Page 1

DR/DH LUBRICATION & MAINTENANCE 0 - 1

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

INTERNATIONAL SYMBOLS

DESCRIPTION ..........................1

PARTS & LUBRICANT RECOMMENDATION

DESCRIPTION

LUBRICANT RECOMMENDATIONS .........2

FLUID TYPES .........................2

FLUID TYPES

DESCRIPTION

ENGINE OIL ..........................3

FUEL REQUIREMENTS - DIESEL ENGINE . . . 4

ENGINE OIL - DIESEL ENGINES ...........4

POWER STEERING FLUID ...............5

ENGINE COOLANT .....................5

TRANSFER CASE ......................6

AXLE ................................6

MANUAL TRANSMISSION ................6

AUTOMATIC TRANSMISSION FLUID ........6

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international symbols to identify engine compartment lubricant and fluid

inspection and fill locations.

OPERATION - AUTOMATIC TRANSMISSION

FLUID ...............................7

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES .....................7

MAINTENANCE SCHEDULES

DESCRIPTION

MAINTENANCE SCHEDULES .............9

24-VALVE CUMMINS TURBO DIESEL

MAINTENANCE SCHEDULES ............17

MAINTENANCE SCHEDULES - SRT/10 .....24

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . 31

HOISTING

STANDARD PROCEDURE - HOISTING .......33

TOWING

STANDARD PROCEDURE ................37

Page 2

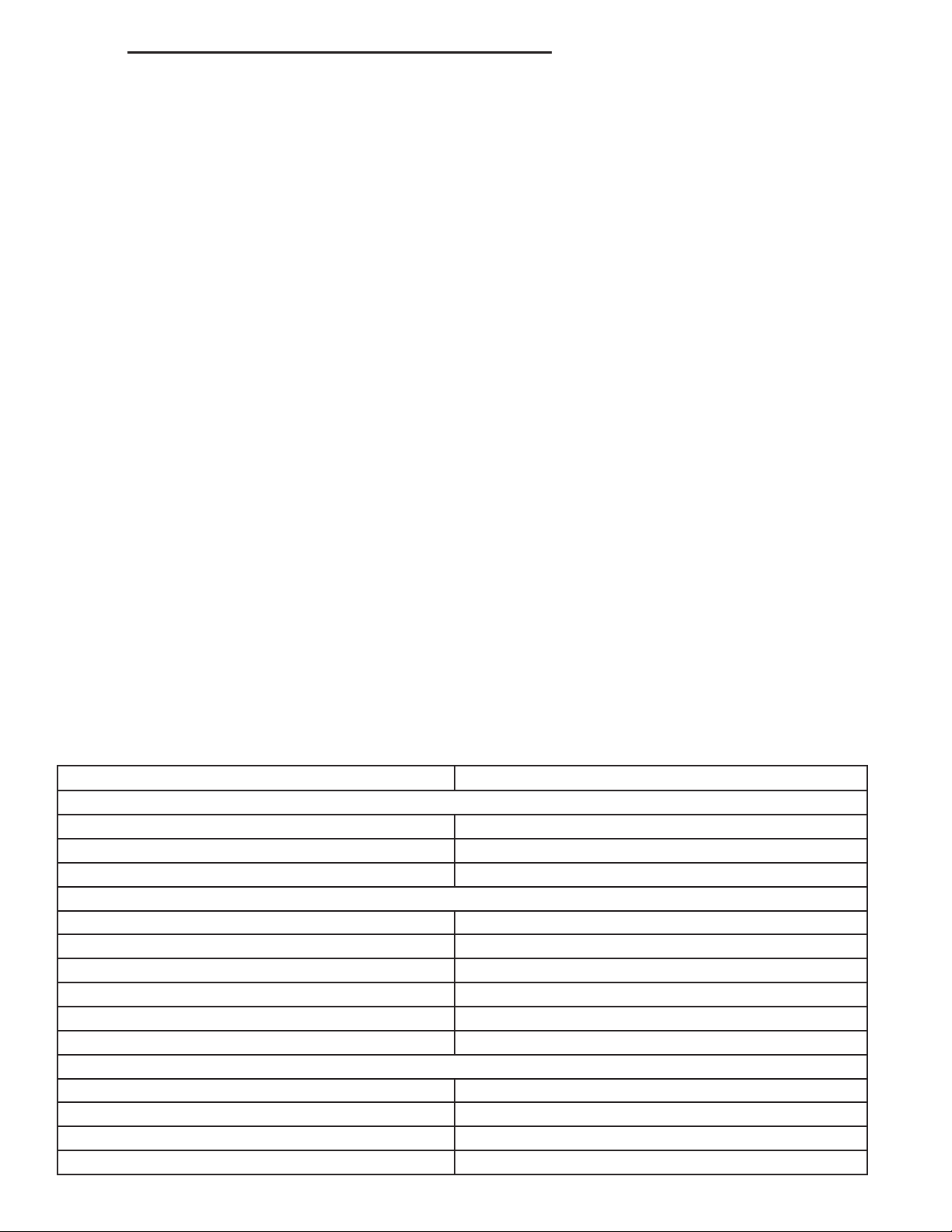

0 - 2 LUBRICATION & MAINTENANCE DR/DH

PARTS & LUBRICANT RECOMMENDATION

DESCRIPTION

LUBRICANT RECOMMENDATIONS

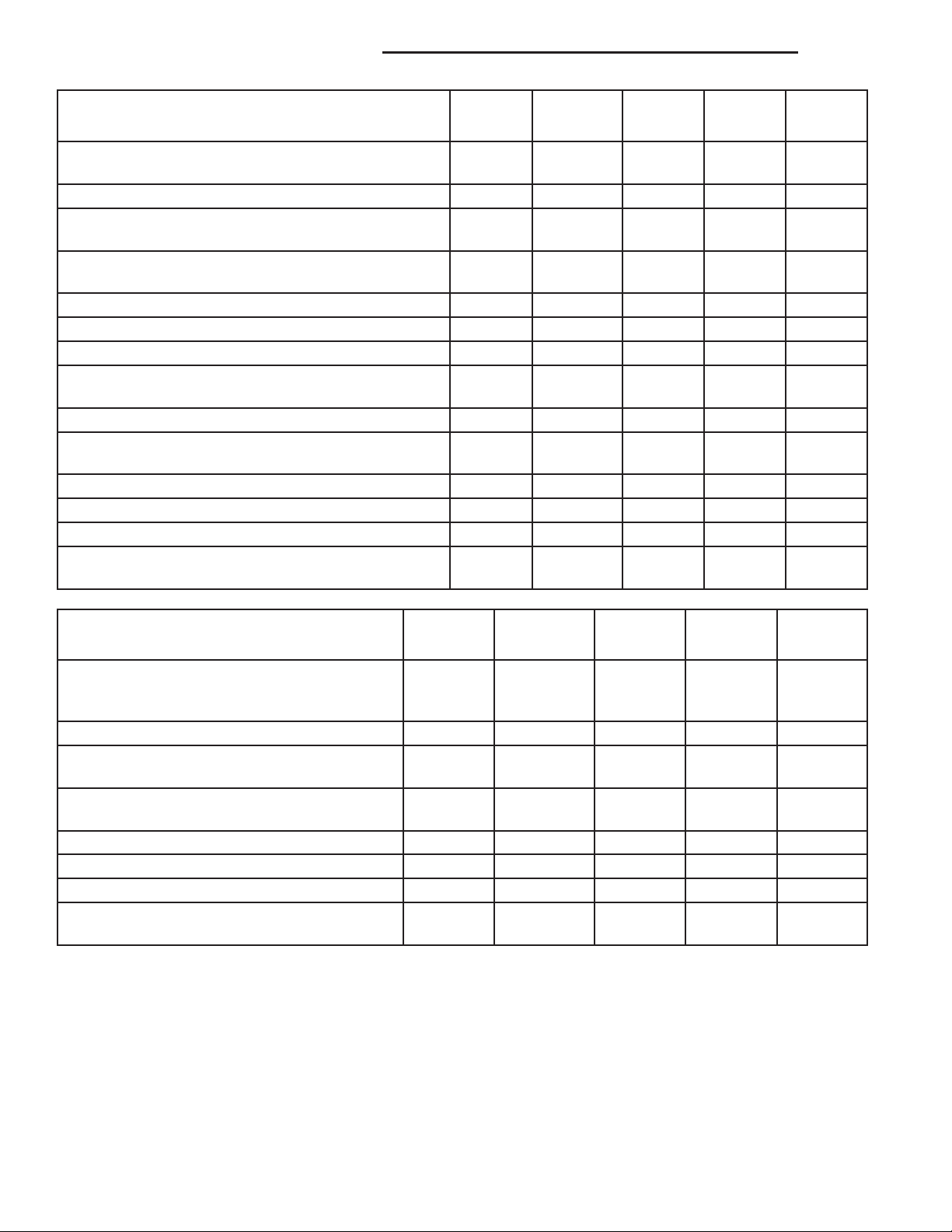

Chassis

Component Fluid, Lubricant, or Genuine Part

Steering Gear & Linkage, Ball

Joints, Prop Shafts & Yokes,

Wheel Bearings

Body

Component Fluid, Lubricant, and Genuine Part

Hinges:

Door & Hood MoparT Engine Oil

Swing Gate MoparT Multi-Purpose Lube NLGI Grade 2 EP, GC-LB

Latches: Door, Hood/Safety

Catch, Swing Gate

Seat Regulator & Track MoparT Multi-Purpose Lube NLGI Grade 2 EP, GC-LB

Lock Cylinders MoparT Lock Cylinder Lube

MoparT Multi-Purpose Lubricant NLGI Grade 2 EP, GC-LB

MoparT Multi-Purpose Lube NLGI Grade 2 EP, GC-LB

FLUID TYPES

When service is required, DaimlerChrysler Corporation recommends that only MoparT brand parts, lubricants and

chemicals be used. MoparT provides the best engineered products for servicing DaimlerChrysler Corporation vehicles.

