BR/BE COOLING 7 - 1

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L ENGINE ..........................1

DESCRIPTION—COOLING SYSTEM FLOW -

5.9L DIESEL ..........................2

DESCRIPTION—HOSE CLAMPS ...........4

OPERATION

OPERATION—HOSE CLAMPS ............4

OPERATION—COOLING SYSTEM .........4

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS .............................4

DIAGNOSIS AND TESTING—ON-BOARD

DIAGNOSTICS (OBD) ...................5

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAKS .......................5

DIAGNOSIS AND TESTING - COOLING

SYSTEM GAS ENGINE ..................7

DIAGNOSIS AND TESTING - COOLING

SYSTEM DIESEL ENGINE ...............13

STANDARD PROCEDURE

STANDARD PROCEDURE - DRAINING

COOLING SYSTEM 5.9L/8.0L ENGINES ....15

STANDARD PROCEDURE—DRAINING

COOLING SYSTEM 5.9L DIESEL ENGINE . . . 15

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 5.9L/8.0L ENGINES ....16

STANDARD PROCEDURE—REFILLING

COOLING SYSTEM 5.9L DIESEL ENGINE . . . 16

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................16

STANDARD PROCEDURE—COOLANT

LEVEL CHECK........................16

STANDARD PROCEDURE - COOLING

SYSTEM CLEANING/REVERSE FLUSHING . . 17

STANDARD PROCEDURE - COOLANT

SELECTION - ADDITIVES ...............17

SPECIFICATIONS

TORQUE ............................18

SPECIAL TOOLS

COOLING ...........................18

ACCESSORY DRIVE ......................19

ENGINE ...............................38

TRANSMISSION .........................78

COOLING

DESCRIPTION

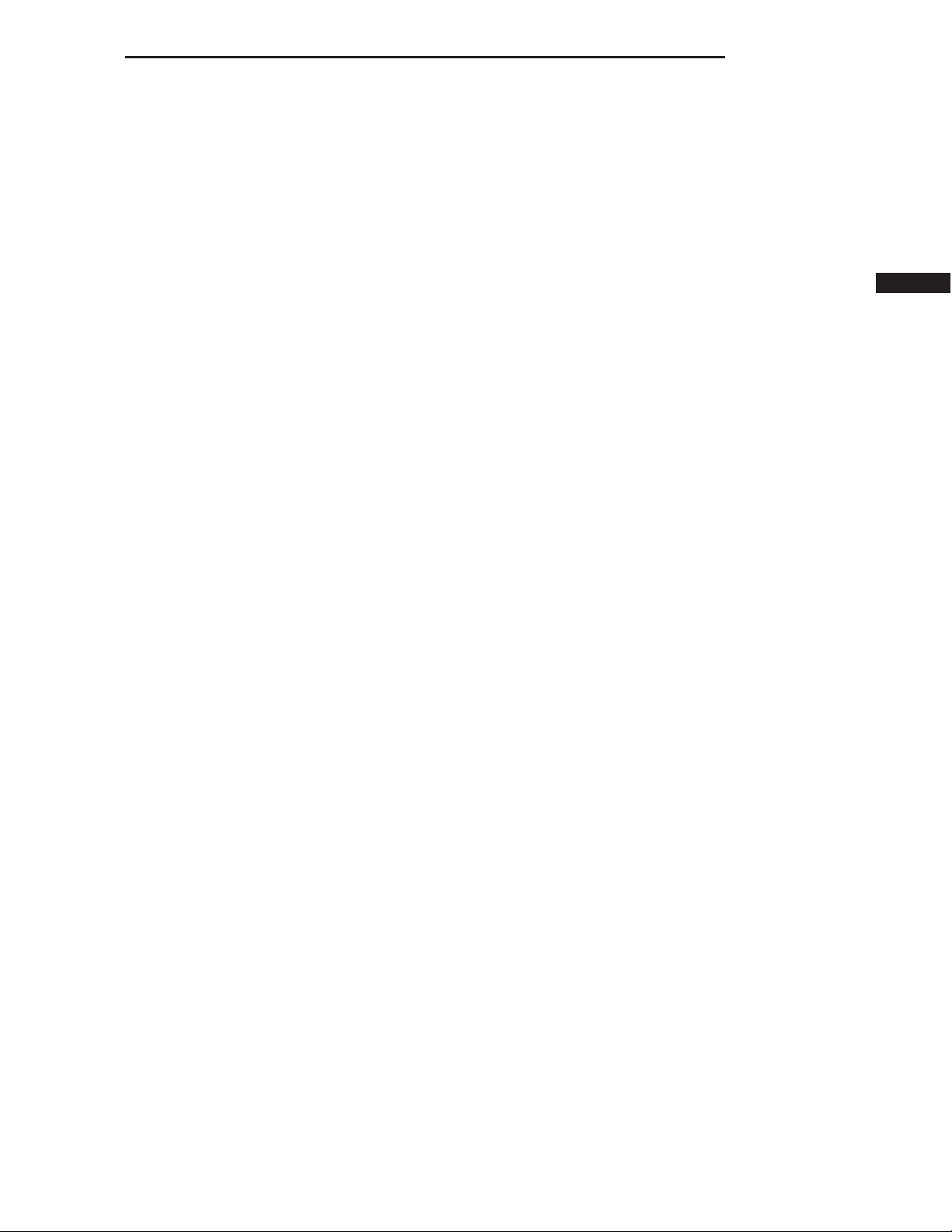

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L ENGINE

The cooling system regulates engine operating temperature. It allows the engine to reach normal operating temperature as quickly as possible. It also

maintains normal operating temperature and prevents overheating.

The cooling system also provides a means of heating the passenger compartment and cooling the automatic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

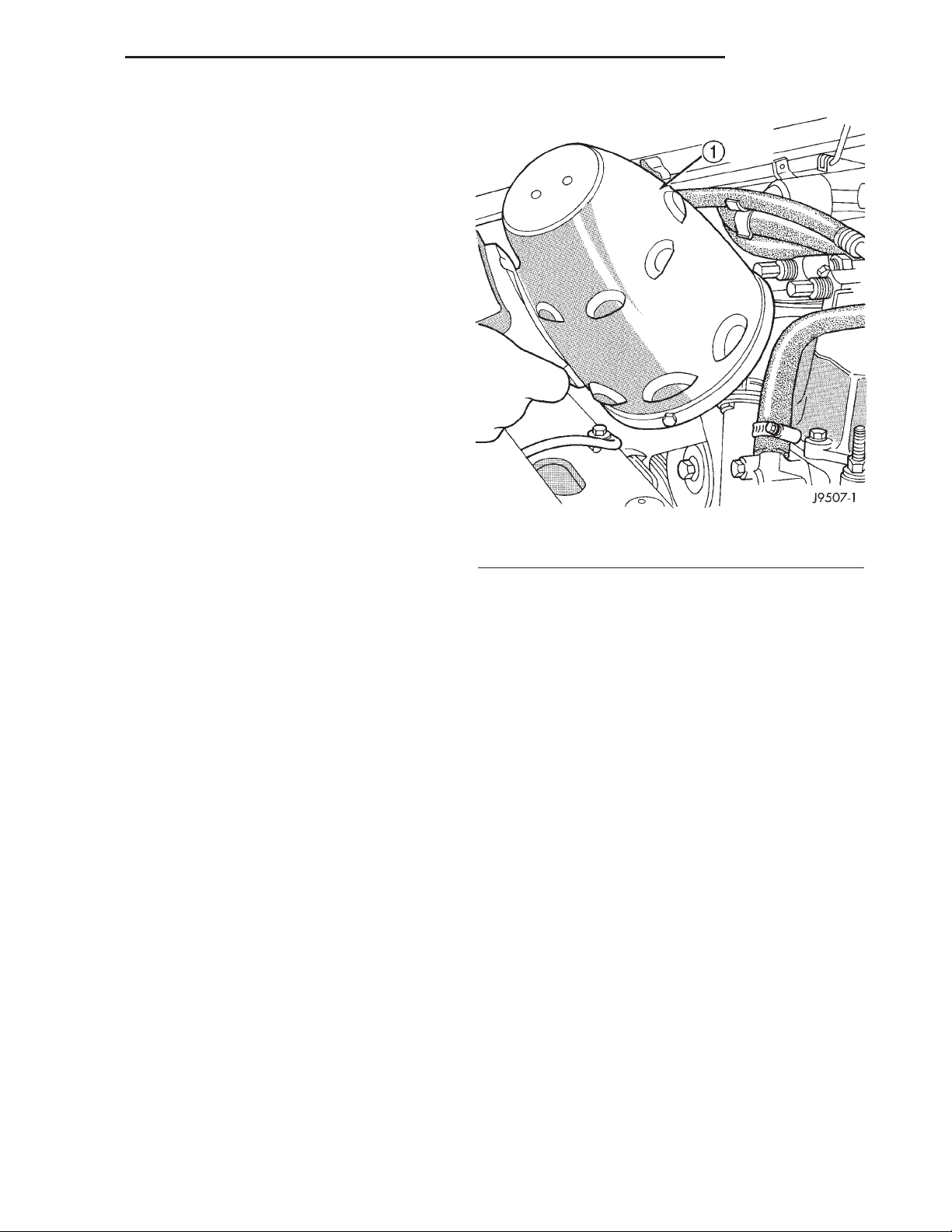

An optional factory installed maximum duty cooling package is available on most models. This package will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures (Fig. 1).

7 - 2 COOLING BR/BE

COOLING (Continued)

Fig. 1 Engine Cooling System Flow

1 - HEATER

2 - BYPASS*

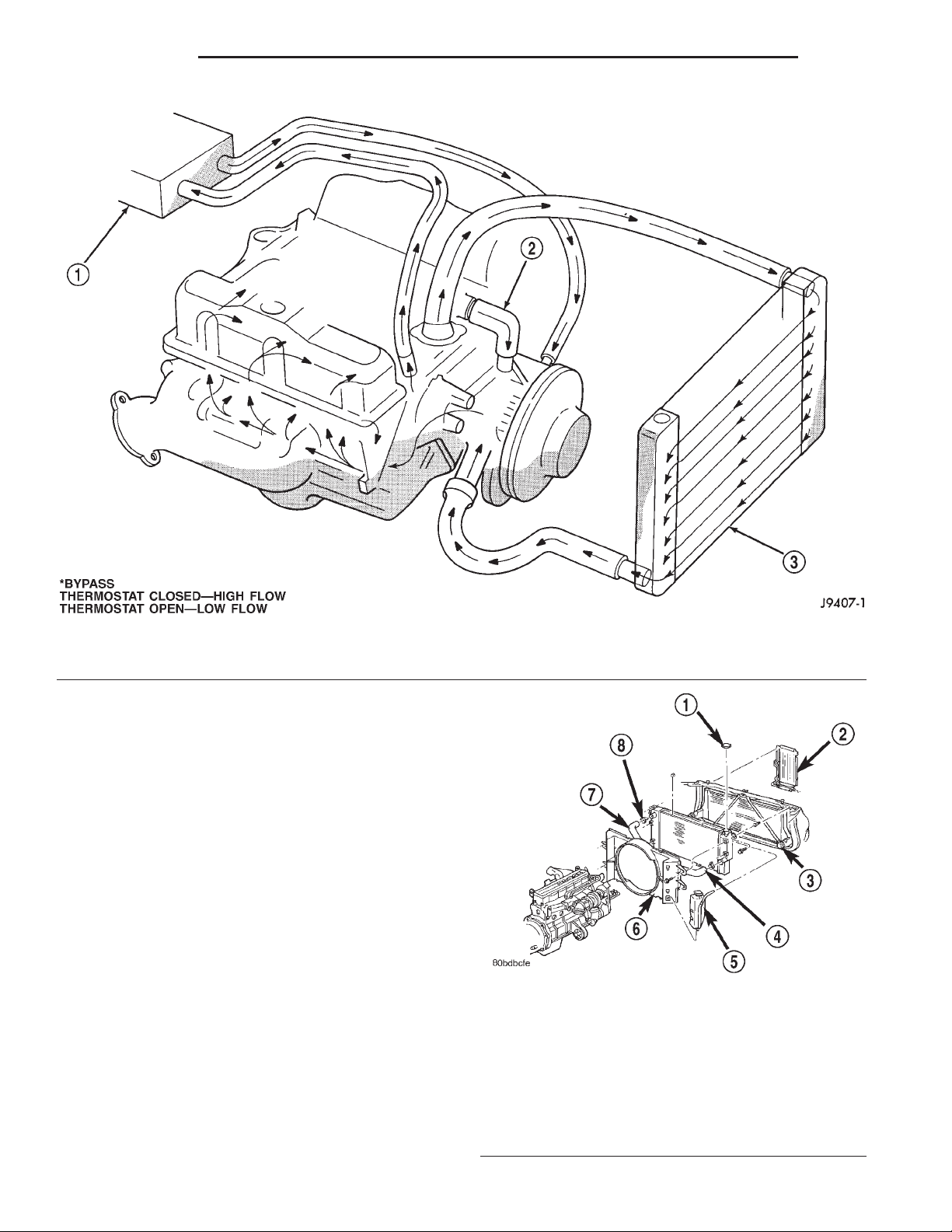

DESCRIPTION—COOLING SYSTEM FLOW -

5.9L DIESEL

The diesel engine cooling system consists of (Fig.

