Page 1

12843 Foothill Blvd. Suite C

Sylmar, California 91342

V: 818.898.3380

F: 818.898.3360

sales@dnfcontrols.com

Model No. 2034CL-N

(&2034CL-N-T)

300 CLIP INSTANT ACCESS SYSTEM

FOR GRASS VALLEY GROUP

PROFILE USING NATIVE PROTOCOL

User Manual

1 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 2

TABLE OF CONTENTS

1. REVISION HISTORY 4

GETTING STARTED . . . 5

2. SYSTEM

DESCRIPTION 5

DEFINITIONS 5

3. SYSTEM

4.

A. ST300-S/SM, VTR/DDR CONTROLLER 6

B. ST420 SHOTBOX 6

LOADING A CLIP 7

5. CAPTURE

6.

A. SETTING AN IN (OUT) POINT 7

B. CLEARING AN IN (OUT) POINT 7

C. GOTO TIME 7

D. GANGING CLIPS WITH PREVIOUSLY SET IN POINTS 7

E. MULTIGANG SUPPORT 8

LEARN 8

A. LEARN ON THE ST300 8

B. LEARNING IN POINTS, SINGLE CLIP 8

C. LEARNING IN POINTS, GANGED CLIPS 8

D. LEARN ON THE SHOTBOX 9

INSTALLATION 6

FUNCTION 7

7. RECALL 9

8. VIEW

A. RECALL ON THE ST300 9

B. RECALL ON THE SHOTBOX 9

CONTENTS OF CUE POINTS ON THE SHOTBOX 9

ADVANCED FEATURES . . . 10

9. LOOPING

A. LOOP CLIP 10

B. SAVING CLIPS THAT AUTOMATICALLY LOOP 10

C. SAVING CLIPS THAT AUTOMATICALLY PLAY TO LOOP 10

10. DUPLICATING

11. TRIMMING

12. RECORDING

13. VIEW

14. TRANSFER

A. TRANSMIT CUE LIST FUNCTION 13

B. RECEIVE CUELIST FUNCTION 14

15. VIEW

16. SHOTBOX

17. SHOTBOX

FUNCTIONS 10

A CLIP 11

A CLIP 11

A NEW CLIP 12

CONTENT OF CUE POINTS ON THE ST300 12

CUELIST 13

SHOTBOX SHOTKEY ASSIGNMENTS 14

SHOTKEY MAPS 15

CONTROL SWITCHES 15

2 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 3

REFERENCE . . . 16

18. SETUP

ST300

19. FUNCTION

20. VIDEO

A. CONFIGURING THE PROFILE FOR NATIVE MODE 22

B. OVERVIEW OF PROFILE CONNECTIONS 22

C. CONNECTION AND CHANNEL ASSIGNMENTS 23

21. COMPLETING

A. PROFILE CONNECTION OPTIONS 24

B. DRIVE/DIRECTORY SELECTION 24

C. NAMING CONVENTIONS 25

D. DEFINING RECORD LOOP LENGTH 25

MENU 16

SETUP DEFAULTS 19

TABLE 20

SERVER SETUP 22

THE PROFILE CONNECTION 24

22. SPECIFICATIONS 26

A. ST300 26

B. ST420 (SHOTBOX) 27

23. TROUBLESHOOTING 28

ST420

24. KEY

25. DNF

TROUBLESHOOTING 28

LAYOUT 29

CONTROLS LIMITED WARRANTY 30

Manual Version ……………………………………. 1.3 110403

Document No.....................................2034CL-N User Manual

3 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 4

1. REVISION HISTORY

081903 Rev. 1.1 Reformatted.

Added Key Layout.

082503 Rev. 1.2 Clarified use of [MARK] & [LEARN] keys.

Replaced Key Layout.

110403 Rev. 1.3 Added DNF Controls Li mited Warranty.

Updated Receive Cue List & Transmit Cue List Function description.

4 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 5

Getting Started . . .

2. SYSTEM DESCRIPTION

Instantly load a video clip at the press of a button.

Instantly load a FILL clip & KEY clip at the press of ONE button, then play out both

channels in sync.

Control up to 4 video channels individually or ganged, and LOOP up to 4 channels in

sync.

The 2034CL-N, 300 Clip Instant Access System consists of the ST300-SSM with Clip software

and the ST420 SHOTBOX. The ST300 and the SHOTBOX share a common, non-volatile Cue

Point memory in the ST300.

The Video Server is the Grass Valley Group PROFILE running Native Protocol.

The 10 banks of 30 switches each, on the SHOTBOX, provide instant access to 300 Clips.

Press [LEARN] on the SHOTBOX to learn the CLIP ID, current IN time of each Clip on up to 4

video channels and the current GANG mode into the selected Shotkey on the SHOTBOX (Cue

Point on the ST300).

Press any Shotkey on the SHOTBOX to instantly recall the learned CLIP ID and cue to the

learned IN time on up to 4 video channels and setup the “learned” GANG mode.

DEFINITIONS

Throughout this document, the Grass Valley Group Profile will be referred to as the “Video

Server.”

The ST300-S/SM as the ST300.

The ST420 as the SHOTBOX.

Words surrounded by brackets, for example, [ENTER], are keys on the ST300 or the SHOT BOX.

[XXX] + [XXX] means hold the two keys down simultaneously.

Softkey refers to the multiple function keys located below the display window.

