Page 1

DR MESSAGE SYSTEMS 8M - 1

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION ..........................1

OPERATION ............................2

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE ............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT .........3

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT .......................3

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT .......................3

STANDARD PROCEDURE - COMPASS

CALIBRATION .........................3

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING ......................4

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................4

REMOVAL

OVERHEAD CONSOLE REMOVAL .........5

INSTALLATION ..........................5

SPECIAL TOOLS

OVERHEAD CONSOLE ..................6

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION ..........................6

OPERATION ............................7

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER ..................7

REMOVAL .............................7

INSTALLATION ..........................7

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION ..........................7

OPERATION ............................8

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER .........8

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING .......................8

REMOVAL .............................10

INSTALLATION .........................10

AMBIENT TEMP SENSOR

DESCRIPTION .........................10

OPERATION ...........................10

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR ...............11

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT ........11

REMOVAL .............................11

INSTALLATION .........................11

UNIVERSAL TRANSMITTER

DESCRIPTION .........................11

OPERATION ...........................12

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER .......................12

STANDARD PROCEDURE

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES .................12

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES .................12

REMOVAL .............................13

OVERHEAD CONSOLE

DESCRIPTION

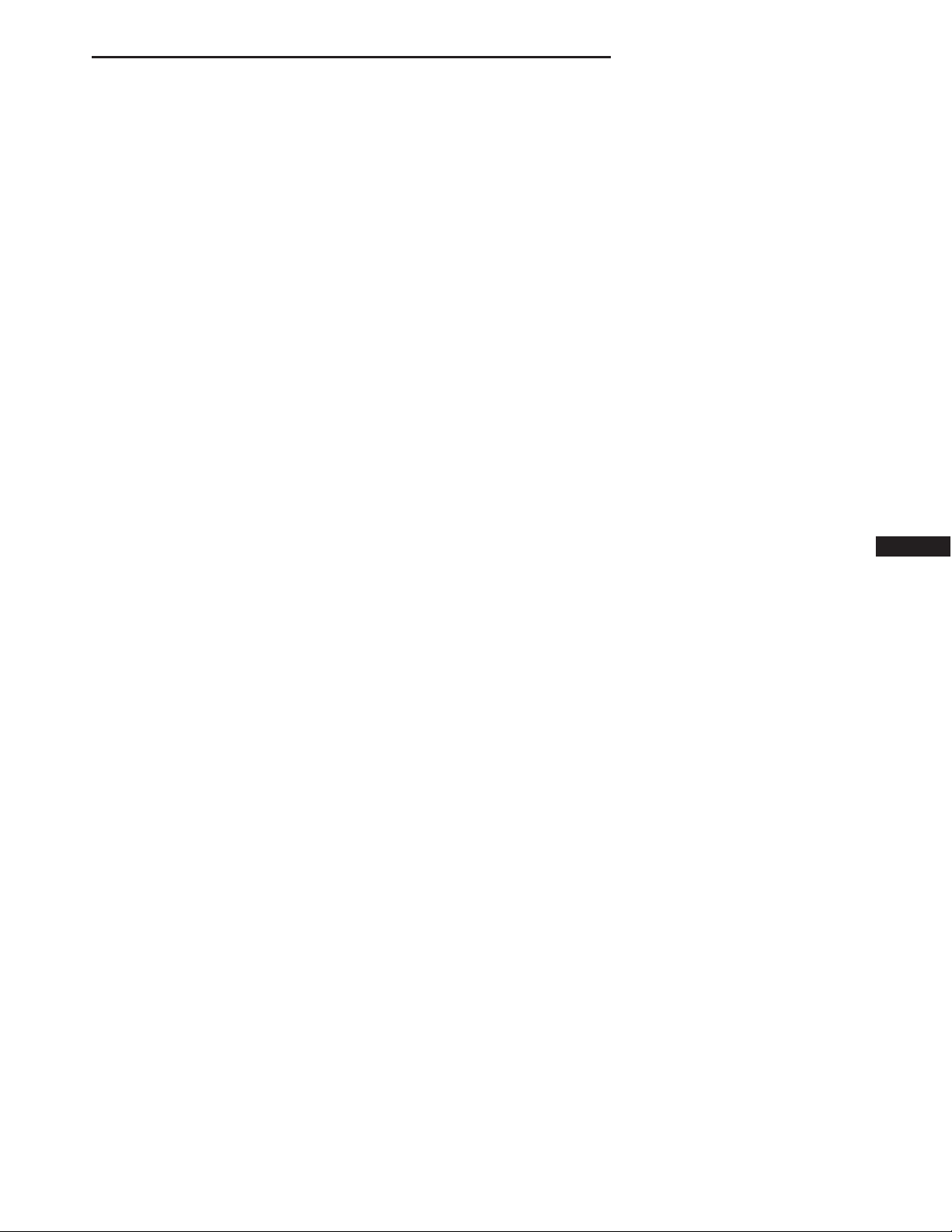

Two different overhead consoles are available on

DR models. The Electronic Vehicle Information Center (EVIC) (Fig. 1) or Compass Mini-Trip Computer

(CMTC). All consoles are equipped with two reading/

courtesy lamps. The overhead console is mounted

with screws and two snap clips to a molded plastic

retainer bracket located above the headliner.

