Page 1

12843 Foothill Blvd. Suite C

Sylmar, California 91342

V: 818.898.3380

F: 818.898.3360

sales@dnfcontrols.com

Model No. 2034CL-L

(& 2034CL-L-T)

300 CLIP INSTANT ACCESS SYSTEM

Louth Protocol

VERSION 3.0 SOFTWARE

NOTE: Supports up to 4 Video Server Channels

User Manual

1 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 2

Table of Contents

1. REVISION HISTORY 4

GETTING STARTED . . . 6

2. SYSTEM

DESCRIPTION 6

DEFINITIONS 6

3. SYSTEM

A. SHOTBOX 7

B. ST300 CONTROLLER 7

4. VIDEO

INSTALLATION 7

SERVER SETUP 9

5. LOAD 9

6. LEARN 10

A. LEARN ON THE SHOTBOX 10

B. LEARN ON THE ST300 10

7. RECALL 11

8. SHOTBOX

9. CLIP

A. RECALL ON THE SHOTBOX 11

B. RECALL ON THE ST300 11

SHOTKEY MAPPING TO SHOTLIST LOCATIONS 11

LIST FUNCTION 11

ADVANCED . . . 12

10. CREATING

11. CREATING

A. MARK IN (OUT) POINT 13

B. DELETE IN (OUT) POINT 13

C. MANUALLY ENTER IN (OUT) POINT 13

A CLIP 12

SUBCLIPS 13

D. CREATE SUBCLIP 13

12. ENTER

13. RECUE

14. VIEW

15. VIEW

16. SHOTBOX

17. CLEAR

18. TRANSFERRING

A. TRANSMIT CUE LIST FUNCTION 16

B. RECEIVE CUELIST FUNCTION 17

RECORD DURATION 14

THE CURRENTLY LOADED CLIP 14

THE CLIP ID OF THE CURRENTLY LOADED CLIP 14

CONTENT OF CUE POINTS ON THE SHOTBOX 15

CONTROL SWITCHES 15

SINGLE CUEPOINT 15

CUELISTS 16

2 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 3

REFERENCE . . . 18

19. SETUP

20. FUNCTION

21. SPECIFICATIONS 22

22. TROUBLESHOOTING 24

23. KEY

24. DNF

A. ST420 TROUBLESHOOTING 24

B. VERSION 3.0 HARDWARE OF ST300 ONLY 24

MENU 18

TABLE 21

LAYOUT 25

CONTROLS LIMITED WARRANTY 26

Manual Version............…........................................ 2.81 040307

Document ID.......................... 2034CL-L_Vs.3.0_User_Manual

3 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 4

1. REVISION HISTORY

052803 Rev. 2.2 Updated SETUP MENU, added key layout.

061903 Rev. 2.3 Added Recall Mode setup, Clear Single Cuepoint section.

062703 Rev. 2.4 Changed Key Layout.

110303 Rev. 2.5 Added DNF Controls Limited Warranty

Updated Receive Cue List & Transmit Cue List Function description.

120903 Rev. 2.6 Added CREATING SUBCLIPS section.

012204 Rev. 2.7 Changed Key Layout.

020504 Rev. 2.8 Added note to cover and System Description: Supports up to 4 Video

Server Channels.

040307 Rev. 2.81 Minor corrections.

4 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 5

5 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 6

Getting Started . . .

2. SYSTEM DESCRIPTION

The 300 Clip Instant Access System consists of the ST300-SSM VTR Controller, ST420

SHOTBOX and Shotlist Software.

The ST300 controls up to 4 video channels individually or ganged.

The Video Server must support Louth Automation Protocol.

SHOTLIST provides fast access to existing video clips stored in Grass Valley Group PROFILE,

LEITCH VR or other DDR / VDR / Video Servers supporting Louth Automation Protocol.

The SHOTLIST can contain up to 300 CLIP IDs, stored in non-volatile memory in the ST300.

Upon receipt of the LEARN command, the ST300 saves the CLIP IDs of the currently loaded

clips, the current time of each clip, the VTRs they are loaded on and the current GANG mode, into

the appropriate Cue Point.

Any clip in the SHOTLIST can be quickly loaded by simply entering the associated 3-digit

number of its location, then pressing [LOAD].

Press [PLAY] to play the clip. Press [RECUE] to recue to the beginning of the clip.

