Page 1

1107 MICRO WINDOW TRANSMITTER

Installation Guide

PROGRAM THE PANEL

When programming the 1107 in the panel, refer to the panel

programming guide as needed.

1

Figure 1: 1107 Micro

Window Transmitter

1. In ZONE INFORMATION, enter the wireless ZONE number.

2. Enter the ZONE NAME.

3. Select NT (Night) as the ZONE TYPE.

4. Select the AREA.

5. At the NEXT ZONE prompt, select NO.

6. Select YES when WIRELESS? displays.

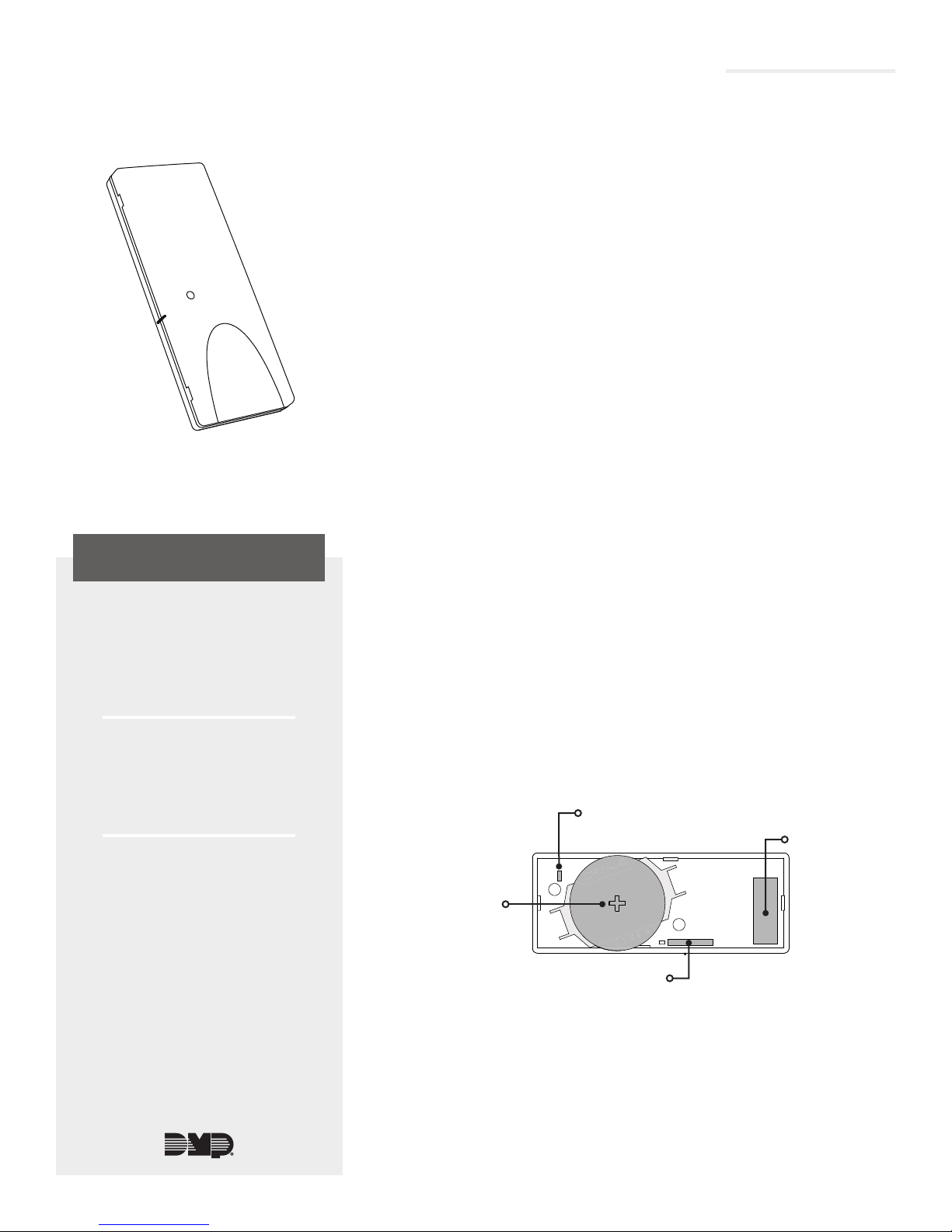

7. Enter the eight-digit SERIAL# and press CMD. See Figure

2 for the serial number location.

