Dodge Chime Buzzer 3500 2005, Chime Buzzer 2500 2005, Chime Buzzer 1500 2005 Service Manual

Page 1

DR/DH CHIME/BUZZER 8B - 1

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER - ELECTRICAL DIAGNOSTICS ... 1 CHIME/BUZZER - SERVICE INFORMATION ..... 12

CHIME/BUZZER - ELECTRICAL DIAGNOSTICS

TABLE OF CONTENTS

page page

CHIME/BUZZER - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

*CHIME SOUNDS WITH DRIVER DOOR

OPEN KEY REMOVED...................2

*KEY IN IGNITION AND DRIVER’S DOOR

OPEN CHIME INOPERATIVE ..............5

*CHIME INOPERATIVE ..................9

*VEHICLE SPEED WARNING CHIME

PROBLEM ...........................10

SCHEMATICS AND DIAGRAMS .............11

CHIME/BUZZER - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

Page 2

8B - 2 CHIME/BUZZER - ELECTRICAL DIAGNOSTICS DR/DH

*CHIME SOUNDS WITH DRIVER DOOR OPEN KEY REMOVED

Page 3

DR/DH CHIME/BUZZER - ELECTRICAL DIAGNOSTICS 8B - 3

*CHIME SOUNDS WITH DRIVER DOOR OPEN KEY REMOVED (CONTINUED)

