Page 1

D-M-E

Pro W eld

™

USER GUIDE

Page 2

D-M-E Pro Weld

™

User Guide

PREFACE

Please read this instruction manual thoroughly before using

your D-M-E Pro Weld™system.

The D-M-E Pro Weld unit is a newly developed resistancetype micro-welding machine. It is powerful enough to weld

0.3mm thick metal sheets and has a wide selection of welding materials in sheet, wire and powder form to choose from.

Applications

♦ Welding can be made to steel molds and dies for plastics,

rubber, die casting, and compression molds.

♦ Welds can be applied on as-rolled steel, pre-hardened

steel, quenched and tempered steel, free cutting steel,

stainless steel, and others.

♦ To build up parting lines, mold seams, 3-point corners

and edges.

♦ To fill in pores, repair of pinholes.

♦ To repair wear, worn areas on slides, ejector pins,

sharp edge molds, and thin core par ts.

♦ To design modification of inser ts and cores.

♦ To add a radius to an inner corner due to a

design change.

♦ To repair the shrinkage that occurs after argon arc

and TIG welding.

♦ To repair damage due to overgrinding, from an

end mill or EDM process.

Page 3

D-M-E

Pro W eld

™

Model No. UMW0001

USER GUIDE

Page 4

2

TABLE OF CONTENTS

Applications

I. Introduction............................................................................5

Advantages 5

II. Specifications........................................................................7

Standard Accessories for Pro Weld™UMW0001 7

Additional Welding Materials 9

III. Parts Nomenclature for Pro Weld UMW0001....................11

IV. General Description of Use ................................................13

IV.1 Function 13

IV.2 Attachment of Electrodes 13

IV.3 Usage of Electrodes 13

➤ Operational Tip 14

IV.4 Start-Up Procedure 14

➤ Operational Tip 16

V. Operation ............................................................................17

V.1 Cautions in Welding Work 17

V.2 Discharge of Stored Energy 18

VI. Welding ................................................................................19

VI.1 Workpiece, Electrode, Welding Materials 19

VI.2 Pro Weld Control Features 20

➤ Operational Tip 21

VI.3 Shaping Electrodes 22

VI.4 Recommended Current Output Levels 23

VI.5 Mold Material/Welding Material 25

VI.6 Pro Weld W elding Process 27

➤ Operational Tip 28

VI.7 Roll Welding Technique 29

Table of Contents

Page 5

3

Table of Contents

VII. Examples of Welding ........................................................ 31

VII.1 Focalization of Current, Electrode Shape 31

and Formation of the Weld Spot

VII.2 Powder Metal Application 32

Welding to a 3-Point Corner, Parting Line, Edge 33

Welding to a Flat Surface 34

Welding an Inner Corner 35

Welding a Pinhole 35

Welding a Crack 36

Welding in a Rib 37

➤ Operational Tip 37

VII.3 Welding of Sheet Material 38

Proper Electrode Contact 38

Positioning of the Sheet Mater ial 38

Welding to a Flat Surface 39

Sheet Material Recession 39

Repair of a 3-Point Cor ner Collapse 40

Repair of a Parting Line or Edge 41

Repair of a Scratch or V-Notched Flaw

and Pinhole 42

Multi-Layer Padding 43

Repair of Base Metal Impurities 45

Repair of an Inner Corner 45

Welding to a Rising Wall 46

Welding to a Narrow or Concave Mold Section 46

VIII. Examples of Bad Welding Work ........................................47

VIII.1 Unconnected Weld Spots 47

VIII.2 Improperly Shaped Electrodes 47

VIII.3 Oxidized Base Metal or Electrodes 48

VIII.4 Bad Conductivity 48

IX. Maintenance Guarantee ....................................................49

Page 6

Page 7

I

I. Introduction

Please read this instruction manual thoroughly before using your

Pro Weld™system.

Pro Weld is a newly developed resistance-type welder. It effectively

builds up material to repair or redesign molds and dies. [Note: It is

not recommended for use on press dies, blow molds (usually made

from aluminum) or aluminum molds.]

