DN ENGINE 9 - 1

ENGINE

TABLE OF CONTENTS

page page

4.7L ENGINE.............................. 1

5.2L ENGINE............................. 86

4.7L ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE.................................2

ENGINE LUBRICATION SYSTEM..............3

CYLINDER BLOCK.........................5

CRANKSHAFT............................5

PISTON AND CONNECTING ROD .............5

CYLINDER HEAD..........................5

VALVE GUIDES ...........................5

VALVES.................................5

VALVE STEM SEAL ........................5

VALVE SPRING ...........................6

HYDRAULIC LASH ADJUSTER ...............6

TIMING DRIVE SYSTEM ....................6

CAMSHAFT ..............................6

ROCKER ARM............................6

CYLINDER HEAD COVER ...................6

OILPAN.................................7

STRUCTURAL DUST COVER ................7

INTAKE MANIFOLD ........................7

EXHAUST MANIFOLD ......................7

DIAGNOSIS AND TESTING

ENGINE DIAGNOSIS—INTRODUCTION.........7

SERVICE DIAGNOSIS—PERFORMANCE .......8

SERVICE DIAGNOSIS—MECHANICAL.........10

SERVICE DIAGNOSIS—LUBRICATION.........11

INTAKE MANIFOLD LEAKAGE DIAGNOSIS .....11

CYLINDER COMPRESSION PRESSURE TEST . . 11

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS ...........................12

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST ........................12

ENGINE OIL LEAK INSPECTION .............13

REAR SEAL AREA LEAKS—INSPECTION ......14

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS ...........................14

CHECKING ENGINE OIL PRESSURE..........15

5.9L ENGINE............................ 135

SERVICE PROCEDURES

FORM-IN-PLACE GASKETS.................15

ENGINE OIL.............................16

REPAIR DAMAGED OR WORN THREADS......17

CYLINDER BORE—HONING ................18

HYDROSTATIC LOCK .....................18

VALVE SERVICE .........................19

ENGINE TIMING—VERIFICATION ............19

TIMING CHAIN—MEASURING WEAR .........22

PISTONS—FITTING.......................22

PISTON RINGS—FITTING ..................24

CONNECTING ROD BEARINGS—FITTING .....25

CRANKSHAFT MAIN BEARINGS .............27

REMOVAL AND INSTALLATION

ENGINE MOUNTS—LEFT AND RIGHT.........28

ENGINE MOUNT—REAR ...................29

STRUCTURAL COVER.....................30

ENGINE ASSEMBLY.......................31

INTAKE MANIFOLD .......................35

EXHAUST MANIFOLDS ....................36

CYLINDER HEAD COVER ..................38

ROCKER ARMS..........................40

CYLINDER HEADS........................41

VALVE SPRINGS AND SEALS ...............46

HYDRAULIC LASH ADJUSTER ..............46

CRANKSHAFT DAMPER ...................47

TIMING CHAIN COVER ....................48

TIMING CHAIN AND SPROCKETS ............49

IDLER SHAFT—TIMING DRIVE ..............55

CAMSHAFTS—IN VEHICLE .................56

CRANKSHAFT MAIN BEARINGS .............61

OIL PAN 4X2 VEHICLE.....................61

OIL PAN 4X4 VEHICLE.....................64

PISTON AND CONNECTING ROD ............65

CRANKSHAFT ...........................67

FLEXPLATE .............................69

9 - 2 4.7L ENGINE DN

OIL PUMP ..............................69

ENGINE OIL PRESSURE SENDING UNIT ......70

CRANKSHAFT OIL SEAL—FRONT............70

CRANKSHAFT OIL SEAL—REAR.............73

ENGINE CORE PLUGS ....................74

DISASSEMBLY AND ASSEMBLY

OIL PUMP ..............................74

CLEANING AND INSPECTION

INTAKE MANIFOLD .......................75

EXHAUST MANIFOLD .....................75

DESCRIPTION AND OPERATION

ENGINE

DESCRIPTION

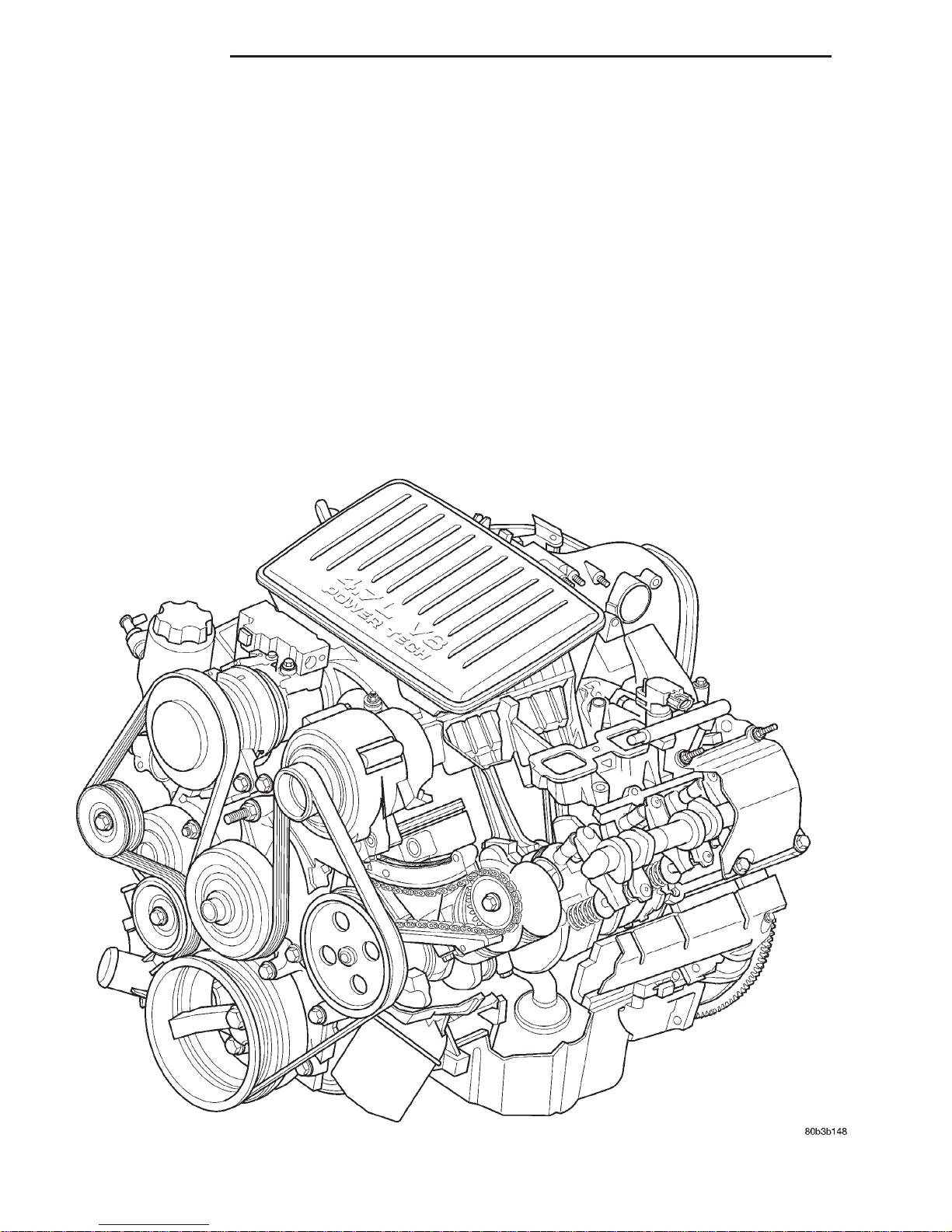

The 4.7 liter (287 CID) eight-cylinder engine is an

90° single overhead camshaft engine. The cast iron

CYLINDER HEADS........................75

PISTON AND CONNECTING ROD ............76

OILPAN................................76

OIL PUMP ..............................76

CYLINDER BLOCK........................76

SPECIFICATIONS

4.7L ENGINE ............................78

TORQUE ...............................81

SPECIAL TOOLS

4.7L ENGINE ............................82

cylinder block is made up of two different components; the first component is the cylinder bore and

upper block, the second component is the bedplate

that comprises the lower portion of the cylinder block

and houses the lower half of the crankshaft main

bearings. The cylinders are numbered from front to

rear with the left bank being numbered 1,3,5 and 7,

and the right bank being numbered 2,4,6 and 8. The

DN 4.7L ENGINE 9 - 3

DESCRIPTION AND OPERATION (Continued)

firing order is 1–8–4–3–6–5–7–2. The engine serial

number is located at the right front side of the

engine block (Fig. 1)

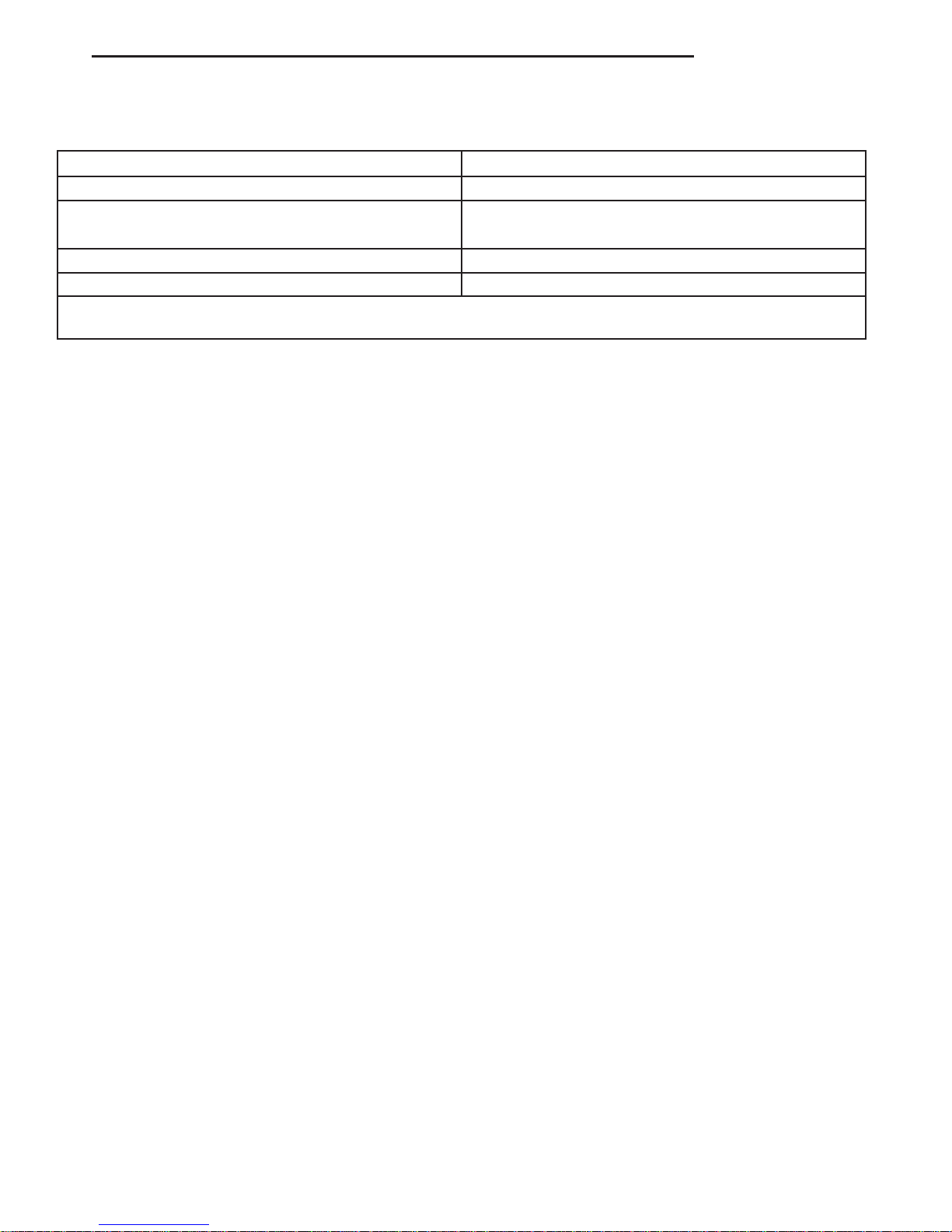

ENGINE LUBRICATION SYSTEM

DESCRIPTION

The lubrication system (Fig. 2) is a full flow filtra-

tion pressure feed type.