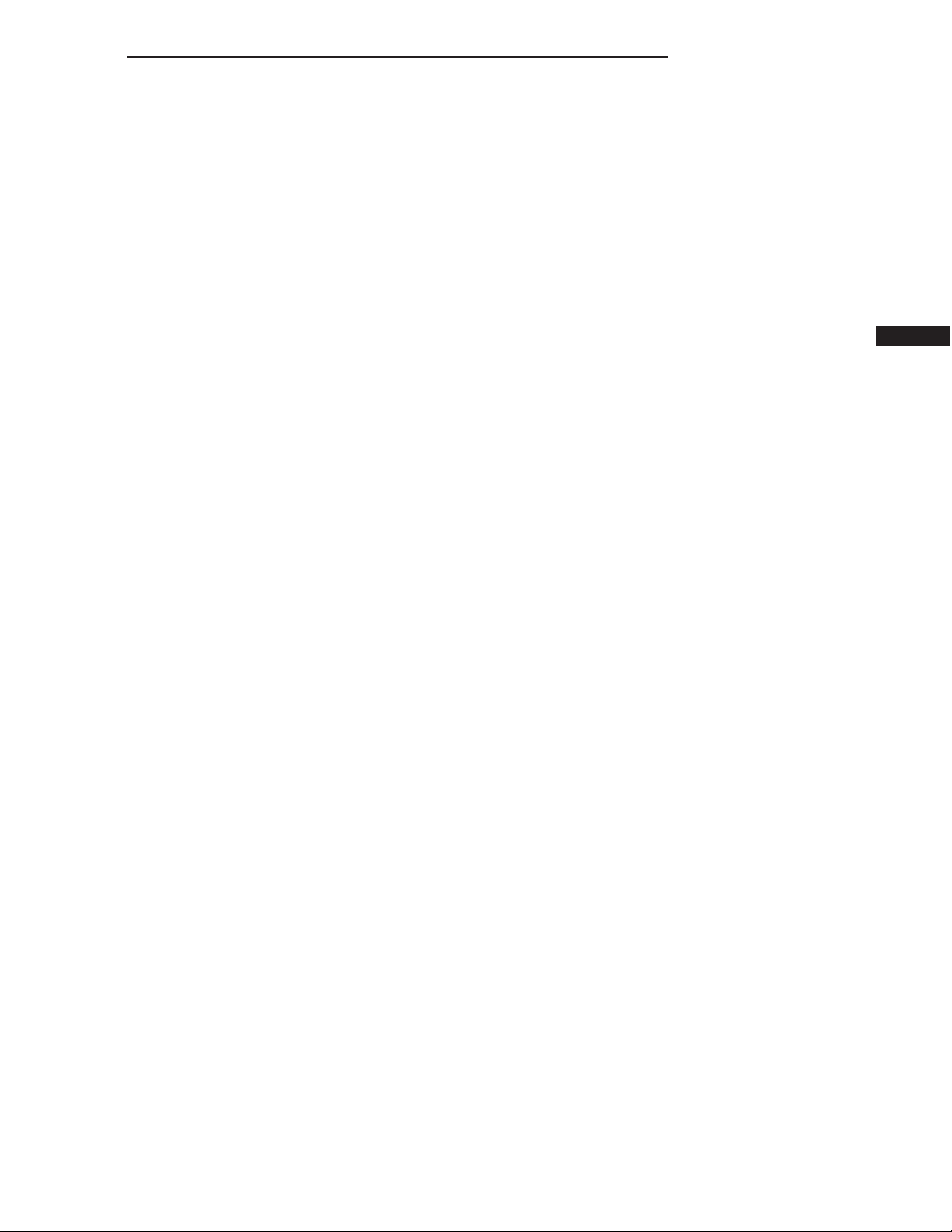

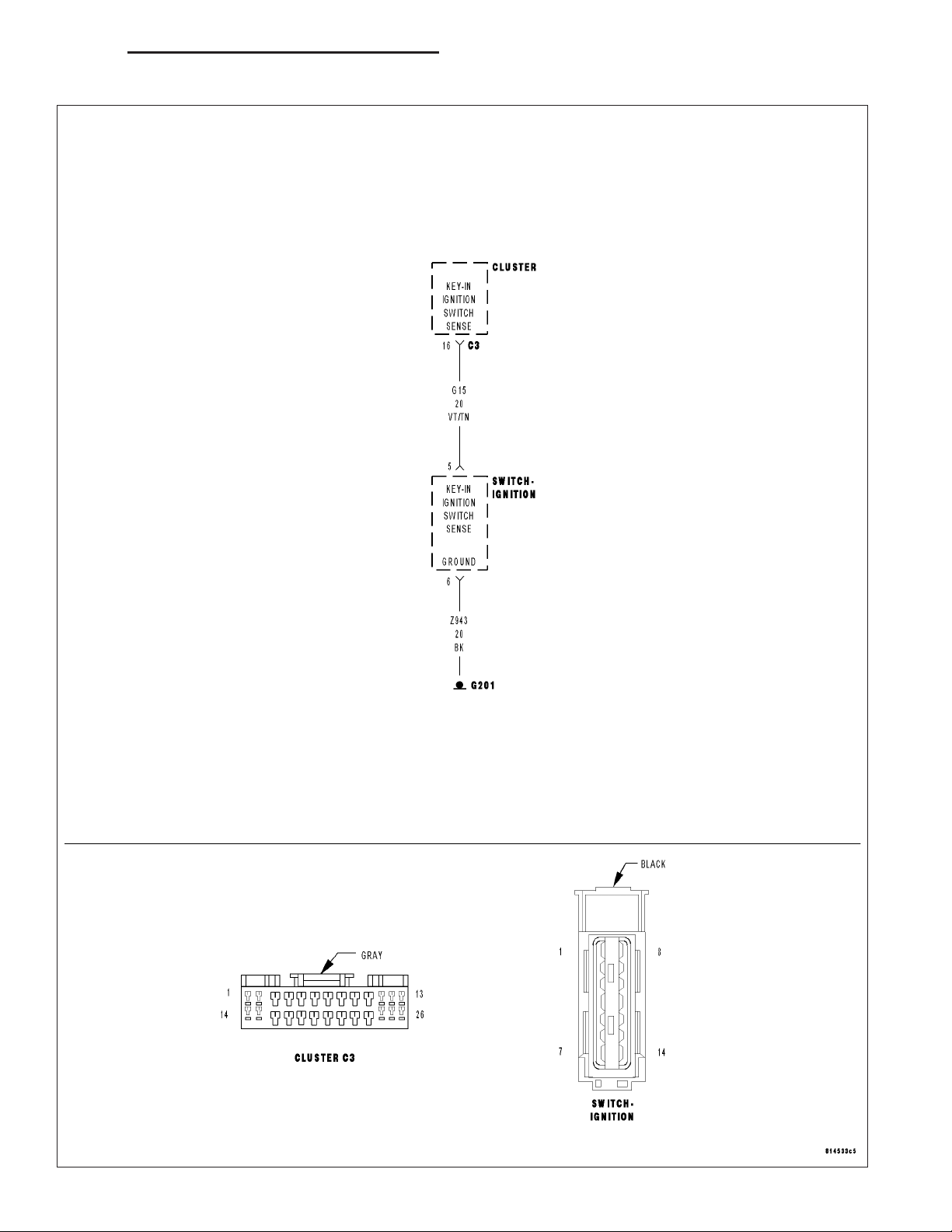

For the Chime system circuit diagram (Refer to 8 - ELECTRICAL/CHIME/BUZZER - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

KEY-IN IGN SW STATUS

IGNITION SWITCH SHORTED

(G26) KEY-IN IGNITION SW SENSE SHORT TO GROUND

CLUSTER

Diagnostic Test

READ KEY-IN IGNITION SWITCH STATUS ON DRBIII

1.

NOTE: Ensure the exterior lamps turn on and off

properly and are off before continuing this test.

With the DRBIIIT select: Electro/Mech Cluster, Input

Output.

Read the Key-In Ign Sw.

Remove the key from the ignition switch.

Does the DRBIIIT show Key-In Ign OPEN?

Yes >>

No >>

Replace and program the Cluster in accordance with the Service Information.

Perform BODY VERIFICATION TEST VER 1 (Refer to BODY VERIFICATION

TEST - VER 1).

Go To 2

Page 4

8B - 4 CHIME/BUZZER - ELECTRICAL DIAGNOSTICS DR/DH

*CHIME SOUNDS WITH DRIVER DOOR OPEN KEY REMOVED (CONTINUED)

