Page 1

12843 Foothill Blvd. Suite C

Sylmar, California 91342

V: 818.898.3380

F: 818.898.3360

sales@dnfcontrols.com

Model No. ST400-CP

Protocol Description

&

USER MANUAL

ST400-CP User Manual Page 1 of 19

Page 2

Table of Contents

_____________________________________________________________________________________________

1. REVISION HISTORY 3

2. OVERVIEW 4

a. DESCRIPTION 4

b. FUNCTION CHART 5

3. INSTALLATION 5

4. POWER

5. PROTOCOL

UP DEFAULTS 9

DESCRIPTION 9

a. COMMUNICATIONS FORMAT 9

b. COMMANDS 9

c. CONFIGURATION TABLES 14

d. COMMAND EXAMPLES 16

6. SPECIFICATIONS 17

POWER CONNECTOR 17

SP2 Connector, RS232 PINOUT 17

SP2 Connector, RS422 PINOUT 17

7. KEY

8. DNF

LAYOUT 18

CONTROLS LIMITED WARRANTY 19

Manual Version …………..…….……………… 1.4 092004

Document No. …….…….……. ST400-CP User Manual.doc

ST400-CP User Manual Page 2 of 19

Page 3

1. REVISION HISTORY

122203 Rev. 1.0 Original Document

010804 Rev. 1.1 Added Highlight Byte to the LCD command.

012304 Rev 1.2 Added RS422 Controller jumper configuration

071304 Rev 1.3 Added “I” command to draw tables.

073004 Rev. 1.4 Added “P” command to clear a part of the display.

092004 Rev. 1.5 Changed wheel position command byte to ‘H’. Fixed bugs in the receive

command process and wheel mode command. Added Discon nect ‘U ’ c o m mand

and Reconnect ‘R’ command for switching VTRS, and added status ‘Z’

command.

ST400-CP User Manual Page 3 of 19

Page 4

2. OVERVIEW

a. DESCRIPTION

The ST400 will operate as an event driven device, transmitting information to the External Control

System (ECS) when a change is detected.

In addition, the ECS may poll the ST400-CP at any time for current status information.

Key Press Decoding

The ST400 will automatically detect and decode changes in the state of its 46 keys. It will return

the state of all keys on the keyboard any time there is a change detected. The state of the keyboard

is returned as 12 bytes, 6 bytes for Key Change bitmap (each key is represented by a bit) and 6

bytes for Key State bitmap of the key (each key is represented by a bit). If a bit is set in the Key

Change Bitmap – the corresponding key’s state was changed. If a bit is cleared in the Key Change

Bitmap, the corresponding key’s state was not changed. If a bit in the Key State bitmap is set – the

corresponding key is pressed. If the bit is cleared, the corresponding key is released.

Key LEDs

The Key LEDs are controlled by the ECS. Using appropriate commands, each led may be

individually controlled, turned ON or OFF. The ECS sends a five (5) byte, bit mapped value to

the ST400 to control the state of each LED. When a bit is set, the LED is turned on. When a bit

is cleared, the LED is turned off.

LCD Display

The LCD Display is controlled by ECS. Using appropriate commands, the ECS can display nullterminated strings at a specified row and column. It can display characters of 4 different sizes –

normal, double-high, double-wide and double-high-double-wide characters. It can also display

highlighted text and draw tables in various parts of the display.

Wheel

The Wheel mode is configured by ECS. Three different wheel modes are supported– Off, Jog, and

Shuttle (with mechanical detents). Wheel Position information will be automatically sent to the

ECS when wheel movement is detected and the current wheel mode is not OFF.

In OFF mode, the wheel will not return position information and the mechanical detents will not

be energized.

In JOG mode, the Wheel Position will be returned as a one byte, signed value that represents the

pulse rate (pulses per time period). A pulse rate of zero means that the wheel has not moved. A

positive position value represents Clockwise movement. A negative position value represents

Counter-Clockwise movement. The mechanical detents will not be energized in JOG mode.

