Page 1

12843 Foothill Blvd. Suite C

Sylmar, California 91342

V: 818.898.3380

F: 818.898.3360

sales@dnfcontrols.com

Model No. SW2X1

-GPI SWITCHER

-RS422 SWITCHER

USER MANUAL

Rev. 1.2

For Use with Rev 2.0 Hardware

SW2X1 User Manual 1 of 15

Page 2

Table of Contents

1. STANDARD FEATURES 4

2. INSTALLATION SW2X1-GPI 4

3. CONNECTION DIAGRAM SW2X1-GPI 5

4. INSTALLATION SW2X1-RS422 6

5. CONNECTION DIAGRAM SW2X1-RS422 6

6. MODE SELECTION SW2X1-GPI 7

a. MODE 1 7

b. MODE 2 7

7. MODE SELECTION SW2X1-RS422

(LOCAL / REMOTE CONTROL) 8

a. MODE 1 8

b. MODE 2 8

8. MODE SELECTION SW2X1-RS422 (2X1 / 1X2 MODE) 9

a. MODE 1 9

b. MODE 2 9

9. WIRING EXAMPLE 10

10. SPECIFICATIONS 11

A. OVERALL 11

B. SW2X1-GPI 12

C. SW2X1-RS422 12

11. FRONT / REAR VIEW 13

a. FRONT VIEW: SW2X1-GPI 13

DNF CONTROLS LIMITED WARRANTY 14

SW2X1 User Manual 2 of 15

Page 3

REVISION HISTORY

072707 Rev. 1.00 Original manual

081707 Rev. 1.01 Added GPI wet-dry jumper description.

102411 Rev. 1.1 Added 1x2 mode for SW2X1-RS422

082312 Rev 1.2 Added polarity indicators to RS422 pin outs

061113 Rev 1.3 Revised wet and dry jumper configuration for SW2x1

GPI

SW2X1 User Manual 3 of 15

Page 4

1. STANDARD FEATURES

The SW2X1, Electronic A / B switch has 2 buffered inputs and one

buffered output for easy interfacing. There are no mechanical multi-pole

switches to wear out or fail.

Front panel control and remote control provide flexible operation to fit

your specific application.

Quickly and easily switch from primary system to backup system at the

press of a button.

In the event of power failure, on-board bypass relays switches “A” input to

output.

2. INSTALLATION SW2X1-GPI

a. Chose whether the GPI will be self powered or have power supplied by

the source equipment. Each GPI is independently settable.

JUMPERS: J1 – J8

Revision 08/16/07

DRY: External circuit powers

INPUT opto-isolator

INPUT is isolated from other inputs

Place jumper over pins 2 and 3

WET: SW2X1 powers INPUT optoisolator

External circuit provides path to

ground

Place jumper over pins 1 and 2

SW2X1 User Manual 4 of 15

Page 5

b. Connect primary GPO source to the A input connector, use male D9

cable connector.

c. connect secondary GPO source to the B input connector, use male D9

cable connector.

d. Connect the destination GPI connections to the Output connector.

e. Connect the power supply’s connector (9-pin female D) into the

housing’s POWER connector (male 9-pin D). The PWR LED on front

panel will light. Power supply is +5VDC. 2A.

f. NOTE: The Power-up state defaults to input A and its status indicator

will light.

Installation is complete.