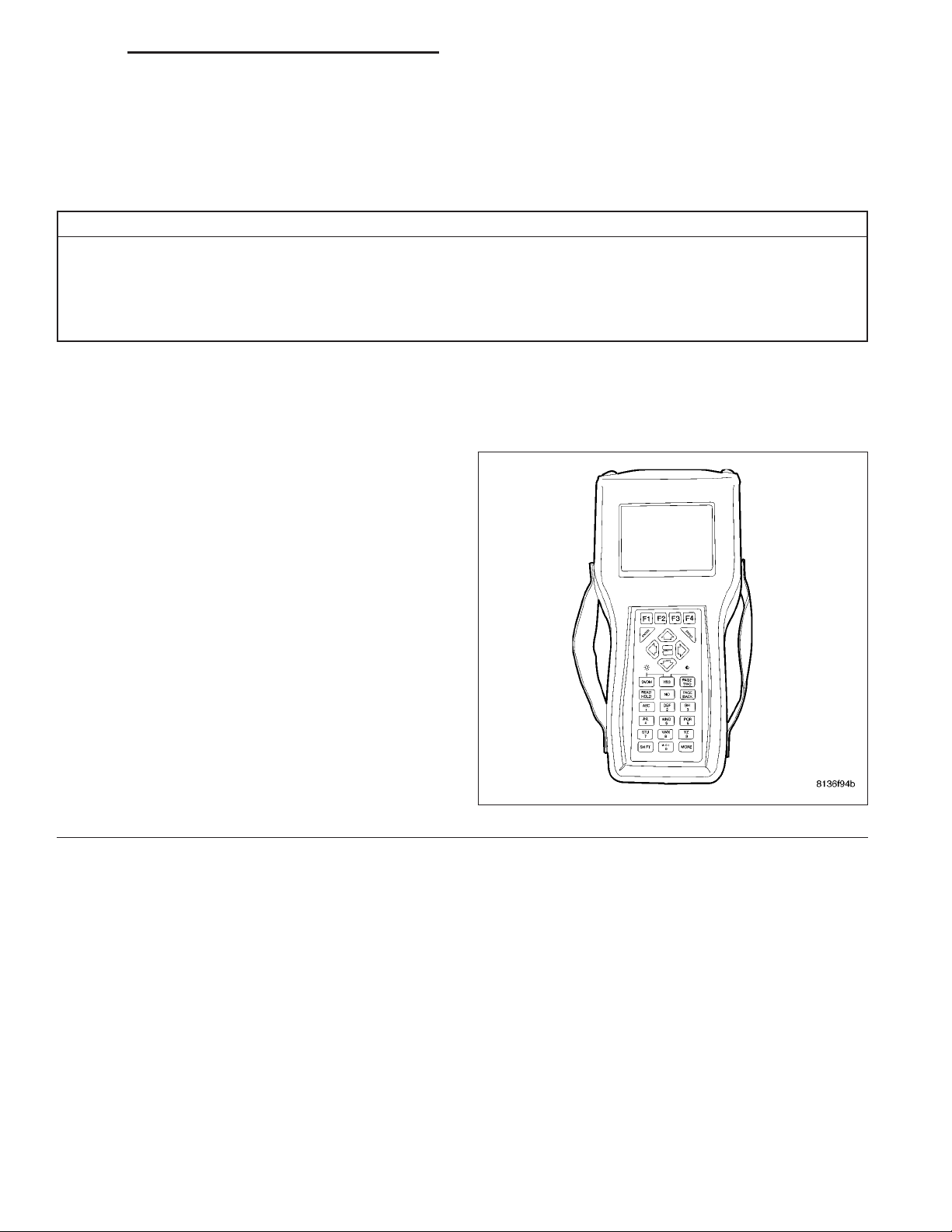

KEY-IN IGN SWITCH SHORTED

2.

Disconnect the Ignition Switch connector.

Did the chime turn off?

