVERS

#B08070-1

FOLDOUT RAMP ROLLER ASM

(NOT SHOWN, FOLDOUT RAMP ONLY)

BRACKET STABILIZER, 2008 - #F08018

ROLLERS CUSHIONED - #22875T11

DOG BONE COVERS

#B2205-1

B PILLAR INTERIOR

DRIVER #B8800-1

PASSENGER #B8801-1

DOOR PANEL INTERIOR

DRIVER #B8802-1

PASSENGER #B8803-1

Wheel Well Cover

Driver #B8808-1

Passenger #B8807-1

Interior Wire Cover #B8806-1

(may need to be painted to match)

inTerior

Page 27

Page 33

SEATBELT PASS, FEMALE, MED. SLATE

PART #1GX881D5AA

SEATBELT PASS. FEMALE, DK. SLATE

PART #1GX881S3AA

CLIP IN FOOTREST11 IN.,DR

#4003-11INCH-D-FOOTREST

#4003-11INCH-P-FOOTREST

CLIP IN COVER FLAP

(NOT SHOWN -

FLAP TO ACCESS SEAT

CONNECTORS)

#B08070

CLIP IN BASE,11

#4003-11-ASM-DR

#4003-11-ASM-PS

(INCLUDES FOOTREST)

TIRE COVER 2008 ASM

#B08060ASM

KNEEL ACCESS COVER

(NO PART NUMBER)

SEATBELT EXT L TRACK

#5086227AA-L

SEATBELT EXT 2008 12"FEM/MALE

(NOT SHOWN) - MAKES SHOULDER

HARNESS LONGER)

#5086227AA-EXT

SEAT BELT MOUNT BRKT "Z"

PART #STBLT1

inTerior

Page 28

Page 34

Kneeler TrouBleShooTing

Symptom Possible Cause Remedy

Kneel on / off switch is turned OFF. Turn kneel switch to the ON position.

Kneel motor or Broken Chain

Review display board. Turn kneel switch to the OFF position

and press OTC reset button. Operate without kneel option

enables. Contact customer service.

After van is lowered to ground the kneeler makes a loud ratcheting sound. Kneel down limit switch was not activated.

Adjust kneel down limit switch. Replace if broken. Contact

customer service.

Kneel on / off switch is turned OFF. Turn kneel switch to the ON position.

Kneel motor .

Review display board. Manually un-kneel van, turn kneel switch

to the OFF position and press OTC reset button. Contact

customer service.

Kneel up limit switch is activated incorrectly.

Adjust kneel up limit switch. Replace if broken. Contact

customer service.

Van raises and while door closing the kneeler ratchets. Kneel up limit switch is not activated.

Once door is closed and van is at normal height, turn kneeling

switch to the OFF position.

Van will NOT RAISE when ramp is stowed.

Van does NOT LOWER to ground while door is opening after Rollx Vans user button

is pressed.

Page 29

Page 35

Kneeler rePlaceMenT ParTS

1

2

3A

4

5

6

15

8

9

10

11

12

13

11

2

6

14

Part# KNEEL SNG OT-02 - Desc. KNEEL ASM CHRY, SNG,

OTC, 2005-12v2 (COMPLETE ASM)

3

Item Qty. Description Part #

1 1 ACTUATOR KNEELING ASM K2XG20-12V-08RX-ASM

2 2 50 CONN LINK N0511-C

3 1 KNEEL CHA IN ASM 2008 6261K534ASM-02 2008

3A 1.5 CHAIN 50 ROLLER 6261K534

4 1 KNEEL CHA IN SW IVEL K05012

5 1 COTTER PIN 98338A220

6 2 FLANGE BRG 10FDU06

7 1 SPRING TORSION ASM LTR-075M-6-5ASM

8 1 SPROCKET FOR #50 CHAIN 6280K249

9 1 KNEEL LIMIT SWITCH ASM 03220-003

10 2 SW ITCH TANG BZ-2RW80-A2 6X284

11 3 HCS 3/8-16 X 1YZ8 QPA 0115105

12 4 PPH MS 6-32 X 1 1/2Z 1128838

13 4 10-32 NYLOCK NMZ 1137015

14 1 ACTUATOR GUIDE ASM K05006ASM

15 1 KNEEL AXLE MOUNT B08022

1 RATCHET REVERSIBLE 800-0072*

1 SOCKET 3/8" 4PW71*

1 BOOT BLK " 2005" KNEELACT 152303*

* Not Shown

Parts on Va n

7

Page 30

Page 36

one Touch SYSTeM TrouBleShooTing

Symptom Remedy

Check that OTC ON/OFF switch is on. The power toggle switch

is on the actual board.

Ensure the connections on the back of the OTC board are tight.

Check the OTC main fuse (40 amp) located near the vehicles

main battery.

Check the OTC Board fuse (1 amp) located in the Rollx Fuse

Panel behind the glove box.

Reset the OTC. The reset is located on the dash by the drivers

left knee or on the OTC Board.

