Page 1

ME-X741-PS-421(B)

3-14

PSHOT625

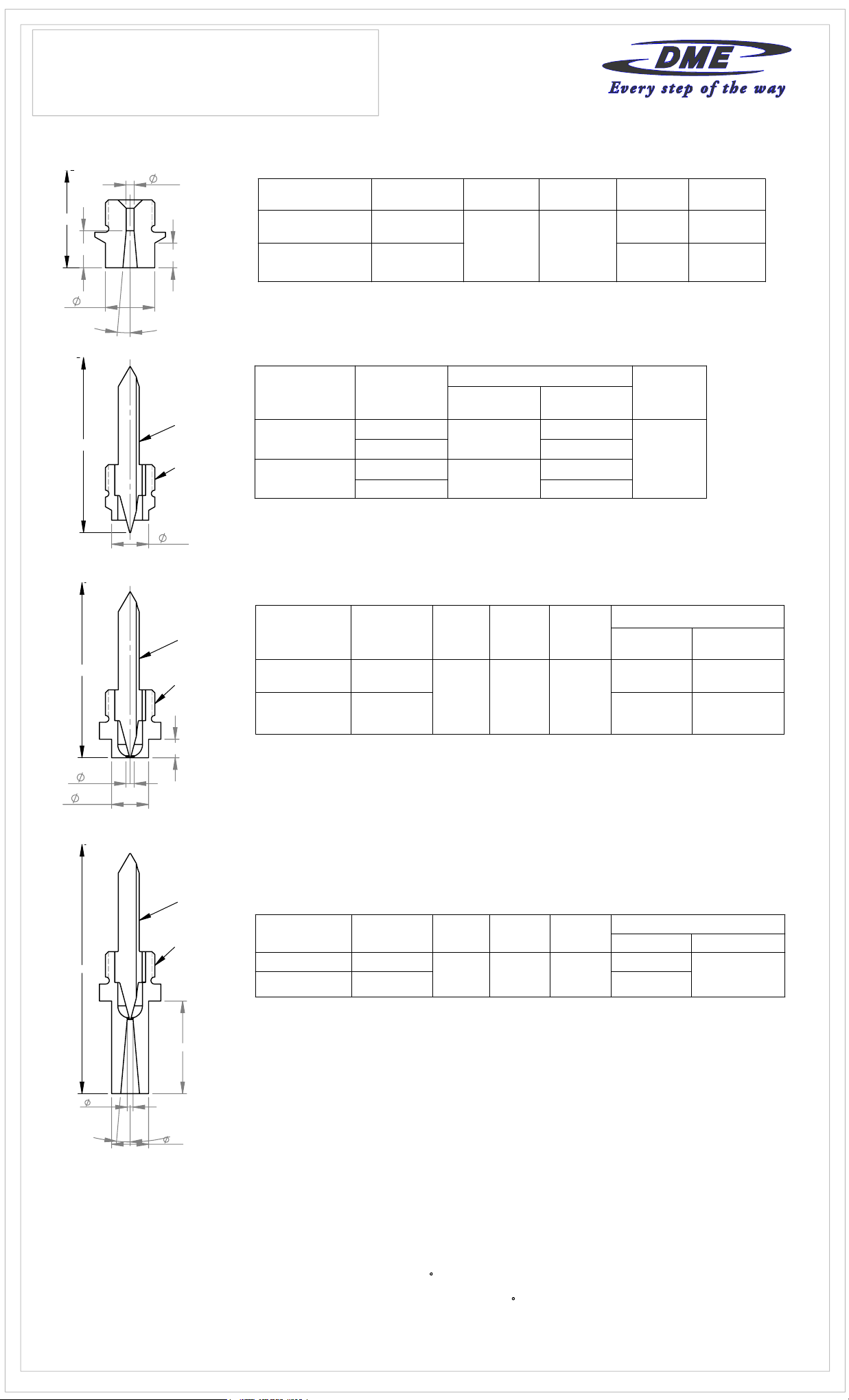

625 SERIES TIP SUB-ASSEMBLIES

PACKING SLIP

Tip Sub-Assemblies

"B"

"A"

"C"

"

A"

"T"

"L"

5°

PER SIDE

NEEDLE

RETAINER TIP

All 625 Series tips have 1"-16 UN threads

Sprue Gate/Extended Sprue Gate

TIP

SPRUE GATE

EXTENDED

SPRUE GATE

ITEM

NUMBER

"B" DIA.