OPERATION

Oil from the oil pan is pumped by a gerotor type oil

pump directly mounted to the crankshaft nose. Oil

pressure is controlled by a relief valve mounted

inside the oil pump housing. For lubrication flow

refer to (Fig. 2).

The camshaft exhaust valve lobes and rocker arms

are lubricated through a small hole in the rocker

arm; oil flows through the lash adjuster then through

the rocker arm and onto the camshaft lobe. Due to

the orentation of the rocker arm, the camshaft intake

lobes are not lubed in the same manner as the

exhaust lobes. The intake lobes are lubed through

internal passages in the camshaft. Oil flows through

a bore in the number 3 camshaft bearing bore, and

as the camshaft turns, a hole in the camshaft aligns

with the hole in the camshaft bore allowing engine

oil to enter the camshaft tube. The oil then exits

through 1.6mm (0.063 in.) holes drilled into the

1 – VEHICLE VIN NUMBER LOCATION

2 – CYLINDER BLOCK RIGHT HAND SIDE

3 – CYLINDER BORE #2

intake lobes, lubricating the lobes and the rocker

arms.

Fig. 1 Engine Identification Location.

ENGINE LUBRICATION FLOW CHART—BLOCK: TABLE 1

FROM TO

Oil Pickup Tube Oil Pump

Oil Pump Oil Filter

Oil Filter Block Main Oil Gallery

Block Main Oil Gallery 1. Crankshaft Main Journal

2. Left Cylinder Head*

3. Right Cylinder Head*

Crankshaft Main Journals Crankshaft Rod Journals

Crankshaft Number One Main Journal 1.Front Timing Chain Idler Shaft

2. Both Secondary Chain Tensioners

Left Cylinder Head See Table 2

Right Cylinder Head See Table 2

* The cylinder head

gaskets have an oil restricter to control oil flow to the cylinder heads.

9 - 4 4.7L ENGINE DN

DESCRIPTION AND OPERATION (Continued)

1 – LEFT CYLINDER HEAD OIL GALLERY

2 – OIL PRESSURE SENSOR LOCATION

3 – TO LEFT CYLINDER HEAD

4 – OIL FEED TO IDLER SHAFT

5 – OIL PUMP OUTLET TO BLOCK

6 – OIL PUMP

Fig. 2 Engine Oil Lubrication System

7 – TO CRANKSHAFT MAIN JOURNALS

8 – RIGHT CYLINDER HEAD OIL GALLERY

9 – TO RIGHT CYLINDER HEAD

10 – CYLINDER BLOCK MAIN GALLERY

11 – OIL FEED TO BOTH SECONDARY TENSIONERS

DN 4.7L ENGINE 9 - 5

2000 DN Service Manual

DESCRIPTION AND OPERATION (Continued)

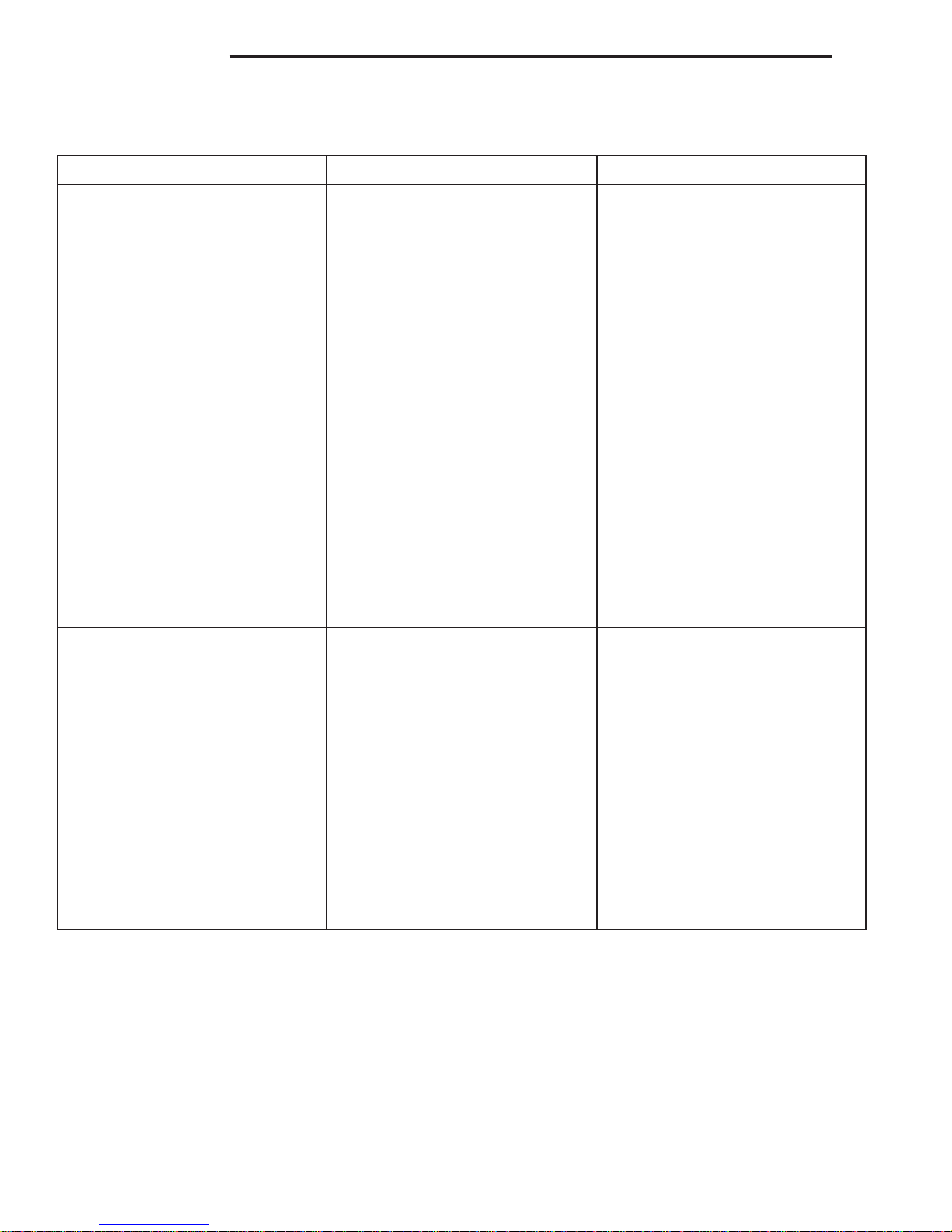

ENGINE LUBRICATION FLOW CHART—CYLINDER HEADS: TABLE 2

FROM TO

Cylinder Head Oil Port (in bolt hole) Diagonal Cross Drilling to Main Oil Gallery

Main Oil Gallery (drilled through head from rear to front)

Base of Camshaft Towers Vertical Drilling Through Tower to Camshaft Bearings**

Lash Adjuster Towers Diagonal Drillings to Hydraulic Lash Adjuster Pockets

** The number three camshaft bearing journal feeds oil into the hollow camshaft tubes. Oil is routed to the intake

lobes, which have oil passages drilled into them to lubricate the rocker arms.

1. Base of Camshaft Towers

2. Lash Adjuster Towers

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

CYLINDER BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate is bolted to

the block. The block design allows coolant flow

between the cylinders bores, and an internal coolant

bypass to a single poppet inlet thermostat is included

in the cast aluminum front cover.

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design

with eight counterweights for balancing purposes.

The crankshaft is supported by five select main bearings with the number three serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The number eight counterweight has provisions for

crankshaft position sensor target wheel mounting.

The select fit main bearing markings are located on

the rear side of the target wheel. The crankshaft oil

seals are one piece design. The front oil seal is

retained in the timing chain cover, and the rear seal

is pressed in to a bore formed by the cylinder block

and the bedplate assembly.

LATE BUILD

The pistons are made of high strength aluminum

alloy. The top ring groove and crown are Not anodized, instead the top ring is coated with an anti-scuff

coating to reduce friction on the top ring. The piston

skirts are coated with a solid lubricant (Molykote) to

reduce friction and provide scuff resistance. The connecting rods are made of forged powdered metal,

with a “fractured cap” design. A pressed fit piston pin

is used to attach the piston and connecting rod.

CYLINDER HEAD

DESCRIPTION

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylinder heads.

VALVE GUIDES

DESCRIPTION

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide reaming is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

PISTON AND CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark connecting rods as damage may result, instead use ink

or a scratch awl.

EARLY BUILD

The pistons are made of a high strength aluminum

alloy with an anodized top ring groove and crown. Piston

skirts are coated with a solid lubricant (Molykote) to

reduce friction and provide scuff resistance. The connecting rods are made of forged powdered metal, with a

“fractured cap” design. A pressed fit piston pin is used to

attach the piston and connecting rod.

VALVES

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

VALVE STEM SEAL

DESCRIPTION

The valve stem seals are made of rubber and incorporate an integral steel valve spring seat. The integral garter spring maintains consistent lubrication

control to the valve stems.

9 - 6 4.7L ENGINE DN

DESCRIPTION AND OPERATION (Continued)

VALVE SPRING

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are common for

intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

HYDRAULIC LASH ADJUSTER

DESCRIPTION

Valve lash is controlled by hydraulic lash adjusters

that are stationary mounted in the cylinder heads.

The lash adjusters have a hole in the ball plunger

that feeds oil through the rocker arm squirt holes for

rocker arm roller and camshaft lobe lubrication.

TIMING DRIVE SYSTEM

DESCRIPTION

The timing drive system has been designed to provide quiet performance and reliability to support a

non-free wheeling engine. Specifically the intake

valves are non-free wheeling and can be easily damaged with forceful engine rotation if camshaft-tocrankshaft timing is incorrect. The timing drive

system consists of a primary chain and two secondary timing chain drives.

OPERATION

The primary timing chain is a single inverted tooth

type. The primary chain drives the large fifty tooth

idler sprocket directly from a 25 tooth crankshaft

sprocket. Primary chain motion is controlled by a

pivoting leaf spring tensioner arm and a fixed guide.

The arm and the guide both use nylon plastic wear

faces for low friction and long wear. The primary

chain receives oil splash lubrication from the secondary chain drive and oil pump leakage. The idler

sprocket assembly connects the primary and secondary chain drives. The idler sprocket assembly consists of two integral thirty tooth sprockets and a fifty

tooth sprocket that is splined to the assembly. The

spline joint is a non – serviceable press fit anti rattle

type. A spiral ring is installed on the outboard side of

the fifty tooth sprocket to prevent spline disengagement. The idler sprocket assembly spins on a stationary idler shaft. The idler shaft is press-fit into the

cylinder block. A large washer on the idler shaft bolt

and the rear flange of the idler shaft are used to control sprocket thrust movement. Pressurized oil is

routed through the center of the idler shaft to provide lubrication for the two bushings used in the

idler sprocket assembly.

There are two secondary drive chains, both are

inverted tooth type, one to drive the camshaft in each

SOHC cylinder head. There are no shaft speed

changes in the secondary chain drive system. Each

secondary chain drives a thirty tooth cam sprocket

directly from the thirty tooth sprocket on the idler

sprocket assembly. A fixed chain guide and a hydraulic oil damped tensioner are used to maintain tension

in each secondary chain system. The hydraulic tensioners for the secondary chain systems are fed pressurized oil from oil reservoir pockets in the block.

Each tensioner also has a mechanical ratchet system

that limits chain slack if the tensioner piston bleeds

down after engine shut down. The tensioner arms

and guides also utilize nylon wear faces for low friction and long wear. The secondary timing chains

receive lubrication from a small orifice in the tensioners. This orifice is protected from clogging by a

fine mesh screen which is located on the back of the

hydraulic tensioners.

CAMSHAFT

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. A steel

post or nose piece is friction-welded to the steel camshaft tube. Five bearing journals are machined into

the camshaft, four on the steel tube and one on the

steel nose piece. Camshaft end play is controlled by

two thrust walls that border the nose piece journal.

