Page 1

DR DIFFERENTIAL & DRIVELINE 3 - 1

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

DIFFERENTIAL & DRIVELINE - ELECTRICAL

DIAGNOSTICS ........................... 1

DIFFERENTIAL & DRIVELINE - SERVICE

INFORMATION......................... 113

DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS

TABLE OF CONTENTS

page page

DIFFERENTIAL & DRIVELINE - ELECTRICAL

DIAGNOSTICS

DIAGNOSIS AND TESTING

C143A - DIFFERENTIAL/LOCKER SELECT

SWITCH PERFORMANCE.....................3

C143B-DIFFERENTIAL/LOCKER SELECT

SWITCH CIRCUIT LOW.......................7

C143C-DIFFERENTIAL/LOCKER SELECT

SWITCH CIRCUIT HIGH.....................11

C1417–FRONT DIFFERENTIAL CONTROL

CIRCUIT LOW..............................15

C1418–FRONT DIFFERENTIAL CONTROL

CIRCUIT HIGH..............................19

C1419–FRONT DIFFERENTIAL CONTROL

CIRCUIT OPEN.............................23

C141D-REAR DIFFERENTIAL CONTROL

CIRCUIT LOW..............................26

C141E–REAR DIFFERENTIAL CONTROL

CIRCUIT HIGH..............................30

C141F–REAR DIFFERENTIAL CONTROL

CIRCUIT OPEN.............................34

C1446-FRONT DIFFERENTIAL RETURN

CIRCUIT LOW..............................37

C1447-FRONT DIFFERENTIAL RETURN