COMPASS DISPLAY

All the available overhead consoles on this model

include Compass information. While in the compass/

temperature mode, the compass will display the

direction in which the vehicle is pointed using the

eight major compass headings (Examples: north is N,

northeast is NE). The self-calibrating compass unit

requires no adjusting in normal use. The only calibration that may prove necessary is to drive the vehicle at 5 to 8 kilometers-per-hour (3 to 5 miles-perhour), on level ground in a square shaped pattern.

This will reorient the compass unit to its vehicle.

The compass unit also will compensate for magnetism the body of the vehicle may acquire during normal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral procession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Magnetic bit drivers used on the fasteners that hold the

Page 2

8M - 2 MESSAGE SYSTEMS DR

OVERHEAD CONSOLE (Continued)

ent temperature sensor, refer to Ambient Temperature Sensor later in this section.

Following are general descriptions of the major

components used in the overhead console. Refer to

Wiring Diagrams for complete circuit schematics.

OPERATION

Refer to the vehicle Owner’s Manual for specific

operation of each overhead console and its systems.

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE

If the problem with the overhead console is an

inaccurate or scrambled display, refer to SELF-DI-

AGNOSTIC TEST later in this text. If the problem

with the overhead console is incorrect Vacuum Fluorescent Display (VFD) dimming levels, use a DRB

IIIt scan tool and the proper Diagnostic Procedures

manual to test for the correct dimming message

inputs being received from the Body Control Module

(BCM) or Front Control Module (FCM) over the

Fig. 1 DR OVERHEAD CONSOLE – EVIC

overhead console assembly to the roof header can

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this section may be

required to restore proper compass operation.

TEMPERATURE DISPLAY

All the available overhead consoles on this model

include Temperature information. The temperature

displays the outside ambient temperature in whole

degrees. The temperature display can be toggled

from Fahrenheit to Celsius by selecting the desired

U.S./Metric option from the customer programmable

features. The displayed temperature is not an instant

reading of conditions, but an average temperature. It

may take the temperature display several minutes to

respond to a major temperature change, such as driving out of a heated garage into winter temperatures.

When the ignition switch is turned to the Off position, the last displayed temperature reading stays in

the electronic control modules, (CMTC, EVIC) memory. When the ignition switch is turned to the On

position again, the electronic module will display the

memory temperature for one minute; then update the

display to the current average temperature reading

within five minutes.

The temperature function is supported by an ambient temperature sensor. This sensor is mounted outside the passenger compartment near the front and

center of the vehicle, and is hard wired to the Front

Control Module (FCM). The FCM sends temperature

status messages to the module over the J1850 PCI

data bus circuit. For more information on the ambi-

J1850 Programmable Communications Interface

(PCI) data bus circuit. If the problem is a no-display

condition, use the following procedure. For complete

circuit diagrams, refer to Overhead Console in the

Wiring Diagrams section of the service manual.

(1) Remove the overhead console from the headliner (Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(2) Check for battery voltage at the overhead console electrical connector. Refer to Wiring for connector information. If OK, go to Step 3. If not OK, Check

for battery voltage at the appropriate B(+) fuse in the

integrated power module, repair the open fused B(+)

circuit as required.

(3) Turn the ignition switch to the On position.

Check the fused ignition switch output circuit(s) at

the overhead console electrical connector. If OK, go to

Step 4. If not OK, repair the open or shorted circuit

as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cavity of the overhead console electrical connector and a

good ground. There should be continuity. If OK, refer

to SELF-DIAGNOSTIC TEST below for further

diagnosis of the electronics module and the J1850

PCI data bus circuit. If not OK, repair the open

ground circuit as required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is built-in to the module to

determine that the electronics module is operating

properly, and that all the J1850 PCI data bus messages are being received for proper operation. To perform the self-diagnostic test proceed as follows:

Page 3

DR MESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

(1) With the ignition switch in the Off position,

simultaneously depress and hold the STEP and

RESET buttons.

(2) Turn the ignition switch to the On position.

(3) Following completion of the test, the electronics

module will display one of the following messages:

a. Pass Self Test (EVIC only), PASS (CMTC) -

The electronics module is working properly.

b. Failed Self Test (EVIC only), FAIL (CMTC) -

The electronics module has an internal failure. The

electronics module is faulty and must be replaced.

c. Failed J1850 Communication (EVIC only),

BUS (CMTC) - The electronics module is not receiving proper message input through the J1850 PCI

data bus circuit. This can result from one or more

faulty electronic modules in the vehicle, or from a

faulty PCI data bus. The use of a DRB IIIt scan tool

and the proper Diagnostic Procedures manual are

required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth’s magnetic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Standard Procedures section of this group.

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT

(1) Remove the overhead console (Refer to 8 ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(2) Remove the electronics module from the overhead console. Refer to the procedure later in this section.