In SHUTTLE mode, Wheel Position will be returned as a one byte, signed value that represents

the position of the wheel. When the SHUTTLE mode command is received, the ST400 sets the

current wheel position as the STILL or zero position of the wheel. The Wheel Position value

indicates movement of the wheel from the STILL position. A positive Wheel Position value

represents Clockwise wheel movement from the STILL position. A negative Wheel Position

value represents Counter-Clockwise wheel movement from STILL position. The mechanical

detents will automatically energize when the maximum clockwise or maximum counter-clockwise

Wheel Position value is reached. The mechanical detents will automatically de-energize when the

Wheel Position value is less than the maximums. Using appropriate commands, the wheel mode,

resolution, maximum clockwise, and maximum counter-clockwise values may be set.

ST400-CP User Manual Page 4 of 19

Page 5

T-bar

The T-bar is always enabled and will automatically send position information to the ESC when

movement is detected. The lowest point in its travel is the STILL or zero position. The T-bar

Position is a one byte, unsigned value that represents the position of the T-bar relative to the

STILL position. The T-bar cannot be configured by the ECS. It’s resolution, maximum and

minimum position values are set by the factory.

b. FUNCTION CHART

Control Panel

Functional Area

Wheel Movement Detection

T-bar Movement Detection

Key Press Detection and Decoding

Wheel Mode Configuration External Control System (ECS)

Key LEDs On/Off ECS

LCD Display Text ECS

Controlled

By

ST400

ST400

ST400

3. INSTALLATION

a. Connect the supplied power supply, Model AP4108, into the connector labeled POWER on the

rear of the ST400. Plug the Power Supply into a wall outlet, 90 VAC to 240 VAC.

b. Plug one end of a 9-conductor, RS422 serial cable into the 9-pin connector labeled SP2 on the rear

of the ST400. Plug the other end of the cable into the 9-pin connector on the External Control

System (ECS).

c. SP2 is configured for RS232 DTE when shipped from the factory. Refer to the following sections

“RS422 DEVICE Configuration” and “RS232 DTE Configuration”, to change the configuration

of SP2.

Installation is complete.

ST400-CP User Manual Page 5 of 19

Page 6

RS422- CONTROLLER Configuration

10A – JUMPER 1 TO 2, 3 TO 4, 5 TO 6, AND 7 TO 8

(Located behind the SP2 connector on the main pcb)

10C – JUMPER 2 TO 3

10D – JUMPER 2 TO 3

10E – JUMPER 2 TO 3

10F – JUMPER 2 TO 3 (V4.1 pcb)

10H – JUMPER 1 TO 2 (V4.1 pcb)

(All located directly in front of 10A header)

JUMPER - W1B, W2B. W3B, AND W5B

(Located between the SP1 and SP2 connectors on the main pcb)

W1 W2 W3 W4

4 2 6 8

10A

3 1 5 7

10C 10D, & 10E

3 2 1

2 2 2 2 2

1 1 1 1

1

W5

ST400-CP User Manual Page 6 of 19

Page 7

RS422 DEVICE Configuration

10A – JUMPER 1 TO 3, 5 TO 7, 2 TO 4, AND 6 TO 8

(Located behind the SP2 connector on the main pcb)

10C – JUMPER 2 TO 3

10D – JUMPER 2 TO 3

10E – JUMPER 2 TO 3

(All located directly in front of 10A header)

JUMPER - W1B, W2B. W3B, AND W5B

(Located between the SP1 and SP2 connectors on the main pcb)

4 2 6 8

10A

3 1 5 7

10C 10D, & 10E

3 2 1

2 2 2 2 2

1 1 1 1

W1 W2 W3 W4

ST400-CP User Manual Page 7 of 19

1

W5

Page 8

RS232 DTE Configuration

10A – JUMPER 1 TO 2 AND 5 TO 6 ONLY

(Located behind the SP2 connector, on the main pcb)

4 2 6 8

10A

3 1 5 7

10C – JUMPER 1 TO 2

10D – JUMPER 1 TO 2

10E – JUMPER 1 TO 2

(All located directly in front of 10A header)

JUMPER – W4B ONLY

(Located between the SP1 and SP2 connectors on the main pcb)

10C 10D, & 10E

3 2 1

2 2 2 2 2

1 1 1 1

W1 W2 W3 W4

1

W5

ST400-CP User Manual Page 8 of 19

Page 9

4. POWER UP DEFAULTS

The ST400 powers up in the following default state:

The LCD display is blank.