CIRCUIT HIGH..............................40

C144A-REAR DIFFERENTIAL RETURN

CIRCUIT LOW..............................44

C144B-REAR DIFFERENTIAL RETURN

CIRCUIT HIGH..............................47

C144E-FRONT DIFFERENTIAL POSITION

SENSOR PERFORMANCE...................51

C1450-FRONT DIFFERENTIAL POSITION

SENSOR CIRCUIT HIGH.....................55

C144F-FRONT DIFFERENTIAL POSITION

SENSOR LOW..............................59

C1452-REAR DIFFERENTIAL POSITION

SENSOR PERFORMANCE...................62

C1453-REAR DIFFERENTIAL POSITION

SENSOR LOW..............................66

C1454-REAR DIFFERENTIAL POSITION

SENSOR CIRCUIT HIGH.....................69

C2100–BATTERY VOLTAGE LOW ............73

C2101–BATTERY VOLTAGE HIGH ............76

C2111-SENSOR SUPPLY 1 VOLTAGE

CIRCUIT LOW..............................79

C2112-SENSOR SUPPLY 1 VOLTAGE

CIRCUIT HIGH..............................82

C2126-SENSOR SUPPLY 2 VOLTAGE

CIRCUIT LOW..............................85

C2127-SENSOR SUPPLY 2 VOLTAGE

CIRCUIT HIGH..............................88

C230F-LOCKER/DIFFERENTIAL INDICATOR

SUPPLY CIRCUIT PREFORMANCE...........91

C2310-STABILIZER/DIFFERENTIAL

INDICATOR SUPPLY CIRCUIT LOW..........95