Only lubricants bearing designations defined by the following organization should be used to service a Chrysler

Corporation vehicle.

• Society of Automotive Engineers (SAE)

• American Petroleum Institute (API)

• National Lubricating Grease Institute (NLGI)

API QUALITY CLASSIFICATION

This symbol on the front of an oil container means

that the oil has been certified by the American Petroleum Institute (API) to meet all the lubrication requirements specified by DaimlerChrysler Corporation.

GEAR LUBRICANTS

SAE ratings also apply to multigrade gear lubricants. In addition, API classification defines the lubricants usage.

Such as API GL-5 and SAE 75W-90.

Page 3

DR/DH LUBRICATION & MAINTENANCE 0 - 3

FLUID TYPES

DESCRIPTION

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL. CONTAMINANTS IN USED ENGINE OIL, CAUSED BY INTERNAL COMBUSTION, CAN BE HAZARDOUS TO YOUR HEALTH. THOROUGHLY WASH EXPOSED SKIN WITH

SOAP AND WATER. DO NOT WASH SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR SOLVENTS,

HEALTH PROBLEMS CAN RESULT. DO NOT POLLUTE, DISPOSE OF USED ENGINE OIL PROPERLY. CONTACT YOUR DEALER OR GOVERNMENT AGENCY FOR LOCATION OF COLLECTION CENTER IN YOUR

AREA.

Only lubricants bearing designations defined by the following organization should be used.

• Society of Automotive Engineers (SAE)

• American Petroleum Institute (API)

• National Lubricating Grease Institute (NLGI)

• Association des Constructeurs Européens d’ Automobiles (European Automobile Manufacturers Association)

(ACEA)

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Certified. MOPART provides engine oils, that meet or exceed this requirement.

SAE VISCOSITY

An SAE viscosity grade is used to specify the viscosity

of engine oil. Use only engine oils with multiple viscosities such as 5W-30 or 10W-30. These are specified

with a dual SAE viscosity grade which indicates the

cold-to-hot temperature viscosity range. Select an

engine oil that is best suited to your particular temperature range and variation. For 3.7L/4.7L engines SAE

5W-30 engine oil is recommended for all operating

temperatures. For 5.7L engines SAE 5W-20 engine

oil is recommended for all operating temperatures.These engine oils improve low temperature starting and vehicle fuel economy. Refer to your engine

oil filler cap for the recommended engine oil viscosity for your vehicle.

ACEA Categories

For countries that use the ACEA European Oil Categories for Service Fill Oils, use engine oils that meet the requirements of ACEA A1/B1, A2/B2, or A3/B3.

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for gasoline engines. The designation of ENERGY CONSERVING

is located on the label of an engine oil container.

Page 4

0 - 4 LUBRICATION & MAINTENANCE DR/DH

CONTAINER IDENTIFICATION

Standard engine oil identification notations have been

adopted to aid in the proper selection of engine oil.

The identifying notations are located on the front label

of engine oil plastic bottles and the top of engine oil

cans.

This symbol means that the oil has been certified by

the American Petroleum Institute (API). DiamlerChrysler only recommend API Certified engine oils.

Use MoparT engine oil or equivalent.

FUEL REQUIREMENTS - DIESEL ENGINE

WARNING: Do not use alcohol or gasoline as a fuel blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed with diesel fuel.

Use good quality diesel fuel from a reputable supplier in your Dodge truck. For most year-round service, number 2

diesel fuel meeting ASTM specification D-975 will provide good performance. If the vehicle is exposed to extreme

cold (below 0°F/-18°C), or is required to operate at colder-than-normal conditions for prolonged periods, use climatized No. 2 diesel fuel or dilute the No. 2 diesel fuel with 50% No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To prevent fuel system trouble, including fuel line freezing in winter,

drain the accumulated water from the fuel/water separator using the fuel/water separator drain provided. If you buy

good-quality fuel and follow the cold-weather advice above, fuel conditioners should not be required in your vehicle.

If available in your area, a high cetane “premium” diesel fuel may offer improved cold starting and warm-up performance.

ENGINE OIL - DIESEL ENGINES

Use only Diesel Engine Oil meeting standard MIL-2104C or API Classification CD or higher or CCML D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is recommended that SAE Grade 10W-40 engine oils that

meet Chrysler material standard MS-6395, be used in

accordance to ACEA B3, B4 specification. European

Grade 10W-40 oils that meet Association des Constructeurs Européens d’ Automobiles (European Automobile Manufacturers Association) (ACEA)

specifications, are also acceptable.

Oils of the SAE 5W-40 grade number are preferred

when minimum temperatures consistently fall below -15°C.

Page 5

DR/DH LUBRICATION & MAINTENANCE 0 - 5

ACEA Categories

For countries that use the ACEA European Oil Categories for Service Fill Oils, use engine oils that meet

the requirements of ACEA A1/B1, A2/B2, or A3/B3.

POWER STEERING FLUID

MoparT ATF +4, Automatic Transmission Fluid is

required in the power steering system. Substitute fluids can induce power steering system failure.

MoparT ATF +4, Automatic Transmission Fluid when

new is red in color. The ATF is dyed red so it can be

identified from other fluids used in the vehicle such as

engine oil or antifreeze. The red color is not permanent and is not an indicator of fluid condition. As the vehicle is

driven, the ATF will begin to look darker in color and may eventually become brown. This is normal. ATF+4 also

has a unique odor that may change with age. Consequently, odor and color cannot be used to indicate the fluid

condition or the need for a fluid change.

ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL BASE COOLANT AND IS HARMFUL IF SWALLOWED OR

INHALED. IF SWALLOWED, DRINK TWO GLASSES OF WATER AND INDUCE VOMITING. IF INHALED, MOVE

TO FRESH AIR AREA. SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT STORE IN OPEN OR UNMARKED

CONTAINERS. WASH SKIN AND CLOTHING THOROUGHLY AFTER COMING IN CONTACT WITH ETHYLENE

GLYCOL. KEEP OUT OF REACH OF CHILDREN. DISPOSE OF GLYCOL BASE COOLANT PROPERLY, CONTACT YOUR DEALER OR GOVERNMENT AGENCY FOR LOCATION OF COLLECTION CENTER IN YOUR

AREA.

WARNING: DO NOT OPEN A COOLING SYSTEM WHEN THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants is not recommended, as they provide less freeze protection and less corrosion protection.

The cooling system is designed around the coolant. The coolant must accept heat from engine metal, in the cylinder

head area near the exhaust valves and engine block. Then coolant carries the heat to the radiator where the tube/

fin radiator can transfer the heat to the air.

The use of aluminum cylinder blocks, cylinder heads, and water pumps requires special corrosion protection.

MoparT Antifreeze/Coolant, 5 Year/100,000 Mile Formula (MS-9769), or the equivalent ethylene glycol base coolant

with organic corrosion inhibitors (called HOAT, for Hybrid Organic Additive Technology) is recommended. This coolant offers the best engine cooling without corrosion when mixed with 50% Ethylene Glycol and 50% distilled water

to obtain a freeze point of -37°C (-35°F). If it loses color or becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are claimed to improve engine cooling.

CAUTION: MoparT Antifreeze/Coolant, 5 Year/100,000 Mile Formula (MS-9769) may not be mixed with any

other type of antifreeze. Mixing of coolants other than specified non-HOAT or other HOAT coolant, may

result in engine damage that may not be covered under the new vehicle warranty, and decreased corrosion

protection.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and distilled water mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mixtures follows:

Page 6

0 - 6 LUBRICATION & MAINTENANCE DR/DH

Pure Distilled Water - Distilled water can absorb more heat than a mixture of water and ethylene-glycol. This is for

purpose of heat transfer only. Water also freezes at a higher temperature and allows corrosion.

100 percent Ethylene-Glycol - The corrosion inhibiting additives in ethylene-glycol need the presence of distilled

water to dissolve. Without water, additives form deposits in system. These act as insulation causing temperature to

rise to as high as 149°C (300°F). This temperature is hot enough to melt plastic and soften solder. The increased

temperature can result in engine detonation. In addition, 100 percent ethylene-glycol freezes at -22°C (-8°F).

50/50 Ethylene-Glycol and Distilled Water - Is the recommended mixture, it provides protection against freezing to

-37°C (-34°F). The antifreeze concentration must always be a minimum of 44 percent, year-round in all climates. If

percentage is lower, engine parts may be eroded by cavitation. Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which prevents freezing down to -67.7°C (-90°F). A higher percentage

will freeze at a warmer temperature. Also, a higher percentage of antifreeze can cause the engine to overheat

because specific heat of antifreeze is lower than that of water.

CAUTION: Richer antifreeze mixtures cannot be measured with normal field equipment and can cause problems associated with 100 percent ethylene-glycol.