DEFINITIONS

Throughout this manual, VTR, DDR, VDR & Video Server will be referred to collectively as

“Video Server.”

The ST300-S/SM is referred to as the ST300.

The ST420 SHOTBOX is referred to as “SHOTBOX.”

SHOTKEY refers to the 1-30 switches on the SHOTBOX.

Words surrounded by brackets, for example, [ENTER], are keys on the ST300 or the

SHOTBOX. [XXX] + [XXX] means hold the two keys down simultaneously.

6 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 7

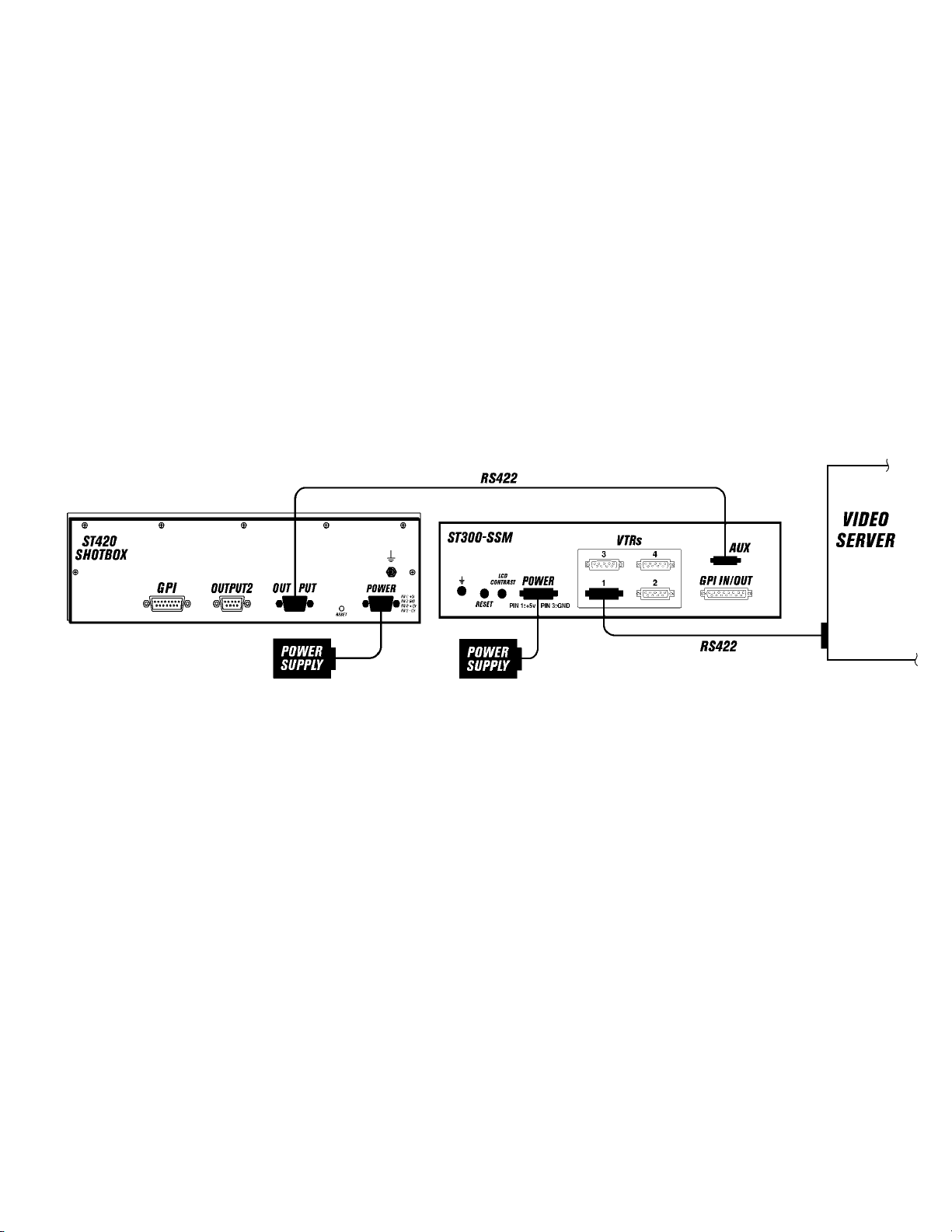

3. SYSTEM INSTALLATION

a. SHOTBOX

1) Plug one end of a standard 9-pin, RS422 serial cable into the OUTPUT

connector on the rear of the SHOTBOX. Plug the other end of the

cable into the AUX connector on the rear of the ST300.

