Page 1

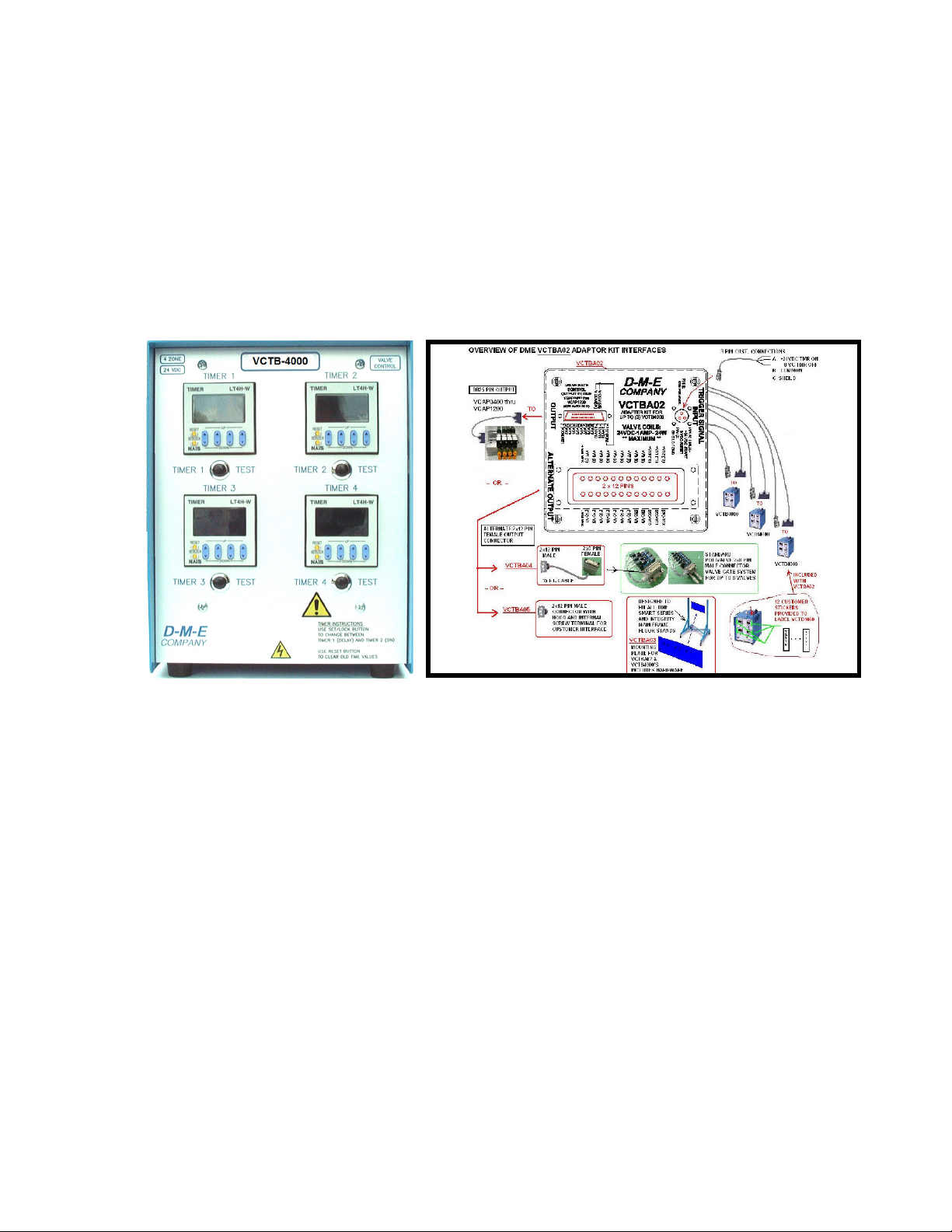

VCTB-4000 Four Zone, 24 Volt DC

Valve Gate Controller

And Accessories VCTBA-01 thru -05

User Manual

D-M-E Company

D-M-E Company VCTB-4000 Page 1

ED-0109-OT-024-( Preliminarry Rev E)

Page 2

SAFETY

D-M-E Company products have been designed to be safe and simple to operate. As with any electronic

equipment, you must observe standard safety procedures to protect both yourself and the equipment.

To Prevent Injuries:

• To avoid electrical shock or fire hazard, do not apply voltage to a terminal that exceeds the range

specified for that terminal.

• To avoid mechanical injury, electrical shock or fire hazard, do not operate this product with covers or

panels removed.

• To avoid electrical shock or fire hazard, do not operate this product when wet.

• To avoid injury or fire hazard, do not operate this product in an explosive atmosphere.