EHT0022

.187

EHT0023

Point Gate (Bodyless)

TYPE

STANDARD

WEAR

RESISTANT

ITEM

NUMBER

EHT1306

EHT1311 EHT0326

EHT1307

EHT1310 EHT1354

NEEDLE

EHN0019

EHN0402

"T" DIA.

1.000

INCLUDES

RETAINER

EHT1354

EHT0326

TIP

"L"

"C"

.250 .500

1.000 1.250

"T" DIA.

.625

"A"

"O"

"T"

"A" + .750

"T"

NEEDLE

RETAINER TIP

"E"

NEEDLE

RETAINER TIP

Point Gate (Full Body)

TYPE

STANDARD

WEAR

RESISTANT

ITEM

NUMBER

EHT2021

EHT2022

"T" DIA.

1.000

Extended Point Gate (Full Body)

TYPE

STANDARD

WEAR

RESISTANT

ITEM

NUMBER

EHT2321

EHT2322

"T" DIA.

1.000

"O" DIA.

.125 .250

"O" DIA.

.125

"E"

"E"

1.000

INCLUDES

NEEDLE

EHN0019

EHN0402

INCLUDES

NEEDLE

EHN0019

EHN0402

RETAINER

TIP

EHT0036

EHT1326

RETAINER

EHN2336

"E"

"O"

5°

PER SIDE

"T"

For selection of gate diameter it is important to take into consideration the materials flow characterisitics, shear rate of resin, molding

conditions, fill time requirements, gate vestiage, wall thickness and configuration of part to be molded. Situations requiring high injection

velocities must be considered when selecting small gate diameters. High injection rates may require larger gates due to shear heat build

up (e.g. high weight thin wall applications). See material manufactures literature for further information regarding materials to be molded.

To compensate for nozzle's growth when heat is applied, the linear expansion of the nozzle (BE) at a given temperature must be added

to the nominal "A" dimension (See catalog for "A" lengths). The formula below shows how to figure boringing depth (dimension "A" + BE)

The tip of the nozzle will now be flush with the cavity line at processing temperature.

Formula for determining this expansion factor is as follows:

BE = "A" dimension x 0.0000063 x (Nozzle set point temperature - 68

EXAMPLE: Given a 4 inch "A" dimension, with a nozzle set point temperature of 500

BE = 4 x 0.0000063 x (500 - 68) = 0.011

Thus "A" + BE will be 4.011

Note: the above information is only given as an example, variations may occour based on mold configurations and cooling factor. In some

instances it may be nessessary to obtain an empirical factor.

F)

F:

Page 2

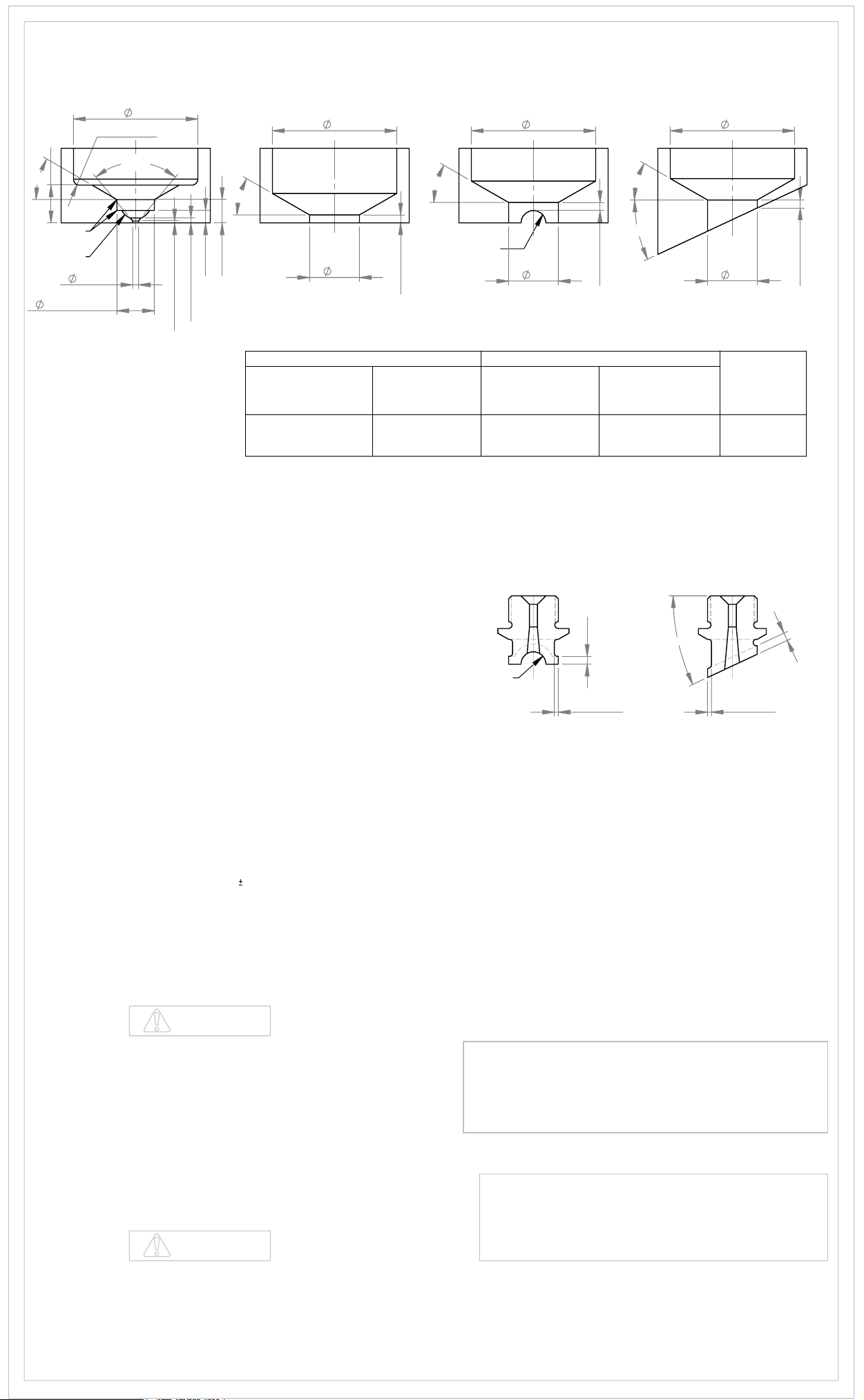

625 SERIES GATE MACHINING DIMENSIONS

0.47

30°

R.010-.015

R.312

0.6250

POINT GATE

(BODYLESS)

"N"

R0.125

80°

"O"

+

0.0005

0.0000

30°

.125

.235

.020 AT TANG.

.005 LAND MAX.

STD. SPRUE AND

POINT GATE

(FULLBODY)

"N"

+.0005

-.0000

"S"

.08 MIN.

"O" DIA.

UNFILLED RESIN

FILLED RESIN

.080 MIN. .100 MIN.

EXTENDED SPRUE

AND EXTENDED POINT

GATE (FULL BODY)

RUNNER DESIGN

30°

CUSTOMER

RADIUS TO

SUIT

+.0005

-.0000

"S"

SQ. COIL OR

CAST-IN

2.125 MAX.

30°

25°

MAX.