2):

• Cross-flow radiator

• Belt driven water pump

• Belt driven mechanical cooling fan

• Thermal viscous fan drive

• Fan shroud

• Radiator pressure cap

• Vertically mounted thermostat

• Coolant reserve/recovery system

• Transmission oil cooler

• Coolant

Coolant flow circuits for the 5.9L diesel engine are

shown in (Fig. 3).

3 - CROSSFLOW RADIATOR

Fig. 2 Cooling System Components 5.9L Diesel

Engine

1 - RADIATOR CAP

2 - AUXILIARY TRANSMISSION OIL COOLER

3 - CHARGE AIR COOLER

4 - RADIATOR LOWER HOSE

5 - OVERFLOW/RESERVOIR BOTTLE

6 - FAN SHROUD

7 - RADIATOR UPPER HOSE

8 - CONSTANT TENSION CLAMP

BR/BE COOLING 7 - 3

COOLING (Continued)

Fig. 3 Cooling System Circulation—Diesel Engine

7 - 4 COOLING BR/BE

COOLING (Continued)

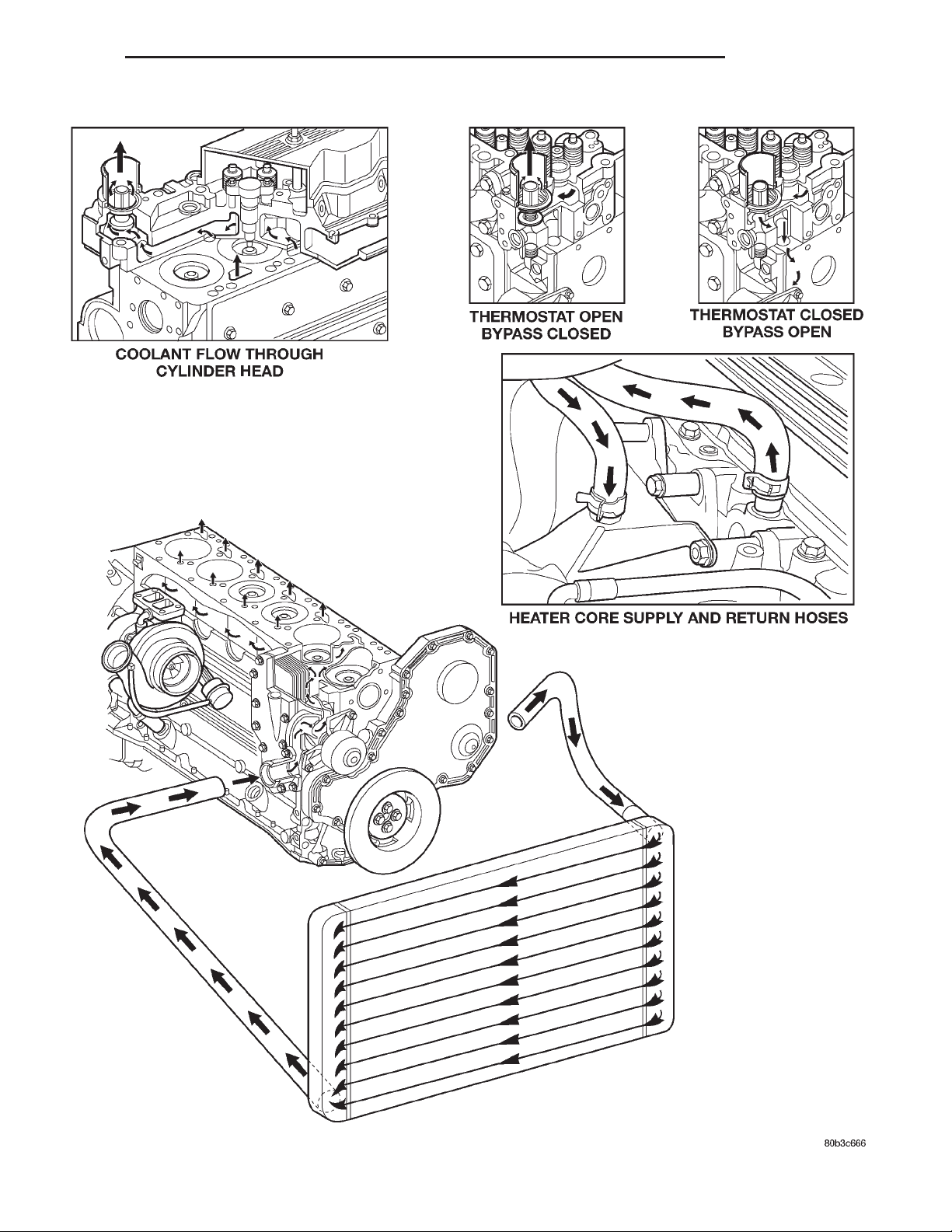

DESCRIPTION—HOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

replacement is necessary, replace with the original

Mopart equipment spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 4).

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the complaint. Abnormal loads on the cooling system such as

the following may be the cause:

• PROLONGED IDLE

• VERY HIGH AMBIENT TEMPERATURE

• SLIGHT TAIL WIND AT IDLE

• SLOW TRAFFIC

• TRAFFIC JAMS

• HIGH SPEED OR STEEP GRADES

Driving techniques that avoid overheating are:

• Idle with A/C off when temperature gauge is at

end of normal range.

• Increasing engine speed for more air flow is rec-

ommended.

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

OPERATION

OPERATION—HOSE CLAMPS

The worm type hose clamp uses a specified torque

value to maintain proper tension on a hose connection.

The spring type hose clamp applies constant tension on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

OPERATION—COOLING SYSTEM

The cooling system regulates engine operating temperature. It allows the engine to reach normal operating temperature as quickly as possible. It also

maintains normal operating temperature and prevents overheating.

The cooling system also provides a means of heating the passenger compartment and cooling the automatic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cooling package is available on most models. This pack-

TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

AIR CONDITIONING; ADD-ON OR AFTER MARKET:

A maximum cooling package should have been

ordered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system components should be installed for model involved per

manufacturer’s specifications.

RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been performed on vehicle that may effect cooling system.

This may be:

• Engine adjustments (incorrect timing)

• Slipping engine accessory drive belt(s)

• Brakes (possibly dragging)

• Changed parts. Incorrect water pump or pump

rotating in wrong direction due to belt not correctly

routed

• Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating complaint, (Refer to 7 - COOLING - DIAGNOSIS AND

TESTING)

BR/BE COOLING 7 - 5

COOLING (Continued)

DIAGNOSIS AND TESTING—ON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system components:

• If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diagnostic Trouble Code (DTC) can be set.

• If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM memory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIPTION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC’s and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIPTION).

Fig. 5 Leak Detection Using Black Light—Typical

1 - TYPICAL BLACK LIGHT TOOL

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service information for operation of the DRB scan tool.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling system. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temperature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examination.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radiator-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

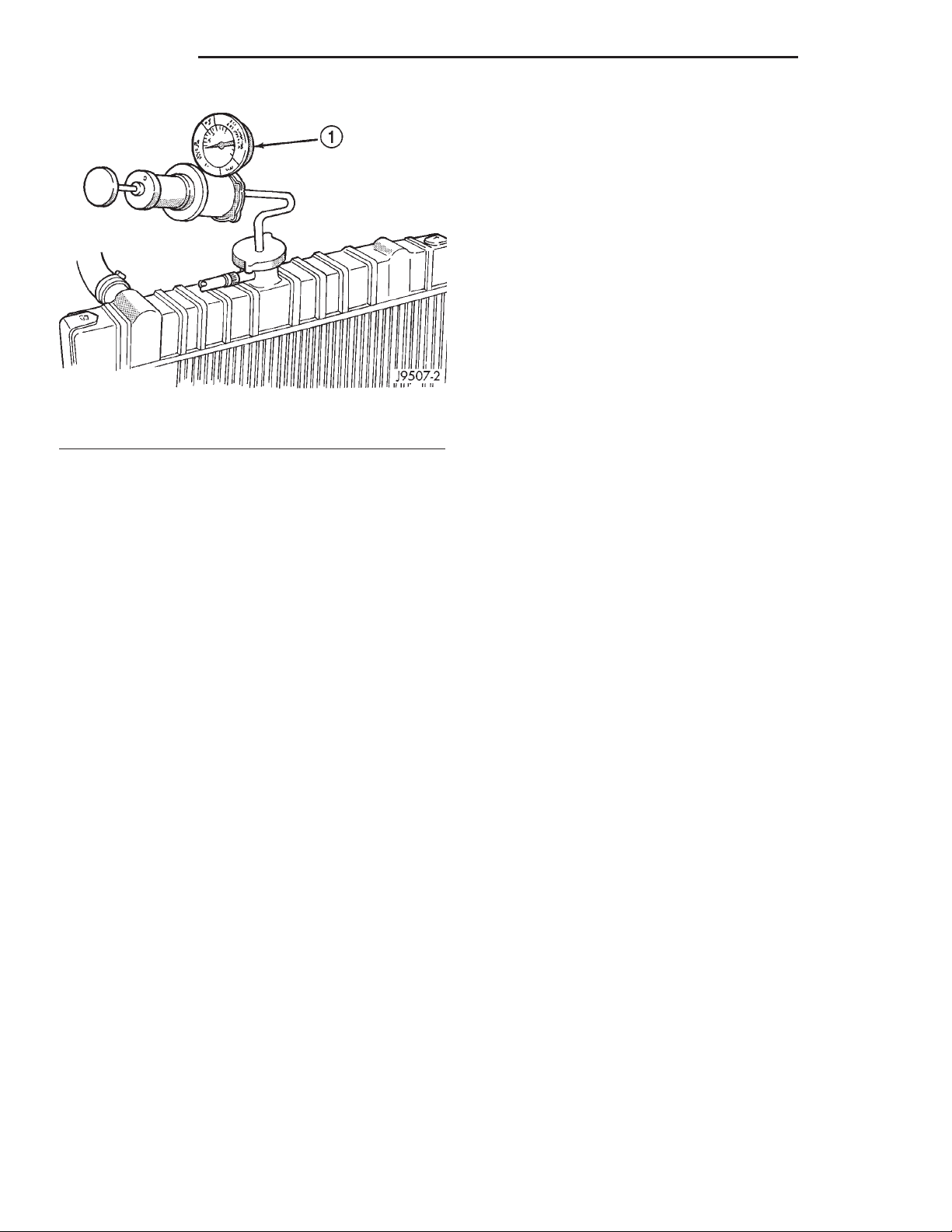

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling system according to following criteria:

Holds Steady: If pointer remains steady for two

minutes, serious coolant leaks are not present in system. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks cannot be detected, inspect for interior leakage or perform Internal Leakage Test.

Drops Slowly: Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

7 - 6 COOLING BR/BE

COOLING (Continued)

combustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter, do not remove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

Fig. 6 Pressure Testing Cooling System—Typical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly: Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water globules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRESSURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a

exhaust pipe may indicate a faulty cylinder head gasket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially available Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAINCOCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open draincock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bubbles do not appear, internal combustion gas leakage

is not present.

BR/BE COOLING 7 - 7

COOLING (Continued)

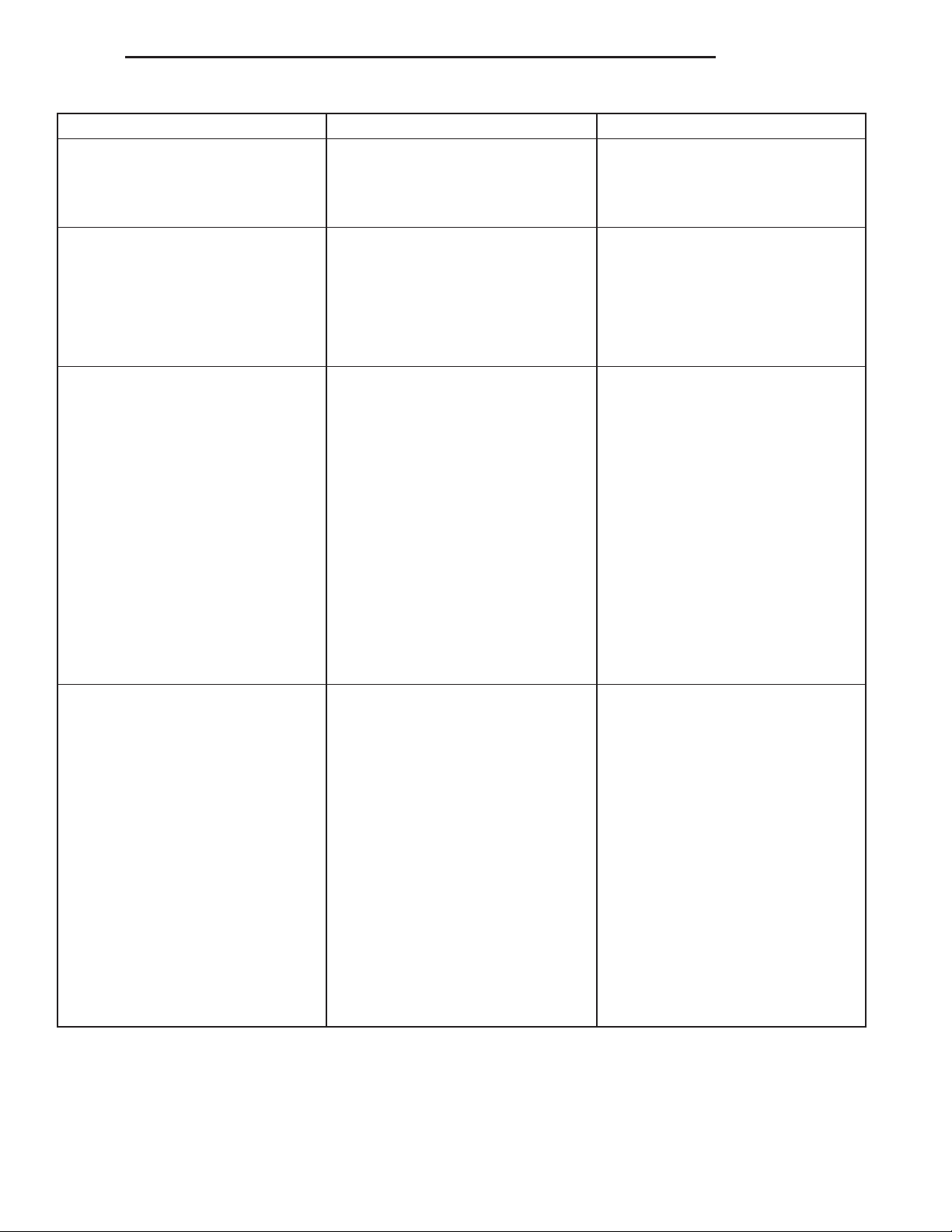

DIAGNOSIS AND TESTING - COOLING SYSTEM GAS ENGINE

COOLING SYSTEM DIAGNOSIS—GASOLINE ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

LOW

1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open thermostat?

