Page 1

InstallatIon GuIde

*

*

*

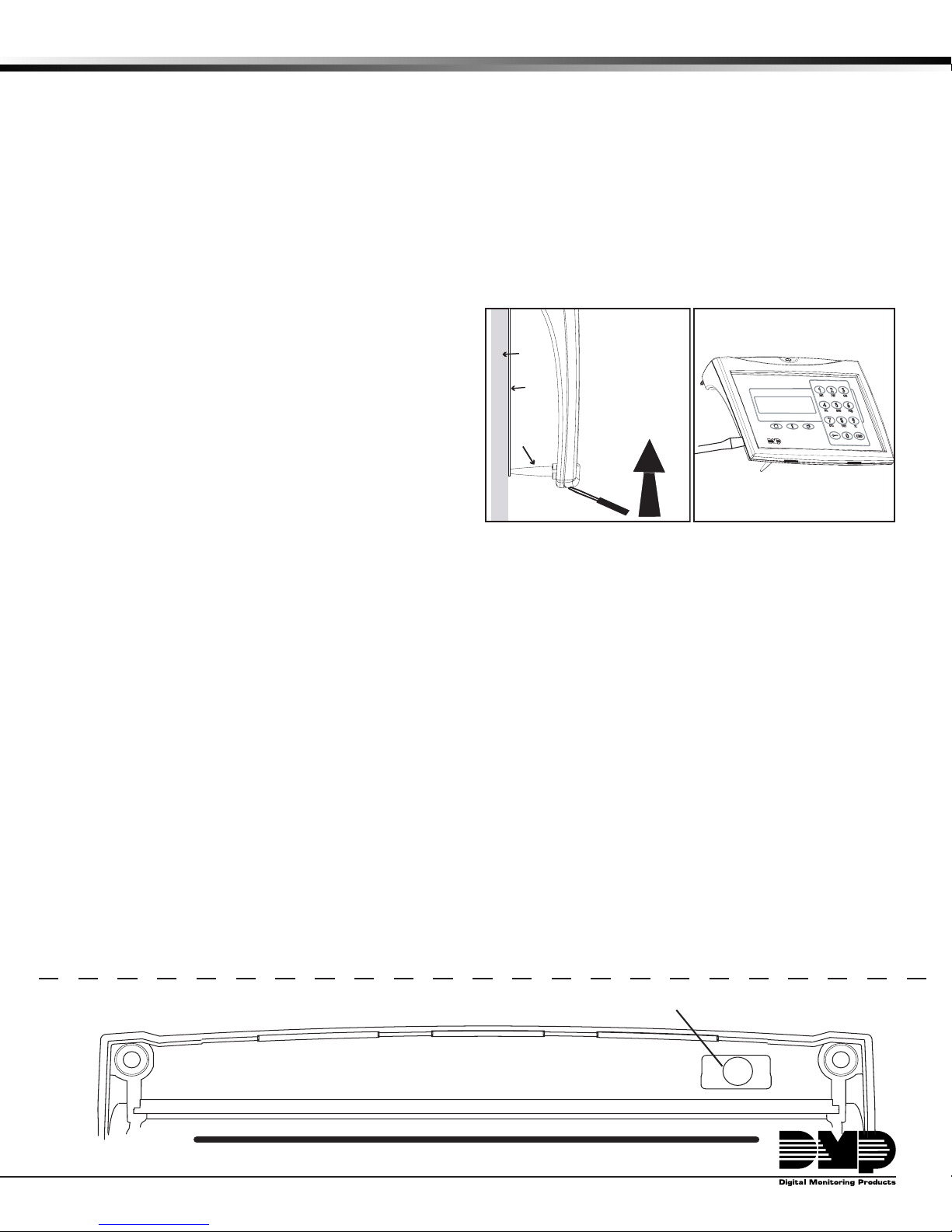

Drill 1/4" Hole for the Wiring Harness

Horizontal Alignment Line

#6 Screw

Location

#6 Screw

Location

✁

Cut along dotted line and use as a drill template to create mounting and wiring holes.

Legs

Glass

Keypad

Front

Building

Wall

778

Backplate

Lift screwdriver

handle up

toward you to

separate keypad

cover from base.