.08 MIN.

"N" DIA.

SQ. COIL OR

CAST-IN

1.875 MIN.

EXTENDED SPRUE

AND EXTENDED POINT

GATE (FULL BODY)

ANGLE DESIGN

"N""N"

+.0005

-.0000

"S"

.08 MIN.

"S" DIA.

1.0005

OPERATING & SERVICING INSTRUCTIONS:

All interchangeable nozzles are similar, and differ only in size and material flow

capacity.

OPERATING PROCEDURE

The nozzles are supplied with a Square (Flat) Coil or Cast-In heater equipped

with a Type "J" Thermocouple.

It is recommended to use a DME closed loop Temperature Controller for optimum

temperature control with Step Smart or Smart Step . These systems will allow

heater to dissipate any moisture and then change automatically to set point. It is

essential to use controllers with the proper votage and wattage capabilities. The

voltage and wattage of each heater is clearly marked on the heater tag. Step

Smart , Smart Step and DME are all registered trademark of DME company.

DISASSEMBLY PROCEDURE

1. Nozzle has been designed to have the tip removed in the press.

2. For removal of tip from nozzle, a 6 point deep well socket is recommended. The

nozzle must be at processing temperature and the heater should be turned off

when removing tip counter-clockwise from the nozzle.

ASSEMBLY PROCEDURE

1.Tip and nozzle thread area must be clean of any material before reassembling.

2. Apply an anti-seize compound on the tip threads.

3. Torque tip into the shank of the nozzle body. Torque and untorque two or three

times making sure there is a good contact between the tip and the nozzle.

Torque the tip into the nozzle using 30

point deep well socket is recommended.

5 ft-lbs. For protection of the tip a six

EXTENDED SPRUE

AND EXTENDED POINT

GATE (FULL BODY)

RUNNER DESIGN

MACHINING

.08

CUSTOMER

RADIUS TO

SUIT

Nozzle body head must be keyed to prevent body from turning when tip is

installed into body. Customer to torque tip into shank of nozzle body in mold

three times to set tip before marking the runner or angle on the tip. This will

ensure that the tip will line up after runner or angle is machined onto tip.

Customer may machine relief on Extended Sprue Gate Tips for molding

heat sensitive or engineering grade materials. (see drawings above)

.04-.06 .04-.06

EXTENDED SPRUE

AND EXTENDED POINT

GATE (FULL BODY)

ANGLE DESIGN

MACHINING

25°

MAX.

.08

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise caution

by reading these instructions before servicing or operating the system.

These instrutions must be passed on to the end user where they should be

read before using this product. Failure to do so can result in serious injury or

death.

DANGER

Failure to comply will result in serious injury or death.

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only with

proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout/tag out

before servicing this device. Do not connect temperature sensor to electrical

power. It will damage the product and it could cause fire, severe injuries or even

death.

If green ground wire present, wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use Voltage or power to drive out

residualmoisture before applying full power. Failure to do so may cause damage

to this product.

WARNING

Failure to comply can result in serious injury or death.

STORED ENERY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating ans servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn.

This product has heated surfaces. Use cation when operating ans servicing the

system to avoid severe burns. Proper protective equipment should be worn.

DME SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO

FOLLOW THE ENCLOSED INSTRUCTIONS AND SPECIFICATIONS.

DME HEREBY TO DISCLAIMS ALL IMPLIED WARRANTIES,

INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE IN NO EVENT SHALL DME BE RESPONSIBLE FOR LOSS

OF USE, REVENUE OR PROFIT, OR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGED.

ME-X741-PS-421(B)

3-14

PSHOT625

625 SERIES TIP SUB-ASSEMBLIES

PACKING SLIP

DME

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6653

CANADA 800-387-6600

www.dme.net

Loading...

Loading...