2. Is the temperature sending unit

connected?

3. Is the temperature gauge

operating OK?

4. Coolant level low in cold ambient

temperatures accompanied with

poor heater performance.

5. Improper operation of internal

heater doors or heater controls.

1. (Refer to 25 - EMISSIONS

CONTROL - DESCRIPTION) for

On-Board Diagnostics and DTC

information. Replace thermostat if

necessary.

2. Check the temperature sensor

connector. (Refer to 8 ELECTRICAL/INSTRUMENT

CLUSTER - SCHEMATIC ELECTRICAL) Repair connector if

necessary.

3. Check gauge operation. (Refer to

8 - ELECTRICAL/INSTRUMENT

CLUSTER/ENGINE

TEMPERATURE GAUGE DESCRIPTION). Repair as

necessary.

4. Check coolant level in the coolant

reserve/overflow tank and the

radiator. Inspect system for leaks.

Repair leaks as necessary. Refer to

the Coolant section of the manual

text for WARNINGS and

CAUTIONS associated with

removing the radiator cap.

5. Inspect heater and repair as

necessary. (Refer to 24 - HEATING

& AIR CONDITIONING DIAGNOSIS AND TESTING) for

procedures.

7 - 8 COOLING BR/BE

COOLING (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

HIGH OR THE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST OR LEAKING FROM THE

COOLING SYSTEM

1. Trailer is being towed, a steep

hill is being climbed, vehicle is

operated in slow moving traffic, or

engine is being idled with very high

ambient (outside) temperatures and

the air conditioning is on. Higher

altitudes could aggravate these

conditions.

2. Is the temperature gauge reading

correctly?

3. Is the temperature warning

illuminating unnecessarily?

4. Coolant low in coolant reserve/

overflow tank and radiator?

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following Step 6.

6. Poor seals at the radiator cap. 6. (a) Check condition of cap and

7. Coolant level low in radiator but

not in coolant reserve/overflow

tank. This means the radiator is not

drawing coolant from the coolant

reserve/overflow tank as the engine

cools

1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and attempt to drive the

vehicle without any of the previous

conditions. Observe the temperature

gauge. The gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause for overheating

and repair. Refer to Possible

Causes (2-20).

2. Check gauge. (Refer to 8 ELECTRICAL/INSTRUMENT

CLUSTER - SCHEMATIC ELECTRICAL). Repair as

necessary.

3. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER SCHEMATIC - ELECTRICAL).

4. Check for coolant leaks and

repair as necessary. (Refer to 7 COOLING - DIAGNOSIS AND

TESTING).

5. Tighten cap

cap seals. Refer to Radiator Cap.

Replace cap if necessary.

(b) Check condition of radiator filler

neck. If neck is bent or damaged,

replace radiator.

7. (a) Check condition of radiator

cap and cap seals. Refer to

Radiator Cap in this Group. Replace

cap if necessary.

(b) Check condition of radiator filler

neck. If neck is bent or damaged,

replace radiator.

(c) Check condition of the hose from

the radiator to the coolant tank. It

should fit tight at both ends without

any kinks or tears. Replace hose if

necessary.

(d) Check coolant reserve/overflow

tank and tanks hoses for blockage.

Repair as necessary.

BR/BE COOLING 7 - 9

COOLING (Continued)

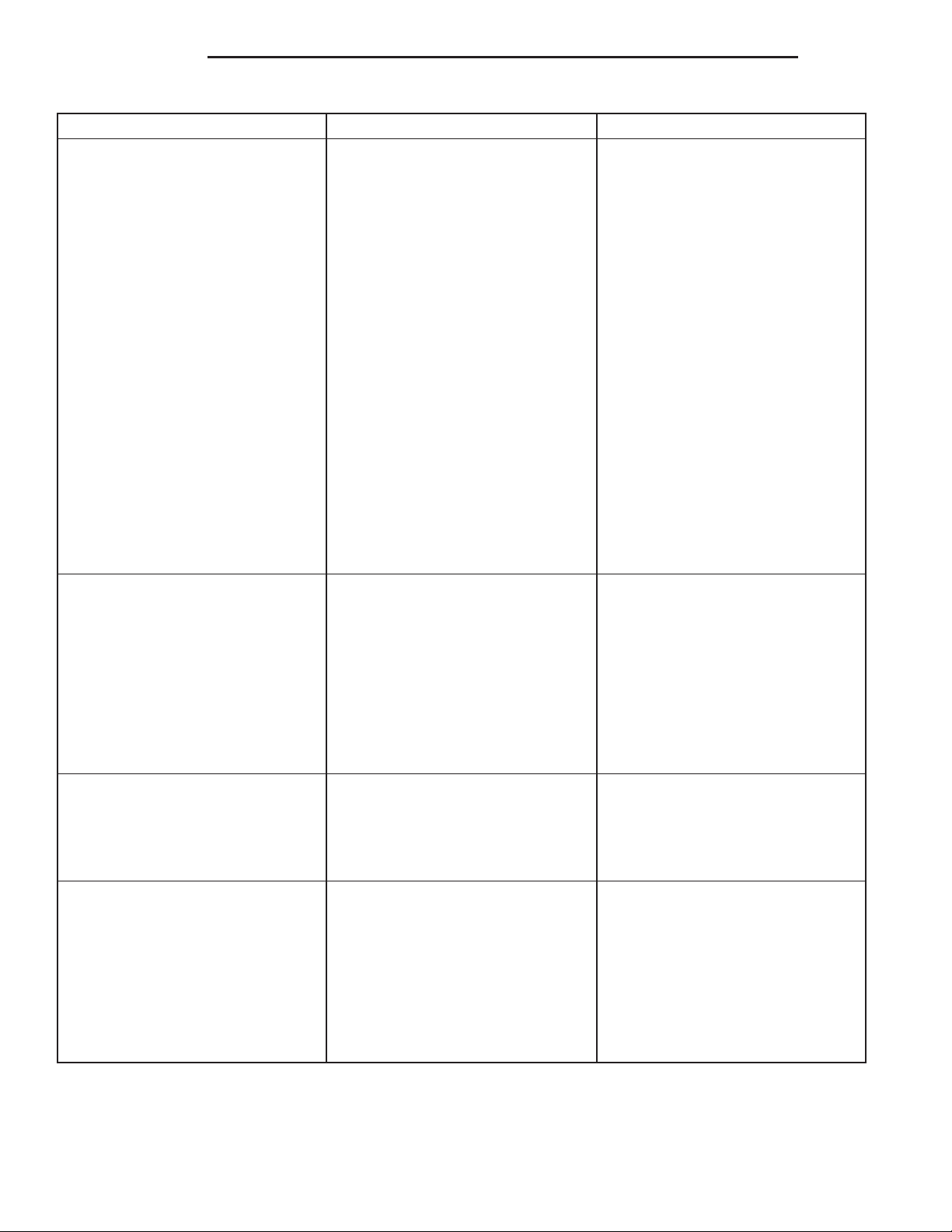

CONDITION POSSIBLE CAUSES CORRECTION

8. Incorrect coolant concentration 8. Check coolant. (Refer to

LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).

9. Coolant not flowing through

system

10. Radiator or A/C condenser fins

are dirty or clogged.

11. Radiator core is corroded or

plugged.

12. Aftermarket A/C installed

without proper radiator.

13. Fuel or ignition system

problems.

14. Dragging brakes. 14. Check and correct as

15. Bug screen or cardboard is

being used, reducing airflow.

16. Thermostat partially or

completely shut.

17. Viscous fan drive not operating

properly.

18. Cylinder head gasket leaking. 18. Check for cylinder head gasket

19. Heater core leaking. 19. Check heater core for leaks.

9. Check for coolant flow at radiator

filler neck with some coolant

removed, engine warm and

thermostat open. Coolant should be

observed flowing through radiator. If

flow is not observed, determine area

of obstruction and repair as

necessary.

10. Remove insects and debris.

(Refer to 7 - COOLING STANDARD PROCEDURE).

11. Have radiator re-cored or

replaced.

12. Install proper radiator.

13. Refer to 14 - Fuel System or 8 Electrical for diagnosis and testing

procedures.

necessary. (Refer to 5 - BRAKES DIAGNOSIS AND TESTING) for

correct procedures.

15. Remove bug screen or

cardboard.

16. Check thermostat operation and

replace as necessary. (Refer to 7 COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT REMOVAL).

17. Check fan drive operation and

replace as necessary. (Refer to 7 COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - REMOVAL).

leaks. (Refer to 7 - COOLING DIAGNOSIS AND TESTING).

(Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING DIAGNOSIS AND TESTING).

Repair as necessary.

7 - 10 COOLING BR/BE

COOLING (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READING

IS INCONSISTENT (FLUCTUATES,

CYCLES OR IS ERRATIC)

1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.

3. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running)

4. Gauge reading high after

re-starting a warmed up (hot)

engine.

5. Coolant level low in radiator (air

will build up in the cooling system

causing the thermostat to open

late).

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing a

thermostat to open late.

7. Water pump impeller loose on

shaft.

8. Loose accessory drive belt.

(water pump slipping)

9. Air leak on the suction side of

the water pump allows air to build

up in cooling system causing

thermostat to open late.

1. A normal condition. No correction

is necessary.

2. Check operation of gauge and

repair if necessary. (Refer to 8 ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING).

3. A normal condition. No correction

is necessary. Gauge should return

to normal range after vehicle is

driven.

4. A normal condition. No correction

is necessary. The gauge should

return to normal range after a few

minutes of engine operation.

5. Check and correct coolant leaks.

(Refer to 7 - COOLING DIAGNOSIS AND TESTING).

6. (a) Check for cylinder head

gasket leaks. (Refer to 7 COOLING - DIAGNOSIS AND

TESTING).

(b) Check for coolant in the engine

oil. Inspect for white steam emitting

from the exhaust system. Repair as

necessary.

7. Check water pump and replace

as necessary. (Refer to 7 COOLING/ENGINE/WATER PUMP REMOVAL).

8. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS

- DIAGNOSIS AND TESTING).

Check and correct as necessary.

9. Locate leak and repair as

necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT

TO COOLANT TANK.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK

1. Pressure relief valve in radiator

cap is defective.

1. Check condition of radiator cap

and cap seals. (Refer to 7 COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING). Replace cap as

necessary.

BR/BE COOLING 7 - 11

COOLING (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE READING

HIGH OR HOT

DETONATION OR PRE-IGNITION

(NOT CAUSED BY IGNITION

SYSTEM). GAUGE MAY OR MAY

NOT BE READING HIGH

HOSE OR HOSES COLLAPSE

WHILE ENGINE IS RUNNING

1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.

1. Engine overheating. 1. Check reason for overheating

2. Freeze point of coolant not

correct. Mixture is too rich or too

lean.

1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

reserve/overflow system.

1. Pressure test and repair as

necessary. (Refer to 7 - COOLING DIAGNOSIS AND TESTING).

and repair as necessary.

2. Check coolant concentration.

(Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES DESCRIPTION).

1. (a) Radiator cap relief valve

stuck. (Refer to 7 - COOLING/

ENGINE/RADIATOR PRESSURE

CAP - DIAGNOSIS AND TESTING).

Replace if necessary

(b) Hose between coolant

reserve/overflow tank and radiator is

kinked. Repair as necessary.

(c) Vent at coolant reserve/overflow

tank is plugged. Clean vent and

repair as necessary.

(d) Reserve/overflow tank is

internally blocked or plugged. Check

for blockage and repair as

necessary.

NOISY VISCOUS FAN/DRIVE 1. Fan blades loose. 1. Replace fan blade assembly.

(Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - REMOVAL)

2. Fan blades striking a surrounding

object.

3. Air obstructions at radiator or air

conditioning condenser.

4. Thermal viscous fan drive has

defective bearing.

5. A certain amount of fan noise

may be evident on models

equipped with a thermal viscous fan

drive. Some of this noise is normal.

2. Locate point of fan blade contact

and repair as necessary.

3. Remove obstructions and/or

clean debris or insects from radiator

or A/C condenser.

4. Replace fan drive. Bearing is not

serviceable. (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

5. (Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH DESCRIPTION) for an explanation

of normal fan noise.