C2311-STABILIZER/DIFFERENTIAL

INDICATOR SUPPLY CIRCUIT HIGH..........99

C2324-STABILIZER BAR INDICATOR

CONTROL CIRCUIT........................104

U0100-LOST COMMUNICATION WITH

ECM/PCM (FDCM).........................109

U0155-NO CLUSTER BUS MESSAGE ........111

Page 2

3 - 2 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

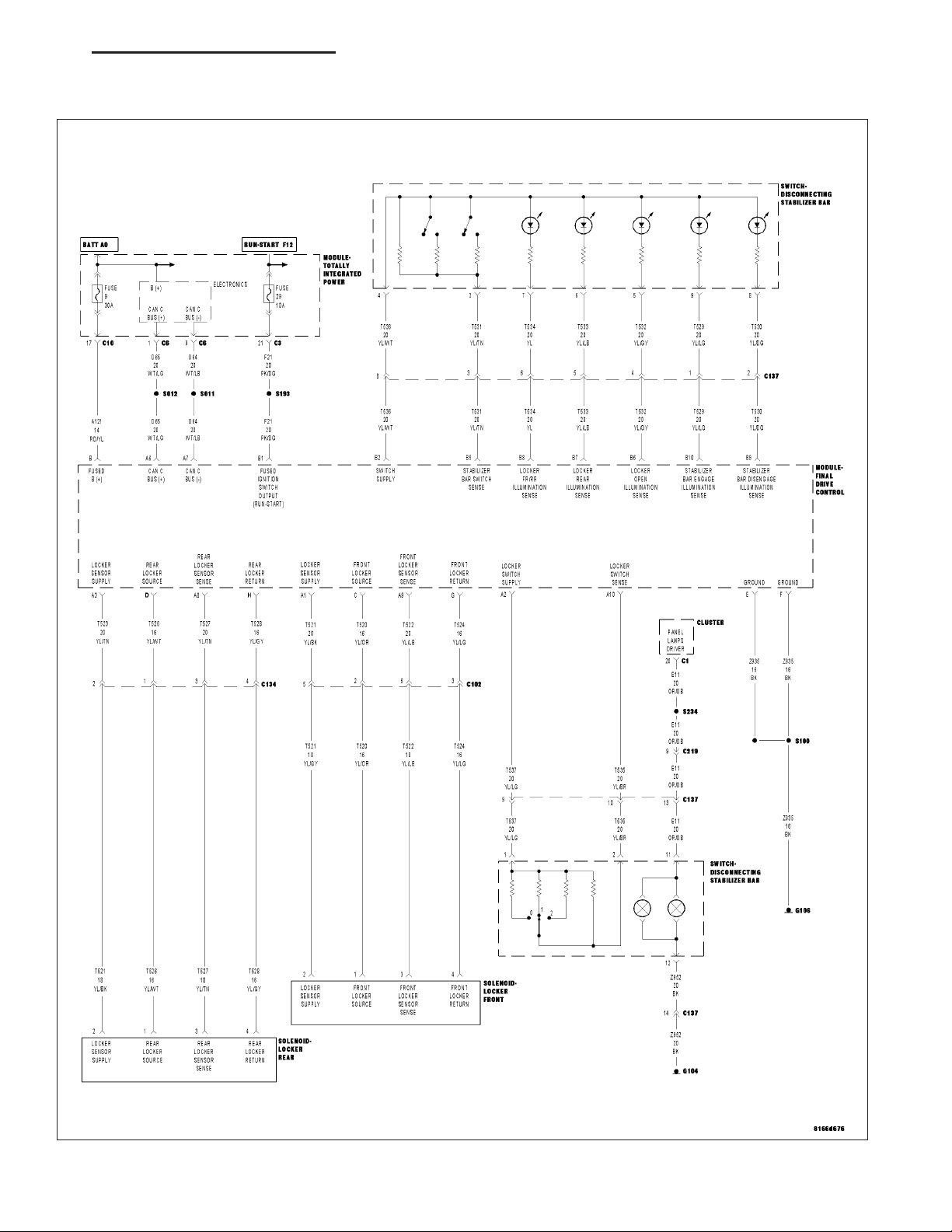

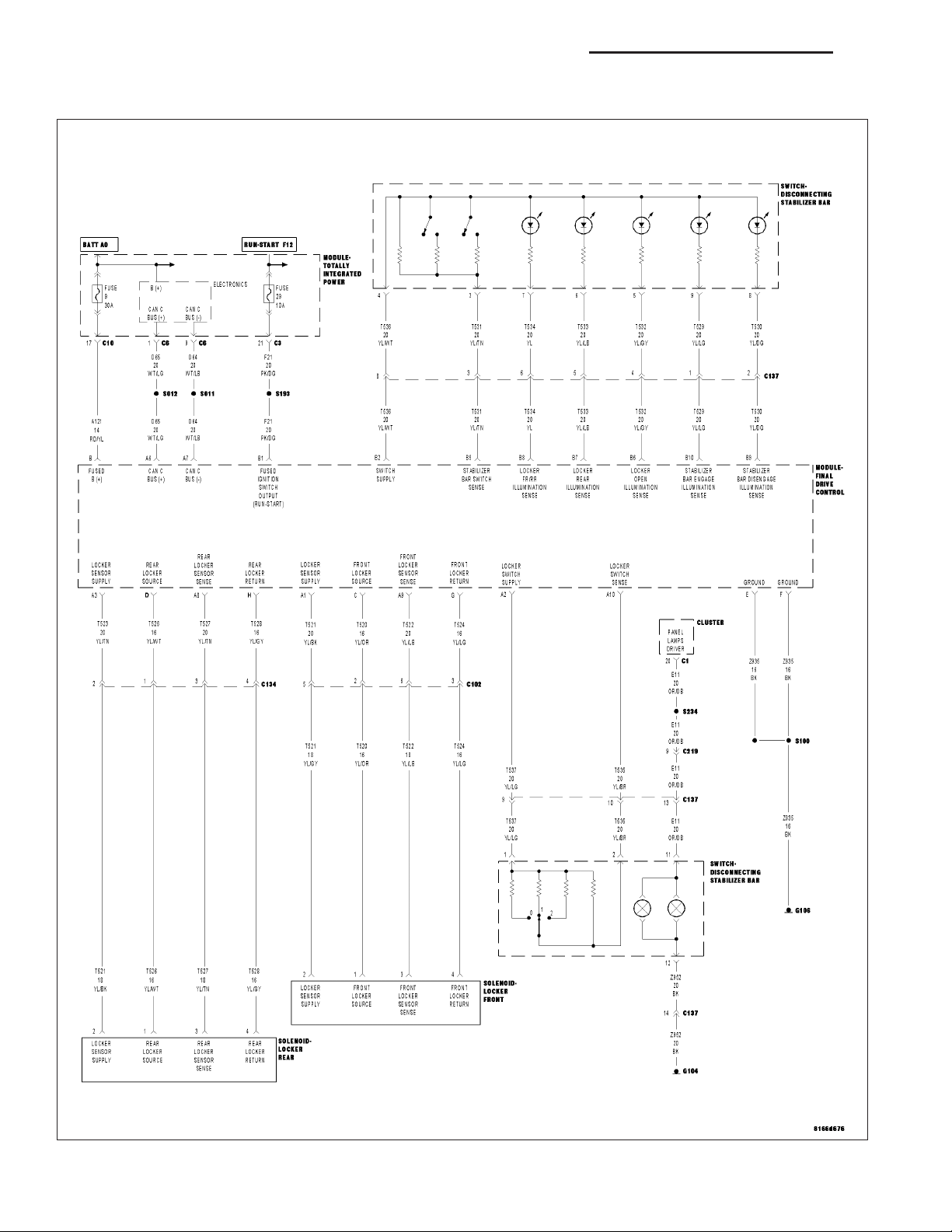

DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

Page 3

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 3

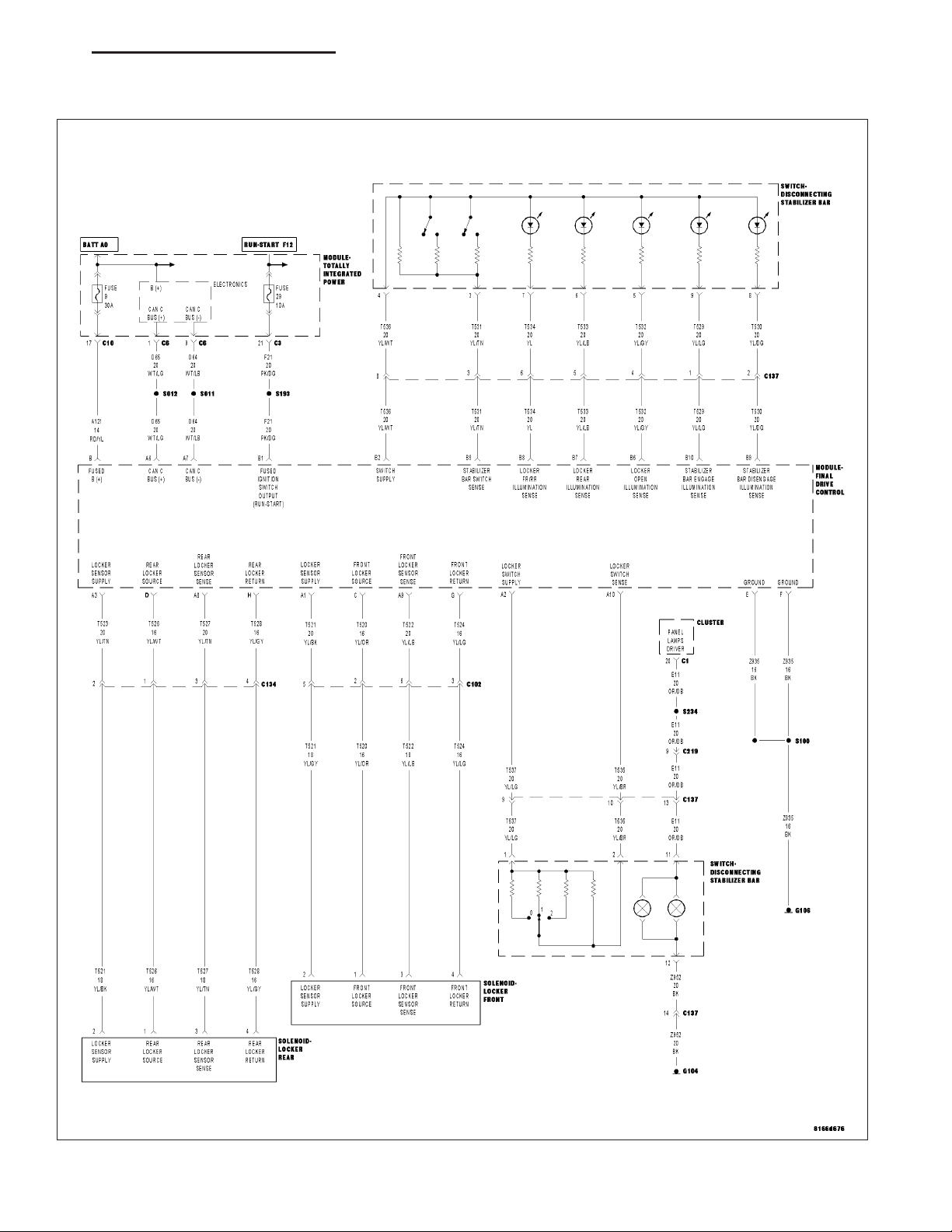

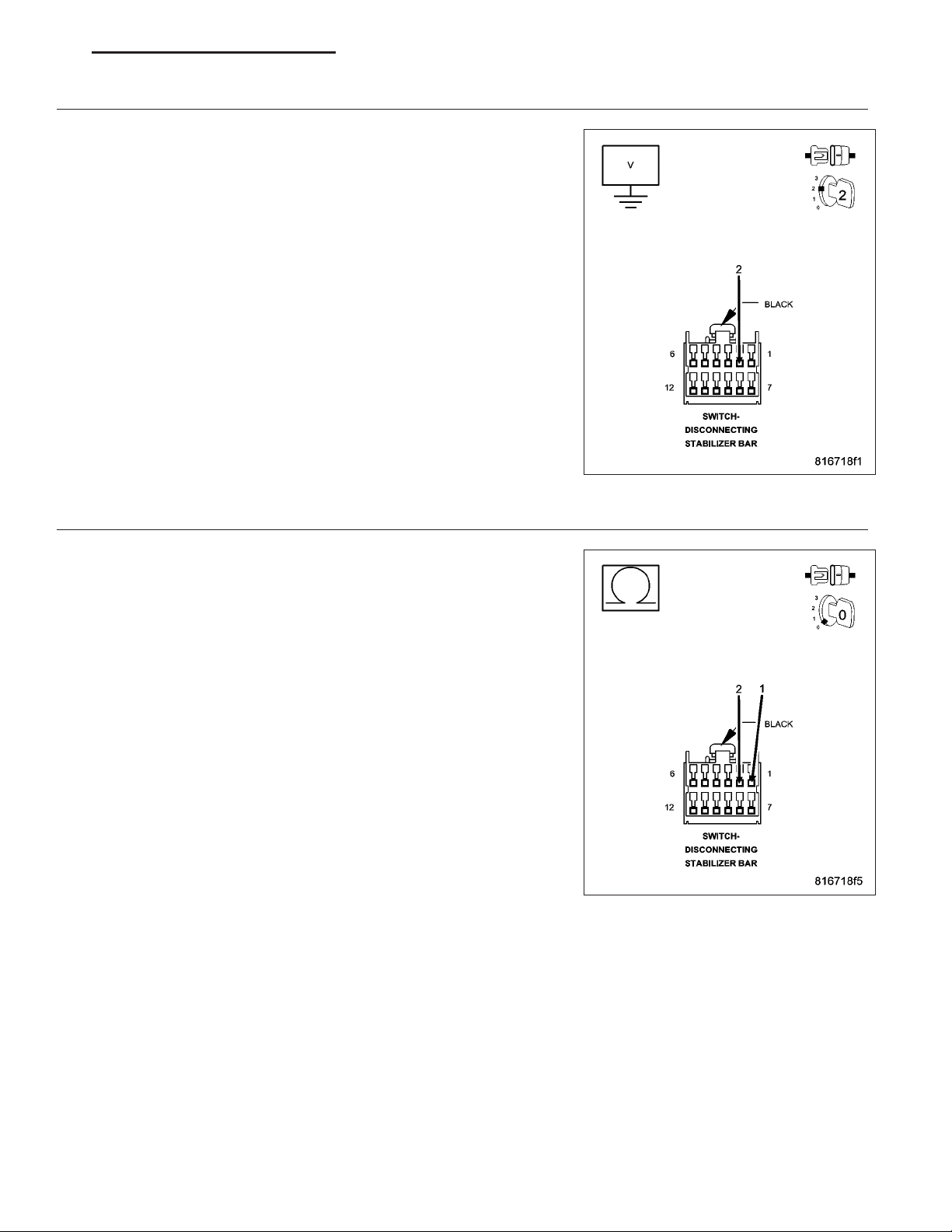

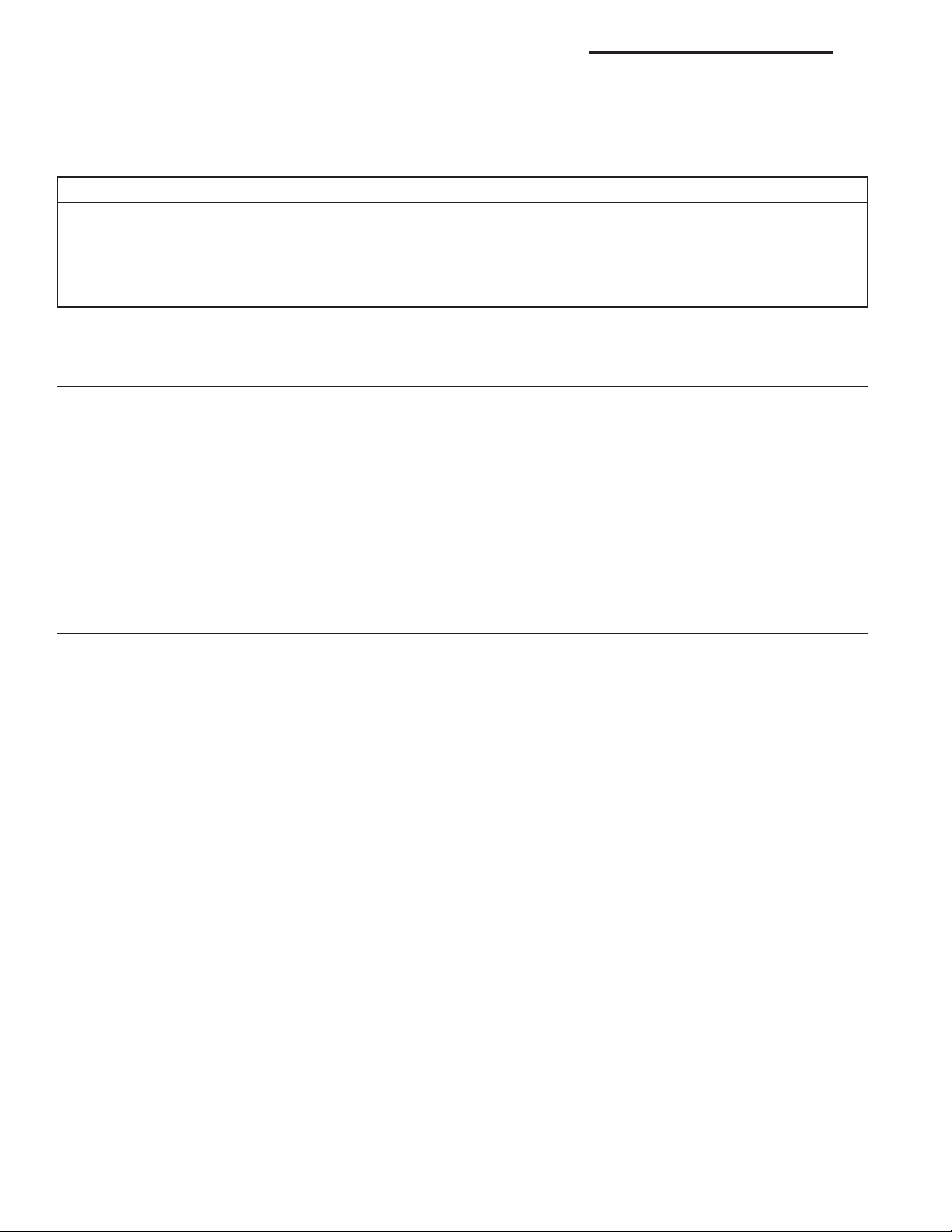

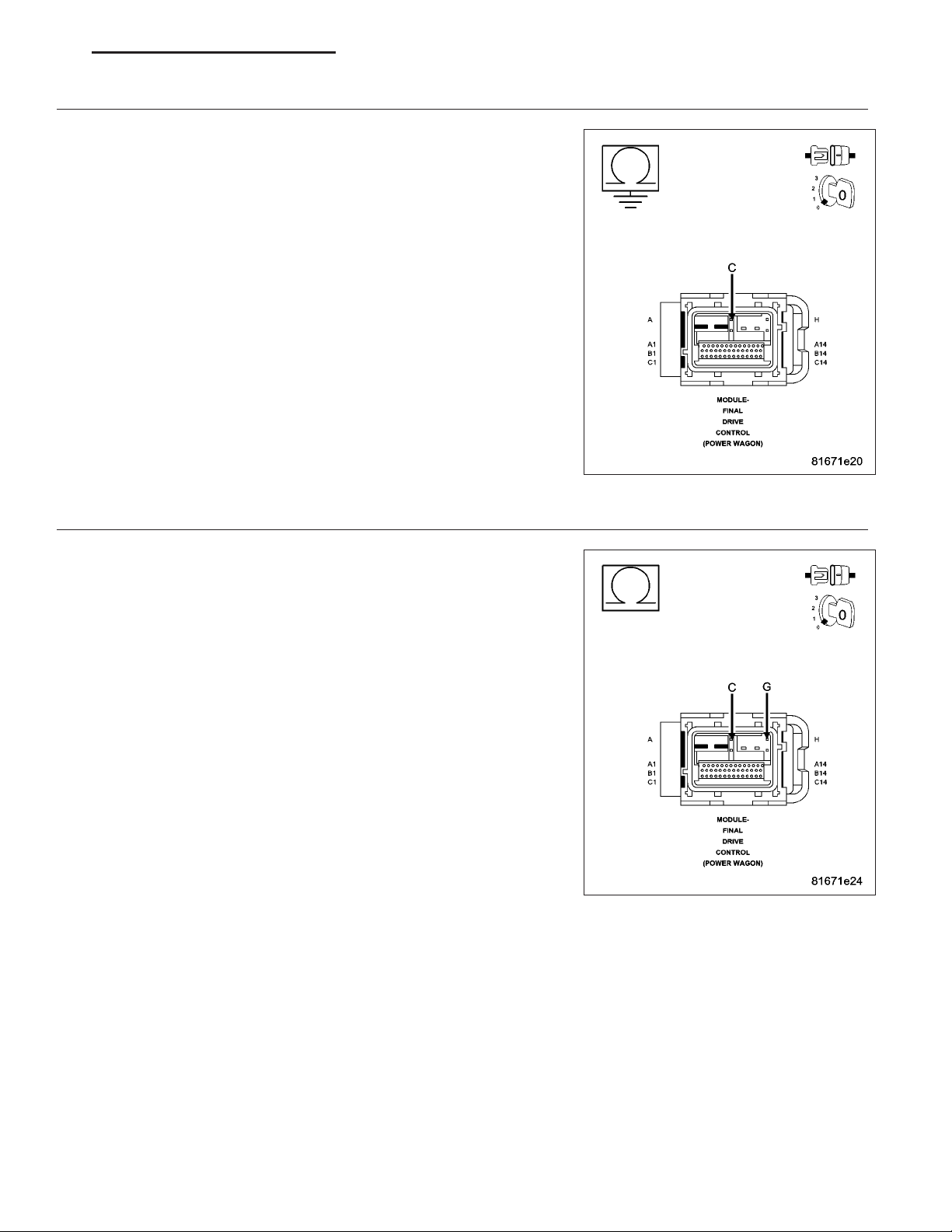

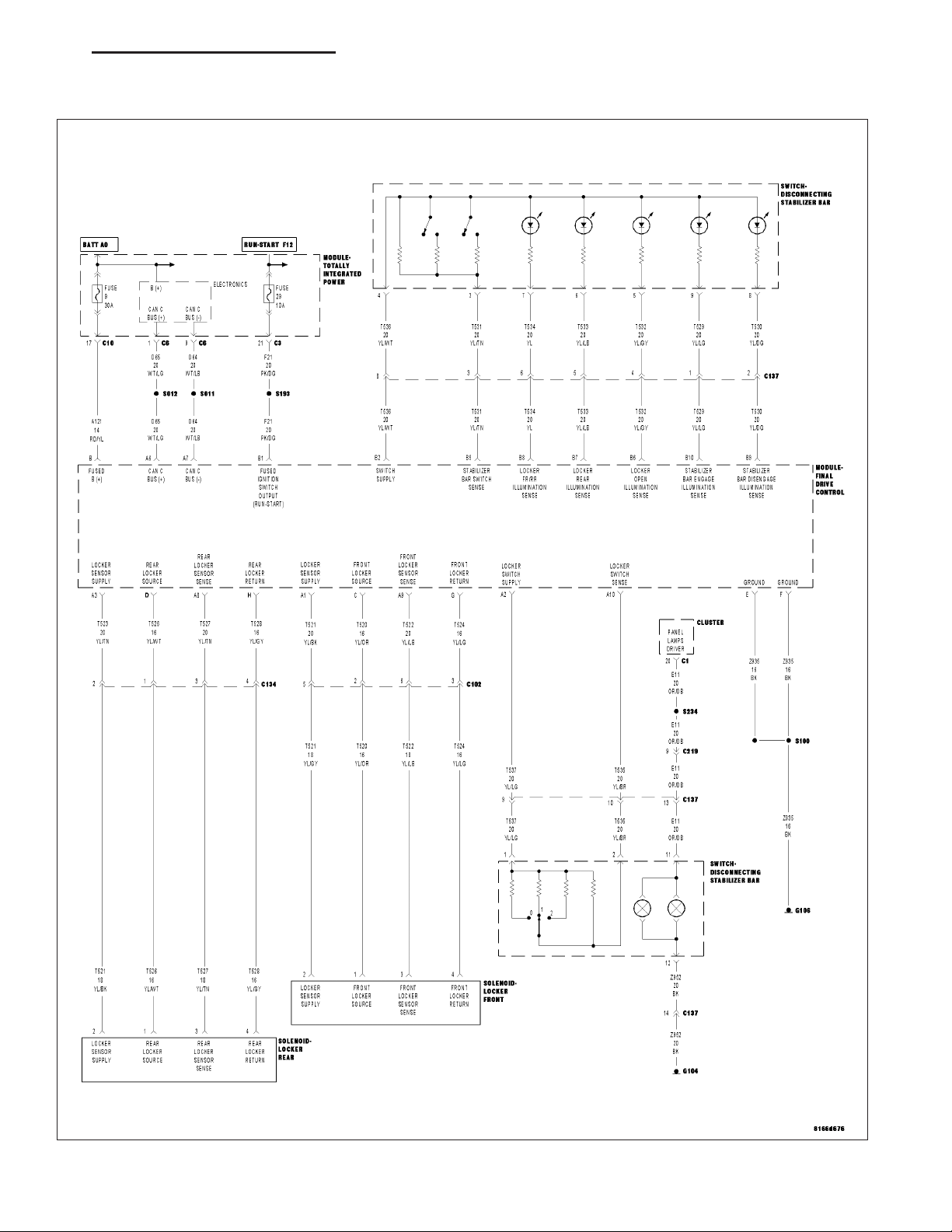

C143A - DIFFERENTIAL/LOCKER SELECT SWITCH PERFORMANCE

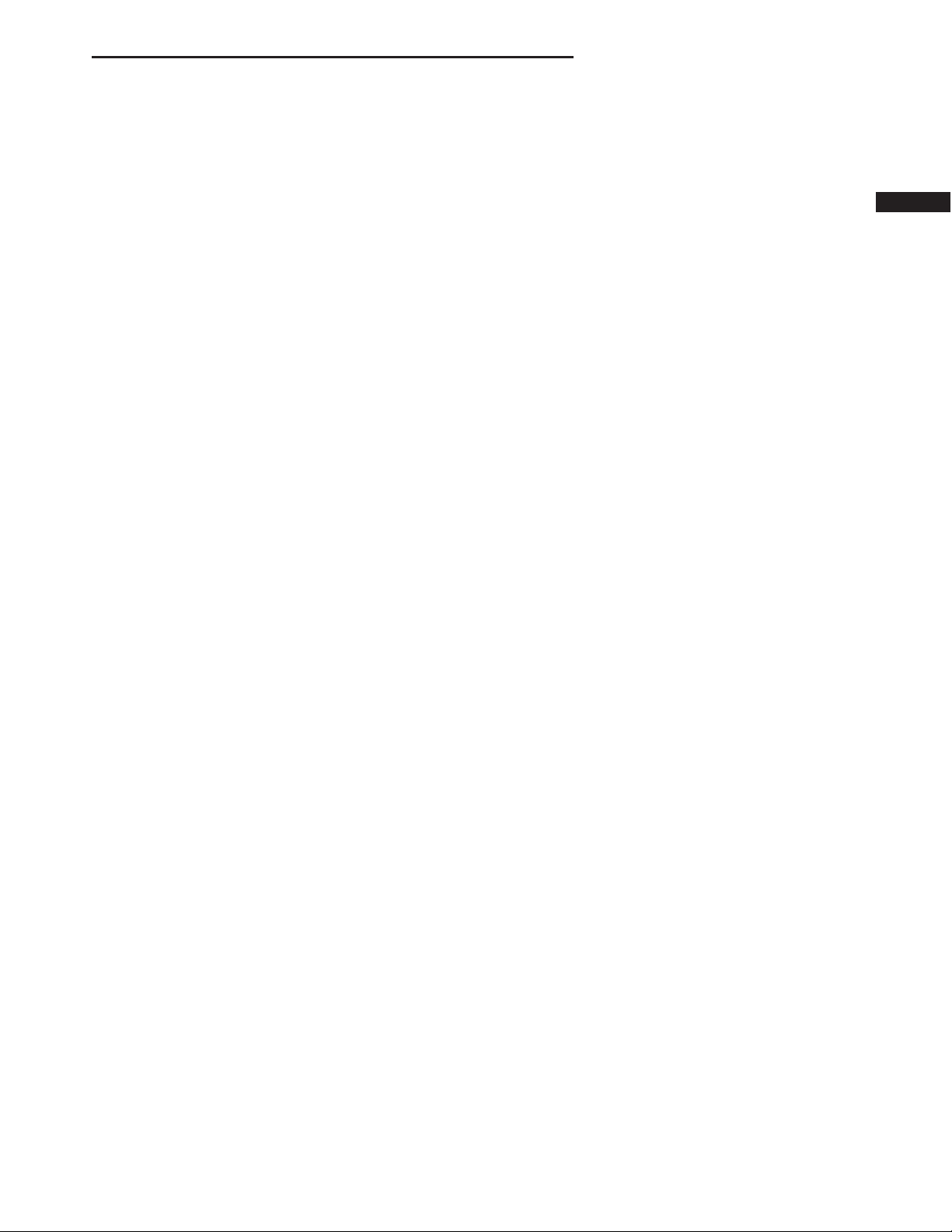

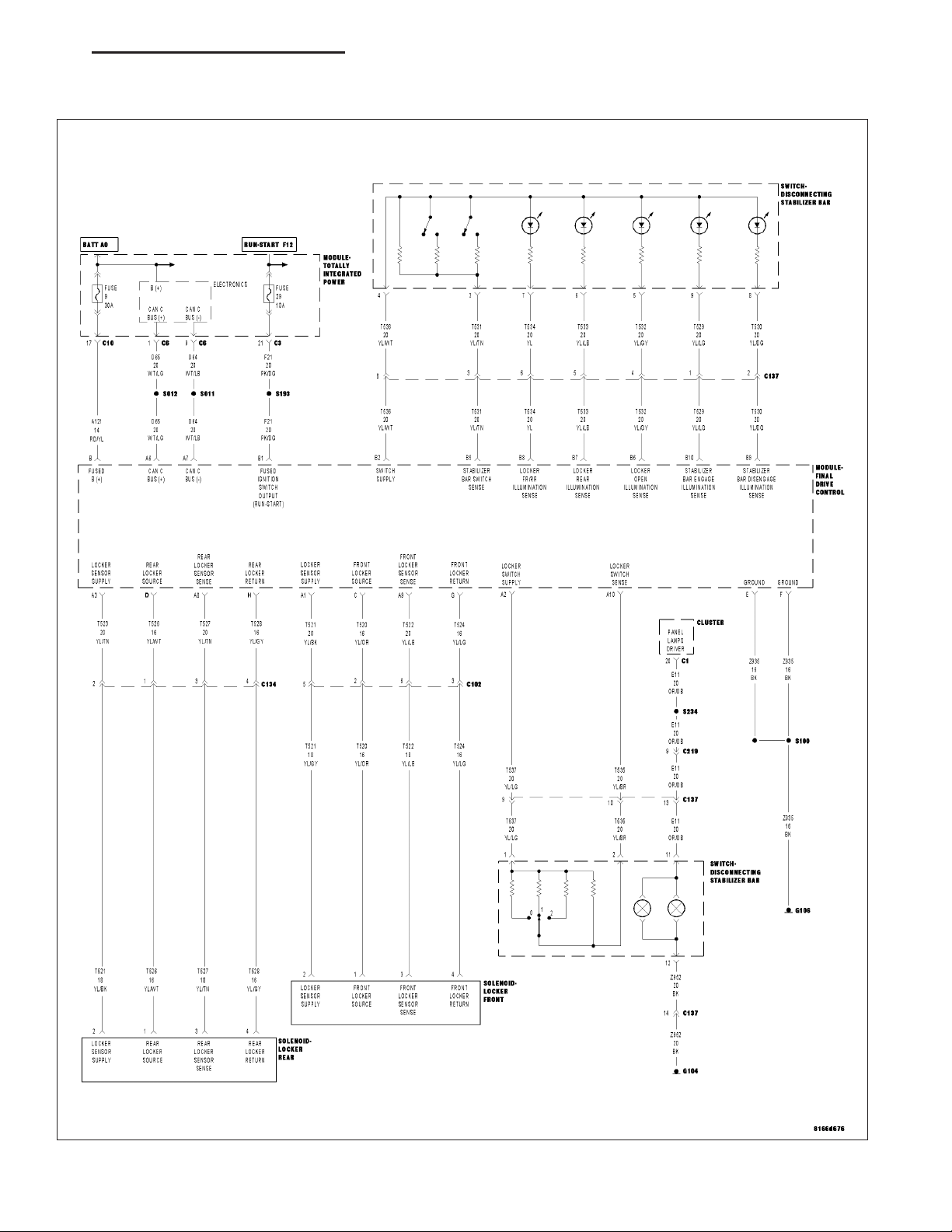

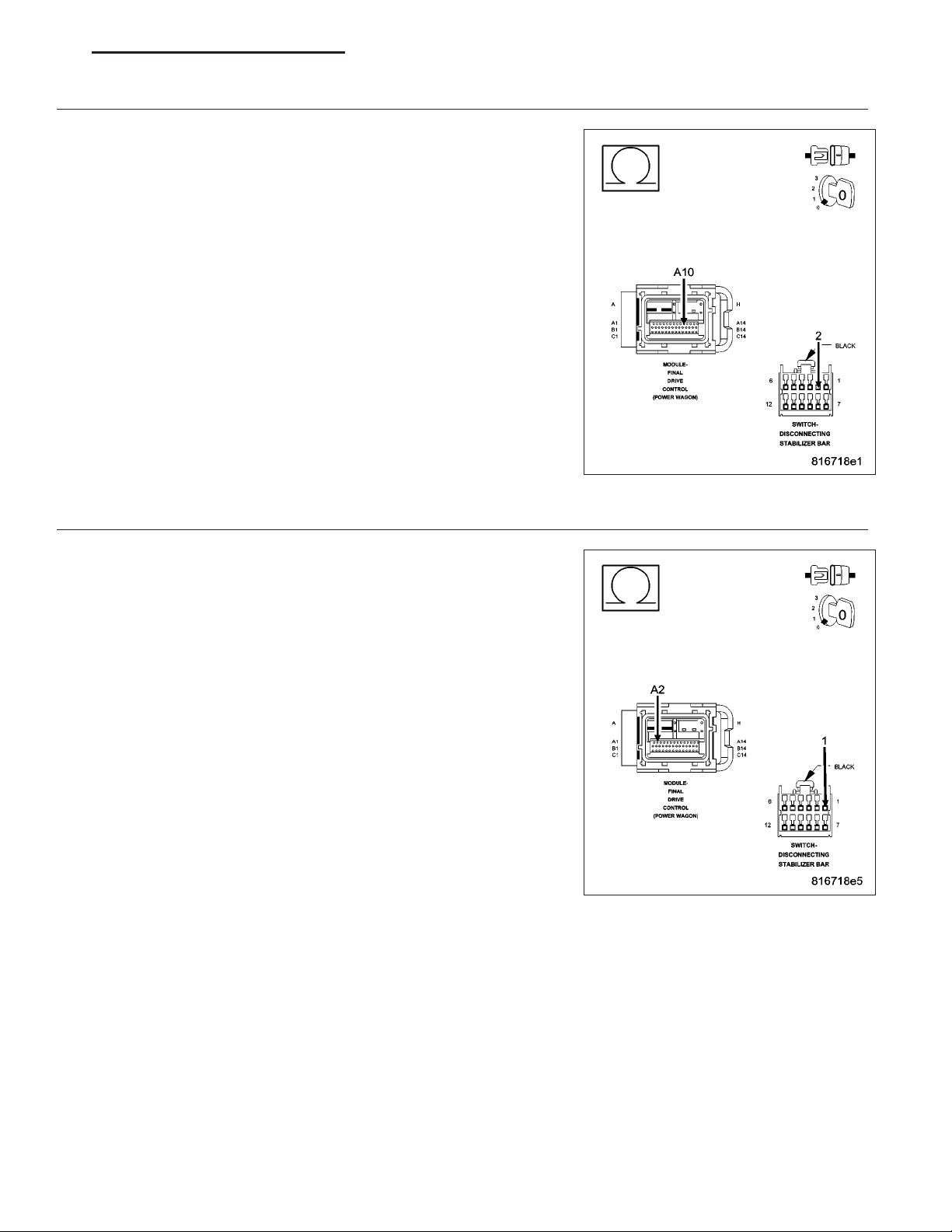

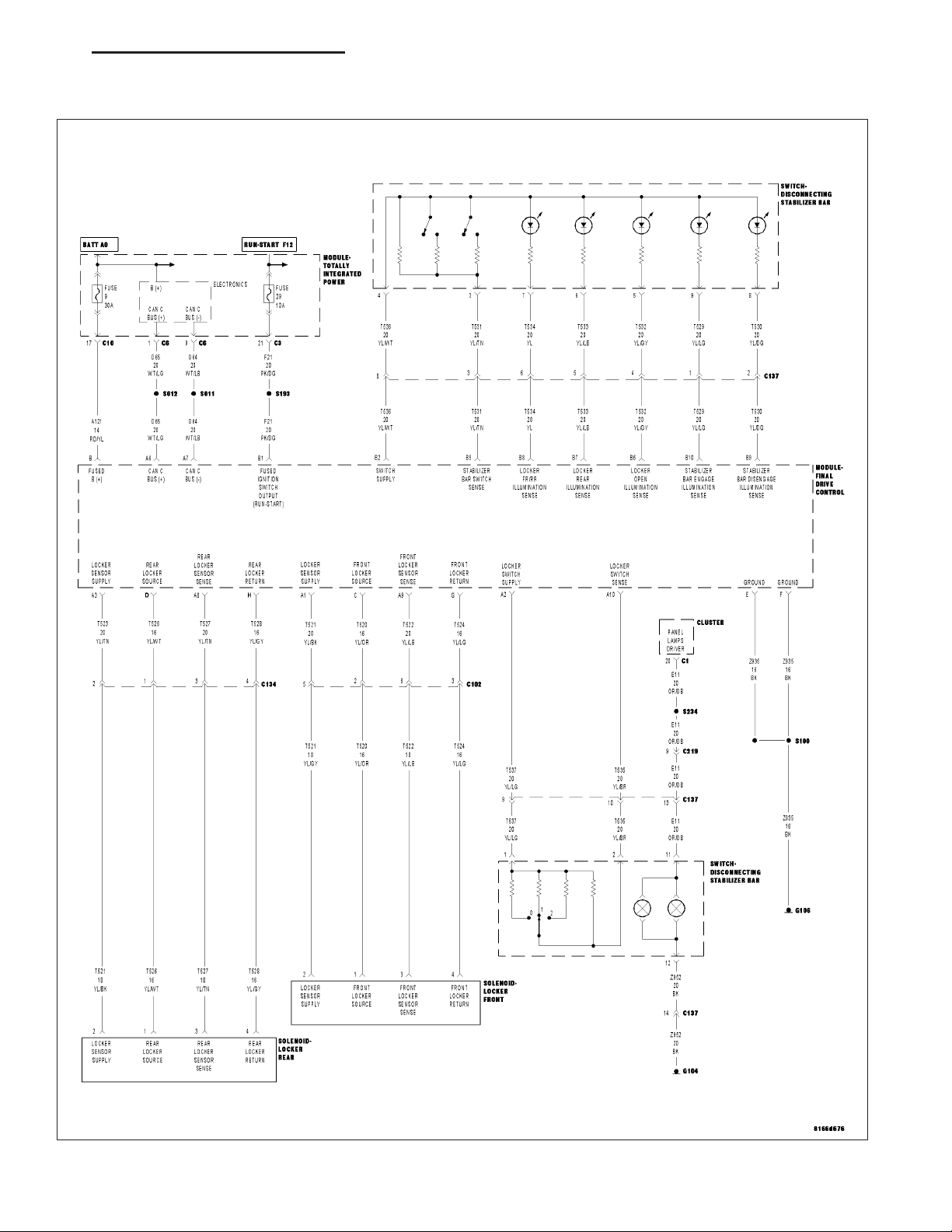

For a complete wiring diagram Refer to Section 8W

Page 4

3 - 4 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on.

• Set Condition:

During switch operation, the FDCM senses the Disconnecting Stabilizer Bar Switch resistance is out of specification.