Engine oil enters the hollow camshafts at the third

journal and lubricates every intake lobe rocker

through a drilled passage in the intake lobe.

ROCKER ARM

DESCRIPTION

The rocker arms are steel stampings with an integral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

CYLINDER HEAD COVER

DESCRIPTION

The cylinder head covers are made of die cast magnesium, and are not interchangeable from side-toside. It is imperative that nothing rest on the

cylinder head covers. Prolonged contact with other

items may wear a hole in the cylinder head cover.

DN 4.7L ENGINE 9 - 7

DESCRIPTION AND OPERATION (Continued)

OIL PAN

DESCRIPTION

The engine oil pan is made of laminated steel and

has a single plane sealing surface. The sandwich

style oil pan gasket has an integrated windage tray

and steel carrier. The sealing area of the gasket is

molded with rubber and is designed to be reused as

long as the gasket is not cut, torn or ripped.

STRUCTURAL DUST COVER

DESCRIPTION

The structural dust cover is made of die cast aluminum and joins the lower half of the transmission

bell housing to the engine bedplate.

OPERATION

The structural cover provides additional powertrain stiffness and reduces noise and vibration.

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite material and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks. Eight studs and

two bolts are used to fasten the intake to the head.

EXHAUST MANIFOLD

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

DIAGNOSIS AND TESTING

ENGINE DIAGNOSIS—INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either performance (e.g., engine idles rough and stalls) or

mechanical (e.g., a strange noise).

Refer to the Service Diagnosis—Performance chart

and the Service Diagnosis—Mechanical chart for possible causes and corrections of malfunctions. Refer to

Group 14, Fuel System for the fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagnosis is provided within the following diagnosis:

• Cylinder Compression Pressure Test.

• Cylinder Combustion Pressure Leakage Test.

• Engine Cylinder Head Gasket Failure Diagnosis.

• Intake Manifold Leakage Diagnosis.

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

9 - 8 4.7L ENGINE DN

DIAGNOSIS AND TESTING (Continued)

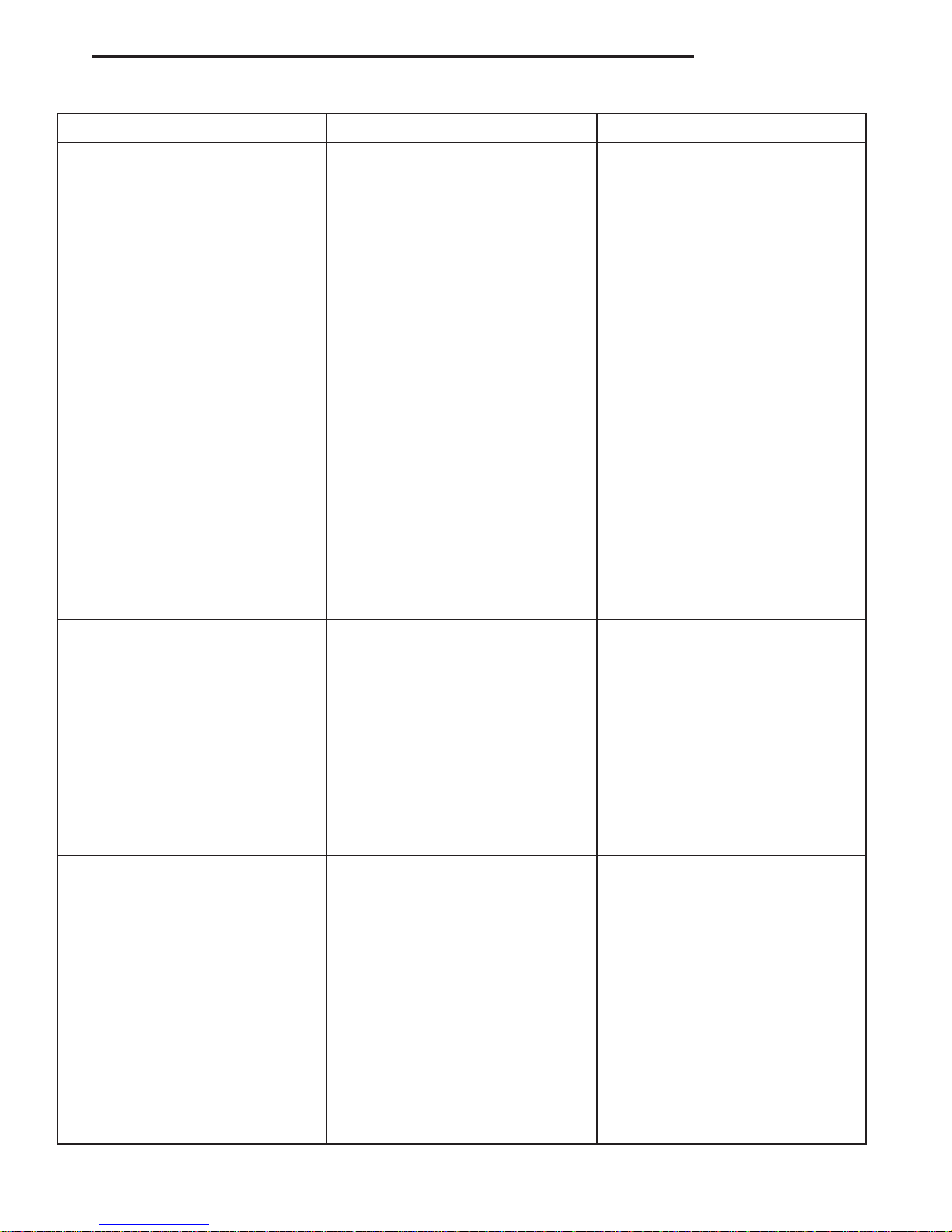

SERVICE DIAGNOSIS—PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.

3. Faulty starter. 3. Refer to Group 8A, Battery/

4. Moisture on ignition wires and

distributor cap.

5. Faulty ignition cables. 5. Replace as necessary.

6. Faulty coil or control unit. 6. Refer to Group 8D, Ignition

7. Incorrect spark plug gap. 7. Refer to Group 8D, Ignition

8. Incorrect ignition timing. 8. Refer to Group 8D, Ignition

9. Dirt or water in fuel system. 9. Clean system and replace fuel

10. Faulty fuel pump, relay or

wiring.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. Refer to Group 14, Fuel System.

2. Idle mixture to lean or to rich. 2. Refer to Group 14, Fuel System.

3. Vacuum leak. 3. Inspect intake manifold and

4. Worn or burned distributor rotor. 4. Replace distributor rotor.

5. Incorrect ignition wiring. 5. Install correct wiring.

6. Faulty coil. 6. Refer to Group 8D, Ignition

7. EGR valve leaking. 7. Refer to Group 25, Emissions

8. Incorrect cam timing. 8. Refer to Valve Timing in this

2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

Starter/ Charging System

Diagnostics.

4. Wipe wires and cap clean and

dry.

System.

System.

System.

filter.

10. Refer to Group 14, Fuel System.

vacuum hoses, repair or replace as

necessary.

System.

Control System.

section.

DN 4.7L ENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE LOSS OF POWER 1. Incorrect ignition timing. 1. Refer to Group 8D, Ignition

System.

2. Worn or burned distributor rotor. 2. Replace distributor rotor.

3. Worn distributor shaft. 3. Refer to Group 8D, Ignition

System.

4. Dirty or incorrectly gapped spark

plugs.

5. Dirt or water in fuel system. 5. Clean system and replace fuel

6. Faulty fuel pump. 6. Refer to Group 14, Fuel System.

7. Blown cylinder head gasket. 7. Replace cylinder head gasket.

8. Low compression. 8. Test compression, repair as

9. Burned, warped or pitted valves. 9. Replace as necessary.

10. Plugged or restricted exhaust

system.

11. Faulty ignition cables. 11. Replace as necessary.

12. Faulty coil. 12. Refer to Group 8D, Ignition

13. Incorrect cam timing. 13. Refer to Valve Timing in this

4. Refer to Group 8D, Ignition

System.

filter.

necessary.

10. Inspect and replace as

necessary.

System.

section.

ENGINE MISSES ON

ACCELERATION

ENGINE MISSES AT HIGH SPEED 1. Spark plugs dirty or incorrectly

1. Spark plugs dirty or incorrectly

gapped.

2. Incorrect ignition timing. 2. Refer to Group 8D, Ignition

3. Dirt in fuel system. 3. Clean fuel system.

4. Burned, warped or pitted valves. 4. Replcae as necessary.

5. Faulty coil. 5. Refer to Group 8D, Ignition

6. Incorrect cam timing. 6. Refer to Valve Timing in this

gapped.

2. Worn Distributor Shaft. 2. Refer to Group 8D, Ignition

3. Worn or burned distributor rotor. 3. Replace distributor rotor.

4. Faulty coil. 4. Refer to Group 8D, Ignition

5. Incorrect ignition timing. 5. Refer to Group 8D, Ignition

6. Dirt or water in fuel system. 6. Clean system and replace fuel

7. Incorrect cam timing. 7. Refer to Valve Timing in this

1. Refer to Group 8D, Ignition

System.

System.

System.

section.

1. Refer to Group 8D, Ignition

System.

System.

System.

System.

filter.

section.

9 - 10 4.7L ENGINE DN

DIAGNOSIS AND TESTING (Continued)

SERVICE DIAGNOSIS—MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

4. Dirt in lash adjusters. 4. Clean lash adjusters.

5. Bent push rods. 5. Replace as necessary.

6. Worn rocker arms. 6. Replace as necessary.

7. Worn tappets 7. Replace as necessary.

8. Worn valve guides. 8. Refer to Valve Service in this

9. Excessive runout of valve seats

on valve faces.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Refer to Group 0, Lubrication and

2. Low oil pressure. 2. Refer to Group 0, Lubrication and

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

1. Refer to Group 0, Lubrication and

Maintenance.

and main bearings for excessive

wear.

section.

9. Service valves and valve seats.

Refer to Valve Service in this

section.

maintenance.

maintenance.

5. Service or replace crankshaft.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Refer to Group 0, Lubrication and

maintenance.

2. Low oil pressure. 2. Refer to Group 0, Lubrication and

maintenance.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check No. 3 main bearing for

wear on flanges.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.

7. Tighten to correct torque

DN 4.7L ENGINE 9 - 11

DIAGNOSIS AND TESTING (Continued)

SERVICE DIAGNOSIS—LUBRICATION

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. 1.

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.

2. Crankshaft rear seal 2. Replace as necessary.

3. Crankshaft seal flange.

Scratched, nicked or grooved.

4. Oil pan flange cracked. 4. Replace oil pan.

5. Timing chain cover seal,

damaged or misaligned.

6. Scratched or damaged vibration

damper hub.

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

(b) Tighten fasteners, Repair or

replace metal parts.

3. Polish or replace crankshaft.

5. Replace seal.

6. Polish or replace damper.

2. Faulty oil pressure sending unit. 2. Replace sending unit.

3. Low oil pressure. 3. Check pump and bearing

4. Clogged oil filter. 4. Replace oil filter.

5. Worn oil pump. 5. Replace as necessary.

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Clean or replace relief valve.

9. Oil pump suction tube loose or

damaged.

OIL PUMPING AT RINGS; SPARK

PLUGS FOULING

1. Worn or damaged rings. 1. Hone cylinder bores and replace

2. Carbon in oil ring slots. 2. Replace rings.

3. Incorrect ring size installed. 3. Replace rings.

4. Worn valve guides. 4. Ream guides and replace valves.

5. Leaking intake gasket. 5. Replace intake gaskets.

6. Leaking valve guide seals. 6. Replace valve guide seals.

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

clearance.

9. Replace as necessary.

rings.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunctions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

9 - 12 4.7L ENGINE DN

DIAGNOSIS AND TESTING (Continued)

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs.

(3) Secure the throttle in the wide-open position.

(4) Disable the fuel system. (Refer to Group 14,

Fuel System for the correct procedure)

(5) Disconnect the ignition coil.

(6) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(7) Record the compression pressure on the 3rd

revolution. Continue the test for the remaining cylinders.

Refer to Engine Specifications for the correct

engine compression pressures.