7 - 12 COOLING BR/BE

COOLING (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

INADEQUATE HEATER

PERFORMANCE. THERMOSTAT

FAILED IN OPEN POSITION

STEAM IS COMING FROM THE

FRONT OF VEHICLE NEAR THE

GRILL AREA WHEN WEATHER IS

WET, ENGINE IS WARMED UP

AND RUNNING, AND VEHICLE IS

STATIONARY. TEMPERATURE

GAUGE IS IN NORMAL RANGE

1. Has a Diagnostic trouble Code

(DTC) been set?

2. Coolant level low 2. (Refer to 7 - COOLING -

3. Obstructions in heater hose/

fittings

4. Heater hose kinked 4. Locate kinked area and repair as

5. Water pump is not pumping

water to/through the heater core.

When the engine is fully warmed

up, both heater hoses should be

hot to the touch. If only one of the

hoses is hot, the water pump may

not be operating correctly or the

heater core may be plugged.

Accessory drive belt may be

slipping causing poor water pump

operation.

1. During wet weather, moisture

(snow, ice or rain condensation) on

the radiator will evaporate when the

thermostat opens. This opening

allows heated water into the

radiator. When the moisture

contacts the hot radiator, steam

may be emitted. This usually occurs

in cold weather with no fan or

airflow to blow it away.

1. (Refer to 25 - EMISSIONS

CONTROL - DESCRIPTION) for

correct procedures and replace

thermostat if necessary

DIAGNOSIS AND TESTING).

3. Remove heater hoses at both

ends and check for obstructions

necessary

5. (Refer to 7 - COOLING/ENGINE/

WATER PUMP - REMOVAL). If a

slipping belt is detected, (Refer to 7

- COOLING/ACCESSORY

DRIVE/DRIVE BELTS - DIAGNOSIS

AND TESTING). If heater core

obstruction is detected, (Refer to 24

- HEATING & AIR CONDITIONING/

PLUMBING/HEATER CORE REMOVAL).

1. Occasional steam emitting from

this area is normal. No repair is

necessary.

COOLANT COLOR 1. Coolant color is not necessarily

an indication of adequate corrosion

or temperature protection. Do not

rely on coolant color for determining

condition of coolant.

COOLANT LEVEL CHANGES IN

COOLANT RESERVE/OVERFLOW

TANK. TEMPERATURE GAUGE IS

IN NORMAL RANGE

1. Level changes are to be

expected as coolant volume

fluctuates with engine temperature.

If the level in the tank was between

the FULL and ADD marks at normal

operating temperature, the level

should return to within that range

after operation at elevated

temperatures.

1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES DESCRIPTION). Adjust coolant

mixture as necessary.

1. A normal condition. No repair is

necessary.

BR/BE COOLING 7 - 13

COOLING (Continued)

DIAGNOSIS AND TESTING - COOLING SYSTEM DIESEL ENGINE

COOLING SYSTEM DIAGNOSIS—DIESEL ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATUREGAUGE READS

LOW

TEMPERATURE GAUGE READS

HIGH. COOLANT MAY OR MAY

NOT BE LEAKING FROM SYSTEM

1. Vehicle is equipped with a heavy

duty cooling system.

2. Temperature gauge not

connected

3. Temperature gauge connected

but not operating.

4. Coolant level low. 4. Fill cooling system. (Refer to 7 -

1. Vehicle overloaded, high ambient

(outside) temperatures with A/C

turned on, stop and go driving or

prolonged operation at idle speeds.

2. Temperature gauge not

functioning correctly.

3. Air traped in cooling 3. Drain cooling system (Refer to 7 -

4. Radiator cap faulty. 4. Replace radiator cap.

5. Plugged A/C or radiator cooling

fins.

6. Coolant mixture incorrect. 6. Drain cooling system (Refer to 7 -

7. Thermostat stuck shut. 7. Replace thermostat.

8. Bug screen or winter front being

used.

9. Viscous fan drive not operating

properly.

10. Cylinder head gasket leaking. 10. Check for leaking head gaskets

11. Heater core leaking. 11. Replace heater core.

12. cooling system hoses leaking. 12. Tighten clamps or Replace

1. None. System operating normaly.

2. Connect gauge.

3. Check gauge. Refer (Refer to 8 ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

COOLING - STANDARD

PROCEDURE)

1. Temporary condition, repair not

required. Notify customer of vehicle

operation instructions located in

Owners Manual.

2. Check gauge. (Refer to 8 ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

COOLING - STANDARD

PROCEDURE) and refill (Refer to 7

- COOLING - STANDARD

PROCEDURE)

5. Clean all debre away from A/C

and radiator cooling fins.

COOLING - STANDARD

PROCEDURE) refill with correct

mixture (Refer to 7 - COOLING STANDARD PROCEDURE).

8. Remove bug screen or winter

front.

9. Check viscous fan (Refer to 7 COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

(Refer to 7 - COOLING DIAGNOSIS AND TESTING).

hoses.

7 - 14 COOLING BR/BE

COOLING (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

13. Brakes dragging. 13. Check brakes. (Refer to 5 BRAKES/HYDRAULIC/

MECHANICAL - DIAGNOSIS AND

TESTING)

TEMPERATURE GAUGE READING

INCONSISTENT ( ERRATIC,

CYCLES OR FLUCTUATES)

RADIATOR CAP LEAKING STEAM

AND /OR COOLANT INTO

RESERVOIR BOTTLE.

(TEMPERATURE GAUGE MAY

READ HIGH)

1. Heavy duty cooling system,

extream cold ambient (outside)

temperature or heater blower motor

in high position.

2. Temperature gauge or gauge

sensor defective.

3. Temporary heavy usage or load. 3. None. Normal condition.

4. Air traped in cooling system. 4. Fill cooling system (Refer to 7 -

5. Water pump 5. Replace water pump.

6. Air leak on suction side of water

pump.

1. Radiator cap defective. 1. Replace radiator cap.

2. Radiator neck surface damaged. 2. Replace radiator.

1. None. System operating normaly.

2. Check gauge. (Refer to 8 ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

COOLING - STANDARD

PROCEDURE).

6. Check for leak. (Refer to 7 COOLING - DIAGNOSIS AND

TESTING)

HOSE OR HOSES COLLAPSE

WHEN ENGINE IS COOLING.

NOISY FAN 1. Fan blade(s) loose, damaged. 1. Replace fan blade assembly.

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED)

1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

reservior/overflow system.

2. Thermal viscous fan drive. 2. None. Normal condition.

3. Fan blades striking surrounding

objects.

4. Thermal viscous fan drive

bearing.

5. Obstructed air flow through

radiator.

1. Radiator and/or A/C condenser

air flow obstructed.

1. Replace radiator cap, check vent

hose between radiator and reservoir

bottle for blockage also check

reservoir bottle vent for blockage.

3. Locate contact point and repair

as necessary.

4. Replace viscous fan drive

assembly.

5. Remove obstruction.

1. Remove obstruction and/or clean.

BR/BE COOLING 7 - 15

COOLING (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

2. Thermal viscous fan drive not

working.

3. Air seals around radiator

damaged or missing.

INADEQUATE HEATER

PERFORMANCE. GUAGE MAY OR

MAY NOT READ LOW.

HEAT ODOR 1. Damaged or missing drive line

1. Heavy duty cooling system, and

cooler ambient temperatures.

2. Obstruction in heater hoses. 2. Remove hoses, remove

3. Water pump damaged. 3. Replace water pump.

heat shields.

2. Thermal viscous fan drive

damaged.

STANDARD PROCEDURE

2. Check fan drive. (Refer to 7 COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

3. Inspect air seals, repair or

replace as necessary.

1. None. Normal condition.

obstruction.

1. Repair or replace damaged or

missing heat shields.

2. Check thermal viscous fan drive.

(Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH DIAGNOSIS AND TESTING)

STANDARD PROCEDURE - DRAINING COOLING

SYSTEM 5.9L/8.0L ENGINES

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAINCOCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

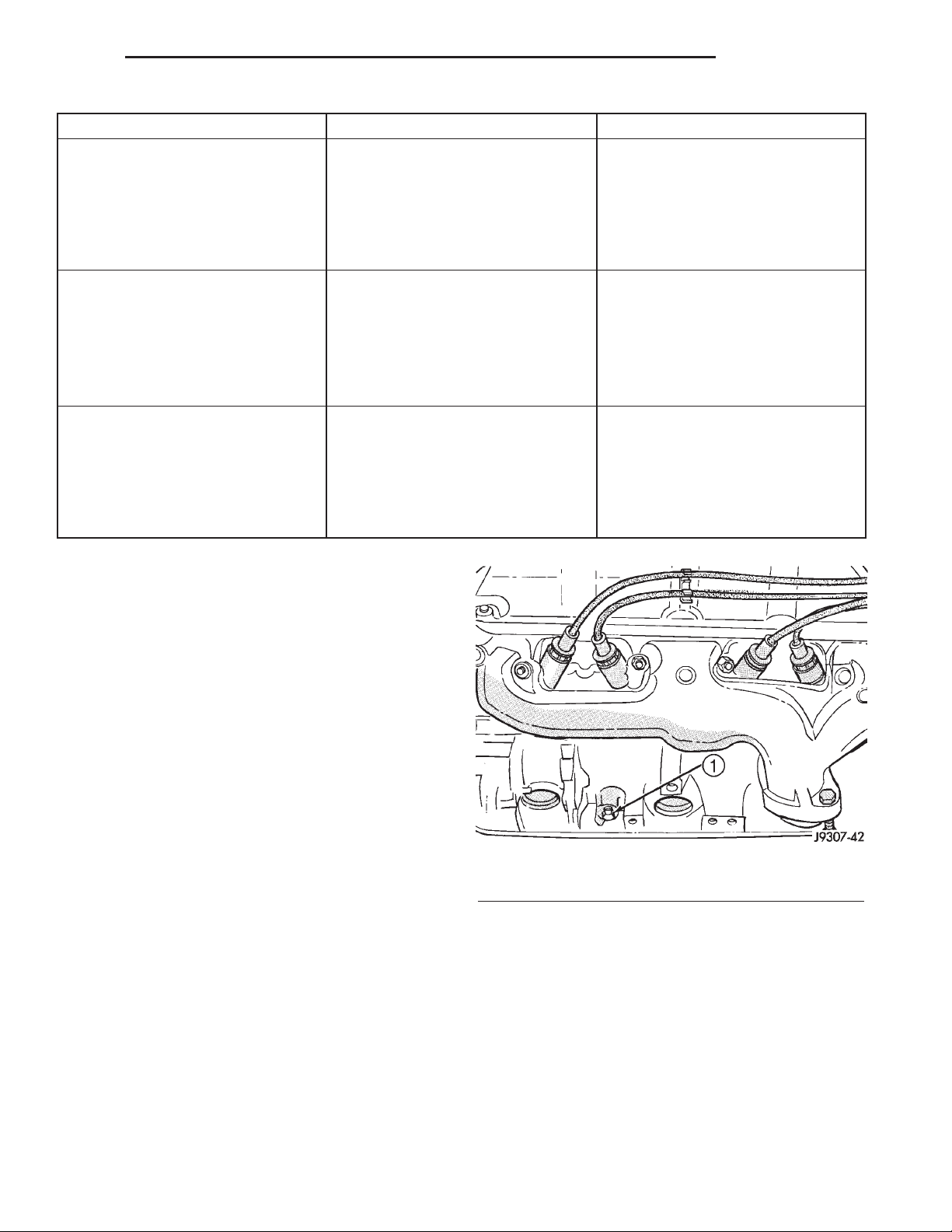

(1) Remove radiator pressure cap.

(2) Loosen radiator petcock.

(3) Remove cylinder block drain plugs. Refer to

(Fig. 7).

STANDARD PROCEDURE—DRAINING COOLING

SYSTEM 5.9L DIESEL ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN PLUG WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Start the engine and place the heater control

temperature selector in the Full-On position. Vacuum

is needed to actuate the heater controls.

Fig. 7 Cylinder Block Drain Plug - 5.9L Engines

1 - BLOCK DRAIN PLUG

(2) Turn the ignition off.

(3) Do not remove radiator cap when draining coolant from reserve/overflow tank. Open radiator drain

plug and when tank is empty, remove radiator cap. If

the coolant reserve/overflow tank does not drain,

(Refer to 7 - COOLING - DIAGNOSIS AND TESTING). The coolant need not be removed from tank

unless the system is being refilled with fresh mixture.

(4) Remove radiator pressure cap.

7 - 16 COOLING BR/BE

COOLING (Continued)

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 5.9L/8.0L ENGINES

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAINCOCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

Clean cooling system prior to refilling. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(1) Install cylinder block drain plugs. Coat the

threads with Mopart Thread Sealant with Teflon.

(2) Close radiator petcock.

(3) Fill cooling system with a 50/50 mixture of

water and antifreeze.

(4) Fill coolant reserve/overflow tank to FULL

mark on indicator stick.

(5) Start and operate engine until thermostat

opens (upper radiator hose warm to touch).

(6) If necessary, add a 50/50 water and antifreeze

mixture to the coolant reserve/overflow tank. This is

done to maintain coolant level between the FULL

and ADD marks. The level in the reserve/overflow

tank may drop below the ADD mark after three or

four warm-up and cool-down cycles.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only Mopart Antifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37°C (-35°F). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

STANDARD PROCEDURE—COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine coolant level inspections. The coolant level can be

checked at coolant recovery bottle.

STANDARD PROCEDURE—REFILLING

COOLING SYSTEM 5.9L DIESEL ENGINE

Clean cooling system prior to refilling (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(1) Close radiator drain plug.

