DR/DH CLUTCH 6 - 1

2005 DR/DH Service Manual Publication No. 81-370-05059 05DR6-1 November, 2004

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

WARNING ..............................1

DIAGNOSIS AND TESTING

CLUTCH .............................1

SPECIFICATIONS ........................5

SPECIAL TOOLS ........................6

DISC CLUTCH

REMOVAL ..............................7

INSTALLATION ..........................8

ADJUSTMENTS

ADJUSTMENT ........................8A

DISC CLUTCH - SRT-10

REMOVAL ..............................9

CLEANING .............................9

INSTALLATION .........................10

HOUSING CLUTCH

DIAGNOSIS AND TESTING

CLUTCH HOUSING ....................10

REMOVAL .............................13

INSTALLATION .........................14

BEARING CLUTCH RELEASE

REMOVAL .............................14

INSTALLATION .........................15

BEARING CLUTCH RELEASE - SRT-10

REMOVAL .............................15

INSTALLATION .........................16

FLYWHEEL

DESCRIPTION .........................16

DIAGNOSIS AND TESTING

FLYWHEEL ..........................16

REMOVAL .............................17

INSTALLATION .........................17

FLYWHEEL - SRT-10

DIAGNOSIS AND TESTING

FLYWHEEL ..........................17

REMOVAL .............................18

INSTALLATION .........................18

BEARING PILOT

REMOVAL .............................19

INSTALLATION .........................19

LINKAGE

REMOVAL .............................20

INSTALLATION .........................20

LINKAGE - SRT-10

REMOVAL .............................21

INSTALLATION .........................22

SWITCH CLUTCH PEDAL POSITION

DIAGNOSIS AND TESTING

CLUTCH PEDAL POSITION SWITCH .......23

SWITCH CLUTCH PEDAL - SRT-10

DIAGNOSIS AND TESTING ................23

REMOVAL .............................24

INSTALLATION .........................25

CLUTCH

WARNING

WARNING: Exercise care when servicing clutch components. Factory installed clutch discs do not contain

asbestos fibers. Dust and dirt on clutch parts may contain asbestos fibers from aftermarket components.

Breathing excessive concentrations of these fibers can cause serious bodily harm. Wear a respirator during

service and never clean clutch components with compressed air or with a dry brush. Either clean the components with water dampened rags or use a vacuum cleaner specifically designed to remove asbestos

fibers and dust. Do not create dust by sanding a clutch discs. Replace the disc if the friction material is

damaged. Dispose of all dust and dirt containing asbestos fibers in sealed bags or containers. This will

minimize exposure to yourself and to others. Follow all recommended safety practices prescribed by the

occupational safety and health administration (OSHA) and the environmental safety agency (EPA), for the

handling and disposal of products containing asbestos. Failure to follow these instructions may result in

personal injury or death

DIAGNOSIS AND TESTING

CLUTCH

Road test and inspect components to determine a clutch problem. Road test the vehicle at normal speeds. Shift the

transmission through all gear ranges and observe clutch action. If clutch chatters, grabs, slips or does not release

6 - 2 CLUTCH DR/DH

properly, remove and inspect clutch components. If problem is noise or hard shifting, further diagnosis may be

needed to the transmission and driveline component.

CLUTCH CONTAMINATION

Contamination is a frequent cause of clutch malfunctions. Oil, water or clutch fluid on the clutch disc and pressure

plate surfaces will cause chatter, slip and grab. Oil contamination indicates a leak at either the rear main seal or

transmission input shaft. Clutch fluid leaks are usually from damaged slave cylinder push rod seals. Heat buildup

caused by slippage between the pressure plate, disc and flywheel can bake the oil residue onto the components.

The glaze-like residue ranges in color from amber to black.

Road splash contamination is dirt/water entering the clutch housing due to loose bolts, housing cracks. Driving

through deep water puddles can force water/road splash into the housing through such openings.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems can be caused by worn or damage clutch components.