(3) Unsnap the lens from the module and replace

lens as necessary.

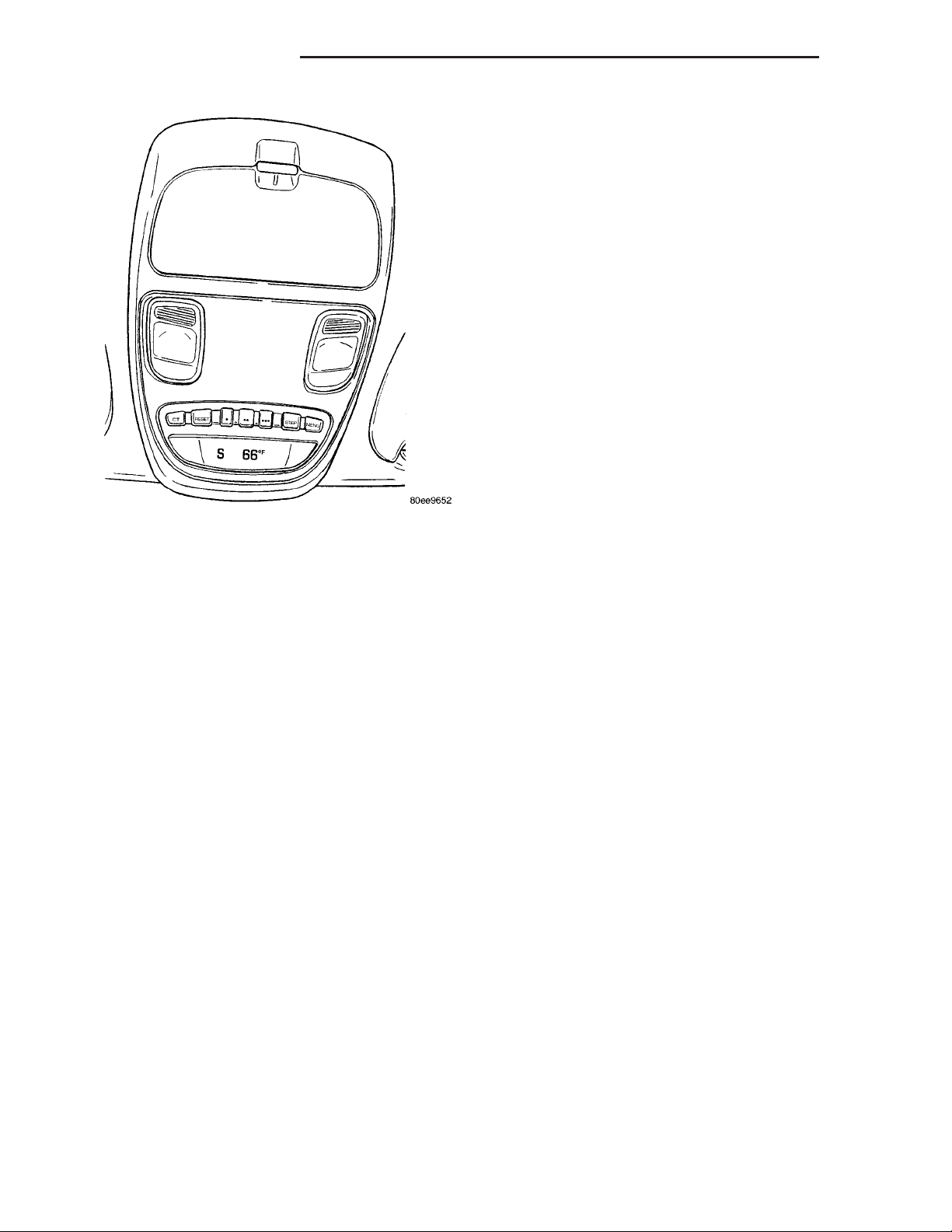

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 2).

(3) Replace lamp(s) as necessary.

NOTE: If the compass reading displays dashes, and

only “CAL” appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Standard Procedures section

of this group.

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the reading/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.

(5) Reverse the above procedure to install.

Fig. 2 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC/CMTC MODULE

3 - ILLUMINATION LAMPS

4 - MODULE RETAINING SCREWS

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when servicing the overhead console.

Page 4

8M - 4 MESSAGE SYSTEMS DR

OVERHEAD CONSOLE (Continued)

The electronic compass unit features a self-calibrating design, which simplifies the calibration procedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism that the vehicle

may acquire during normal use. If the compass readings appear to be erratic or out of calibration, perform the following calibration procedure. Also, new

service replacement Electronic Modules (EVIC,

CMTC) must have their compass calibrated using

this procedure. Do not attempt to calibrate the compass near large metal objects such as other vehicles,

large buildings, or bridges; or, near overhead or

underground power lines.

NOTE: Whenever the compass is calibrated manually, the variance number must also be reset. Refer

to Compass Variation Adjustment in this group.

To calibrate the compass manually proceed as follows:

(1) Turn the ignition switch to the On position. If

the compass/temperature data is not currently being

displayed, momentarily depress and release the C/T

push button to reach the compass/temperature display.