Possible Causes

SWITCH INTERMITTENT

DISCONNECTING STABILIZER BAR SWITCH

(T537) LOCKER SWITCH SUPPLY CIRCUIT

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN/HIGH RESISTANCE

FDCM

DTC ACTIVE

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Turn the ignition on, engine not running

With the scan tool, read FDCM DTC(s).

Is the DTC active at this time?

Yes >>

No >>

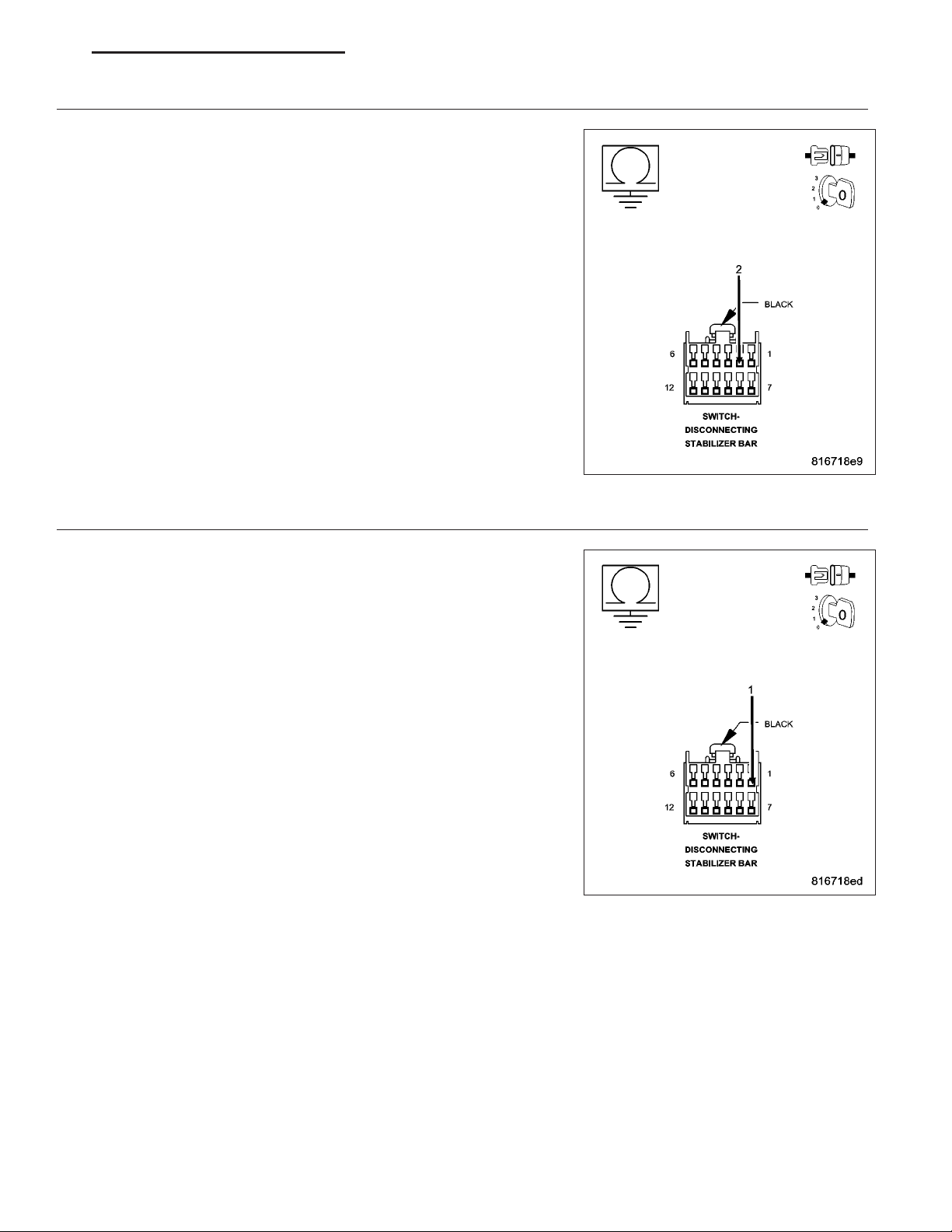

DISCONNECTING STABILIZER BAR SWITCH OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Disconnecting Stabilizer Bar Switch harness connector.

Remove the Disconnecting Stabilizer Bar Switch.

Measure the resistance on the Disconnecting Stabilizer Bar Switch between the Locker Switch Supply terminal and

the Locker Switch Sense terminal.

The resistance must read as follows for each position of the switch.

• UNLOCK: 5454 ohms +/- 5%

• RR: 1940 ohms +/- 5%

• FR/RR: 1075 ohms +/- 5%

Does the ohmmeter read correctly for each position of the Disconnecting Stabilizer Bar Switch

Yes >>

No >>

Go To 2

Go To 5

Go To 3

Replace the Disconnecting Stabilizer Bar Switch.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Page 5

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 5

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN

3.

Disconnect the FDCM harness connector.

Measure the resistance of the (T535) Locker Switch Sense circuit

between the Disconnecting Stabilizer Bar Switch and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

(T537) LOCKER SWITCH SUPPLY CIRCUIT OPEN

4.

Measure the resistance of the (T537) Locker Switch Supply circuit

between the Disconnecting Stabilizer Bar Switch and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Go To 4

Repair the open or high resistance in the (T535) Locker

Switch Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUS-

PENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Replace the FDCM in accordance with the Service Information

Perform FDCM VERIFICATION TEST.

Repair the open or high resistance in the (T537) Locker

Switch Supply circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUS-

PENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Page 6

3 - 6 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

While monitoring the TRAC State on the scan tool, move the switch to each position. The scan tool display must

match the position on the actual switch.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 7