Release problems can cause hard shifting and noise. Look for leaks at clutch cylinders, connecting line and loose

slave cylinder bolts. Also worn/loose release fork, pivot stud, clutch disc, pressure plate or release bearing.

Engagement problems can cause slip, chatter/shudder and noisy operation. The causes may be clutch disc con-

tamination, wear, distortion or flywheel damage.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment with the crankshaft and transmission input shaft. Misalignment

caused by excessive runout or warpage of any clutch component will cause grab, chatter and improper clutch

release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial (face) runout of a new disc should not exceed 0.50 mm (0.020 in.).

Measure runout about 6 mm (1/4 in.) from the outer edge of the disc facing. Obtain another disc if runout is excessive.

Check condition of the clutch before installation. A warped cover or diaphragm spring will cause grab and incomplete release or engagement. Be careful when handling the cover and disc. Impact can distort the cover, diaphragm

spring, release fingers and the hub of the clutch disc.

Use an alignment tool when positioning the disc on the flywheel. The tool prevents accidental misalignment which

could result in cover distortion and disc damage.

A frequent cause of clutch cover distortion (and consequent misalignment) is improper bolt tightening.

FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is suspected. Flywheel runout should not exceed 0.08 mm (0.003

in.). Measure runout at the outer edge of the flywheel face with a dial indicator.

Common causes of runout are:

• heat warpage

• improper machining

• incorrect bolt tightening

• improper seating on crankshaft flange shoulder

• foreign material on crankshaft flange

Flywheel machining is not recommended. The flywheel clutch surface is machined to a unique contour and machining will negate this feature. Minor flywheel scoring can be cleaned up by hand with 180 grit emery or with turning

equipment. Remove only enough material to reduce scoring (approximately 0.001 - 0.003 in.). Heavy stock removal

is not recommended. Replace the flywheel if scoring is severe and deeper than 0.076 mm (0.003 in.). Excessive

stock removal can result in flywheel cracking or warpage after installation; it can also weaken the flywheel and

interfere with proper clutch release.

Clean the crankshaft flange before mounting the flywheel. Dirt and grease on the flange surface may cock the flywheel causing excessive runout. Use new bolts when remounting a flywheel and secure the bolts with Mopar Lock

DR/DH CLUTCH 6 - 3

And Seal or equivalent. Tighten flywheel bolts to specified torque only. Overtightening can distort the flywheel hub

causing runout.

DIAGNOSIS CHART

The diagnosis charts Diagnosis Chart describe common clutch problems, causes and correction.

Diagnosis Chart

CONDITION POSSIBLE CAUSES CORRECTION

Disc facing worn out 1. Normal wear. 1. Replace cover and disc.

Clutch disc facing contaminated with

oil, grease, or clutch fluid.

Clutch is running partially

disengaged.

Flywheel below minimum thickness

specification.

Clutch disc, cover and/or diaphragm

spring warped or distorted.

2. Driver frequently rides (slips) the

clutch. Results in rapid overheating

and wear.

3. Insufficient clutch cover

diaphragm spring tension.

1. Leak at rear main engine seal or

transmission input shaft seal.

2. Excessive amount of grease

applied to the input shaft splines.

3. Road splash, water entering

housing.

4. Slave cylinder leaking. 4. Replace hydraulic clutch linkage.

1. Release bearing sticking or

binding and does not return to the

normal running position.

1. Improper flywheel machining.

Flywheel has excessive taper or

excessive material removal.

1. Rough handling. Impact bent

cover, spring, or disc.

2. Replace cover and disc.

3. Replace cover and disc.

1. Replace appropriate seal.

2. Remove grease and apply the

correct amount of grease.

3. Replace clutch disc. Clean clutch

cover and reuse if in good condition.

1. Verify failure. Replace the release

bearing and transmission front

bearing retainer as necessary.

1. Replace flywheel.

1. Replace disc or cover as

necessary.

Facing on flywheel side of disc torn,

gouged, or worn.

Clutch disc facing burnt. Flywheel

and cover pressure plate surfaces

heavily glazed.