7760 LCD Glass Keypad

Description

The DMP Model 7760 LCD Glass Keypad offers the same functionality and exible features as standard DMP keypads.

The contemporary glass touch design offers an elegant, sleek look to accent any decor. Each 7760 keypad provides a

32‑character touchscreen backlit display, keyboard with easy‑to‑read lettering, three Panic icons, a multi‑functional AC

Power/Armed LED, and an internal speaker.

Installing the Keypad

The keypad housing is designed to easily install using two #6 screws on a at surface or optional 778 backplate. The

keypad housing is made up of two parts: a hinged cover and a base which contains the circuit board, glass touchscreen,

and keyboard components. A single 4‑wire harness is used to connect the 7760 to the keypad bus of a DMP control panel.

Figure 2 shows the back of the keypad with the 4‑wire harness connected.

Remove the Cover

Use the following steps and Figures 1 and 2 to remove the

hinged keypad cover.

1. Insert a at screwdriver into one of the slots on the

bottom of the keypad and gently lift the screwdriver

handle toward you while pulling the halves apart.

Repeat with the other slot.

2. Using your screwdriver, gently separate the left and

right sides of the cover by applying slight inward

pressure along the seam to disengage the internal

side snaps.

3. Gently lift the cover and remove from the four cover

hinges at the top and set aside.

Figure 1: Loosen bottom

of cover

Install the Base

Use the following steps to install the keypad base. Cut off the template below to use for mounting.

1. Place the template on the wall where the keypad is to be mounted and level using the horizontal alignment line.

2. Mark the two #6 screw locations and the wiring harness opening locations on the wall.

3. Install the two supplied #6 wall anchors where marked.

4. Drill a wiring harness hole no larger than 1/4” in diameter where indicated. Feed the 4‑conductor wire through

the created opening.

Note: Make sure the wire harness opening is small enough to be covered by the keypad base.

5. Connect the 4‑wire harness to the 4‑conductor Keypad bus wire from the wall.

6. Gently plug the 4‑wire harness connector onto the 4‑pin header through the opening in the back of the keypad.

See Figure 3.

7. Mount the 7760 keypad base to the #6 wall anchors using the provided #6 screws.

Replace the Cover

Use the following steps to reinstall the keypad cover.

1. Gently realign the top four hinges and set the cover into place.

2. Lower the cover and gently snap the two bottom latches and two internal side latches into place by squeezing the

base and cover together to reduce the stress on the legs. (See Figure 3)