All LEDs are off.

The wheel is set to OFF mode.

The ST400 is ready to receive commands from ECS.

5. PROTOCOL DESCRIPTION

a. COMMUNICATIONS FORMAT

Baud Rate 38.4K

Parity ODD

Data Bits 8

Start Bit 1

Stop Bit 1

b. COMMANDS

Command Format: STX + BC + CMD + DATA + CHECKSUM

STX = 0x02

BC = Byte Count, 1 byte

Byte Count includes all data bytes between BC and Checksum, exclusively.

CMD = 1 byte

DATA = Data bytes, command specific

CHECKSUM = Simple 8 bit sum of ALL preceding bytes (including STX)

ACK = STX + 01 + 0x04 + Checksum

NAK = STX + 01 + 0x05 + Checksum

KeyChange0 … KeyChange5 – bitmap of the keys that have changed their state

ST400 External Control System

Key Change Command:

STX+ BC + ’K’+ KeyChange0 + KeyChange1 + … + KeyChange5 + KeyData0 + KeyData1 +

… + KeyData5 + ChecksumÆ Æ

BC: Byte count = 13

If a corresponding bit is set - there was a change, if a bit is cleared – no change from the

previous state. See Keyboard Decode Table for bitmap dec oding

KeyData0 … KeyData5 – state of the keyboard

If a corresponding bit is set - the key is pressed, if a bit is cleared – the key is released.

See Keyboard Decode Table for bitmap decoding.

Å Å No response required

NOTE- Key Press/Release status is sent on every key change. If all KeyData = 0, then all keys

have been released.

ST400-CP User Manual Page 9 of 19

Page 10

Key Change Status Request Command:

Å Å STX + 01 + ‘S’ + Checksum

STX+ BC + ’S’+ KeyData0 + KeyData1 + … + KeyData5 + Checksum Æ Æ

BC: Byte count = 7

KeyData0 … KeyData5 – state of the keyboard

IF a corresponding bit is set - the key is pressed, if a bit is cleared – he key is released.

See Keyboard Decode Table for bitmap decoding.

ST400 External Control System

Key LED Control:

Å Å STX + BC + ‘L’ + Led Data1 + Led Data2 + … + Led Data5 + Checksum

BC: Byte count = 6

Data1= LED1 (Lsb) to LED8 (Msb)

Data2= LED9 (Lsb) to LED16 (Msb)

Data3= LED17 (Lsb) to LED24 (Msb)

Data4= LED25 (Lsb) to LED32 (Msb)

Data5= LED33 (Lsb) to LED34 (Msb)

STX + 01 + ACK + Checksum Æ Æ

Wheel Mode:

Å Å STX + BC + ‘M’+ Wheel Divide + Min Position + Max Position +

Mode byte + Checksum

BC: Byte count = 5

Wheel Divide = 1 (highest resolution) to 96 (lowest resolution)

Min Position = The lowest number that may be returned as the wheel

position. It’s a signed value that ranges between 0 and –127.

Max Position = The highest number that may be returned as the wheel

position. It’s a signed value that ranges between 0 and +127.

Mode byte: 0= Off

1= Jog

2= Shuttle

STX + 01 + ACK + Checksum Æ Æ

Wheel Position: (Automatically sent when movement is detected)

STX + 02 + ‘H’ + Wheel Position Byte + Checksum Æ Æ

BC: Byte Count = 2

Wheel Position Byte = -16 Æ +16

Å Å No response required

T-bar Position: (Automatically sent when movement is detected)

STX + BC + ‘T’ + T-bar Position Byte + Checksum Æ Æ

BC: Byte Count = 2

T-bar Position Byte = 0 Æ +64

Å Å No response required

ST400-CP User Manual Page 10 of 19

Page 11

Wheel Position Request:

Å Å STX + BC + ‘W’ + Checksum

BC: Byte Count = 1

STX + 02 + ‘W’ + Wheel Position Byte + Checksum Æ Æ

BC: Byte Count = 2

Wheel Position Byte = -16 Æ +16

T-bar Position Request:

Å Å STX + BC + ‘T’ + Checksum

BC: Byte Count = 1

STX + BC + ‘T’ + T-bar Position Byte + Checksum Æ Æ

BC: Byte Count = 2

T-bar Position Byte = 0 Æ +64

ST400 External Control System

Blank the LCD Display:

Å Å STX + BC + “B” + Checksum

BC: Byte Count = 1

STX + 01 + ACK + ChecksumÆ Æ

When this command is received, the whole display is cleared.