8. Enter the SUPRVSN TIME and press CMD.

9. At the NEXT ZONE prompt, select YES if you are finished

programming the zone. Select NO if you would like to

access additional programming options.

DESCRIPTION

The 1107 Micro Window Transmitter is

a low-profile 1100 Series transmitter

that can be used on windows. It is

powered by a 3V coin cell battery

and contains a single reed switch.

Compatibility

All DMP 1100 Series Wireless

Receivers and burglary panels.

What is Included?

• 1107 transmitter PCB

mounted in a two-part

housing

• One magnet with

a standard and a

commercial housing

• One CR2430 3V coin cell

Lithium battery

• Double-sided tape

2

INSTALL THE BATTERY

After the transmitter has been programmed into the panel, install

the battery. Use a 3.0V lithium battery, DMP Model CR2432, or

the equivalent battery from a local retail outlet. Keep in mind,

when setting up a wireless system, program zones and connect

the receiver before installing batteries in the transmitters.

1. Insert a small screwdriver into each notch in the housing

cover and lift until the cover comes o. Do not twist the

screwdriver.

2. Observing polarity, place the battery in the holder with

the positive (+) side up. Press it into place. See Figure 2

for the battery location.

Survey

LED

Battery

Location

Internal

Reed Switch

Figure 2: Battery Location and

PCB Features

Serial

Number

Page 2

3

SELECT A LOCATION

The 1107 provides a survey capability to allow one person to confirm communication with the wireless receiver

or panel while the cover is removed. This allows you to easily determine the best location for the 1107. Be sure

to choose a location away from large metal objects.

1. Hold the 1107 transmitter and the included magnet in the exact desired location.

2. Move the magnet away from the transmitter to send data to the receiver and determine if

communication is confirmed or faulty. See Figure 2 for LED locations.

Confirmed: If communication is confirmed, the survey LED turns on when data is sent to the

receiver and o when acknowledgement is received.

Faulty: If communication is faulty, the LED remains on for up to 8 seconds or flashes multiple

times in quick succession.

3. Relocate the 1107 or receiver until the LED confirms clear communication. Proper communication

between the 1107 and receiver is verified when the LED blinks immediately on and immediately o each

time the magnet is removed.