CAUTION: Due to the use of the one-way check

valve, the engine must not be operating when refilling the cooling system.

NOTE: The diesel engine is equipped with a oneway check valve (jiggle pin). The check valve is

used as a servicing feature and will vent air when

the system is being filled. Water pressure (or flow)

will hold the valve closed.

(2) Fill the cooling system with a 50/50 mixture of

water and antifreeze.

(3) Fill coolant reserve/overflow tank to the FULL

mark.

(4) Start and operate engine until thermostat

opens. Upper radiator hose should be warm to touch.

(5) If necessary, add 50/50 water and antifreeze

mixture to the coolant reserve/overflow tank to maintain coolant level. This level should be between the

ADD and FULL marks. The level in the reserve/overflow tank may drop below the ADD mark after three

or four warm-up and cool-down cycles.

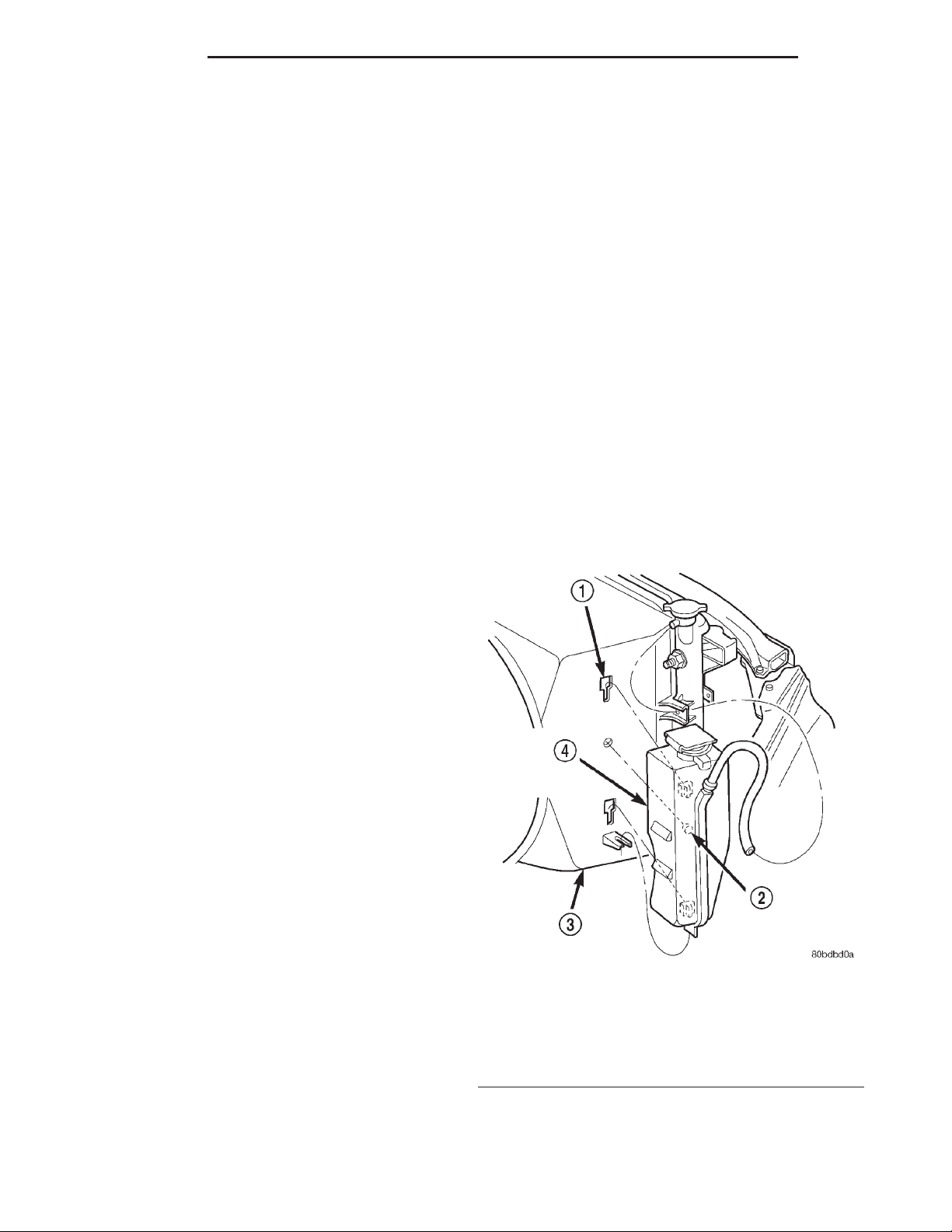

Fig. 8 COOLANT RESERVE/OVERFLOW TANK—ALL

EXCEPT 8.0L V-10 ENGINE

1 - T-SLOTS

2 - ALIGNMENT PIN

3 - FAN SHROUD

4 - COOLANT RESERVE/OVERFLOW TANK

BR/BE COOLING 7 - 17

COOLING (Continued)

The coolant reserve/overflow system provides a

quick method for determining coolant level without

removing radiator pressure cap. With engine not running, open the coolant recovery bottle cap and

remove coolant level indicator dipstick to observe

coolant level in coolant recovery bottle. The coolant

level should be between ADD and FULL marks. If

the coolant level is at or below the ADD mark, fill

the recovery bottle with a 50/50 mixture of antifreeze

and water ONE QUART AT A TIME. Repeat this procedure until the coolant level is at the FULL mark

(Fig. 8).

STANDARD PROCEDURE - COOLING SYSTEM

CLEANING/REVERSE FLUSHING

CLEANING

Drain cooling system and refill with water. Run

engine with radiator cap installed until upper radiator hose is hot. Stop engine and drain water from

system. If water is dirty, fill system with water, run

engine and drain system. Repeat until water drains

clean.

REVERSE FLUSHING

Reverse flushing of cooling system is the forcing of

water through the cooling system. This is done using

air pressure in the opposite direction of normal coolant flow. It is usually only necessary with very dirty

systems with evidence of partial plugging.

REVERSE FLUSHING ENGINE

Drain cooling system. Remove thermostat housing

and thermostat. Install thermostat housing. Disconnect radiator upper hose from radiator and attach

flushing gun to hose. Disconnect radiator lower hose

from water pump and attach a lead-away hose to

water pump inlet fitting.

CAUTION: On vehicles equipped with a heater water

control valve, be sure heater control valve is closed

(heat off). This will prevent coolant flow with scale

and other deposits from entering heater core.

Connect water supply hose and air supply hose to

flushing gun. Allow engine to fill with water. When

engine is filled, apply air in short blasts, allowing

system to fill between air blasts. Continue until clean

water flows through the lead away hose.

Remove lead away hose, flushing gun, water supply hose and air supply hose. Remove thermostat

housing and install thermostat. Install thermostat

housing with a replacement gasket. Refer to Thermostat Replacement. Connect radiator hoses. Refill cooling system with correct antifreeze/water mixture.

Refer to Refilling the Cooling System.

CHEMICAL CLEANING

In some instances, use a radiator cleaner (Mopar

Radiator Kleen or equivalent) before flushing. This

will soften scale and other deposits and aid flushing

operation.

REVERSE FLUSHING RADIATOR

Disconnect radiator hoses from radiator inlet and

outlet. Attach a section of radiator hose to radiator

bottom outlet fitting and insert flushing gun. Connect a water supply hose and air supply hose to

flushing gun.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result.

Allow radiator to fill with water. When radiator is

filled, apply air in short blasts. Allow radiator to

refill between blasts. Continue this reverse flushing

until clean water flows out through rear of radiator

cooling tube passages. Have radiator cleaned more

extensively by a radiator repair shop.

CAUTION: Follow manufacturers instructions when

using these products.

STANDARD PROCEDURE - COOLANT

SELECTION - ADDITIVES

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only Mopart Antifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37°C (-35°F). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

7 - 18 COOLING BR/BE

COOLING (Continued)

SPECIFICATIONS

TORQUE

DESCRIPTION N·m Ft. In.

Lbs. Lbs

Belt Tensioner Pulley 5.9L

Engine-Bolt 61 45 —

Belt Tensioner Pulley 8.0L

Engine—

Bolt 88 65 —

Belt Tensioner to Mounting

Bracket—

Bolt 5.9L Engine 67 50 —

Belt Tensioner to Mounting

Bracket—

Bolt 8.0L Engine 41 30 —

Block Heater—Screw Gas

Engines

Block Heater—Hex Diesel

Engine

Fan Shroud to Radiator

Mounting—

Bolts 6 — 50

Heater Hose Fitting at Water

Pump—(8.0L) 16 — 142

Idler Pulley Mounting—Bolts

Gas Engines 61 45 —

Radiator Mounting—Bolts 11 — 95

Thermal Viscous Fan to

Hub—(Diesel)

Thermostat Housing—Bolts

5.9L 23 — 200

Thermostat Housing—Bolts

8.0L

Thermostat Housing—Bolts

Diesel

Water Pump Mounting—Bolts

Gas Engines 40 30 —

Water Pump Mounting—Bolts

Diesel

2—17

43 32 —

57 42 —

25 — 220

24 — 212

24 — 212

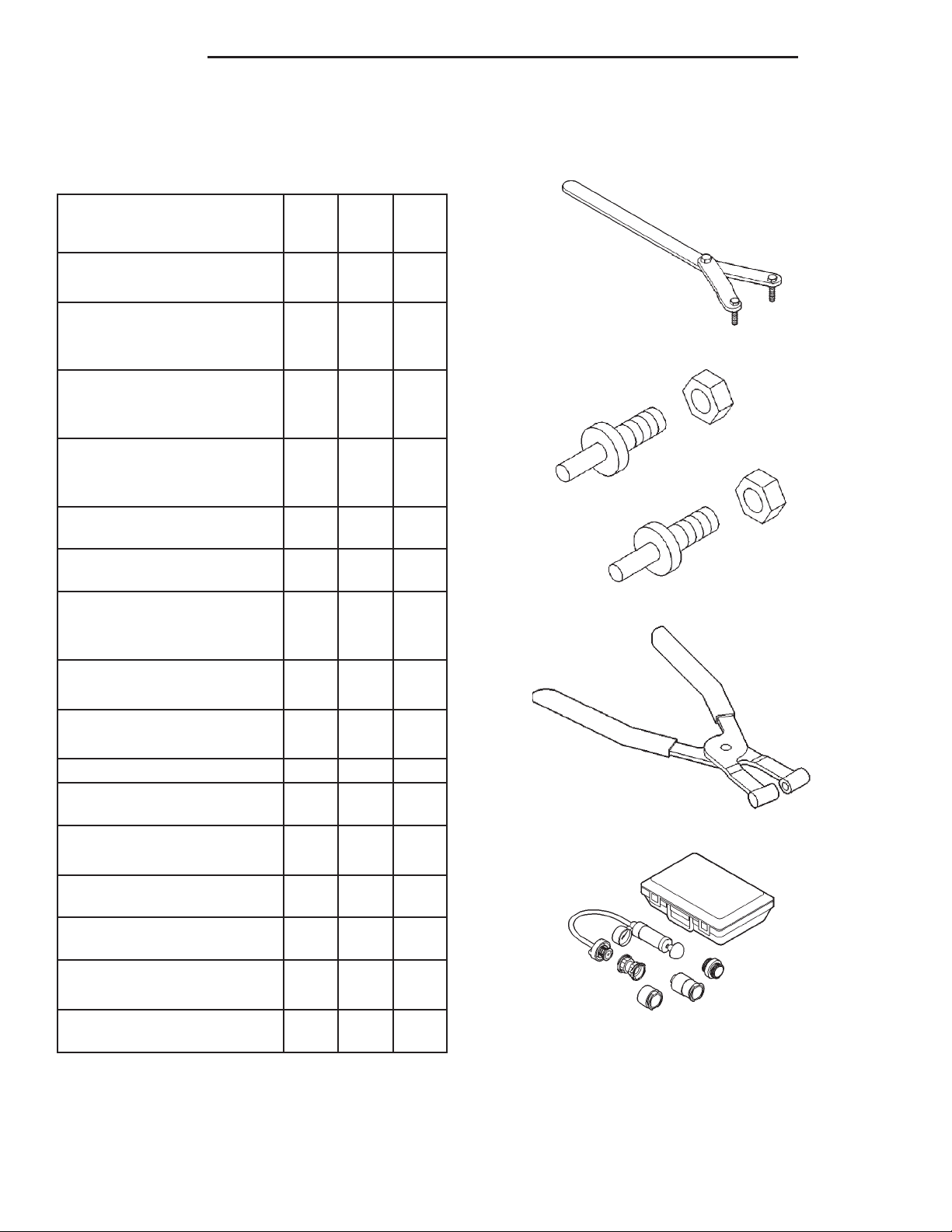

SPECIAL TOOLS

COOLING

SPANNER WRENCH 6958

Adapter Pins 8346

Pliers 6094

Pressure Tester 7700–A

BR/BE ACCESSORY DRIVE 7 - 19

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

BELT TENSIONERS - 5.9L

DESCRIPTION .........................19

OPERATION ...........................19

REMOVAL .............................19

INSTALLATION .........................20

BELT TENSIONERS - 8.0L

DESCRIPTION .........................20

OPERATION ...........................21

REMOVAL .............................21

INSTALLATION .........................22

BELT TENSIONERS - 5.9L DIESEL

DESCRIPTION .........................23

OPERATION ...........................23

REMOVAL .............................23

INSTALLATION .........................23

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT .........................24

REMOVAL .............................26

BELT TENSIONERS - 5.9L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine accessories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capacity, reduced generator output rate, and greatly

reduced belt life.