(2) Depress the RESET push button and hold the

button down until “CAL” appears in the display. This

takes about ten seconds, and appears about five seconds after “VAR = XX” is displayed.

(3) Release the RESET push button.

(4) Drive the vehicle on a level surface, away from

large metal objects and power lines, through three or

more complete turns at between five and eight kilometers-per-hour (three and five miles-per-hour) in

not less than 48 seconds. The “CAL” message will

disappear from the display to indicate that the compass is now calibrated.

NOTE: If the “CAL” message remains in the display,

either there is excessive magnetism near the compass, or the unit is faulty. Repeat the calibration

procedure one more time.

NOTE: If the wrong direction is still indicated in the

compass display, the area selected for calibration

may be too close to a strong magnetic field. Repeat

the calibration procedure in another location.

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

(1) Be certain that the ignition switch is in the Off

position, before you begin the demagnetizing procedure.

(2) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(3) Slowly approach the head of the overhead console mounting screw with the degaussing tool connected.

(4) Contact the head of the screw with the plastic

coated tip of the degaussing tool for about two seconds.

(5) With the degaussing tool still energized, slowly

back it away from the screw. When the tip of the tool

is at least 61 centimeters (2 feet) from the screw

head, disconnect the tool.

(6) Place a piece of paper approximately 22 by 28

centimeters (8.5 by 11 inches), oriented on the vehicle

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 3). The purpose of the paper is to protect the roof panel from

scratches, and to define the area to be demagnetized.

(7) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(8) Slowly approach the center line of the roof

panel at the windshield header, with the degaussing

tool connected.

(9) Contact the roof panel with the plastic coated

tip of the degaussing tool. Be sure that the template

is in place to avoid scratching the roof panel. Using a

slow, back-and-forth sweeping motion, and allowing

13 millimeters (0.50 inch) between passes, move the

tool at least 11 centimeters (4 inches) to each side of

the roof center line, and 28 centimeters (11 inches)

back from the windshield header.

(10) With the degaussing tool still energized,

slowly back it away from the roof panel. When the

tip of the tool is at least 61 centimeters (2 feet) from

the roof panel, disconnect the tool.

(11) Calibrate the compass and adjust the compass

variance (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE - STANDARD PROCEDURE).

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console forward mounting screw and the roof panel above the

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT

Compass variance, also known as magnetic declination, is the difference in angle between magnetic

north and true geographic north. In some geographic

locations, the difference between magnetic and geo-

Page 5

DR MESSAGE SYSTEMS 8M - 5

OVERHEAD CONSOLE (Continued)

(4) Release the RESET push button. “VAR =XX ”

will remain in the display. “XX” equals the current

variance zone setting.

(5) Depress and release the STEP push button to

step through the zone numbers, until the zone number for your geographic location appears in the display.

(6) Depress and release the RESET push button

to enter the displayed zone number into the EVIC/

CMTC module memory.

(7) Confirm that the correct directions are now

indicated by the compass.

REMOVAL

OVERHEAD CONSOLE REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console retaining screws,

located in the sunglass storage bin.

(3) Using your fingertips, grasp the sides of the

overhead console and pull straight down evenly to

disengage the two snap clips at the front of the unit.

(4) Lower the overhead console far enough to

access the wire harness connectors.

(5) Disconnect the EVIC, CMTC electronic module

and the reading/courtesy lamps electrical connectors.

(6) Remove the overhead console from the vehicle.

Fig. 3 Roof Demagnetizing Pattern

graphic north is great enough to cause the compass

to give false readings. If this problem occurs, the

compass variance setting may need to be changed.

To set the compass variance:

(1) Using the Variance Settings map, find your

geographic location and note the zone number (Fig.

4).

(2) Turn the ignition switch to the On position. If

the compass/temperature data is not currently being

displayed, momentarily depress and release the C/T

push button to reach the compass/temperature display.

(3) Depress the RESET push button and hold the

button down until “VAR = XX” appears in the display.

This takes about five seconds.

INSTALLATION

(1) Position the overhead console in the vehicle.

(2) Connect the EVIC, CMTC electronic module

and the reading/courtesy lamps electrical connectors.

(3) Grasp the sides of the overhead console and

push straight up evenly to engage the two snap clips

at the rear of the unit.

(4) Install the overhead console retaining screw,

located in the front of console. Torque the screw to

1.2 N·m (10 in. lbs.).

(5) Connect the negative battery cable.

Page 6

8M - 6 MESSAGE SYSTEMS DR

OVERHEAD CONSOLE (Continued)

Fig. 4 Variance Settings

SPECIAL TOOLS

OVERHEAD CONSOLE

DEGAUSSING TOOL #6029

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The Compass Mini-Trip Computer (CMTC) is a

module located in the overhead console. The CMTC is

equipped with a mini-trip feature. The CMTC consists of a electronic control module with a vacuum

fluorescent display (VFD) and function switches. The

CMTC consists of a electronic module that displays

compass, trip computer, and temperature features.