• To avoid burn hazards, do not operate valve gates with operator gates open. Correct hookup of valve

gates should only be performed with all operator guards in place.

• To avoid burn hazards and possible damage to equipment, do not leave hot runner systems at

elevated temperature for extended periods of time. When the mold and machine are not operating,

disconnect the molding machines injection unit from the hot runner system so that pressure may

discharge through the sprue or manifold extension nozzle. Make sure the molding machines purge

guard is in place.

To Prevent Product Damage:

⋅ Do not operate this product from a power source that applies more than the voltages specified.

⋅ Do not apply any external voltage to the injection forward input. Only a contact closure or solid state

relay should be used as an input.

DME RIGHTS

Copyright D-M-E Company 2004. All rights reserved.

D-M-E Company products are covered by USA and foreign patents, issued and pending. Information in

this publication supersedes that in all previously published material. Specifications and any changes are

reserved.

Printed in the United States of America

D-M-E Company

29111 Stephenson Highway

Madison Heights, MI 48071

D-M-E Company and D-M-E are registered trademarks of D-M-E Company.

D-M-E Company VCTB-4000 Page 2

ED-0109-OT-024-( Preliminarry Rev E)

Page 3

WARRANTY

D-M-E Company warrants that this product will be free from defects in materials and workmanship for a

period of three (3) years from the date of shipment. If any such product proves defective during this

warranty period, D-M-E Company, at its option, either will repair the defective product without charge for

parts and labor, or will provide a replacement in exchange for the defective product.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or

inadequate maintenance and care. D-M-E Company shall not be obligated to furnish service under this

warranty a) to repair damage resulting from attempts by personnel other than D-M-E Company

representatives to repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; or c) to service a product that has been modified or integrated with

other products when the effect of such modification or integration increases the time or difficulty of

servicing the product.

D-M-E Company VCTB-4000 Page 3

ED-0109-OT-024-( Preliminarry Rev E)

Page 4

VCTB-4000

Four Zone, 24 Volt DC

Valve Gate Controller

GENERAL DESCRIPTION

This manual describes the installation,

operation and servicing of the Valve Gate

Controller.

The VCTB-4000 Valve Gate Controller is

designed to provide time based control of

up to four 24 volt DC valves used to actuate

pneumatic valve gate cylinders. It can also

be used to operate some hydraulic valves.

The VCTB-4000 is small in size so that it is

extremely portable and requires minimal

counter space.

The Controller uses DIN style solid state

timers to provide long life and high

reliability. Each timer is capable of dual time

functions so that each zone can be

programmed with a delay time (timer 1) and

an on time (timer 2). The timers in turn drive

larger solid state relays that are individually

fused against faults.

The Controller is designed to operate from a

wide supply of operating voltages (88 to 264

Volts AC) so that this one device can be

used with almost any available power

source. This also makes it easier to relocate

the controller between different plants or

even different countries. The standard

product offering comes with a 125 volt AC

plug (North American Standard). This plug

may be removed and replaced with any

number of 240 VAC plugs. Units may also

be custom ordered with other plugs, as

required.

A single DB-025 cable connects the

controller to up to four remotely located

valves minimizing required wiring and air

connections, thereby making the molding

environment neater.

DME offers valve and manifold systems that

accept the DB-025 cable directly. For other

systems that have independent valve

connections, breakout boxes are available

that accept the DB-025 connector and

provide a terminal strip for individual valve

connections.

D-M-E Company VCTB-4000 Page 4

ED-0109-OT-024-( Preliminarry Rev E)

Page 5

Test buttons are available for each zone to

assist in determining the correct hookup of

each of the valves.

UNPACKING AND INSPECTION

After unpacking, inspect your controller and

check for any damage that may have

occurred during shipment.

Check for proper operation of power switch

by turning the switch on and off with no

voltage applied.

Check all electrical connectors for visual

damage.

If any damaged is observed, return the

controller to D-M-E for repair or

replacement.

INSTALLATION

You are installing a piece of electronic

equipment, which should not be subjected to

any physical or environmental abuse.

Select a cool, dry, well-ventilated,

environmentally clean location, away from

heat, moisture and liquid carrying lines, i.e.:

water cooling hoses, hydraulic hoses, etc.

Connection of Trigger Signal

Using the cable supplied with the controller,

connect the controller to the injection

molding machine. The best way to

accomplish this is to supply a dry contact

(relay) closure that is triggered by the

injection forward signal of the molding

machine. A solid state relay contact can be

also be used. It should source power from

contact A to contact C.