2) Connect the 5 VDC, 1Amp POWER SUPPLY into the POWER connector on

the rear of the SHOTBOX. Plug the POWER SUPPLY into an outlet, 90 VAC

to 240 VAC.

b. ST300 CONTROLLER

1) Plug one end of a 9-conductor, RS422 serial cable int o the VTR 1 (2 , 3 or 4)

connector on the rear of the ST300. Plug the other end of the cable into the 9pin REMOTE connector on the Video Server.

2) Connect the +5, +12, -12 VDC POWER SUPPLY into the POWER connector

on the rear of the ST300. Plug the Power Supply into an outlet, 90 VAC to 240

VAC.

3) Assign logical Louth ports to ST300’s VTR connectors.

a) Press [MENU].

b) Turn the Wheel until VTR Louth Address is displayed.

c) Press VTR[1], VTR[2], VTR[3] or VTR[4] to select VTR.

d) Assign a Louth Port address for that VTR 0-9. (0 turns that channel

OFF.)

e) The second line of the display will show “Input=Enter, Out=ESC”

f) Press [ENTER] to select an Input Port.

(A “-“ will appear in front of the selected number.)

OR

Press [ESC] to select an Out Port.

g) Repeat steps c – f to assign a Louth Address to ALL VTRs you want to

use.

h) Press [ESC] to leave the MENU mode.

4) Check the other options in the SETUP MENU prior to using the ST300 to

confirm proper Record mode and other User settable modes.

Installation is complete.

7 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 8

CONNECTION DIAGRAM

8 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 9

4. VIDEO SERVER SETUP

a) Select LOUTH Broadcast communications protocol on the VIDEO SERVER to be

controlled.

b) If required, assign a serial port on the VIDEO SERVER through which the

ST300 will control it.

NOTE: In LOUTH mode, the VIDEO SERVER O

(INSERT and ASSEMBLE record modes are disabled.)

Setup is complete.

5. LOAD

a. Select a VTR by pressing VTR[1], VTR[2], VTR[3] or VTR[4].

b. Load the desired clip using the CLIP LIST function. (See Section 9, CLIP LIST

FUNCTION.)

c. Repeat steps a - b until clips are loaded into the desired VTRs.

d. Set the GANG mode, if required. (Refer to the Function Table for Details.)

NLY allows Full Record.

9 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 10

6. LEARN

a. LEARN ON THE SHOTBOX

1) Press [LEARN]. The LEARN indicator will turn on.

2) Select the desired BANK and ShotKey.

3) The Learned CLIP ID will be displayed on the pressed key.

NOTE: This will overwrite what you have assigned to the key previou s ly.

4) The ST300 will remember the loaded clip(s), current time and gang

5) Press [LEARN] to exit at any time.

NOTE: The [LEARN] key toggles LEARN mode on/off.

b. LEARN ON THE ST300

1) Select the desired Cue Point by pressing [NEXT CUE], [LAST CUE] or by

2) Press [SHIFT] + [MARK] to initiate the LEARN.

3) Press the VTR key desired, [1],[2],[3], [4].

4) Press [MARK] and the ST300 will:

configuration of the active VTR(s).

manually entering the Cue Point using the numeric keypad.

The selected Cue Point number is shown on the bottom line of the display.

The display will show:

LEARN (save) the VTR Number (1,2,3,4), loaded CLIP ID and current IN/OUT

time to the selected Cue Point.

Press VTR:

MARK-Lrn ESC-Cancel

10 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 11

7. RECALL

a. RECALL ON THE SHOTBOX

Select the desired Cue Point by pressing the BANK and ShotKey.

b. RECALL ON THE ST300

1) Select the desired Cue Point by pressing [NEXT CUE], [LAST CUE]

or by manually entering the Cue Point using the numeric keypad.

The selected Cue Point number is shown on the bottom line of the display.

2) Press [LOAD] on th e ST300.

The ST300 will automatically load the Learned clips on the Learned VTRs, cue

the clips to the Learned time, then set the Learned GANG mode.

