Page 1

INSTALLATION AND PROGRAMMING GUIDE

XTLplus SERIES PANELS

Page 2

MODEL XTLplus SERIES

INSTALLATION AND PROGRAMMING GUIDE

FCC NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment o and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

This device has been designed to operate with the integrated 1100 Series PCB antenna having a maximum

gain of 1.0 dB. Antennas having a gain greater than 1.0 dB are strictly prohibited for use with this device.

The required antenna impedance is 50 ohms.

If necessary, the installer should consult the dealer or an experienced radio/television technician

for additional suggestions. The installer may nd the following booklet, prepared by the Federal

Communications Commission, helpful:

“How to identify and Resolve Radio-TV Interference Problems.”

This booklet is available from the U.S. Government Printing Oce, Washington D.C. 20402

Stock No. 004-000-00345-4

© 2017 Digital Monitoring Products, Inc.

Information furnished by DMP is believed to be accurate and reliable.

This information is subject to change without notice.

Page 3

TABLE OF CONTENTS

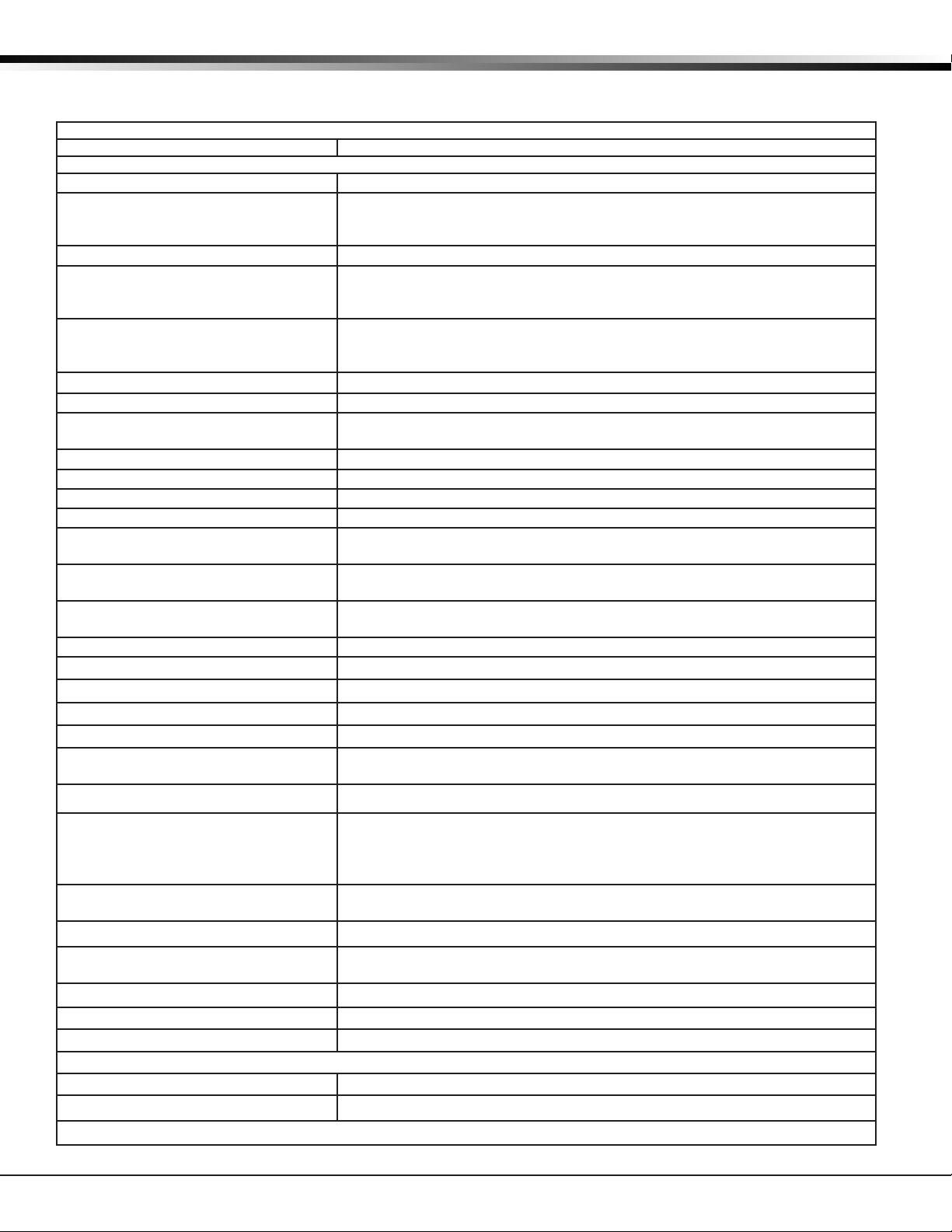

Panel Specications

1.1 Power Supply ......................................................................................................... 1

1.2 Communication ...................................................................................................... 1

1.3 Keypads ................................................................................................................. 1

1.4 Number of Zones .................................................................................................... 1

1.5 EnclosureSpecications .......................................................................................... 1

Introduction

2.1 SystemCongurations ............................................................................................ 1

2.2 Caution Notes ........................................................................................................ 1

2.3 Compliance Instructions .......................................................................................... 1

System Components

3.1 Accessory Devices .................................................................................................. 2

Installation

4.1 MountingLocationInformation ................................................................................ 3

4.2 MountingtheEnclosure .......................................................................................... 3

Primary Power Supply

5.1 DC Input ................................................................................................................ 3

Secondary Power Supply

6.1 Standby Battery ..................................................................................................... 4

6.2 Replacement .......................................................................................................... 4

6.3 Battery Supervision ................................................................................................. 4

LED Operation

7.1 BacklitLogo ........................................................................................................... 5

RESET Button

8.1 Description ............................................................................................................. 5

TAMPER Button

9.1 Description ............................................................................................................ 5

PROG Programming Connection

10.1 Description ............................................................................................................. 5

On-Board 1100 Series Wireless

11.1 Wireless Antenna .................................................................................................... 5

11.2 WirelessLEDOperation ........................................................................................... 5

Wireless Zones

12.1 Description ............................................................................................................. 6

Wireless Key Fobs and Outputs

13.1 Description ............................................................................................................. 6

Flash LOAD Button

14.1 Description ............................................................................................................. 6

On-Board Z-Wave Connection

15.1 Description ............................................................................................................ 6

On-Board Wi-Fi Network

16.1 Description ............................................................................................................. 6

16.2 Wi-FiLEDs ............................................................................................................. 6

Cellular Connection

17.1 Description ............................................................................................................. 7

Wireless Keypads

18.1 MountingWirelessKeypads ..................................................................................... 7

Programming Introduction

19.1 BeforeYouBegin .................................................................................................... 8

19.2 GettingStarted ....................................................................................................... 8

19.3 Keypad .................................................................................................................10

19.4 Special Keys ..........................................................................................................10

19.5 EnteringAlphaCharacters ......................................................................................11

19.6 EnteringNon-AlphaCharacters ...............................................................................11

19.7 KeypadDisplaysCurrentProgramming ....................................................................11

XTLplus Installation and Programming Guide Digital Monitoring Products

i

Page 4

TABLE OF CONTENTS

19.8 ProgrammingMenu ...............................................................................................12

19.9 ProgrammerLockoutCodes ....................................................................................12

19.10 Reset Timeout .......................................................................................................12

Initialization

20.1 Initialization ..........................................................................................................13

20.2 Clear All Codes ......................................................................................................13

20.3 ClearAllSchedules ................................................................................................13

20.4 Clear Events ..........................................................................................................13

20.5 ClearZoneProgramming ........................................................................................13

20.6 Clear Communication .............................................................................................13

20.7 Clear Wi-Fi ............................................................................................................13

20.8 Set to Factory Defaults ...........................................................................................13

Fast Programming

21.1 FastProgram .........................................................................................................14

21.2 Account Number ....................................................................................................14

21.3 First IP Address .....................................................................................................14

21.4 App Key ................................................................................................................14

21.5 System .................................................................................................................14

21.6 Hours from GMT ....................................................................................................14

21.7 WeatherZipCode ..................................................................................................14

21.8 Enter Siren Serial Number ......................................................................................14

21.9 Zone Number ........................................................................................................14

21.10 Zone Name ...........................................................................................................14

21.11 Zone Type .............................................................................................................14

21.12 AreaAssignment ...................................................................................................14

21.13 Serial Number Entry ..............................................................................................14

21.14 Stop .....................................................................................................................14

Communication

22.1 Communication .....................................................................................................15

22.2 Account Number ....................................................................................................15

22.3 Transmission Delay ................................................................................................15

22.4 Communication Type .............................................................................................15

22.5 Backup Cellular .....................................................................................................15

22.6 Test Time ..............................................................................................................15

22.7 Test Days ..............................................................................................................15

22.8 Check-InMinutes ...................................................................................................15

22.9 Fail Time ...............................................................................................................15

22.10 Send Communication Trouble .................................................................................16

22.11 First Cell APN ........................................................................................................16

22.12 Second Cell APN ....................................................................................................16

22.13 Receiver1Programming ........................................................................................16

22.14 Alarm Reports .......................................................................................................16

22.15 Supervisory/Trouble Reports ...................................................................................16

22.16 Opening/ClosingandUserReports ..........................................................................16

22.17 Test Report ...........................................................................................................16

22.18 First IP Address .....................................................................................................16

22.19 First IP Port ...........................................................................................................16