CYLINDER HEAD GASKET FAILURE DIAGNOSIS

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

• Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

• Loss of engine power

• Engine misfiring

• Poor fuel economy

• Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

• Engine overheating

• Loss of coolant

• Excessive steam (white smoke) emitting from

exhaust

• Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the procedures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approximately a 50–70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRESSURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCESSIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester’s pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

• Exhaust and intake valve leaks (improper seat-

ing).

• Leaks between adjacent cylinders or into water

jacket.

• Any causes for combustion/compression pressure

loss.

(1) Check the coolant level and fill as required. DO

NOT install the radiator cap.

(2) Start and operate the engine until it attains

normal operating temperature, then turn the engine

OFF.

(3) Remove the spark plugs.

(4) Remove the oil filler cap.

(5) Remove the air cleaner.

Calibrate the tester according to the manufacturer’s

(6)

instructions. The shop air source for testing should maintain 483 kPa (70 psi) minimum, 1,379 kPa (200 psi) maximum and 552 kPa (80 psi) recommended.

(7) Perform the test procedures on each cylinder

according to the tester manufacturer’s instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE: At 552 kPa (80 psi) input pressure, a minimum of 414 kPa (60 psi) should be maintained in the cylinder.

Refer to the Cylinder Combustion Pressure Leakage Test Diagnosis chart.

DN 4.7L ENGINE 9 - 13

DIAGNOSIS AND TESTING (Continued)

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODY

AIR ESCAPES THROUGH

TAILPIPE

AIR ESCAPES THROUGH

RADIATOR

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERS

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLY

Intake valve bent, burnt, or not

seated properly

Exhaust valve bent, burnt, or not

seated properly

Head gasket leaking or cracked

cylinder head or block

Head gasket leaking or crack in

cylinder head or block between

adjacent cylinders

Stuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wall

Inspect valve and valve seat.

Reface or replace, as necessary

Inspect valve and valve seat.

Reface or replace, as necessary

Remove cylinder head and inspect.

Replace defective part

Remove cylinder head and inspect.

Replace gasket, head, or block as

necessary

Inspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at various speeds for approximately 24km (15 miles), and

repeat inspection.

(4) If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the suspected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

9 - 14 4.7L ENGINE DN

DIAGNOSIS AND TESTING (Continued)

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crankcase as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until disassembled.

REAR SEAL AREA LEAKS—INSPECTION

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces. See Group 9, Engines, for

proper repair procedures of these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until disassembled. Refer to the service Diagnosis—Mechanical, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, Refer to Group

9, Engines—Crankshaft Rear Oil Seals, for proper

replacement procedures.

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylinder head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maximum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

DN 4.7L ENGINE 9 - 15

DIAGNOSIS AND TESTING (Continued)

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit (Fig. 3) and

install gauge assembly C-3292.

Fig. 3 Oil Pressure Sending Unit

1 – BELT

2 – OIL PRESSURE SENSOR

3 – OIL FILTER

4 – ELEC. CONNECTOR

(2) Run engine until thermostat opens.

(3) Oil Pressure:

• Curb Idle—25 Kpa (4 psi) minimum

• 3000 rpm—170 - 550 KPa (25 - 80 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

SERVICE PROCEDURES

FORM-IN-PLACE GASKETS

There are several places where form-in-place gaskets are used on the engine. DO NOT use form-in-

place gasket material unless specified. Care

must be taken when applying form-in-place gaskets.

Bead size, continuity and location are of great importance. Too thin a bead can result in leakage while too

much can result in spill-over. A continuous bead of

the proper width is essential to obtain a leak-free

joint.

Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber

Adhesive Sealant and Mopar Gasket Maker). Each

have different properties and cannot be used interchangeably.

MOPAR SILICONE RUBBER ADHESIVE SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture

in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of a year and will not properly cure

if over aged. Always inspect the package for the expiration date before use.

MOPAR GASKET MAKER

Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezed

between smooth machined metallic surfaces. It will

not cure if left in the uncovered tube. DO NOT use

on flexible metal flanges.

SURFACE PREPARATION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some

instances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket contact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

minutes). The use of a locating dowel is recommended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the material surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a

9 - 16 4.7L ENGINE DN

SERVICE PROCEDURES (Continued)

locating dowel is recommended during assembly to

prevent smearing the material off location.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certified. MOPARt provides engine oils that conform to

this service grade.

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CONSERVING is located on the label of an engine oil container.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 5).

Fig. 5 Engine Oil Container Standard Notations

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

rear of the engine on the 4.7L engines. (Fig. 6).

SAE VISCOSITY

An SAE viscosity grade is used to specify the viscosity of engine oil. Use only engine oils with multiple viscosities such as 5W-30 or 10W-30 in the 4.7L

engines. These are specified with a dual SAE viscosity grade which indicates the cold-to-hot temperature

viscosity range. Select an engine oil that is best

suited to your particular temperature range and variation (Fig. 4).

Fig. 4 Temperature/Engine Oil Viscosity—4.7L

Engine

Fig. 6 Engine Oil Dipstick 4.7L Engine

1 – TRANSMISSION DIPSTICK

2 – ENGINE OIL DIPSTICK

3 – ENGINE OIL FILL CAP

DN 4.7L ENGINE 9 - 17

SERVICE PROCEDURES (Continued)

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhibited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten minutes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

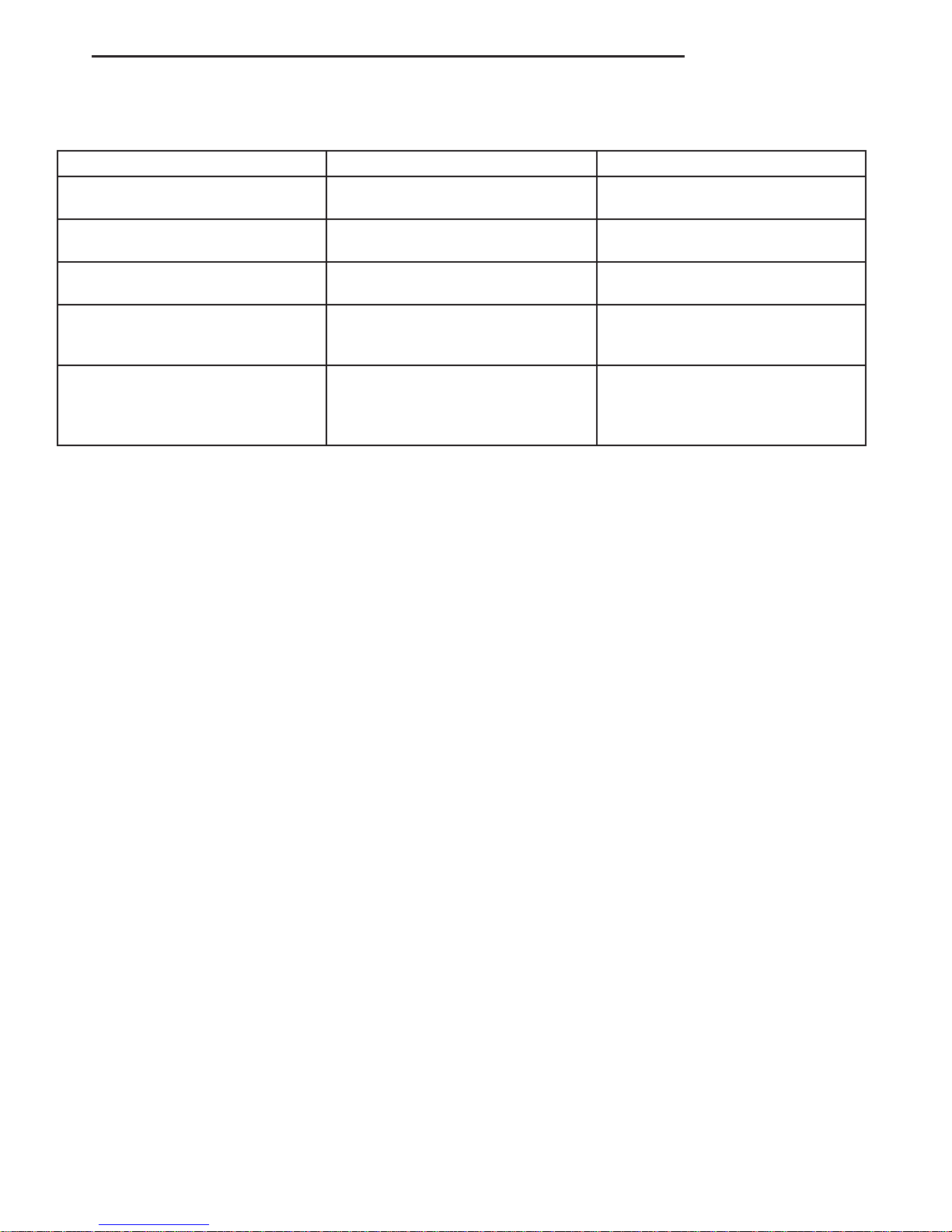

OIL FILTER REMOVAL

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise (Fig. 7) to

remove it from the cylinder block oil filter boss.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating temperature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this section.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

ENGINE OIL FILTER CHANGE

Fig. 7 Oil Filter—4.7L Engine

1 – ENGINE OIL FILTER

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

OIL FILTER INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 8) hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

FILTER SPECIFICATION

All engines are equipped with a high quality fullflow, disposable type oil filter. DaimlerChrysler Corporation recommends a Mopar or equivalent oil filter

be used.

REPAIR DAMAGED OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

9 - 18 4.7L ENGINE DN

SERVICE PROCEDURES (Continued)

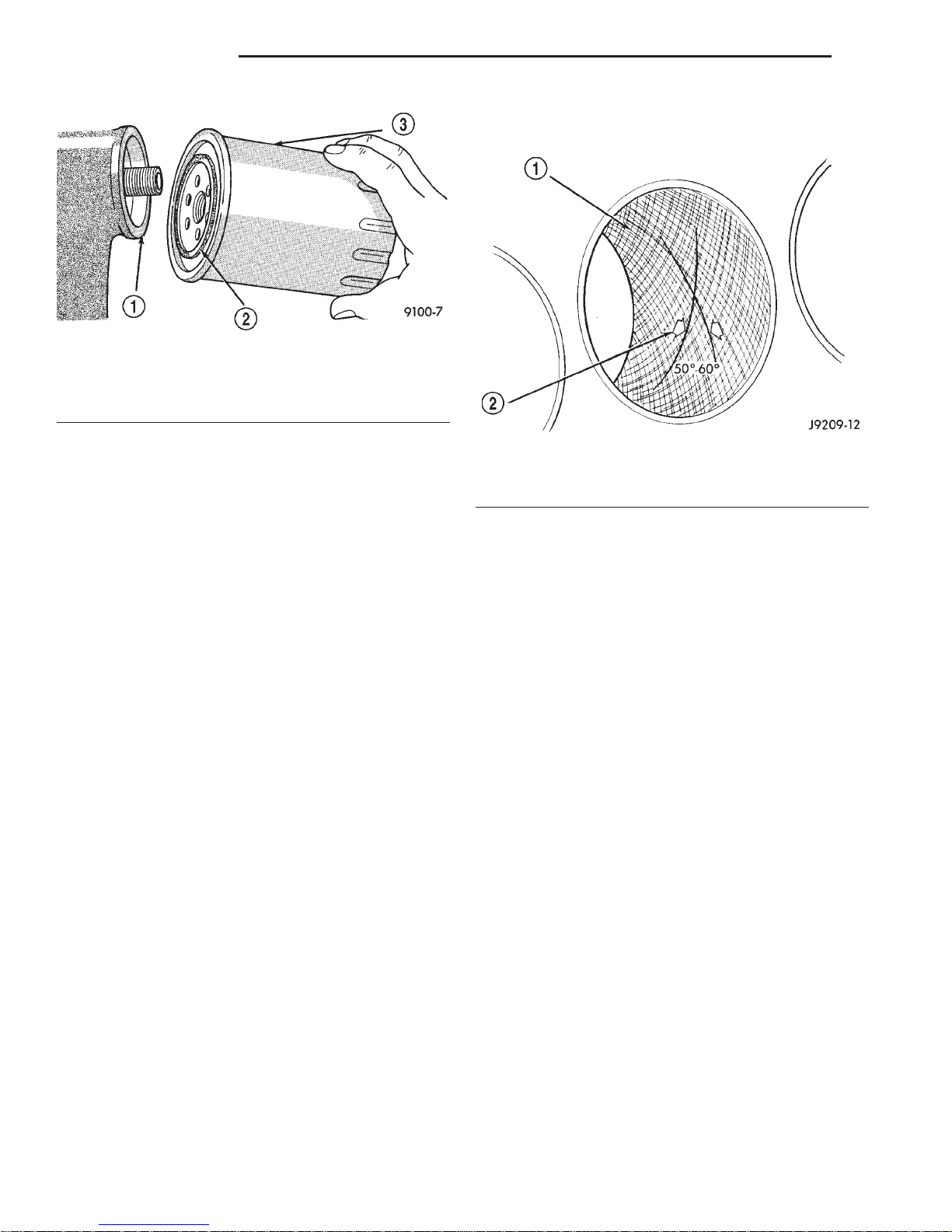

The hone marks should INTERSECT at 50° to 60°

for proper seating of rings (Fig. 9).