It is not necessary to adjust belt tension on the

5.9L engines. These engines are equipped with an

automatic belt tensioner (Fig. 1). The tensioner maintains correct belt tension at all times. Due to use of

this belt tensioner, do not attempt to use a belt tension gauge on 5.9L engines.

INSTALLATION .........................26

DRIVE BELTS - 8.0L

DIAGNOSIS AND TESTING—ACCESSORY

DRIVE BELT .........................27

REMOVAL .............................29

INSTALLATION .........................29

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTING—ACCESSORY

DRIVE BELT .........................30

REMOVAL .............................32

INSTALLATION .........................32

VACUUM PUMP - 5.9L DIESEL

DESCRIPTION .........................33

OPERATION ...........................34

DIAGNOSIS AND TESTING—VACUUM PUMP

OUTPUT ............................34

REMOVAL .............................34

INSTALLATION .........................36

Fig. 1 Automatic Belt Tensioner - 5.9L Engines

1 - AUTOMATIC TENSIONER

2 - COIL AND BRACKET

3 - SCREW AND WASHER

OPERATION

The automatic belt tensioner maintains belt tension by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRESSURE, DO NOT ATTEMPT TO DISASSEMBLE AUTOMATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

(1) Remove accessory drive belt. (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS REMOVAL).

(2) Disconnect wiring and secondary cable from

ignition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts). Do not remove coil mounting

bracket from cylinder head.

7 - 20 ACCESSORY DRIVE BR/BE

BELT TENSIONERS - 5.9L (Continued)

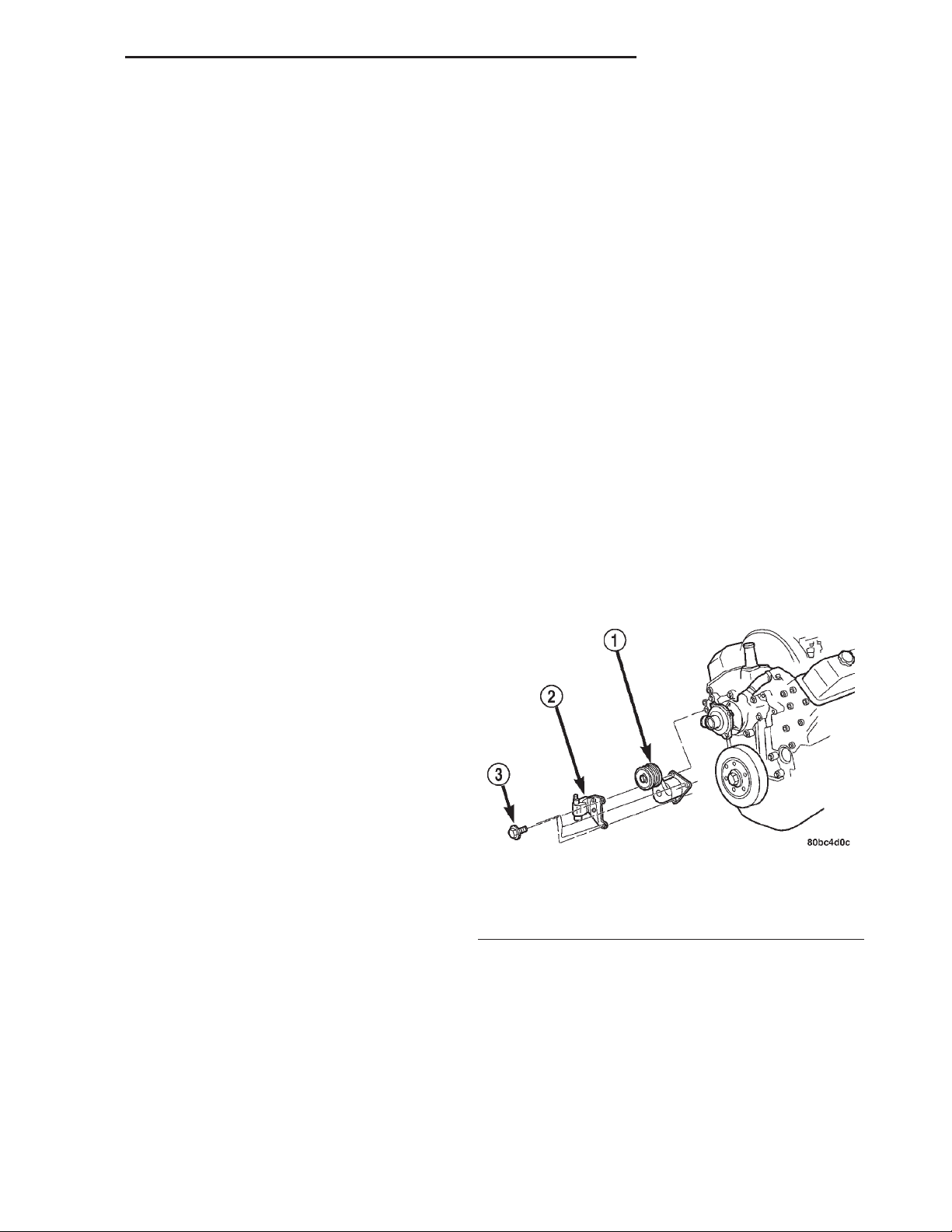

(4) Remove tensioner assembly from mounting

bracket (one nut) (Fig. 2).

(4) Install coil to coil bracket. If nuts and bolts are

used to secure coil to coil bracket, tighten to 11 N·m

(100 in. lbs.) torque. If coil mounting bracket has

been tapped for coil mounting bolts, tighten bolts to 5

N·m (50 in. lbs.) torque.

(5) Install drive belt. (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

(6) Check belt indexing marks (Fig. 2).

BELT TENSIONERS - 8.0L

DESCRIPTION

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

Drive belts on 8.0L engines are equipped with a

spring loaded automatic belt tensioner (Fig. 3) This

belt tensioner will be used with all belt configurations, such as with or without power steering or air

conditioning.

The tensioner is equipped with an indexing arrow

(Fig. 4) on back of tensioner and an indexing mark

on tensioner housing.

Fig. 2 Tensioner Indexing Marks and Mounting Nut

1 - TENSIONER ASSEMBLY

2 - TENSIONER MOUNTING NUT

3 - INDEXING ARROW

4 - INDEXING MARK

(5) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N·m (45 ft. lbs.) torque.

(2) Install tensioner assembly to mounting

bracket. An indexing tab is located on back of tensioner. Align this tab to slot in mounting bracket.

Tighten nut to 67 N·m (50 ft. lbs.) torque.

(3) Connect all wiring to ignition coil.

CAUTION: To prevent damage to coil case, coil

mounting bolts must be torqued.

Fig. 3 Belt Tensioner—8.0L V-10 Engines

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

BR/BE ACCESSORY DRIVE 7 - 21

BELT TENSIONERS - 8.0L (Continued)

• Belt incorrectly routed.

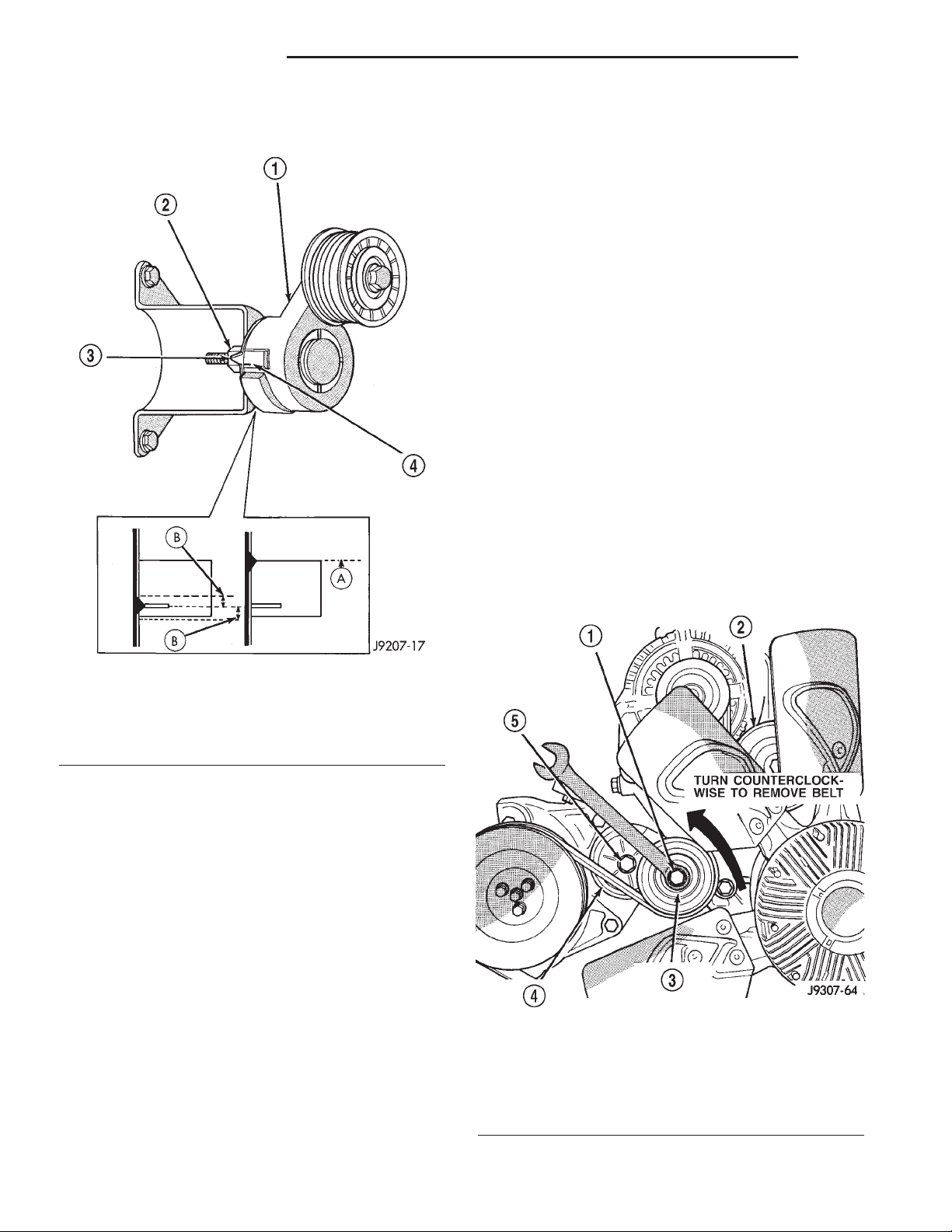

A used belt should be replaced if tensioner indexing arrow has moved to point-A (Fig. 5). Tensioner

travel stops at point-A.

Fig. 4 Indexing Marks—8.0L Engines Typical

1 - TENSIONER ASSEMBLY

2 - TENSIONER MOUNTING NUT

3 - INDEXING ARROW

4 - INDEXING MARK

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

If a new belt is being installed, the arrow must be

within approximately 3 mm (1/8 in.) of indexing

mark (point B-) (Fig. 5). Belt is considered new if it

has been used 15 minutes or less. If this specification

cannot be met, check for:

• The wrong belt being installed (incorrect length/

width)

• Worn bearings on an engine accessory (A/C compressor, power steering pump, water pump, idler pulley or generator)

• A pulley on an engine accessory being loose

• Misalignment of an engine accessory

Fig. 5 Indexing Marks—8.0L Engines Typical

1 - TENSIONER ASSEMBLY

2 - TENSIONER MOUNTING NUT

3 - INDEXING ARROW

4 - INDEXING MARK

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRESSURE, DO NOT ATTEMPT TO DISASSEMBLE AUTOMATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

CAUTION: If the pulley is to be removed from the

tensioner, its mounting bolt has left-hand threads.

(1) Remove accessory drive belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS REMOVAL).