2. Improper bolt tightening

procedure.

1. Flywheel surface scored or

nicked.

2. Clutch disc sticking or binding on

transmission input shaft.

1. Frequent operation under high

loads or hard acceleration

conditions.

2. Driver frequently rides (slips)

clutch. Results in rapid wear and

overheating of disc and cover.

2. Tighten clutch cover using proper

procedure.

1. Correct surface condition if

possible. Replace flywheel and disc

as necessary.

2. Inspect components and

correct/replace as necessary.

1. Correct condition of flywheel and

pressure plate surface. Replace

clutch cover and disc. Alert driver to

problem cause.

2. Correct condition of flywheel and

pressure plate surface. Replace

clutch cover and disc. Alert driver to

problem cause.

6 - 4 CLUTCH DR/DH

CONDITION POSSIBLE CAUSES CORRECTION

Clutch disc binds on input shaft

splines.

Clutch disc rusted to flywheel and/or

pressure plate.

Pilot bearing seized, loose, or rollers

are worn.

Clutch will not disengage properly. 1. Low hydraulic linkage fluid level. 1. Add hydraulic linkage fluid.

1. Clutch disc hub splines damaged

during installation.

2. Input shaft splines rough,

damaged, or corroded.

1. Clutch not used for an extended

period of time (e.g. long term

vehicle storage).

1. Bearing cocked during

installation.

2. Bearing defective. 2. Install a new bearing.

3. Bearing not lubricated. 3. Install a new bearing.

4. Clutch misalignment. 4. Inspect clutch and correct as

2. Clutch cover loose. 2. Follow proper bolt tightening

3. Clutch disc bent or distorted. 3. Replace clutch disc.

4. Clutch cover diaphragm spring

bent or warped.

5. Clutch disc installed backwards. 5. Remove and install clutch disc

6. Release fork bent or fork pivot

loose or damaged.

7. Clutch master or slave cylinder

failure.

1. Clean, smooth, and lubricate hub

splines if possible. Replace disc if

necessary.

2. Clean, smooth, and lubricate

shaft splines if possible. Replace

input shaft if necessary.

1. Sand rusted surfaces with 180

grit sanding paper. Replace clutch

cover and flywheel if necessary.

1. Install a new bearing.

necessary. Install and lubricate a

new bearing.

procedure.

4. Replace clutch cover.

correctly.

6. Replace fork or pivot as

necessary.

7. Replace hydraulic linkage

assembly.

Clutch pedal squeak. 1. Pivot pin loose. 1. Tighten pivot pin if possible.

Replace clutch pedal if necessary.

2. Master cylinder bushing not

lubricated.

3. Pedal bushings worn out or

cracked.

4. Rough surface on front bearing

retainer.

Clutch master or slave cylinder

plunger dragging andør binding

Release bearing is noisy. 1. Release bearing defective or

1. Master or slave cylinder

components worn or corroded.

damaged.

2. Lubricate master cylinder

bushing.

3. Replace and lubricate bushings.

4. Replace front bearing retainer.

1. Replace clutch hydraulic linkage

assembly.

1. Replace release bearing.

DR/DH CLUTCH 6 - 5

CONDITION POSSIBLE CAUSES CORRECTION

Contact surface of release bearing

damaged.

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.

SPECIFICATIONS

TORQUE SPECIFICATIONS

1. Clutch cover incorrect or release

fingers bent or distorted.

2. Release bearing defective or

damaged.

3. Release bearing misaligned. 3. Check and correct runout of

1. Clutch pressure plate position

incorrect.

2. Clutch cover, spring, or release

fingers bent or distorted.

3. Clutch disc damaged or

distorted.

4. Clutch misalignment. 4. Check alignment and runout of

1. Replace clutch cover and release

bearing.

2. Replace the release bearing.

clutch components. Check front

bearing sleeve for damage/

alignment. Repair as necessary.

1. Replace clutch disc and cover.

2. Replace clutch disc and cover.

2. Replace clutch disc.

flywheel, disc, pressure plate, andør

clutch housing. Correct as

necessary.