8. SHOTBOX SHOTKEY MAPPING TO SHOTLIST LOCATIONS

The SWITCHES on the SHOTBOX access the SHOTLIST locations as follows:

BANK 0, SWITCHES 1 Æ 30 access SHOTLIST locations 001 to 030.

BANK 1, SWITCHES 1 Æ 30 access SHOTLIST locations 101 to 130.

BANK 2, SWITCHES 1 Æ 30 access SHOTLIST locations 201 to 230.

BANK 3, SWITCHES 1 Æ 30 access SHOTLIST locations 301 to 330.

BANK 4, SWITCHES 1 Æ 50 access SHOTLIST locations 401 to 430.

BANK 5, SWITCHES 1 Æ 30 access SHOTLIST locations 501 to 530.

BANK 6, SWITCHES 1 Æ 30 access SHOTLIST locations 601 to 630.

BANK 7, SWITCHES 1 Æ 30 access SHOTLIST locations 701 to 730.

BANK 8, SWITCHES 1 Æ 30 access SHOTLIST locations 801 to 830.

BANK 9, SWITCHES 1 Æ 30 access SHOTLIST locations 901 to 930.

9. CLIP LIST FUNCTION

a. Press [CLIP LIST] to view the list of CLIP IDs that are resident on the Video Server.

The CLIP LIST indicator will turn on.

b. Turn the Wheel to view clip IDs on the Server.

OR

Enter a CLIP ID (maximum of eight characters) using the numeric keypad

OR the SHOTBOX’s “qwerty” keyboard.

d. Press [LOAD] on the ST300 or SHOTBOX to load the entered CLIP ID.

11 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 12

Advanced . . .

10. CREATING A CLIP

a. Select Louth Input Port. (See SYSTEM INSTALLATION, Section 3.)

b. Select the desired clip Duration. (See ENTER RECORD DURATION, Section 12.)

c. Press [CLIP LIST]. The CLIP LIST indicator will turn on.

The display will show “CREATE NEW CLIP.”

d. Press [LOAD]. The display will show the default CLIP ID.

e. Press [LOAD] to accept the default CLIP ID.

OR

Use [NEXT CUE], [LAST CUE] and Wheel to edit the CLIP ID.

Use the [NEXT CUE] and [LAST CUE] keys to position the cursor.

Turn the Wheel to select the desired letter.

OR

Enter a name with a maximum of 8 characters on the SHOTBOX keyboard.

f. Press [LOAD] on the ST300 or on the SHOTBOX to create the selected CLIP ID.

g. If the selected CLIP ID already exists, a warning message will be displayed. To load the

existing clip, press [ENTER]. Press [ESC] to exit without loading the existing clip.

NOTE: On the SHOTBOX, for numbers, use bank keys 0-9, with 0 being “10.”

h. Press [REC] or [REC] + [PLAY] (depending on the selection made in MENU) to start

recording the clip.

i. Press [STOP] to stop recording the clip.

NOTE: You can ONLY create new clips if the INPUT Port is selected.

You must first create a clip to record on.

12 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 13

11. CREATING SUBCLIPS

a. MARK IN (OUT) POINT

1) Press [IN] ([OUT]).

2) The current Timecode is saved as [IN] ([OUT]) point. IN ([OUT]) indicator

turns on.

b. DELETE IN (OUT) POINT

1) Press [DEL] key and [IN] ([OUT]).

2) The [IN] ([OUT]) point is cleared. The [IN] ([OUT]) indicator is turned off.

c. MANUALLY ENTER IN (OUT) POINT

1) Press [SHIFT] and [IN] ([OUT]).

2) The display prompts to ente r new [IN] ([OUT]) point

3) Type in the new timecode using numeric keypad.

4) Press [ENTER] to save the new [IN] ([OUT]) point.

OR

Press [ESC] to leave without saving

OR

Press [RECUE] to save the new [IN] ([OUT]) point and recue to it.

d. CREATE SUBCLIP

1) Mark or Enter IN and OUT points as described above.

2) Press [SHIFT] + [CLIP LIST] keys.

3) The display prompts to enter a subcl i p name.

4) Enter the name using the Shotbox key b oa rd or the numeric keypad.

5) Press [ENTER].

6) The subclip with the specified name and the IN and OUT points is created.