Yes >>

No >>

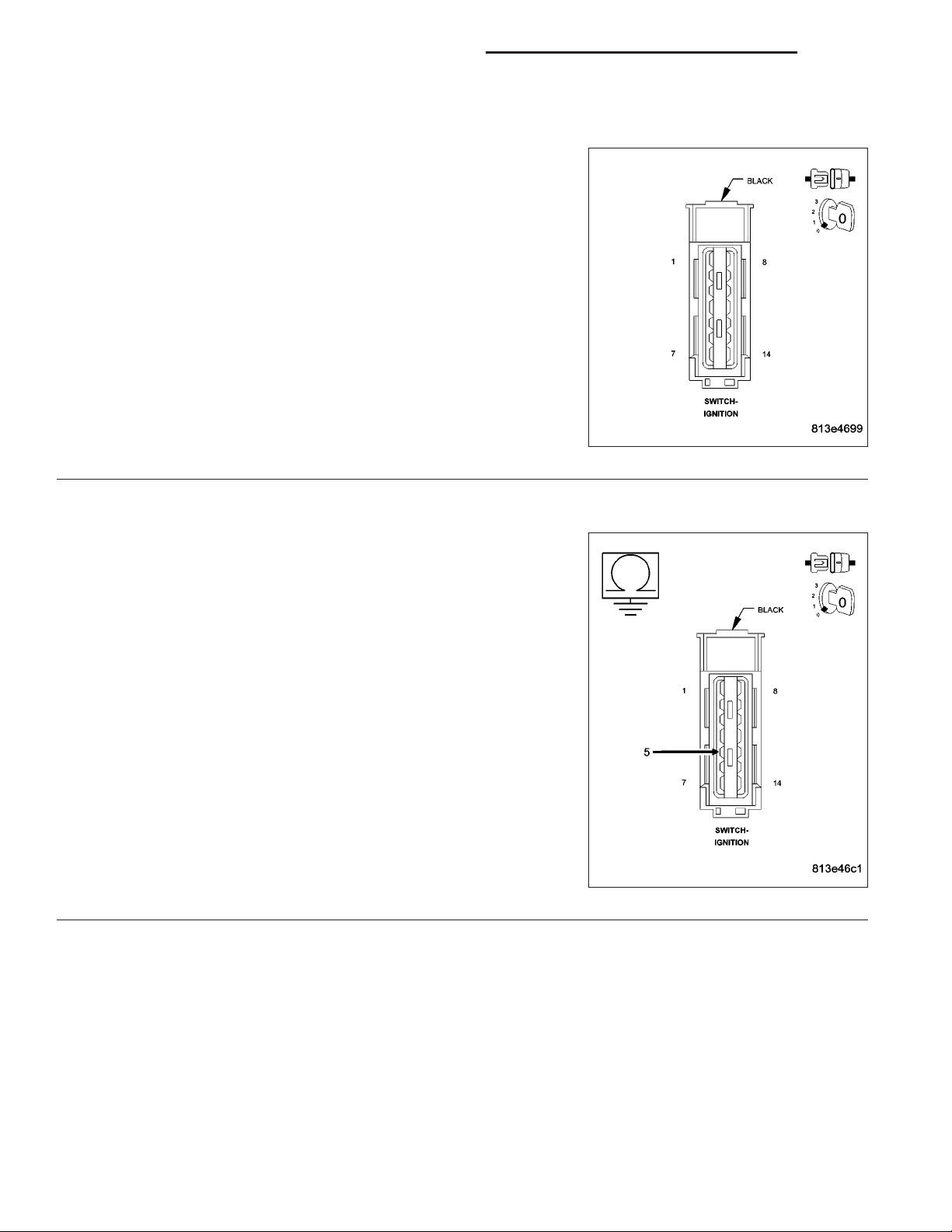

(G26) KEY-IN IGNITION SWITCH SENSE WIRE SHORT TO GROUND

3.

Turn ignition off.

Disconnect the Ignition Switch connector.

Disconnect the Cluster C3 connector.

Measure the resistance of the (G26) Key-in Ignition Switch Sense cir-

cuit to ground at the Ignition Switch connector.

Is the resistance below 100.0 ohms?

Check the Ignition Lock Cylinder for damage. If OK

replace the Ignition Switch.

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Go To 3

Yes >>

No >>

Repair the (G26) Key-In Ignition Switch Sense wire for a

short to ground.

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Replace and program the Cluster in accordance with the

Service Information.

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Page 5

DR/DH CHIME/BUZZER - ELECTRICAL DIAGNOSTICS 8B - 5

*KEY IN IGNITION AND DRIVER’S DOOR OPEN CHIME INOPERATIVE

Page 6

8B - 6 CHIME/BUZZER - ELECTRICAL DIAGNOSTICS DR/DH

*KEY IN IGNITION AND DRIVER’S DOOR OPEN CHIME INOPERATIVE (CONTINUED)

For the Chime system circuit diagram (Refer to 8 - ELECTRICAL/CHIME/BUZZER - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z42) GROUND OPEN

(G26) KEY-IN IGNITION SWITCH OPEN

IGNITION SWITCH

CLUSTER

Diagnostic Test

READ KEY-IN IGNITION SWITCH STATUS ON DRBIII

1.

NOTE: The driver’s door ajar switch must be operational for the result of this test to be valid.

Ensure that the Key is still in the Ignition Switch.

With the DRBIIIT select: Electro/Mech Cluster, Input

Output.

Read the Key-In Ign Sw.

Does the DRBIIIT show Key-In Ign CLOSED?

Yes >>

No >>

Replace and program the Cluster in accordance with the Service Information.

Perform BODY VERIFICATION TEST VER 1 (Refer to BODY VERIFICATION

TEST - VER 1).

Go To 2

Page 7

DR/DH CHIME/BUZZER - ELECTRICAL DIAGNOSTICS 8B - 7

*KEY IN IGNITION AND DRIVER’S DOOR OPEN CHIME INOPERATIVE (CONTINUED)

IGNITION SWITCH GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Ignition Switch connector.

Turn all lights off.

Measure the resistance between ground and the (Z42) Ground circuit

in the ignition switch harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

IGNITION SWITCH OPEN

3.

Connect the ignition switch connector if disconnected.

Turn ignition on.

With the ignition switch connector connected, back jumper the (G26)

Key-In Ignition Switch Sense circuit to ground at the ignition switch

connector.

With the DRBIIIT, enter Instrument Cluster Input/Outputs and observe

the Key-In Ign Sw status.

Does the DRBIII display Key-In Ign SW: Closed?

Yes >>

No >>

Go To 3

Repair the (Z42) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Replace the Ignition Switch.

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Go To 4

Page 8

8B - 8 CHIME/BUZZER - ELECTRICAL DIAGNOSTICS DR/DH

*KEY IN IGNITION AND DRIVER’S DOOR OPEN CHIME INOPERATIVE (CONTINUED)

KEY-IN IGNITION SWITCH SENSE CIRCUIT OPEN

4.

Turn the ignition off.

Disconnect the Ignition Switch harness connector.

Disconnect the Cluster C3 harness connector.

Measure the resistance of the (G26) Key-In Ignition Switch Sense cir-

cuit between the ignition switch connector and the Instrument Cluster

C3 connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace and program the Instrument Cluster in accordance with the Service Information.

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Repair the (G26) Key-In Ignition Switch Sense circuit for

an open

Perform BODY VERIFICATION TEST - VER 1 (Refer to

BODY VERIFICATION TEST - VER 1).

Page 9

DR/DH CHIME/BUZZER - ELECTRICAL DIAGNOSTICS 8B - 9

*CHIME INOPERATIVE

For the Chime system circuit diagram (Refer to 8 - ELECTRICAL/CHIME/BUZZER - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

CLUSTER

Diagnostic Test

ACTUATE THE CHIME WITH THE DRBIII

1.

Turn the ignition on.

Close the doors.

With the DRBIIIT select: Electro/Mech Cluster and

actuate the Chime.

Does the chime sound when actuated by the

DRBIIIT?

Yes >>

No >>

If the chime operates as it should, check

for other reasons that the chime is being

inoperative.