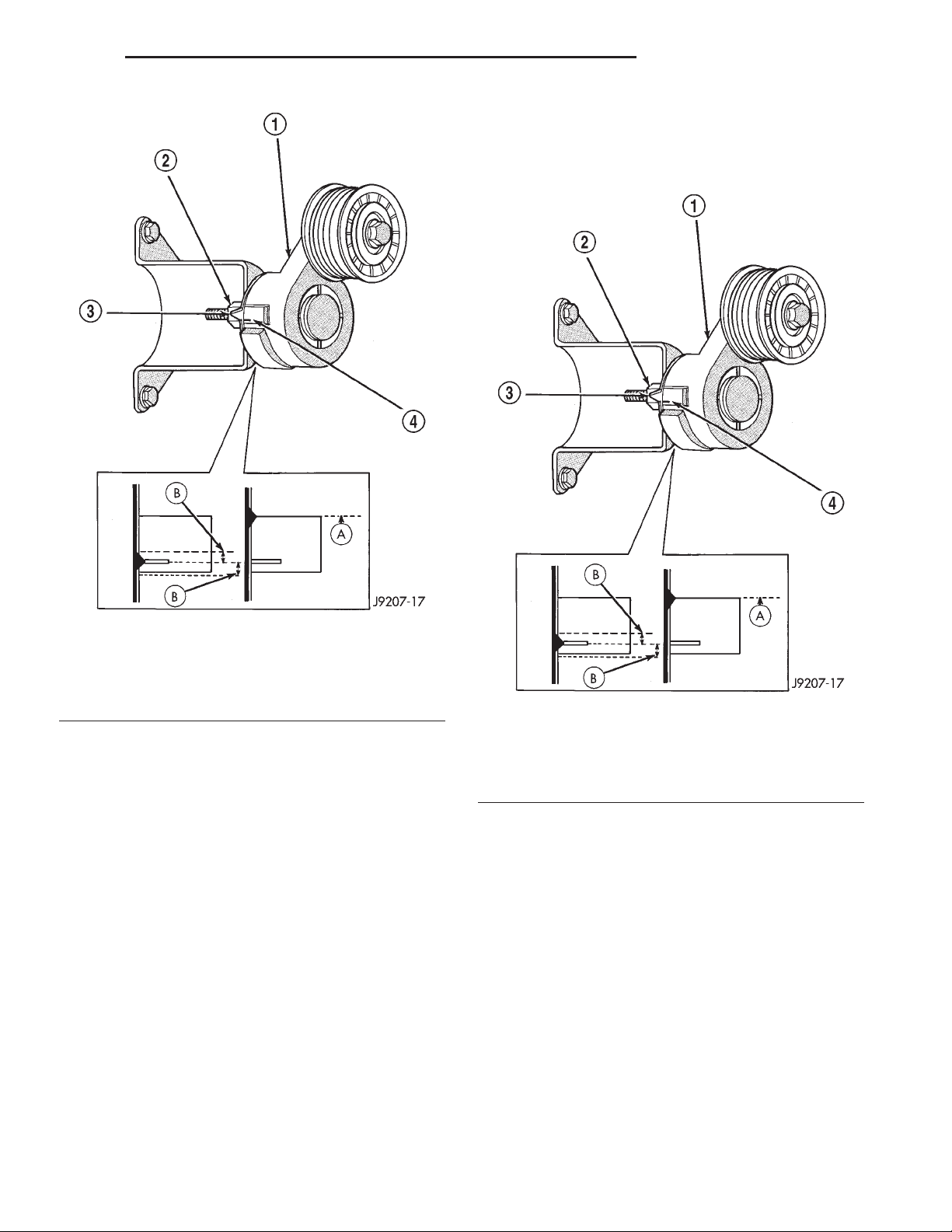

(2) Remove tensioner mounting bolt (Fig. 6) and

remove tensioner.

7 - 22 ACCESSORY DRIVE BR/BE

BELT TENSIONERS - 8.0L (Continued)

Fig. 7 Tensioner Dowel Pin

1 - BELT TENSIONER

2 - DOWEL PIN

Fig. 6 Belt Tensioner

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

INSTALLATION

CAUTION: If the pulley is to be removed from the

tensioner, its mounting bolt has left-hand threads.

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 88 N·m (65 ft. lbs.) torque.

(2) Install tensioner assembly to mounting

bracket. A dowel pin is located on back of tensioner

(Fig. 7). Align this to dowel hole (Fig. 8) in tensioner

mounting bracket. Tighten bolt to 41 N·m (30 ft. lbs.)

torque.

(3) Install drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

Fig. 8 Tensioner Dowel Hole

1 - DOWEL PIN HOLE

2 - TENSIONER MOUNTING BRACKET

BR/BE ACCESSORY DRIVE 7 - 23

BELT TENSIONERS - 5.9L

DIESEL

DESCRIPTION

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

• Worn bearings on an engine accessory (A/C compressor, power steering pump, water pump, idler pulley or generator)

• A pulley on an engine accessory being loose

• Misalignment of an engine accessory

• Belt incorrectly routed.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRESSURE, DO NOT ATTEMPT TO DISASSEMBLE AUTOMATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS REMOVAL).

(2) Remove tensioner mounting bolt (Fig. 10) and

remove tensioner.

Fig. 9 Belt

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89 SQUARE BOLT

5 - MOUNT. BOLT

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

If a new belt is being installed, the arrow must be

within approximately 3 mm (1/8 in.) of indexing

mark. Belt is considered new if it has been used 15

minutes or less. If this specification cannot be met,

check for:

• The wrong belt being installed (incorrect length/

width)

Fig. 10 Automatic Belt Tensioner Diesel Engine—

Typical

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89 SQUARE BOLT

5 - MOUNT. BOLT

INSTALLATION

(1) Install tensioner assembly to mounting

bracket. A dowel is located on back of tensioner. Align

this dowel to hole in tensioner mounting bracket.

Tighten bolt to 41 N·m (30 ft. lbs.) torque.

(2) Install drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

7 - 24 ACCESSORY DRIVE BR/BE

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

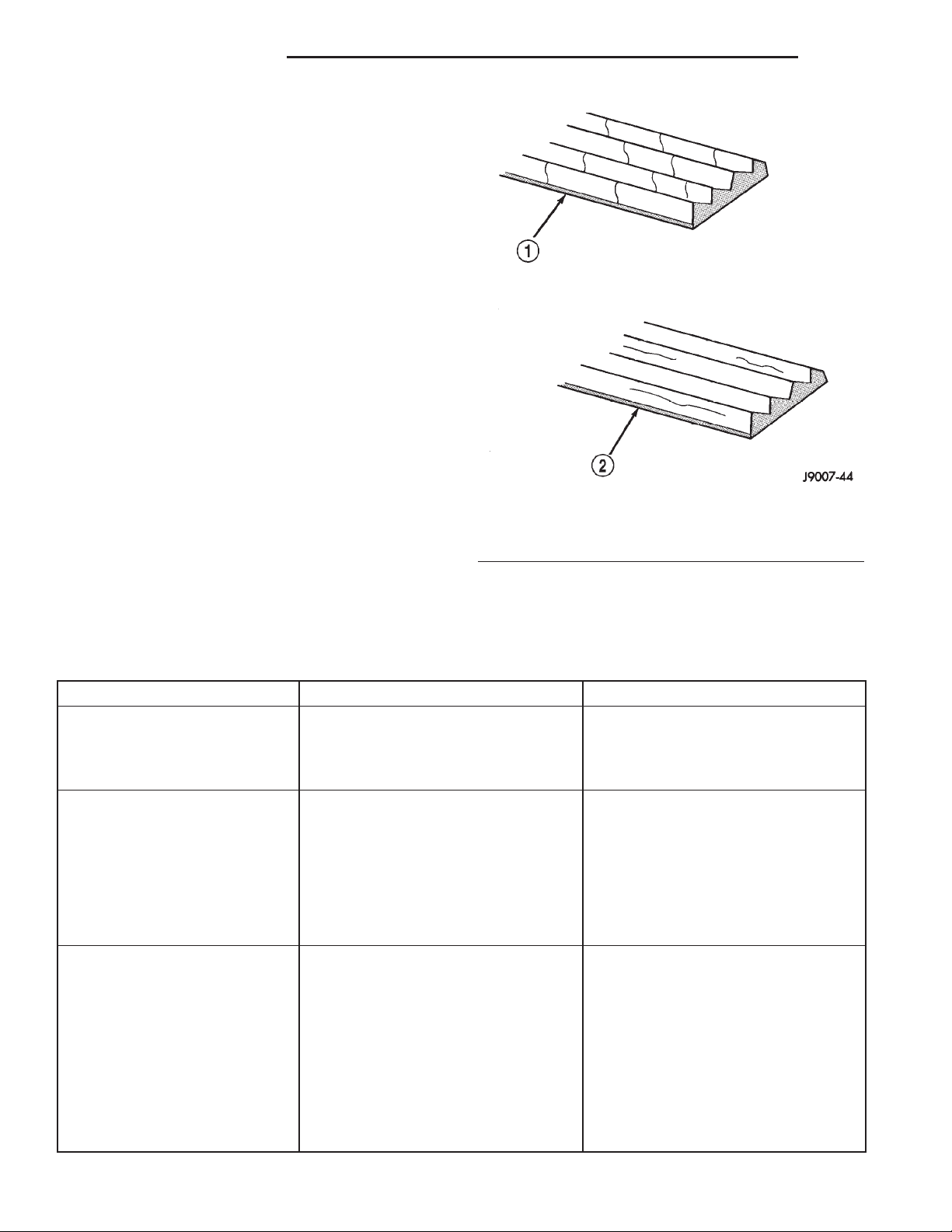

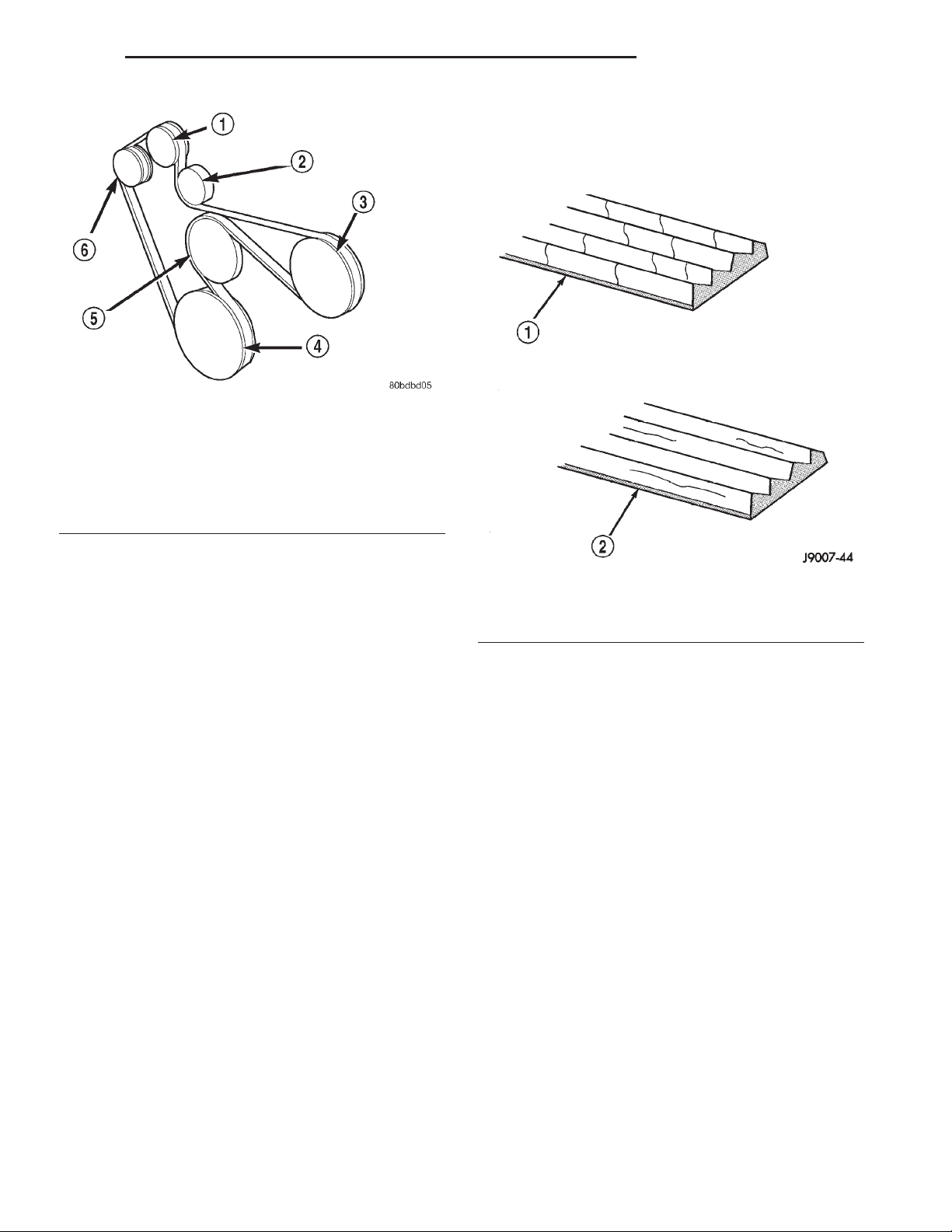

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 11), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) are not normal. Any belt with cracks running along a rib must

be replaced (Fig. 11). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

Fig. 11 Belt Wear Patterns

ACCESSORY DRIVE BELT DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

RIB CHUNKING (One or more

ribs has separated from belt

body)

RIB OR BELT WEAR 1. Pulley misaligned 1. Align pulley(s)

BELT SLIPS 1. Belt slipping because of insufficient

1. Foreign objects imbedded in pulley

grooves.