4

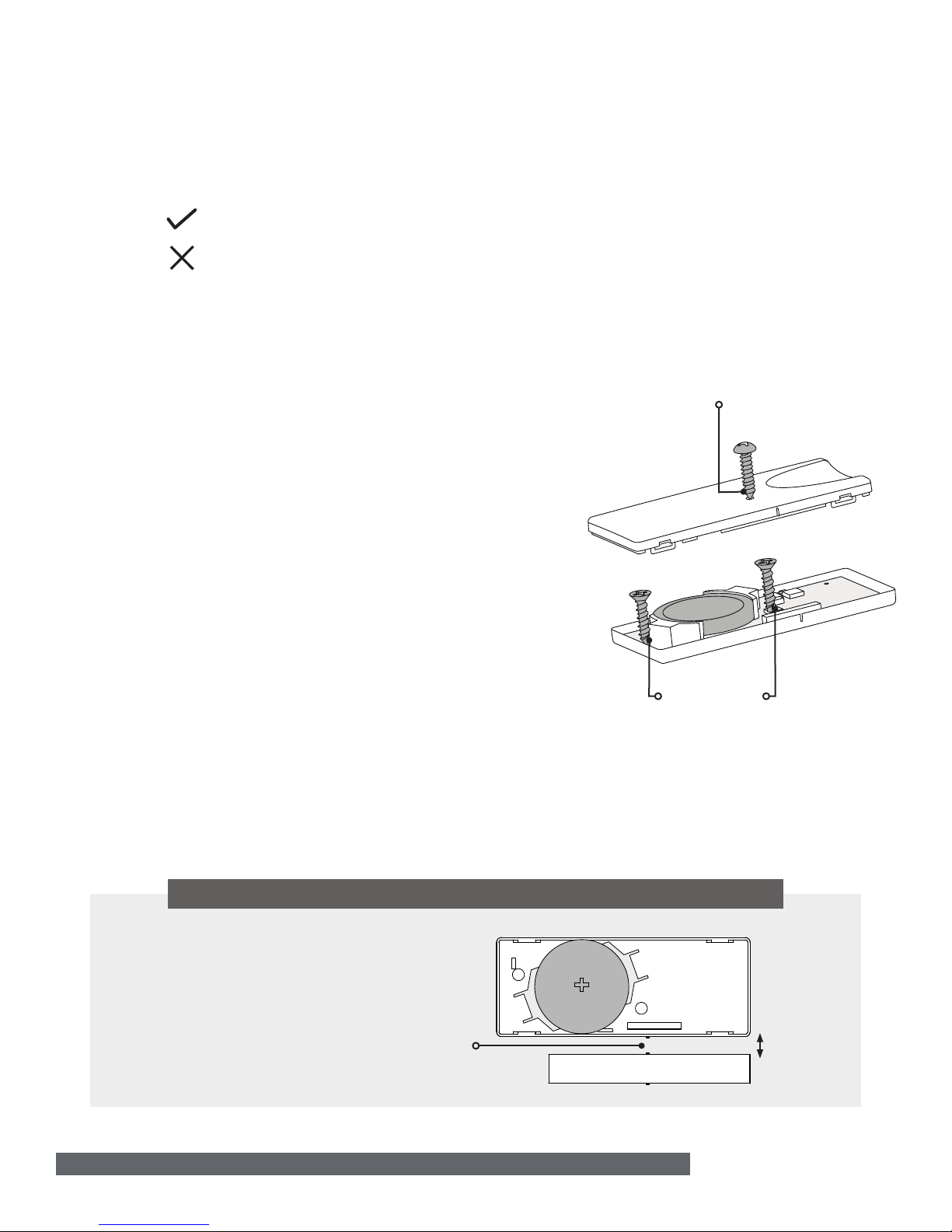

MOUNT THE 1107 TRANSMITTER

The transmitter and magnet assembly should have no more than

1/2” between the assembled housings after installation. When

mounting on metal (ferrous) surfaces, this distance is slightly

less. DMP recommends mounting the transmitter on the window

frame and the magnet assembly on the window.

1. Hold the transmitter base in place with the reed switch

alignment marker near where the magnet assembly

will be mounted. See How to Align the Transmitter and

Magnet Assembly for more information.

Note: Do not remove the PCB from the housing during

installation.

2. Place the two supplied #4 flat-head screws into the

mounting holes to secure the housing base to the surface.

See Figure 3.

3. Replace the cover.

For environments where the cover could be dislodged, the

optional #4 pan-head securing screw can be used instead of the

center flat-head screw to secure the entire transmitter and cover

to the mounting surface. See Figure 3.

For even quicker installations, use the included doublesided tape instead of the screws to attach the housing to the

mounting surface.

Pan-Head Securing

Screw (optional)

Flat-Head

Mounting Screws

Figure 3: Mounting

Hole Locations

HOW TO ALIGN THE TRANSMITTER AND MAGNET ASSEMBLY

When you mount the transmitter

and magnet assembly, use the

alignment markers to ensure that the

transmitter’s internal reed switch is

lined up with the magnet.

There should be no more than a

1/2” inch of space between the

transmitter and the magnet assembly.

2 DIGITAL MONITORING PRODUCTS | 1107 INSTALLATION GUIDE

Alignment

Markers

1/2” Max

Distance

Page 3

5

MOUNT THE MAGNET ASSEMBLY

Only one magnet assembly is required for internal reed switch

operation. Depending on the installation requirements, you can use

either the standard or commercial magnet assembly.