Check battery voltage.

Van has been sitting for an extended period of time. Charge the

battery.

Check the current draw by placing an ammeter in series with the

negative terminal on the battery with all doors closed and engine

off. The draw varies, but awake, the system should be less than

.850 amps and when sleeping, less than .050 amps. Additional

equipment installed will also vary these numbers. See Battery

section for more information.

The OTC display is garbled.

Reset the OTC. The reset is located on the dash by the drivers

left knee or on the OTC Board.

The van's battery is dead.

No power to One Touch Controller (OTC).

Battery is low. Turn off the OTC and charge battery. Note: The

alarm will sound when the battery voltage is below 11.4 vdc. This

is to prevent the OTC system from draining the battery far

enough as to prevent the vehicle from starting. This level is

adjustable in the board's Setup menu.

OTC beeps 4 times when the user tries to

run a normal open/close cycle.

Important: If OTC Board is removed, the OEM System will not operate normally unless the CAN

Bus Shunt is installed. The shunt is attached to the wire harness behind the OTC board. See OTC

Wiring Diagram for more information.

Page 31

Page 37

one Touch SYSTeM overvieW

The Rollx Vans One Touch Controller, known as the OTC, is a Single Board Computer specifically

designed for the Rollx Vans system.

The OTC system was designed to be independent to the operation of the Chrysler computer system.

When power is removed from the OTC, it has no effect on the operation of the Chrysler system as long as

the OTC Shunt Plug is installed into the OTC Main Harness on all 2008 Chrysler Vans due to the CAN

BUS system (see OTC Wiring Diagram for more information).

The OTC is a low power system. When the OTC is in Sleep Mode with the Display disabled, it typically

draws less then 10ma of current from the battery. When awake in Idle Mode (not running a cycle) with the

Display enabled, it typically draws less than 200ma of current from the battery.

The current state of the OTC can be determined by viewing the Display. During open or close operation

the progress of the system can be tracked by watching the Display.

OTC V8.0

8

Sequence of Operation

Open Cycle

1) The OTC is activated by any Rollx Vans User Switch or Remote being pressed.

2) Door unlock command sent (1 sec.) To Front Passenger Door Control Module to unlock all doors.

3) Door open command sent to OEM B-Pillar Door Open/Close Button to open the passenger sliding door.

4) Door starts to open.

5) Kneeler motor is turned on and starts to lower van.

*If door fails to open within 2 seconds of User Switch being pressed, cycle stops (van unkneels and

cycle is ended)

6) Door reaches open position and activates Rollx Vans Door Open Limit Switch.

7) Passenger sliding door is disabled by OTC interrupting the CAN Bus signal with built in relay.

8) Ramp motor is turned on and starts to deploy.

9) Kneeler stops lowering when Kneel Down Limit Switch is activated.

10) Ramp stops deploying when Ramp Down Limit Switch is activated.

11) OTC enters Idle Mode.

12) OTC enters Sleep Mode.

Close Cycle

1) The OTC is activated by any Rollx Vans User Switch or Remote being pressed.

2) Ramp motor is turned on and starts to stow.

3) After a few seconds (ramp is off the ground and begun to slide into van) kneeler motor is turned on and

starts to raise the van.

4) Kneeler stops raising when Kneel Up Limit Switch is activated.

5) Ramp stops stowing when Ramp Up Limit Switch is activated.

6) Passenger sliding door is enabled by OTC reconnecting the CAN Bus signal with built in relay.

7) Door close command sent to OEM B-Pillar Door Open/Close Button to close the passenger sliding door.

8) OTC receives signal from OEM Door Ajar Pin Switch that door is closed.

9) OTC enters Idle Mode.

10) OTC enters Sleep Mode.

Note: There are “Watch Dogs” programmed in the OTC software that act as timers to end a function if the

function does not complete within a certain amount of expected and very reasonable time.

Page 32

Page 38

INPUTS

KNEEL DISABLE SWITCH ( ) Allows the user to enable (the “I” position) or disable (the “O”

position) the kneeling system. There is no display for this input.

OTC CONTROLLER POWER ( ) Supplies power to the OTC Board

USER SWITCH INPUT ( ) Active while any Rollx Vans user button or Rollx Vans remote is

pressed.

NEUTRAL INPUT ( ) Indicates the status of the gear shifter. When active, the van is either in

neutral or park. The OTC system will not run a operational cycle unless the van is in neutral or park.

DOOR OPEN LIMIT INPUT ( ) Active when the right side sliding door is fully open.

DOOR CLOSE LIMIT INPUT ( ) Active when the right side sliding door is fully shut.

OUTPUTS

System Status: Indicates if the system is ready to except a command. It is off when the OTC is in sleep

mode. V8.0 Display will show Rollx Vans: Idle.