Mounting Template

Figure 2: Loosen side

of cover

Page 2

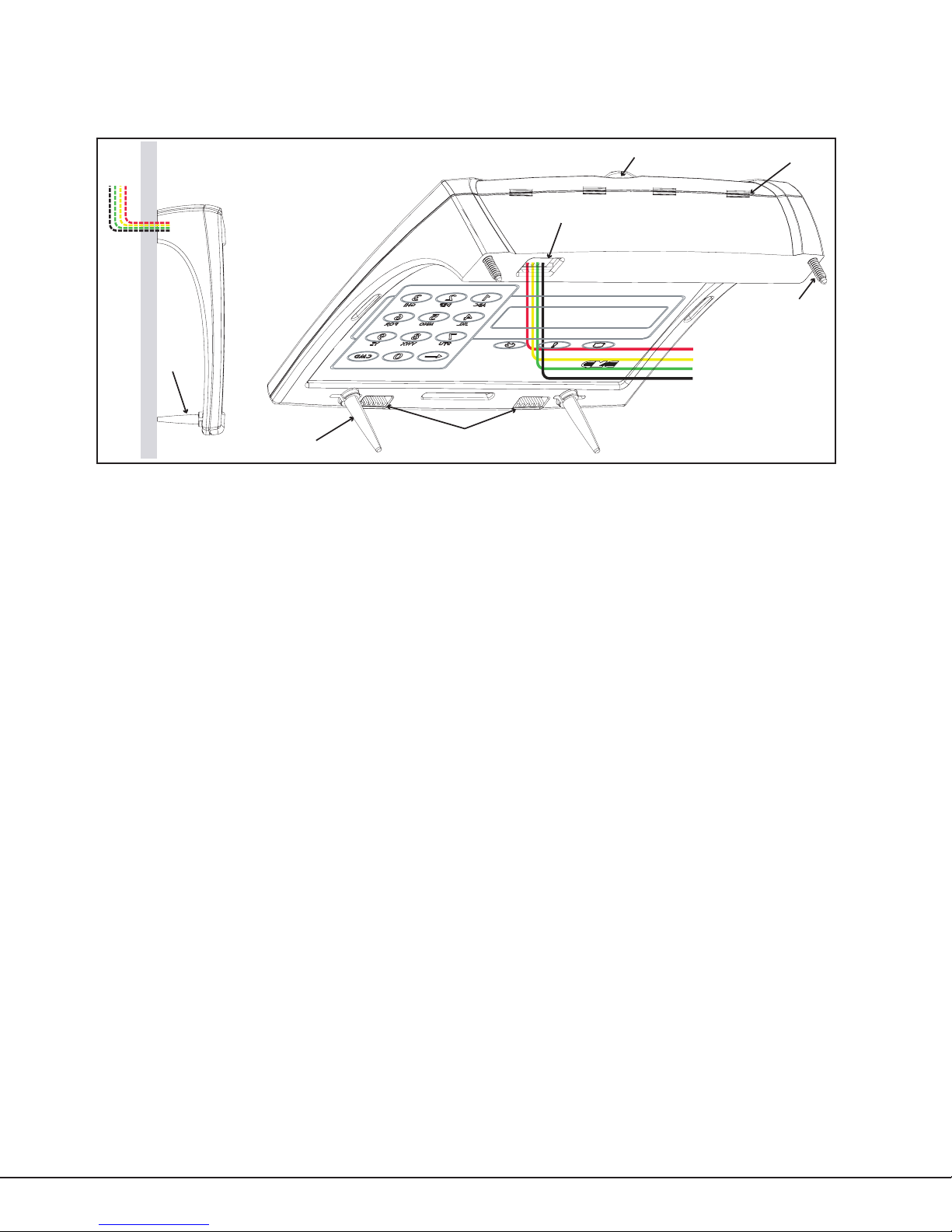

Harness Wiring

Black – Ground

Green – Receive Data

Yellow – Send Data

Red – Keypad Power

Surface Mounting

Screws (2)

Squeeze latches to

connect keypad cover to back.

Leg

Glass

Keypad

Front

Building

Wall

Plug 4-Wire Harness

into J4 Header

To

Panel

Keypad

Bus

Cover Hinge (4)

AC/Armed LED

Glass

Keypad Rear

Legs (2)

Figure 3 shows wiring harness mounting location and wiring assignments. Observe wire colors when connecting the

Red, Yellow, Green, and Black wires to the keypad bus. When wiring directly to the panel terminals, connect Red to

panel terminal 7, Yellow to terminal 8, Green to 9, and Black to panel terminal 10.

Figure 3: Keypad Side Mounting and Back Showing Wiring Harness Assignments

Wiring Specications

When planning a keypad bus installation, keep in mind the following specications:

1. DMP recommends using 18 or 22‑gauge unshielded wire for all keypad and LX‑Bus circuits. Do Not use twisted

pair or shielded wire for LX‑Bus and keypad bus data circuits. To maintain auxiliary power integrity when

using 22‑gauge wire do not exceed 500 feet. When using 18‑gauge wire do not exceed 1,000 feet. Install an

additional power supply to increase the wire length or add devices.

2. Maximum distance for any one circuit (length of wire) is 2,500 feet regardless of the wire gauge. This distance

can be in the form of one long wire run or multiple branches with all wiring totaling no more than 2,500 feet.

As wire distance from the panel increases, DC voltage on the wire decreases.

3. Each panel allows a specic number of supervised keypads. Additional keypads can be added in the

unsupervised mode. Refer to the panel installation guide for the specic number of supervised keypads

allowed.

4. Maximum voltage drop between the panel (or auxiliary power supply) and any device is 2.0 VDC. If the voltage

at any device is less than the required level, add an auxiliary power supply at the end of the circuit. When

voltage is too low, the devices cannot operate properly.