22.20 Second IP Address .................................................................................................16

22.21 Second IP Port ......................................................................................................16

22.22 Receiver2Programming ........................................................................................17

22.23 Alarm Reports .......................................................................................................17

22.24 Supervisory/Trouble Reports ...................................................................................17

22.25 Opening/ClosingandUserReports ..........................................................................17

22.26 Test Report ...........................................................................................................17

22.27 First IP Address .....................................................................................................17

22.28 First IP Port ...........................................................................................................17

22.29 Second IP Address .................................................................................................17

22.30 Second IP Port ......................................................................................................17

Digital Monitoring Products XTLplus Installation and Programming Guide

ii

Page 5

TABLE OF CONTENTS

Network Options

23.1 NetworkOptions ...................................................................................................17

23.2 Wi-Fi Setup ...........................................................................................................17

23.2.1 WPS .....................................................................................................................18

23.2.2 List .......................................................................................................................18

23.2.3 Manual .................................................................................................................18

23.2.4 Test ......................................................................................................................19

23.3 Wireless Security Type ...........................................................................................19

23.4 Wireless Network Key ............................................................................................19

23.5 DHCP....................................................................................................................19

23.6 LocalIPAddress ....................................................................................................19

23.7 Gateway Address ...................................................................................................19

23.8 Subnet Mask .........................................................................................................19

23.9 DNS Server ...........................................................................................................19

23.10 ProgrammingPort .................................................................................................19

Messaging Setup

24.1 MessagingSetup ...................................................................................................19

24.2 EnableMessaging ..................................................................................................20

24.3 System Name ........................................................................................................20

24.4 Destination 1 .........................................................................................................20

24.5 Destination1UserNumber ....................................................................................20

24.6 Destination 2 .........................................................................................................20

24.7 Destination2UserNumber ....................................................................................20

24.8 Destination 3 .........................................................................................................20

24.9 Destination3UserNumber ....................................................................................20

24.10 O/CSMS ...............................................................................................................20

24.11 MonthlyLimit ........................................................................................................20

Device Setup

25.1 Device Setup .........................................................................................................20

25.2 Device Number......................................................................................................20

25.3 Device Name .........................................................................................................21

25.4 Wireless ................................................................................................................21

25.5 Serial Number .......................................................................................................21

25.6 Supervision Time ...................................................................................................21

Remote Options

26.1 RemoteOptions ....................................................................................................21

26.2 Remote Key ..........................................................................................................21

26.3 Remote Disarm .....................................................................................................21

26.4 App Key ................................................................................................................21

System Reports

27.1 System Reports .....................................................................................................22

27.2 Opening/ClosingReports ........................................................................................22

27.3 Abort Reports ........................................................................................................22

27.4 Zone Restoral Reports ............................................................................................22

27.5 Bypass Reports......................................................................................................22

27.6 CodeChangeReports ............................................................................................22

27.7 Ambush ................................................................................................................22

27.8 LateToOpen ........................................................................................................22

27.9 Early To Close .......................................................................................................22

System Options

28.1 SystemOptions .....................................................................................................23

28.2 System .................................................................................................................23

28.3 ClosingCode .........................................................................................................23

28.4 ClosingCheck ........................................................................................................23

28.5 Entry Delay 1 ........................................................................................................23

28.6 Exit Delay .............................................................................................................23

28.7 Cross Zone Time ...................................................................................................23

28.8 Power Fail Delay ....................................................................................................24

XTLplus Installation and Programming Guide Digital Monitoring Products

iii

Page 6

TABLE OF CONTENTS

28.9 SwingerBypassTrips .............................................................................................24

28.10 ResetSwingerBypass ............................................................................................24

28.11 Zone Activity Hours ................................................................................................24

28.12 Arm Activity Days ..................................................................................................24

28.13 TimeZoneChanges ...............................................................................................24

28.14 Time Display .........................................................................................................25

28.15 House Code ..........................................................................................................25

28.15.1 DetectWirelessJamming .......................................................................................25

28.15.2 Wireless Audible Annunciation ................................................................................25

28.16 Enable Keypad Panic Keys ......................................................................................25

28.17 OccupiedPremises ................................................................................................25

28.18 UseFalseAlarmQuestion .......................................................................................25

28.19 WeatherZipCode ..................................................................................................25

Bell Options

29.1 BellOptions ..........................................................................................................26

29.2 BellCutoTime .....................................................................................................26

29.3 Automatic Bell Test ................................................................................................26

29.4 BellOutput ...........................................................................................................26

29.5 Bell Action.............................................................................................................26

29.5.1 Fire ......................................................................................................................26

29.5.2 Burglary ................................................................................................................26

29.5.3 Supervisory ...........................................................................................................26

29.5.4 Panic ....................................................................................................................26

29.5.5 Emergency ............................................................................................................26

29.5.6 Auxiliary 1 .............................................................................................................26

29.5.7 Auxiliary 2 .............................................................................................................26

Output Options

30.1 OutputOptions ......................................................................................................27

30.2 CommunicationFailureOutput ................................................................................27

30.3 FireAlarmOutput ..................................................................................................27

30.4 FireTroubleOutput................................................................................................27

30.5 AmbushOutput .....................................................................................................27

30.6 BeginExitOutput ..................................................................................................27

30.7 EndExitOutput .....................................................................................................27

30.8 ReadyOutput ........................................................................................................27

30.9 ArmedOutput .......................................................................................................27

30.10 DisarmedOutput ...................................................................................................27

30.11 BurglaryOutput .....................................................................................................27

30.12 Arm-AlarmOutput .................................................................................................27

30.13 Heat Saver Temperature ........................................................................................28

30.14 Cool Saver Temperature .........................................................................................28

Output Setup

31.1 OutputSetup ........................................................................................................28

31.2 OutputNumber .....................................................................................................28

31.3 OutputName ........................................................................................................28

31.4 Serial Number .......................................................................................................28

31.5 Supervision Time ...................................................................................................28

31.6 TripwithPanelBellOption .....................................................................................29

Area Information

32.1 Area Information ...................................................................................................29

32.2 Area Number .........................................................................................................29

32.3 Area Name ............................................................................................................29

32.4 AutomaticArming ..................................................................................................29

32.4.1 Bad Zones .............................................................................................................29

32.5 AutomaticDisarming ..............................................................................................29

Zone Information

33.1 Zone Information ...................................................................................................30

33.2 Zone Number ........................................................................................................30

Digital Monitoring Products XTLplus Installation and Programming Guide

iv

Page 7

TABLE OF CONTENTS

33.3 Key Fob ................................................................................................................31

33.4 Zone Name ...........................................................................................................31

33.5 Zone Type .............................................................................................................31

33.6 ArmingZoneAssignment .......................................................................................31

33.7 AreaAssignment ...................................................................................................32

33.7.1 Style .....................................................................................................................32

33.8 DMP Wireless .........................................................................................................32

33.8.1 Serial Number Entry ..............................................................................................32

33.8.2 Contact .................................................................................................................32

33.8.3 Supervision Time ...................................................................................................33

33.8.4 LEDOperation .......................................................................................................33

33.8.5 Disarm/Disable ......................................................................................................33

33.8.6 Wireless PIR Pulse Count .......................................................................................33

33.8.7 Wireless PIR Sensitivity ..........................................................................................33

33.8.8 Next Zone .............................................................................................................33

33.9 1144 Series Key Fobs ..........................................................................................33

33.9.1 KeyFobUserNumber ............................................................................................34

33.9.2 Key Fob Serial Number ...........................................................................................34

33.9.3 Key Fob Supervision Time ......................................................................................34

33.9.4 Number of Key Fob Buttons ....................................................................................34

33.9.5 Key Fob Button Selection (Four Buttons) .................................................................34

33.9.6 Key Fob Button Selection (Two Buttons) ..................................................................34

33.9.7 Button Action ........................................................................................................34

33.9.8 Button Press Time .................................................................................................35

33.9.9 Arm/Disarm Area Selection .....................................................................................35

33.9.10 OutputNumber .....................................................................................................35

33.9.11 OutputAction ........................................................................................................35

33.10 Alarm Action .........................................................................................................35

33.11 DisarmedOpen .....................................................................................................36

33.11.1 MessageToTransmit .............................................................................................36

33.11.2 OutputNumber .....................................................................................................36

33.11.3 OutputAction ........................................................................................................36

33.12 SwingerBypass .....................................................................................................36

33.13 Prewarn Address ...................................................................................................37

33.14 Entry Delay ...........................................................................................................37

33.15 Cross Zone ............................................................................................................37

33.16 Priority ..................................................................................................................37

33.17 TracCount .........................................................................................................37

33.18 Zone Audit Days ....................................................................................................37

33.19 ReceiverRouting ...................................................................................................37

33.20 Zone Number ........................................................................................................38

Stop

34.1 Stop .....................................................................................................................38

Set Lockout Code

35.1 SetLockoutCode ..................................................................................................38

Appendix

36.1 StatusList .............................................................................................................39

36.2 Transmission Delay ................................................................................................39

36.3 False Alarm Reduction ............................................................................................39

36.4 DiagnosticsFunction ..............................................................................................39

36.5 UsingtheWalkTest ...............................................................................................41

Walk Test ..............................................................................................................41

TripCounterForDMPWirelessCheck-inTest(WLS) .................................................41

TestEndWarning ..................................................................................................42

Failed Zones Display ..............................................................................................42

36.6 KeypadSpeakerOperation .....................................................................................42

36.7 CrossZoning .........................................................................................................42