Alternatively, a limit switch that is operated

from mold closure can be used as the

trigger signal. The limit switch can be

mounted to the tie bar to catch the closing

of the moving half of the mold. It may also

be mounted to the mold to detect contact of

the mold halves.

Contact B of the connector supplies a

ground signal to provide shielding of the

cable assembly.

Connection of Controller to Valves

Use an appropriate length DB-025 cable

with a male connector on one and a female

on the other to connect from the controller

to the valves. The cable must have

conductors with a minimum size of 20

gauge to run hydraulic valves.

Conductor numbers 1, 2, 3 and 4 supply

+24 VDC power to valves 1, 2, 3 and 4,

respectively. Conductor 13 supplies ground

to all of the valves.

Connection of AC Power to Controller

The standard offering of the controller is

provided with a 120 VAC connector. The

controller is designed to run from any

voltage between 88 VAC and 264 VAC.

Connect the brown conductor of the power

cable to L1 (or hot), the blue conductor to L2

(or neutral) and the green conductor with the

yellow stripe to ground. Do not operate the

controller without the ground conductor

connected.

NOTE: ALL NATIONAL AND LOCAL

ELECTRICAL CODES MUST BE

FOLLOWED WHEN CONNECTING THIS

EQUIPMENT.

Trigger Signal Connection

Black

Red

A

C

B

OPERATION

Timer Setup

Do not perform this step until all electrical

connections are performed.

Turn controller power on. The timer displays

should illuminate. If they do not illuminate,

see the Maintenance and Repair sections

below.

Each timer unit has two internal timers.

Timer 1 sets the delay between when the

trigger signal is received and the valve is to

open. This is referred to as the “delay”

D-M-E Company VCTB-4000 Page 5

ED-0109-OT-024-( Preliminarry Rev E)

Page 6

timer. Timer 2 sets the duration the valve is

open. This is referred to as the “on” timer.

Use the SET/LOCK button on the front of

the timer to select between the delay timer

(Timer 1) and the on timer (Timer 2). The

Timer unit front panel will display which

timer is selected. (See page 8)

Use the up and down arrow buttons below

the display to set the desired time value.

Each time value can be set to any value

between 00.00 seconds to 99.99 seconds.

To set any valve to open immediately, set

the delay timer (Timer 1) value to 00.00

seconds.

If the sum of the delay and the on timer is

set to a value larger than the time the

trigger signal is active, internal electronics

will automatically reset the timers at the end

of the trigger signal.

When triggered, “Timer 1” (delay timer) of

each of the timers will be displayed. The

timer will count down until it reaches zero.

When Timer 1 reaches zero, Timer 2 (on

timer) will be displayed and the timer will

count down until it reaches zero. If the

Timer 1 value is zero, Timer 2 will be

displayed when the trigger signal is

displayed, Timer 1 will not be displayed.

Proper setting of each of the “on” timers is

determined by part weight or size. For most

applications, the on timer should run

through the injection fill phase and into the

pack (and hold, if present) phases of the

injection molding machine.

NOTE: The TEST buttons on the front panel

do not actuate the timers. The buttons

bypass the timers and actuate the solid

state relays directly.

The test buttons below each of the timers

can be used to verify correct connection to

the valve gates. Warning!: verification

should be performed with the operator

gates closed to prevent injury from hot

plastic.

Verify correct operation of the timers once

the trigger signal is applied.

MAINTENANCE AND REPAIR

NOTE: DISCONNECT POWER BEFORE

SERVICING. ONLY ELECTRICIANS OR

TRAINED SERVICE PERSONNEL

SHOULD REMOVE ACCESS PANELS TO

SERVICE INTERNAL COMPONENTS.

Timers Do Not Illuminate

Make sure controller is plugged in and that

outlet power is on. Some molding machine

outlets may not be energized if machine

power is off.

If controller is plugged in and outlet has

power, check fuses 1 and 2 on top of the

controller. See the figure of the top plate.

Use only ABC-3 fuses as replacements.

(See page 7).

If a single timer does not illuminate, it may

require replacement. See timer replacement

at the end of this section. The timers are

designed to operate for 10 million cycles so

they should not require replacement very

often.

Timers Illuminate But Don’t Run

Check the trigger signal cable and make

sure it is connected. If the cable is

connected, disconnect the cable from the

controller and ensure the molding machine

provides a contact closure when expected

by checking the signal between pins A and

C.

If you can see a contact closure between

pins A and C. You can also check for the

presence of 24 volts DC between pins A and

C of the trigger signal connector on the top

of the unit.

Timer(s) Run But Valve(s) Don’t Open

Check cable connection(s) between the

controller and the valve(s). If cable damage

is suspected, replace the cable.