TRANSFER CASE

Recommended lubricant for the NV241 GENII, NV271, NV243, NV244 GENII, and NV273 transfer cases is MoparT

ATF +4, Automatic Transmission Fluid.

AXLE

NOTE: DaimlerChrysler recommends using MoparT lubricants or lubricants of equal quality.

FRONT AXLE

• C205F - MoparT Gear Lubricant 75W-90

• 9 1/4 AA - MoparT Synthetic Gear Lubricant 75W-90

• 9 1/4 AA EL- MoparT Synthetic Gear Lubricant 75W-90

REAR AXLE

• 9 1/4 - MoparT Synthetic Gear Lubricant 75W-140

• 10 1/2 AA - MoparT Synthetic Gear Lubricant 75W-90

• 10 1/2 AA EL- MoparT Synthetic Gear Lubricant 75W-90

• 11 1/2 AA - MoparT Synthetic Gear Lubricant 75W-90

• 248RBI - MoparT Gear & Axle Lubricant SAE 90

NOTE: Trac-LokT differentials require Limited Slip Additive in the lubricant. Trac-Rite™ / Trac-Rite EL™ differentials DO NOT require Limited Slip Additive.

MANUAL TRANSMISSION

NOTE: DaimlerChrysler recommends using MoparT lubricants or lubricants of equal quality.

• NV5600 - MoparT Manual Transmission Lubricant

• NV4500 - MoparT Synthetic 75W-85 Manual Transmission Lubricant

• Getrag 238 - MoparT ATF+4 Transmission Fluid

• G 56 - MoparT ATF+4 Transmission Fluid

• T-56 - MoparT Synthetic 75W-85 Manual Transmission Lubricant

AUTOMATIC TRANSMISSION FLUID

NOTE: Refer to Service Procedures in this group for fluid level checking procedures.

Page 7

DR/DH LUBRICATION & MAINTENANCE 0 - 7

MoparT ATF +4, Automatic Transmission Fluid is the recommended fluid for DaimlerChrysler automatic transmissions.

Dexron II fluid IS NOT recommended. Clutch chatter can result from the use of improper fluid.

MoparT ATF +4, Automatic Transmission Fluid when new is red in color. The ATF is dyed red so it can be identified

from other fluids used in the vehicle such as engine oil or antifreeze. The red color is not permanent and is not an

indicator of fluid condition. As the vehicle is driven, the ATF will begin to look darker in color and may eventually

become brown. This is normal. ATF+4 also has a unique odor that may change with age. Consequently, odor and

color cannot be used to indicate the fluid condition or the need for a fluid change.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the addition of any fluids to the transmission, other than those automatic transmission fluids listed above. Exceptions to this policy are the use of special dyes to aid in detecting fluid

leaks.

Various “special” additives and supplements exist that claim to improve shift feel and/or quality. These additives and

others also claim to improve converter clutch operation and inhibit overheating, oxidation, varnish, and sludge.

These claims have not been supported to the satisfaction of DaimlerChrysler and these additives must not be

used. The use of transmission “sealers” should also be avoided, since they may adversely affect the integrity of

transmission seals.

OPERATION - AUTOMATIC TRANSMISSION FLUID

The automatic transmission fluid is selected based upon several qualities. The fluid must provide a high level of

protection for the internal components by providing a lubricating film between adjacent metal components. The fluid

must also be thermally stable so that it can maintain a consistent viscosity through a large temperature range. If the

viscosity stays constant through the temperature range of operation, transmission operation and shift feel will remain

consistent. Transmission fluid must also be a good conductor of heat. The fluid must absorb heat from the internal

transmission components and transfer that heat to the transmission case.

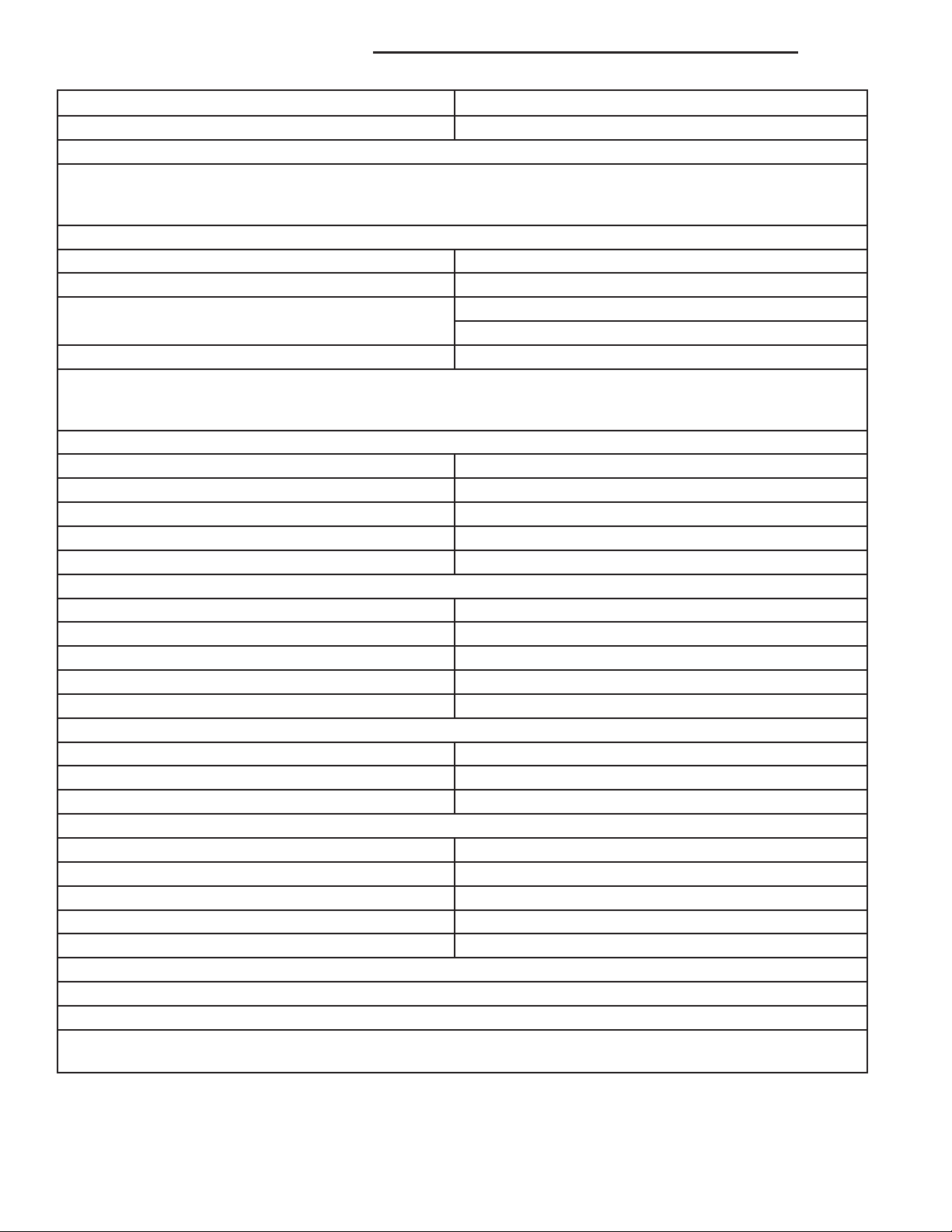

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK

1500 Short Box 98 L (26 gal.)*

2500/3500 Short Box 128L (34 gal.)*

All Long Box 132 L (35 gal.)*

ENGINE OIL WITH FILTER

3.7L 4.7 L (5.0 qts.)

4.7L 5.6 L (6.0 qts.)

5.7L 6.6 L (7.0 qts.)

5.9L DIESEL 11.4 L (12.0 qts.)

8.3L - Oil Service Quantity 8.2L (8.75 qts.)

8.3L - Engine Overhaul Quantity 9.4L (10.0 qts.)

COOLING SYSTEM

3.7L 15.4 L (16.2 qts.)**

4.7L 15.4 L (16.2 qts.)**

5.7L 15.4L (16.2 qts.)**

5.9L Diesel Engine 28L (29.5 qts.)**

Page 8

0 - 8 LUBRICATION & MAINTENANCE DR/DH

DESCRIPTION SPECIFICATION

8.3L 15.1L (18 qts.)

POWER STEERING

Power steering fluid capacities are dependent on engine/chassis options as well as steering gear/cooler options.

Depending on type and size of internal cooler, length and inside diameter of cooler lines, or use of an auxiliary

cooler, these capacities may vary. Refer to 19, Steering for proper fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 48RE 3.8 L (4.0 qts.)

Overhaul - 48RE 14-16L (29-33 pts.) L

Service Fill - 45RFE/545RFE

Overhaul - 45RFE/545RFE 14-16 L (29-33 pts.) L

L Dry fill capacity. Depending on type and size of internal cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these figures may vary. (Refer to 21 - TRANSMISSION/AUTOMATIC/FLUID -

STANDARD PROCEDURE)

MANUAL TRANSMISSION

G56 5.67 L (12 pts.)

GETRAG 238 2.2 L (4.2 pts.)

NV5600 4.50 L (9.5 pts.)

NV4500 3.79 L (8.0 pts.)

TREMEC T-56 2.27 L (4.8 pts.)

TRANSFER CASE

NV241 GENII 1.6 L (3.4 pts.)

NV243 1.6 L (3.4 pts.)

NV244 GENII 1.6 L (3.4 pts.)

NV271 1.89 L (4.0 pts.)

NV273 1.89 L (4.0 pts.)