36.8 Zone Type Descriptions ..........................................................................................43

XTLplus Installation and Programming Guide Digital Monitoring Products

v

Page 8

TABLE OF CONTENTS

36.9 Zone Type Defaults ................................................................................................44

36.10 CommonKeypadMessages ....................................................................................45

Listed Compliance Specications

37.1 Introduction ..........................................................................................................45

37.2 UseMarking ..........................................................................................................45

37.2 LocationsandWiring .............................................................................................45

37.3 NFPA 72 ...............................................................................................................45

37.4 TypesOfService ....................................................................................................45

37.5 PoliceStationPhoneNumbers ................................................................................45

37.6 Bypass Reports......................................................................................................45

37.7 SystemTesting ......................................................................................................45

37.8 FCC Notice ............................................................................................................46

Household Burglar-Alarm System Units

ANSI/UL 1023

38.1 BellCuto .............................................................................................................46

38.2 Entry Delay ...........................................................................................................46

38.3 Exit Delay .............................................................................................................46

38.4 Wireless External Contact .......................................................................................46

38.5 Wireless Supervision Time ......................................................................................46

38.6 Wireless Audible Annunciation ................................................................................46

38.7 Panel location ........................................................................................................46

38.8 Test Frequency ......................................................................................................46

Central Station Burglar Alarm Units

ANSI/UL 1610

39.1 Supervision ...........................................................................................................46

39.2 Remote Disarm .....................................................................................................46

39.3 Central Station ......................................................................................................46

40.1 BellOutputDenition .............................................................................................46

40.2 HouseholdSystem .................................................................................................46

40.3 Wireless Supervision Time ......................................................................................46

40.4 WirelessFireVerication ........................................................................................46

40.5 Battery Standby ....................................................................................................46

40.6 Test Frequency ......................................................................................................46

False Alarm Reduction Programmable Options

ANSI/SIA CP-01-2010

41.1 ShippingDefaultsandRecommendedProgramming .................................................47

Revisions to This Document

Certications

Ordering Information

Accessories

Digital Monitoring Products XTLplus Installation and Programming Guide

vi

Page 9

1.1 Power Supply

Model 372-500-W plug-in DC power supply

Input: 120VAC, 60 Hz

Output: 12VDC

Standby Battery: DMP 3.8VDC Lithium, 800mAh

Optional Standby Battery DMP 3.8VDC Lithium, 3500mAh

All circuits inherent power limited

1.2 Communication

Optional CDMA cellular module to send messages to DMP Model SCS-1R or SCS-VR Central Station Receivers.

Built-in Wi-Fi™ network alarm signal communication to DMP Model SCS-1R or SCS-VR Central

Station Receivers.

1.3 Keypads

You can associate up to 4 alphanumeric 9000 Series or 9862 Graphic Touchscreen Wireless Keypads.

1.4 Number of Zones

• XTLplus has 48 wireless initiating zones numbered 1-48

• Zone and Output numbers 51 to 54 and 61 to 64 can support 1144 Series Key Fobs, Output Modules,

or sirens

1.5 Enclosure Specications

PANEL SPECIFICATIONS

Panel Specications

Size Color

5.5” W x 3.75” H x 1” D White (W)

2.1 System Congurations

The panel can be programmed to operate as any of the following system types:

• All/Perimeter system that provides one perimeter area and one interior area

• Home/Sleep/Away system that provides one perimeter, one interior, and one bedroom area. The bedroom

area provides for any protection devices the user wants disarmed during their sleeping hours and armed in

the Away mode.

• Six area system that provides areas of protection that can be independently armed or disarmed.

2.2 Caution Notes

Throughout this guide you will see caution notes containing information you need to know when installing

the panel. These cautions are indicated with a yield sign. Whenever you see a caution note, make sure you

completely read and understand its information. Failing to follow the caution note can cause damage to the

equipment or improper operation of one or more components in the system.

2.3 Compliance Instructions

For applications that must conform to a local authorities installation standard or a National Recognized

Testing Laboratory certicated system, please see the Listed Compliance Specications section near the end

of this guide for additional instructions.

INTRODUCTION

Introduction

XTLplus Installation and Programming Guide Digital Monitoring Products

1

Page 10

SYSTEM COMPONENTS

System Components

3.1 Accessory Devices

Cellular Communicator Cards

265C CDMA Cellular Communicator

DMP Two-Way Wireless Devices

1100R Repeater Provides additional range for wireless devices.

1101 Universal Transmitter Provides both internal and external contacts that may be used at the same time

1102 Universal Transmitter Provides one external contact. Provides Disarm/Disable functionality.

1103 Universal Transmitter

1106 Universal Transmitter Provides both internal and external contacts that may be used at the same time

1107 Micro Window Transmitter* Provides survey capability for window applications.

1114 Four-Zone Expander* Provides four wireless zones with EOL resisters.

1115 Wireless Termperature Sensor and

Flood Detector

1116 Relay Output* Provides one Form C relay.

1117 LED Annunciator* Provides a visual system status indicator.

1119 Door Sounder* Provides a wireless sounder with integrated door contact.

1121 PIR Motion Detector* Provides motion detection with pet immunity.

1126R Motion Detector* Ceiling mount motion detector with panel programmable sensitivity and Disarm/

1127C/1127W PIR Motion Detector Wall mount motion detector with panel programmable sensitivity and Disarm/

1129 Glassbreak Detector* Detects the shattering of framed glass mounted in an outside wall and provides

1131 Recessed Contact*

1135 Siren* Provides a wireless siren.

1137 Wireless LED Emergency Light* Provides emergency indoor path lighting.

1139 Bill Trap* Provides a silent alarm option for use in cash drawers.

1141 Wall Button* One-button wireless transmitter designed to be wall-mounted.

1142BC Two-button Panic Belt Clip

Transmitter

1142 Two-button Panic Transmitter

Allows you to connect the XTLplus to any compatible CDMA/SMS network.

to yield two individual reporting zones from one wireless transmitter. Provides

Disarm/Disable functionality.

Provides bothinternalandexternalcontactsthatmaybeusedatthesametime

toyieldtwoindividualreportingzonesfromonewirelesstransmitter.RequiresEOL

resistor for external contact. Provides Disarm/Disable functionality.

to yield two individual reporting zones from one wireless transmitter. Provides

Disarm/Disable functionality.

Temperature and ood detector wth an internal temperature sensor. Can

be paired with 470PB or T280R remote sensors.

Disable functionality.

Disable functionality.

full-pattern coverage and false-alarm immunity.

Provides concealed protection for doors, windows or other applications.

Provides portable two-button panic operation.

Provides permanently mounted under-the-counter two-button panic operation.

1144-4 (Four-Button)*

1144-2 (Two-Button)*

1144-1 (One-Button)*

1144-D (Two-Button)*

1148 Personal Pendant Wireless emergency transmitter to be worn as a wristband or on a break-away

1154 4-Zone Takeover Module Converts up to four existing normally closed, hardwired zones into wireless zones.

1164/1164NS Wireless Commercial Smoke Battery powered, wireless, low prole, photoelectric smoke detector. The 1164

1183-135F Heat Detector Fixed temperature heat detector.

1183-135R Heat Detector Fixed temperature and rate-of-rise heat detector.

1184 Carbon Monoxide Detector Carbon Monoxide detector.

Keypads

9000 Series LCD Keypads Allows you to control the panel from various remote locations.

9862 Wireless Graphic Touchscreen Keypad Allows you to control the panel from various remote locations.

* These devices have not been investigated and shall not be used in listed installations.

Digital Monitoring Products XTLplus Installation and Programming Guide

2

Key Fob transmitters designed to clip onto a key ring or lanyard.

lanyard.

also oers a synchronized sounder.

Page 11

4.1 Mounting Location Information

A location should be selected that is centrally located between the 1100 Series transmitters used in the

installation. Install the XTLplus away from metal objects. Mounting the panel on or near metal surfaces

impairs performance. When selecting the proper mounting location of a transmitter, refer to the LED Survey

Operation section of the specic installation guide for the transmitter being installed.