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Slave Cylinder Nuts 23 17 -

Clutch Master Cylinder

Nuts

Pressure Plate Bolts - V6

&V8

Pressure Plate Bolts - V10 30 22.5 -

Pressure Plate Bolts -

Diesel

Release Bearing Pivot 23 17 -

Flywheel Bolts 95 70 -

Dual Mass Flywheel To

Adapter Bolts

Dual Mass Flywheel

Adapter To Crankshaft

Bolts

28 21 -

50 37 -

30 22.5 -

55 40 -

137 100 -

6 - 6 CLUTCH DR/DH

SPECIAL TOOLS

LINE DISCONNECT TOOL 6638

DR/DH CLUTCH 6 - 7

2005 DR/DH Service Manual Publication No. 81-370-05059 05DR6-7 November, 2004

DISC CLUTCH

REMOVAL

1. Support engine with wood block and adjustable

jack stand, to prevent strain on engine mounts.

2. Remove transmission and transfer case, if

equipped.

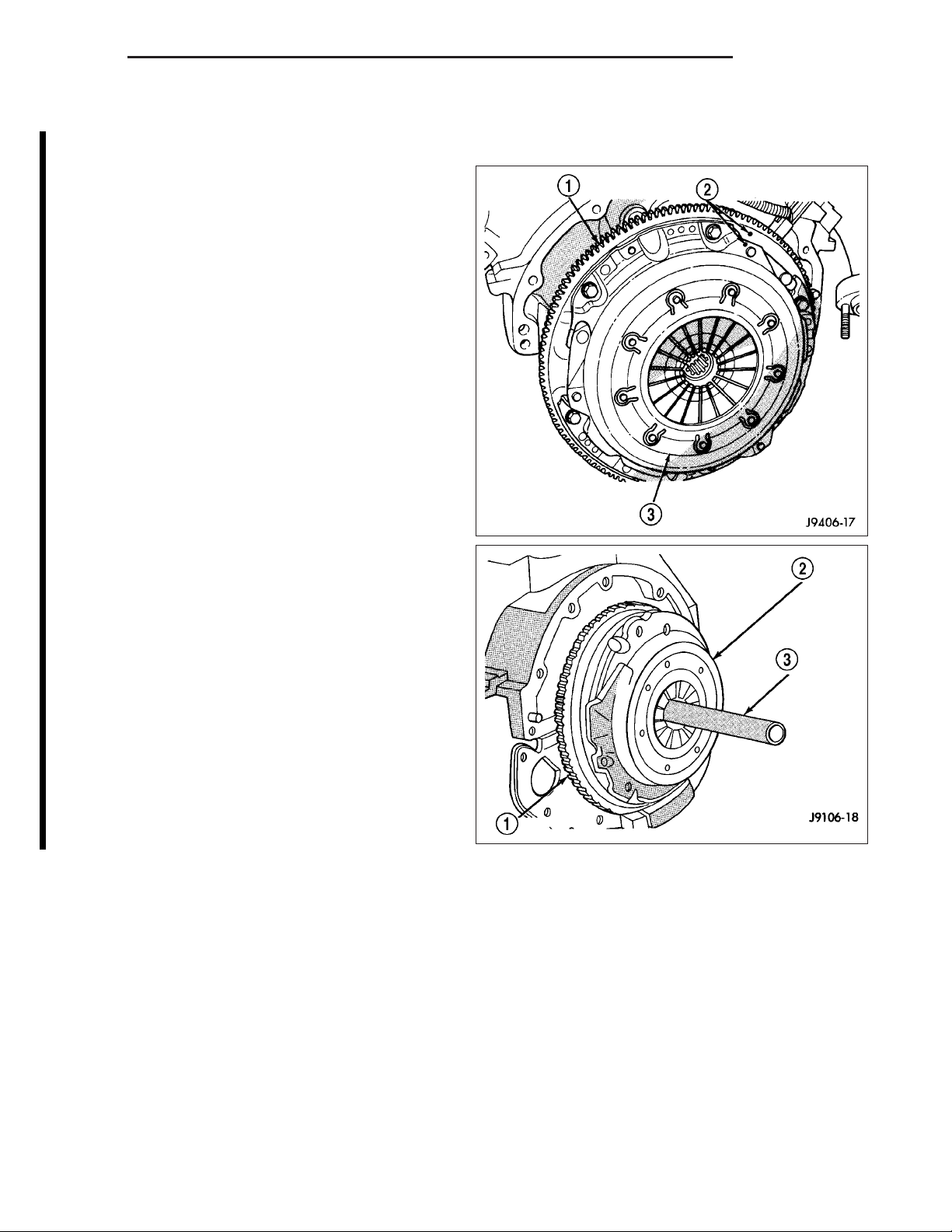

3. If pressure plate (3) will be reused, mark (2) the

position on flywheel (1) with paint or scriber. Also

note location marks on the pressure next to the

bolt holes. The mark will be a L or a circle with an

Xinit.

4. Insert clutch alignment tool (3) through pressure

plate (2) and into pilot bushing, to hold disc in

place while removing bolts.

5. Loosen pressure plate bolts evenly, a few threads

at a time and in a diagonal pattern to prevent warping the plate.