Perform BODY VERIFICATION TEST VER 1 (Refer to BODY VERIFICATION

TEST - VER 1).

Replace and program the Cluster in accordance with the Service Information.

Perform BODY VERIFICATION TEST VER 1 (Refer to BODY VERIFICATION

TEST - VER 1).

Page 10

8B - 10 CHIME/BUZZER - ELECTRICAL DIAGNOSTICS DR/DH

*VEHICLE SPEED WARNING CHIME PROBLEM

For the Chime system circuit diagram (Refer to 8 - ELECTRICAL/CHIME/BUZZER - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

INCORRECT COUNTRY CODE PROGRAMMED IN CLUSTER

CLUSTER

Diagnostic Test

WITH THE DRBIII CHECK THE COUNTRY CODE SETTING

1.

NOTE: The high speed warning chime is for Gulf

Coast Countries only.

Turn the ignition on.

With the DRBIIIT in Miscellaneous check the Cluster

country code setting.

Is the country code incorrect?

Yes >>

No >>

Program the correct country code.

Perform BODY VERIFICATION TEST -

VER 1 (Refer to BODY VERIFICATION

TEST - VER 1).

Replace and program the Cluster in accordance with the Service Information.

Perform BODY VERIFICATION TEST VER 1 (Refer to BODY VERIFICATION

TEST - VER 1).

Page 11

DR/DH CHIME/BUZZER - ELECTRICAL DIAGNOSTICS 8B - 11

SCHEMATICS AND DIAGRAMS

CHIME SYSTEM

Page 12

8B - 12 CHIME/BUZZER - SERVICE INFORMATION DR/DH

CHIME/BUZZER - SERVICE INFORMATION

TABLE OF CONTENTS

page page

CHIME/BUZZER - SERVICE INFORMATION

DESCRIPTION .........................12

OPERATION ...........................13

DIAGNOSIS AND TESTING

CHIME WARNING SYSTEM ..............15

CHIME/BUZZER - SERVICE INFORMATION

DESCRIPTION

A chime warning system is standard factory-installed equipment. The chime warning system uses an electromechanical transducer and an electromechanical relay that are soldered onto the electronic circuit board inside of the

ElectroMechanical Instrument Cluster (EMIC) (1) to provide audible indications of various vehicle conditions that

may require the attention of the vehicle operator or occupants. The EMIC also includes the hardware and software

necessary to serve as the electronic body control module and is sometimes referred to as the Cab Compartment

Node or CCN.

Page 13

DR/DH CHIME/BUZZER - SERVICE INFORMATION 8B - 13

The electromechanical transducer generates beep tones and chime tones, while the electromechanical relay generates click tones to emulate the sounds associated with conventional turn signal and hazard warning flasher operation. The microprocessor-based EMIC utilizes electronic chime request messages received from other modules in

the vehicle over the Programmable Communications Interface (PCI) data bus network along with hard wired inputs

to monitor many sensors and switches throughout the vehicle. In response to those inputs, the circuitry and programming of the EMIC allow it to control the audible outputs that are produced through its on-board transducer and

relay.

The EMIC is capable of producing the following audible outputs:

• Slow Rate Repetitive Click - Repeated “click” tones that are issued at a slow rate of about 50 clicks per

minute.

• Fast Rate Repetitive Click - Repeated “click” tones that are issued at a fast rate of more than about 100

clicks per minute.

• Fixed Duration Beep - A short, sharp, single tactile “beep” tone.

• Single Chime Tone - A single “chime” tone.

• Slow Rate Repetitive Chime - Repeated “chime” tones that are issued at a slow rate of about 50 chimes per

minute.

• Fast Rate Repetitive Chime - Repeated “chime” tones that are issued at a fast rate of about 180 chimes per

minute.

Hard wired circuitry connects the EMIC and the various chime warning system switch and sensor inputs to their

modules and to each other through the electrical system of the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout the vehicle and retained by many different methods. These

circuits may be connected to each other, to the vehicle electrical system and to the EMIC through the use of a

combination of soldered splices, splice block connectors, and many different types of wire harness terminal connectors and insulators. Refer to the appropriate wiring information. The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further details on wire harness routing and retention, as well as pinout and location views for the various wire harness connectors, splices and grounds.

The EMIC chime warning system circuits and components cannot be adjusted or repaired. If the EMIC circuitry, the

on-board transducer or the relay are damaged or faulty, the EMIC unit must be replaced.

OPERATION

The chime warning system operates on battery voltage received through the Ignition-Off Draw (IOD) fuse in the

Power Distribution Center (PDC) on a non-switched fused B(+) circuit so that the system may operate regardless of

the ignition switch position. The chime warning system also monitors the ignition switch position so that some chime

features are functional only with the ignition switch in the On position, while others are functional regardless of the

ignition switch position.

The chime warning system provides an audible indication to the vehicle operator or occupants under the following

conditions:

• Airbag Indicator Warning - The ElectroMechanical Instrument Cluster (EMIC) transducer will generate one

short chime when the ignition switch is in the On position, and an electronic message is received over the

Programmable Communications Interface (PCI) data bus from the Airbag Control Module (ACM) requesting

“Airbag” indicator illumination. This warning will only occur following completion of the “Airbag” indicator bulb

test, and will only occur once during any ignition cycle.