5 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 6

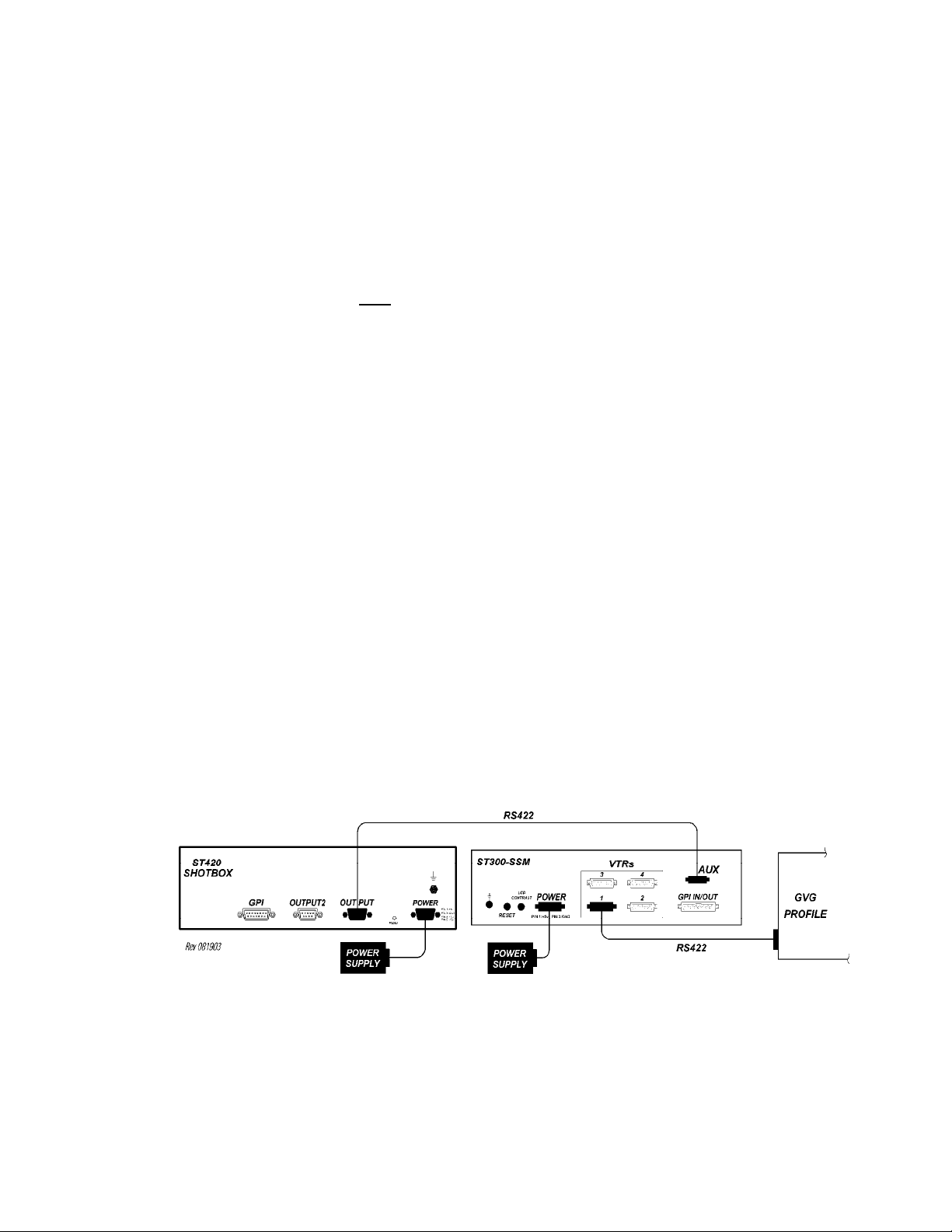

3. SYSTEM INSTALLATION

a. ST300-S/SM, VTR/DDR CONTROLLER

1) Plug one end of a 9-conductor, RS422 serial cable into the VTR 1 (2, 3 or 4)

connector on the rear of the ST300. Plug the other end of the cable into the 9pin REMOTE connector on the Video Server.

2) Connect the +5, +12, -12 VDC POWER SUPPLY into the POWER connector

on the rear of the ST300. Plug the Power Supply into an outlet, 90 VAC to 240

VAC.

Do NOT

3) Check SETUP MENU prior to using the ST300 to confirm proper Record mode

and other User settable modes. See CONFIGURING THE PROFILE FOR

NATIVE MODE, Section 20.a.

b. ST420 SHOTBOX

1) Plug one end of a 9-conductor, RS422 serial cable into the OUTPUT connector

on the rear of the SHOTBOX. Plug the other end of the cable into the “AUX”

connector on the ST300.

2) Connect the +5,VDC POWER SUPPLY into the POWER connector on the rear

of the SHOTBOX. Plug the Power Supply into a wall outlet, 90 VAC - 240

VAC.

Installation is complete.

Hotplug!!!

CONNECTION DIAGRAM

6 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 7

4. LOADING A CLIP

a. Select a VTR by pressing VTR [1], VTR [2] or VTR [3].

b. Press [CLIP LIST] to view the list of Clips that exist in the VIDEO SERVER.

The CLIP LIST indicator comes on.

c. The display now shows:

d. Turn the Wheel.

The top line of the display will show:

(“xxxxxxxx” is the 8-character CLIP ID)

Turn the Wheel clockwise to scroll forward, or counter-clockwise to scroll backward,

through the list of available CLIP IDs.

OR

Enter the ID (if a clip has one) from the numeric keypad.

e. Press [LOAD] to load the current CLIP ID shown on the top line of the display.

f. Locate the clip to the desired IN time.

Create New Clip?

LOAD=OK WHEEL=Next

XXXXXXXX LOAD=OK

ENTER ID:

5. CAPTURE FUNCTION

a. SETTING AN IN (OUT) POINT

1) Locate the clip to the desired IN (OUT) time.