13 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 14

12. ENTER RECORD DURATION

a. Press [SHIFT] + [REC].

b. The display shows current Record Duration.

c. Enter the desired Record Duration using the ST300’s numeric keypad.

d. Press [ENTER] to save the entered value.

OR

Press [ESC] to exit without saving.

13. RECUE THE CURRENTLY LOADED CLIP

a. Press [RECUE] to reload the currently loaded clip to the IN point.

b. Press [SHIFT] + [RECUE].

The display will show: “xx:xx:xx:xx”

(Where xx:xx:xx:xx = Last entered RECUE time.)

“Enter RECUE time “

Enter the desired time using the ST300’s numeric keypad.

Press [ENTER] to reload the currently loaded clip at the entered time.

OR

Press [ESC] to exit without searching.

14. VIEW THE CLIP ID OF THE CURRENTLY LOADED CLIP

a. Press and hold [SHIFT], then press and release [LOAD].

b. The bottom line will show: “Loaded Clip: xxxxxxxx”

Where xxxxxxxx is the CLIP ID.

14 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 15

15. VIEW CONTENT OF CUE POINTS ON THE SHOTBOX

a. Press [VIEW]. The VIEW indicator comes on.

b. Press the switch for which you would like to see the content.

c. The switch turns RED and the content (CLIP ID) of the corresponding Cue Point is

displayed on a virtual display.

For Example:

Note: All the remaining switches are not illuminated.

d. Release the keys to return to normal operation.

VTR 1

Clip 23

VTR 2

Clip 13

VTR 3

Clip 77

VTR 4

No Assignment

16. SHOTBOX CONTROL SWITCHES

a. [PLAY]: Plays out the selected clip.

b. [RECUE]: Returns to the beginning of the clip.

c. [STOP]: Stops playout of the clip.

17. CLEAR SINGLE CUEPOINT

On the Shotbox, press [SHIFT] + the Shotkey, the content of which you wish to clear. The

Shotkey becomes blank, the corresponding cuepoint is cleared.

15 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 16

18. TRANSFERRING CUELISTS

a. TRANSMIT CUE LIST FUNCTION

The TRANSMIT CUELIST function allows you to transmit your list of Cue Points to a

PC, using the provided utility software on the PC, or to another ST300. Transfer to a PC

requires OpSuite 3.0 software, which runs on a Windows-based computer. Contact DNF

Controls for more information.

1) TO TRANSMIT CUE POINTS TO THE ST300

a) Connect the VTR4 connector on the rear of the ST300 to the VTR4

connector of the receiving ST300 using an RS422 9-pin cable with TX

and RX lines crossed.

(A “turnaround” cable)

b) Press [MENU].

c) Scroll the Wheel until “Transmit CUE List? YES=Enter, Exit=ESC” is

displayed.

d) Press [ENTER] to start transmitting.

The Display shows “Waiting to transmit” on the first line.

e) When the Receiver is ready, transfer starts automatically.

The Display now shows “Transmitting cuelist.”

f) After the transfer is over, the display shows “Transfer is over” for one

second and then shows “Waiting to transmit” again.

g) Connect another ST300 to transmit the list again.

OR

Press [ESC] twice to exit the MENU mode.

2) TO TRANSMIT CUE POINTS TO THE PC

a) Connect the VTR4 connector on the back of the ST300 to one of the

COM ports on the PC using a RS422 to RS232 adapter.

b) Repeat steps b - g of the “TO TRANSMIT CUE POINTS TO THE

ST300” section.

16 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 17

b. RECEIVE CUELIST FUNCTION

The RECEIVE CUELIST function allows you to receive your list of Cue Points from a

PC or from another ST300. Transfer to a PC requires OpSuite 3.0 software, which runs

on a Windows-based computer. Contact DNF Controls for more information.

1) TO RECEIVE CUE POINTS FROM THE ST300

a) Connect the VTR4 connector on the back of the ST300 from the VTR4

connector of the transmitting ST300 using RS422 9-pin cable with TX

and RX lines crossed.

(A “Turnaround” Cable)

b) Press [MENU].

c) Scroll the Wheel until “Receive CUE List? YES=Enter, Exit=ESC” is

displayed.

d) Press [ENTER] to start receiving.

The Display shows “Waiting to receive” on the first line.

e) When the Transmitter is ready, transfer starts automatically.