Refer to the LX‑Bus/Keypad Bus Wiring Application Note (LT‑2031). Also see the 710/710F Module Installation Sheet

(LT‑0310) for more information.

Additional Power Supply

If the current draw for all keypads exceeds the panel output, you can provide additional current by adding a Model

505‑12 auxiliary power supply. Connect all keypad Black ground wires to the power supply negative terminal. Run

a wire from the power supply negative terminal to the panel common ground terminal 10. Connect all keypad Red

power wires to the power supply positive terminal. Do NOT connect the power supply positive terminal to any panel

terminal. Refer to the 504‑24 and 505‑12 Power Supply Installation Guide (LT‑0453) for more information.

Digital Monitoring Products 7760 Keypad Installation Guide

2

Page 3

Keypad Bus Monitor

AC Power/Armed LED

Three Panic Icons (Optional)

32-Character

Display with

Four Touch

Select Areas

Data Entry

Keyboard

COMMAND KeyBack Arrow Key

Logo

Police Emergency Fire

For Fire Protective systems, the 893/893A Module must be installed in the XR500 Series or XR200 control panel to

monitor the keypad bus and sound an audible trouble whenever the keypad bus fails to operate. Refer to the 893/

893A Module Installation Sheet (LT‑0135).

Touchscreen Display

The 7760 is an integrated LCD with a touchscreen user interface that can be programmed to turn off (clear glass)

during periods when the keypad is not in use. See Backlighting Brightness under End‑User Options. Touch the area

over each key, icon, or other selection to operate the keypad.

Warning: DO NOT use any sharp objects to operate the touchscreen such as a pen or pencil.

Figure 4: 7760 LCD Glass Keypad

Keypad Backlighting

The touchscreen illuminates at full brightness any time the glass is touched. When the speaker is sounding, the

backlight illuminates at one‑half (1/2) brightness. During an alarm condition, the backlight turns Red. When all

alarm conditions are cleared from the display, the Red backlight returns to Blue and the user‑selected brightness.

This user selected brightness may be set to off which allows the glass graphic display to turn off (clear glass).

Simply touch the glass anywhere and the backlight illuminates for data entry.

AC Power/Armed LED Operation

The LED indicates the Power and Armed status of the panel. Depending on the operation, the LED displays in Red or

Blue as listed in the table.

Color and Activity Operation

Blue Steady Panel Disarmed, AC Power OK, Battery OK

Blue Blinking Panel Disarmed, AC Power OK, Battery Fault

No Light Panel Disarmed, AC Power Fault, Battery OK

Red Steady Panel Armed, AC Power OK, Battery OK

Red/Blue Alternate Panel Armed, AC Power OK, Battery Fault

Red Blinking Panel Armed, AC Power Fault, Battery OK

Panic Icons

All 7760 keypads offer an optional Panic function that allows users to send

Panic, Emergency, or Fire reports to the central station. You must enable

the Panic function in Installer Options in order to use the Panic Icons. See

Programming Keypad Options later in this document. The Panic Icons are

shown in Figure 5.

The user must touch and hold the Icon for two seconds until a beep from the keypad is heard. At the beep, the

panel sends the following zone alarm reports to the central station:

Panic (Police Icon) ‑ Zone 19 + Device Address

Emergency - non‑medical (Exclamation Point Icon) ‑ Zone 29 + Device Address

Fire (Flame Icon) ‑ Zone 39 + Device Address

Figure 5: Panic Icons

7760 Keypad Installation Guide Digital Monitoring Products

3

Page 4

Internal Speaker Operation

32-Character Display

Panic Icons

First Letter

Select Area 1

Second Letter

Select Area 2

Third Letter

Select Area 3

Special Character

Select Area 4

Keyboard

keys

COMMAND

Key

Back

Arrow Key

ABC( DEF) GHI!

JKL? MNO/ PQR&

STU$ VWX, YZ

(SPACE)'

–.*#

To uch 9 Key and

Select Area 3 to

enter a blank

space in the text.

The Glass keypad emits standard tones for key touches, entry delay, and system alerts. The speaker also provides

distinct burglary, re, zone monitor, and prewarn cadences. The keypad provides an alternate prewarn entry delay

cadence that occurs when the keypad is displaying a zone alarm.