2) Press [IN] ([OUT]).

The IN (OUT) indicator comes on.

b. CLEARING AN IN (OUT) POINT

Press and hold [DEL], then press and release [IN] ([OUT]).

The IN (OUT) indicator goes off.

c. GOTO TIME

1) Press [SHIFT] + [RECUE] to enter a search time.

2) Enter the desired time using the numeric keypad.

3) Press [RECUE] OR [ENTER] to GOTO the selected time.

d. GANGING CLIPS WITH PREVIOUSLY SET IN POINTS

If a gang is established with the master having an IN point, the gang relationship will be

relative to the master IN point and all slave IN points will be overwritten.

7 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 8

e. MULTIGANG SUPPORT

2 gangs are allowed to exist on the ST300 simultaneously. As long as the loading of a

Cue Point or a selection of a gang does not interfere with another gang, any gang is legal.

For example:

Load clips on all four VTRs

Press [SHIFT] + VTR [1]; then press VTR [1], then VTR[2]

Press [ESC]

Press [SHIFT] + VTR [3]; then press VTR [3], then VTR [4]

Press [ESC]

The two gangs will exist without conflict. Learn either one of these gangs into a Cue

Point and load into the Cue Point. The load will never conflict with the other gang.

6. LEARN

NOTE: The ST300 and SHOTBOX share common

If a LEARN is done on the SHOTBOX, it doesn’t need to be LEARNed on the ST300.

a. LEARN ON THE ST300

1) Select a VTR by pressing VTR [1], VTR [2], VTR [3] or VTR [4].

2) LOAD a Clip. If LEARNING a Gang, load all clips and set the Gang.

3) Select the desired Cue Point by pressing [NEXT CUE], [LAST CUE] or by

4) Press [SHIFT] + [MARK] to initiate the LEARN of the current configuration.

5) Press VTR [1], VTR [2], VTR [3] or VTR [4] to select the VTRs.

6) Press [MARK] and the ST300 will: LEARN (save) the Cue Point, CLIP IDs, IN

b. LEARNING IN POINTS, SINGLE CLIP

If the learned clip has an IN point marked, the LEARN time will be the IN point. If there

is no learned IN point, then the current location will be the learned time and will be made

the IN point upon learning.

c. LEARNING IN POINTS, GANGED CLIPS

If the master has no IN point, the current location of each clip in the gang will be learned

as IN points. IF the slaves have IN points, the slaved IN points will be overwritten.

memory in the ST300.

manually entering the Cue Point using the numeric keypad.

The selected Cue Point number is shown on the bottom line of the display.

The display shows:

and OUT Times, Current Directory and Ganged VTRs.

Select VTR:

Learn - OK, ESC-Cancel

8 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 9

d. LEARN ON THE SHOTBOX

1) Press [LEARN].

2) Select Bank and press Shotkey

7. RECALL

a. RECALL ON THE ST300

1) Select the desired Cue Point by pressing [NEXT CUE], [LAST CUE],

2) Press [LOAD] on the ST300.

b. RECALL ON THE SHOTBOX

1) Select the desired BANK, pressing BANK [0]-[9].

2) Select the desired Shotkey and press.

or by manually entering the Cue Point using the numeric keypad.

The selected Cue Point number is shown on the bottom line of the display.

The ST300 will automatically load the Learned clips on the Learned VTRs, cue

the clips to the Learned time, then set the Learned GANG mode.

8. VIEW CONTENTS OF CUE POINTS ON THE

SHOTBOX

a. Press and hold [VIEW].

Select the desired bank key, then the desired switch key.

The display will show assignments for all four VTRs in either the first 4 or last 4 buttons

on the first row of display keys.

b. Press the selected switch again to see which clips are assigned to this Cue Point on VTR3

and VTR4.

9 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 10

Advanced Features . . .

9. LOOPING FUNCTIONS

Loop: Play from the IN point to the OUT point continuously.

Play to Loop: Played from the beginning of clip to the OUT point of the clip, then, playback

continues at the IN point of the clip, then the clip plays in a continuous loop from the IN point to

the OUT point.

a. LOOP CLIP

1) Press [LOOP ENABLE] after a clip is loaded to place any clip in loop mode.

To loop clips in GANG mode, the Master Clip should be loaded in loop mode.

All the clips in the Gang will loop when [PLAY] is pressed.

NOTE: Clips will now loop from the IN point to the END

point (if set).

2) Press [SHIFT] + [LOOP ENABLE] to Play To Loop.

b. SAVING CLIPS THAT AUTOMATICALLY LOOP

To automatically Loop a clip each time it is loaded, DUPLICATE the clip and assign the

suffix “*” to the CLIP ID.

On the ST300: Press [ENTER] + [0] to add a “*” at the end of the clip name

c. SAVING CLIPS THAT AUTOMATICALLY PLAY TO

LOOP

1) To automatically Play to Loop a clip each time it is loaded, DUPLICATE the

clip and assign the suffix “#” to the CLIP ID.

On the ST300: Press [ENTER] + [1] to add a “#” at the end of the clip name.

2) Locate the desired IN, then OUT point.

Press [IN]([OUT]) to set the IN(OUT) point. The IN(OUT) indicator will turn

on.

3) Select the desired Cue Point by pressing [NEXT CUE], [LAST CUE], or by

manually entering the Cue Point using the numeric keypad.

The selected Cue Point number is shown on the bottom line of the display.

4) Press [SHIFT] + [MARK] to initiate the LEARN of the current configuration.

The display shows:

5) Press VTR [1], VTR [2], VTR [3] or VTR [4] to select the VTRs.