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 7

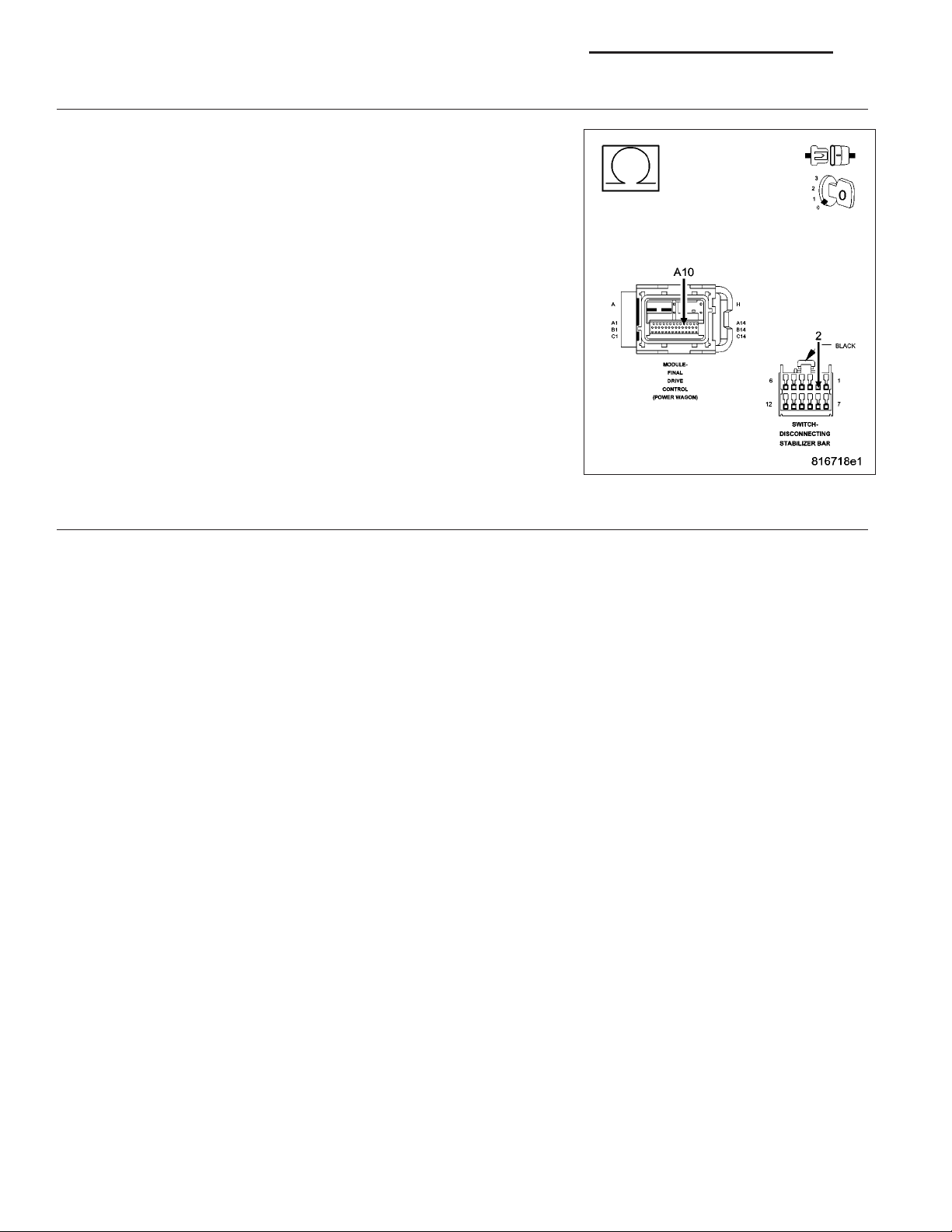

C143B-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 8

3 - 8 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on.

• Set Condition:

During switch operation, the FDCM senses the Disconnecting Stabilizer Bar Switch sense is below 0.25 volt.

Possible Causes

SWITCH INTERMITTENT

DISCONNECTING STABILIZER BAR SWITCH

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORTED TO GROUND

(T535) LOCKER SWITCH SENSE CIRCUIT SHORT TO GROUND

FDCM

DTC ACTIVE

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Turn the ignition on, engine not running

With the scan tool, read FDCM DTC(s).

Is the DTC active at this time?

Yes >>

No >>

DISCONNECTING STABILIZER BAR SWITCH OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Disconnecting Stabilizer Bar Switch harness connector.

Remove the Disconnecting Stabilizer Bar Switch.

Measure the resistance on the Disconnecting Stabilizer Bar Switch between the Locker Switch Supply terminal and

the Locker Switch Sense terminal.

The resistance must read as follows for each position of the switch.

• UNLOCK: 5454 ohms +/- 5%

• RR: 1940 ohms +/- 5%

• FR/RR: 1075 ohms +/- 5%

Does the ohmmeter read correctly for each position of the Disconnecting Stabilizer Bar Switch

Yes >>

No >>

Go To 2

Go To 5

Go To 3

Replace the Disconnecting Stabilizer Bar Switch.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Page 9

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 9

(T535) LOCKER SWITCH SENSE CIRCUIT SHORTED TO GROUND

3.

Disconnect the FDCM harness connector.

Measure the resistance of the (T535) Locker Switch Sense circuit in the

Disconnecting Stabilizer Bar Switch harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORT TO GROUND

4.

Measure the resistance of the (T537) Locker Switch Supply circuit in the

Disconnecting Stabilizer Bar Switch harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

Repair the short to ground in the (T535) Locker Switch

Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair the short to ground in the (T537) Locker Switch Supply circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Replace the FDCM in accordance with the Service Information

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Page 10

3 - 10 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

While monitoring the TRAC State on the scan tool, move the switch to each position. The scan tool display must

match the position on the actual switch.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 11

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 11

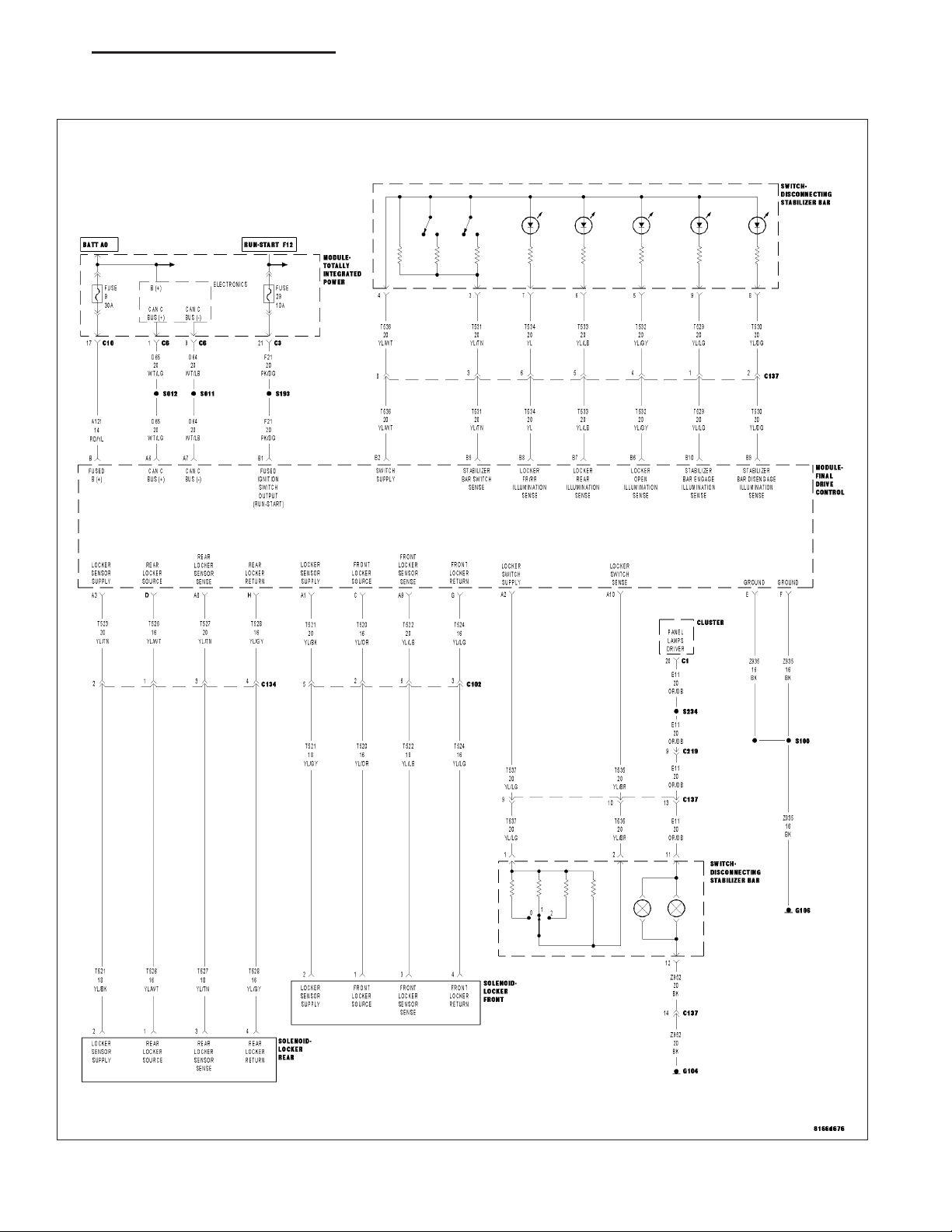

C143C-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 12

3 - 12 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on.

• Set Condition:

During switch operation, the FDCM senses the Disconnecting Stabilizer Bar Switch Sense circuit is above 4.5

volts.

Possible Causes

SWITCH INTERMITTENT

DISCONNECTING STABILIZER SWTICH

(T535) LOCKER SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORTED TO (T535) LOCKER SWITCH SENSE CIRCUIT

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN

FDCM

DTC ACTIVE

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Turn the ignition on, engine not running

With the scan tool, read FDCM DTC(s).

Is the DTC active at this time?

Yes >>

No >>

DISCONNECTING STABILIZER SWTICH OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Disconnecting Stabilizer Bar Switch harness connector.

Remove the Disconnecting Stabilizer Bar Switch.

Measure the resistance on the Disconnecting Stabilizer Bar Switch between the Locker Switch Supply terminal and

the Locker Switch Sense terminal.

The resistance must read as follows for each position of the switch.

• UNLOCK: 5454 ohms +/- 5%

• RR: 1940 ohms +/- 5%

• FR/RR: 1075 ohms +/- 5%

Does the ohmmeter read correctly for each position of the Disconnecting Stabilizer Bar Switch

Yes >>

No >>

Go To 2

Go To 6

Go To 3

Replace the Disconnecting Stabilizer Bar Switch.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Page 13

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 13

(T535) LOCKER SWITCH SENSE CIRCUIT SHORTED TO VOLTAGE

3.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage of the (T535) Locker Switch Sense circuit in the

Disconnecting Stabilizer Bar Switch harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORTED TO (T535) LOCKER SWITCH SENSE CIRCUIT

4.

Measure the resistance between (T537) Locker Switch Supply circuit

and the (T535) Locker Switch Sense circuit in the Disconnecting Stabilizer Bar Switch harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the short to voltage in the (T535) Locker Switch

Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair the short between (T537) Locker Switch Supply circuit and the (T535) Locker Switch Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 5

Page 14

3 - 14 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN

5.

Measure the resistance of the (T535) Locker Switch Sense circuit

between the Disconnecting Stabilizer Bar Switch and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

While monitoring the TRAC State on the scan tool, move the switch to each position. The scan tool display must

match the position on the actual switch.

Were there any problems found?