The Display now shows “Receiving cuelist.”

f) After the transfer is over the display shows “Done-Success! Press any

key…”

g) Press any key. The display shows “Receive cuelist?” message.

h) Press [ESC] to exit the MENU mode.

2) TO RECEIVE CUE POINTS FROM THE PC

a) Connect the VTR4 connector on the back of the ST300 to one of the

COM ports on the PC using RS422 to RS232 adapter

b) Repeat steps b – h of the “TO RECEIVE CUE POINTS FROM THE

ST300” section.

17 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 18

Reference . . .

19. SETUP MENU

Press [MENU]. The MENU indicator will turn on.

Turn the Wheel to select item to change.

Press [MENU] OR use the Softkeys to change the desired mode for that option.

Turn the Wheel at anytime to select another item.

Press [ESC] at anytime to exit. The MENU indicator will turn off.

MENU MODES (Turning Wheel Clockwise)

SET LOUTH PORT

RECORD

EXTENDED IDs

CLIP SOM

RECALL MODE

VIDEO STANDARD

WIND MODE

Allows user to select Louth Port for each VTR.

Press [MENU] to select the desired record mode: Lockout or Crash (Full).

Toggle Extended IDs ON/OFF.

Extended IDs ON allows access up to 32 characters, OFF – up to 8 characters.

Press displayed softkey to toggle between “ZERO” and “NOT ZERO.”

Select ZERO if the clips that you are using start with 00:00:00:00.

Select NOT ZERO if the clips that you are using do not start with

00:00:00:00.

Press Normal or Redirect (Redir).

When one and only one clip is learned into a Cue Point, the Clip will be

REDIRECTED to load on the currently selected VTR if REDIR is on.

If REDIR is off, the Clip will be loaded on the VTR it is LEARNED into.

Press displayed softkey to select PAL, NTSC (non-dr o p fr ame), or DF (drop

frame).

Press Softkey to select:

HOLD (Fast wind is maintained only while key is depressed.)

OR

LATCH (Fast wind is initiated and maintained with momentary key press.)

Select fast wind speed (3.9 to 23.7) by pressing Softkey below SPD.

18 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 19

SLOMO

ST300 SETUP

DISPLAY SOFTWARE

VERSION

SYNC

ST300 display shows

(Non T-Bar Version):

SLOMO with: WHEEL

SpdRange Preset

Press Softkey [SPEED] to select SLOMO speed ranges:

Press Softkey to select: 0 Æ +200% OR –100% Æ +200%.

NOTE: 100% is normal speed

Press Softkey [BACK] to return to SLOMO MENU.

Press [ESC] to exit SETUP MENU and save changes.

OR

Turn the Wheel to select another item.

ST300 display shows

(T-Bar Version):

SLOMO with: TBAR

WHEEL

Press Softkey [TBAR] (or [WHEEL]) to toggle between them.

The T-BAR has a speed range of 0 Æ +200% with a detent at +100% play

speed OR a range of 0 Æ +100% (detent at +100% Play speed).

NOTE: 100% is normal speed

For Wheel only:

Press Softkey [PRSET] to select the SLOMO Preset Speed Mode.

Press Softkey [UPDATE].

When exiting SLOMO mode, the last used speed is saved in the Preset

Speed register.

Press Softkey [STATIC].

The Preset Speed register is NOT updated when exiting SLOMO mode.

It is only changed by [SHIFT] + [SLOMO] (PRESET SLOMO).

ST300 SETUP

Clear Cues SetDefault

Press Softkey beneath ClearCues to clear all Cue Points to 00:00:00:00.

Press Softkey [YES] when asked “Are You Sure?”

Press Softkey beneath SetDefault to set ST300 to default settings.

Press Softkey [YES] when asked “Are You Sure?”

The version number for the currently installed software is displayed.

Toggle the softkey to enable/disable reference Video.

19 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 20

RECORD

PREROLL

TRANSMIT

CUELIST

RECEIVE CUELIST

Press Softkey to select single button or 2-button recor d.

RECORD = [REC] Only OR [REC] + [PLAY].

Enter Preroll value.

Transmits Cuelist to another ST300 or to a PC.

Receives Cuelist from another ST300 or a PC.

20 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 21

2 0. FUNCTION TABLE

Function

GOTO

ENTERED TIME

GANG [SHIFT] + [VTR #1]

FFWD

JOG [JOG] Select JOG mode and enable Wheel.