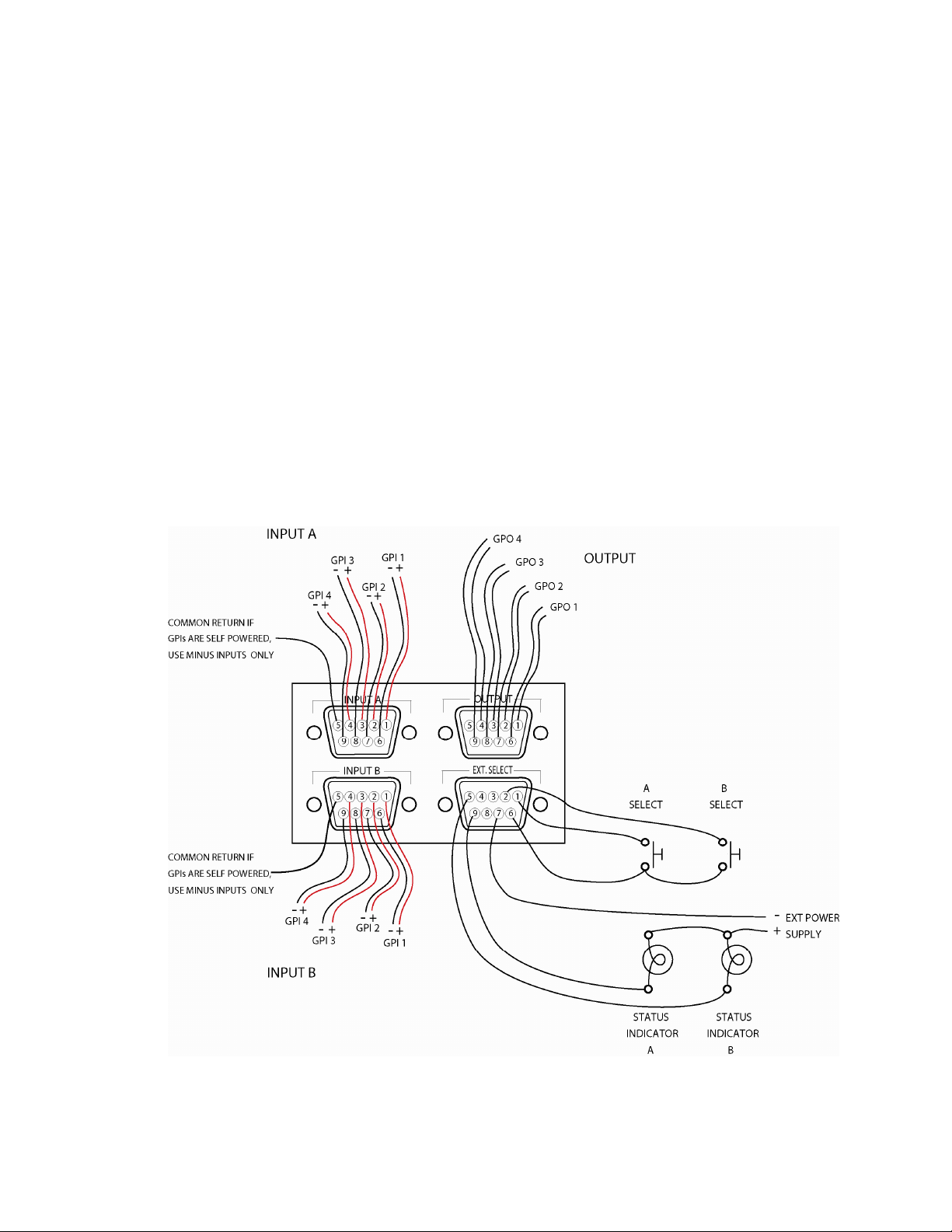

3. CONNECTION DIAGRAM SW2X1-GPI

SW2X1 User Manual 5 of 15

Page 6

4. INSTALLATION SW2X1-RS422

a. Connect one end of an RS422 cable (9-pin D-type, male to male, 1 to 1)

into the rear panel connector (9-pin D-type) labeled INPUT A. Connect

the other end to an RS422 serial source (controller #1).

b. Connect a second RS422 serial source (controller #2) in the same

manner to INPUT B.

c. Connect an RS422 serially controlled VTR, (using an RS422, 9-pin D-

type male to male cable) into the 9-pin female connector labeled

OUTPUT.

d. Connect the power supply’s connector (9-pin female D) into the

housing’s POWER connector (male 9-pin D). The PWR LED on front

panel will light. Power supply is +5VDC. 2A.

e. NOTE: The Power-up state defaults to input A and its status indicator

will light.

Installation is complete.

5. CONNECTION DIAGRAM SW2X1-RS422

SW2X1 User Manual 6 of 15

Page 7

6. MODE SELECTION SW2X1-GPI

The SW2X1-GPI supports two modes of operation.

a. MODE 1

Remote and local control is possible.

Active A input or A switch = Select A input.

Active B input or B switch = Select B input.

This is the default mode. The jumper is installed

over pins 3 and 4 on header J11 on the PCB.

The mode of operation is determined ONLY at

POWER UP. Changing the jumper after power up

will have no effect. Power MUST be turned off then

on to change the SW2X1’s MODE.

Jumper Diagram for Mode 1.

b. MODE 2

Remote control ONLY is possible. Local control is

disabled.