6) Press [MARK] and the ST300 will: LEARN (save) the Cue Point, CLIP IDs, IN

and OUT Times, Current Directory and Ganged VTRs.

of the clip or the OUT

Select VTR:

Learn - OK, ESC-Cancel

10 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 11

10. DUPLICATING A CLIP

a. To save a copy of a clip, first LOAD the clip.

b. Set the IN and OUT points at the start and end of the clip.

c. Press [SHIFT] + [CLIP LIST]. The display will show:

d. Press [LOAD].

Enter a numeric CLIP ID using the numeric keypad on the ST300.

OR

Enter an alphanumeric CLIP ID using the SHOTBOX “qwerty” keyboard, using

NAMING CONVENTIONS, Section 21.c.

To add looping functions to the duplicated clips, LOOPING FUNCTIONS, Section 9, for

more information.

e. Press [LOAD] to save.

OR

Press [ESC] to abort without saving.

“Save Trimmed Clip?”

LOAD = Yes Wheel = Next

11. TRIMMING A CLIP

a. To make a sub-clip, first LOAD the clip.

b. Locate the desired IN, then OUT point.

Press [IN]([OUT]) to set the IN(OUT) point. The IN(OUT) indicator will turn on.

c. Press [SHIFT] + [CLIP LIST]. The display will show:

d. Press [LOAD].

e. After pressing [LOAD], the display shows: “Manually enter ID”

Enter a numeric CLIP ID using the numeric keypad on the ST300.

OR

Enter an alphanumeric CLIP ID using the SHOTBOX “qwerty” keyboard, using the

Naming Conventions in Section 21.c.

f. Press [LOAD] to save the trimmed clip.

OR

Press [ESC] to abort without saving.

“Save Trimmed Clip?”

LOAD = Yes Wheel = Next

11 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 12

12. RECORDING A NEW CLIP

a. To make a new clip and insert video from either another Profile channel or an external

source, first press [CLIP LIST]. The Clip List indicator comes on.

b. Since there is no clip loaded, the display now shows:

c. Press [LOAD].

d. After pressing [LOAD], the display shows: “Manually enter ID”

Enter a numeric CLIP ID using the numeric keypad on the ST300.

OR

An alphanumeric CLIP ID using the SHOTBOX “qwerty” keyboard, using the Naming

Conventions in Section 22.c.

e. Press [LOAD] to save the new CLIP ID.

OR

Press [ESC] to abort without saving.

f. Recall the Clip and then start the video that will be inserted.

g. Press [RECORD].

h. Press [STOP] when finished.

Create New Clip?

LOAD= OK WHEEL= Next

13. VIEW CONTENT OF CUE POINTS ON THE ST300

a. Select the VTR to examine the contents of a Cue Point by pressing [1], [2], [3] or [4].

b. Press [NEXT CUE] or [LAST CUE] to step through the Cue Points.

OR

Enter a 1-, 2- or 3-digit number on the numeric keypad, followed by [ENTER].

The contents of the selected Cue Point are shown on the bottom line of the display.

12 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 13

14. TRANSFER CUELIST

The TRANSMIT CUELIST function allows the transmittal of a list of Cue Points to a PC, using

the provided utility software on the PC, or to another ST300. Transfer to a PC requires OpSuite

3.0 software, which runs on a Windows- ba s ed computer. Contact DNF Controls for more

information.

a. TRANSMIT CUE LIST FUNCTION

1) TO TRANSMIT CUE POINTS TO THE ST300

a) Connect the VTR 4 connector on the rear of the ST300 to the VTR 4

connector of the receiving ST300 using an RS422 9-pin cable with TX

and RX lines crossed.

(A “turnaround” cable)

b) Press [MENU] and scroll the Wheel until “Transmit CUE List?

YES=Enter, Exit=ESC” is displayed.

c) Press [ENTER] to start transmitting.

The Display shows “Waiting to transmit” on the first line.

d) When the Receiver is ready, transfer starts automatically.

The Display now shows “Transmitting cuelist.”

e) After the transfer is over, the display shows “Transfer is over” for one

second

and then shows “Waiting to transmit” again.

f) Connect another ST300 to transmit the list again.

OR

Press [ESC] twice to exit the MENU mode.

2) TO TRANSMIT CUE POINTS TO THE PC

a) Connect the VTR4 connector on the back of the ST300 to one of the

COM ports on the PC using a RS422 to RS232 adapter.

b) Repeat steps b-f of the TRANSMIT CUE POINTS to the ST300

section.

13 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 14

b. RECEIVE CUELIST FUNCTION

The RECEIVE CUELIST function allows the reception of a list of Cue Points from a PC

or from another ST300. Transfer to a PC requires OpSuite 3.0 software, which runs on a

Windows-based computer. Contact DNF Controls for more information.

1) TO RECEIVE CUE POINTS FROM THE ST300

a) Connect the VTR4 connector on the back of the ST300 from the VTR4

connector of the transmitting ST300 using RS422 9-pin cable with TX

and RX lines crossed.

(A “Turnaround” Cable)

b) Press [MENU] and scroll the Wheel until

“Receive CUE List? YES=Enter, Exit=ESC” is displayed.

c) Press [ENTER] to start receiving.

The Display shows “Waiting to receive” on the first line.

d) When the Transmitter is ready, transfer starts automatically.

The Display now shows “Receiving cuelist.”

e) After the transfer is over the display shows “Done-Success! Press any

key…”

f) Press any key. The display shows “Receive cuelist?” message.

g) Press [ESC] to exit the MENU mode.