FRONT AXLE ± .03 L (1 oz)

C205F 1.6 L (56 oz.)

9 1/4 AA 2.2 L (76 oz.)

9 1/4 AA EL 2.2 L (76 oz.)

REAR AXLE ± .03 L (1 oz)

9 1/4 2.1 L (72 oz.)***

10 1/2 AA 2.5 L (85 oz.)

10 1/2 AA EL 2.5 L (85 oz.)

11 1/2 AA 3.6 L (122 oz.)

248RBI (DANA 60) 2.8 L (46 oz.)****

**** Add 147 ml (5 oz.) of Limited Slip Additive

*** With Trac-Lok add 118 ml (4 oz.) of Limited Slip Additive.

** Includes 0.9L (1.0 qts.) for coolant reservoir.

*Nominal refill capacities are shown. A variation may be observed from vehicle to vehicle due to manufacturing

tolerance and refill procedure.

4X2 - 5.2 L (11.0 pts.)

4X4 - 6.2 L (13.0 pts.)

Page 9

DR/DH LUBRICATION & MAINTENANCE 0 - 9

MAINTENANCE SCHEDULES

DESCRIPTION

MAINTENANCE SCHEDULES

There are two maintenance schedules that show the required service for your vehicle.

First is Schedule “B”. It is for vehicles that are operated under the conditions that are listed below and at the

beginning of the schedule.

• Day or night temperatures are below 32° F (0° C).

• Stop and go driving.

• Extensive engine idling.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• More than 50% of your driving is at sustained high speeds during hot weather, above 90° F C (32°).

• Trailer towing.

• Snowplowing.

• Heavy Loading.

• Taxi, police, or delivery service (commercial service).

• Off-road or desert operation.

• If equipped for and operating with E-85 (ethanol) fuel.

NOTE: If ANY of these apply to you then change your engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule “B” of the (Maintenance Schedules( section of this manual.

NOTE: If ANY of these apply to you then flush and replace your engine coolant every 102,000 miles (163 000

km) or 60 months, whichever comes first and follow schedule “B” of the (Maintenance Schedules( section

of this manual.

NOTE: Most vehicles are operated under the conditions listed for Schedule (B(.

Second is Schedule “A”. It is for vehicles that are not operated under any of the conditions listed under Schedule

9B9.

Use the schedule that best describes your driving conditions. Where time and mileage are listed, follow the interval

that occurs first.

NOTE: Under no circumstances should oil change intervals exceed 6000 miles (10 000 km) or 6 months

whichever comes first.

CAUTION: Failure to perform the required maintenance items may result in damage to the vehicle.

At Each Stop for Fuel

• Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accuracy of the oil level reading. Add oil only when the level is

at or below the ADD or MIN mark.

• Check the windshield washer solvent and add if required.

Once a Month

• Check tire pressure and look for unusual wear or damage.

• Inspect the battery and clean and tighten the terminals as required.

• Check the fluid levels of coolant bottle, brake master cylinder, and transmission and add as needed.

• Check all lights and all other electrical items for correct operation.

Page 10

0 - 10 LUBRICATION & MAINTENANCE DR/DH

At Each Oil Change

• Change the engine oil filter.

• Drivetrain/Steering/Suspension Grease Fittings (if equipped)

• Inspect the exhaust system.

• Inspect the brake hoses.

• Inspect the CV joints (if equipped) and front suspension components.

• Check the automatic transmission fluid level.

• Check the manual transmission fluid level.

• Check the coolant level, hoses, and clamps.

Schedule “B”

Follow schedule “B” if you usually operate your vehicle under one or more of the following conditions.

• Day or night temperatures are below 32° F (0° C).

• Stop and go driving.

• Extensive engine idling.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• More than 50% of your driving is at sustained high speeds during hot weather, above 90° F C (32°).

• Trailer towing.

• Snowplowing.

• Heavy Loading.

• Taxi, police, or delivery service (commercial service).

• Off-road or desert operation.

• If equipped for and operating with E-85 (ethanol) fuel.

NOTE: If ANY of these apply to you then change your engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule “B” of the (Maintenance Schedules( section of this manual.

NOTE: If ANY of these apply to you then flush and replace your engine coolant every 102,000 miles (163 000

km) or 60 months, whichever comes first and follow schedule “B” of the (Maintenance Schedules( section

of this manual.

If none of these apply to you, then change your engine oil at every interval shown on schedule 9A9 of the 9Maintenance Schedules9 section of this manual.

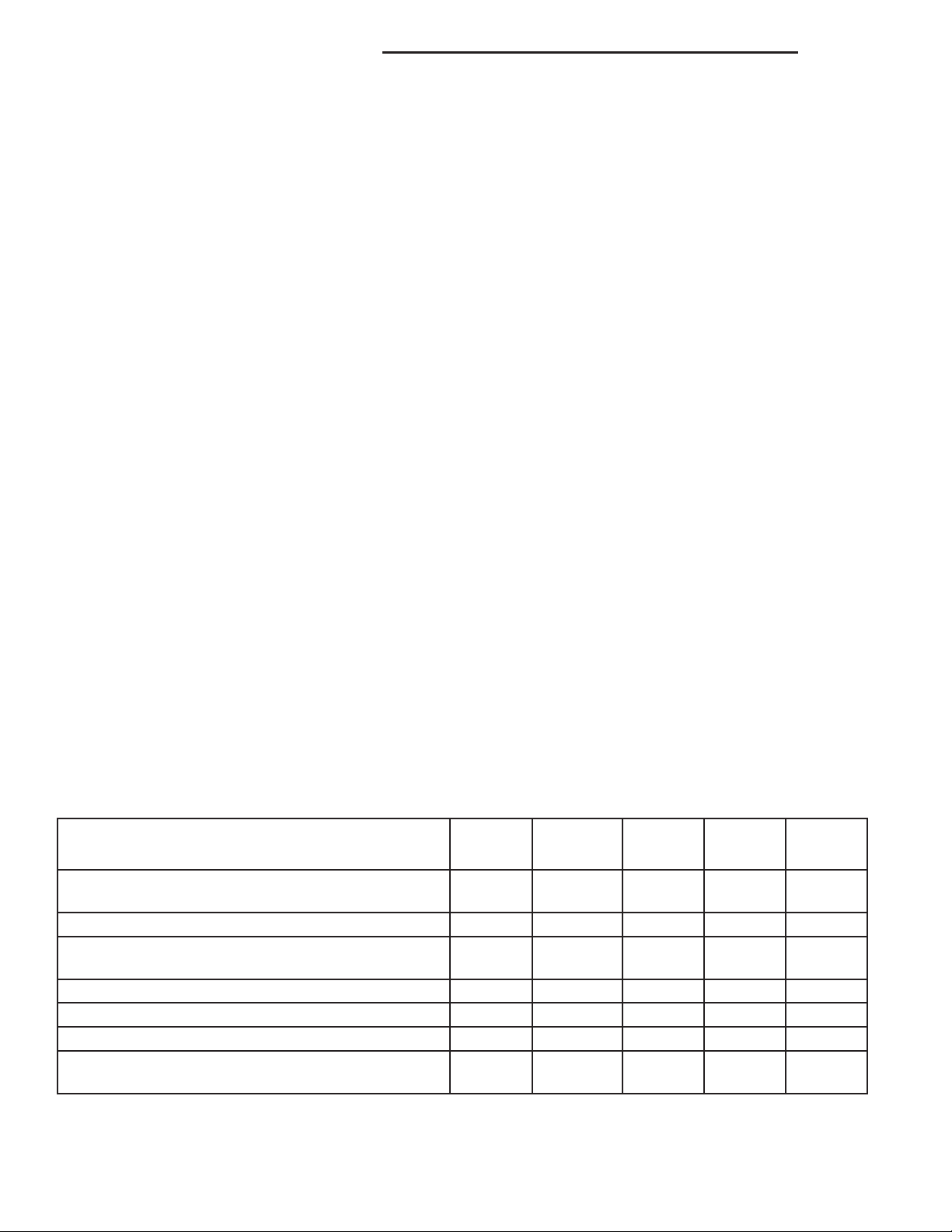

Miles 3,000 6,000 9,000 12,000 15,000

(Kilometers) (5 000) (10 000) (14 000) (19 000) (24 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