Actuating the STEP push button will cause the

CMTC to change mode of operation when the ignition

is ON. Example:

• Average miles per gallon (ECO)

• Distance to empty (DTE)

• Trip odometer (ODO)

RADIO FREQUENCY DETECTOR #9001

• Elapsed time (ET)

• Off

Actuating the C/T push button will cause the

CMTC to change to Compass/Temperature display.

Page 7

DR MESSAGE SYSTEMS 8M - 7

COMPASS/MINI-TRIP COMPUTER (Continued)

OPERATION

The Compass Mini-Trip Computer module in the

overhead console has buttons used to select various

functions. The CMTC selector buttons will not operate until the ignition is in the RUN position.

When the ignition switch is first turned to the

RUN position the CMTC display;

• Returns to the last mode setting selected before

the ignition was last switched OFF.

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

Compass Mini-Trip Computer (CMTC) data is

obtained from other electronic modules (CCN, FCM

and JTEC) on the J1850 Data Bus circuit. The

CMTC will display dashes (- -) for any of the screens

it did not receive the bus messages. The label corresponding to the missing information will be lit. If no

compass mini-trip computer data is displayed, check

the J1850 Data Bus circuit communications and the

other modules.

Refer to Overhead Console Diagnosis and Testing

for instructions on performing a CMTC module SelfDiagnostic Test. The DRB IIIt is recommended for

checking the J1850 Data Bus circuit and the other

modules. Perform the CMTC self diagnosis before

replacing the CMTC module.

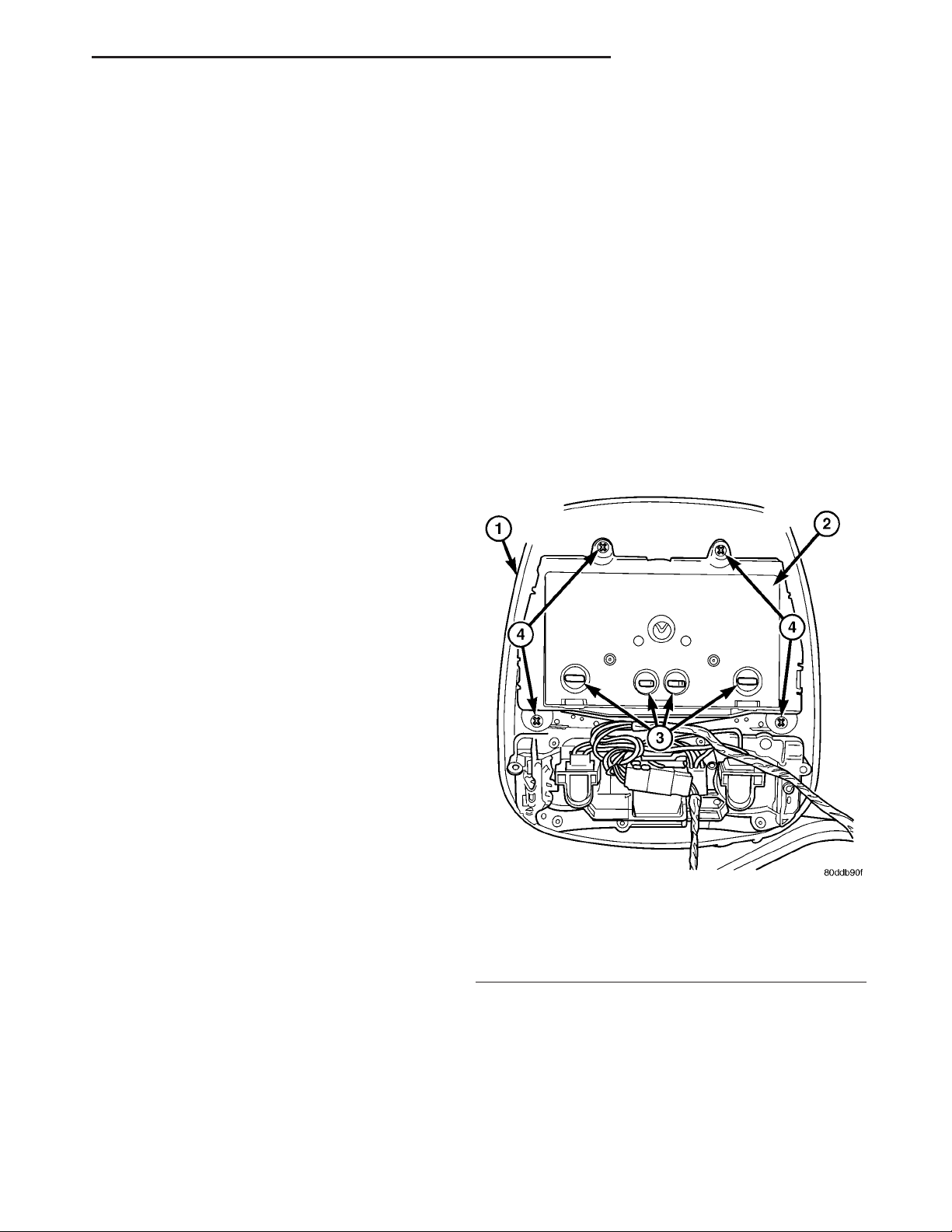

Fig. 5 OVERHEAD CONSOLE MODULE REMOVAL

1 - COMPASS MINI-TRIP COMPUTER MODULE

2 - OVERHEAD CONSOLE

pass Calibration in the Standard Procedures section of this group for the procedures.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console from the headliner.(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(3) Remove the screws holding Compass Mini-Trip

Computer module in the overhead console (Fig. 5).