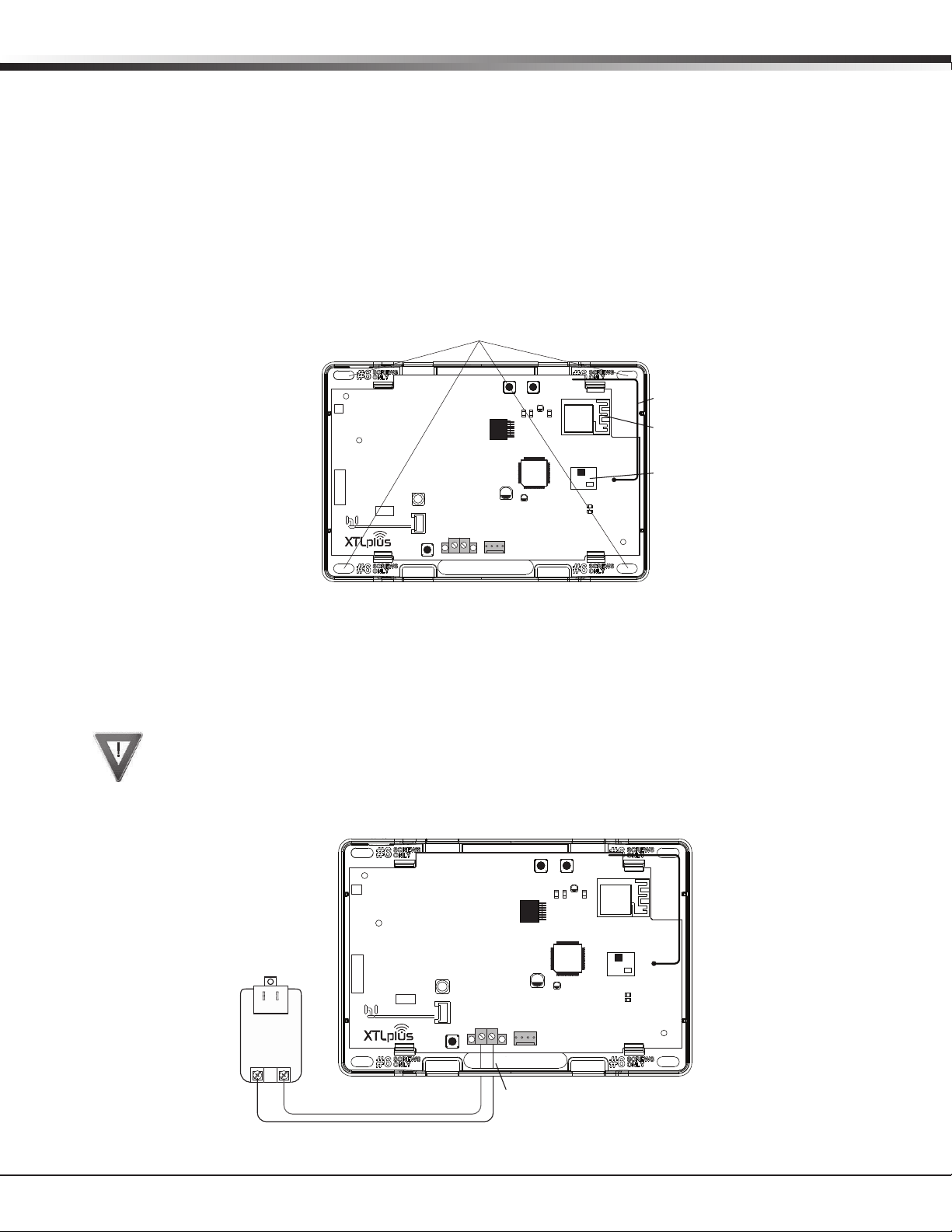

4.2 Mounting the Enclosure

The enclosure for the panel must be mounted using the provided #6 screws in the four mounting holes shown

in Figure 1. Mount the enclosure in a secure, dry place away from metal objects to protect the panel from

damage due to tampering or the elements. Mount the panel a minimum of 4 feet from any wireless

transmitters or repeaters. It is not necessary to remove the PCB when installing the enclosure.

LPC-0181

R1

LEV

N

S

INSTALL GUIDE

LT-1434

©

WWW.DMP.COM

BAT

Installation

Mounting Hole Locations

2015 DMP

MODULE

RESETLOAD

CELL

INSTALLATION

Antenna

WiFi

ZWave

Module

5.1 DC Input

Mount the panel near a wall outlet for the Model 372-500-W plug-in DC power supply. In addition to powering

the panel, the DC plug-in power supply also charges the back-up battery. The 372-500-W must be located

within 100 feet of the panel using 22 AWG wire. Use the following steps to connect the plug-in power supply:

OBSERVE POLARITY

1. Using 22 AWG wire, connect the panel DC terminal (+) to the positive terminal on the power supply.

2. Connect the panel DC terminal (-) to the negative terminal on the power supply. See Figure 2.

3. Plug the power supply into a 120 Volt AC, 60Hz dedicated outlet not controlled by a switch.

Model 372-500-W

DC Plug-in

Power Supply

R B

PROG

+ DC -

Figure 1: Mounting Hole Locations

Primary Power Supply

LPC-0181

R1

LEV

N

S

INSTALL GUIDE

LT-1434

©

2015 DMP

WWW.DMP.COM

BAT

MODULE

RESETLOAD

CELL

+ DC -

_

+

Use 22 AWG for

Power Supply connection

PROG

R B

Wire Exits for DC

Power Supply

Figure 2: DC Power Supply Connection

XTLplus Installation and Programming Guide Digital Monitoring Products

3

Page 12

INSTALLATION

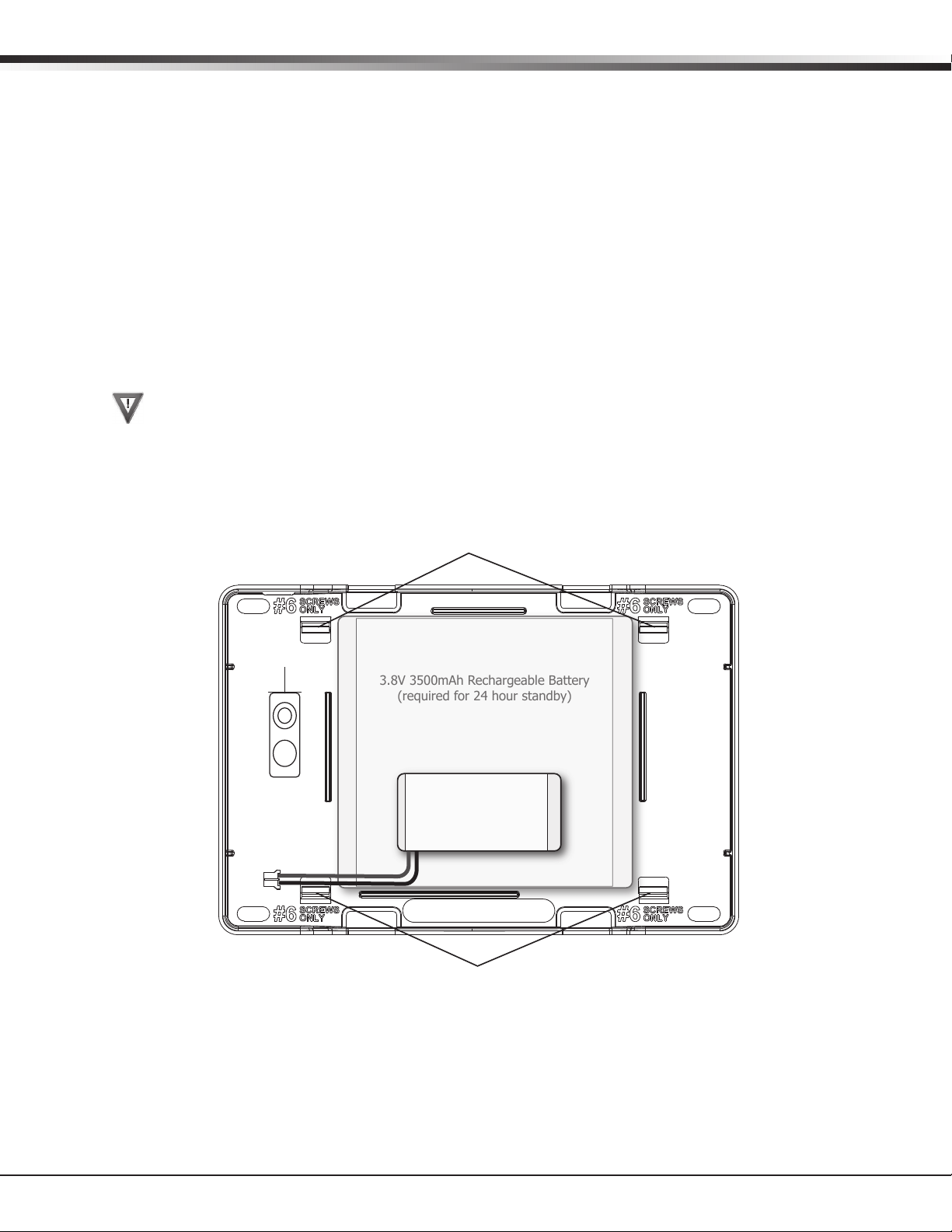

3.8V 3500mAh Rechargeable Battery

(required for 24 hour standby)

6.1 Standby Battery

The XTLplus 800mAh rechargeable battery is used to provide 4 hours of standby battery power when DC

power is not available. The battery is intended for backup power only and not to operate the panel on a

daily basis. If the battery is low, or not plugged into the BAT battery connector, a low battery condition

is indicated by the panel. If 24 hour standby battery power is needed, connect the 3500mAh battery. See

Figure 3.

Note: If removing the panel from service, disconnect the backup battery from the BAT connector.

6.2 Replacement

Use the following steps to replace the XTLplus standby battery. DMP recommends replacing the battery every

3 years under normal use.

1. Unplug the BAT battery connector from the XTLplus panel.

2. Loosen the top PCB snaps.

3. Lean the panel PCB forward and lift out from the bottom PCB snaps.

4. Remove and properly dispose of the used battery.

Caution: Risk of re, explosion, and burns. Do not disassemble, heat above 212°F (100°C), or

incinerate. Properly dispose of used batteries.

5. Place the new battery into the XTLplus housing base with the battery wires directed toward the bottom

left corner. See Figure 3.

6. Set the XTLplus PCB into the bottom snaps and press into the top snaps to secure in place.

7. Plug the battery into the BAT panel connector.

Secondary Power Supply

Battery

Connector

6.3 Battery Supervision

The panel tests the battery once every hour when DC power is present. This test occurs 15 minutes past

each hour and lasts for ve seconds. A load is placed on the battery and if the battery voltage is low, a low

battery is detected. If DC power has failed, a low battery is detected any time the battery voltage falls

below 3.7V.