Fig. 8 Oil Filter Sealing Surface—Typical

1 – SEALING SURFACE

2 – RUBBER GASKET

3 – OIL FILTER

Damaged or worn threads can be repaired. Essentially, this repair consists of:

• Drilling out worn or damaged threads.

• Tapping the hole with a special Heli-Coil Tap, or

equivalent.

• Installing an insert into the tapped hole to bring

the hole back to its original thread size.

CYLINDER BORE—HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylinder surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be sufficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

Fig. 9 Cylinder Bore Crosshatch Pattern

1 – CROSSHATCH PATTERN

2 – INTERSECTANGLE

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper crosshatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50° to 60°

angle. Faster up and down strokes increase the crosshatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and detergent. Dry parts thoroughly. Use a clean, white, lintfree cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the battery negative cable.

(3) Inspect air cleaner, induction system and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the

engine.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crankshaft using a breaker bar and socket.

DN 4.7L ENGINE 9 - 19

SERVICE PROCEDURES (Continued)

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N·m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil.

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

VALVE SERVICE

REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete surface must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 – 2.36 mm (0.0689 –

0.0928 in.) and the exhaust seat must be 1.71 – 2.32

mm (0.0673 – 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 – 45 degrees angle.

Fig. 10 Valve Assembly Configuration

1 – VALVE LOCKS (3–BEAD)

2 – RETAINER

3 – VALVE STEM OIL SEAL

4 – INTAKE VALVE

5 – EXHAUST VALVE

6 – VALVE SPRING

ENGINE TIMING—VERIFICATION

CAUTION: The 4.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

NOTE: The blue link plates on the chains and the

dots on the camshaft drive sprockets may not line

up during the timing verification procedure. The

blue link plates are lined up with the sprocket dots

only when re-timing the complete timing drive.

Once the timing drive is rotated blue link-to-dot

alignment is no longer valid.

Engine base timing can be verified by the following

procedure:

(1) Remove the cylinder head covers. Refer to the

procedure in this section.

(2) Using a mirror, locate the TDC arrow on the

front cover (Fig. 11). Rotate the crankshaft until the

mark on the crankshaft damper is aligned with the

TDC arrow on the front cover. The engine is now at

TDC.

9 - 20 4.7L ENGINE DN

SERVICE PROCEDURES (Continued)

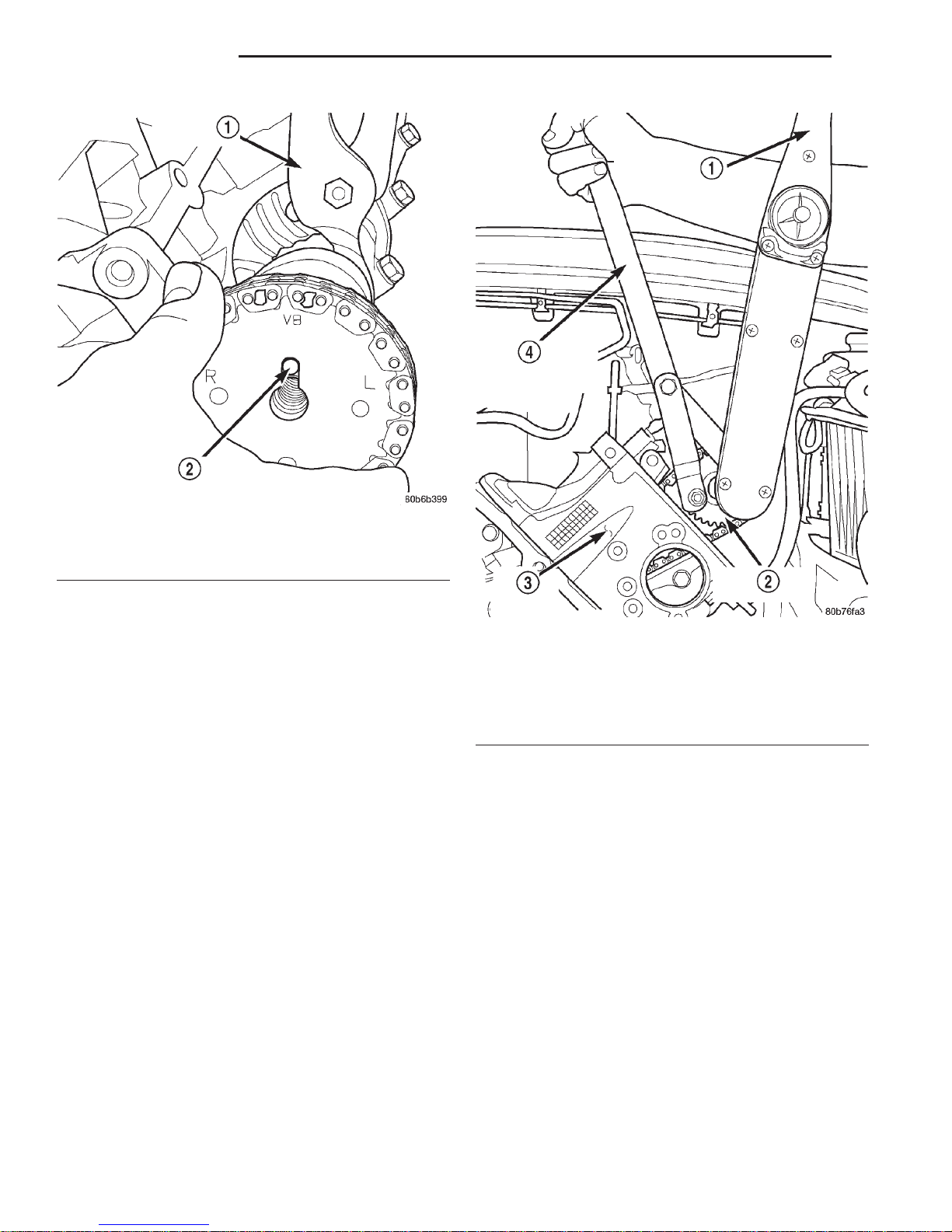

SINGLE CAMSHAFT TIMING

NOTE: to adjust the timing on one camshaft, preform the following procedure.

(1) Using Chain Tensioner Wedge, special tool

8350, stabilize the secondary chain drive. For reference purposes, mark the chain-to-sprocket position

(Fig. 13).

(2) Remove the camshaft drive gear retaining bolt.

(3) Carefully remove the camshaft drive gear from

the camshaft.

(4) Re-index the camshaft drive gear in the chain

until the V8 mark is at the same position as the V8

mark on the opposite camshaft drive gear.

NOTE: When gripping the camshaft, place the pliers on the tube portion of the camshaft only. Do not

grip the lobes or the sprocket areas.

(5) Using a suitable pair of adjustable pliers,

rotate the camshaft until the alignment dowel on the

Fig. 11 Engine Top Dead Center (TDC) Indicator

Mark

1 – TIMING CHAIN COVER

2 – CRANKSHAFT TIMING MARKS

(3) Note the location of the V8 mark stamped into

the camshaft drive gears (Fig. 12). If the V8 mark on

each camshaft drive gear is at the twelve o’clock position, the engine is at TDC on the exhaust stroke. If

the V8 mark on each gear is at the six o’clock position, the engine is at TDC on the compression stroke.

(4) If both of the camshaft drive gears are off in

the same or opposite directions, the primary chain or

both secondary chains are at fault. Refer to Timing

Chain and Sprockets procedure in this section.

(5) If only one of the camshaft drive gears is off

and the other is correct, the problem is confined to

one secondary chain. Refer to Single camshaft timing, in this procedure.

(6) If both camshaft drive gear V8 marks are at

the twelve o’clock or the six o’ clock position the

engine base timing is correct. Reinstall the cylinder

head covers.

camshaft is aligned with the slot in the camshaft

drive gear (Fig. 14).

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Failure to do so may cause over-torqueing of bolt

resulting in bolt failure.

(6) Position the camshaft drive gear onto the camshaft, remove oil from bolt then install the retaining

bolt. Using Special Tools, Spanner Wrench 6958 with

Adapter Pins 8346 and a suitable torque wrench,

Tighten retaining bolt to 122N·m (90 ft. Lbs.) (Fig.

15) (Fig. 16).

(7) Remove special tool 8350.

(8) Rotate the crankshaft two full revolutions, then

reverify that the camshaft drive gear V8 marks are

in fact aligned.

(9) Install the cylinder head covers. Refer to Cylinder Head Cover in this section.

DN 4.7L ENGINE 9 - 21

SERVICE PROCEDURES (Continued)

1 – LEFT CYLINDER HEAD

2 – RIGHT CYLINDER HEAD

Fig. 12 Camshaft Sprocket V8 Marks

Fig. 13 Securing Timing Chain Tensioners Using Timing Chain Wedge

1 – LEFT CYLINDER HEAD

2 – RIGHT CYLINDER HEAD

3 – SPECIAL TOOL 8350 WEDGE

4 – SPECIAL TOOL 8350 WEDGE

9 - 22 4.7L ENGINE DN

SERVICE PROCEDURES (Continued)

Fig. 14 Camshaft Dowel To Sprocket Alignment

1 – ADJUSTABLE PLIERS

2 – CAMSHAFT DOWEL

TIMING CHAIN—MEASURING WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

(1) Remove the timing chain cover. Refer to Timing

Chain Cover in this section for procedure.

(2) To determine if the secondary timing chains

are worn, rotate the engine clockwise until maximum

tensioner piston extension is obtained. Measure the

distance between the secondary timing chain tensioner housing and the step ledge on the piston (Fig.

17). The measurement at point (A) must be less than

15mm (.5906 inches).

(3) If the measurement exceeds the specification

the secondary timing chains are worn and require

replacement. Refer to Timing Chain and Sprockets in

this section for procedure.