XXXXX

XX

X

Page 11

DR/DH LUBRICATION & MAINTENANCE 0 - 11

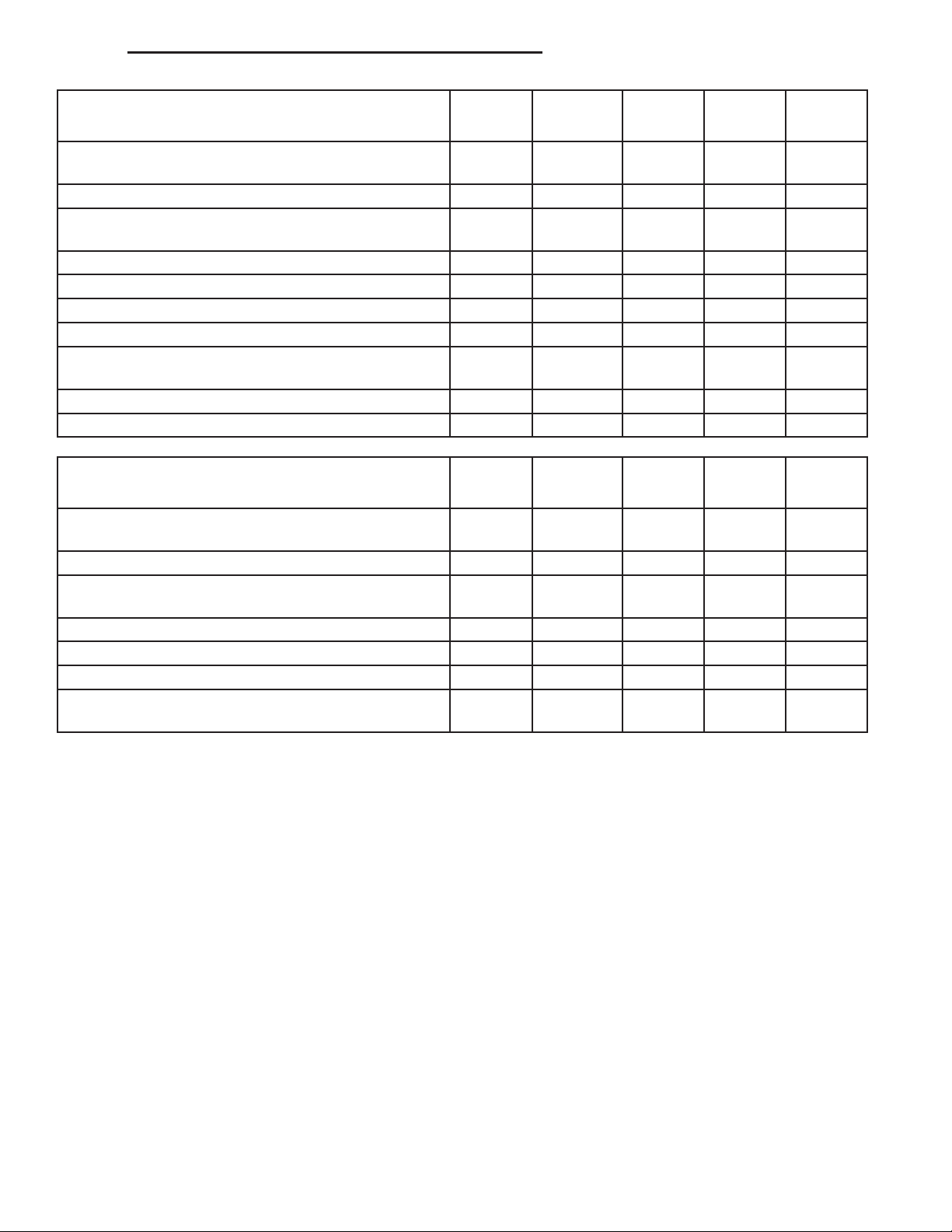

Miles 18,000 21,000 24,000 27,000 30,000

(Kilometers) (29 000) (34 000) (38 000) (43 000) (48 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Rotate tires. X X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Check transfer case fluid level (4X4). X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

Replace spark plugs. X

Inspect PCV valve, replace as necessary. X

Miles 33,000 36,000 39,000 42,000 45,000

(Kilometers) (53 000) (58 000) (62 000) (67 000) (72 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

XXXXX

XXX

X

XXXXX

XX

X

Page 12

0 - 12 LUBRICATION & MAINTENANCE DR/DH

Miles 48,000 51,000 54,000 57,000 60,000

(Kilometers) (77 000) (82 000) (86 000) (91 000) (96 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Rotate tires. X X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Flush and replace engine coolant at 60 months,

regardless of mileage.

Drain and refill transfer case fluid (4X4). X

Change rear axle fluid. X

Change front axle fluid (4X4). X

Change 6-spd manual transmission fluid 2500/3500

models only.

Inspect brake linings. X X

Inspect engine air cleaner filter, replace if

necessary.

Replace spark plugs. X

Replace ignition cables. X

Inspect PCV valve, replace as necessary. X

Drain and refill automatic transmission fluid and

change main sump filter*.

XXXXX

XXX

X

X

X

Miles 63,000 66,000 69,000 72,000 75,000

(Kilometers) (101 000) (106 000) (110 000) (115 000) (120 000)

Change engine oil and engine oil filter at

interval shown or 3 months, whichever comes

first.

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Inspect engine air cleaner filter. Replace if

necessary.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Inspect brake linings. X

Inspect auto tension drive belt and replace if

required. (3.7L/4.7L/5.7L).

XXXXX

XX

X

X

Page 13

DR/DH LUBRICATION & MAINTENANCE 0 - 13

Miles 78,000 81,000 84,000 87,000 90,000

(Kilometers) (125 000) (130 000) (134 000) (139 000) (144 000)

Change engine oil and engine oil filter at

interval shown or 3 months, whichever comes

first.

Rotate tires. X X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Check transfer case fluid level (4X4). X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

Replace spark plugs. X

Inspect PCV valve, replace as necessary. X

Inspect auto tension drive belt and replace if

required (3.7L/4.7L/5.7L).

XXXXX

XXX

X

X‡

Miles 93,000 96,000 99,000 100,000 102,000

(Kilometers) (149 000) (154 000) (158 000) (160 000) (163 000)

Change engine oil and engine oil filter at

interval shown or 3 months, whichever comes

first.

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Flush and replace engine coolant. X

Flush and replace Power Steering Fluid. X

Inspect brake linings. X

XXX X

XX

Page 14

0 - 14 LUBRICATION & MAINTENANCE DR/DH

Miles 105,000 108,000 111,000 114,000 117,000 120,000

(Kilometers) (168 000) (173 000) (178 000) (182 000) (187 000) (192 000)

Change engine oil and engine oil

filter at interval shown or 3 months,

whichever comes first.

Rotate tires. X X X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.

Drain and refill transfer case fluid

(4X4).

Change rear axle fluid. X X

Change front axle fluid (4X4). X X

Change 6-spd manual transmission

fluid 2500/3500 models only.

Inspect brake linings. X X

Inspect engine air cleaner filter,

replace if necessary.

Replace spark plugs. X

Replace ignition cables. X

Inspect PCV valve, replace as

necessary.

Inspect auto tension drive belt and

replace if required (3.7L/4.7L/5.7L).

Drain and refill automatic

transmission fluid and change main

sump and spin-on cooler return filter

(if equipped)*.

X X XXXX

XXX

X

X

XX

X

X‡ X‡

X

* This applies only if the vehicle is used for frequent trailer towing, snowplowing, fleet vehicle or commercial service.

‡ This maintenance is not required if previously replaced.

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all

receipts.

Page 15

DR/DH LUBRICATION & MAINTENANCE 0 - 15

Schedule “A”

Miles 6,000 12,000 18,000 24,000 30,000

(Kilometers) (10 000) (19 000) (29 000) (38 000) (48 000)

[Months] [6] [12] [18] [24] [30]

Change engine oil and engine oil filter. X X X X X

Rotate tires. X X X X X

Check transfer case fluid level (4X4). X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Inspect brake linings. X

Isnpect engine air cleaner filter. Replace if

necessary.

Replace spark plugs. X

Miles 36,000 42,000 48,000 54,000 60,000 66,000

(Kilometers) (58 000) (67 000) (77 000) (84 000) (96 000) (106 000)

[Months] [36] [42] [48] [54] [60] [66]

Change engine oil and engine oil

filter.

Rotate tires. X X X X X X

Check transfer case fluid level (4X4). X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.

Flush and replace engine coolant at

60 months, regardless of mileage.

Inspect brake linings. X X

Isnpect engine air cleaner filter.

Replace if necessary.

Replace spark plugs. X

Inspect PCV valve, replace as

necessary.

Replace ignition cables. X

X X XXX

X X XXXX

XXXXX

X

X

X

X

X

Page 16

0 - 16 LUBRICATION & MAINTENANCE DR/DH

Miles 72,000 78,000 84,000 90,000 96,000 100,000

(Kilometers) (115000) (125 000) (134 000) (144 000) (154 000) 160 000

[Months] [72] [78] [84] [90] [96]

Change engine oil and engine oil filter. X X X X X

Rotate tires. X X X X X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.

Check transfer case fluid level (4X4). X

Flush and replace Power Steering

Fluid.

Inspect brake linings. X X

Isnpect engine air cleaner filter.

Replace if necessary.

Replace spark plugs. X

Inspect PCV valve, replace as

necessary.

Inspect auto tension drive belt and

replace if required (3.7L/4.7L/5.7L).

X X XXX

X

X

X

X

Miles 102,000 108,000 114,000 120,000

(Kilometers) (163 000) (173 000) (182 000) (192 000)

[Months] [102] [108] [114] [120]

Change engine oil and engine oil filter. X X X X

Rotate tires. X X X X

Drain and refill transfer case fluid (4X4). X

Flush and replace engine coolant, if not done at 60 mos. X

Lubricate outer tie rod ends 2500/3500 (4X4) models only. X X X X

Inspect brake linings. X

Inspect auto tension drive belt and replace if required

(3.7L/4.7L/5.7L).

Replace ignition cables. X

Isnpect engine air cleaner filter. Replace if necessary. X

Replace spark plugs. X

Inspect PCV Valve, replace as necessary X

‡ This maintenance is not required if previously replaced.

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all

receipts.

WARNING:

You can be badly injured working on or around a motor vehicle. Do only that service work for which you

have the knowledge and the right equipment. If you have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

X‡

X‡

Page 17

DR/DH LUBRICATION & MAINTENANCE 0 - 17

24-VALVE CUMMINS TURBO DIESEL MAINTENANCE SCHEDULES

There are two maintenance schedules that show the required service for your vehicle.