Top PCB Snaps

3.8V 800mAh

Rechargeable

Battery

Bottom PCB Snaps

Figure 3: Standby Battery Replacement

Digital Monitoring Products XTLplus Installation and Programming Guide

4

Page 13

7.1 Backlit Logo

The backlit logo indicates the Power and Armed status of the panel. Depending on the operation, the LED

displays in Red or Green as listed in the table.

Color and Activity Operation

Green Steady Panel Disarmed, Primary Power OK, Battery OK

Green Blinking Panel Disarmed, Primary Power OK, Battery Fault

No Light Panel Disarmed, Primary Power Fault, Battery OK

Red Steady Panel Armed, Primary Power OK, Battery OK

Red/Green Alternate Panel Armed, Primary Power OK, Battery Fault

Red Blinking Panel Armed, Primary Power Fault, Battery OK

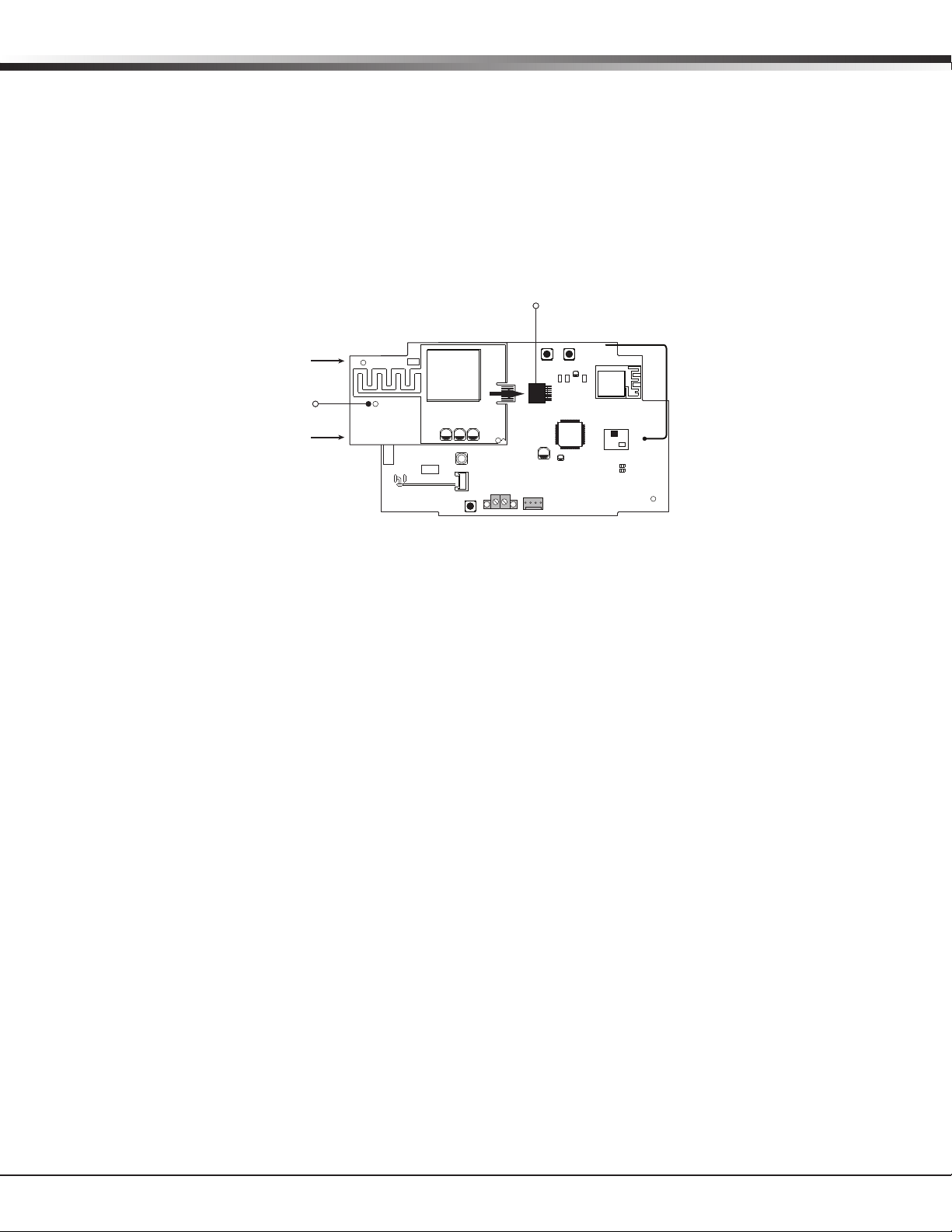

8.1 Description

The RESET button is located on the top of the circuit board and is used to reset the XTLplus microprocessor.

To reset the panel prior to reprogramming, press the RESET button without powering down the system. After

resetting the panel, begin programming within 30 minutes. If you wait longer than 30 minutes, you must

reset the panel again. See Figure 4 for RESET button location.

9.1 Description

The tamper button is pressed when the cover of the XTLplus is secured onto the enclosure. When the cover

is removed, the XTLplus sends a Tamper Trouble message to the Central Station.

INSTALLATION

LED Operation

RESET Button

TAMPER Button

PROG Programming Connection

10.1 Description

Onsite programming can be completed using an associated wireless keypad or by connecting a hardwired

keypad to the PROG header.

On-Board 1100 Series Wireless

11.1 Wireless Antenna

The XTLplus Wireless Antenna is integrated into the circuit board. The panel’s built-in wireless receiver

operates with DMP 1100 Series transmitters. See section 3.1 for a list of accessory devices.

11.2 Wireless LED Operation

The wireless LEDs are located in the upper right of the circuit board below

the RESET button and

function as follows:

Green: The green LED ashes every time the receiver transmits (32 times

per second). If the panel is reset, or the panel is powered o, the green

LED is o. Under normal operation, the green LED ashes constantly with no

interruption or change.

Yellow: The yellow LED ashes every time the panel receives a message from

a programmed wireless transmitter. When a message is sent by a transmitter,

typically by pressing or releasing the TAMPER button, the yellow LED should

ash indicating that the panel received a message from the transmitter.

If the LED never ashes, the transmitter is not getting through to the panel. This could be because of a

misprogrammed serial number or the transmitter is too far away. Under normal operation, the yellow LED

ashes at every trip of every wireless transmitter and when the transmitters perform their periodic check-in.

It is not unusual for this LED to stay o for many minutes at a time when no transmitters are communicating.

See Figure 4 for Wireless LED locations.

Green

Transmit

LED

Figure 4: XTLplus Wireless

RESETLOAD

Yellow

Receive

LED

LED’s

WiFi

LED

XTLplus Installation and Programming Guide Digital Monitoring Products

5

Page 14

INSTALLATION

12.1 Description

XTLplus panels provide 48 wireless zones numbered 1 to 48. A default zone name, zone type, and area

assignment are described and can be changed in Zone Information programming as needed. The defaults are

provided as a programming convenience to help reduce installation time.

13.1 Description

XTLplus panels provide 8 wireless key fob or output addresses numbered 51 to 54 and 61 to 64. A default

name is provided as a programming convenience to help reduce installation time. The default names are

described in the programming sections of this guide and can be changed in Output Information or Zone

Information programming as needed

14.1 Description

The XTLplus panel software can be updated via the panel’s PROG programming header. To update the panel

with a new software version, complete the following steps at the protected premises:

Model 399 Cable

Connect a DMP 399 Cable from the PROG header to the serial port of your PC operating Remote Link and

containing the XTLplus RU le.

1. Start Remote Link and create or open the control panel account that matches the panel to be updated.

2. Set the Connection Information Type to Direct with a baud rate of 38400 and choose the appropriate

COM port.

3. Select Panel>Remote Update, then select the correct RU le for the panel.

4. Press and hold the LOAD button, then press and release the RESET button.

5. Release the LOAD button and click <Update> in Remote Link.

6. After the software update is completed, remove the 399 cable and press the RESET button to resume

normal panel operation.

Model 400 USB Flash Module

1. Press and hold the LOAD button. While holding the LOAD button, press and release the RESET button

2. Release the LOAD button.

3. Connect the USB ash drive to the Model 400 and connect the assembly to the panels PROG header. The

LED on the Model 400 will ash and display steady green.

4. Press and release the LOAD button on the Model 400 to initiate the rmware update. The LED on model

400 will ash slowly. If the LED displays fast ashes it means the rmware update was unsuccessful.

5. The update will take approximately 4.5 minutes and when complete the LED on the Model 400 will display

steady green.

6. Press and release the RESET button then remove the USB ash drive and Model 400 assembly. For

additional information see Model 400 USB Flash Module Installation Guide (LT-1402).

Wireless Zones

Wireless Key Fobs and Outputs

Flash LOAD Button

On-Board Z-Wave Connection

15.1 Description

The XTLplus features an on-board Z-Wave controller that allows short range radio control of Z-Wave devices

that you or your installation company may provide such as; lighting control modules, thermostat controls,

doors, and garage doors. Z-Wave Setup allows you to program the system to control the Z-Wave devices

from Smartphones using the DMP Virtual Keypad App or with the Virtual Keypad Browser. The available setup

options are: Add, List, Remove, Favorites, Transfer and Optimize.

On-Board Wi-Fi Network

16.1 Description

The XTLplus is compatible with 2.4 GHz b/g/n Wi-Fi networks.