2. Installation damage 2. Replace belt

2. Abrasive environment 2. Clean pulley(s). Replace belt if

3. Rusted pulley(s) 3. Clean rust from pulley(s)

4. Sharp or jagged pulley groove tips 4. Replace pulley. Inspect belt.

5. Belt rubber deteriorated 5. Replace belt

tension

2. Belt or pulley exposed to

substance that has reduced friction

(belt dressing, oil, ethylene glycol)

3. Driven component bearing failure

(seizure)

4. Belt glazed or hardened from heat

and excessive slippage

1. Remove foreign objects from pulley

grooves. Replace belt.

necessary

1. Inspect/Replace tensioner if

necessary

2. Replace belt and clean pulleys

3. Replace faulty component or

bearing

4. Replace belt.

BR/BE ACCESSORY DRIVE 7 - 25

DRIVE BELTS - 5.9L (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

LONGITUDAL BELT

CRACKING

9GROOVE JUMPING9

(Belt does not maintain correct

position on pulley)

BELT BROKEN

(Note: Identify and correct

problem before new belt is

installed)

1. Belt has mistracked from pulley

groove

2. Pulley groove tip has worn away

rubber to tensile member

1. Incorrect belt tension 1. Inspect/Replace tensioner if

2. Pulley(s) not within design

tolerance

3. Foreign object(s) in grooves 3. Remove foreign objects from

4. Pulley misalignment 4. Align component

5. Belt cordline is broken 5. Replace belt

1. Incorrect belt tension 1. Replace Inspect/Replace tensioner

2. Tensile member damaged during

belt installation

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing failure 4. Replace defective component and

1. Replace belt

2. Replace belt

necessary

2. Replace pulley(s)

grooves

if necessary

2. Replace belt

belt

NOISE

(Objectionable squeal, squeak,

or rumble is heard or felt while

drive belt is in operation)

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has

cracked or separated from body

of belt)

CORD EDGE FAILURE

(Tensile member exposed at

edges of belt or separated from

belt body)

1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration

1. Tension sheeting contacting

stationary object

2. Excessive heat causing woven

fabric to age

3. Tension sheeting splice has

fractured

1. Incorrect belt tension 1. Inspect/Replace tensioner if

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix

5. Locate defective driven component

and repair

1. Correct rubbing condition

2. Replace belt

3. Replace belt

necessary

4. Replace belt

7 - 26 ACCESSORY DRIVE BR/BE

DRIVE BELTS - 5.9L (Continued)

REMOVAL

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these schematics and the Belt Routing Label, use the schematics on Belt Routing Label. This label is located

in the engine compartment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

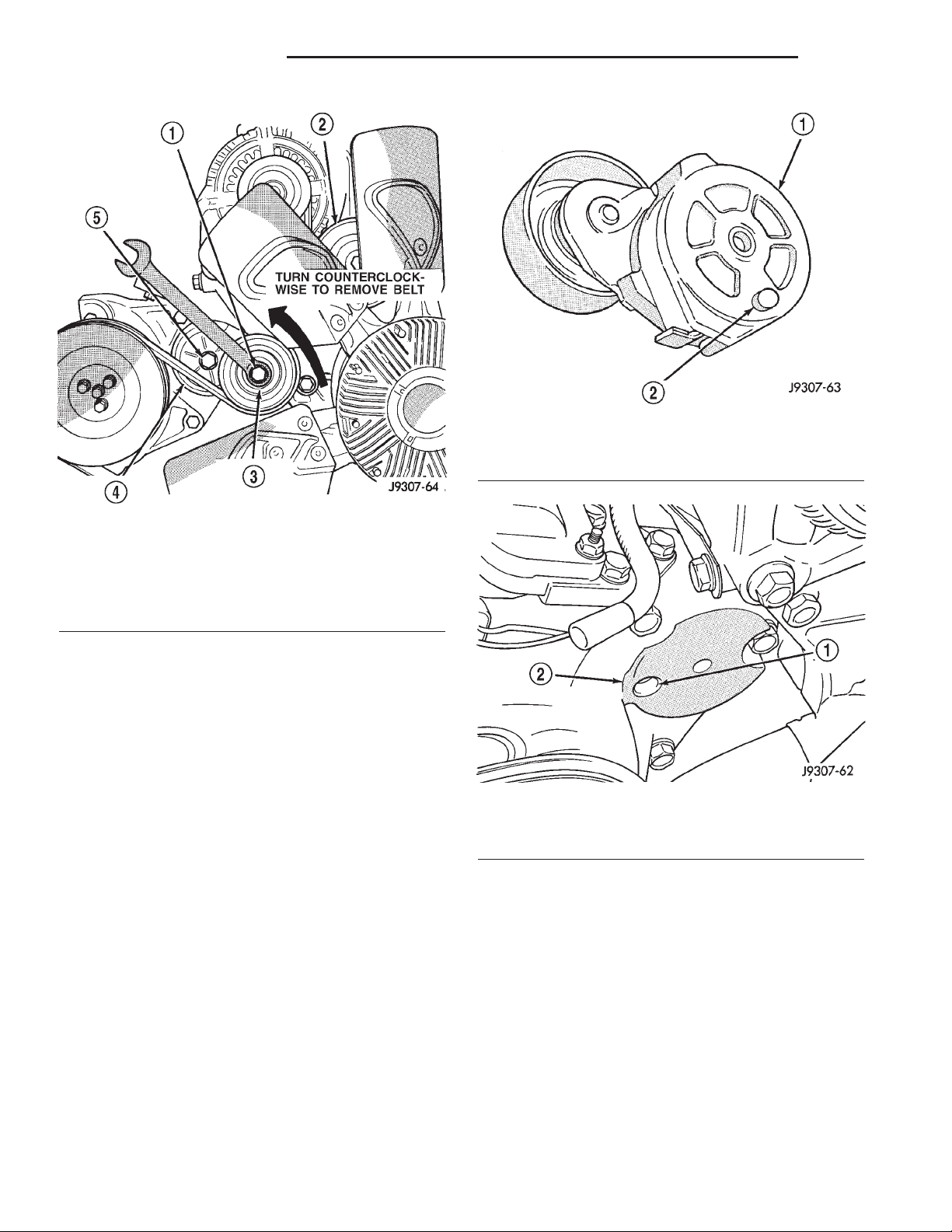

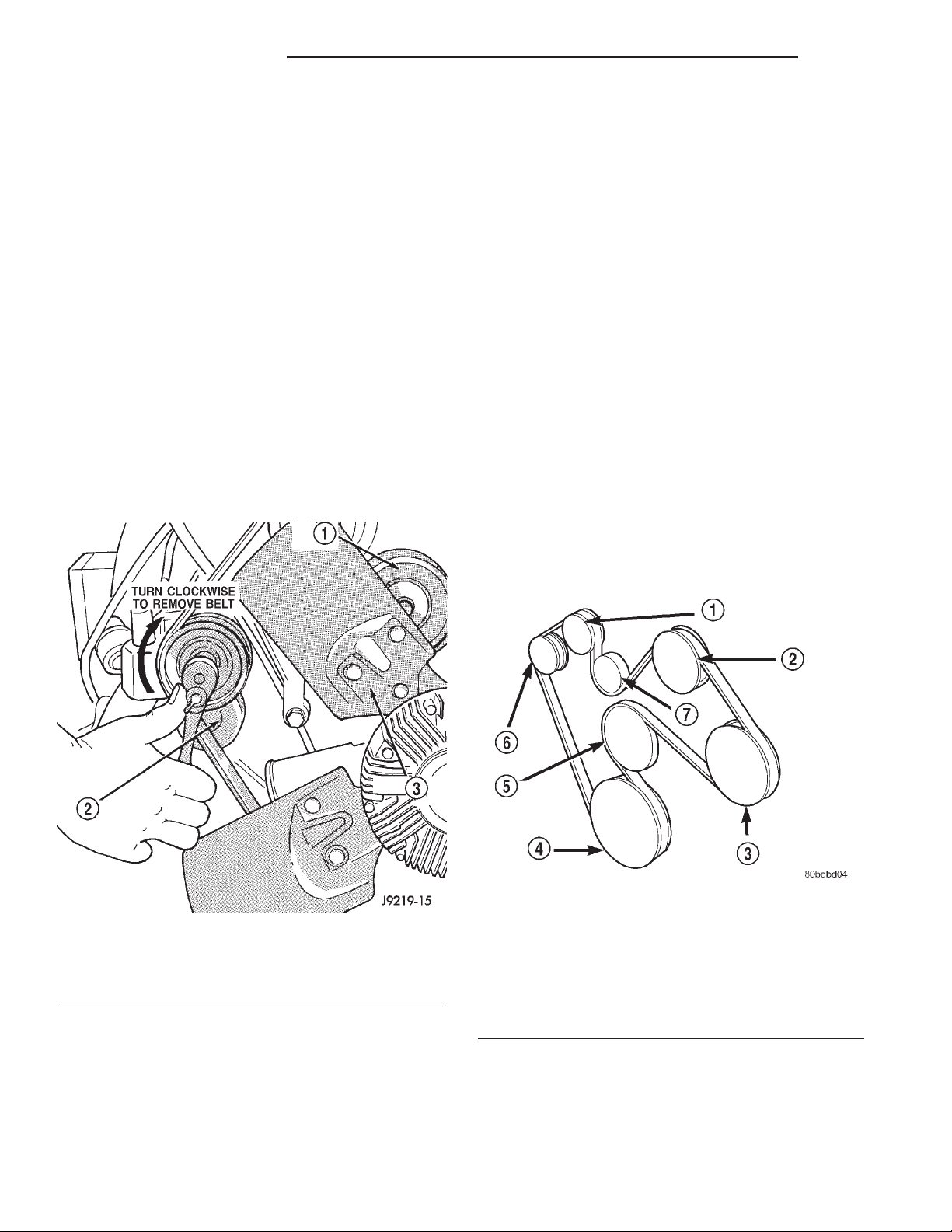

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 12). This

belt tensioner will be used on all belt configurations,

such as with or without power steering or air conditioning. For more information, (Refer to 7 - COOLING/ACCESSORY DRIVE/BELT TENSIONERS DESCRIPTION).

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(2) Rotate tensioner assembly clockwise (as viewed

from front) until tension has been relieved from belt.

(3) Remove belt from idler pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 13) (Fig. 14) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleys except idler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(3) Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place.

Remove wrench. Be sure belt is properly seated on

all pulleys.

(4) Check belt indexing marks.

Fig. 12 Belt Tensioner - 5.9L Gas Engines

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

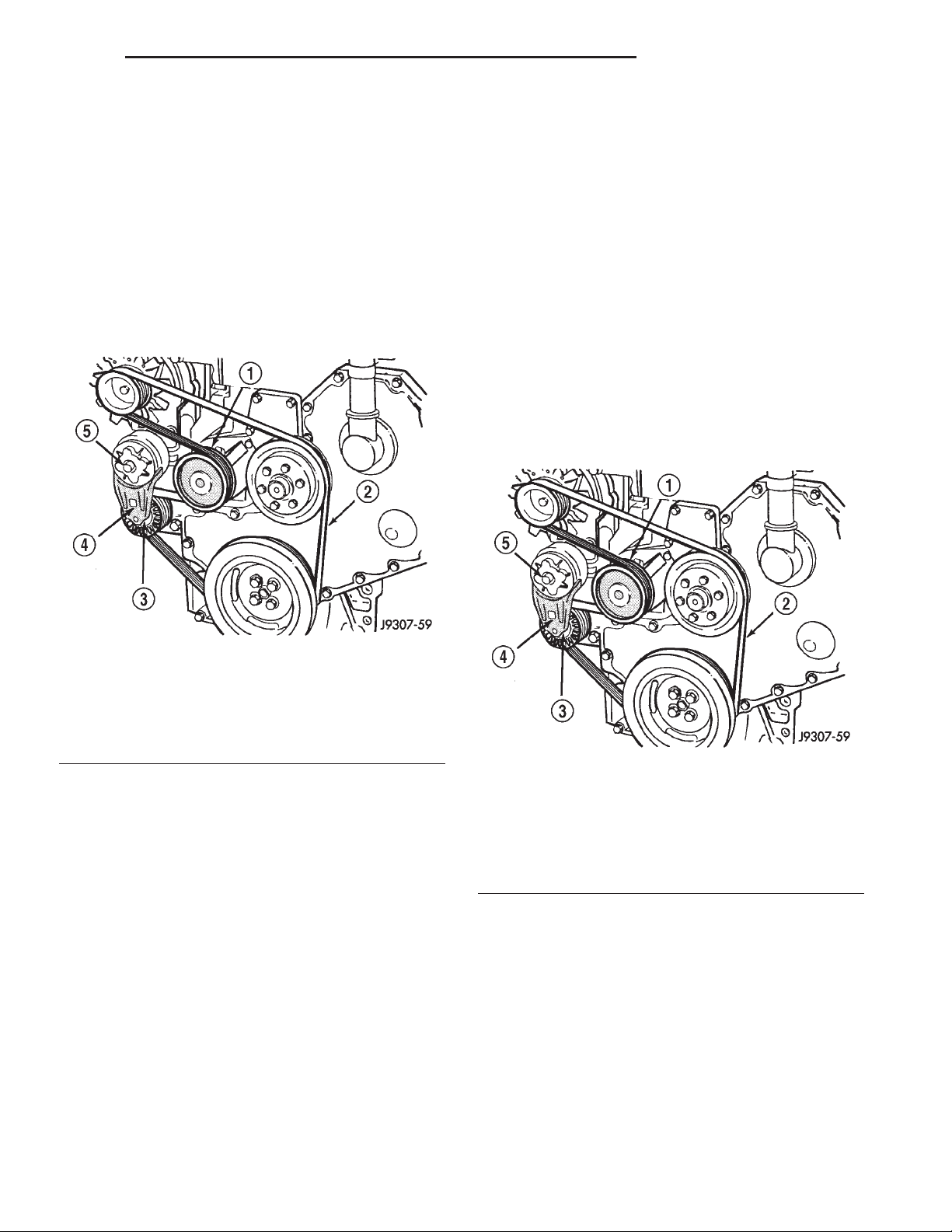

Fig. 13 Belt Routing - 5.9L Engines with A/C

1 - GENERATOR PULLEY

2 - A/C PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

7 - IDLER PULLEY

BR/BE ACCESSORY DRIVE 7 - 27

DRIVE BELTS - 5.9L (Continued)

be replaced (Fig. 15). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

Fig. 14 Belt Routing - 5.9L Engines Without A/C

1 - GENERATOR PULLEY

2 - IDLER PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

DRIVE BELTS - 8.0L

DIAGNOSIS AND TESTING—ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 15), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) are not normal. Any belt with cracks running along a rib must

Fig. 15 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

Loading...

Loading...