First is Schedule “B”. It is for vehicles that are operated under the conditions that are listed below and at the

beginning of the schedule.

• Frequent short trips where the engine does not achieve full operating temperature (operating temperature

defined as 190° F (66° C ) coolant temperature).

• Extensive engine idling (over 10 minutes per hour of operation) at ambient temperatures less than 32° F (0°

C).

• Driving in dusty conditions.

• Frequent trailer towing.

• Taxi, police, or delivery service (commercial service).

• Off-road or desert operation.

• Extensive operation at high engine speeds (greater than 2900 rpm) and loads (greater than 70% throttle).

NOTE: Most vehicles are operated under the conditions listed for Schedule (B(.

Second is Schedule “A”. It is for vehicles that are not operated under any of the conditions listed under Schedule

9B9.

Use the schedule that best describes your driving conditions. Where time and mileage are listed, follow the interval

that occurs first.

CAUTION: Failure to perform the required maintenance items may result in damage to the vehicle.

At Each Stop for Fuel

• Check the engine oil level about 15 minutes after a fully warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accuracy of the oil level reading. Add oil only when the level is

at or below the ADD or MIN mark.

• Check the windshield washer solvent and add if required.

• Drain water from the fuel filter.

Once a Month

• Check tire pressure and look for unusual wear or damage.

• Inspect the batteries and clean and tighten the terminals as required.

• Check the fluid levels of coolant reservoir, brake master cylinder, and transmission and transfer case (if

equipped), add as needed.

• Check Filter Minder™. Replace air cleaner filter element if necessary.

• Check all lights and all other electrical items for correct operation.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect the brake hoses.

• Inspect the CV joints (if equipped) and front suspension components.

• Check the automatic transmission fluid level.

• Check the manual transmission fluid level.

• Check the coolant level, hoses, and clamps.

Page 18

0 - 18 LUBRICATION & MAINTENANCE DR/DH

Schedule “B”

Follow schedule “B” if you usually operate your vehicle under one or more of the following conditions.

• Frequent short trips where the engine does not achieve full operating temperature (operating temperature

defined as 190° F (66° C ) coolant temperature).

• Extensive engine idling (over 10 minutes per hour of operation) at ambient temperatures less than 32° F (0°

C).

• Driving in dusty conditions.

• Frequent trailer towing.

• Taxi, police, or delivery service (commercial service).

• Off-road or desert operation.

• Extensive operation at high engine speeds (greater than 2900 rpm) and loads (greater than 70% throttle).

Miles 3,750 7,500 11,250 15,000 18,750

(Kilometers) (6 000) (12 000) (18 000) (24 000) (30 000)

Change engine oil and engine oil filter. X X

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Inspect water pump weep hole for blockage. X

Replace fuel filter element. Clean the water in fuel

sensor.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Inspect brake linings. X

Inspect and adjust parking brake if necessary. X

XX

X

Miles 22,500 26,250 30,000 33,750 37,500

(Kilometers) (36 000) (42 000) (48 000) (54 000) (60 000)

Change engine oil and engine oil filter. X X X

Rotate tires. X X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Inspect drive belt, replace as required. X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for blockage. X

Replace fuel filter element. Clean the water in fuel

sensor.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Check transfer case fluid level (4X4). X

Drain and refill automatic transmission fluid. Replace

filter and adjust bands (48RE only).

XXX

X

X

Page 19

DR/DH LUBRICATION & MAINTENANCE 0 - 19

Miles 41,250 45,000 48,750 52,500 56,250

(Kilometers) (66 000) (72 000) (78 000) (84 000) (90 000)

Change engine oil and engine oil filter. X X

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Inspect drive belt, replace as required. X

Inspect water pump weep hole for blockage. X

Replace fuel filter element. Clean the water in fuel

sensor.

Inspect brake linings. X

Inspect and adjust parking brake if necessary. X

Change rear axle fluid. X

Change front axle fluid (4X4). X

Miles 60,000 63,750 67,500 71,250 75,000

(Kilometers) (96 000) (102 000) (108 000) (114 000) (120 000)

Change engine oil and engine oil filter. X X X

Rotate tires. X X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Inspect drive belt, replace as required. X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for blockage. X X

Replace fuel filter element. Clean the water in

fuel sensor.

Inspect front wheel bearings. X

Change rear axle fluid. X X

Change front axle fluid (4X4). X X

Change 6-spd manual transmission (G-56) fluid

2500/3500 models only.

Inspect brake linings. X X

Inspect and adjust parking brake if necessary. X X

Drain and refill transfer case fluid (4X4). X

Drain and refill automatic transmission fluid

and change main sump filter (545 RFE only).

Drain and refill automatic transmission fluid.

Replace filter and adjust bands (48RE only).

XXX

XX

X

X

XX

X

X

Page 20

0 - 20 LUBRICATION & MAINTENANCE DR/DH

Miles 78,750 82,500 86,250 90,000 93,750

(Kilometers) (126 000) (132 000) (138 000) (144 000) (150 000)

Change engine oil and engine oil filter. X X

Rotate tires. X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Inspect drive belt, replace as required. X

Change rear axle fluid. X

Change front axle fluid (4X4). X

Check transfer case fluid level (4X4). X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for blockage. X

Replace fuel filter element. Clean the water in

fuel sensor.

Inspect front wheel bearings. X

Inspect brake linings. X

Inspect and adjust parking brake if necessary. X

Drain and refill automatic transmission fluid.

Replace filter and adjust bands (48RE only).

XX

X

X

Miles 97,500 100,000 101,250 105,000 108,750 112,500

(Kilometers) (156 000) (160 000) (162 000) (168 000) (174 000) (180 000)

Change engine oil and engine oil

filter.

Rotate tires. X X X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.

Flush and replace engine coolant. X

Inspect drive belt, replace as

required.

Inspect water pump weep hole for

blockage.

Replace fuel filter element. Clean

the water in fuel sensor.

Change rear axle fluid. X

Change front axle fluid (4X4). X

Inspect brake linings. X

Inspect and adjust parking brake if

necessary.

XXX

XXX

X

X

X

X

Page 21

DR/DH LUBRICATION & MAINTENANCE 0 - 21

Miles 116,250 120,000 123,750 127,500 131,250 135,000

(Kilometers) (186 000) (192 000) (198 000) (204 000) (210 000) (216 000)

Change engine oil and engine oil

filter.

Rotate tires. X X X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.

Clean engine air filter canister. X

Adjust valve lash clearance. X

Inspect drive belts, replace as

required.

Drain and refill transfer case fluid

(4X4).

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for

blockage.

Replace fuel filter element. Clean

the water in fuel sensor.

Inspect front wheel bearings. X

Change rear axle fluid. X X

Change front axle fluid (4X4). X X

Change 6-spd manual transmission

(G-56) fluid 2500/3500 models only.

Inspect brake linings. X X

Inspect and adjust parking brake if

necessary.

Drain and refill automatic

transmission fluid and change main

sump and spin-on cooler return filter

(if equipped) (545 RFE only).

Drain and refill automatic

transmission fluid. Replace filter and

adjust bands (48RE only).

XXX

XXX

X

X

XX

XX

X

XX

X

X

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all

receipts.

Page 22

0 - 22 LUBRICATION & MAINTENANCE DR/DH

Schedule “A”

Miles 7,500 15,000 22,500 30,000 37,500

(Kilometers) (12 000) (24 000) (36 000) (48 000) (60 000)

[Months] [6] [12] [18] [24] [30]

Change engine oil and engine oil filter. X X

Rotate tires. X X X X X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.

Check transfer case fluid level (4X4). X

Inspect water pump weep hole for blockage X X

Replace fuel filter element. Clean the water in fuel

sensor.

Inspect drive belts, replace as necessary. X

Inspect brake linings. X

Inspect and adjust parking brake if necessary. X

Inspect fan hub. X

Inspect damper. X

Inspect front wheel bearings. X

XXXXX

XX

Miles 45,000 52,500 60,000 67,500 75,000

(Kilometers) (72 000) (84 000) (96 000) (108 000) (120 000)

[Months] [36] [42] [48] [54] [60]

Change engine oil and engine oil filter. X X X

Rotate tires. X X X X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Check transfer case fluid level. X

Flush and replace engine coolant at 60

months, regardless of mileage.

Inspect drive belts, replace as necessary. X X

Inspect water pump weep hole for blockage X X X

Replace fuel filter element. Clean the water in

fuel sensor.

Inspect brake linings. X X

Inspect and adjust parking brake if necessary. X X

Inspect fan hub. X

Inspect damper. X

Inspect front wheel bearings. X

Replace fuel filter element. Clean the water in

fuel sensor

XXXXX

X

XXX

X

Page 23

DR/DH LUBRICATION & MAINTENANCE 0 - 23

Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X X

Rotate tires. X X X X X

Lubricate outer tie rod ends 2500/3500 (4X4)

models only.

Flush and replace engine coolant, if not done

at 60 mos.

Check transfer case fluid level (4X4). X

Inspect drive belt, replace as required. X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for blockage. X X

Replace fuel filter element. Clean the water in

fuel sensor.

Inspect front wheel bearings. X

Inspect brake linings. X

Inspect and adjust parking brake if necessary. X

Drain and refill automatic transmission fluid.