2) TO RECEIVE CUE POINTS FROM THE PC

a) Connect the VTR4 connector on the back of the ST300 to one of the

COM ports on the PC using RS422 to RS232 adapter.

b) Repeat steps b-g of the RECEIVE CUE POINTS from the ST300

section.

15. VIEW SHOTBOX SHOTKEY ASSIGNMENTS

a. Press [VIEW]. The VIEW indicator comes on.

b. Press the desired switch to see the content.

c. The switch turns RED and the content (CLIP ID) of the corresponding Cue Point is

displayed on a virtual display.

For Example:

NOTE: All the remaining switches are not illuminated.

d. Release the keys to return to normal operation

14 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

VTR 1

Clip 23

VTR 2

Clip 13

VTR 3

Clip 77

VTR 4

No Assignment

Page 15

16. SHOTBOX SHOTKEY MAPS

The SWITCHES on the SHOTBOX access the SHOTLIST locations as follows:

BANK 0, SWITCHES 1 Æ 30 access SHOTLIST locations 001 Æ 030.

BANK 1, SWITCHES 1 Æ 30 access SHOTLIST locations 101 Æ 130.

BANK 2, SWITCHES 1 Æ 30 access SHOTLIST locations 201 Æ 230.

BANK 3, SWITCHES 1 Æ 30 access SHOTLIST locations 301 Æ 330.

BANK 4, SWITCHES 1 Æ 50 access SHOTLIST locations 401 Æ 430.

BANK 5, SWITCHES 1 Æ 30 access SHOTLIST locations 501 Æ 530.

BANK 6, SWITCHES 1 Æ 30 access SHOTLIST locations 601 Æ 630.

BANK 7, SWITCHES 1 Æ 30 access SHOTLIST locations 701 Æ 730.

BANK 8, SWITCHES 1 Æ 30 access SHOTLIST locations 801 Æ 830.

BANK 9, SWITCHES 1 Æ 30 access SHOTLIST locations 901 Æ 930.

17. SHOTBOX CONTROL SWITCHES

a. [PLAY]: Plays out the selected clip.

b. [RECUE]: Returns to the beginning of the clip.

c. [STOP]: Stops playout of the clip.

The CONTROL Switch indicators show the real-time status of the Video Server.

15 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 16

Reference . . .

18. SETUP MENU

Press [MENU]. The MENU indicator will turn on.

Turn the Wheel to select item to change.

Press [MENU] OR use the Softkeys to change the desired mode for that option.

Turn the Wheel at anytime to select another item.

Press [ESC] at anytime to exit SETUP MENU. The MENU indicator will turn off.

IMPORTANT NOTE: Please set the following MENU items during initial installation.

ST300 Setup: Clear Mem; Set Defaults

ST300 Config: Select Directory

MENU MODES

DISPLAY

SOFTWARE

VERSION

RECORD MODE

CHANNEL

CONNECTOR

ASSIGNMENT

RECORD

LOOP TIME

RECORD

RECALL MODE

LEARN MODE

MARK-Q

The version number and date for the currently stalled software is displayed.

For example:

Press Softkey to select the desired mode: Lockout or Crash (Full).

Press VTR key for CH (Channel) and CN (Connector) assignment.

Press VTR keys for Record Loop Length.

Then, enter HH:MM:SS:FF.

Press Softkey to select single button or 2-button recor d.

RECORD = [REC] Only OR [REC] + [PLAY]

Press Normal or Redirect (Redir).

If [REDIR] is on: The Clip will be REDIRECTED to load on the currently selected

VTR.

If [NORMAL] is on: The Clip will be loaded on the VTR it is LEARNED into.

In normal mode, LEARN the IN/Current time and OUT points as well as any gang

information.

In CLR_LRN mode, the IN and OUT points are cleared after LEARN is done. This

is used to set multiple Cue Points with individual IN and OUT points in the SAME

video clip.

Press Softkey to:

Enable ADVANCE to next Cue Point, when [MARK] is pressed.

OR

Maintain CURRENT Cue Point when [MARK] is pressed.

(Turning wheel Clockwise)

2034CL-N V3.0

011400

16 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 17

TAPE TIME

STOP MODE

WIND MODE

SLOMO

MAX SHUTTLE

SPEED

DATA PORT

TRANSMIT

CUELIST

RECEIVE

CUELIST SET

TO PROFILE

MODE

NDF = non-drop frame. DF = drop frame.

PB = while playing a clip, when [STOP] is pressed, the Profile freezes on last good

video.

PB/EE = When [STOP] is pressed the first time, the Profile freezes on last good

video. When [STOP] is pressed a second time, video out is switched to video in.

Press Softkey to select:

HOLD (fast wind is maintained only while key is depressed).

OR

LATCH (fast wind is initiated and maintained with momentary key press).

Select fast wind speed (04X, etc.) by pressing Softkey.

ST300 display shows:

(Non T-Bar Version):

SLOMO with: WHEEL

SpdRange Preset

ST300 display shows:

(T-Bar Version)

SLOMO with: TBAR

Wheel

NOTE - The T-BAR has a fixed speed range of 0 Æ +300 with a detent at +100%

play speed.

For Wheel only:

Press Softkey [SPDRANGE] to select SLOMO speed ranges:

Press Softkey to select: 0 Æ +300 OR -100 Æ +300.

Press Softkey [BACK] to return to SLOMO MENU.

Press [ESC] to exit OR turn the Wheel to select another item.

For Wheel only:

Press Softkey [PRESET] to select the SLOMO Preset Speed Mode

Press Softkey [UPDATE]. When exiting SLOMO mode, the last used speed is

saved in the Preset Speed register.