(4) Disconnect the CMTC module electrical connector. Depress the retaining tab and pull straight

apart.

(5) Remove CMTC module from console assembly.

INSTALLATION

(1) Position the compass mini-trip computer module in the overhead console.

(2) Install the screws holding the compass minitrip computer module in the overhead console.

(3) Connect the module electrical connector.

(4) Install the overhead console on the headliner(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE - INSTALLATION).

(5) Connect the negative battery cable.

(6) Check CMTC module function.

NOTE: If a new module has been installed, the compass will have to be calibrated and the variance set.

Refer to Compass Variation Adjustment and Com-

ELECTRONIC VEHICLE INFO

CENTER

DESCRIPTION

The Electronic Vehicle Information Center (EVIC)

is a module located in the overhead console on some

models. The EVIC module features a large Vacuum

Fluorescent Display (VFD) screen for displaying

information, and back-lit push button switches

labeled C/T (compass/temperature), RESET, STEP,

and MENU.

The EVIC module contains a central processing

unit and interfaces with other electronic modules in

the vehicle over the Programmable Communications

Interface (PCI) J1850 data bus circuit. The PCI data

bus circuit allows the sharing of sensor information.

This helps to reduce wire harness complexity, reduce

internal controller hardware, and reduce component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabilities.

The EVIC “Menu” push button provides the vehicle

operator with a user interface, which allows the

selection of several optional customer programmable

electronic features to suit individual preferences.

Page 8

8M - 8 MESSAGE SYSTEMS DR

ELECTRONIC VEHICLE INFO CENTER (Continued)

Refer to ELECTRONIC VEHICLE INFORMATION CENTER PROGRAMMING in the Standard

Procedures section of this group for more information

on the customer programmable feature options.

If the vehicle is equipped with the optional universal transmitter transceiver, the EVIC will also display messages and an icon indicating when the

universal transmitter transceiver is being trained,

which of the three transmitter buttons is transmitting, and when the transceiver is cleared.

Data input for all EVIC functions, including VFD

dimming level, is received through the J1850 PCI

data bus circuit. The EVIC module uses its internal

programming and all of its data inputs to calculate

and display the requested data. If the data displayed

is incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclusive, the use of a DRB IIIt scan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the EVIC module and the J1850

PCI data bus circuit.

The EVIC module cannot be repaired, and is available for service only as a unit. If any part is faulty or

damaged, the complete EVIC module must be

replaced.

OPERATION

The Electronic Vehicle Information Center is wired

to both constant 12v and ignition switched sources of

battery current so that some of its features remain

operational at any time, while others may only operate with the ignition switch in the On position. When

the ignition switch is turned to the On position, the

EVIC module display will return to the last function

being displayed before the ignition was turned to the

Off position.

The compass/temperature display is the normal

EVIC display. With the ignition switch in the On

position, momentarily depressing and releasing the

C/T (compass/temperature) push button switch will

cause the EVIC to return to the compass/temperature display mode from any other mode. While in the

compass/temperature display mode, momentarily

depressing and releasing the Step push button will

step through the available trip computer display

options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CENTER PROGRAMMING in the Standard Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control functions and setting procedures for the EVIC module,

see the owner’s manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from other electronic modules (CCN,

FCM, JTEC) on the J1850 Data Bus circuit. The

EVIC will display dashes (- -) for any of the screens

it did not receive the bus messages. The label corresponding to the missing information will be lit. If no

EVIC data is displayed, check the J1850 Data Bus

circuit communications and the other modules. If the

brightness level is improper check the J1850 Data

Bus circuit.

Refer to Overhead Console Diagnosis and Testing

for instructions on performing a EVIC module SelfDiagnostic Test. The DRB IIIt is recommended for

checking the J1850 Data Bus circuit and other modules. Perform the EVIC self diagnosis before replacing the EVIC module.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehicle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter the

EVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

Page 9

DR MESSAGE SYSTEMS 8M - 9

ELECTRONIC VEHICLE INFO CENTER (Continued)

(2) Momentarily depress and release the Menu

push button to step through the programmable features list. Each programmable feature and its currently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(3) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(4) The option that last appears in the display

with a programmable feature before exiting the programming mode, becomes the newly selected programmable feature option.

(5) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the programmable features menu list is reached, whichever

occurs first.

PROGRAMMABLE FEATURES

• LANGUAGE? - The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default

is English. All EVIC display nomenclature, including

the trip computer functions, warning messages and

the programmable features appear in the selected

language.