• Compass Mini-Trip Computer Global Reset - The EMIC transducer will generate one short chime when the

ignition switch is in the On position, and an electronic message is received over the PCI data bus from the

optional Compass Mini-Trip Computer (CMTC) requesting that the CMTC average fuel economy, trip odometer

and distance to empty data be reset. The CMTC monitors hard wired inputs from the U.S./Metric and Reset

button switches to determine the proper reset messages to send to the EMIC.

• Door Ajar Indicator Warning - The EMIC transducer will generate one short chime when the ignition switch

is in the On position, a hard wired input is received indicating that the status of any door ajar switch has

changed, and an electronic message is received over the PCI data bus indicating that the vehicle is moving.

• Engine Coolant Temperature High Warning (Diesel Engine Only) - The EMIC transducer will generate a

single chime tone when the “Check Gauges” indicator is illuminated for a high or critical engine coolant temperature condition. The instrument cluster uses engine coolant temperature message inputs received from the

diesel Engine Control Module (ECM) over the PCI data bus to illuminate the “Check Gauges” indicator for a

coolant temperature high condition.

Page 14

8B - 14 CHIME/BUZZER - SERVICE INFORMATION DR/DH

• Fasten Seat Belt Indicator Warning - The EMIC transducer will generate repetitive chimes at a slow rate to

announce that a hard wired input from the seat belt switch indicates that the driver side front seat belt is not

fastened with the ignition switch in the On position. The chime warning system also supports the enhanced

seatbelt reminder (beltminder) when this feature is enabled. (Refer to 8 - ELECTRICAL/INSTRUMENT CLUSTER/SEATBELT INDICATOR - OPERATION).

• Head/Park Lamps-On Warning - The EMIC transducer will generate repetitive chimes at a fast rate to indi-

cate that hard wired inputs from the driver door ajar switch, the headlamp switch, and the ignition switch indicate that the exterior lamps are turned On with the driver side front door opened and the ignition switch in the

Off position. The chimes will continue to sound until the exterior lamps are turned Off, the driver side front door

is closed, or the ignition switch is turned to the On position, or the battery saver (load shed) time-out expires,

whichever occurs first.

• Key-In-Ignition Warning - The EMIC transducer will generate repetitive chimes at a fast rate to announce that

the hard wired inputs from the driver door ajar switch, the ignition switch, and the key-in ignition switch circuitry

of the ignition switch indicate that the key is in the ignition lock cylinder with the driver side front door open and

the ignition switch in the Off position. The chimes will continue to sound until the key is removed from the

ignition lock cylinder, the driver side front door is closed, or the ignition switch is turned to the On position,

whichever occurs first.

• Low Fuel Indicator Warning - The EMIC transducer will generate one short chime tone when the “Low Fuel”

indicator is illuminated by the instrument cluster circuitry. This chime will only occur once during any ignition

cycle.

• Low Oil Pressure Warning (Diesel Engine Only) - The EMIC transducer will generate repetitive chimes at a

fast rate when the “Check Gauges” indicator is illuminated for a low oil pressure condition. The instrument

cluster uses engine speed and oil pressure message inputs received from the diesel Engine Control Module

(ECM) over the PCI data bus indicating that the engine is running and that the oil pressure is low to illuminate

the “Check Gauges” indicator. The chimes will continue to sound for five seconds, until the engine oil pressure

message indicates that the oil pressure is not low, or until the engine speed message indicates that the engine

is not running, whichever occurs first. This chime will only occur once during any ignition cycle.

• Low Wash Indicator Warning - The EMIC transducer will generate one short chime when the “Low Washer

Fluid” indicator is illuminated by the instrument cluster circuitry. This chime will only occur once during any

ignition cycle.

• Overspeed Warning - The EMIC transducer will generate repetitive chimes at a slow rate to indicate that the

vehicle speed is over a pre-programmed speed value. The EMIC monitors electronic vehicle speed messages

received over the PCI data bus. This feature is only enabled on an EMIC that has been programmed with a

Middle East Gulf Coast Country (GCC) country code.

• Park Brake Reminder - The EMIC transducer will generate ten repetitive chimes at a slow rate to announce

that the hard wired input from the park brake switch and a vehicle speed message input received over the PCI

data bus indicate that the park brake is applied and the vehicle is moving. This chime will repeat each time the

input conditions are met.

• Sentry Key “Customer Learn” Mode Announcement - The EMIC transducer will generate one short chime

to confirm that an electronic “Customer Learn” mode message has been received over the PCI data bus to

indicate the Sentry Key Immobilizer Module (SKIM) is prepared for programming additional sentry key transponders. This chime feature is only active on vehicles equipped with the optional Sentry Key Immobilizer

System (SKIS), and sold in markets where “Customer Learn” programming is an allowed feature.

• Trans Overtemp Indicator Warning (Automatic Transmission Only) - The EMIC transducer will generate

repetitive chimes at a slow rate when the “Trans Temp” indicator is illuminated by the instrument cluster circuitry for a high or critical transmission fluid temperature condition. This chime will repeat each time the trans

overtemp indicator is cycled from Off to On.

• Turn Signal/Hazard Warning Flasher Emulation - The EMIC relay will generate repetitive clicks at a slow

rate to emulate an electromechanical flasher when the turn signal or hazard warning system are operating.

The EMIC relay will generate repetitive clicks at a fast rate to indicate that the right or left turn signal are

operating with one or more bulbs inoperative. In either case, the clicks will continue until the turn signal and

hazard warning systems are turned off.