Press Softkey [STATIC]. The Preset Speed register is NOT updated when exiting

SLOMO mode.

It is only changed by [SHIFT] + [SLOMO] (PRESET SLOMO).

Press Softkey to select maximum shuttle speed of the Profile.

Select the VTR Connector (1-4) through which the cue list may be transmitted or

received.

Transmits Cuelist to another ST300 or to a PC.

Receives Cuelist from another ST300 or a PC.

Press Softkey [YES] to set ST300 to parameters currently stored in the Profile.

17 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 18

UNASSIGNED

PORT OPTION

AUTO

ALIGNMENT

ST300 SETUP

ST300 CONFIG

Recovers Profile resources which have been opene d by a not her device.

Press any key to allow the ST300 to report any unassigned resources.

When prompted, “Press any key for unassigned resources.”

Option will automatically realign slaves which are not on the same connector

master. This automatic realignment will occur after pressing stop or after one second

has elapsed while still. The second, delayed realignment will occur only in Shuttle,

Slomo and Jog.

(Supported ONLY in units with –a option.)

Press Softkey beneath ClearMem to clear all Cue Points to 00:00:00:00.

Press Softkey [YES] when asked “Are You Sure?”

Press Softkey beneath SetDefault to set ST300 to default settings.

Press Softkey [YES] to save.

Press Softkey [DRIVE] then press Softkeys to save the default drive or turn the

Wheel to change the drive.

Press Softkey [ENTER] to return to the ST300 CONFIG screen.

Press Softkey [DIRECTORY] to save the default directory or turn the Wheel to

change the directory.

Press Softkey [ENTER] to save the selected directory and return to the ST300

CONFIG screen.

NOTE: Choose DEFAULT when first setting up the system or when eproms are

upgraded.

as the

18 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 19

ST300 SETUP DEFAULTS

RECORD

CHANNEL, CONNECTOR

ASSIGNMENT

RECORD

RECALL MODE

LEARN MODE

MARK-Q

TAPE TIME

STOP MODE

WIND MODE

SLOMO with

MAX SHUTTLE

DATA PORT

AUTO ALIGNMENT

NOTE: The directory chosen in the MENU will be the directory selected upon reset.

If the Profile’s working directory is changed by other programs, when the ST300 starts it will change to the

directory last chosen from the menu.

When installing an upgrade eprom:

Clear the Cue Point memory

Set factory defaults

Set the directory

Then, reenter the CLIP IDs at the appropriate Cue Points or download them from a PC to which the list has

been previously saved, using the Transfer Utility or Operator’s Suite.

Also, enter into the MENU any changes from the default settings. Failure to follow this procedure may

lead to corruption of the Clips and unpredictable operation.

Lockout

CN1 for all. CHA, CHB, CHC, CHD, respectively.

RECORD = [REC] Only.

Normal

Normal mode

CURRENT Cue Point

NDF

PB

LATCH

Wheel

8 X

CN4

OFF

19 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 20

19. FUNCTION TABLE

Function Key Press Description

GOTO ENTERED

TIME

GANG [SHIFT] + [VTR #1]

FFWD

JOG [JOG] Select JOG mode and enable Wheel.

[SHIFT] + [RECUE] Search the VTR to the manually entered time.

Use the ST300 numeric keypad. Press [ENTER] or

[RECUE].

[SHIFT] + [ANY VTR KEY] gang enable mode.

OR

[SHIFT] + [VTR #2]

OR

[SHIFT] + [VTR #3]

OR

[SHIFT] + [VTR #4]

[FFWD] Press and HOLD to shuttle. Release key to stop. Set

Then, one at a time, press the VTR keys to be included

in the gang. The LED above the key will turn on.

Press the VTR key again to remove from gang, the

LED above the key will turn off.

Press [ESC] to exit and save the gang.

The VTR LEDs that are on show the gang.

The flashing LED shows which VTR is currently

selected (and is monitoring Time Code on the

display).

WIND Speed in MENU.

LAST CUE [LAST CUE] Step to the previous Cue Point Location.

NEXT CUE [NEXT CUE] Step to the next Cue Point Location.

RECORD [REC] Places VTR into the Record mode selected by

RECORD MODE in the SETUP MENU. Press

[RECORD] or [RECORD] + [PLAY].

REWIND [RWD] Press and HOLD to shuttle. Release key to stop. Set

WIND Speed in MENU.

SHUTTLE [SHUTTLE] Select SHUTTLE mode and enable Wheel.

SAVE TRIMMED

CLIP

DISPLAY

CURRENT

DIRECTORY

DISPLAY

DIRECTORY

CURRENT CUE

POINT IS SAVED

IN

[SHIFT] + [CLIP LIST]

[SHIFT] +

[NEXT CUE]

[SHIFT] +

[LAST CUE]

Save Clip from the IN to the OUT point.

Displays the current directory.

Displays the directory that the clips in the CURRENT

Cue Point are saved in.

20 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 21

DISPLAY

DURATION OF

CLIP and

WHICH CLIP IS

LOADED

PRESET SLOMO

SPEED

SLOMO

STOP [STOP] Press once to STILL frame VTR.

[SHIFT] + [LOAD] Display duration of currently loaded clip and which

clip is loaded.

[SHIFT] + [SLOMO] Turn Wheel to preset slo-mo speed.

[SLOMO] Press [SLOMO] to slo-mo the VTR.

Turn the Wheel (or move the T-Bar if available) to

change the play speed.

Press [SLOMO] to STILL frame

OR press any transport key to exit SLOMO.

Press again to put VTR into STOP mode.