Violet wire

2 White/Red wires

Blue wire

Green wire

Orange/Red wire

Violet/Yellow wire

Red/Green wire

Red/White wire

Yellow/Green wire

Yellow/White wire

Red wire

Red/Black wire

Yellow/Black wire

Yellow/Red wire

Orange/Blue

Orange

Red/Blue wire

Green/White

RAMP UP LIMIT INPUT ( ) Active when the ramp in the up position.

RAMP DOWN LIMIT INPUT ( ) Active when the ramp is in the down position.

KNEEL DOWN LIMIT INPUT ( ) Active when the kneeler is in the down position.

KNEEL UP LIMIT INPUT ( ) Active when the kneeler is in the up position.

RAMP DOWN MOTOR OUTPUT ( ) Active when the OTC is driving the ramp down (V6.0 & V8.0

OTC boards have obstacle detection monitoring this output).

RAMP UP MOTOR OUTPUT ( ) Active when the OTC is driving the ramp up (V6.0 & V8.0

OTC boards have obstacle detection monitoring this output).

KNEEL DOWN MOTOR OUTPUT ( ) Active when the OTC is driving the kneeler up

KNEEL UP MOTOR OUTPUT ( ) Active when the OTC is driving the kneeler up.

DOOR DISABLE OUTPUT ( ) Used by the OTC to disable the Chrysler right side door

controller anytime it wants to open the ramp. This prevents the right side door controller from banging the

right side sliding door against the ramp.

DOOR CONTROL OUTPUT ( ) OTC sends a command to the Chrysler system to open or close the

right side sliding door.

RAMP DISABLE OUTPUT ( ) Active anytime when the OTC is driving the ramp up or down. It

indicates the ramp manual mode is disabled.

DOOR UNLOCK OUTPUT ( ) OTC sends a command to the Chrysler system to unlock the

doors at the beginning of an open cycle.

one Touch SYSTeM overvieW

Page 33

Page 39

one Touch SYSTeM - v8.0 BaSic inTerface

ESC

ENTER

DOWN

UP

Rollx Vans

Idle

Kneel Up

ESC

ENTER

DOWN

UP

Manual

Kneeler

Kneel Down

ESC

ENTER

DOWN

UP

Data Logger

Setup

Password

Required

(Move to previous Log Entry)

ESC

ENTER

DOWN

UP

#02 0000:00:00

Status: Err# XX

#02 0000:00:00

Scrolls Error Info

Scrolls

Last Error

ESC

ENTER

DOWN

UP

#03 0000:00:00

Status: Err# XX

#03 0000:00:00

Scrolls Error Info

ESC

ENTER

DOWN

UP

#01 0000:00:00

Status: Err# XX

#01 0000:00:00

Scrolls Error Info

START

(Move to next Log Entry)

To get into setup a password is required. Setup options

include Cycle Tester, Battery Alarm Level, Debugger,

Cycle Counter, Ramp Type, Kneeler Mode, and Obstacle

Detection Level. For more info on Debugger see next

page. Also see OTC 6.0 User Interface Flowchart for

more in depth information.

One Touch Controller Basic Operation

1) How to manually kneel van

2) How to check software and hardware versions

3) How to review error codes in Data Logger

ESC

ENTER

DOWN

UP

Rollx Vans Service

800-956-6668

ESC

ENTER

DOWN

UP

Serial #

XXXXX

Hardware Version

V-X.XX

Software Version

Mod X

Page 34

Page 40

Password Good

Setup

Data Logger Mode

START

Options within Setup

ESC

ENTER

DOWN

UP

Setup

View Data Log

Setup

Engineering

Setup

Cycle Counters

Setup

Kneeler

Setup

Battery Alarm

Setup

Cycle Tester

Setup

Serial Number

Setup

Debug

Setup

Hobbs Meter

Select “Log All Mode” or “Log Error Only Mode” to decide

which type of errors to record. Default is “Log Error Only

Mode”.

View the past 30 errors recorded. Hit enter to view Error

Details.

Displays the number of Open and Close cycles.

Select if Kneel System installed or not. Default is “Yes”.

Select the Battery Alarm Trip Point between 10.9 vdc and

12.4 vdc. If OTC reads vdc below Trip Point, OTC will not

operate. Default is “11.5 vdc).

Select the number of cycles between 10 and 99 you want

the system to run automatically in order to test. Hit Esc to

stop.

Select between “Input Test Mode” and “Output Test Mode”

to test OTC System operation. THIS IS VERY USEFUL.

For more information see How To Use Debugger on next

page.

Displays current Clock Time.

Setup

OB Detect Level

Select the sensitivity of the ramp’s obstacle detection

between 0 and 9. “0” is the weakest and “9” is the

strongest (ramp is very hard to stop at “9”). Default is “5”.

one Touch SYSTeM - v8.0 advanced inTerface - SeTuP

Page 35

Page 41

one Touch SYSTeM - v8.0 advanced inTerface - deBugger

Output Test Mode

Ramp Down

START

How to Use Debugger

(Output Test Mode)

ESC

ENTER

DOWN

UP

Output Test Mode

Output Test Mode

Door Unlock

Output Test Mode

Door Close

Output Test Mode

Door Open

Output Test Mode

Kneel Down

Output Test Mode

Kneel Up

Output Test Mode

Ramp Enable

Output Test Mode

Ramp Up

Relay should click and ramp should go out.

