Page 1

ME-G55-0512-G 11-2010 SXP9997

INSTALLATION DATA FOR STELLAR WITH

HIGH PERFORMANCE HEATER

a) SXF5000 or SXF5100 retainer used with

SXT4010, SXT5010 or SXT5200 TIPS

b) SXT1040 - Sprue Tip

Please read carefully before installing

and/or removing nozzle from mold

FOR NOZZLE BODY P/N'S:

SXB4048, SXB4068, SXB4088, SXB4108,

SXB4128 & SXB4148

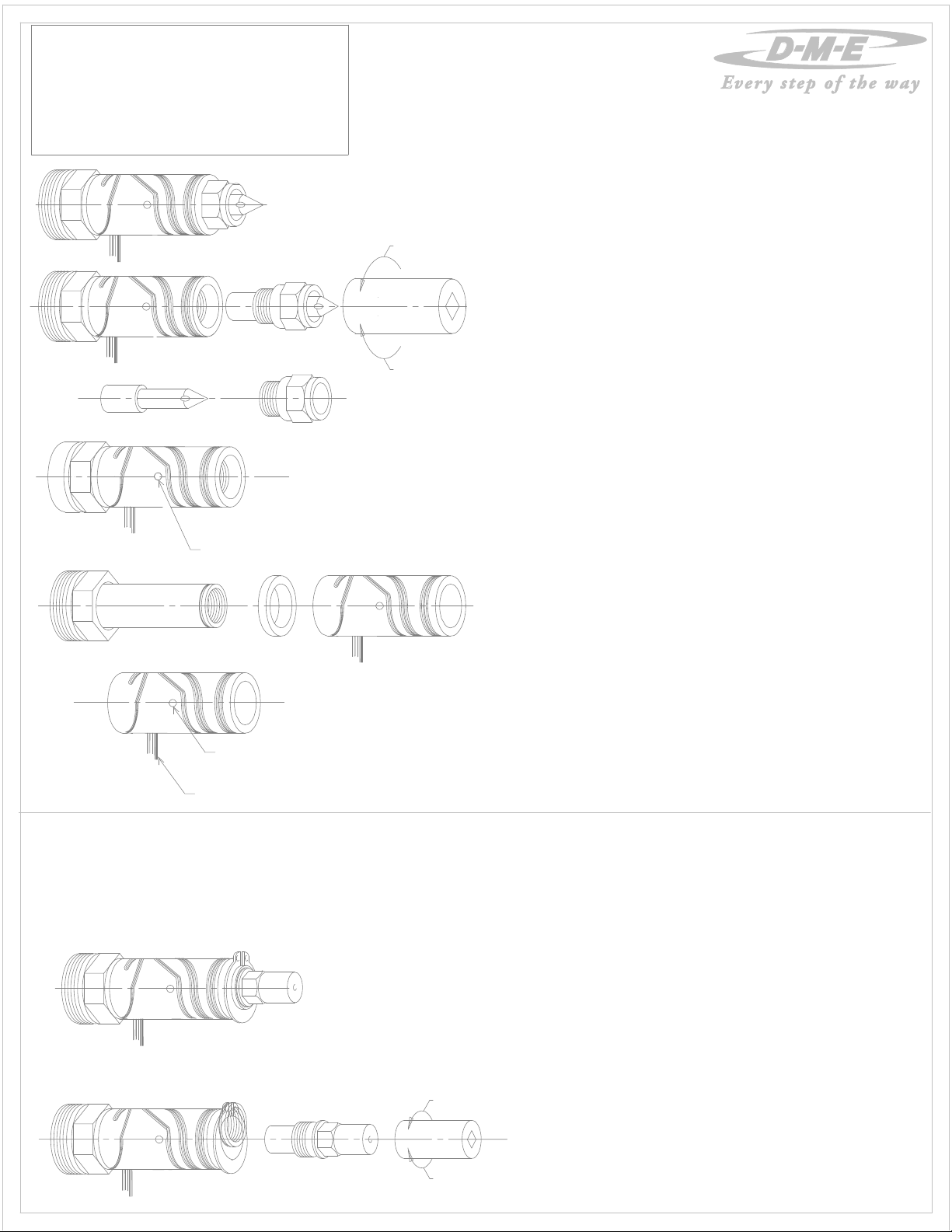

Fig. #1

Fig. #2

Fig. #3

Fig. #4

Removal Holes

Fig. #5

Removal Holes

REMOVE

SXW0003

10mm deep well

6 point socket

ASSEMBLE

10. If the heater is hard to remove use the removal holes placed

11. Bend heater and thermocouple leads only if needed to better fit

12. Slide spacer and heater over nozzle body

13.

14. Assemble tip into retainer.

15. Thread retainer clockwise into the nozzle body and torque to 11.3Nm

(8.3 ft-lbs/100 in-lbs) using DME Catalog No. SXW0003, 10mm

HEATER REPLACEMENT INSTRUCTIONS

FOR POINT GATE AND THRU HOLE TIPS

1. STELLAR nozzle sub-assembly with tip sub-assembly. (see Fig. #1)

Threaded style nozzle with point gate tip shown.