Replace filter and adjust bands (48 RE only).

XXXXX

X

XX

X

Page 24

0 - 24 LUBRICATION & MAINTENANCE DR/DH

Miles 112,500 120,000 127,500 135,000 142,500 150,000

(Kilometers) (181 000) (193 000) (205 000) (217 000) (229 000) (241 000)

[Months] [90] [96] [102] [108] [114] [150]

Change engine oil and engine oil

filter.

Rotate tires. X X X X X X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.

Flush and replace engine coolant, if

it has been 160 000 km (100, 000

miles) or 60 months since last

change.

Inspect drive belt, replace as

required.

Drain and refill transfer case fluid

(4X4).

Check tranfer case fluid level (4X4). X

Inspect fan hub. X X

Inspect damper. X X

Inspect water pump weep hole for

blockage.

Replace fuel filter element. Clean

the water in fuel sensor.

Inspect front wheel bearings. X X

Inspect brake linings. X X

Inspect and adjust parking brake if

necessary.

Adjust valve lash clearance. X

X X XXXX

XX

XX

XXX

X

X

XXX

XXX

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all

receipts.

WARNING:

You can be badly injured working on or around a motor vehicle. Do only that service work for which you

have the knowledge and the right equipment. If you have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

MAINTENANCE SCHEDULES - SRT/10

There are two maintenance schedules that show the required service for your vehicle.

First is Schedule “B”. It is for vehicles that are operated under the conditions that are listed below and at the

beginning of the schedule.

• Day or night temperatures are below 32° F (0° C).

• Stop and go driving.

• Extensive engine idling.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• More than 50% of your driving is at sustained high speeds during hot weather, above 90° F C (32°).

• Drag Race Operation.

• Heavy Loading.

• Taxi, police, or delivery service (commercial service).

• Off-road or desert operation.

Page 25

DR/DH LUBRICATION & MAINTENANCE 0 - 25

• If equipped for and operating with E-85 (ethanol) fuel.

NOTE: If ANY of these apply to you then change your engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule “B” of the (Maintenance Schedules( section of this manual.

NOTE: If ANY of these apply to you then flush and replace your engine coolant every 102,000 miles (163 000

km) or 60 months, whichever comes first and follow schedule “B” of the (Maintenance Schedules( section

of this manual.

NOTE: Most vehicles are operated under the conditions listed for Schedule (B(.

Second is Schedule “A”. It is for vehicles that are not operated under any of the conditions listed under Schedule

9B9.

Use the schedule that best describes your driving conditions. Where time and mileage are listed, follow the interval

that occurs first.

NOTE: Under no circumstances should oil change intervals exceed 6000 miles (10 000 km) or 6 months

whichever comes first.

CAUTION: Failure to perform the required maintenance items may result in damage to the vehicle.

At Each Stop for Fuel

• Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accuracy of the oil level reading. Add oil only when the level is

at or below the ADD or MIN mark.

• Check the windshield washer solvent and add if required.

Once a Month

• Check tire pressure and look for unusual wear or damage.

• Inspect the battery and clean and tighten the terminals as required.

• Check the fluid levels of coolant bottle, brake master cylinder, and transmission and add as needed.

• Check all lights and all other electrical items for correct operation.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect the brake hoses.

• Inspect the CV joints (if equipped) and front suspension components.

• Check the automatic transmission fluid level.

• Check the manual transmission fluid level.

• Check the coolant level, hoses, and clamps.

Schedule “B”

Follow schedule “B” if you usually operate your vehicle under one or more of the following conditions.

• Day or night temperatures are below 32° F (0° C).

• Stop and go driving.

• Extensive engine idling.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• More than 50% of your driving is at sustained high speeds during hot weather, above 90° F C (32°).

• Drag Race Operation.

• Heavy Loading.

• Taxi, police, or delivery service (commercial service).

Page 26

0 - 26 LUBRICATION & MAINTENANCE DR/DH

• Off-road or desert operation.

• If equipped for and operating with E-85 (ethanol) fuel.

NOTE: If ANY of these apply to you then change your engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule “B” of the (Maintenance Schedules( section of this manual.

NOTE: If ANY of these apply to you then flush and replace your engine coolant every 102,000 miles (163 000

km) or 60 months, whichever comes first and follow schedule “B” of the (Maintenance Schedules( section

of this manual.

If none of these apply to you, then change your engine oil at every interval shown on schedule 9A9 of the 9Maintenance Schedules9 section of this manual.

Miles 3,000 6,000 9,000 12,000 15,000

(Kilometers) (5 000) (10 000) (14 000) (19 000) (24 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Drain and refill automatic transmission fluid. Replace

filter and adjust bands.*

Rotate tires. X X

Change rear axle fluid. X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

XXXXX

X

X

Miles 18,000 21,000 24,000 27,000 30,000

(Kilometers) (29 000) (34 000) (38 000) (43 000) (48 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Drain and refill automatic transmission fluid. Replace

filter and adjust bands.

Rotate tires. X X X

Change rear axle fluid. X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

Replace spark plugs. X

Inspect and replace, if necessary, the PCV valve. X*

XXXXX

X

X

Page 27

DR/DH LUBRICATION & MAINTENANCE 0 - 27

Miles 33,000 36,000 39,000 42,000 45,000

(Kilometers) (53 000) (58 000) (62 000) (67 000) (72 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Drain and refill automatic transmission fluid. Replace

filter and adjust bands.*

Rotate tires. X X

Change rear axle fluid. X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

Miles 48,000 51,000 54,000 57,000 60,000

(Kilometers) (77 000) (82 000) (86 000) (91 000) (96 000)

Change engine oil and engine oil filter at interval

shown or 3 months, whichever comes first.

Drain and refill automatic transmission fluid. Replace

filter and adjust bands.

Rotate tires. X X X

Change rear axle fluid. X

Inspect brake linings. X X

Inspect engine air cleaner filter, replace if

necessary.

Replace spark plugs. X

Replace ignition cables. X

Inspect and replace, if necessary, the PCV valve. X*

Flush and replace engine coolant at 60 months , if not

done at 102,000 miles (163 000 km)

XXXXX

X

X

XXXXX

X

X

X

Miles 63,000 66,000 69,000 72,000 75,000

(Kilometers) (101 000) (106 000) (110 000) (115 000) (120 000)

Change engine oil and engine oil filter at

interval shown or 3 months, whichever comes

first.

Drain and refill automatic transmission fluid.

Replace filter and adjust bands.*

Rotate tires. X X

Inspect engine air cleaner filter. X

Change rear axle fluid. X

Inspect brake linings. X

Inspect auto tension drive belt and replace if

required.

XXXXX

X

X

Page 28

0 - 28 LUBRICATION & MAINTENANCE DR/DH

Miles 78,000 81,000 84,000 87,000 90,000

(Kilometers) (125 000) (130 000) (134 000) (139 000) (144 000)

Change engine oil and engine oil filter at

interval shown or 3 months, whichever comes

first.

Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

Rotate tires. X X X

Change rear axle fluid. X

Inspect brake linings. X

Inspect engine air cleaner filter, replace if

necessary.

Replace spark plugs. X

Inspect PCV valve, replace as necessary. X*

Inspect auto tension drive belt and replace if

required.

Miles 93,000 96,000 99,000 100,000 102,000

(Kilometers) (149 000) (154 000) (158 000) (160 000) (163 000)

Change engine oil and engine oil filter at

interval shown or 3 months, whichever comes

first.

Rotate tires. X X

Flush and replace engine coolant. X

Flush and replace Power Steering Fluid. X

Inspect brake linings. X

XXXXX

X

X

X‡

XXX X

Page 29

DR/DH LUBRICATION & MAINTENANCE 0 - 29

Miles 105,000 108,000 111,000 114,000 117,000 120,000

(Kilometers) (168 000) (173 000) (178 000) (182 000) (187 000) (192 000)

Change engine oil and engine oil

filter at interval shown or 3 months,

whichever comes first.

Drain and refill automatic

transmission fluid. Replace filter and

adjust bands.*

Drain and refill automatic

transmission fluid. Replace filter and

adjust bands.

Rotate tires. X X X

Change rear axle fluid. X X

Inspect brake linings. X X

Inspect engine air cleaner filter,

replace if necessary.

Replace spark plugs. X

Replace ignition cables. X

Inspect and replace, if necessary,

the PCV valve.

Inspect auto tension drive belt and

replace if required.

X X XXXX

X

X

XX

X*

X‡ X‡

* Drain and refill automatic transmission fluid. Replace filter and adjust bands every 15, 000 miles if vehicle is used

for frequent wide open throttle upshifts (For example Drag Racing).

‡ This maintenance is not required if previously replaced.

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all

receipts.

Page 30

0 - 30 LUBRICATION & MAINTENANCE DR/DH

Schedule “A”

Miles 6,000 12,000 18,000 24,000 30,000

(Kilometers) (10 000) (19 000) (29 000) (38 000) (48 000)

[Months] [6] [12] [18] [24] [30]

Change engine oil and engine oil filter. X X X X X

Rotate tires. X X X X X

Inspect brake linings. X

Replace engine air cleaner filter. X

Replace spark plugs. X

Miles 36,000 42,000 48,000 54,000 60,000 66,000

(Kilometers) (58 000) (67 000) (77 000) (84 000) (96 000) (106 000)

[Months] [36] [42] [48] [54] [60] [66]

Change engine oil and engine oil

filter.