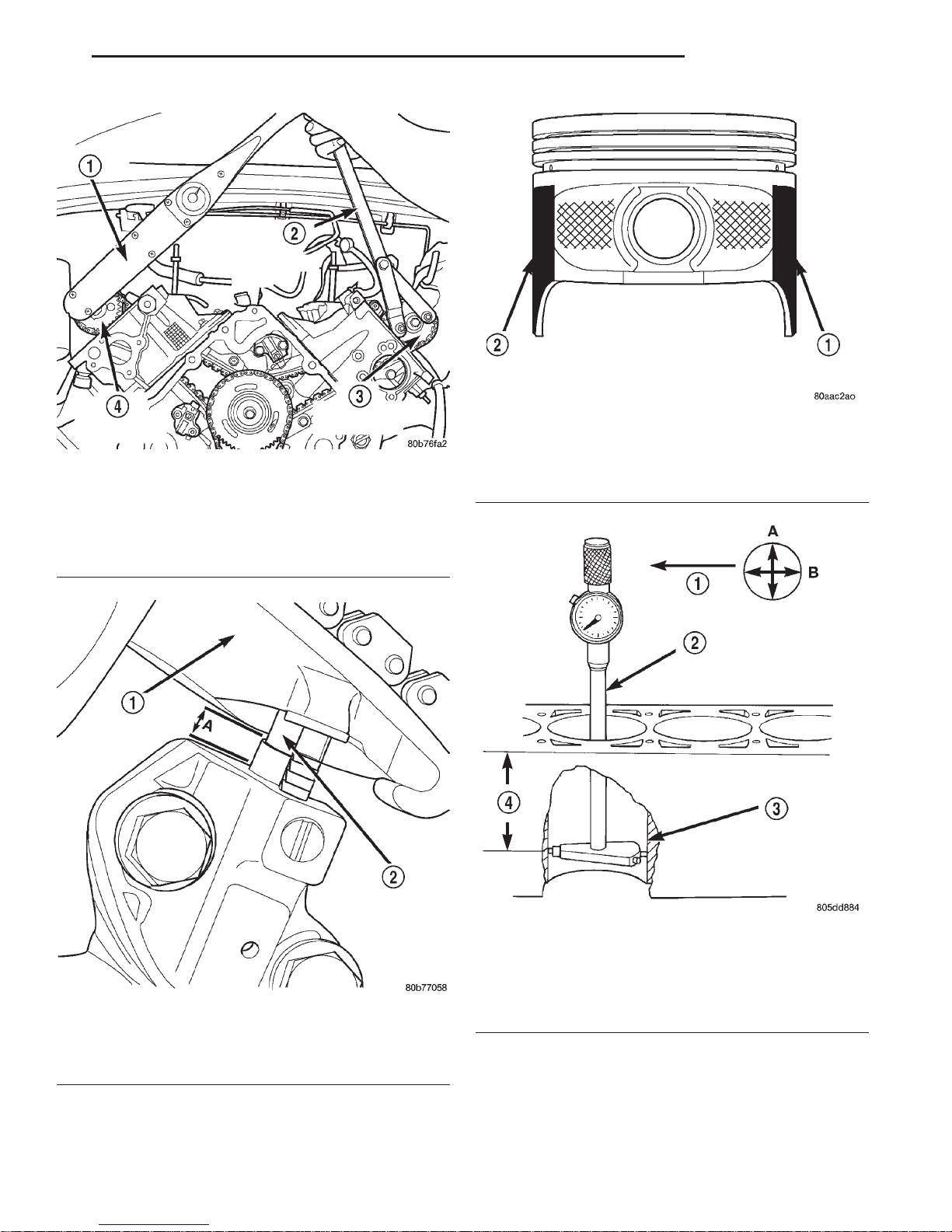

PISTONS—FITTING

BORE GAGE METHOD

(1) To correctly select the proper size piston, a cylinder bore gauge, capable of reading in 0.003 mm

(.0001 in.) INCREMENTS is required. If a bore

gauge is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 49.5 mm (1-15/16 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

Fig. 15 Camshaft Sprocket Installation—Left

Cylinder Head

1 – TORQUE WRENCH

2 – CAMSHAFT SPROCKET

3 – LEFT CYLINDER HEAD

4 – SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

an additional bore reading 90 degrees to that at point

B (Fig. 19).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled. Tin

coated pistons should not be used as replacements for

coated pistons.

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not provide accurate results (Fig. 18). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge is MANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

DN 4.7L ENGINE 9 - 23

SERVICE PROCEDURES (Continued)

Fig. 18 Moly Coated Piston

Fig. 16 Camshaft Sprocket Installation—Right

Cylinder Head

1 – TORQUE WRENCH

2 – SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 – LEFT CAMSHAFT SPROCKET

4 – RIGHT CAMSHAFT SPROCKET

1 – MOLY COATED

2 – MOLY COATED

Fig. 17 Measuring Secondary Timing Chains For

Stretch

1 – SECONDARY TENSIONER ARM

2 – SECONDARY CHAIN TENSIONER PISTON

Fig. 19 Bore Gauge—Typical

1 – FRONT

2 – BORE GAUGE

3 – CYLINDER BORE

4 – 49.5 MM

(1–15/16 in)

9 - 24 4.7L ENGINE DN

2000 DN Service Manual

SERVICE PROCEDURES (Continued)

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

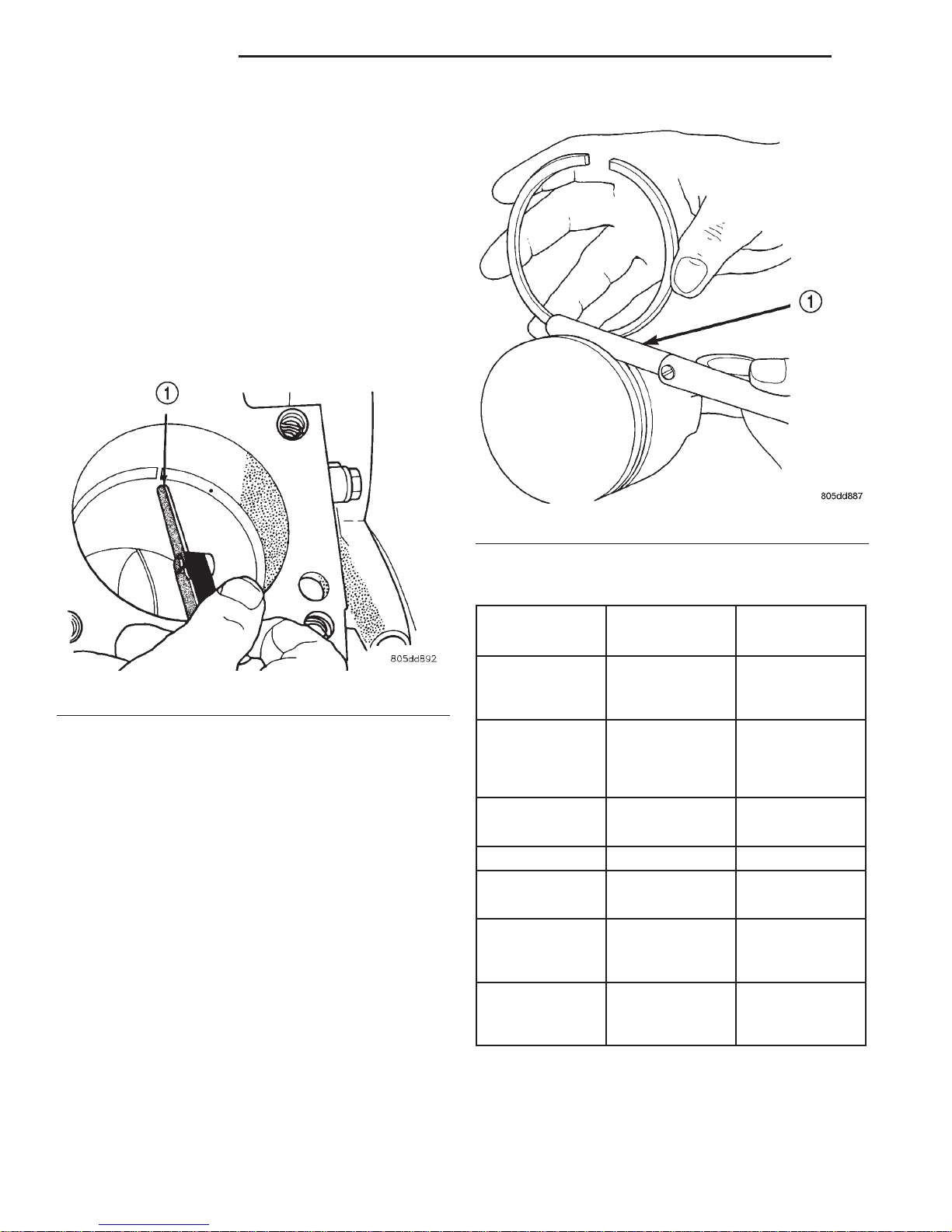

PISTON RINGS—FITTING

RING END GAP

Before reinstalling used rings or installing new

rings, the ring clearances must be checked.

(1) Wipe the cylinder bore clean.

(2) Insert the ring in the cylinder bore.

NOTE: The ring gap measurement must be made

with the ring positioned at least 12mm (0.50 inch.)

from bottom of cylinder bore.

(3) Using a piston, to ensure that the ring is

squared in the cylinder bore, slide the ring downward

into the cylinder.

(4) Using a feeler gauge check the ring end gap

(Fig. 20). Replace any rings not within specification.

Fig. 20 Ring End Gap Measurement—Typical

1 – FEELER GAUGE

PISTON RING SIDE CLEARANCE

NOTE: Make sure the piston ring grooves are clean

and free of nicks and burrs.

(5) Measure the ring side clearance as shown (Fig.

21) make sure the feeler gauge fits snugly between

the ring land and the ring. Replace any ring not

within specification.

(6) Rotate the ring around the piston, the ring

must rotate in the groove with out binding.

EARLY BUILD

(7) The No. 1 and No. 2 piston rings have a different cross section. Ensure No. 2 ring is installed with

manufacturers I.D. mark (Dot) facing up, towards top

of the piston.

LATE BUILD

The No. 1 and No. 2 piston rings have a different

cross section. Ensure No. 2 ring is installed with

manufacturers I.D. mark (Dot) facing up, towards top

of the piston. On late build engines the piston top

ring groove and crown are not anodized therefore,

the No. 1 piston ring is coated with an anti-friction

coating. Care must be used to ensure that when

Fig. 21 Measuring Piston Ring Side Clearance

1 – FEELER GAUGE

PISTON RING SPECIFICATION CHART

Ring Position Groove Maximum

Clearance Clearance

Upper Ring .051-.094mm 0.11mm

(0.0020-.0037

in.)

Intermediate

Ring

Oil Control Ring .019-.229mm .25mm

(Steel Rails) (.0007-.0090 in.) (0.010 in.)

Ring Position Ring Gap Wear Limit

Upper Ring 0.20-0.36mm 0.40mm

Intermediate

Ring

Oil Control Ring 0.025-0.76mm 1.52mm

(Steel Rail) (0.010- 0.030

0.04-0.08mm 0.10mm

(0.0016-0.0031

in.)

(0.008-0.014 in.) (0.0016in.)

0.37-0.63mm 0.71mm

(0.014-0.025 in.) (0.028in.)

in.)

(0.004 in.)

(0.004 in.)

(0.060in.)

installing piston rings on late build engines that the

correct No. 1 piston ring be installed, failure to use

the correct piston ring can cause severe damage to

the piston and/or cylinder block.