Use extreme caution when using the Output Test Mode. The

Output Test Modes sends the signal directly to the OTC Relay

Board which results in power going to the called motor. No

safeties are in place (ie. The Ramp Down will operate the ramp

regardless if the door is open or closed.

Closes the passenger sliding door.

Opens the passenger sliding door.

Press and hold to operate the kneeler and lower the van.

Relay should click.

Press and hold to operate the kneeler and raise the van.

Relay should click.

Relay should click and ramp should go in.

All OEM Doors should unlock.

Relay should click.

Page 36

Page 42

one Touch SYSTeM - v8.0 advanced inTerface - deBugger

Input Test Mode

Ramp Up

START

How to Use Debugger

(Input Test Mode)

ESC

ENTER

DOWN

UP

Input Test Mode

Input Test Mode

Neutral

Input Test Mode

Door Close

Input Test Mode

Door Open

Input Test Mode

Kneel Sw

Input Test Mode

Kneel Down

Input Test Mode

Kneel Up

Input Test Mode

Ramp Down

ON when ramp is all the way in.

The Input Test mode is very useful for testing the various limit

switches the systems requires. To operate:

1) Select a Limit Switch (Input) you would like to test from the

list below.

2) Notice if the Switch is “On” or “Off” when it is suppose to be.

The audible beeps let you test the switch by hand without

looking at the OTC Board.

- On (activated) = Double Beeps

- Off (not activated) = Single Beeps

ON when passenger sliding door is closed.

ON when passenger sliding door is all the way open.

ON when Dash Kneel On/Off switch is on.

ON when kneeler is all the way down (knelt).

ON when ramp is all the way out.

ON when van is in Park or Neutral.

ON when kneeler is all the way up (normal).

Page 37

Page 43

one Touch SYSTeM - v8.0 error codeS

Code Description - What Caused the Code

Error 1 - Battery Low Error

Everytime before the OTC cycles, it checks the Main

Battery's voltage. If reading is below the value set in the

OTC Setup, the OTC will continue to operate, but will

indicate a low battery warning. The default value is 11.5

volts.

Diagnostic Tests More Information

Rollx Vans recommends starting your van every 4-5 days,

allow it to run 15-20 minutes to keep the battery at a

sufficient state of charge.

A timer is included on the OTC that will shut it off after 5

minutes UNLESS in Setup Mode. Update OTC if needed.

Perform a Draw Test

Follow instuctions in 'Battery Information - Draw Test Procedure'

Section

For information about OTC Interface and how to use the Debugger, please refer to 'One Touch System - v8.0

Advanced Interace' section. Remember, in Input Test Mode, double beeps indicate the switch is on or activated and

single beeps indicate that it is not. Also refer to the 'One Touch System - Relay Board Troubleshooting' for more

information about the Relay Board, its Overide Switches and LED Indicator Lights.

Code Description - What Caused the Code

Error 11 - Door Control Error

Door Control Output failure (The OTC did not successfully

control the door to open or close). The OTC did not

receive the signal that the door came off the OEM Door

Ajar Switch when opening or did not receive the signal that

the door came off the Rollx Vans Door Open Switch when

closing. Once the OTC sends the signal to open the door,

it waits about 2 seconds to see if the Door Ajar Switch is

not activated. If the Door Ajar Switch is still active, this

message will appear.

Diagnostic Tests More Information

Output Test

Place OTC in Debug - Output Test Mode to verify OTC operates

the door correctly by sending signal to OEM B-Pillar Switch

and/or OEM Front Passenger Door Unlock Switch.

1) Check Door Open.

2) Check Door Close.

3) Check Door Unlock.

4) Check Ramp Enable. This closes a relay on the OTC Relay

Board that enables the ramp to run (prevents the ramp from

running if the door is not open, door open enables ramp enable).

OEM B-Pillar Switch / Door On/Off

If off, the OEM Overhead Power Sliding Door On/Off

Switch will prevent the door from operating from the OEM

B-Pillar Switch. The OTC uses this switch to open or close

the door. When off, the OTC can not control the door.

Make sure the switch is on and try hitting the OEM B-Pillar

switch. If the door still does not work, likely an OEM issue.

If OEM function works, but OTC does not check wiring.

Door Unlock Switch

Door must be unlocked to open. First try OEM Unlock

Switch in Passenger Front Door. The OTC uses this switch

to unlock all the doors before an Door Open Command is

sent. If OEM Switch does not unlock doors, likely an OEM

issue. If OEM functions, but OTC does not check wiring.

Door Ajar Switch

If the OEM Door Ajar Switch is not deactivated within 2

seconds of the start of the cycle, Door Control Error will be

returned.