LAST CUE [LAST CUE] Step to the previous Cue Point Location.

NEXT CUE [NEXT CUE] Step to the next Cue Point Location.

RECORD [REC] Places VTR into the Record mode selected by RECORD MODE

REWIND

SHUTTLE [SHUTTLE] Select SHUTTLE mode and enable Wheel.

SLOMO

SLO-MO SPEED

PRESET

STOP [STOP] Press once to STILL frame VTR.

TIME MODE

SELECT

[SHIFT] + [RECUE] Search the VTR to the manually entered time.

OR

[SHIFT] + [VTR #2]

OR

[SHIFT] + [VTR #3]

OR

[SHIFT] + [VTR #4]

[FFWD] Press and HOLD to shuttle. Release key to stop. Set WIND

[RWD] Press and HOLD to shuttle. Release key to stop. Set WIND

[SLOMO] Press [SLOMO] to slo-mo the VTR. Turn the Wheel (or move

[SHIFT] + [SLOMO] For WHEEL ONLY: Press [SHIFT] + [SLOMO] to preset the

[TIME MODE] Press to toggle between ET (Elapsed Time) and

Key Press Description

Use the ST300 numeric keypad. Press [ENTER] OR [RECUE].

NOTE: Use 00:00:00:00 to recue a clip to ET=0 if start time is

not ET=0

Individually press the VTR keys to be included in the gang. The

LED above the key will turn on. Press the VTR key again to

remove from gang. The LED above the key will turn off. Press

[ESC] to exit.

The VTR LEDs that are on show the gang.

The flashing LED shows which VTR is currently selected.

Speed in MENU.

in the SETUP MENU. Press [RECORD] OR [RECORD] +

[PLAY].

Speed in MENU.

the T-Bar, if available) to change the play speed.

Press [SLOMO] to STILL frame.

OR

Press any transport key to exit SLOMO.

slo-mo speed. Turn the Wheel to select desired speed.

Press [ESC] or any transport key to exit.

Press again to put VTR into STOP mode.

RT (Running Time) display modes.

21 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 22

21. SPECIFICATIONS

ST300

Power: 90 VAC to 265 VAC adapter supplied with IEC connector

Size: (L” x W” x H”) 10 1/2” x 6” x 1.5” (front) 3.0” (rear)

(-T Bar Version) (L” x W” x H”) 12 5/8” x 6” x 1.5” (front) 3.0” (rear)

Weight: 4 lbs.

Rear Panel Connectors: VTR1, VTR2, VTR3, VTR4 ……. All DB9F

GPI ............................................…. DBF15F

Power ............................................. DB9M

Aux ................................................ DB9F

Display: Easy to read 2-line, back-lit LCD display

(User adjustable contrast)

Jog/Shuttle Wheel: With mechanical detents

Optional “T”-bar: Slo-mo 0-200% of Play Speed (2X Normal Speed )

RS422 SERIAL CONNECTOR

9-Pin D-Type, Female

(VTR1-VTR4)

Pin # 1 Frame Ground 6 Receive Common

2 Receive A Í 7 Receive B Í

3 Transmit B Î 8 Transmit A Î

4 Transmit Common 9 Frame Ground

5 Spare

POWER CONNECTOR

9-Pin D-Type, Male

Pin # 1 +5v DC 6 +5 VDC

2 +5v DC 7 Ground

3 Ground 8 Ground

4 +12 VDC 9 Ground

5 –12 VDC

AUX PORT RS422 SERIAL CONNECTOR

9-Pin D-Type, Female

Pin # 1 Frame Ground 6 Transmit Common

2 Receive A Í 7 Receive B Í

3 Transmit B Î 8 Transmit A Î

4 Receive Common 9 Frame Ground

5 Spare

22 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 23

GPI IN/OUT Connector

15-Pin D-Type, Female (DB15F)

Pin # Function Pin # Function

1 GPI OUT 1 9 PLAY

2 GPI OUT 2 10 STOP

3 GPI OUT 3 11 RECUE

4 GPI OUT 4 12 NEXT CUE

5 GPI OUT 5 13 LAST CUE

6 GPI OUT 6 14 RECALL

7 GPI OUT 7 15 GPI 7 IN (disabled)

8 Ground

ST420 (SHOTBOX)

Power: 90 VAC to 265 VAC adapter supplied with IEC connector

Size: [L” x W” x H”] 12” x 7.25” x 1.5” (front) 3.5” (rear)

Weight: 5.5 lbs.