Display On:

Å Å STX + BC + “N” + Checksum

BC: Byte Count = 1

STX + 01 + ACK + ChecksumÆ Æ

When this command is received, the display turns ON.

Display Off:

Å Å STX + BC + “F” + Checksum

STX + 01 + ACK + ChecksumÆ Æ

When this command is received, the display turns OFF.

ST400-CP User Manual Page 11 of 19

Page 12

LCD Display Text:

Å Å STX + BC + “D” + Row + Column + Size + Highlight Byte + Text (null-

terminated) + Checksum

BC – Byte count of all bytes of the command excluding STX and Checksum

Row – Starting row of the display from 0 to 29

Column – Starting column of text – from 0 to 39

Size - 00 – Normal

01 – Double Wide

02 – Double High

03 – Double Wide, Double High

Highlight Byte – 00 – Highlight off (black characters on the white background)

01 – Highlight on (white characters on the black background)

Text – Up to 248 bytes of data, null terminated.

STX + 01 + ACK + ChecksumÆ Æ

NOTES:

The row and column are always set based on normal (the smallest) character size.

You should double the row number if you’re using Double High characters (size = 2 or 3) and you

should double the column number anytime you’re using Double Wide Characters (size = 1 or 3).

When the text reaches the end of line, it wraps around to the next line, starting with Column 0.

When the text reaches the bottom of the screen, it does not wrap around to the top of the display.

The text is truncated.

If there is no text added to the command (NULL-termination immediately follows the SIZE byte),

the specified row gets cleared (column byte is disregarded).

LCD Insert Table:

Å Å STX + BC + “I” + Border style (single-line or double-line)

+ Intersections style (single-line or double-line)

+ Number of Rows

+ Number of Columns

+ X coordinate of the Upper Left-hand Corner

+ Y coordinate of the Upper Left-hand Corner

+ Width of Column 1 (in characters)

+ ...

+ Width of Column n (in characters)

+ Height of Row 1 (in characters)

+ ...

+ Height of Row n (in characters)

+ Checksum

Where:

BC – Byte count of all bytes of the command excluding STX and Checksum

Single Line = 0

Double Line = 1

Number of Rows = 1 – 29

Number of Columns = 1 – 39

X coordin a te of the Upper Left-hand Corner = 0 – 39

Y coordin a te of the Upper Left-hand Corner = 0 – 29

The Width of an individual column may vary between 0 and 39 depending on the number of

columns defined (see Note 1 below)

The Height of an individual row may vary between 0 and 29 depending on the number of rows

defined (see Note 2 below)

STX + 01 + ACK + ChecksumÆ Æ

ST400-CP User Manual Page 12 of 19

Page 13

NOTES:

1. Total width of (Column1+ ...+ Column n) cannot exceed Maximum Width.

Maximum Width = Total Display Length – X coordinate of the Upper Left-hand Corner – Number of Lines

Total Display Length = 40 characters

Number of Lines = Number of Columns + 1

2. Total height of (Row1 + ... + Row n) cannot exceed Maximum Height

Maximum Height = Total Display Height – Y coordinate of the Upper Left-hand Corner – Number of Lines

Total Display Hight = 30

Number of Lines = Number of Rows + 1

3. All intersections are drawn in the same style lines (single-line or doubl e-l ine depending on the specified style).

4. All outside boarders are drawn in the same style lines (single-line or double-line depending on the specified

style).