If the valve cable is determined to be good,

check the small fuses on top of the internal

solid state relays. If any of these fuses are

determined to be open, check the affected

zone valves and cable connections for short

D-M-E Company VCTB-4000 Page 6

ED-0109-OT-024-( Preliminarry Rev E)

Page 7

circuits. Replace defective fuses only after

determining that the related valves and

connections are in good order. The

controller was designed to run valves with

coil powers as high as 31 watts.

If the fuses on top of the solid state relays

are good, it is possible that a solid state

relay may require replacement.

Replacement fuses and relays are available

from DME. See page7.

Timer Replacement

If timer replacement appears to be

necessary, we recommend returning the unit

to DME or have it serviced by another

known qualified service technician.

Replacement timers are available from

DME. Use part number RPM-0100.

The replacement timer must be setup

before installation. A small access plate on

the right side of the timer gives access to a

bank of small switches. Open the plate. Set

all switches except switch number four to

“ON”. Replace the damaged timer making

sure to locate all wires in the proper

location. Tighten all unused screws. The

provided instructions also give details on

correct mounting of the timer.

The first time the unit is powered up, set the

timer to “Integrate A” mode by performing

the following: (1) Press and hold the

SET/LOCK button, (2) Press the right most

up or down arrow, (3) Release the

SET/LOCK button, (4) Continue pressing

the right most up or down arrow until “In-A”

is displayed, (5) Press the reset key. The

timer is now ready for use.

OUTPUT CURRENT LIMITATIONS

The controller is designed to power four

valves with a maximum power requirement

of approximately 31 watts each. This is

usually sufficient to power hydraulic valves

typically used with valve gate controls.

CONNECTORS AND CABLES:

The required power and trigger signal

cables are provided with the controller.

RETURN POLICY

The D-M-E® VCTB-4000™ is warranted for 1-year parts

and labor, excluding fuses. Contact D-M-E Customer

Service for return authorization for repairs, or warranties.

Replacement parts are also available through the

Customer Service Department.

D-M-E Customer Service

In U.S.: 1-800-626-6653

In Canada: 1-905-677-6370

SERVICE CENTER U.S.A.

D-M-E WORLD HEADQUARTERS

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS, MICHIGAN 48071

TELEFAX: (248) 398-6174

D-M-E® is a registered trademark of D-M-E Company.

REPLACEMENT PARTS

DESCRIPTION

Fuse 1 and 2 ABC-3

Solid State Relay Fuses

(T5 series, 4 amp, 250

VAC)

Solid State Relay RPM-0099

Replacement Timer RPM-0100

Trigger Cable RPM-0101

CATALOG

NUMBER

RPM-0098

D-M-E Company VCTB-4000 Page 7

ED-0109-OT-024-( Preliminarry Rev E)

Page 8

2

Shield

1

5

2

3

NOTE: TRIGGER INPUT #5 (Customer Connection to Trigger signal dry contact – Injection Forward)

1. Power switch

2. Main Fuses: replace with

3. Power Entry Cord

4. Valve Output Connector

5. Trigger Signal Input

Trigger Signal Connection

TOP PLATE

Bussman ABC-3 only!

Black

Red

A

C

B

Note: Valve Output Valve # 4 Above

PINS 1, 2, 3 and 4 supply +24 VDC Control power to valves 1, 2, 3 and 4, respectively. PIN 13 supplies

ground to all of the valves.

D-M-E Company VCTB-4000 Page 8

ED-0109-OT-024-( Preliminarry Rev E)

Page 9

2

1

INSIDE OF UNIT WITH REAR COVER REMOVED

(AS VIEWED FROM REAR OF UNIT)

1. Solid State Relays (zone 1 closest,

zone 4 furthest)

2. Solid State Relay Fuses (replace

with T5 series, 4 amp, RPM-0098)

Use SET/LOCK button to

(delay) and T2 (on) timers.

Use up and down arrows

to change time values

TIMERS

change between T1

TIMER SETUP

Set all switches except 4

to ON (as shown).

Switches are on right

side of timer behind a

cover plate

TIMER TEST BUTTON

The button below each of the

timers can be used to test the

associated valve. The button

does not activate the timer

D-M-E Company VCTB-4000 Page 9

ED-0109-OT-024-( Preliminarry Rev E)

Page 10

Instructions Installation Instructions for the

VCTBA-01 Valve Gate Control Interface Accessory

( Cable is wired for 8 zones, but only controls 4 zones when connected to the VCTB4000 as shown below )

VCTBA01 shown with 2x8 Polyvalve Assembly VCTBA01 shown connected to VCTB4000 & Polyvalve Assemby

VCTBA01 ACCESSORY: VCTB4000 TO POLIVALVE 2X8 CONNECTOR

D-M-E Company VCTB-4000 Page 10

ED-0109-OT-024-( Preliminarry Rev E)

Page 11

Installation Instructions for the

VCTBA-02 Valve Gate Control Interface Accessory

& Support Accessories VCTBA-03, VCTBA-04 & VCTBA-05

D-M-E Company VCTB-4000 Page 11

ED-0109-OT-024-( Preliminarry Rev E)

Page 12

ASSEMBLY INSTRUCTIONS

Step 1. Assemble the VCTBA03 “VCTB-4000 Mounting Plate”

to the mainframe floorstand using the supplied hardware.