DN 4.7L ENGINE 9 - 25

SERVICE PROCEDURES (Continued)

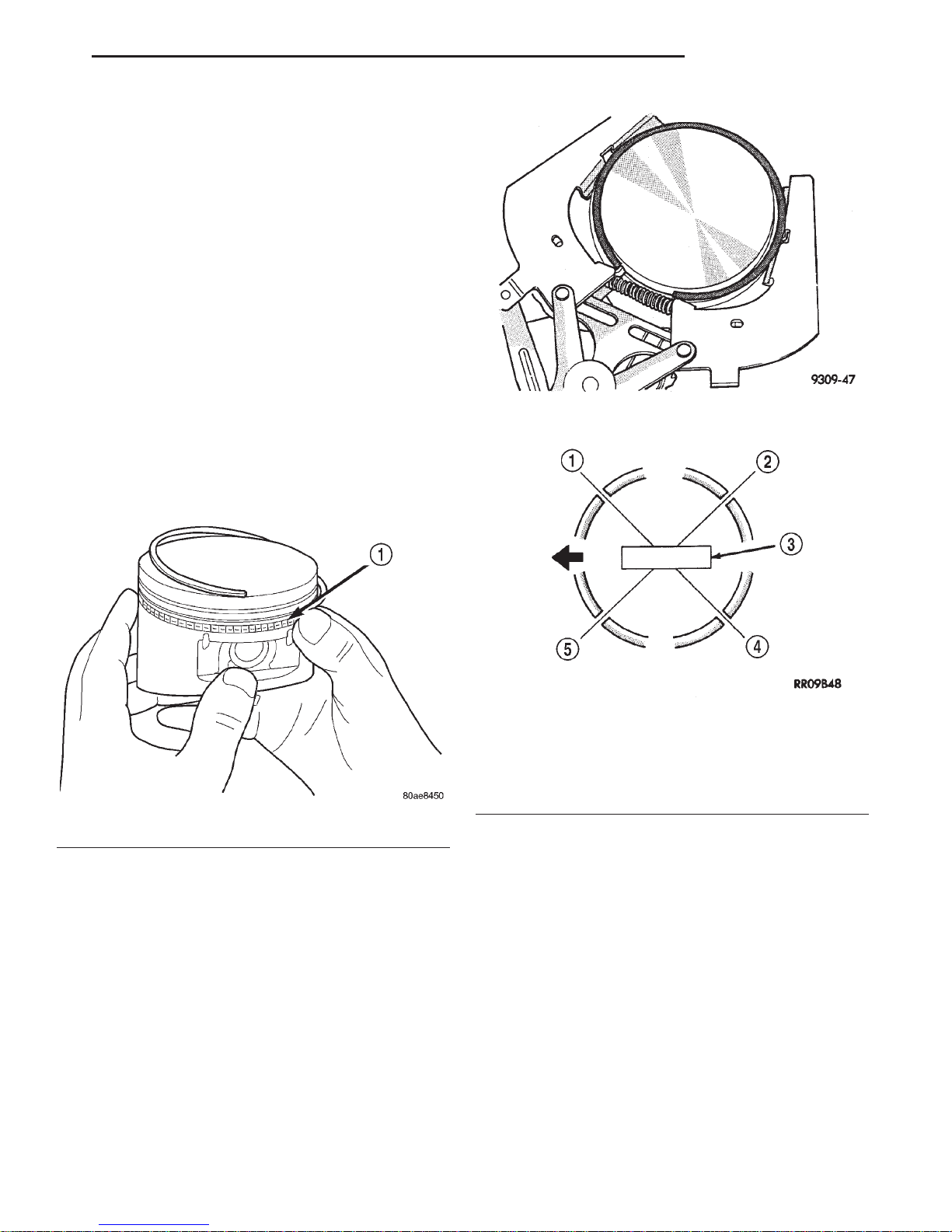

NOTE: Piston rings are installed in the following

order:

• Oil ring expander.

• Upper oil ring side rail.

• Lower oil ring side rail.

• No. 2 Intermediate piston ring.

• No. 1 Upper piston ring.

(8) Install the oil ring expander.

(9) Install upper side rail (Fig. 22) by placing one

end between the piston ring groove and the expander

ring. Hold end firmly and press down the portion to

be installed until side rail is in position. Repeat this

step for the lower side rail.

(10) Install No. 2 intermediate piston ring using a

piston ring installer (Fig. 23).

(11) Install No. 1 upper piston ring using a piston

ring installer (Fig. 23).

(12) Position piston ring end gaps as shown in

(Fig. 24). It is important that expander ring gap is at

least 45° from the side rail gaps, but not on the piston pin center or on the thrust direction.

Fig. 23 Upper and Intermediate Rings—Installation

Fig. 22 Side Rail—Installation

1 – SIDE RAIL END

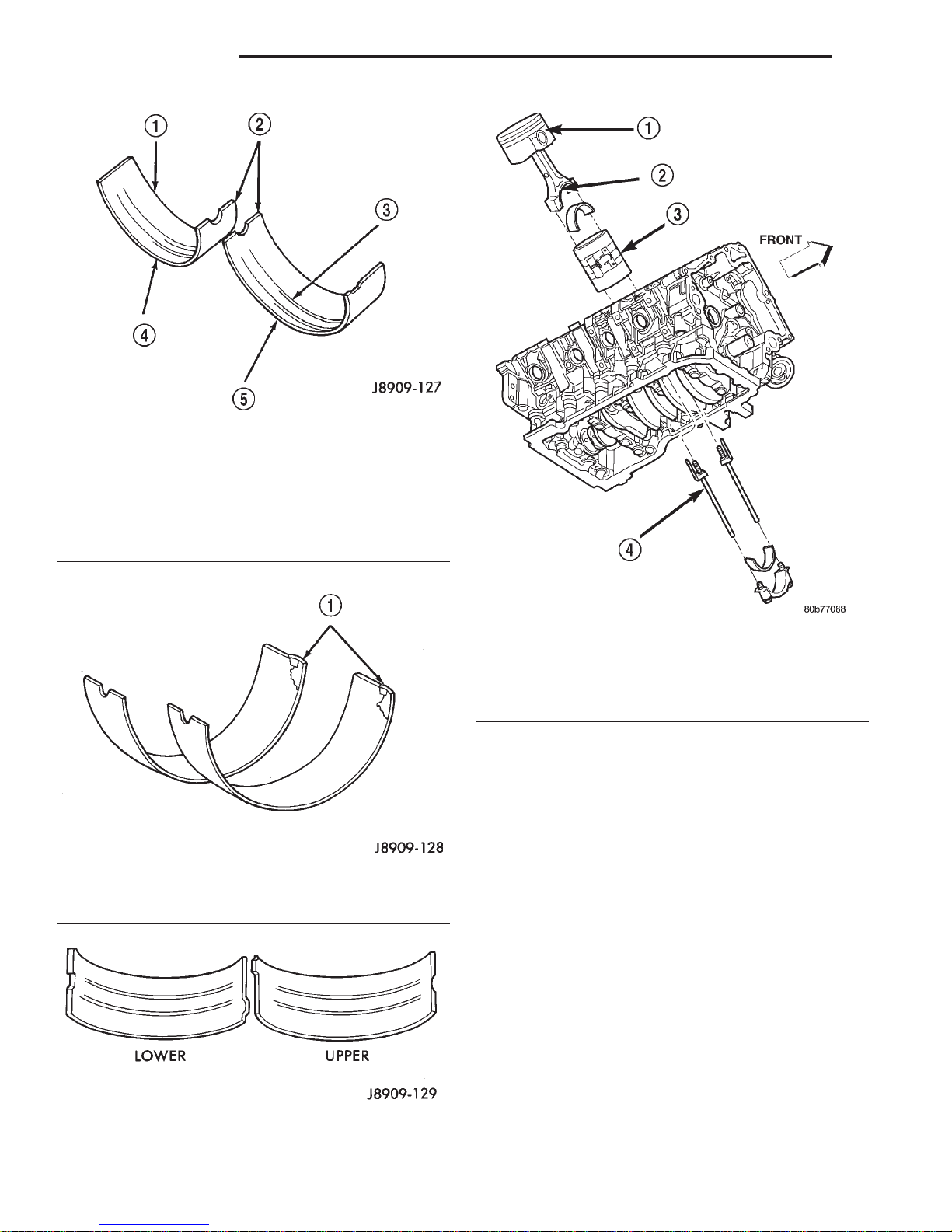

CONNECTING ROD BEARINGS—FITTING

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Fig. 25) (Fig. 26). Check the

bearings for normal wear patterns, scoring, grooving,

fatigue and pitting (Fig. 27). Replace any bearing

that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft connecting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

Fig. 24 Piston Ring End Gap Position

1 – SIDE RAIL UPPER

2 – NO. 1 RING GAP

3 – PISTON PIN

4 – SIDE RAIL LOWER

5 – NO. 2 RING GAP AND SPACER EXPANDER GAP

alignment. Replace misaligned, bent or twisted connecting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and install

in connecting rod.

(3) Use piston ring compressor and Guide Pins

Special Tool 8507 (Fig. 28) to install the rod and piston assemblies. The oil slinger slots in the rods must

face front of the engine. The “F”’s near the piston

wrist pin bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plastigage across full width of the lower insert at the center of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

9 - 26 4.7L ENGINE DN

SERVICE PROCEDURES (Continued)

Fig. 25 Connecting Rod Bearing Inspection

1 – UPPER BEARING HALF

2 – MATING EDGES

3 – GROOVES CAUSED BY ROD BOLTS SCRATCHING

JOURNAL DURING INSTALLATION

4 – WEAR PATTERN — ALWAYS GREATER ON UPPER

BEARING

5 – LOWER BEARING HALF

Fig. 26 Locking Tab Inspection

1 – ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 27 Scoring Caused by Insufficient Lubrication

or by Damaged Crankshaft Pin Journal

Fig. 28 Piston and Connecting Rod—Installation

1 – “F” TOWARD FRONT OF ENGINE

2 – OIL SLINGER SLOT

3 – RING COMPRESSOR

4 – SPECIAL TOOL 8507

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N·m (20 ft. lbs.) plus a

90° turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 29). Refer to

Engine Specifications for the proper clearance. Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replacement of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

DN 4.7L ENGINE 9 - 27

SERVICE PROCEDURES (Continued)

Fig. 29 Measuring Bearing Clearance with

Plastigage

1 – PLASTIGAGE SCALE

2 – COMPRESSED PLASTIGAGE

Bearing

SIZE USED WITH

Mark

JOURNAL SIZE

.025 US .025 mm 50.983-50.967 mm

(.001 in.) (2.0073-2.0066 in.)

Std. STANDARD 50.992-51.008 mm

(2.0076-2.0082 in.)

.250 US .250 mm 50.758-50.742 mm

(.010 in.) (1.9984-1.9978 in.)

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N·m (20 ft. lbs.) plus a 90° turn.

Slide snug-fitting feeler gauge between the connecting rod and crankshaft journal flange (Fig. 30).

Refer to Engine Specifications for the proper clearance. Replace the connecting rod if the side clearance

is not within specification.

CRANKSHAFT MAIN BEARINGS

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 31).

NOTE: If any of the crankshaft journals are scored,

remove the engine for crankshaft repair.

Fig. 30 Checking Connecting Rod Side Clearance—

Typical

Fig. 31 Main Bearing Wear Patterns

1 – UPPER INSERT

2 – NO WEAR IN THIS AREA

3 – LOW AREA IN BEARING LINING

4 – LOWER INSERT

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block.

Refer to Crankshaft in this section for procedure.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90°

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

9 - 28 4.7L ENGINE DN

SERVICE PROCEDURES (Continued)

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block. Refer

to Crankshaft in this section for procedure.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in three

grades. The chart below identifies the three service

grades available.

GRADE SIZE mm

(in.)

MARKING JOURNAL SIZE

A .008 mm U/S 63.488-63.496 mm

(.0004 in.)

U/S

B STANDARD 63.496-63.504 mm

C .008 mm O/S 63.504-63.512 mm

(.0004 in.)

O/S

FOR USE WITH

(2.4996-2.4999 in.)

(2.4996-2.4999 in.)

(2.5002-2.5005 in.)