Rear Panel Connectors: Power ............... DB9M

OUTPUT ......... DB9F

Aux ...............… DB9F

Display: Six characters on each of three lines on each Shotkey.

Liquid Crystal Display

RS422 SERIAL CONNECTOR

9-Pin D-Type, Female

(“OUTPUT”)

Pin # 1 Frame Ground 6 Transmit Common

2 Transmit A Î 7 Transmit B Î

3 Receive B Í 8 Receive A Í

4 Receive Common 9 Frame Ground

5 Spare

POWER CONNECTOR

9-Pin D-Type, Male

Pin # 1 +5v DC 6 No Connection

2 +5v DC 7 Ground

3 Ground 8 Ground

4 No Connection 9 Ground

5 No Connection

NOTE: The GPI connector and OUTPUT 2 are not used with this System.

23 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 24

22. TROUBLESHOOTING

a. ST420 TROUBLESHOOTING

1) All keys are RED - no communication with ST300.

2) All keys are dark - no communication between the ST300 and the Video Server.

3) The version of the ST420 must comply in the software version with the ST300 it

is connected to.

To determine the software version of the ST420 do the following:

a) Press [SHIFT] + [STOP] + [PLAY].

The key that displays the current version is RED.

b) The ST420 displays:

“SELECT ST300 V2.1 or V2.0 or V3.0”

Press the key for the software version of the ST300 you are using.

Please refer to the ST300 to determine the version if needed.

b. VERSION 3.0 HARDWARE OF ST300 ONLY

VIDEO REFERENCE SETUP

Plug the video reference BNC cable into the BNC connector on the back of the ST300.

Plug the same video reference into the SYNC IN connector on the rear of the Video

Server.

Press [MENU].

1) Turn the Wheel until the display says “SYNC.”

2) Press the Softkeys to toggle between SYNC ON and OFF. (Default = ON)

Installing sync into the ST300 and the Video Server, and selecting Sync ON will

help assure that several channels in the gang will roll in sync. (For example, Fill and

Key.)

24 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 25

23. KEY LAYOUT

25 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Page 26

24. DNF CONTROLS LIMITED WARRANTY

DNF Controls warrants its product to be free from defects in material and workmanship for a period of one

(1) year from the date of sale to the original purchaser from DNF Controls.

In order to enforce the rights under this warranty, the customer must first contact DNF’s Customer Support

Department to afford the opportunity of identifying and fixing the prob lem without sending the unit in for

repair. If DNF’s Customer Support Department cannot fix the problem, the customer will be issued a

Returned Merchandise Authorization number (RMA). The customer will then ship the defective product

prepaid to DNF Controls with the RMA number clearly indicated on the customer’s shipping document.

The merchandise is to be shipped to:

DNF Controls

12843 Foothill Blvd., Suite C

Sylmar, CA 91342

USA

Failure to obtain a proper RMA number prior to returning the product may result in t he return not being

accepted, or in a charge for the required repair.

DNF Controls, at its option, will repair or replace the defective unit. DNF Controls will return the unit

prepaid to the customer. The method of shipment is at the discretion of DNF Controls, principally UPS

Ground for shipments within the United States of America. Shipments to international customers will be

sent via air. Should a customer require the product to be returned in a more expeditious manner, the return

shipment will be billed to their freight account.

This warranty will be considered null and void if accident, misuse, abuse, improper line voltage, fire, water,

lightning or other acts of God damaged the product. All repair parts are to be supplied by DNF Controls,

either directly or through its authorized dealer network. Similarly, any repair work not performed by either

DNF Controls or its authorized dealer may void the warranty.

After the warranty period has expired, DNF Controls offers repair services at prices listed in the DNF

Controls Price List. DNF Controls reserves the right to refuse repair of any unit outside the warranty

period that is deemed non-repairable.

DNF Controls shall not be liable for direct, indirect, incidental, consequential or other types of damage

resulting from the use of the product.

# # #

26 2034CL-L, Vs.3.0, 300 Clip Instant Access System, Louth Protocol

Loading...

Loading...