Standard Magnet Assembly

1. Place the magnet assembly base on the surface nearest

the transmitter’s internal reed switch location. Be sure to

align the markers on the transmitter and magnet assembly.

2. Use the provided #4 flat-head screws or included

double-sided tape to secure the base in place.

3. Snap the magnet into the magnet assembly cover, then

snap the cover onto the base.

Commercial Magnet Assembly

1. Snap the magnet into the magnet assembly cover.

2. Place the cover on the surface nearest to the internal

reed switch location. Be sure to align the markers on the

transmitter and magnet assembly.

3. Use the supplied #4 flat-head screws to mount the

magnet assembly. See Figure 5.

Cover

Magnet

Base

Figure 4: Standard

Magnet Assembly

Cover

Magnet

Figure 5: Commercial

Magnet Assembly

REPLACE THE BATTERY

1. Insert a small screwdriver into the notch in the housing cover and lift until the cover comes o. Do not twist the

screwdriver.

2. Remove the old battery and dispose of it properly.

3. Observing polarity, place the new battery in the holder and press into place.

4. Snap the transmitter housing cover back on the base.

Caution: Properly dispose of used batteries. Do not recharge, disassemble, heat above 212°F (100°C), or incinerate.

Risk of fire, explosion, and burns.

Sensor Reset to Clear LOBAT

When the battery needs to be replaced, a LO B AT message will display on the keypad. Once the battery is replaced, a

sensor reset is required at the system keypad to clear the LO BAT message.

1. On a Thinline keypad, press and hold “2” for two seconds. On a touchscreen keypad press RESET.

2. Enter your user code if required.

3. The keypad displays SENSORS OFF followed by SENSORS ON.

1107 INSTALLATION GUIDE | DIGITAL MONITORING PRODUCTS 3

Page 4

FCC INFORMATION

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. this device must accept any interference received, including interference that may cause undesired operation.

The antenna used for this transmitter must be installed to provide a separation distance of at least 20 cm (7.874 in.) from all persons. It

must not be located or operated in conjunction with any other antenna or transmitter.

Changes or modifications made by the user and not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment o and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Industry Canada Information

This device complies with Industry Canada Licence-exempt RSS standard(s). Operation is subject to the following two conditions:

1. this device may not cause interference, and

2. this device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes : (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter

tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

This system has been evaluated for RF Exposure per RSS-102 and is in compliance with the limits specified by Health Canada Safety

Code 6. The system must be installed at a minimum separation distance from the antenna to a general bystander of 7.87 inches (20 cm)

to maintain compliance with the General Population limits.

L’exposition aux radiofréquences de ce système a été évaluée selon la norme RSS-102 et est jugée conforme aux limites établies par le

Code de sécurité 6 de Santé Canada. Le système doit être installé à une distance minimale de 7.87 pouces (20 cm) séparant l’antenne

d’une personne présente en conformité avec les limites permises d’exposition du grand public.

1107 MICRO WINDOW

TRANSMITTER

Specifications

Battery

Life Expectancy 2 Years (normal operation)

Type 3.0V Lithium CR2430

Frequency Range 905-927 MHz

Dimensions

Transmitter 2.625” L x 1” W x .3125” H

Standard Mag. 2.125” L x .375” W x .3125” H

Commercial Mag. 2.125” L x .375” W x .3125” H

Color White

Housing Material Flame-Retardant ABS

Designed, engineered, and

manufactured in Springfield, Missouri

© 2017 Digital Monitoring Products, Inc.

LT-1156 17483

Patents

U.S. Patent No. 7,239,236

Certifications

FCC Part 15 Registration ID CCKPC0133

Industry Canada Registration ID 5251A-PC0133

INTRUSION • FIRE • ACCESS • NETWORKS

2500 North Partnership Boulevard

Springfield, Missouri 65803-8877

800-641-4282 | dmp.com

Loading...

Loading...