PLAYBACK

RESOLUTION

PLAY TO LOOP [SHIFT] +

LOOP ENABLE [SHIFT] + [PLAY] Plays clip from beginning to end then repeats.

GOTO end of

CLIP

GOTO beginning

of CLIP

TIME MODE

SELECT

[SHIFT] + [STOP] Toggles between interlaced video and line doubled.

Loops From the IN point to the OUT point of a clip

[LOOP ENABLE]

[SHIFT] + [FFWD] Position to last frame of clip.

[SHIFT] + [REW] Position to first frame of clip.

[TIME MODE] Press to toggle between Timecode (TC), VITC (VT)

continuously.

or Tape Timer (TM) display modes.

21 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 22

20. VIDEO SERVER SETUP

Configuring the Profile for operation with Grass Valley Group Native Protocol.

(1) Configuring the PDR AND (2) Opening a Prolink session MUST

DNF System can be used.

a. CONFIGURING THE PROFILE FOR NATIVE MODE

The ST300 Controller with NATIVE protocol communicates with the PROFILE through

the PROLINK program, on the PROFILE. Prolink uses Configuration Files found in the

PROFILE/CONFIGS Directory. These files are called: VTR1.CFG, VTR2.CFG,

VTR3.CFG and VTR4.CFG. These files do not affect the operation of VDR Panel.

Prolink and VDR Panel share resources so that the total number of PROLINK channels

used and VDR Panels opened cannot exceed the available number of resources (typically

4 channels).

If CFGEDLIN.EXE is in the Profile directory, use CFGEDLIN.EXE to configure the

.CFG files.

If you do not have CFG.EXE, install PDRCFG.EXE. Instructions for installing

PDRCFG.EXE accompany the disk.

b. OVERVIEW OF PROFILE CONNECTIONS

Physical access to the Profile is made through its RS-422 breakout box. A Profile session

activated with Prolink establishes which port(s) Profile will use for serial

communications.

The communications link is complete when a connection is made from a connector on the

ST300 to an open session\port on the Profile.

A correctly configured connection consists of a connector and a channel.

Connections for the ST300 are called CN1, CN2, CN3 and CN4 and refer to the 9-pin

ports on the back of the ST300 labeled VTR1, VTR2, VTR3 and VTR 4.

Channels for the ST300, CH A, CH B, CH C and CH D refer to the Profile’s Channel 1,

Channel 2, Channel 3 and Channel 4.

The numeric\alpha translation is made in the ST300 in order to comply with the VDR

Panel Software which refers to the numbered channels as Panel A, Panel B, Panel C and

Panel D.

be done BEFORE the

22 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 23

c. CONNECTION AND CHANNEL ASSIGNMENTS

1) Press [MENU], turn the Wheel to “Press VTR key for CH and CN

assignments.”

2) Press VTR [1]. NOTE: VTR [X] toggles between CH and CN assignments.

3) “VTR 1 Connection” is displayed on the top line.

The bottom line of the display shows “CHA CHB CHC >>> OFF”

4) Press the keys under these selections to choose a channel.

Select “>>>” to view more channels.

5) Select VTR [2], [3] and [4] and repeat steps 3 through 5.

6) Press [ESC] at anytime to exit MENU mode.

NOTE: Set all unused VTR Connections and Channels to OFF.

23 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 24

21. COMPLETING THE PROFILE CONNECTION

So far in this setup, the session P1 has been opened on the Profile and is ready for communication.

Noting the port\session number just selected (P1), locate the P1 connector on the Profile’s

breakout box and connect an RS-422 cable from Port 1 to the connection called “VTR1” on the

back of the ST300.

The default values for channel connections CHA, CHB, CHC and CHD on the ST300 are for

VTR1 (CN1). Upon connection, the ST300 will be communicating with the Profile on all

available channels.

This is the connection just built:

From: To:

Profile Session P1 ST300 ‘VTR1’

On Port 1 Connection 1

VTR Connection Channel

1 CN1 CHA

2 CN1 CHB

3 CN1 CHC

4 CN1 CHD

a. PROFILE CONNECTION OPTIONS

Open another session and connect an RS-422 cable to another ‘VTR’ label on the back of

the ST300.

From the setup menu on the ST300, assign any ST300 VTR to the new connection (CN).

The ST300 VTR just assigned will be communicating with the Profile via the new

connector.

The program displays a screen titled “Channels.” Assign a Video, Audio and Timecode

CODECs, Video Input and Video Output as required to Channels 1-4.

If a resource is in use, it will be highlighted in Red.

Click OK when all assignments have been made.

b. DRIVE/DIRECTORY SELECTION

To change the PROFILE Drive or Directory where Clips will be saved:

1) Press [MENU] and scroll to the Drive/Directory selection.

2) Select Drive or Directory by pressing the Softkey

3) Scro ll to the desired Drive/Directory and press [ENTER].

The selected drive/directory will be used for locating and loading clips.

NOTE: When a Drive/Directory changes, the Clip List created using a different Drive/

Directory is no longer valid. Set all unused VTR Connections and Channels to

OFF.

under the menu item.

24 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 25

c. NAMING CONVENTIONS

The ST300 Native Mode Controller can load clips that meet the following requirements:

1) Clip names cannot exceed 8 characters.

2) A space cannot be embedded within the clip name.

3) The clip name must be in uppercase characters only.

4) All special characters can be used.

d. DEFINING RECORD LOOP LENGTH

If the length of time is entered and then set to record, a clip will be recorded for that

length and then loop back to the beginning and continue recording.

25 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 26

22. SPECIFICATIONS

a. ST300

Power: 90 VAC to 265 VAC adapter supplied with IEC connector

Size: (L” x W” x H”) 12” x 6” x 1.5” (front) 3.0” (rear)

Weight: 4 lbs.