Input Test

Place OTC in Debug - Input Test Mode to verify limits operate

correctly.

1) Check Door Open (Rollx Vans Door Open Switch), by

opening door all the way in Door Open.

2) Check Door Close (OEM Door Ajar Switch), by close door

all the way in Door Close. Rollx Vans taps into OEM Door Ajar

Switch in Lower B-Pillar (See OTC Wiring for more

information).

Page 38

Page 44

one Touch SYSTeM - v8.0 error codeS

Code Description - What Caused the Code

Error 18 - Ramp Obstacle

Detection Error

OTC detected that the ramp may have hit an obstruction

on the in or out cycle. The OTC detects an obstruction by

measuring the current generated from the ramp motor.

The obstruction could be something in the way or a Ramp

Limit is not recognized. If this current exceeds the set limit

in the OTC Setup (default is 5, scale is 1-10 with 1 being

the most sensative)

Diagnostic Tests More Information

Check Error Log for multiple Obstactle Detection Errors. If

there are many, raise the level in Setup.

Setup - OB Detect Level (default is 5, scale is 1-10 with 1

being the most sensative)

Input Test

Place OTC in Debug - Input Test Mode to verify limits operate

correctly.

1) Check Ramp Up [Limit Switch] by operating the ramp with

Power Overide Switch (ITF Ramp) or manually raising (Folding

Ramp).

2) Check Ramp Down [Limit Switch] by operating the ramp

with Power Overide Switch (ITF Ramp) or manually raising

(Folding Ramp).

If a Ramp Limit Switch fails, the Obstacle Detection should

activate and cause an error. If the Obstacle Detection

does not activate, the Ramp Watchdog Timer should. This

will also cause an error (Error 27) and end the cycle.

Code Description - What Caused the Code

Error 23 - Neutral Status Error

Everytime before the OTC cycles, it checks to make sure

the van is in Park. This is for safety and can not be

changed.

Diagnostic Tests More Information

Input Test

Place OTC in Debug - Input Test Mode to verify OTC recognizes

if the van is in Park correctly

1) Check Neutral by placing the van in and out of Park and

listening for the double beeps from the debugger.

Refer to Important Item Information or OTC Wiring

Diagram for more information about where Rollx Vans gets

this signal.

Code Description - What Caused the Code

Error 25 - Emergency Stop

Error

Anytime a Rollx Vans User or Remote Button is pressed

during an open or close cycle, the system will stop

immediately. If a Hard Wired User Button is held down

long enough, the OTC will think it has been pressed twice

and thus, cause an error.

Diagnostic Tests More Information

Operate User Button to verify working correctly.

This is a safety feature and can not be changed.

Code Description - What Caused the Code

Error 27 - Ramp Watchdog

Error

Once the OTC sends the signal to start running the ramp

motor in or out, a timer starts. If enough time passes

before the proper limit switch is activated at the end of the

cycle, the OTC will return this error. This is a safety feature

to limit power to the motor in case of mulitple failures.

Diagnostic Tests More Information

Operate the In-The-Floor ramp with Power Overide to help

determine if motor and ramp are functioning correctly.

Not available on Folding Ramps.

Output Test

Place OTC in Debug - Output Test Mode to verify OTC operates

the ramp motor correctly.

1) Check Ramp Open.

2) Check Ramp Close.

Several factors such as low battery, cold weather or debris

can prevent the motor from operating correctly. If low

battery, very cold or a bad motor, the motor may run too

slow causing this watchdog to activate. Debris can also

prevent the motor or ramp operating at correct speed, also

causing this error.

Input Test

Place OTC in Debug - Input Test Mode to verify limits operate

correctly.

1) Check Ramp Up [Limit Switch] by operating the ramp with

Power Overide Switch (ITF Ramp) or manually raising (Folding

Ramp).

2) Check Ramp Down [Limit Switch] by operating the ramp

with Power Overide Switch (ITF Ramp) or manually raising

(Folding Ramp).

If a Ramp Limit Switch fails, the Obstacle Detection should

activate and cause an error (Error 18). If the Obstacle

Detection does not activate, the Ramp Watchdog Timer

should. This will also cause an error.

If OTC Debug Output Test does not activate the motor

being tested, try the overides located on the OTC Relay

Board. This will inidicate a communication problem

between the One Touch Controller and One Touch Relay

Board.

Page 39

Page 45

one Touch SYSTeM - v8.0 error codeS

Code Description - What Caused the Code

Error 28 - Door Watchdog Error

Once the OTC sends the signal to operate the OEM Door,

a timer starts. If enough time passes before the proper

limit switch is activated at the end of the cycle, the OTC will

return this error.

Diagnostic Tests More Information

Operate the OEM Door with the OEM B-Pillar Switch to

determine of OEM Door is functioning properly.

If OEM B-Pillar Switch is not working, try the OEM

Overhead Door Switch and make sure the OEM Overhead

Door On/Off Switch is on.