The LOCKOUT LED is turned on.

Remote B input inactive = Select A input.

Remote B input active = Select B input.

The jumper is installed over pins 1 and 2 on

header J11 on the PCB.

The mode of operation is determined ONLY at

POWER UP. Changing the jumper after power up

will have no effect. Power MUST be turned off

then on to change the SW2X1’s MODE.

Jumper Diagram for Mode 2.

SW2X1 User Manual 7 of 15

Page 8

7. MODE SELECTION SW2X1-RS422 (LOCAL /

REMOTE CONTROL)

The SW2X1-RS422 supports two modes of control.

a. MODE 1

Remote and local control is possible.

Active A input or A switch = Select A input.

Active B input or B switch = Select B input.

This is the default mode. A jumper is installed over pins 3 and 4 on

the J1 header on the PCB.

The mode of operation is determined ONLY at POWER UP. Changing

the jumper after power up will have no effect. Power MUST be turned

off then on to change the SW2X1’s MODE.

Jumper Diagram for Mode 1.

b. MODE 2

Remote control ONLY is possible. Local control is disabled.

The LOCKOUT LED is turned on.

Remote B input inactive = Select A input.

Remote B input active = Select B input.

A jumper is installed over pins 1 and 2 on the J1 header on the PCB.

The mode of operation is determined ONLY at POWER UP. Changing

the jumper after power up will have no effect. Power MUST be turned

off then on to change the SW2X1’s MODE.

Jumper Diagram for Mode 2.

SW2X1 User Manual 8 of 15

Page 9

8. MODE SELECTION SW2X1-RS422 (2X1 /

1X2 MODE)

The SW2X1-RS422 supports two modes of operation.

a. MODE 1

The unit operates in 2 in / 1 out mode.

This is the default mode. A jumper is installed over pins 1 and 2 on the

J3 header on the PCB.

The mode of operation is determined ONLY at POWER UP. Changing

the jumper after power up will have no effect. Power MUST be turned

off then on to change the SW2X1’s MODE.

Jumper Diagram for Mode 1

b. MODE 2

The unit operates in 1 in / 2 out mode.

A jumper is installed over pins 2 and 3 on the J3 header on the PCB.

The mode of operation is determined ONLY at POWER UP. Changing

the jumper after power up will have no effect. Power MUST be turned

off then on to change the SW2X1’s MODE.

Jumper Diagram for Mode 2

SW2X1 User Manual 9 of 15

Page 10

OPERATION

a. To use the front panel controls, ensure that LOCKOUT switch on front

panel is set to the right side. LOCKOUT LED will not illuminate.

b. To select a source, press the red ENABLE switch simultaneously with

a black SELECT switch, A or B. The selected input's status indicator

will light.

c. Setting the LOCKOUT switch to ON (to the left side) will disable the

front panel ENABLE and SELECT switches. The LOCKOUT LED will

illuminate. In LOCKOUT, the SW2X1 can only be controlled via the

EXTERNAL SELECT connector on the rear panel.

9. WIRING EXAMPLE

SW2X1 User Manual 10 of 15

Page 11

10. SPECIFICATIONS

A. OVERALL

Power: 90 VAC to 265 VAC adapter supplied with IEC connector

Size: (H” x W” x D”) 1.75” x 19” x 4.25”

Weight: 6 lbs.

Rear Panel Connectors: INPUT A, INPUT B (D9F)

OUTPUT, EXT. SELECT (D9F)

Power (D9M)

Ground #6-32 threaded stud

Front Panel Controls: Enable, Select A, Select B (All pushbutton

switches).

Lockout ON/OFF (Recessed slide

switch).

Front Panel Indicators: Power, Lockout On, A, B. All red LEDs.

EXTERNAL SELECT CONNECTOR

9-Pin D-Type Female (D9F)

Pin # Description

1 External select A (Active low, opto-isolated internally)

2 External select B (Active low, opto-isolated internally)

3 n/c

4 n/c

5 LED B (external) drive, B input status indicator

6 GROUND

7 GROUND

8 n/c

9 LED A (external) drive, A input status indicator

NOTE:

There are no internal current limiting resistors for the open collector status

indicator drives. A 470 ohm resistor in series with a + 5 Vdc power supply is

recommended.

Limit lamp current to 50mA MAXIMUM.