16.2 Wi-Fi LEDs

The Green Wi-Fi LED is located to the right of the wireless LEDs in the upper right of the circuit board.

Wi-Fi LED displays solid when the network is connected and is o when there is no network connectivity. See

Figure 4 for Wi-Fi LED location.

Cellular Connection

Digital Monitoring Products XTLplus Installation and Programming Guide

6

Page 15

17.1 Description

The CELL MODULE header is provided to connect a 265C CDMA Cellular Communicator. The 265C provides

an integrated PCB antenna. Refer to the 265C Cellular Communicator Installation Guide (LT-1450) complete

installation information.

Installing the 265C on the XTLplus:

1. Avoiding a sharp angle and keeping the 265C PCB parallel to the XTLplus PCB, slide the 265C PCB into the

XTLplus 8-pin CELL MODULE connector. Apply even pressure to the end of the 265C PCB to fully seat the

module. See Figure 5.

2. Align the stando hole in the 265C with the stando on the XTLplus PCB and snap in place.

Stando

Hole

LEV

MODEL 265C

N

S

LPC-0181

R1

INSTALL GUIDE

LT-1434

INSTALLATION

Eight-Pin CELL MODULE

Connector

©

2015 DMP

WWW.DMP.COM

MODULE

LEV

BAT

RESETLOAD

CELL

Figure 5: 265C Installed on the XTLplus

18.1 Mounting Wireless Keypads

DMP Wireless keypads have removable covers that allow the base to be mounted on a wall, desk stand or

other at surface using the screw holes provided on each corner.

R B

PROG

+ DC -

Wireless Keypads

XTLplus Installation and Programming Guide Digital Monitoring Products

7

Page 16

PROGRAMMING INTRODUCTION

Programming Introduction

19.1 Before You Begin

Before starting to program, we recommend you read through the contents of this manual. The information in

this document allows you to quickly learn the programming options and operational capabilities of the

XTLplus panel.

After this Introduction, the remaining sections describe the functions of each of the programming menu

items along with their available options. The panel contains all of its programming information in an onboard processor and does not require an external programmer.

In addition to this manual, you should also be familiar with the following XTLplus documents:

• XTLplus User’s Guide

• XTLplus Fast Programming Sheet

• XTLplus Programming Sheet

Programming Information Sheet

Included with each XTLplus panel is the Programming Sheet. This sheet lists the various options available

for programming the panel. Before starting, completely ll out the sheet with the programming options you

intend to enter into the panel.

Having completed programming sheets available while entering data helps to prevent errors and can shorten

the length of time you spend programming. Completed sheets also provide you with an accurate account of

the panel’s program you can keep on le for future system service or expansion.

The remainder of the Introduction explains starting and ending a programming session.

19.2 Getting Started

Ground yourself before handling the panel! Touch any grounded metal before touching the panel to

discharge static.

The panel should be completely installed before you begin programming. Make sure the AC and battery wires

are correctly installed.

Program from a Wireless or LCD Keypad

The panel can be programmed using a wireless keypad that has been auto paired or manually associated

with the panel. You can also program the panel using an LCD keypad connected to the panel PROG header.

Auto WPS

The panel oers a convenient way to connect to a Wi-Fi network. Press the WPS button on your router

within 5 minutes of powering the panel to automatically connect to the Wi-Fi network.

Wireless Keypad Auto Pairing

Wireless keypad auto pairing allows you to skip the Wireless Keypad Association process and automatically

connect your keypad to the panel. Auto pairing is only available for 9800 Series Wireless Graphics

Touchscreen Keypads (Version 109 or higher) that do not have a previously assigned house code. A maximum

of four wireless keypads are allowed on each panel.

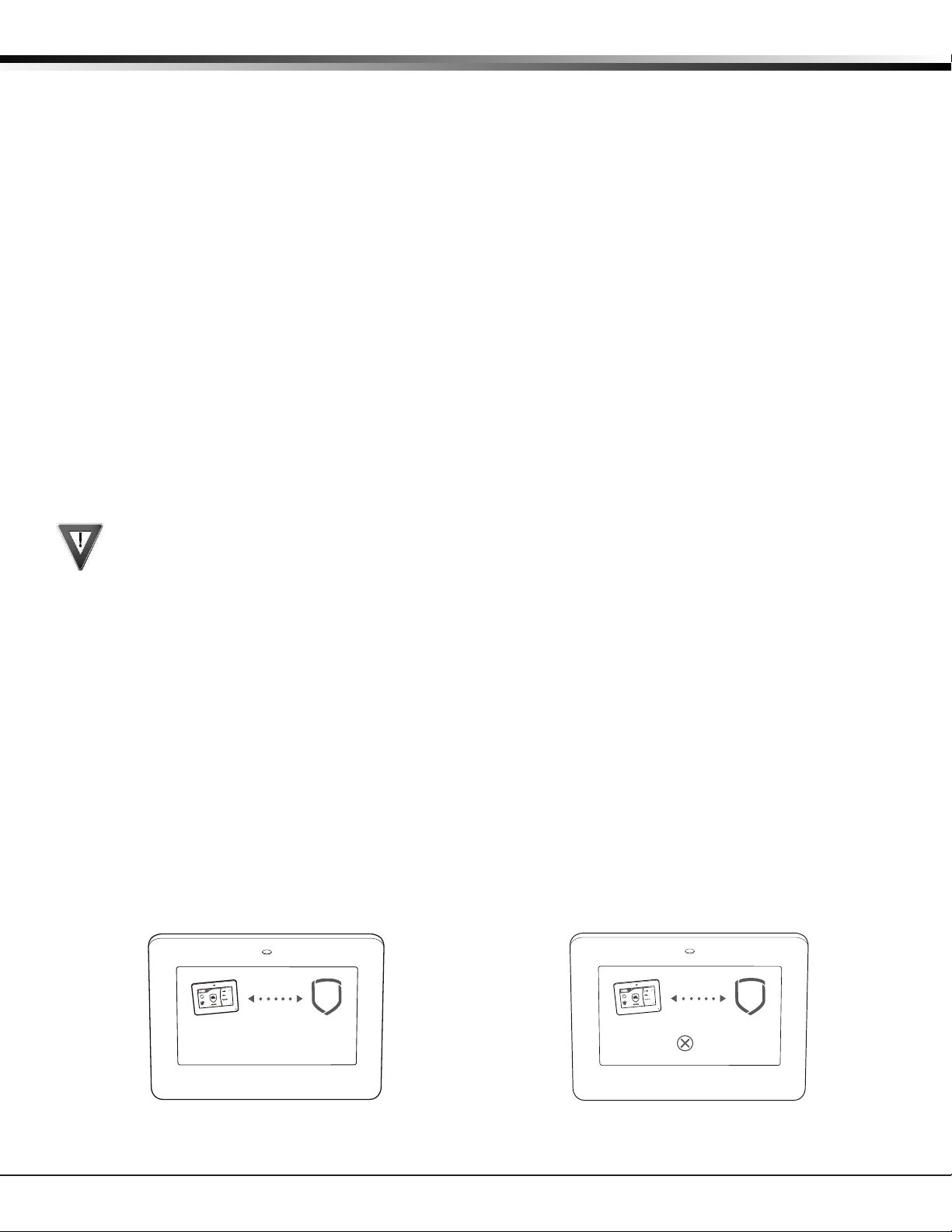

To pair a 9800 Series keypad with an XTLplus panel, power up both the panel and the keypad. A 10 minute

pairing timer begins. The auto pairing process starts immediately and the keypad displays Pairing Keypad

With System. See Figure 6. If the panel acquires the keypad during that time, the home screen displays

signaling that pairing is complete.

CURRENT

82

HI LO

98 77

TODAY

HI LO

98 77

WEDNESDAY

Pairing Keypad With System...