Input Test

Place OTC in Debug - Input Test Mode to verify limits operate

correctly.

1) Check Door Open (Rollx Vans Door Open Switch), by

opening door all the way in Door Open.

2) Check Door Close (OEM Door Ajar Switch), by close door

all the way in Door Close. Rollx Vans taps into OEM Door Ajar

Switch in Lower B-Pillar (See OTC Wiring for more

information).

If Door Limits function correctly and door cycles open and close

okay, the issue is with the door taking too long to open or close.

Check alignment or motor.

Output Test

Place OTC in Debug - Output Test Mode to verify OTC operates

the door correctly by sending signal to OEM B-Pillar Switch

and/or OEM Front Passenger Door Unlock Switch.

1) Check Door Open.

2) Check Door Close.

If an Output is an issue, the Door Control Error (Error 11)

will likely display.

Code Description - What Caused the Code

Error 29 - Kneeler Watchdog

Error

Once the OTC sends the signal to operate the Kneeler, a

timer starts. If enough time passes before the proper limit

switch is activated at the end of the cycle, the OTC will

return this error.

Diagnostic Tests More Information

Operate the Kneeler with Power Overide to help determine

if motor is functioning correctly.

Reset - Esc - Kneel Up/Kneel Down

Input Test

Place OTC in Debug - Input Test Mode to verify limits operate

correctly.

1) Check Kneel Up [Limit Switch], by raising Kneeler until

switch is activated or activate switch by hand.

2) Check Kneel Down [Limit Switch], by Lowering Kneeler until

switch is activated or activate switch by hand.

Testing with Power Overide is preferreed since it will incidicate

if Limit Switch is being properly activated by Actuator's Guide.

When Kneel Actuator reaches its runlimit, it will begin to ratchet

making a terrible sound. This is simply the motor's clutch

mechanism, is not damaging but should try and be minimized.

Output Test

Place OTC in Debug - Output Test Mode to verify OTC operates

the Kneeler correctly.

1) Check Kneel Up.

2) Check Kneel Down.

If OTC Debug Output Test does not activate the motor

being tested, try the overides located on the OTC Relay

Board. This will inidicate a communication problem

between the One Touch Controller and One Touch Relay

Board.

Also a low battery, bad motor or cold weather causing the

motor to run very slowly can return this error.

Code Description - What Caused the Code

Error 33 - Door Ajar Error

The OTC will not run a Cycle if the door is Ajar (Not fully

opened or closed). If Ramp deployed, open door fully. If ramp

stowed, fully close and latch door.

Diagnostic Tests More Information

Operate the OEM Door with the OEM B-Pillar Switch to

determine of OEM Door is functioning properly.

If OEM B-Pillar Switch is not working, try the OEM

Overhead Door Switch and make sure the OEM Overhead

Door On/Off Switch is on.

Input Test

Place OTC in Debug - Input Test Mode to verify limits operate

correctly.

1) Check Door Open (Rollx Vans Door Open Switch), by

opening door all the way in Door Open.

2) Check Door Close (OEM Door Ajar Switch), by close door

all the way in Door Close. Rollx Vans taps into OEM Door Ajar

Switch in Lower B-Pillar (See OTC Wiring for more

information).

Page 40

Page 46

one Touch SYSTeM - relaY Board TrouBleShooTing

RELAY BD OTC VERSION 2

P.N. 08044-003

ORDER #OTCV8 RELAY BD

OUTPUTS

Run to the Kneeler and Ramp Motors

INPUTS

Run from the OTC Control Board

LED Indicator Lights

Manual push button test switches

*Pressing the switches should operate each

function as shown on the board as long as the board

is working properly. Remember, in order to run the ramp,

the Ramp Enable must also be pressed at the same time.

Pressing a switch is the same as sending a

ground to the terminal.

Page 41

Page 47

This page was intentionally left blank

Page 42

Page 48

in The floor TrouBleShooTing

Symptom Possible Cause Remedy

Door open limit switch is not being activated.

When a Open Cycle starts, the OTC will send a

command to the Chrysler System to unlock the

doors. It then sends a second command to the

Chrysler System to open the Right Side Sliding

Door. The OTC Computer then waits two

seconds and checks the Door Closed Limit

Switch. If it finds it still indicates the door is

closed, it assumes that a person (or and

obstacle) stopped the door opening sequence. It

then ends the open cycle and goes back into Idle

Mode. After ten to fifteen seconds it goes back

into Sleep Mode. This is the sequence of events

you will see if the Door Closed Limit Switch

malfunctions (sticks closed).

Ramp motor not engaged.

Engage ramp motor. Refer to the "Manual

Operation" section of this manual.

Ramp down limit switch needs adjustment to

deactivate.

Press Rollx Vans user button again to unkneel

van and close door. Review display on OTC

board and contact customer service.

Ramp motor.

Review display on OTC board and contact

customer service.