Replace the FDCM in accordance with the Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Repair the open in the (T535) Locker Switch Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUS-

PENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 15

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 15

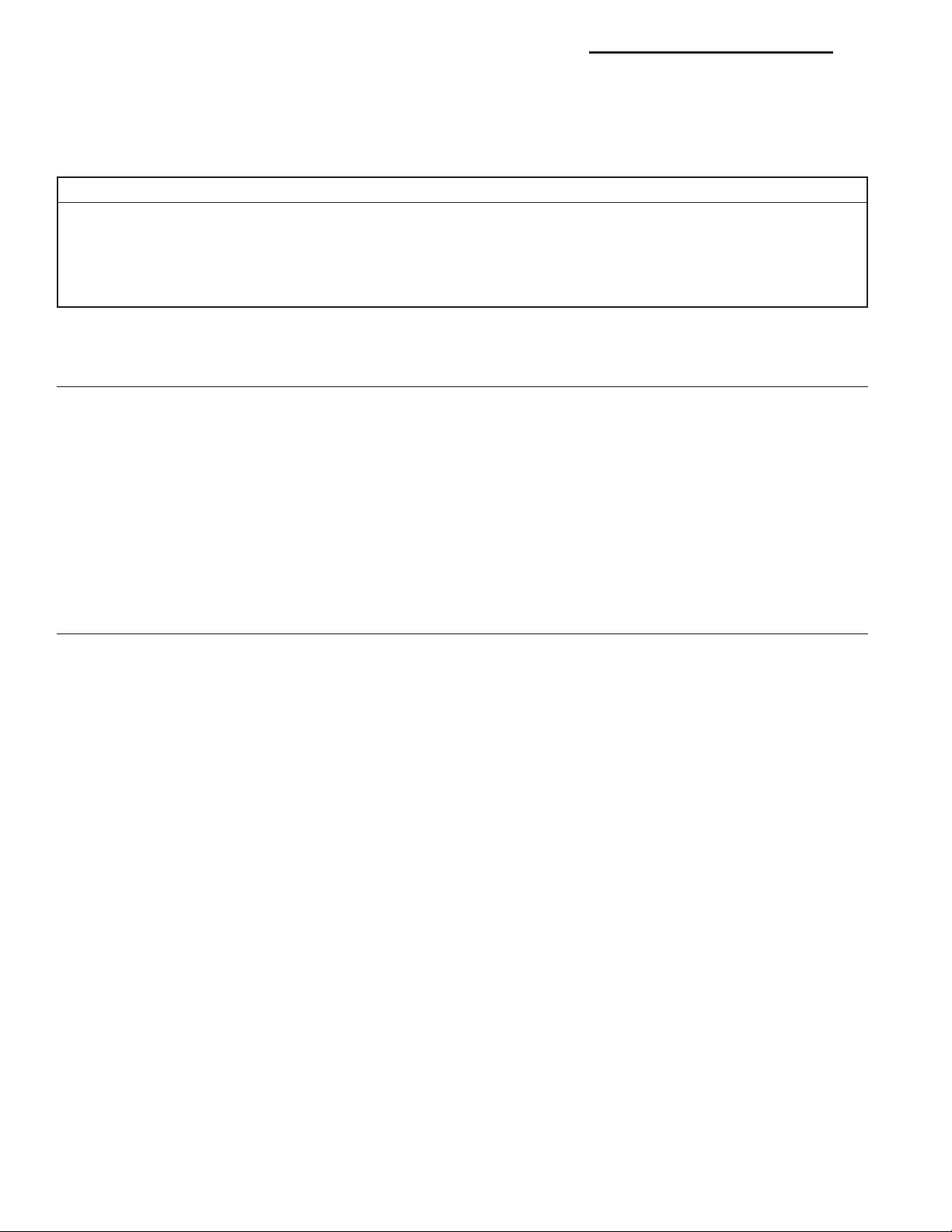

C1417–FRONT DIFFERENTIAL CONTROL CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 16

3 - 16 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is shorted low.

Possible Causes

FRONT LOCKER SOLENOID

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO GROUND

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO FRONT LOCKER RETURN CIRCUIT

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With the scan tool, actuate the Front Locker Solenoid.

Does the test light illuminate and flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 17

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 17

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO GROUND

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T520) Front Locker Source circuit at the

FDCM harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO (T524) FRONT LOCKER RETURN CIRCUIT

4.

Measure the resistance between the (T520) Front Locker Source circuit

and the (T524) Front Locker Return circuit in the FDCM harness connector.

Is the resistance below 100 ohms?

Yes >>

No >>

Repair the short to ground in the Front Locker Source circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair the short between (T520) Front Locker Source circuit

and the (T524) Front Locker Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 5

Page 18

3 - 18 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 19

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 19

C1418–FRONT DIFFERENTIAL CONTROL CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 20

3 - 20 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is shorted high.

Possible Causes

FRONT LOCKER SOLENOID

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

(T524) FRONT LOCKER RETURN CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With a scan tool, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 21

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 21

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage on the (T520) Front Locker Source circuit at the

FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T524) FRONT LOCKER RETURN CIRCUIT OPEN

4.

Measure the resistance of the (T524) Front Locker Return circuit form

the in the Front Locker Solenoid harness connector and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the short to voltage in the (T520) Front Locker

Source circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Go To 5

Repair the open in the (T524) Front Locker Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Page 22

3 - 22 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 23

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 23

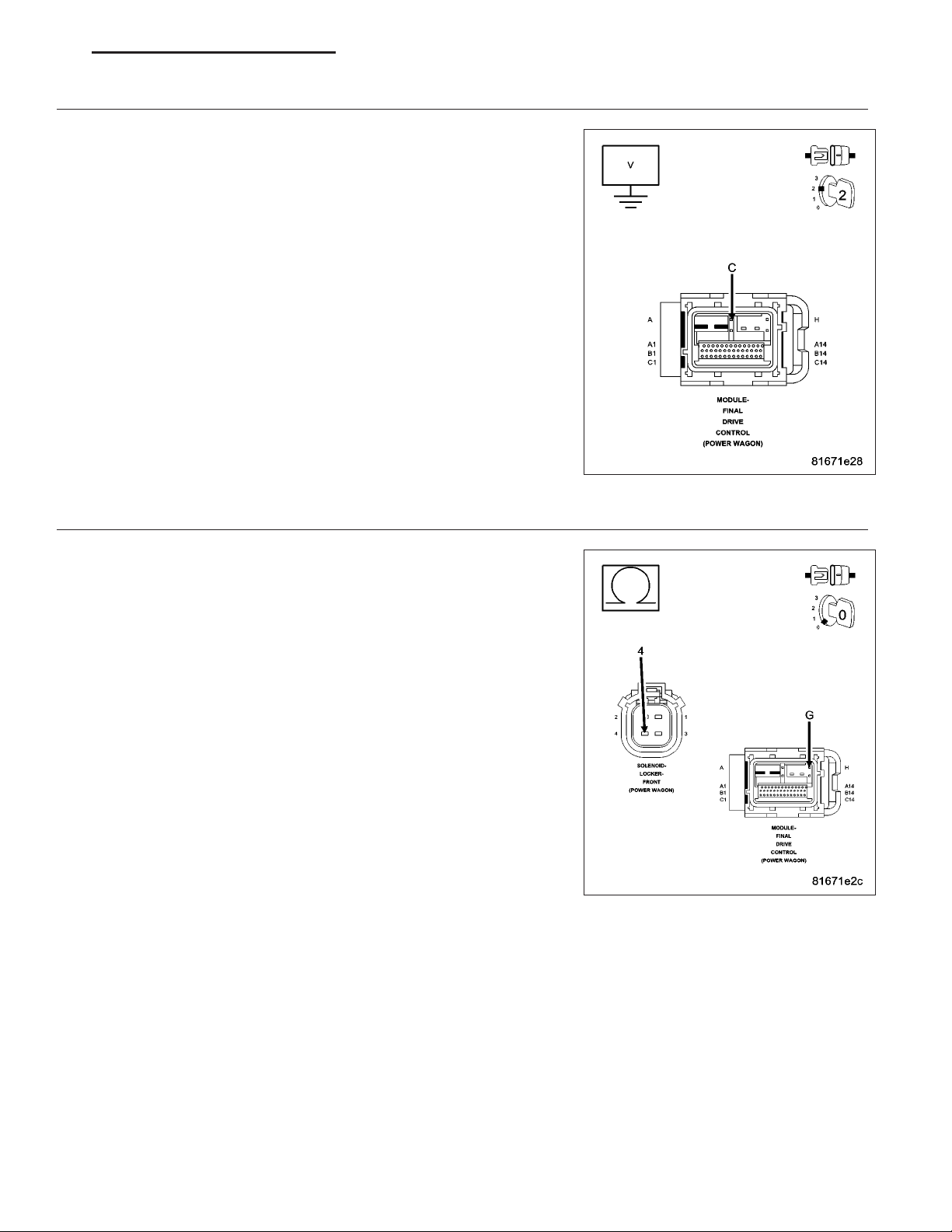

C1419–FRONT DIFFERENTIAL CONTROL CIRCUIT OPEN

For a complete wiring diagram Refer to Section 8W.

Page 24

3 - 24 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is open.

Possible Causes

FRONT LOCKER SOLENOID

(T520) FRONT LOCKER SOURCE CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With a scan tool, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 25

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 25

(T520) FRONT LOCKER SOURCE CIRCUIT OPEN

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the resistance of the (T520) Front Locker Source circuit from

the FDCM harness connector and the Front Locker Solenoid harness

connector.

Is the resistances below 5.0 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Go To 4

Repair the open in the Front Locker Source circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 26

3 - 26 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

C141D-REAR DIFFERENTIAL CONTROL CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 27

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 27

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the RR or FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is shorted low.

Possible Causes

REAR LOCKER SOLENOID

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO GROUND

(T528) REAR LOCKER SOURCE CIRCUIT SHORTED TO (T528) REAR LOCKER RETURN CIRCUIT

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a scan tool, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 28

3 - 28 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO GROUND

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T526) Rear Locker Source circuit at the

FDCM harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO (T528) REAR LOCKER RETURN CIRCUIT

4.

Measure the resistance between the (T526) Rear Locker Source circuit

and the (T528) Rear Locker Return circuit in the FDCM harness connector.

Is the resistance below 100 ohms?

Yes >>

No >>

Repair the short to ground in the Rear Locker Source circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair the short between (T526) Rear Locker Source circuit

and the (T528) Rear Locker Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 5

Page 29

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 29

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 30

3 - 30 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

C141E–REAR DIFFERENTIAL CONTROL CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 31

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 31

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is shorted high.

Possible Causes

REAR LOCKER SOLENOID

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

(T528) REAR LOCKER RETURN CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a scan tool, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 32

3 - 32 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage on the (T526) Rear Locker Source circuit at the

FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T528) REAR LOCKER RETURN CIRCUIT OPEN

4.