End-User Options

The 7760 Keypads provide three adjustments the end‑user can make through a User Options Menu. The user can also

view the keypad model number and address in User Options.

To access User Options, touch and hold the center of the logo for two seconds. The 32‑character display changes to

SET BRIGHTNESS. Touch the CMD (COMMAND) key to display the next option or touch the <— (Back Arrow) to exit the

User Options function. See Figure 5.

Note: The End‑User Options function automatically terminates after approximately 20 seconds of no activity.

SET BRIGHTNESS

Backlighting Brightness

< >

SET TONE

Speaker Tone

< >

SET VOLUME LEVEL

Volume Level

< >

MODEL NUMBER

Model Number

7760 V100 030805

KEYPAD ADDRESS

Keypad Address

01

Set the backlight illumination and AC Power/Armed LED brightness level. In the

touchscreen display below SET BRIGHTNESS, touch the left < to lower the backlight

brightness and the right > to raise the backlight brightness. If the brightness level is

lowered, it reverts to maximum intensity whenever the glass is touched during normal

operation. If the glass is not touched, and the speaker has not sounded for 30 seconds,

the user‑selected standby brightness level restores.

Note: If the brightness level is set to the lowest level, after 30 seconds of no activity,

the screen display turns off and will vanish from sight. Simply touch the glass

anywhere and the display and backlight illuminates.

Set the keypad speaker tone. At the SET TONE display, use the left < to lower the tone

and the right > to raise the tone.

Set the keypad speaker volume level for key touches and entry delay tone conditions.

During alarm and trouble conditions, the volume is always at maximum level. Use the

left < to decrease the keypad volume and the right > to increase the volume.

The LCD displays the keypad model number and the keypad rmware version and date.

The user cannot change this information.

The LCD displays the current keypad address. While in User Options, the user cannot

change the keypad address. Touch the (<— ) Back Arrow key to exit the User Options

function.

Entering Characters

Figure 6 shows the location of the alpha and non‑alphanumeric characters and the 32‑character display areas to

touch to enter information. The non‑alpha special characters do not display on the keyboard but are listed on

Figure 5 for reference. The special characters available are as follows starting with the 1 digit key to the 9 digit

key: ( ) ! ? / & $ ‚ ’ and ‑ . * # for the 0 key.

Digital Monitoring Products 7760 Keypad Installation Guide

4

Figure 6: Entering Alpha and Non-Alpha Characters

Page 5

You can use the keyboard to enter alpha characters and special, non‑alpha characters. To enter an alpha character,

touch the key that has the desired letter shown below it. The keyboard display shows the number on that key. To

change the number to a letter, touch the Select area of the 32‑character display that corresponds to the letter

location under the key.

For example, if you touch key number 1, the letters for that key are A, B, and C. Touch Select Area 1 for A, Select

Area 2 for B, Select Area 3 for C, and Select Area 4 for the special character. Enter a space by touching 9 then the

Select Area 3. Refer to Figure 6 as needed.

Installer Options Menu

The 7760 keypad also contains Keypad Options and Keypad Diagnostics programs that allow installers and service

technicians to congure and test keypad operation.

Note: The Installer Options function automatically terminates after approximately two minutes of no activity.

Access the Installer Options Menu

Access the Keypad Options Menu or Keypad Diagnostics Menu through the User Options function. Touch the Logo for

two seconds to display the SET BRIGHTNESS option. Immediately enter the code 3577 (INST) and touch CMD. The

display changes to KPD OPT (keypad options), KPD DIAG (keypad diagnostics) and STOP.

Keypad Options

The Keypad Options menu allows you to set the keypad address, select supervised or unsupervised mode, change the

default keypad message, and enable any or all Panic Icons.

KPD KPD

OPT DIAG STOP

CURRENT KEYPAD

ADDRESS: 01

KEYPAD MODE:

*SUP UNSUP

DEFAULT KEYPAD MSG:

Keypad Options (KPD OPT)

To program keypad options, touch KPD OPT. The display changes to CURRENT KEYPAD

ADDRESS: # #.