5. The display within the table will be cleared. The display outside the table borders will not be touched.

LCD Clear Part of the Display:

Å Å STX + BC + “P” + Number of Rows (height of the space to clear),

+ Number of Columns (width of the space to clear)

+ X coordinate of the Upper Left-hand Corner

+ Y coordinate of the Upper Left-hand Corner

+ Checksum

Where:

BC – Byte count of all bytes of the command excluding STX and Checksum

Number of Rows = 1 – 29

Number of Columns = 1 – 39

X coordin a te of the Upper Left-hand Corner = 0 – 39

Y coordin a te of the Upper Left-hand Corner = 0 – 29

STX + 01 + ACK + ChecksumÆ Æ

This command allows to clear a box on the display. All parameters assume small-size characters.

Channel Disconnect:

STX + 01 + ”U” + ChecksumÆ Æ

This command is sent automatically to the active channel prior to switching VTR channels.

Channel Reconnect:

STX + 01 + “R” + ChecksumÆ Æ

This command is sent automatically to the new selected channel when switching VTR channels.

CP Status:

Å Å STX + BC + “Z” + Checksum

STX + 02 + “Z” + STATUS + ChecksumÆ Æ

This command returns the current status of the ST400-CP.

Possible STATUS: 00 = Status OK

01 = Busy

02 = Error

ST400-CP User Manual Page 13 of 19

Page 14

c. CONFIGURATION TABLES

1) LED Data Format Table:

LED DATA1:

Led ON: Bit= 1 Led

OFF: Bit= 0

Bit7= LED #8

Bit6= LED #7

Bit5= LED #6

Bit4= LED #5

Bit3= LED #4

Bit2= LED #3

Bit1= LED #2

Bit0= LED #1

LED DATA2:

Led ON: Bit= 1 Led

OFF: Bit= 0

Bit7= LED #16

Bit6= LED #15

Bit5= LED #14

Bit4= LED #13

Bit3= LED #12

Bit2= LED #11

Bit1= LED #10

Bit0= LED #9

LED DATA3:

Led ON: Bit= 1 Led

OFF: Bit= 0

Bit7= LED #24

Bit6= LED #23

Bit5= LED #22

Bit4= LED #21

Bit3= LED #20

Bit2= LED #19

Bit1= LED #18

LED DATA4:

Led ON: Bit= 1 Led OFF: Bit= 0

Bit7= LED #32

Bit6= LED #31

Bit5= LED #30

Bit4= LED #29

Bit3= LED #28

Bit2= LED #27

Bit1= LED #26

Bit0= LED #25

LED DATA5:

Led ON: Bit= 1 Led OFF: Bit= 0

Bit7= Undefined

Bit6= Undefined

Bit5= Undefined

Bit4= Undefined

Bit3= Undefined

Bit2= Undefined

Bit1= LED #34

Bit0= LED #33

Bit0= LED #17

ST400-CP User Manual Page 14 of 19

Page 15

2) Keyboard Decoding Table:

In a Change Bitmap:

Bit = 1 – the key’s state has changed, Bit = 0 – the state has not changed.

In a State Bitmap:

Bit = 1 – the key is pressed, Bit = 0 – the key is released.

KeyData0:

Bit0= Key 1

Bit1= Key 2

Bit2= Key 3

Bit3= Key 4

Bit4= Key 5

Bit5= Key 6

Bit6= Key 7

Bit7= Key 8

KeyData1:

Bit0= Key 9

Bit1= Key 10

Bit2= Key 11

Bit3= Key 12

Bit4= Key 13

Bit5= Key 14

Bit6= Key 15

Bit7= Key 16

KeyData2:

Bit0= Key 17

Bit1= Key 18

Bit2= Key 19

Bit3= Key 20

Bit4= Key 21

Bit5= Key 22

Bit6= Key 23

Bit7= Key 24

KeyData3:

Bit0= Key 25

Bit1= Key 26

Bit2= Key 27

Bit3= Key 28

Bit4= Key 29

Bit5= Key 30

Bit6= Key 31

Bit7= Key 32

KeyData4:

Bit0= Key 33

Bit1= Key 34

Bit2= Key 35

Bit3= Key 36

Bit4= Key 37

Bit5= Key 38

Bit6= Key 39

Bit7= Key 40

KeyData5:

Bit0= Key 41

Bit1= Key 42

Bit2= Key 43

Bit3= Key 44

Bit4= Key 45

Bit5= Key 46

Bit6= Undefined

Bit7= Undefined

ST400-CP User Manual Page 15 of 19

Page 16

d. COMMAND EXAMPLES

ST400 External Control System

1) Keyboard status request with the response that indicates that all keys are released.