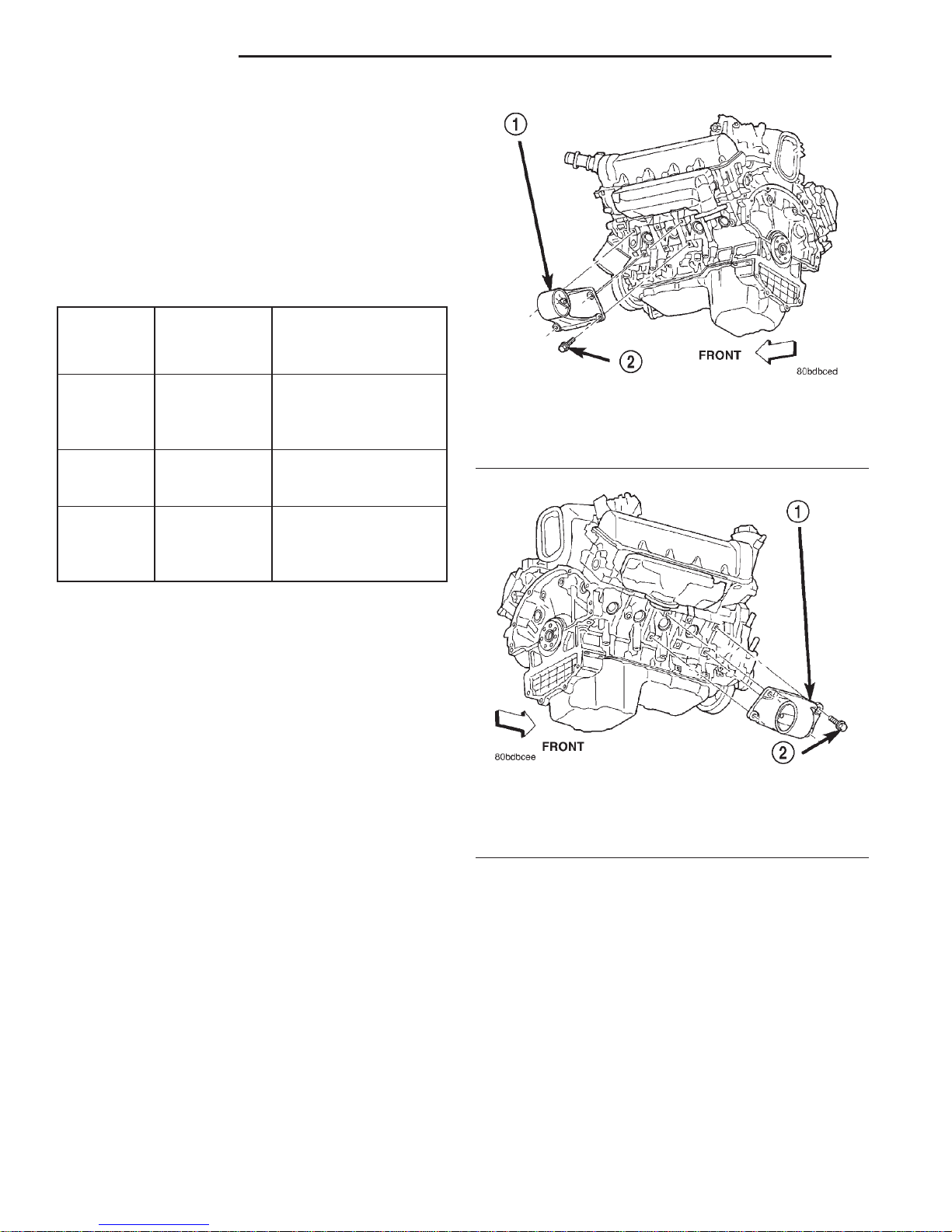

REMOVAL AND INSTALLATION

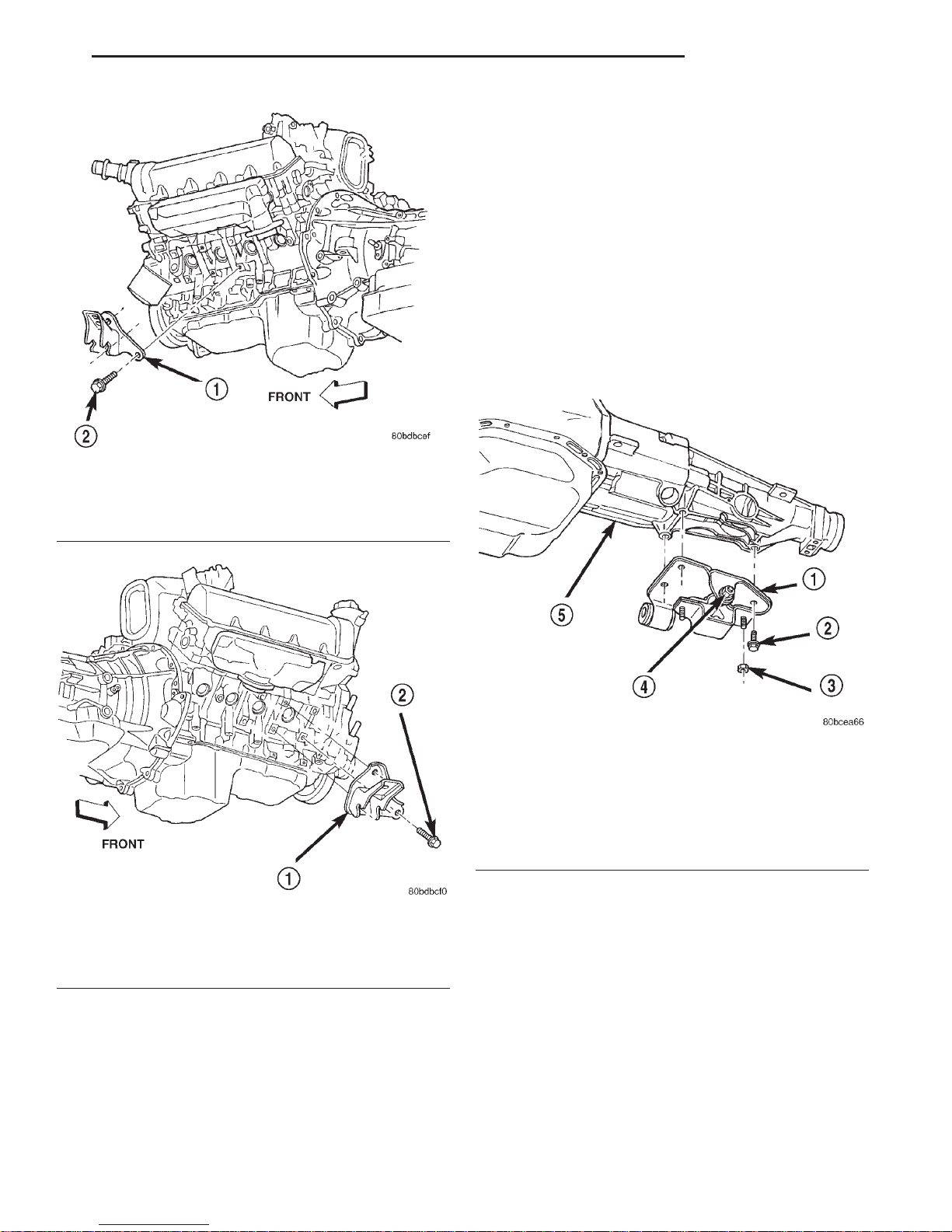

ENGINE MOUNTS—LEFT AND RIGHT

REMOVAL

(1) Disconnect the negative cable from the battery.

CAUTION: Remove the fan blade, fan clutch and

fan shroud before raising engine. Failure to do so

may cause damage to the fan blade, fan clutch and

fan shroud.

(2) Remove the fan blade, fan clutch and fan

shroud. Refer to Group 7. for procedure.

(3) Remove the engine oil filter.

(4) Support the engine with a suitable jack and a

block of wood across the full width of the engine oil

pan.

(5) Remove the four (4) cylinder block-to-insulator

mount bolts and the nut from the engine insulator

mount through bolt (4x2 Vehicles only) (Fig. 32) (Fig.

33).

(6) Remove the three (3) cylinder block-to-insulator

mount bolts and loosen the nut from the engine insulator mount through bolt (4x4 Vehicles only) (Fig. 34)

(Fig. 35).

(7) Using the jack, raise the engine high enough to

remove the engine insulator mount through bolt and

the insulator mount.

Fig. 32 Engine Insulator Mount 4x2 Vehicle—Left

Side

1 – ENGINE INSULATOR MOUNT-LEFT SIDE

2 – MOUNTING BOLT

Fig. 33 Engine Insulator Mount 4x2 Vehicle—Right

Side

1 – ENGINE INSULATOR MOUNT-RIGHT SIDE

2 – MOUNTING BOLT

INSTALLATION

(1) Position the insulator mount and install the

insulator mount through bolt.

(2) Lower the engine until the four cylinder block-

to-insulator mount bolts can be installed.

(3) Remove the jack and block of wood.

(4) Torque the cylinder block-to-insulator mount

bolts to 61N·m ( 45 ft. lbs.).

(5) Install and torque the through bolt retaining

nut to 61N·m (45 ft. lbs.).

(6) Install the fan blade, fan clutch and fan

shroud.

DN 4.7L ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

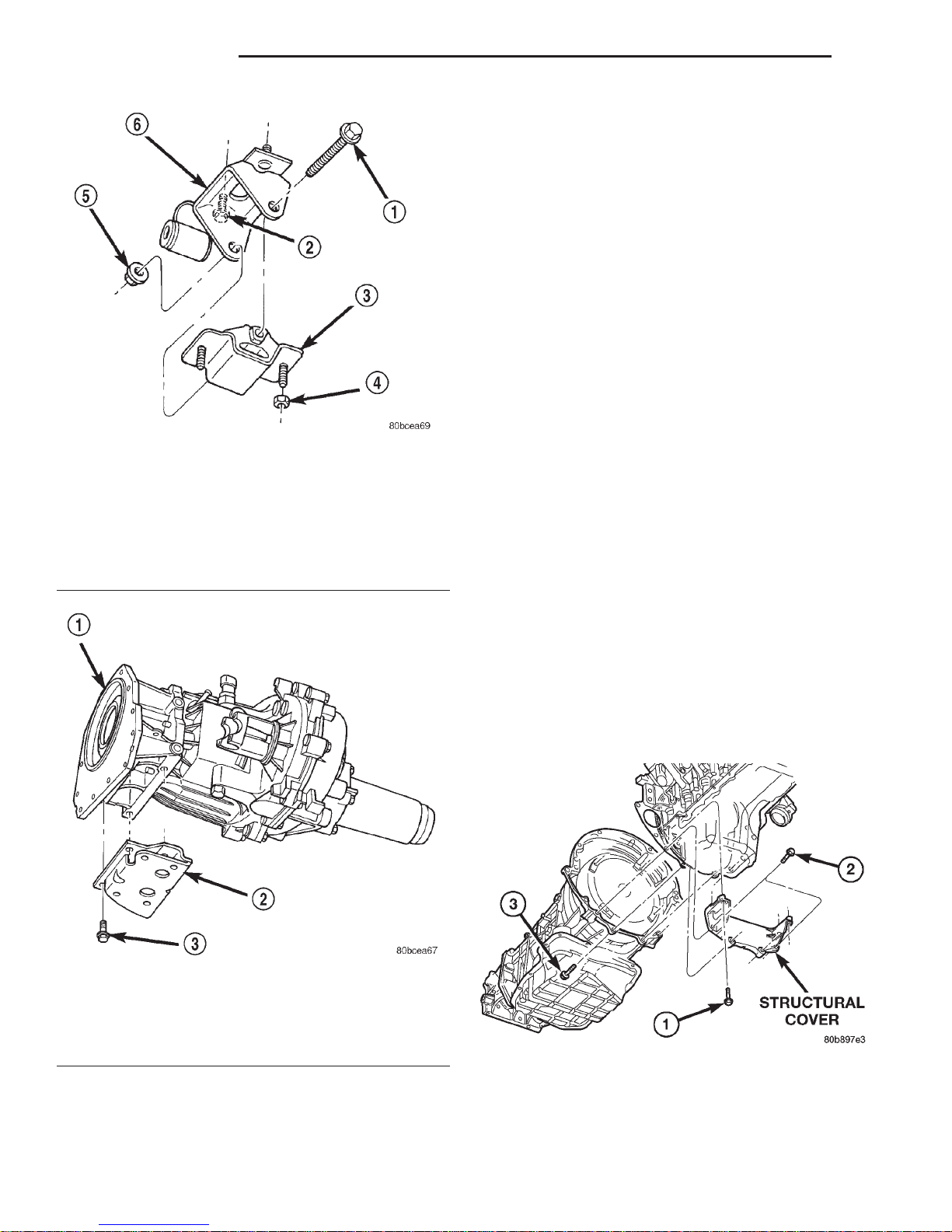

(4) Remove the four bolts and washers retaining

the mount to the transmission (4x4 automatic transmission only) (Fig. 38).

(5) Raise the transmission enough to remove the

through bolt (Manual transmission and 4x2 automatic transmission only) (Fig. 36) (Fig. 37).

(6) Raise the transmission and remove the bolts

retaining the mount to the crossmember (4x4 automatic transmission only) (Fig. 38).

(7) Remove the two nuts retaining the isolator to

the crossmember (Manual transmission and 4x2

automatic transmission only) (Fig. 36) (Fig. 37).

(8) Remove the bolts (two bolts manual transmission)(three bolts 4x2 automatic transmission) retaining the insulator bracket to the transmission.

Fig. 34 Engine Insulator Mount 4x4 Vehicle—Left

Side

1 – ENGINE INSULATOR MOUNT-LEFT SIDE

2 – MOUNTING BOLT