The mounting plate is designed to work with either the standard

“G” Series ® MFS512G or Integrity ® IFSS1000 or IFSA1000

(with or without the upright extension kit IFSE1000).

Step 2. Install the VCTB-4000 mounting studs provided with the

VCTBA03 mounting plate. The mounting plate can accommodate

one, two or three VCTB-4000 controllers.

The photo below illustrates controller positioning.

Step 3. The VCTBA02 interface accessory is to be installed on

the back side of the mounting plate. Use the (4) large flush head

bolts provided in the kit.

Step 3a. The large flush head bolts should be fastened to the

mounting plate using the provided nuts and washers.

Step 3b. When using the VCTBA02 mounted behind the VCTB4000 controllers it will be necessary to install the provided flat

washers behind the (2) center position VCTB-4000 mounting

studs.

D-M-E Company VCTB-4000 Page 12

ED-0109-OT-024-( Preliminarry Rev E)

Page 13

Step 4. Install the VCTBA02 on the studs installed in step 3

above. Note the direction of the control and trigger cables (in the

upward direction).

Step 7. Route and connect each of the three VCTBA02 trigger

cables to the associated VCTB-4000 controllers. A zone number

label identifies the cable ends.

Step 5. Install the supplied zone labels and write the associated

valve gate control zone number in the label box with an indelible

marker. NOTE that each VCTB-4000 four controllers need to be

grouped together. For example, VCTB-4000 #1 will become

zones 1-4, VCTB#2 will become zones 5-8, and so on.

Step 6. Route and connect each four-zone valve control cables of

the VCTBA02 to the associated zoned VCTB-4000 controllers. A

zone number label identifies the cable ends.

Step 8. Connect the TRIGGER INPUT CABLE of the VCTBA02

to the molding machine +24 VDC injection forward signal.

NOTE THAT THE TRIGGER INPUT OF THE VCTBA02 IS

NOT A DRY CONTACT CLOSURE CONNECTION! The

VCTBA02 trigger input requires +24 VDC to trigger the

connected VCTB-4000 controllers.

Step 9. Connect the VCTBA01 eight zone valve control cable to

the standard DB-25 output connector of the VCTBA02, and

connect to the mold valve gate control input connector.

D-M-E Company VCTB-4000 Page 13

ED-0109-OT-024-( Preliminarry Rev E)

Page 14

- OR –

Connect the VCTB04 eight zone control cable to the “alternate”

output connector of the VCTBA02.

P/N: VCTBA05

A twelve-zone control cable connection can be made using the

twelve-zone accessory output mating cable connector kit

VCTBA05.

Step 10. Mount the temperature control mainframe to the

MFS512G mainframe floorstand.

A standard MFP12G is shown above. To mount a standard

MFP8G, use the mainframe adapter plates provided with the

MFS512G floorstand kit.

Alternative Mounting: The VCTBA03 mounting plate can also

be mounted below the standard mainframe as shown above. To

use this mount, the VCTB-4000 mounting studs on the mounting

plate must be installed in the lower position. Also, will be

necessary to route the VCTBA02 control and trigger cables

between the mainframe and mounting plate before either is

mounted to the stand.

D-M-E Company VCTB-4000 Page 14

ED-0109-OT-024-( Preliminarry Rev E)

Page 15

NOTES:

ECN’S:

ECN-0622 Changed Model Number from TGV-4000 to VCTB-4000

ECN-0627 Changed pin out of valve connector

ECN-0651 Changed warranty period from 1 to 3 years

ECN-XXXX Preliminary REV E - Added VCTBA-01, VCTBA-02, VCTBA-03, VCTBA-04,

VCTBA-05 Assembly Instructions.

APPROVAL:

SENIOR PRODUCT ENGINEER: _____________________________ DATE: ______________

MANAGER OF ELECTRONICS: ______________________________ DATE: ______________

D-M-E Company VCTB-4000 Page 15

ED-0109-OT-024-( Preliminarry Rev E)

Loading...

Loading...