ÍÍ 0x2 + 0x01 + ‘S’ + 0x56

0x2 + 0x07 + ‘S’ + 0x00 + 0x00 + 0x00 + 0x00 + 0x00 + 0x00 + 0x5C ÎÎ

2) Instruction to turn on LEDs 1 and 9.

ÍÍ 0x2 + 0x06 + ‘L’ + 0x01 + 0x01 + 0x00 + 0x00 + 0x00+ 0x56

0x02 + 0x01 +0x04 +0x07 ÎÎ

ST400-CP User Manual Page 16 of 19

Page 17

6. SPECIFICATIONS

Power: 90 VAC to 265 VAC adapter supplied with IEC connector

APX Model #AP4108

+5v @ 4A, +12v @ 1.0A, -12V @ 0.6A

Size: [L” x W” x H”] 12 3/4” x 8” x 1 3/4” (front) 3 5/8” (rear)

[8 5/8” high to top of display]

Weight: 10 lbs.

Rear Panel Connectors: VTR1, 2, 3, 4, 5, 6, 7, 8 (All DB9F)

GPI (DBF25F)

Power (DB9M)

Keyboard (6-pin mini DIN)

Ref. Video In (BNC)

Ground Threaded stud

Display: Easy to read, back-lit LCD display

Jog/Shuttle Wheel: With mechanical detents

POWER CONNECTOR

9-Pin D-Type, Female (DB9M)