6. Remove bolts completely and remove pressure

plate, disc and alignment tool.

6 - 8 CLUTCH DR/DH

2005 DR/DH Service Manual Publication No. 81-370-05059 05DR6-8 November, 2004

INSTALLATION

CAUTION: Before installing a clutch disc on 5.9L

Diesel with Dual Mass Flywheel and self-adjusting

pressure plate, the pressure plate must be reset.

Failure to reset the pressure will result in damage

to the clutch disc.

1. Check runout and free operation of new clutch

disc.

2. Lubricate crankshaft pilot bearing with a NLGI - 2

rated grease.

3. Install clutch alignment tool in clutch disc hub with

the raised side of hub is facing away from the flywheel.

NOTE: Flywheel side is imprinted on the disc face.

4. Install alignment tool (3) in pilot bearing and position disc on the flywheel (1).

5. Position pressure plate over disc (2) and onto the flywheel.

6. Align and hold pressure plate in position and install bolts finger tight.

7. Tighten bolts evenly and a few threads at a time in a diagonal pattern.

CAUTION: Bolts must be tightened evenly and to specified torque to avoid warping pressure plate cover.

8. Tighten pressure plate bolts to:

• V6 & V8 Engines - 50 N·m (37 ft. lbs.)

• V10 & Diesel Engines - 30 N·m (22.5 ft. lbs.)