2. Safety glasses and gloves should be worn when working on the mold.

3. Turn nozzle heater on, and set at 10-38°C (50-100°F) below set

point of processing temperature to allow for easier tip removal.

4. Carefully clean plastic material from around tip and retainer.

5. Remove retainer with 10mm deep well 6 point socket turning

counterclockwise.(see Fig. #2) Socket will fit over the front seal

off area when placed on retainer hex.

DO NOT DAMAGE SEAL OFF AREA.

6. Carefully remove tip from retainer. (see Fig. #3) Inspect seal

off area for out of roundness and/or score marks and replace

retainer if either condition occurs. Inspect tip for any wear and

replace if wear has occurred.

7. Clean plastic material from thread and counterbore areas in nozzle

body to ensure proper assembly. (see Fig. #4)

8. Turn off nozzle heater and disconnect heater and thermocouple

leads from connectors on mold. Allow nozzle time to cool down.

9. Remove heater and spacer from nozzle body.

(see Fig. #5)

180 deg apart on the heater body. (see Fig. #4)

Do not use the leads to pull the heater off.

in the wire channel.

For most cases the heater leads will exit into the wire channel.

CAUTION !

REPEATED BENDING OF HEATER AND THERMOCOUPLE LEADS CAN

FRACTURE LEAD WIRES. TRY TO BEND ONLY ONCE, IF POSSIBLE.

(see Fig. #5).

DO NOT LUBRICATE OR USE ANTI-SEIZE ON RETAINER THREADS.

deep well 6 point socket tool and torque wrench. (see Fig. #2)

16. Wire heater and thermocouple leads to connectors on mold.

Fig. #6

T/C wires, Black (+) & White (-)

1. STELLAR nozzle sub-assembly with tip installed. (see Fig. #10)

Threaded style nozzle and sprue gate tip shown.

2. Safety glasses and gloves should be worn when working on the mold.

3. Turn nozzle heater on, and set at 10-38°C (50-100°F) below set

point of processing temperature to allow for easier tip removal.

4. Remove sprue gate tip with a 8mm deep well socket turning

counterclockwise. Do not damage 7mm diameter seal-off area or

front molding surface (see Fig# 11).

5. Clean plastic material from nozzle and tip threads. Also, clean

plastic material from tip counterbore in nozzle body to ensure

proper assembly.

Fig. #10

6. Turn off nozzle heater and allow to cool down.

7. Remove Heater Clip with Snap Ring Pliers.

8. Follow steps #9 to #12 from "Instructions for Point gate and thru hole tips".

REMOVE

8mm

Fig. #11

ASSEMBLE

HEATER REPLACEMENT INSTRUCTIONS

FOR SPRUE GATE TIPS

9. Place Heater Clip onto Nozzle Body using Snap Ring Pliers.

10. DO NOT LUBRICATE OR USE ANTI-SEIZE ON THREADS.

11. Thread tip clockwise into the nozzle body and torque to 16Nm

(12ft-lbs/144in-lbs) using a 8mm deep well socket

and torque wrench

12. Wire heater and thermocouple leads to connectors on mold.

(see Fig#11).