Page 15

DR/DH CHIME/BUZZER - SERVICE INFORMATION 8B - 15

• Turn Signal On Warning - The EMIC transducer will generate repetitive chimes at a slow rate to indicate that

a turn signal has been active continuously for 1.6 kilometers (1 mile) with the vehicle speed greater than 22

kilometers-per-hour (15 miles-per hour). Vehicles built for markets other than the United States and Canada

have a revised distance threshold of 4 kilometers for this feature. The chime will continue until the turn signal

input becomes inactive or until the vehicle speed message indicates that the speed is less than 22 kilometersper-hour (15 miles-per-hour), whichever occurs first. The hazard warning flashers will not activate this chime

feature.

• Warning Indicator Announcement - The EMIC transducer will generate one short chime each time the

“Check Gauges” indicator is illuminated by the instrument cluster circuitry. The “Check Gauges” indicator may

be illuminated when any critical engine or transmission systems are operating outside of their normal parameters. The instrument cluster monitors electronic messages received over the PCI data bus to determine when

to illuminate the “Check Gauges” indicator.

The EMIC provides chime service for all available features in the chime warning system. The EMIC relies upon its

internal programming, numerous hard wired inputs, and electronic message inputs received from other modules

over the PCI data bus network to provide the chime warning system features. The internal programming of the

EMIC determines the priority of each chime request input that is received, as well as the rate and duration of each

chime that is to be generated.

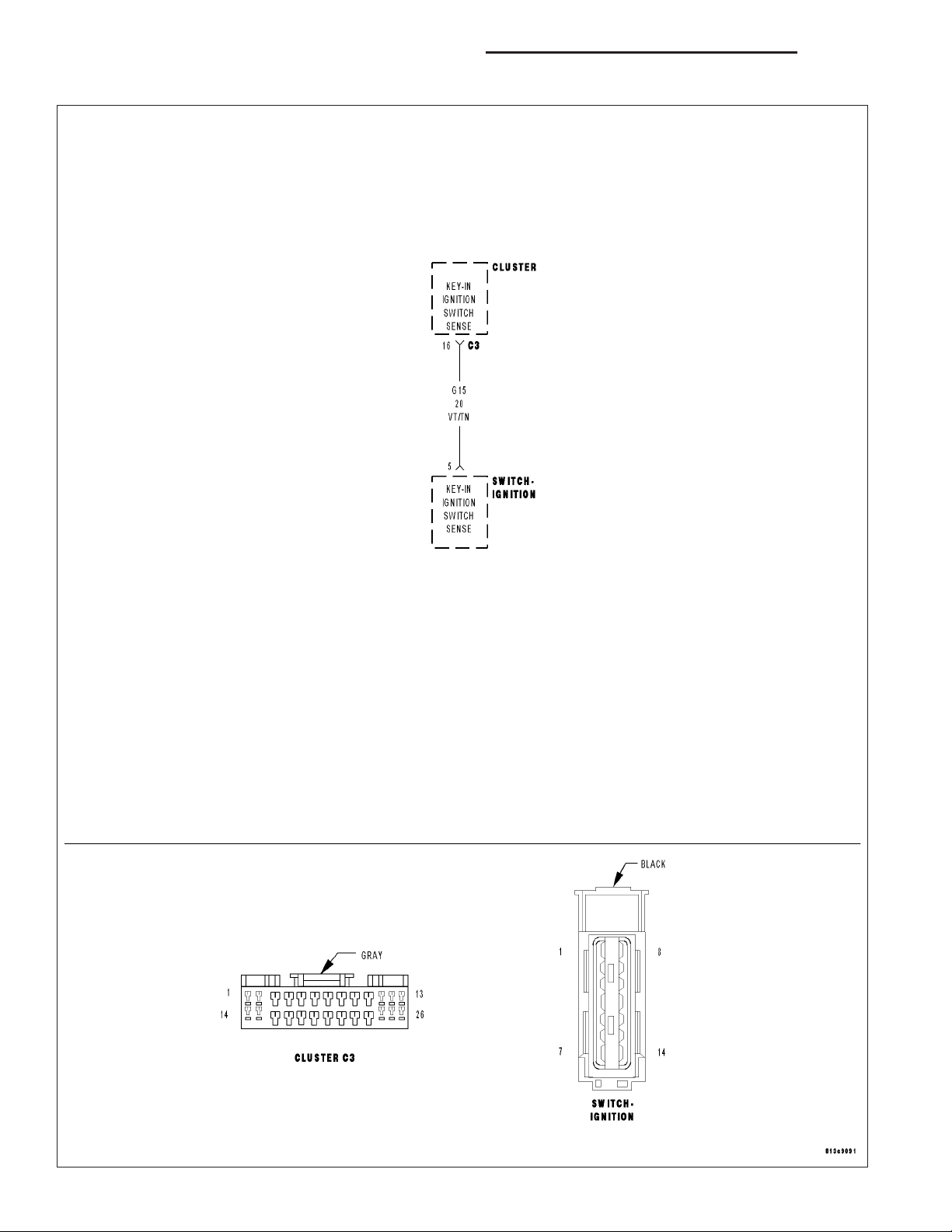

The hard wired chime warning system inputs to the EMIC may be diagnosed and tested using conventional diagnostic tools and methods. However, conventional diagnostic methods may not prove conclusive in the diagnosis of

the EMIC, the PCI data bus, or the electronic messages received by the EMIC from other modules for control of the

chime warning system. The most reliable, efficient and accurate means to diagnose the EMIC, the PCI data bus, or

the electronic message inputs used for the chime warning system requires the use of a diagnostic scan tool. Refer

to the appropriate diagnostic information.