Rotate tires. X X X X X X

Flush and replace engine coolant at

60 months, regardless of mileage.

Inspect brake linings. X X

Replace engine air cleaner filter. X

Replace spark plugs. X

Inspect and replace, if necessary,

the PCV valve.

Replace ignition cables. X

X X XXX

X

X*

X

Miles 72,000 78,000 84,000 90,000 96,000 100,000

(Kilometers) (115000) (125 000) (134 000) (144 000) (154 000) 160 000

[Months] [72] [78] [84] [90] [96]

Change engine oil and engine oil filter. X X X X X

Drain and refill automatic transmission

fluid. Replace filter and adjust bands.

Rotate tires. X X X X X

Flush and replace Power Steering

Fluid.

Inspect brake linings. X X

Replace engine air cleaner filter. X

Replace spark plugs. X

Inspect and replace, if necessary,

the PCV valve.

Inspect auto tension drive belt and

replace if required.

X*

X

X

X

Page 31

DR/DH LUBRICATION & MAINTENANCE 0 - 31

Miles 102,000 108,000 114,000 120,000

(Kilometers) (163 000) (173 000) (182 000) (192 000)

[Months] [102] [108] [114] [120]

Change engine oil and engine oil filter. X X X X

Rotate tires. X X X X

Flush and replace engine coolant, if not done at 60 mos. X

Flush and replace engine coolant, if not done at 102, 000

miles.

Inspect brake linings. X

Inspect auto tension drive belt and replace if required. X‡ X‡

Replace ignition cables. X

Replace engine air cleaner filter. X

Replace spark plugs. X

Inspect and replace, if necessary, the PCV valve. X*

* This maintenance is recommended by the manufacture to the owner, but is not required to maintain the emissions

warranty.

‡ This maintenance is not required if previously replaced.

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all

receipts.

X

WARNING:

You can be badly injured working on or around a motor vehicle. Do only that service work for which you

have the knowledge and the right equipment. If you have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS AND WARNINGS IN THE BATTERY SYSTEM SECTION OF

THE SERVICE MANUAL. (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY - STANDARD PROCEDURE)

• DO NOT JUMP START A FROZEN BATTERY, PERSONAL INJURY CAN RESULT.

• IF EQUIPPED, DO NOT JUMP START WHEN MAINTENANCE FREE BATTERY INDICATOR DOT IS YELLOW

OR BRIGHT COLOR.

• DO NOT JUMP START A VEHICLE WHEN THE BATTERY FLUID IS BELOW THE TOP OF LEAD PLATES.

• DO NOT ALLOW JUMPER CABLE CLAMPS TO TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

• DO NOT USE OPEN FLAME NEAR BATTERY.

• REMOVE METALLIC JEWELRY WORN ON HANDS OR WRISTS TO AVOID INJURY BY ACCIDENTAL ARC-

ING OF BATTERY CURRENT.

• WHEN USING A HIGH OUTPUT BOOSTING DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a booster, do not allow vehicles to touch. Electrical systems can

be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

1. Raise hood on disabled vehicle and visually inspect engine compartment for:

• Battery cable clamp condition, clean if necessary.

• Frozen battery.

Page 32

0 - 32 LUBRICATION & MAINTENANCE DR/DH

• Yellow or bright color test indicator, if equipped.

• Low battery fluid level.

• Generator drive belt condition and tension.

• Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on disabled vehicle is severe, damage to booster vehicle charging system can result.

2. When using another vehicle as a booster source, park the booster vehicle within cable reach. Turn off all acces-

sories, set the parking brake, place the automatic transmission in PARK or the manual transmission in NEUTRAL

and turn the ignition OFF.

3. On disabled vehicle, place gear selector in park or neutral and set park brake. Turn off all accessories.

4. Connect jumper cables to booster battery. RED clamp to positive terminal (+). BLACK clamp to negative terminal

(-). DO NOT allow clamps at opposite end of cables to touch, electrical arc will result. Review all warnings in this

procedure.

5. On disabled vehicle, connect RED jumper cable clamp to positive (+) terminal. Connect BLACK jumper cable

clamp to engine ground as close to the ground cable attaching point as possible.

6. Start the engine in the vehicle which has the booster battery, let the engine idle a few minutes, then start the

engine in the vehicle with the discharged battery.

CAUTION: Do not crank starter motor on disabled vehicle for more than 15 seconds, starter will overheat

and could fail.

7. Allow battery in disabled vehicle to charge to at least 12.4 volts (75% charge) before attempting to start engine.

If engine does not start within 15 seconds, stop cranking engine and allow starter to cool (15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

• Disconnect BLACK cable clamp from engine ground on disabled vehicle.

• When using a Booster vehicle, disconnect BLACK cable clamp from battery negative terminal. Disconnect RED

cable clamp from battery positive terminal.

• Disconnect RED cable clamp from battery positive terminal on disabled vehicle.

Page 33

DR/DH LUBRICATION & MAINTENANCE 0 - 33

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner’s Manual for emergency vehicle

lifting procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHICLE. WHEN A CHASSIS OR DRIVETRAIN COMPONENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

Page 34

0 - 34 LUBRICATION & MAINTENANCE DR/DH

FLOOR JACK

When properly positioned, a floor jack can be used to

lift a vehicle. Support the vehicle in the raised position

with jack stands at the front and rear ends of the

frame rails.

CAUTION: Do not lift vehicle with a floor jack positioned under:

• An axle tube.

• A body side sill.

• A steering linkage component.

• A drive shaft.

• The engine or transmission oil pan.

• The fuel tank.

• A front suspension arm.

NOTE: Use the correct front frame rail lifting locations only.

1 - BODY MOUNT BRACKET

2 - FRONT LIFT PAD

3 - TRANSMISSION CROSSMEMBER BRACKET

4 - FRAME RAIL

Page 35

DR/DH LUBRICATION & MAINTENANCE 0 - 35

NOTE: Use the correct rear frame rail lifting locations only.

1 - FRAME RAIL

2 - REAR LIFT PAD

3 - LEAF SPRING MOUNTING BRACKET

4 - BOX MOUNTING BRACKET

HOIST

A vehicle can be lifted with:

• A single-post, frame-contact hoist.

• A twin-post, chassis hoist.

• A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly.

Page 36

0 - 36 LUBRICATION & MAINTENANCE DR/DH

NOTE: The forward lifting pads should be positioned against the forward flange of the transmission crossmember brackets at the bottom of the

frame rail.

1 - BODY MOUNT BRACKET

2 - FRONT LIFT PAD

3 - TRANSMISSION CROSSMEMBER BRACKET

4 - FRAME RAIL

NOTE: The real lifting pads should be wedged

between the forward flange of the leaf spring

bracket and the frame rail. Safety stands should

be placed under the frame rails at the front and

rear ends.

1 - FRAME RAIL

2 - REAR LIFT PAD

3 - LEAF SPRING MOUNTING BRACKET

4 - BOX MOUNTING BRACKET

Page 37

DR/DH LUBRICATION & MAINTENANCE 0 - 37

TOWING

STANDARD PROCEDURE

A vehicle equipped with SAE approved sling-type towing equipment can be used to tow all vehicles. When

towing a 4WD vehicle using a wheel-lift towing device,

use tow dollies under the opposite end of the vehicle.

A vehicle with flat-bed device can also be used to

transport a disabled vehicle.

A wooden crossbeam may be required for proper connection when using the sling-type, front-end towing

method.

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be observed when towing a vehicle:

• Secure loose and protruding parts.

• Always use a safety chain system that is independent of the lifting and towing equipment.

• Do not allow towing equipment to contact the disabled vehicle’s fuel tank.

• Do not allow anyone under the disabled vehicle while it is lifted by the towing device.

• Do not allow passengers to ride in a vehicle being towed.

• Always observe state and local laws regarding towing regulations.

• Do not tow a vehicle in a manner that could jeopardize the safety of the operator, pedestrians or other motor-

ists.

• Do not attach tow chains, T-hooks, J-hooks, or a tow sling to a bumper, steering linkage, drive shafts or a

non-reinforced frame hole.

• Do not tow a heavily loaded vehicle. Damage to the cab, cargo box or frame may result. Use a flatbed device

to transport a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed, install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels are a minimum 100 mm (4 in) from the ground. Be sure there

is adequate ground clearance at the opposite end of the vehicle, especially when towing over rough terrain or steep

rises in the road. If necessary, remove the wheels from the lifted end of the vehicle and lower the vehicle closer to

the ground, to increase the ground clearance at the opposite end of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used, the approach ramp angle should not exceed 15 degrees.

Page 38

0 - 38 LUBRICATION & MAINTENANCE DR/DH

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not available, use a flat bed hauler. A Wheel-lift or Sling-type device can

be used on 4WD vehicles provided all the wheels are lifted off the ground using tow dollies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be transported on a flat-bed device. A Wheel-lift or Sling-type

device can be used provided all the wheels are lifted off the ground using tow dollies.

WARNING: WHEN TOWING A DISABLED VEHICLE AND THE DRIVE WHEELS ARE SECURED IN A WHEEL

LIFT OR TOW DOLLIES, ENSURE THE TRANSMISSION IS IN THE PARK POSITION (AUTOMATIC TRANSMISSION) OR A FORWARD DRIVE GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air dams, spoilers, and/or ground effect panels. To avoid component damage, a wheel-lift towing vehicle or a flat-bed hauling vehicle is recommended.

Loading...

Loading...