• DISPLAY U.S. OR METRIC? - The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure.

• SERVICE INTV. = - The options include from

3200 to 12000 kilometers in 800 kilometer increments (2000 to 6000 miles in 500 mile increments).

The default is 12000 kilometers (6000 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears, RESET SERVICE

DISTANCE? - The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated distance since the last previous message.

• AUTO DOOR LOCKS? - The options include

Yes and No. The default is Yes. When Yes is selected,

all doors lock automatically when vehicle speed

reaches 25 kilometers-per-hour (15 miles-per-hour). If

YES is selected, a second programmable feature

appears, AUTO UNLOCK ON EXIT? - The options

again include Yes and No. The default is No. When

Yes is selected, following each Auto Door Lock event

all doors will automatically unlock when the driver

door is opened, if the vehicle is stopped and the

transmission gear selector is in Park or Neutral. The

Auto Door Unlock event will only occur once following each Auto Door Lock event.

• REMOTE UNLOCK - The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE transmitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

• SOUND HORN ON LOCK? - The options

include On and Off. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected independent of the FLASH LIGHTS WITH LOCKS? programmable feature.

• FLASH LIGHTS WITH LOCKS? - The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected independent of the SOUND HORN ON LOCK? programmable feature.

• HEADLAMP DELAY = - The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the headlamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

• TRAIN REMOTE - When this feature is

selected the driver can choose to train up to four

remote keyless entry transmitters. The options

include Yes and No. The default is No. When Yes is

selected and the MENU button is pressed the EVIC

will display “PRESS REMOTE LOCK & UNLOCK

THEN PRESS UNLOCK”, followed by a chime to

indicate the training sequence can commence. You

have approximately 30 seconds to train up to four

transmitters, after each transmitter is trained a

chime will sound indicating that the training was

successful. If remote link to memory is “YES” , the

first transmitter trained will be associated with

Page 10

8M - 10 MESSAGE SYSTEMS DR

ELECTRONIC VEHICLE INFO CENTER (Continued)

memory setting 1 and the second transmitter trained

will be associated with memory setting 2. Additional

transmitters will not be associated with a memory

setting. When you have finished training the transmitters, press the menu button again and the EVIC

will display “TRAIN DONE “X” TRAINED. If no

transmitters are trained within approximately 30

seconds the EVIC will display “TRAIN TIMEOUT”.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the overhead console from the headliner.(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(4) Install the overhead console on the headliner(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE - INSTALLATION).

(5) Connect the battery negative cable.

(6) Check EVIC module function.

NOTE: If a new EVIC module has been installed, the

compass will have to be calibrated and the variance

set. Refer to Compass Variation Adjustment and

Compass Calibration in the Standard Procedures

section of this group for the procedures.

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the overhead console. The ambient temperature messages are

received from the Front Control Module (FCM) over

the Programmable Communications Interface (PCI)

J1850 data bus circuit. The FCM receives a hard

wired input from the ambient temperature sensor

(Fig. 7). The ambient temperature sensor is a variable resistor mounted to the underside of the hood,

in the engine compartment.

Fig. 6 OVERHEAD CONSOLE MODULE REMOVAL

1 - ELECTRONIC VEHICLE INFORMATION MODULE

2 - OVERHEAD CONSOLE

(3) Disconnect the EVIC module electrical connector. Depress the retaining tab and pull straight

apart.

(4) Remove the screws holding the EVIC module in

the overhead console (Fig. 6).

(5) Remove EVIC module from console assembly.

INSTALLATION

(1) Position the EVIC module in the overhead console.

(2) Install the screws holding the EVIC module in

the overhead console.

(3) Connect the EVIC module electrical connector.

Fig. 7 Ambient Temperature Sensor - Typical

For more information on the front control module,

refer to Front Control Module in the Electronic

Control Modules section of this manual. For complete

circuit diagrams, refer to Wiring. The ambient temperature sensor cannot be adjusted or repaired and,

if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the Front Control Module. The resistance in the sensor changes as temperature changes,

changing the temperature sensor signal circuit voltage to the Front Control Module. Based upon the

resistance in the sensor, the Front Control Module

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The Front Control Module

Page 11

DR MESSAGE SYSTEMS 8M - 11

AMBIENT TEMP SENSOR (Continued)

then sends the proper ambient temperature messages to the EVIC, CMTC over the PCI J1850 data

bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Front Control Module, the Programmable Communications Interface (PCI) data bus, and a portion of the

Electronics module. If any portion of the ambient

temperature sensor circuit fails, the Front Control

Module will self-diagnose the circuit.

For complete circuit diagrams, refer to Wiring.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire harness connector.

(2) Measure the resistance of the ambient temperature sensor. At 24° C (75° F), the sensor resistance

should be approximately 10.3 kilohms. At 30° C (86°

F), the sensor resistance should be approximately

7.57 kilohms. The sensor resistance should decrease

as the temperature rises. If OK, refer to Diagnosis

and Testing - Ambient Temperature Sensor Circuit in this group. If not OK, replace the faulty

ambient temperature sensor.