DIAGNOSIS AND TESTING

CHIME WARNING SYSTEM

WARNING: To avoid personal injury or death, on vehicles equipped with airbags, disable the supplemental

restraint system before attempting any steering wheel, steering column, airbag, seat belt tensioner, impact

sensor, or instrument panel component diagnosis or service. Disconnect and isolate the battery negative

(ground) cable, then wait two minutes for the system capacitor to discharge before performing further diagnosis or service. This is the only sure way to disable the supplemental restraint system. Failure to take the

proper precautions could result in accidental airbag deployment.

The hard wired chime warning system inputs to the ElectroMechanical Instrument Cluster (EMIC), as well as other

hard wired circuits for this system may be diagnosed and tested using conventional diagnostic tools and methods.

Refer to the appropriate wiring information. The wiring information includes wiring diagrams, proper wire and connector repair procedures, details of wire harness routing and retention, connector pin-out information and location

views for the various wire harness connectors, splices and grounds.

However, conventional diagnostic methods may not prove conclusive in the diagnosis of the EMIC, the Programmable Communications Interface (PCI) data bus, or the electronic message inputs used by the EMIC to provide

chime warning system service. The most reliable, efficient, and accurate means to diagnose the EMIC, the PCI data

bus, and the electronic message inputs for the chime warning system requires the use of a diagnostic scan tool.

Refer to the appropriate diagnostic information.

Page 16

8B - 16 CHIME/BUZZER - SERVICE INFORMATION DR/DH

CONDITION POSSIBLE CAUSES CORRECTION

NO SEAT BELT WARNING

CHIME WITH SEAT BELT

UNBUCKLED, BUT OTHER

CHIME FEATURES OK

SEAT BELT WARNING CHIME

WITH SEAT BELT BUCKLED

1. Seat belt switch ground

circuit open.

2. Seat belt switch sense circuit

open.

3. Faulty seat belt switch. 3. Check for continuity between the ground

1. Seat belt switch sense circuit

shorted.

2. Faulty seat belt switch. 2. Check for continuity between the ground

1. Check for continuity between the ground

circuit for the driver seat belt switch and a

good ground. Repair open ground circuit, if

required.

2. Check for continuity between the seat

belt switch sense circuit for the driver seat

belt switch and the instrument cluster

connector. Repair the open seat belt switch

sense circuit, if required.

circuit and the driver seat belt switch sense

circuit of the seat belt switch. There should

be continuity with the seat belt unbuckled.

Replace the faulty seat belt, if required.

1. With the driver seat belt switch and the

instrument cluster connector disconnected,

there should be no continuity between the

seat belt switch sense circuit and a good

ground. Repair the shorted seat belt switch

sense circuit, if required.

circuit cavity and the seat belt switch sense

circuit of the driver seat belt switch. There

should be no continuity with the seat belt

buckled. Replace the faulty seat belt, if

required.

NO KEY-IN IGNITION

WARNING CHIME, BUT

OTHER CHIME FEATURES OK

1. Driver door ajar switch sense

circuit open.

2. Key-in ignition switch sense

circuit open.

3. Key-in ignition switch ground

circuit open.

4. Faulty ignition switch. 4. Check for continuity between the ground

1. Check for continuity between the driver

door ajar switch sense circuit connector and

the instrument cluster connector. Repair the

open driver door ajar switch sense circuit, if

required.

2. Check for continuity between the key-in

ignition switch sense circuit connector and

instrument cluster connector. Repair the

open key-in ignition switch sense circuit, if

required.

3. Check for continuity between the ground

circuit cavity of the ignition switch connector

and a good ground. Repair the open ground

circuit, if required

circuit terminal and the key-in ignition switch

sense circuit terminal in the ignition switch

connector. There should be continuity with a

key in the ignition lock cylinder. Replace the

faulty ignition switch, if required.

Page 17

DR/DH CHIME/BUZZER - SERVICE INFORMATION 8B - 17

CONDITION POSSIBLE CAUSES CORRECTION

NO EXTERIOR LAMPS-ON

WARNING CHIME, BUT

OTHER CHIME FEATURES OK

NO CHIMES AND OTHER

INSTRUMENT CLUSTER

FEATURES ERRATIC OR

DISABLED

1. Driver door ajar switch sense

circuit open.

2. Headlamp switch signal

circuit open.

1. Instrument cluster ground

circuit(s) open.

2. Instrument cluster fused B(+)

circuit(s) open.

3. Instrument cluster fused

ignition switch output (run-start)

circuit open.

4. Faulty instrument cluster. 4. Replace the faulty instrument cluster, if

1. Check for continuity between the driver

door ajar switch sense circuit connector and

the instrument cluster connector. Repair the

open driver door ajar switch sense circuit, if

required.

2. Check for continuity between the

headlamp switch output circuit connector

and the and the instrument cluster

connector. Repair the open headlamp

switch signal circuit, if required.

1. Check for continuity between the ground

circuits of the instrument cluster connector

and a good ground. Repair the open ground

circuits(s), if required.

2. Check for battery voltage at the B(+)

circuits of the instrument cluster connector.

Repair the open fused B(+) circuit(s), if

required.

3. With the ignition switch in the On

position, check for battery voltage at the

fused ignition switch output (run-start) circuit

of the instrument cluster connector. Repair

the open fused ignition switch output

(run-start) circuit, if required.

required.

NO CHIMES, BUT ALL OTHER

INSTRUMENT CLUSTER

FEATURES OK

1. Faulty instrument cluster. 1. Replace the faulty instrument cluster, if

required.

Page 18

Loading...

Loading...