Rear Panel Connectors: VTR1, VTR2, VTR3, VTR4 (All DB9F)

GPI (DBF15F)

Power (DB9M)

Aux (DB9F)

Display: Easy to read 2-line, back-lit LCD display

Jog/Shuttle Wheel: With mechanical detents.

Optional “T”-bar: Slo-mo 0-300% of Play Sp eed

RS422 SERIAL CONNECTOR

9-Pin D-Type, Female (DB9F)

Pin # 1 Frame Ground 6 Receive Common

2 Receive A Í 7 Receive B Í

3 Transmit B Î 8 Transmit A Î

4 Transmit Common 9 Frame Ground

5 Spare

POWER CONNECTOR

9-Pin D-Type, Male (DB9M)

Pin # 1 +5v DC 6 +5 VDC

2 +5v DC 7 Ground

3 Ground 8 Ground

4 +12 VDC 9 Ground

5 –12 VDC

AUX PORT RS422 SERIAL CONNECTOR

9-Pin D-Type, Female

Pin # 1 Frame Ground 6 Transmit Common

2 Receive AÍ 7 Receive B Í

3 Transmit B Î 8 Transmit A Î

4 Receive Common 9 Frame Ground

5 Spare

(User adjustable contrast)

26 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 27

GPI IN/OUT CONNECTOR

15-Pin D-Type, Female (DB15F)

Pin # Function Pin # Function

1 GPI OUT 1 9 GPI IN 1 = RECORD

2 GPI OUT 2 10 GPI IN 2 = PLAY

3 GPI OUT 3 11 GPI IN 3 – STOP

4 GPI OUT 4 12 GPI IN 4 = RECUE

5 GPI OUT 5 13 HPI IN 5 = LOAD

6 GPI OUT 6 14 GPI IN 6 = NEXT CUE

7 GPI OUT 7 15 GPI IN 7 = LAST CUE

8 Common: GPI IN and GPI OUT

b. ST420 (SHOTBOX)

Power: 90 VAC to 265 VAC adapter supplied with IEC connector

Size: [L” x W” x H”] 11.5” x 6 .5” x 1.75” (front) 3.5” (rear)

Weight: 4 lbs.

Rear Panel Connectors: Out (DB9F)

GPI (DBF15F)

Power (DB9M)

Aux (DB9F)

RS422 SERIAL CONNECTOR (OUTPUT)

9-Pin D-Type, Female

Pin # 1 Frame Ground 6 Transmit Common

2 Transmit A Î 7 Transmit B Î

3 Receive B Í 8 Receive A Í

4 Receive Common 9 Frame Ground

5 Spare

NOTE: OUTPUT 2 connector is not programmed in this model.

POWER CONNECTOR

9-Pin D-Type, Male

Pin # 1 +5v DC 6 No Connection

2 +5v DC 7 Ground

3 Ground 8 Ground

4 No Connection 9 Ground

5 No Connection

27 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 28

23. TROUBLESHOOTING

ST420 TROUBLESHOOTING

a. All keys are RED - No communication with ST300.

b. All keys are dark - No communication between the ST300 and the Video Server.

c. The version of the ST420 must comply in the software version with the ST300 it is

connected to. To determine the software version of the ST420 do the following:

1) Press [SHIFT] + [STOP] + [PLAY]. The key that displays the current version

is RED.

2) The ST420 displays: “SELECT ST300 V2.1 or V2.0 or V3.0.”

Press the key for the software version of ST300 you are using.

Please refer to the ST300 to determine the Version if needed.

28 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 29

24. KEY LAYOUT

29 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Page 30

25. DNF CONTROLS LIMITED WARRANTY

DNF Controls warrants its product to be free from defects in material and workmanship for a period of one

(1) year from the date of sale to the original purchaser from DNF Controls.

In order to enforce the rights under this warranty, the customer must first contact DNF’s Customer Support

Department to afford the opportunity of identifying and fixing the pr oblem without sending the unit in for

repair. If DNF’s Customer Support Department cannot fix the problem, the customer will be issued a

Returned Merchandise Authorization number (RMA). The customer will then ship the defective product

prepaid to DNF Controls with the RMA number clearly indicated on the customer’s shipping document.

The merchandise is to be shipped to:

DNF Controls

12843 Foothill Blvd., Suite C

Sylmar, CA 91342

USA

Failure to obtain a proper RMA number prior to returning the product may result in the return not being

accepted, or in a charge for the required repair.

DNF Controls, at its option, will repair or replace the defective unit. DNF Controls will return the unit

prepaid to the customer. The method of shipment is at the discretion of DNF Controls, principally UPS

Ground for shipments within the United States of America. Shipments to international customers will be

sent via air. Should a customer require the product to be returned in a more expeditious manner, the return

shipment will be billed to their freight account.

This warranty will be considered null and void if accident, misuse, abuse, improper line voltage, fire, water,

lightning or other acts of God damaged the product. All repair parts are to be supplied by DNF Controls,

either directly or through its authorized dealer network. Similarly, any repair work not performed by either

DNF Controls or its authorized dealer may void the warranty.

After the warranty period has expired, DNF Controls offers repair services at prices listed in the DNF

Controls Price List. DNF Controls reserves the right to refuse repair of any unit outside the warranty

period that is deemed non-repairable.

DNF Controls shall not be liable for direct, indirect, incidental, consequential or other types of damage

resulting from the use of the product.

# # #

30 2034CL-N, 300 Clip Instant Access System, Profile, NATIVE Protocol

Loading...

Loading...