OTC program failure.

Press OTC reset button.

Ramp motor not engaged.

Engage ramp motor. Refer to the "Manual

Operation" section of this manual.

Ramp motor.

Review display on OTC board and contact

customer service.

Low voltage from the battery.

Start vehicle. Press OTC reset button and press

Rollx Vans user button again.

Ramp will deploy before door is all

the way open.

Door open limit switch is shorted to ground or

malfuctioning.

Examine door open limit switch, connections,

and wiring.

Clear obstruction and press Rollx Vans user

button.

Review display on OTC board and contact

customer service.

Ramp will start to deploy or stow

then stop functioning.

Pressure on cover plate.

Ensure that there are no objects on top of cover

plate.

Ramp will STOP AND REVERSE

mid-cycle.

Ramp will NOT DEPLOY after door

opens automatically.

Obstacle is detected.

Ramp will NOT STOW

automatically.

Page 43

Page 49

in floor (MeTal SPringS ) rePlaceMenT ParTS

16 8 3/8 NYLON FLAT WASHER 1107632

4 ROLLER, ITF RAMP PLATE N1-N1DXLA

17 1 RAMP ITF ASM N005001ASM

18 2 5/16-18X2 S/S FHSCS 1173912

19 1 TRACK FLOOR PLATE FRONT ASM N05017ASM

20 1 TRACK FLOOR PLATE REAR ASM N05016ASM

21 1 TRACK TRACK EXT.BKT, LOWER 08,ASM B08032ASM

21a 1 DOOR OPEN SWITCH ASSEMBLY 05089-002

22 1 ALUMINUM UNTHREADED (ACTIVATOR) 92510A351

23 2 PRECISION MINATURE IDLER 2483K18

24 1 ROLLER PLATE 2008, CHYSLER N05003ASM

26 1 CONN LINK #35 CARBON CHRLCL035

27 1 LOCKING HOLE & VENT 24412

28 4 SS TORX BHCS 1/4-20 10929-02112

30 4 1/4 USS F/W Z 1133004

31 2 TEFLON BLOCK FOR ITF RAMP N05049

32 4 RIVETS 97517A130

33 2 SPACER ROLLER CUSHIONED N05048

34 1 SEE PAGE 15

35 1 SEE PAGE 15

36 1 CARPET TRIM FRONT N05021G-F

37 1 CARPET TRIM BACK N05021G-B

38 1 FLOOR TRACK DRIVER N08025-11

39 1 FLOOR TRACK PASSENGER N08026-11

31

30

3

13

23

28

27

1

3

4

5

7

9

10

14

15

17

18

19

24

26

30

Item Qty. Description Pa rt #

1 1 ITF ACCESS PLATE N05019

2 1 MOTOR GEAR BOX ITF 2008 ASM N08111ASM

1 MOTOR WITH GEAR ONLY

N08111-MTR/GEAR ASM

3 6 1/4-20 YZ NE NYLOCK 1137183

4 10 CHAIN ROLLER SS #35 35

5 1 TENSIONER/SPROCKET ASM ITF 10005

6 2 ROLLERS CUSHIONED 22875T11

7 8 SS TORX BHCS 1/4-20 10929-02112

8 1 FLAP ASM ITF RAMP N05014ASM

3 PRECISION MINATURE IDLER* 2483K18

3 5/16" x 1/16" NYLN WSHR 76002

3 HCS 1/4-20X1 1/4 YZ8QP* 0115007

3 1/4-20 YZ NE NYLOCK* 1137183

9 7 SS TORX BHCS 1/4-20 10929-02112

10 2 HCS1/4-20X1YZ8 QPACK 0115005

12 2 HCS 1/4-20 X 3/4 YZ8 QPA 0115003

13 1 CHAIN ANCHOR N05033

14 4 FPH MS 10-32X3/8 Z K 29504

15 2 RAMP SPRING N05044

20

33

37

21

36

16

8

12

2

35

34

6

32

21a

22

38

39

Page 44

Page 50

Symptom Possible Cause Remedy

Ramp fuse or circuit breaker is blown.

Press Rollx Vans user button again to unkneel

van and close door. Reset circuit breaker or

check ramp fuse and replace if needed with 15

amp glass fuse located in glove box.

Door open limit switch is not being activated.

When a Open Cycle starts, the OTC will send a

command to the Chrysler System to unlock the

doors. It then sends a second command to the

Chrysler System to open the Right Side Sliding

Door. The OTC Computer then waits two

seconds and checks the Door Closed Limit

Switch. If it finds it still indicates the door is

closed, it assumes that a person (or and

obstacle) stopped the door opening sequence. It

then ends the open cycle and goes back into Idle

Mode. After ten to fifteen seconds it goes back

into Sleep Mode. This is the sequence of events

you will see if the Door Closed Limit Switch

malfunctions (sticks closed). This switch is

located in the Right Side Sliding Door Latch

Assembly.