Pin # 1 +5v DC 6 +5 VDC

2 +5v DC 7 Ground

3 Ground 8 Ground

4 +12 VDC 9 Ground

5 –12 VDC

SP2 Connector, RS232 PINOUT

9-Pin D-Type, Female

Pin # 1 No connection 6 No connection

2 Receive Í 7 No connection

3 Transmit Î 8 No connection

4 No connection 9 No connection

5 Ground

SP2 Connector, RS422 PINOUT

9-Pin D-Type, Female

Pin # 1 Frame Ground 6 No connection

2 Transmit A Î 7 Transmit B Î

3 Receive B Í 8 Receive A Í

4 Ground 9 Frame Ground

6 No connection

ST400-CP User Manual Page 17 of 19

Page 18

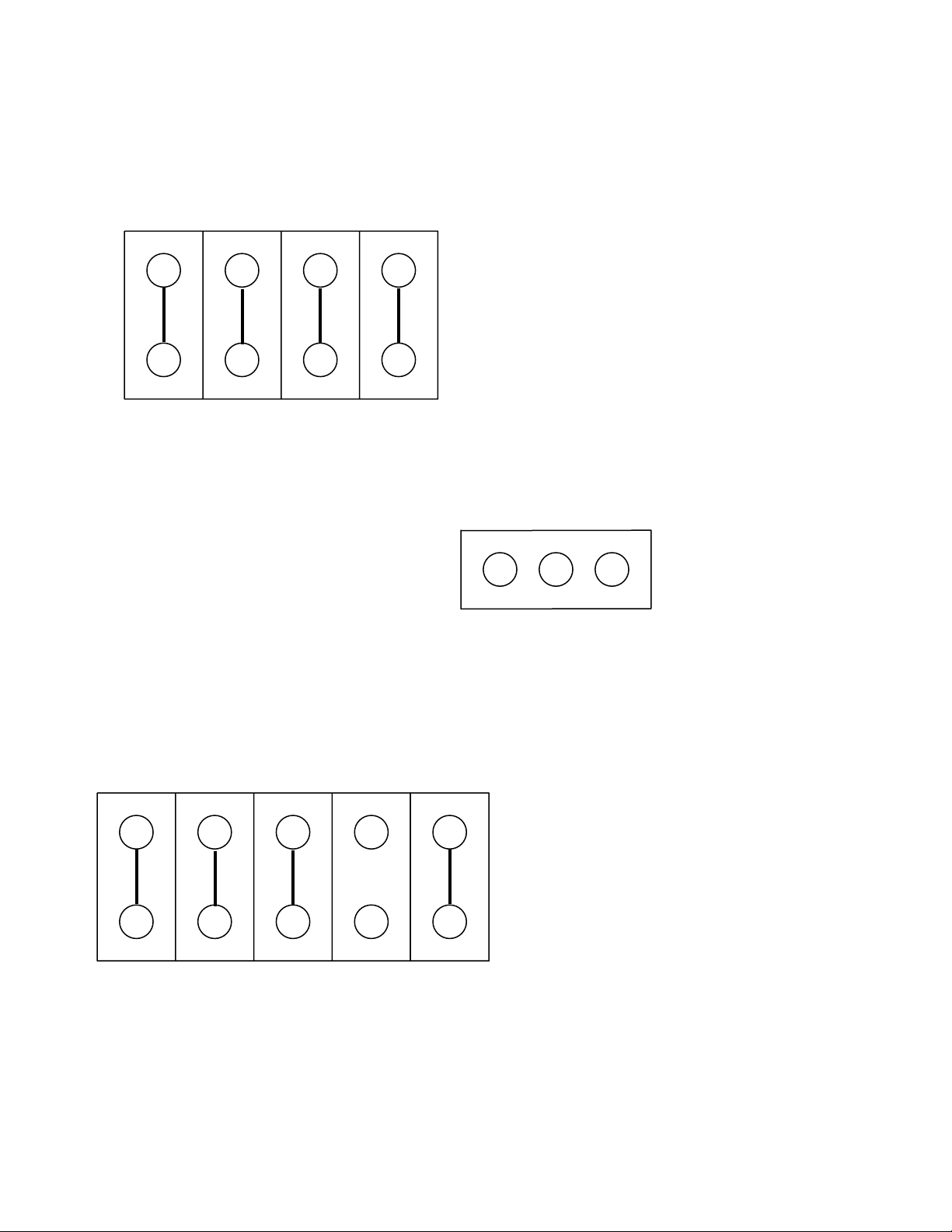

7. KEY LAYOUT

ST400-CP User Manual Page 18 of 19

Page 19

8. DNF CONTROLS LIMITED WARRANTY

DNF Controls warrants its product to be free from defects in material and workmanship for a period of one (1) year

from the date of sale to the original purchaser from DNF Controls.

In order to enforce the rights under this warranty, the customer must first contact DNF’s Customer Support

Department to afford the opportunity of identifying and fixing the problem without sending the unit in for repair. If

DNF’s Customer Support Department cannot fix the problem, the customer will be issued a Returned Merchandise

Authorization number (RMA). The customer will then ship the defective product prepaid to DNF Controls with the

RMA number clearly indicated on the customer’s shipping document. The merchandise is to be shipped to:

DNF Controls

12843 Foothill Blvd., Suite C

Sylmar, CA 91342

USA

Failure to obtain a proper RMA number prior to returning the product may result in the return not being accepted, or

in a charge for the required repair.

DNF Controls, at its option, will repair or replace the defective unit. DNF Controls will return the unit prepaid to

the customer. The method of shipment is at the discretion of DNF Controls, principally UPS Ground for shipments

within the United States of America. Shipments to international customers will be sent via air. Should a customer

require the product to be returned in a more expeditious manner, the return shipment will be billed to their freight

account.

This warranty will be considered null and void if accident, misuse, abuse, improper line voltage, fire, water,

lightning or other acts of God damaged the product. All repair parts are to be supplied by DNF Controls, either

directly or through its authorized dealer network. Similarly, any repair work not performed by either DNF Controls

or its authorized dealer may void the warranty.

After the warranty period has expired, DNF Controls offers repair services at prices listed in the DNF Controls Price

List. DNF Controls reserves the right to refuse repair of any unit outside the warranty period that is deemed nonrepairable.

DNF Controls shall not be liable for direct, indirect, incidental, consequential or other types o f damage resulting

from the use of the product.

# # #

ST400-CP User Manual Page 19 of 19

Loading...

Loading...