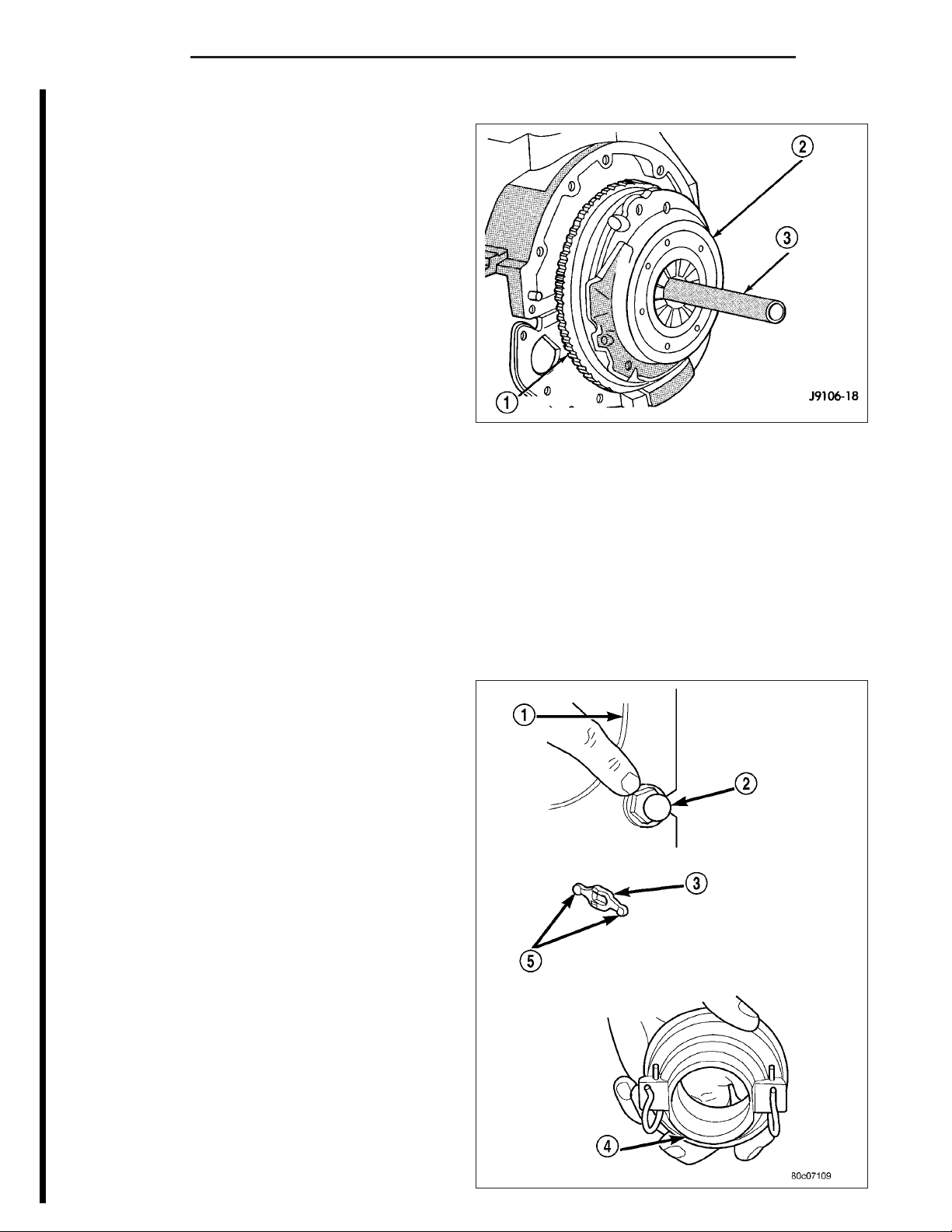

9. Remove release lever (3) and release bearing from

clutch housing (1). Apply Mopar high temperature

bearing grease to bore (4) of release bearing,

release lever (5) contact surfaces and release lever

pivot stud (2).

DR/DH CLUTCH 6 - 8A

2005 DR/DH Service Manual Publication No. 81-370-05059 05DR6-8A November, 2004

10. Apply light coat of Mopar high temperature bear-

ing grease to splines (3) of transmission input

shaft (1) and to release bearing slide surface of

the transmission front bearing retainer (2).

CAUTION: Do not over lubricate shaft splines. This

can result in grease contamination of the disc.

11. Wipe pilot bearing surface clean.

12. Install release lever and bearing in clutch housing.

Verify spring clip (2) that retain lever on pivot ball

(4) and release bearing (3) clips (1) on lever (1)

are installed properly.

NOTE: If release lever is installed correctly, the

lever part number will be toward the bottom of the

transmission and right side up. There is also a

stamped “I” in the lever which goes to the pivot

ball side of the transmission.

13. Install transmission and transfer case if equipped.

14. Check fluid level in clutch master cylinder.

ADJUSTMENTS

ADJUSTMENT

NOTE: Perform the following procedure, when

replacing only the clutch disc on 5.9L Diesel with

Dual Mass Flywheel and self-adjusting pressure

plate. The pressure plate must be reset before

installing a new disc.

1. Place pressure plate with disc on a press.

2. Center press ram (2) on the pressure plate diaphragm spring fingers (1).

3. Compress the diaphragm spring fingers (1), until

tension is released from the stepped adjusting ring.

Loading...

Loading...