Figure 6: Auto Pairing in Progress Display

Figure 7: Auto Pairing Failed Display

CURRENT

82

HI LO

98 77

TODAY

HI LO

98 77

WEDNESDAY

PAIRING FAILED

Digital Monitoring Products XTLplus Installation and Programming Guide

8

Page 17

PROGRAMMING INTRODUCTION

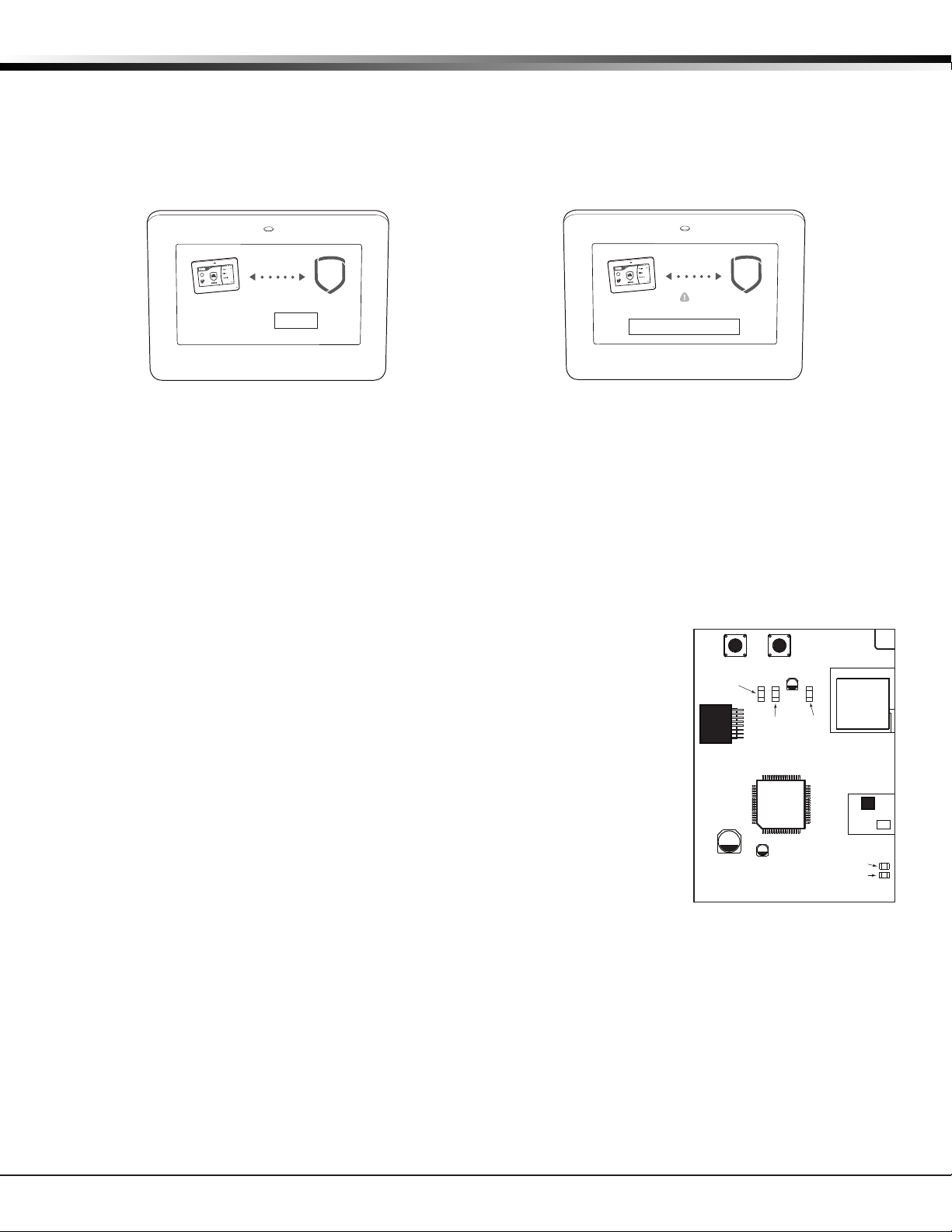

If the panel does not acquire the keypad by the end of the 10 minute pairing timer, the keypad displays

Pairing Failed, followed by the Reset screen. See Figure 7 and Figure 8. Reset your panel and tap the Pair

button to restart the pairing process.

If the keypad loses communication with the panel, the No Communication With System display appears and

provides the option to reattempt pairing. See Figure 9.

CURRENT

82

HI LO

98 77

TODAY

HI LO

98 77

WEDNESDAY

Reset your

1

System.

Press button:

2

PAIR

Figure 8: Auto Pairing Reset Display

Figure 9: Auto Pairing No Communication Display

CURRENT

82

HI LO

98 77

TODAY

HI LO

98 77

WEDNESDAY

No Communication With System

!

Press To Pair With System

?

Wireless Keypad Association

To enable wireless keypad association operation on a LCD Wireless keypad, press and hold the Back Arrow

and CMD until SET BRIGHTNESS displays. Enter the code 3577 (INST) and press CMD. Press KPD RF to start the

RF survey communication. The keypad displays its wireless serial number and RF SURVEY.

To enable association operation on a Wireless Graphics Touchscreen keypad, access the Options menu

through the carousel menu. While in the Options display, press the Installer Options icon. Enter the code

3577 (INST) and press CMD. Press KPD RF to start the RF survey communication. The keypad displays its

wireless serial number and RF SURVEY.

The keypad Power/Armed LED turns Red, indicating communication has not yet been established with the

panel receiver.

To enable association operation in the XTLplus Series panel, press the XTLplus

Series RESET button three times allowing the wireless TRANSMIT LED (TX)

located near the top of the PCB to begin ashing between each press. When

in keypad association, the XTLplus Series Red and Green logo LEDs turn on

steady.

For 60 seconds, the panel listens for wireless keypads that are in RF Survey

and have not been programmed, or associated into another panel. Wireless

Green

Transmit

LED

RESETLOAD

Yellow

Receive

LED

WiFi

LED

keypads are assigned to the rst open device position in Device Setup

automatically, based upon the order in which they are detected. When

successful communication has been established, the Power/Armed LED turns

Blue on Graphics keypads or Green on LCD keypads.

Note: A maximum of four wireless keypads are allowed on each panel.

See the 9000 Series Wireless Keypad Installation Guide (LT-1107) or 9862

Graphic Touchscreen Wireless Keypad Installation Guide (LT-1367) for

Red LED

Green LED

additional information.

Arming Type Auto Detect (on select keypads)

When the XTLplus panel’s arming type (A/P, H/S/A, Area) is changed, 9800

Figure 10: XTLplus Backlit

Logo LED’s

Series keypads (Version 109 or higher) will automatically sync their arming

type to match the panel. This prevents you from having to manually change the keypad arming type to

match the XTLplus panel’s settings.

XTLplus Installation and Programming Guide Digital Monitoring Products

9

Page 18

PROGRAMMING INTRODUCTION

MON 5:35 AM

DISARMED

Panic

Chime

Check-In

Reset

Interactive Shield

Proximity Card

Reader

Micro SD

Card Slot

Carousel

Menu

Dealer

Logo

Local Weather

Conditions

TODAY

WEDNESDAY

82

98 77

80

LO

74

HI

HI LO

CURRENT

32-Character Display

Data Entry Digit keys

COMMAND Key

Back Arrow Key

Select Keys

Backlit Logo

and Proximity

Antenna

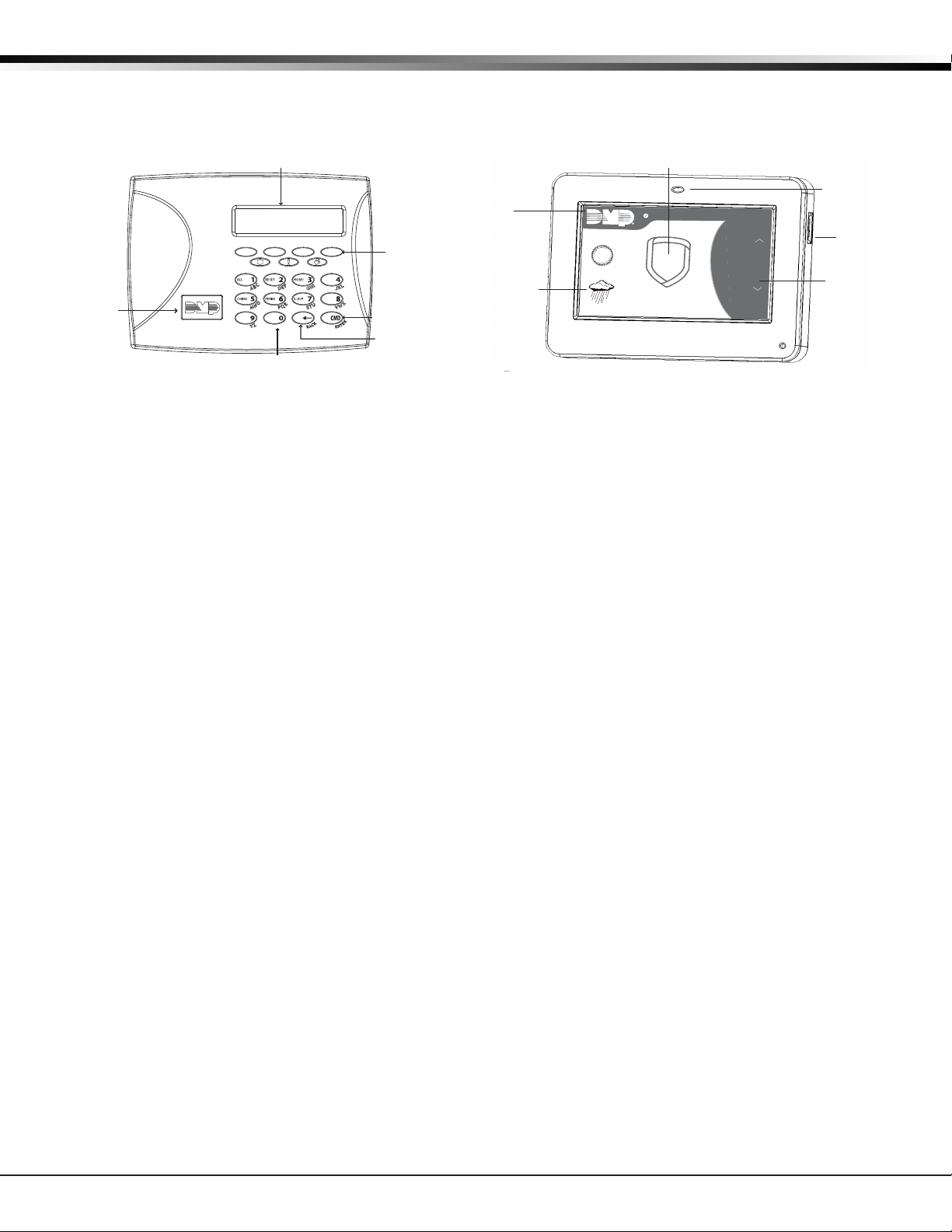

19.3 Keypad

Associate up to four DMP 9060, 9062 Wireless LCD Keypads or 9862 Graphic Touchscreen Wireless Keypads to

the XTLplus panel. The operation is shown and described in the following sections.