Page 2

ME-G55-0512-G 11-2010 SXP9997

INSTALLATION DATA FOR STELLAR WITH

HIGH PERFORMANCE HEATER

a) SXF5000 or SXF5100 retainer used with

SXT4010, SXT5010 or SXT5200 TIPS

b) SXT1040 - Sprue Tip

Please read carefully before installing

and/or removing nozzle from mold

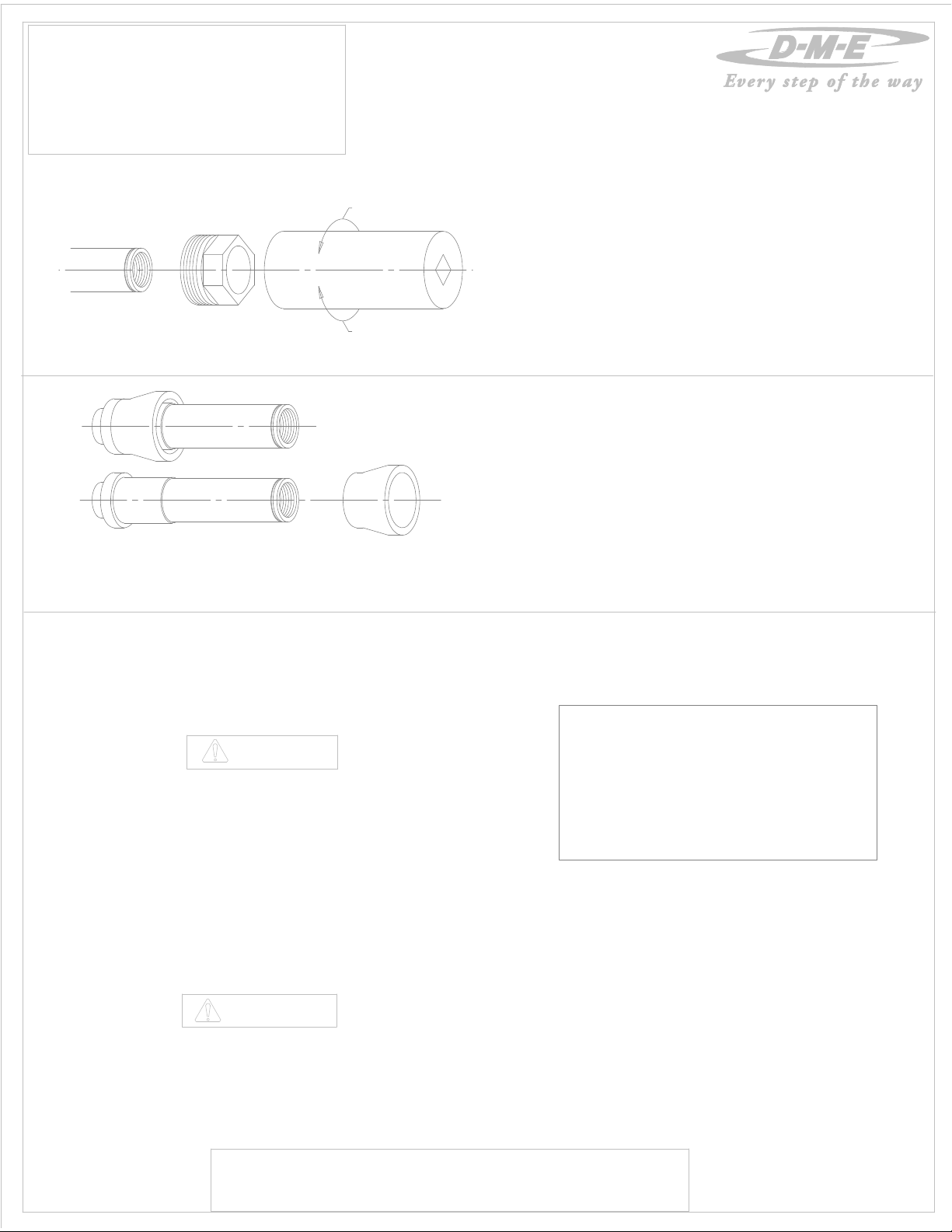

Fig. #7

NOZZLE BODY (THREADED STYLE) REMOVAL INSTRUCTIONS

NOTE: NUT SOCKET TOOL SXW0002 SHOULD BE ORDERED SEPARATELY.

REMOVE

SXW0002

ASSEMBLE

1. Steps #1 thru #9 of Instructions for Point Gate and thru hole tips

must be taken before nozzle can be removed from manifold.

2. Remove nut counterclockwise with socket tool

D-M-E cat. no. SXW0002 (see Fig. #7).

3. Remove nozzle body from manifold.

4. Clean plastic material from thread and counterbore

areas in manifold to ensure proper assembly.

5. Apply high temperature anti-seize compound to nut threads to

prevent galling or seizing. Use Fel-Pro C5A or equivalent

anti-seize compound.

6. Place nozzle body into manifold and thread nut clockwise into the

manifold and torque

to 81Nm (60 ft-lbs) using nut socket tool.

7. Follow steps #11 thru #16 of "Intructions for Point Gate &

Thru Hole hole tips" for final assembly".

8. Reassemble manifold into the mold.

NOZZLE BODY (COMPRESSION STYLE) REMOVAL INSTRUCTIONS

Fig. #8

Fig. #9

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

DANGER

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

1. Steps #1 thru #9 of Instructions for Point Gate and thru hole tips

must be taken before nozzle can be removed from mold.

2. Carefully remove manifold from mold base.

3. Remove nozzle body from manifold.

4. Remove nozzle head from nozzle body (see Fig. #8 & Fig. #9).

5. Carefully clean area where nozzle body and

manifold seat together.

6. Assemble nozzle head and nozzle into nozzle plate.

7. Reassemble manifold into the mold.

8. Follow steps #11 thru #16 of "Intructions for Point Gate &

Thru Hole hole tips" for final assembly.

9. Reassemble manifold into the mold.

WIRING INFORMATION

High Performance Heaters are supplied with 2"

pre-stripped 46" long leads.

Heaters are 230 VAC.

2 power leads are MULTI COLOR

1 ground lead is GREEN.

Thermocouples are "J" Type.

Thermocouples are supplied with 46" long leads.

1 T/C lead is WHITE and negative (-) constantan

(non-magnetic).

1 T/C lead is BLACK and positive (+) iron (magnetic).

WARNING

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn. This product

has heated surfaces. Use caution when operating and servicing the system

to avoid severe burns. Proper protective equipment should be worn.

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

D-M-E COMPANY

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6656

CANADA 800-387-6600

www.dme.net

Loading...

Loading...