Measure the resistance of the (T528) Rear Locker Return circuit form

the in the Rear Locker Solenoid harness connector and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the short to voltage in the (T526) Rear Locker

Source circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Go To 5

Repair the open in the (T528) Rear Locker Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Page 33

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 33

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 34

3 - 34 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

C141F–REAR DIFFERENTIAL CONTROL CIRCUIT OPEN

For a complete wiring diagram Refer to Section 8W.

Page 35

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 35

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is open.

Possible Causes

REAR LOCKER SOLENOID

(T526) REAR LOCKER SOURCE CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a scan tool, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 36

3 - 36 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T526) REAR LOCKER SOURCE CIRCUIT OPEN

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the resistance of the (T526) Rear Locker Source circuit from

the FDCM harness connector and the Rear Locker Solenoid harness

connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Go To 4

Repair the open in the Rear Locker Source circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 37

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 37

C1446-FRONT DIFFERENTIAL RETURN CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 38

3 - 38 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is shorted low.

Possible Causes

FRONT LOCKER SOLENOID

(T526) FRONT LOCKER RETURN CIRCUIT SHORTED TO GROUND

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With a scan tool, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 39

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 39

(T524) FRONT LOCKER RETURN CIRCUIT SHORTED TO GROUND

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T524) Front Locker Return circuit in the

FDCM harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Repair the short to ground in (T524) Front Locker Return

circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 40

3 - 40 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

C1447-FRONT DIFFERENTIAL RETURN CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 41

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 41

• When Monitored:

Ignition on. Disconnection Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is shorted low.

Possible Causes

FRONT LOCKER SOLENOID

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO GROUND

(T524) FRONT LOCKER RETURN CIRCUIT SHORTED TO (T520) FRONT LOCKER SOURCE CIRCUIT

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With thescan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With ascan tool, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 42

3 - 42 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T524) FRONT LOCKER RETURN CIRCUIT SHORTED TO BATTERY VOLTAGE

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage of the (T524) Front Locker Return circuit at the

FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T524) FRONT LOCKER RETURN CIRCUIT SHORTED TO (T520) FRONT LOCKER SOURCE CIRCUIT

4.

Turn the ignition off.

Measure the resistance between the (T520) Front Locker Source circuit

and the (T524) Front Locker Return circuit in the FDCM harness connector.

Is the resistance below 100 ohms?

Yes >>

No >>

Repair the short to voltage in the (T524) Front Locker

Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair the short between (T520) Front Locker Source circuit

and the (T524) Front Locker Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 5

Page 43

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 43

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 44

3 - 44 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

C144A-REAR DIFFERENTIAL RETURN CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 45

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 45

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the RR or FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is shorted low.

Possible Causes

REAR LOCKER SOLENOID

(T528) REAR LOCKER RETURN CIRCUIT SHORTED TO GROUND

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a scan tool, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 46

3 - 46 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T528) REAR LOCKER RETURN CIRCUIT SHORTED TO GROUND

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T528) Rear Locker Return circuit in the

FDCM harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Repair the short to ground in (T528) Rear Locker Return

circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 47

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 47

C144B-REAR DIFFERENTIAL RETURN CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 48

3 - 48 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the RR or FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is shorted low.

Possible Causes

REAR LOCKER SOLENOID

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO GROUND

(T528) REAR LOCKER RETURN CIRCUIT SHORTED TO (T526) REAR LOCKER SOURCE CIRCUIT

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a scan tool, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 49

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 49

(T528) REAR LOCKER RETURN CIRCUIT SHORTED TO BATTERY VOLTAGE

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage of the (T528) Rear Locker Return circuit at the

FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T528) REAR LOCKER RETURN CIRCUIT SHORTED TO (T526) REAR LOCKER SOURCE CIRCUIT

4.

Turn the ignition off.

Measure the resistance between the (T526) Rear Locker Source circuit

and the (T528) Rear Locker Return circuit in the FDCM harness connector.

Is the resistance below 100 ohms?

Yes >>

No >>

Repair the short to voltage in the (T528) Rear Locker

Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair the short between (T526) Rear Locker Source circuit

and the (T528) Rear Locker Return circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 5

Page 50

3 - 50 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 51

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 51

C144E-FRONT DIFFERENTIAL POSITION SENSOR PERFORMANCE

For a complete wiring diagram Refer to Section 8W.

Page 52

3 - 52 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

The ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects that the Front Differential Position Sensor is in an unexpected state.

Possible Causes

(T522) FRONT DIFFERENTIAL POSITION SENSOR (WIRING, CONNECTOR AND/OR TERMINAL CONDITION)

FRONT DIFFERENTIAL POSITION SENSOR

(T522) FRONT LOCKER SENSOR SENSE OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT DIFFERENTIAL POSITION SENSOR WIRING

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Using the scan tool, actuate the Front Locker Solenoid.

Monitor the Front Differential Position Sensor State.

Wiggle the related wiring harness from the FDCM to the Front Locker Solenoid connector at the axle.

With a scan tool, actuate the Front Locker Solenoid.

Does the state on the scan tool change while wiggling the wiring harness?

Yes >>

No >>

Go To 2

Go To 6

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit. Check the

Locker Solenoid terminals and connectors for corrosion and/or dirt that may compromise the connection.

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 53

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 53

FRONT DIFFERENTIAL POSITION SENSOR OPERATION

3.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a jumper wire, jumper across from the (T522) Front Locker Sensor Sense circuit and the (T521) Locker Sen-

sor Supply circuit in the Front Locker Solenoid harness connector.

While monitoring the sensor state on the scan tool, tap the jumper wire on and off the (T522) Front Locker Sensor

Sense circuit terminal. Hold the jumper wire on and off the terminal for a minimum of 3 seconds.

Does the state change on the scan tool while tapping the terminal?

Yes >>

No >>

(T522) FRONT LOCKER SENSOR SENSE CIRCUIT OPEN

4.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T522) Front Locker Sensor Sense circuit

between the Front Locker Solenoid harness connector and the FDCM

harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 4

Go To 5

Repair the open in the Front Locker Sensor Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Page 54

3 - 54 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 55

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 55

C1450-FRONT DIFFERENTIAL POSITION SENSOR CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 56

3 - 56 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects that the Front Differential Position Sensor is shorted to voltage.

Possible Causes

(T522) FRONT LOCKER SENSOR SENSE SHORTED TO BATTERY VOLTAGE

FRONT DIFFERENTIAL POSITION SENSOR

(T522) FRONT LOCKER SENSOR SENSE OPEN

(T522) FRONT LOCKER SENSOR SENSE SHORTED TO (T521) LOCKER SENSOR SUPPLY

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

(T522) FRONT LOCKER SENSOR SENSE SHORTED TO BATTERY VOLTAGE

2.

NOTE: Before continuing with the below diagnostic test, ensure

the FDCM harness connector seal is installed correctly. Inspect the

terminals on both harness connector and the module for damage.

Failure to do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage on the (T522) Front Locker Sensor Sense circuit in

the FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

Go To 2

Go To 7

Repair the short to voltage in the (T522) Front Locker Sensor Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 3

Page 57

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 57

FRONT DIFFERENTIAL POSITION SENSOR OPERATION

3.

Turn the ignition off.

Connect the FDCM harness connector.

Ignition on, engine not running.

Using a jumper wire, jumper across from the (T522) Front Locker Sensor Sense circuit and the (T521) Locker Sen-

sor Supply circuit in the Front Locker Solenoid harness connector.

While monitoring the sensor state on the scan tool, tap the jumper wire on and off the (T522) Front Locker Sensor

Sense circuit terminal. Hold the jumper wire on and off the terminal for a minimum of 3 seconds.

Does the state change on the scan tool while tapping the terminal?

Yes >>

No >>

(T522) FRONT LOCKER SENSOR SENSE CIRCUIT OPEN

4.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T522) Front Locker Sensor Sense circuit

between the Front Locker Solenoid harness connector and the FDCM

harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 4

Go To 5

Repair the open in the (T522) Front Locker Sensor Sense

circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUS-

PENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Page 58

3 - 58 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

(T522) FRONT LOCKER SENSOR SENSE CIRCUIT SHORTED TO (T521) LOCKER SENSOR 1 SUPPLY

5.

Measure the resistance between the (T522) Front Locker Sensor Sense

circuit and the (T521) Locker Sensor 1 Supply circuit in the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

FDCM

6.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Repair the short between the (T522) Front Locker Sensor

Sense circuit and the (T521) Locker Sensor 1 Supply circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 6

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

7.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Test Complete.

Page 59

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 59

C144F-FRONT DIFFERENTIAL POSITION SENSOR LOW

For a complete wiring diagram Refer to Section 8W.

Page 60

3 - 60 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Ignition on. Disconnecting Stabilizer Bar Switch in the FR/RR position.

• Set Condition:

The FDCM detects that the Front Differential Position Sensor is short low.

Possible Causes

FRONT DIFFERENTIAL POSITION SENSOR

(T522) FRONT LOCKER SENSOR SENSE SHORTED TO GROUND

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT DIFFERENTIAL POSITION SENSOR OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Using the scan tool, ignition on, monitor the Front Locker Sensor state.

Disconnect the Front Locker Solenoid harness connector.

Does the state change on the scan tool from Locked to Unlocked?

Yes >>

No >>

Go To 2

Go To 5

Replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Go To 3

Page 61

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 61

(T522) FRONT LOCKER SENSOR SENSE CIRCUIT SHORTED TO GROUND

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T522) Front Locker Sensor Sense circuit

in the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Repair the short to ground in the (T522) Front Locker Sensor Sense circuit.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD PROCEDURE)

Go To 4

Repair as necessary.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the scan tool, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST.

Perform FDCM VERIFICATION TEST. (Refer to 2 - SUSPENSION/ACTIVE CHASSIS - STANDARD

PROCEDURE)

Page 62

3 - 62 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR

C1452-REAR DIFFERENTIAL POSITION SENSOR PERFORMANCE

For a complete wiring diagram Refer to Section 8W.

Page 63

DR DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 63

• When Monitored:

The ignition on. Disconnecting Stabilizer Bar Switch in the RR or FR/RR position.

• Set Condition:

The FDCM detects that the Rear Differential Position Sensor is in an unexpected state.

Possible Causes

REAR DIFFERENTIAL POSITION SENSOR (WIRING, CONNECTOR AND/OR TERMINAL CONDITION)

REAR DIFFERENTIAL POSITION SENSOR

REAR LOCKER SENSOR SENSE OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the scan tool, read DTCs.