19.4 Special Keys

Digital Monitoring Products XTLplus Installation and Programming Guide

10

Figure 11: 9000 Series Wireless Keypad

Figure 12: 9862 Graphic Touchscreen Keypad

The following special keys or areas are common to all DMP keypads.

COMMAND (CMD) Key

Pressing the COMMAND key allows you to go forward through the programming menu and through each

step of a programming sec tion. As you go through the programming, the keypad display shows any current

programming already stored in the panel memory. If no change is required for an option, press the COMMAND

key to advance to the next step.

The COMMAND key is also used to enter information into the panel’s memory such as phone numbers or zone

names. Press the COMMAND key after entering information.

Back Arrow (<—) Key

Use the Back Arrow key to back up one step while programming. The Back Arrow key is also used when an

error is made while entering in formation. Press the Back Arrow key once to erase the last character entered.

Select Keys or Areas

The top row of keys are called the select keys on Thinline and Aqualite keypads or select areas on Graphic

Touchscreen keypads. Each time you need to press a select key or area, the keypad displays the function or

options above one of the keys or in the select areas. Displaying choices above individual select keys or in

select areas allows them to be used for many dierent applications. For example, you can enter AM or PM

when programming the automatic test time or answer YES or NO for a system option.

During programming, the select keys allow you to change infor mation currently in panel memory by pressing

the appropriate select key under the display. You then enter the new information using the keypad data

entry digit keys.

When there are more than four re sponse options avail able, press the COMMAND key to display the remaining

options. Pressing the Back Arrow key allows you to review the previous four choices.

The select keys are also used for choosing a section from the pro gramming menu. When the programming

section name you want displays, press any select key.

On Wireless, Thinline and Aqualite keypads, when instructed to press the rst select key, press the far left

select key; the second select key is the second from the left; third select key is second from the right; and

the fourth select key is the far right key. See Figure 11.

On Graphic Touchscreen Keypads, when instructed to press the rst select key, touch select area 1; the

second select key touch select area 2; third select key touch select area 3; and the fourth select key touch

select area 4. See Figure 12.

Page 19

PROGRAMMING INTRODUCTION

THEN

Press the third top row

Select key.

The keypad displays the new

selection. Press CMD to advance.

YESBELL TST

NOBELL TST

19.5 Entering Alpha Characters

Some options during programming require you to enter alpha characters. To enter an alpha character, press

the key that has that letter written below it. The keypad displays the number digit of the key. Next, press

the select key or area that corresponds to the loca tion of the letter under the key. Pressing a dierent

select key or area changes the letter. When an other digit key is pressed, the last letter displayed is retained

and the process starts over.

19.6 Entering Non-Alpha Characters

To enter a space in an alpha entry, press the 9 digit key followed by the third select key or area. The three

characters on the 9 digit key are Y, Z, and space. You can also enter the following characters: – (dash),

. (period), * (asterisk), and # (pound sign) using the 0 (zero) key and the four select keys or areas from left

to right. For example, to enter a – (dash), press 0 (zero) and then the left select key or area. A dash now

appears in the keypad display. The table below shows the character locations for DMP keypads.

Number Select Key or

Area 1

Select Key or

Area 2

1 A B C (

2 D E F )

3 G H I !

4 J K L ?

5 M N O /

6 P

Q

7 S T U @

8 V W X ,

9 Y Z space _

0 - . * #

19.7 Keypad Displays Current Programming

Each programming option displayed at the keypad shows the currently selected option in the panel memory.

These options are either shown as a number, a blank, or a NO or YES. To change a number or blank to a new

number, press any select key. The current option is replaced with a dash. Press the number(s) on the keypad

you want to enter as the new number for that option. It is not necessary to enter numbers with leading

zeros. The panel automatically right justies the number when you press the COMMAND key.

To change a programming option that requires a NO or YES response, press the select key for the response

not selected. See Figure 13.

For example, if the current option is selected as YES and you want to change it to NO, press the third select

key. The display changes to NO. Press the COMMAND key to display the next option.

Select Key or

Area 3

R &

Select Key or

Area 4

XTLplus Installation and Programming Guide Digital Monitoring Products

Figure 13: Changing the Current Programming Option

11

Page 20

PROGRAMMING INTRODUCTION

19.8 Programming Menu

Accessing the Programmer

To access the programmer function of the XTLplus:

Use a standard LCD keypad, connect to the PROG header and set the keypad to Address 1.

Press the RESET button for two seconds.

Enter the code 6653 (PROG).

The keypad displays: PROGRAMMER.

Remove the hardwired keypad when programming is completed.

You are now ready to start programming the XTLplus panel. Pressing the COMMAND key scrolls you through

the programming menu items listed below.

Menu Item Section in This Manual Menu Item Section in This Manual

Initialization 20 BellOptions 29

FastProgram 21 OutputOptions 30

Communication 22 OutputSetup 31

NetworkOptions 23 Area Information 32

MessagingSetup 24 Zone Information 33

Device Setup 25 Stop 34

RemoteOptions 26

System Reports 27 Appendix 36

SystemOptions 28

Set Lockout Code

35

To select a section for programming, press any select key when the name of that section displays on the

keypad. The detailed instructions for each programming step are found in sections 20 to 35 of this manual.

19.9 Programmer Lockout Codes

Although the XTLplus panel allows access to Programming without a lockout code, it is available to program

one to restrict programming access to authorized individuals only. You can do this by using SET LOCKOUT

CODE at the end of the programming menu.

Installing a lockout code

1. After entering the Programmer menu, the keypad displays PROGRAMMER. Press the COMMAND key until

SET LOCKOUT CODE is displayed (after STOP).

2. Press any select key. At the ENTER CODE: - display, enter a 1- to 5-digit programmer lockout code.

Press COMMAND.

3. The display shows ENTER AGAIN. Enter the same lockout code again and press COMMAND. The display

shows CODE CHANGED. The new code number must now be entered before the Programmer menu can

be accessed.

The lockout code should be written down and kept in a secure place with access limited to authorized

persons only.

Lost Lockout Code requires factory reset: If you lose or forget the lockout code, the panel must be sent

back to the factory to be reset. There is no eld option for gaining access to the panel without a valid

lockout code.

19.10 Reset Timeout

The XTLplus has a feature that requires you to enter the Programmer within 30 minutes of resetting the

panel. After 30 minutes, if you attempt to program by entering the 6653 (PROG) code, the keypad displays:

RESET PANEL. You must reset the panel and enter the program code within the next 30 minutes.

If you are already in the Programmer and do not press any keys on the programming keypad for 30 minutes,

the panel terminates programming. All data entered up to that point is saved in the panel’s memory.

To exit the panel’s Programmer you must use the Stop function. The STOP option is the second to the last

option in programming. The programming session is then terminated and the keypad returns to the

Status List.

Digital Monitoring Products XTLplus Installation and Programming Guide

12

Page 21

Initialization

20.1 Initialization

INITIALIZATION

This function allows you to set the panel’s programmed memory back to the

factory defaults.

After you select YES to clear a section of memory, the panel asks if you are sure

you want to clear the memory. This is a safeguard against accidently erasing part

of your programming. No memory is cleared from the programming until you

answer YES to the SURE? YES NO option.

For each section of the panel program you

can initialize, a NO or YES option is provided.

CODES? NO YES

Selecting NO advances

you to the next prompt.

SCHEDS? NO YES

INITIALIZATION

Selecting YES advances you to

a confirmation prompt.

SURE?

If you select YES, the panel initializes that section of

the program and advances you to the next prompt.

If you select NO, the panel advances you to the next

section prompt but does not initialize that section of

the program.

YES

NO

20.2 Clear All Codes

20.3 Clear All Schedules

20.4 Clear Events

20.5 Clear Zone Programming

20.6 Clear Communication

20.7 Clear Wi-Fi

20.8 Set to Factory Defaults

CODES? NO YES

SURE? YES NO

SCHEDS? NO YES

SURE? YES NO

EVENTS? NO YES

SURE? YES NO

ZONES? NO YES

SURE? YES NO

COMM? NO YES

SURE? YES NO

CLEARWIFINOYES

SURE?YESNO

DEFAULTS?NO YES

SURE? YES NO

NO - leaves existing user codes intact.

YES - clears the user code memory and assigns the user code number 99 to user 99

on the XTLplus.

NO - Leaves existing schedules intact.

YES - Clears all schedules from the XTLplus programming.

NO - leaves existing event memory intact.

YES - clears all event memory currently held in the panel’s Display Events buer.

NO - leaves existing zone information intact.

YES - sets all zones in the system to * UNUSED *.

NO - Leaves existing communication and messaging programming intact.

YES - Resets communication and messaging programming to factory defaults.

NO - Leaves existing Wi-Fi programming intact.

YES - Resets Wi-Fi programming to factory defaults.

NO - leaves the remainder of the existing panel programming intact.

YES - sets the panel’s programming back to factory default selections and clears all

Z-Wave device programming and Favorites from the panel. Selecting YES does not

clear the panel’s event memory, zones, user code information, or schedules.

XTLplus Installation and Programming Guide Digital Monitoring Products

13

Page 22

FAST PROGRAMMING

Fast Programming

21.1 Fast Program

21.2 Account Number

21.3 First IP Address

21.4 App Key

21.5 System

21.6 Hours from GMT

21.7 Weather Zip Code