Ramp down limit switch needs adjustment to

deactivate.

Press Rollx Vans user button again to unkneel

van and close door. Review display on OTC

board and contact customer service.

Ramp motor.

Press Rollx Vans user button again to unkneel

van and close door. Review display on OTC

board and contact customer service.

OTC program failure.

Press OTC reset button.

Ramp fuse or circuit breaker is blown.

Press Rollx Vans user button again to unkneel

van and close door. Reset circuit breaker or

check ramp fuse and replace if needed with 15

amp glass fuse located in glove box.

Ramp motor.

Review display on OTC board and contact

customer service.

Ramp will deploy before door is all

the way open.

Door open limit switch is shorted to ground or

malfuctioning.

Examine door open limit switch, connections,

and wiring.

Clear obstruction and press Rollx Vans user

button.

Review display on OTC board and contact

customer service.

Ramp will STOP AND REVERSE

mid-cycle.

Obstacle is detected.

Ramp will NOT STOW

automatically.

Ramp will NOT DEPLOY after door

opens automatically.

folding raMP TrouBleShooTing

Page 45

Page 51

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

21A

RLXR1000-04-OTC / RLXR1000-04-MB / RLXR1000-04-NARROW-MB

Item Qty. Description Part #

1 1 MOTOR RAMP (Does not include connector (OTC only) K01325A350

2 2 CAM FOR PICK UP ARM ALUM RLXRP00CAM-ALUM

3 2 #8-32X1/4 CUP POINT SET SCREW N/A

4 1 ROLLER CROWNED YOKE CY36L

5 1 5/16-18 X 1-1/4 BHSCS 1124072

6 4 5/16-18 X 1-1/4 FHSC 1124257

7 1 BEARING/BUSHING SF-2432-8

8 1 RAMP LIMIT SWITCH ASM 03220-004

9 2 SWITCH MINI SNAP ACTING 7779K62

10 1 SWITCH SPACER STD RAMP RLXRPOO-14

11 2 S/S PPHMS 4-40X1 1/2 72498

12 2 #4 sae 5/16od z f/w 1133066

Item Qty. Description Part #

13 2 4-40 S/S NYLOK NUT 1170854

14 1 RAMP CABLE W/BALL SHANK, RLXR1100

15 1 BHSCS 5/16-18 X 7/8 24070

16 1 5/16-18HX JAM Z 1137023

17 3 5/16-18 FLAT NYLON WASHERS 76062

18 1 CB 10AMP RESETTABLE CB-PM3-10

19 2 HCS 3/8-24 X 1 YZ8 18834

19A 2 3/8 HI-ALLOY L/W YZ 1133893

19B 2 3/8 USS F/W Z 1133008

20 1 WOODRUFF KEY, 3/16X3/4 FLAT BOTTOM N/A

21 1 PICK UP ARM (RAMP) RLXR2005 (INCLUDES SET SCREW)

21A 1 1/4-20X3/8 CUP POINT SET SCREW N/A

22 1 5/16-18X1 3/4 FHSCS 1124259

22 1 5/16-18X1 3/4 FHSCS* 1124259

23 1 5/16-18HX JAM Z 1136204

COVER RAMP NEW GENERATION 10068

* For motor bar ramps only

folding raMP rePlaceMenT ParTS

Page 46

Page 52

1

2

3

4

5

6

7

8

9

10

11

12

13

14

9

10

15

16

RLXR1000-05-OTC / RLXR1000-05-MB / RLXR1000-05-NARROW-MB

Item Qty. Description Part #

1 1 RAMP STANDARD (RAMP NARROW) RLXR4000 (RLXR4000N)

2 1 RAMP CABLE W/BALL SHANK, RLXR1100

3 3 CLAMP INSULATED 3/8" 8863T13

4 3 1/4-20 X 1/2 BHSCS 1124049

5 3 1/4-20 NTE JAM NYLOK 1137020

6 3 10-32 X 3/4 BHSCS 1124042

7 6 #10 SAE F/W Z 1133074

8 2 1/4 HI-ALLOY L/W YZ 1133891

9 2 3/8 USS F/W Z 1133008

10 2 3/8-16 YZ8 NE NYLOCK 1137185

Item Qty. Description Part #

11 1 HCS 1/4-20X1/2 YZ8 QPA 0115001

12 12 1/4-20X5/8 SS BUTTON HEAD CAP SCREW 10929-02786

13 1 HINGE, RAMP FOLDING W BOLTS RLRX4006

14 1 CABLE GUIDE (ROUND DISC) RLXR1025

15 4 RIVETS* 97517A130

15 4 #4 sae 5/16od z f/w 1133066

15 1 RUBBER BULB SEAL BACK FOAM* NX504B1

16 0.4 ANTI-RATTLE RUBBER URETH FOR (Motor Bar Only)* 27036

17 1 HINGE UPPER RAMP FO PAINTED RLXR1007

18 12 1/4-20 KEPS NUT 1137410