POWER CONNECTOR

9-Pin D-Type Male, (D9M)

PIN# Description PIN# Description

1 +5 Vdc 6 +5 Vdc

2 +5 Vdc 7 Ground

3 Ground 8 Ground

4 n/c 9 Ground

5 n/c

MODULE: P1 (2 PIN MOLEX)

Pin# Description

1 +5VDC (left on P1, near card edge)

2 GND (right on P1)

SW2X1 User Manual 11 of 15

Page 12

B. SW2X1-GPI

GPI INPUT CONNECTOR

9-Pin D-Type Female (D9F)

Pin# Description Pin# Description

1. GPI 1 + (A) or internal pull-up 6. GPI 1 - (K)

2. GPI 2 + (A) or internal pull-up 7. GPI 2 - (K)

3. GPI 3 + (A) or internal pull-up 8. GPI 3 - (K)

4. GPI 4 + (A) or internal pull-up 9. GPI 4 - (K)

5. Ground

Note: Internal pull-up is jumper selectable for each GPI, then only a

connection from the 'K' pin to ground is required for GPI activation.

GPI OUTPUT CONNECTOR

9-Pin D-Type Female (D9F)

Pin# Description Pin# Description

1. GPO 1 N.O. 6. GPO 1 COM

2. GPO 2 N.O. 7. GPO 2 COM

3. GPO 3 N.O. 8. GPO 3 COM

4. GPO 4 N.O. 9. GPO 4 COM

5. Ground

C. SW2X1-RS422

RS422 SERIAL INPUT (Device Configuration)

9-Pin D-Type Female (D9F)

Pin# Description

1 Frame Ground

2 Transmit A(-)

3 Receive B(+)

4 Transmit common

5 Spare

6 Receive common

7 Transmit B(+)

8 Receive A(-)

9 Frame Ground

RS422 SERIAL OUTPUT (Controller Configuration)

9-Pin D-Type Female (D9F)

Pin# Description

1 Frame Ground

2 Receive A(-)

3 Transmit B(+)

4 Transmit common

5 Spare

6 Receive common

7 Receive B(+)

8 Transmit A(-)

9 Frame Ground

SW2X1 User Manual 12 of 15

Page 13

11. FRONT / REAR VIEW

a. FRONT VIEW: SW2X1-GPI

b. FRONT VIEW: SW2X1-RS422

c. REAR VIEW: SW2X1

SW2X1 User Manual 13 of 15

Page 14

DNF CONTROLS LIMITED WARRANTY

DNF Controls warrants its product to be free from defects in material and

workmanship for a period of one (1) year from the date of sale to the original

purchaser from DNF Controls.

In order to enforce the rights under this warranty, the customer must first contact

DNF’s Customer Support Department to afford the opportunity of identifying and

fixing the problem without sending the unit in for repair. If DNF’s Customer Support

Department cannot fix the problem, the customer will be issued a Returned

Merchandise Authorization number (RMA). The customer will then ship the defective

product prepaid to DNF Controls with the RMA number clearly indicated on the

customer’s shipping document. The merchandise is to be shipped to:

DNF Controls

12843 Foothill Blvd., Suite C

Sylmar, CA 91342

USA

Failure to obtain a proper RMA number prior to returning the product may result in

the return not being accepted, or in a charge for the required repair.

DNF Controls, at its option, will repair or replace the defective unit. DNF Controls will

return the unit prepaid to the customer. The method of shipment is at the discretion

of DNF Controls, principally UPS Ground for shipments within the United States of

America. Shipments to international customers will be sent via air. Should a

customer require the product to be returned in a more expeditious manner, the

return shipment will be billed to their freight account.

This warranty will be considered null and void if accident, misuse, abuse, improper

line voltage, fire, water, lightning, or other acts of God damaged the product. All

repair parts are to be supplied by DNF Controls, either directly or through its

authorized dealer network. Similarly, any repair work not performed by either DNF

Controls or its authorized dealer may void the warranty.

After the warranty period has expired, DNF Controls offers repair services.

Equipment is evaluated and repair price quoted prior to any work performed. DNF

Controls reserves the right to refuse repair of any unit outside the warranty period

that is deemed non-repairable.

DNF Controls shall not be liable for direct, indirect, incidental, consequential or other

types of damage resulting from the use of the product.

# # #

SW2X1 User Manual 14 of 15

Loading...

Loading...