The resistance welding method creates high energy discharges in

very short cycles through a capacitance circuit. Almost no heat is

created and, therefore, the base mold material is not altered or

damaged.

The Pro Weld micro welding technique is revolutionizing the repair

of molds by keeping this wor k in-house. Pro Weld welds 0.1mm,

0.2mm and 0.3mm thick metal sheets or strips, metal wire and

metal powder to the damaged area. It is extremely easy to use,

reduces downtime and improves quality.

Advantages

♦ No scaling or flaking occurs after welding as the sheet, wire and

powder metals used are free from impurities, and because the

weld has high strength, homogeneity and reliability.

♦ Easy to operate, no special training necessary.

♦ Hand and machine finishing is easier as the amount of weld

metal is not excessive.

♦ As the process emits almost no heat, there will be no shrinkage,

distortion, deformation or discoloration of the mold.

♦ No welding fumes or toxic gases are emitted.

5

Introduction

Page 8

6

Introduction

I

♦ The process is optimally suited for small areas and micro

welding.

♦ Hardening and plating can be done after welding.

♦ Welding work time is greatly reduced.Roll welding a 3/8" (10mm)

long parting line can be done in 1 minute, treating a pinhole in

30 seconds.

♦ As the capacitor system charges slowly and unloads quickly, an

input power can be used with low loading capacity.

♦ A built-in microprocessor allows stored energy to be easily

adjusted.

♦ High quality selection of welding materials in 0.1 and 0.2mm

thick metal sheet, 0.2-0.5mm diameter wire and powder metal.

♦ After the initial weld, if more padding is required, re-welding

can be done easily.

♦ Pro Weld is powerful enough to weld 0.3mm thick sheet.