(4) Remove the jumper wire from the ambient temperature sensor wire harness connector. Check for

continuity between the sensor return circuit cavity of

the Front Control Module wire harness connector

and a good ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted sensor return circuit as required.

(5) Check for continuity between the ambient temperature sensor signal circuit cavity of the Front

Control Module wire harness connector and a good

ground. There should be no continuity. If OK, refer to

Diagnosis and Testing - Overhead Console in

this group. If not OK, repair the shorted ambient

temperature sensor signal circuit as required.

REMOVAL

(1) Open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Working on the underside of the hood, remove

screw holding sensor to hood panel.

(4) Disconnect the sensor electrical connector and

remove sensor from vehicle.

INSTALLATION

(1) Connect the sensor electrical connector.

(2) Working on the underside of the hood, install

screw holding sensor to hood panel.

(3) Connect the battery negative cable.

(4) Close the hood.

NOTE: The ambient temperature sensor is a very

sensitive device. When testing, be certain the temperature sensor has had time to stabilize (room

temperature) before attempting to read the sensor

resistance. Failure to let the ambient temperature

sensor temperature stabilize could result in a misleading test.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire harness connector and the Front Control Module wire

harness connector.

(2) Connect a jumper wire between the two terminals of the ambient temperature sensor wire harness

connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the Front Control Module wire harness connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return or

signal circuit as required.

UNIVERSAL TRANSMITTER

DESCRIPTION

Some DR models are equipped with a universal

transmitter transceiver. The universal transmitter is

integral to the Electronic Vehicle Information Center

(EVIC) and the Compass Mini-Trip Computer

(CMTC), which is located in the overhead console.

The only visible component of the universal transmitter are the three transmitter push buttons centered

between the modules push buttons located just rearward of the display screen in the overhead console.

The three universal transmitter push buttons are

identified with one, two or three light indicators so

that they be easily identified.

Each of the three universal transmitter push buttons control an independent radio transmitter channel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security systems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

Page 12

8M - 12 MESSAGE SYSTEMS DR

UNIVERSAL TRANSMITTER (Continued)

tion. The universal transmitter is capable of operating systems using either rolling code or non-rolling

code technology.

The electronics module displays messages and a

small house-shaped icon with one, two or three dots

corresponding to the three transmitter buttons to

indicate the status of the universal transmitter. The

EVIC messages are:

• Clearing Channels - Indicates that all of the

transmitter codes stored in the universal transmitter

have been successfully cleared.

• Channel “X” Training - Indicates that the uni-

versal transmitter is in its transmitter learning

mode.

• Channel “X” Trained - Indicates that the uni-

versal transmitter has successfully acquired a new

transmitter code.

• Channel “X” Transmitting - Indicates that a

trained universal transmitter button has been

depressed and that the universal transmitter is

transmitting.

The universal transmitter cannot be repaired, and

is available for service only as a unit with the EVIC

or CMTC modules. If any part of the universal transmitter is faulty or damaged, the complete EVIC or

CMTC module must be replaced.

(2) Hold the RF detector within one inch of the

TRAINED universal transmitter and press any of the

transmitters buttons.

(3) The red signal detection LEDs will light and

the tool will beep if a radio signal is detected. Repeat

this test three times.

OPERATION

The universal transmitter operates on a nonswitched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, programming procedures and operation of the universal

transmitter, see the owner’s manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is operating normally, see the owner’s manual in the vehicle

glove box for instructions on training the Transmitter. Retrain the Transmitter with a known good

transmitter as instructed in the owner’s manual and

test the Transmitter operation again. If the unit is

still inoperative, test the universal transmitter with

Radio Frequency Detector special tool. If both the

Transmitter and the EVIC module are inoperative,

refer to Electronic Vehicle Information Center

Diagnosis and Testing in this group for further

diagnosis. For complete circuit diagrams, refer to

Wiring Diagrams. (Fig. 8) as described below:

(1) Turn the Radio Frequency (RF) Detector ON. A

“chirp” will sound and the green power LED will

light. If the green LED does not light, replace the

battery.

Fig. 8 RADIO FREQUENCY DETECTOR

1 - SIGNAL DETECTION LED’S

2 - POWER LED

3 - ON/OFF SWITCH

4 - 9V BATTERY

STANDARD PROCEDURE

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down the two outside buttons until the display

confirms the operation.

NOTE: Individual channels cannot be erased. Erasing the transmitter codes will erase ALL programmed codes.

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the codes by pressing the two outside

buttons. Release the buttons when the display confirms the operation (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

Page 13

DR MESSAGE SYSTEMS 8M - 13

UNIVERSAL TRANSMITTER (Continued)

versal transmitter and push the buttons on both

transmitters.

(4) Release both buttons. Your universal transmitter is now “trained”. To train the other buttons,

repeat Step 3 and Step 4. Be sure to keep your handheld transmitter in case you need to retrain the universal transmitter.

REMOVAL

(1) For universal transmitter removal and installation procedure, (Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - REMOVAL and INSTALLATION).

Loading...

Loading...