Keypad Address

Set the keypad address from 01 to 05 with the XRSuper6 and XR20, from 01 to 08 with

the XR40, and 01 to 16 with the, XR500 Series, and XR2500F. The factory default

address is set at 01. To change the current address, touch any 32‑character display

Select area to clear the current address, then enter the new address. It is not

necessary to enter a leading zero for addresses 01 to 09.

Note: On XRSuper6 and XR20 panels, keypad Address 5 is designated for unsupervised

operation only.

Keypad Mode

Congure the keypad for either supervised or unsupervised operation. Supervised

keypads cannot share addresses with other keypads. Unsupervised keypads can operate

with other unsupervised keypads sharing the same address. To change the current

setting, touch SUP or UNSUP. An asterisk appears next to the selected option.

Note: Unsupervised addresses cannot be used when the Device Fail Output of the

control panel has a programmed value other than zero.

Default Keypad Message

Enter a custom message of up to 16‑characters to appear on the keypad display top line

whenever that line is not being used for any other purpose by the control panel. Touch

any 32‑character display Select area to clear the current message and use the keyboard

keys to enter a new custom display.

ARM PANIC KEYS:

*PN *EM *FI

Arm Panic Icons

Use this option to congure the Panic Icons. To enable or disable a Panic Icon, touch

the icon name: PN (Panic), EM (Emergency), and FI (Fire). Once the panic icon is

enabled, an asterisk displays next to the description and the respective Panic icon will

display for the user. Refer to the Panic Icon Options section earlier in this document.

7760 Keypad Installation Guide Digital Monitoring Products

5

Page 6

Keypad Diagnostics

The Keypad Diagnostics menu allows installers and technicians to test keypad operation.

KPD KPD

OPT DIAG STOP

PRESS KEY TO

TEST

Exiting the Installer Options

When done, touch the CMD key once to return to the Installer Options screen. Touch STOP to exit the Installer

Options function.

Keypad Diagnostics (KPD DIAG)

The Keypad Diagnostic option allows you to check the display segments, check the

keyboard backlighting, and test individual keys.

Touch KPD DIAG. The keypad turns on all of the 32‑character display segments and

illuminates the Blue backlighting. A few seconds later the keypad turns the Blue

lighting off and illuminates Red. The keypad then alternates between these two states.

Touch CMD at any time to continue.

Test Individual Keys

The display changes to PRESS KEY TO TEST. This option allows you to test each key on

the keyboard to ensure it is operating properly. Touch and hold each key for about

two seconds. The key number being held appears in the display. Verify the correct

number displays before testing the next key. The Panic icons will display for test even

if they are not enabled for standard operation. The four distinct Select areas of the

32‑character display can also be tested and will be displayed as Top 1, Top 2 Top 3, and

Top 4.

Cleaning the Glass Display

Clean the Glass touchscreen using a water dampened soft lint‑free cloth. Apply the water onto the cloth, do NOT

apply directly onto the Glass touchscreen. After cleaning, wipe the touchscreen dry with a dry soft lint‑free cloth.

FCC Information

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Changes or modications made by the user and not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

‑ Reorient or relocate the receiving antenna.

‑ Increase the separation between the equipment and receiver.

‑ Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

‑ Consult the dealer or an experienced radio/TV technician for help.

Specications

Operating Range 9.5 VDC to 14 VDC

Normal Standby 65mA

Alarm 115mA

Dimensions 6.9” W x 4.75” H x 1.4” D

Touch Durability 50 million touches in a

single pixel

Accessories

4‑wire Harness Model 300 (included)

Keypad Backplate Model 778

Model 778L

800‑641‑4282

www.dmp.com

Made in the USA

Compatibility

All DMP Command Processor™ panels.

Listings and Approvals

FCC Part 15

Underwriters Laboratories (UL) Listed

UL 365 Police Connected Burglar

UL 609 Local Burglar

UL 1023 Household Burglar

UL 1076 Proprietary Burglar

UL 1610 Central Station Burglar

UL 985 Household Fire Warning

INTRUSION • FIRE • ACCESS • NETWORKS

2500 North Partnership Boulevard

Springfield, Missouri 65803‑8877

8062

LT‑0851 1.01 © 2008 Digital Monitoring Products, Inc.

Loading...

Loading...