Page 9

7

II. Specifications

II

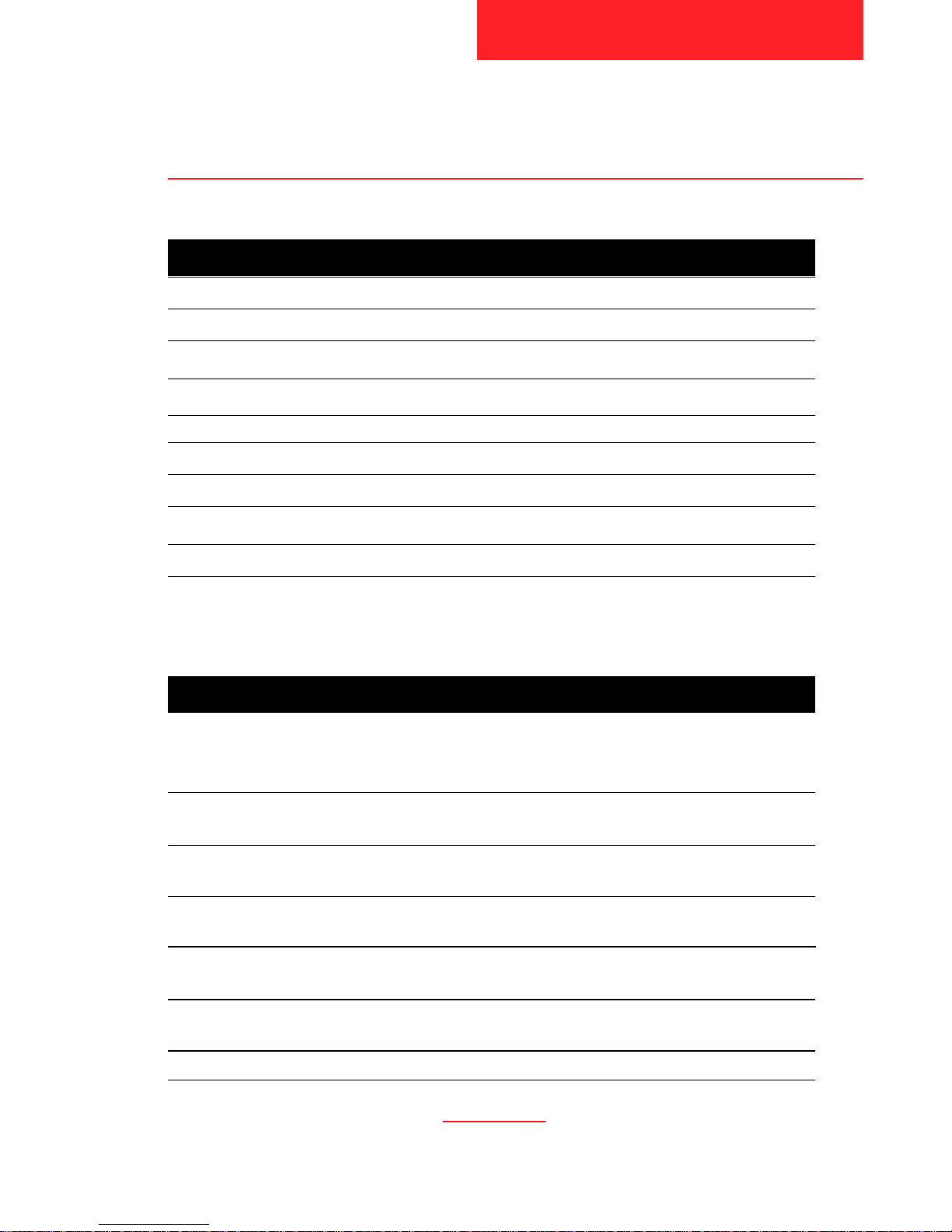

Standard Accessories for Pro Weld UMW0001

Specifications

Power pack with welding cord, grounding

cord and plate, power cord, foot switch and

all accessories listed below

N51–Standard SKH-51 steel powder (50 grams)

(63 Rc; for D-2/M-2/S-7 steels)

N80–Standard NAK80 steel powder (50 grams)

(38-40 Rc; for P-20/P-21 steels)

NAK80–Standard steel sheet (10 sheets,

0.1T x 5W x 100L) (38-40 Rc; for P-20/P-21 steels)

NTA1–Ni Alloy sheet (10 sheets, 0.1T x 30W x 70L)

(135HV; for all steels)

NTA2–Ni Alloy sheet (10 sheets, 0.2T x 30W x 70L)

(135HV; for all steels)

Protective glasses

Catalog No. Description

Complete Pro Weld system includes: (Dimensions in millimeters)

UMW0001

UMW0002

UMW0003

UMW0004

UMW0005

UMW0006

UMW0007

Model Pro W eld UMW0001

Input Voltage 120 VAC

Consumable Power 600 VA

Output Power 700W

Output Voltage 0 - 9V

Output Current 0 - 1100 Amps

Control System SCR Switching System

Auto Timer On 0.5 sec.

Dimensions (inches) W6.5 x D17.75 x H16

Weight 62 lbs

Page 10

Catalog No. Description

II

Specifications

8

Protective gloves

Magnet electrode (2 dia. x 50L)

Magnet electrode (3 dia. x 50L)

Magnet electrode (4 dia. x 60L)

Magnet electrode (4 dia. x 50L)

Standard electrode (2 dia. x 50L)

Standard electrode (3 dia. x 50L)

Standard electrode (4 dia. x 50L)

Standard electrode (1.2T x 5W x 35L)

Standard electrode holder (black)

(used with UMW0015)

Magnet electrode holder (brown)

(used with UMW0011 and UMW0012)

Standard electrode holder (black)

(used with UMW0016)

Standard electrode holder (black)

(used with UMW0013)

Standard electrode holder (black)

(used with UMW0014)

Magnet electrode holder (brown)

(used with UMW0009 and UMW0010)

Tool box

Sheet metal shears

Screw and wrench set

Fuse (2A)

Insulation tape

UMW0008

UMW0009

UMW0010

UMW0011

UMW0012

UMW0013

UMW0014

UMW0015

UMW0016

UMW0017

UMW0018

UMW0019

UMW0020

UMW0021

UMW0022

UMW0023

UMW0024

UMW0025

UMW0026

UMW0027

Standard Accessories for Pro Weld UMW0001 (continued)

Complete Pro Weld system includes: (Dimensions in millimeters)

Page 11

II

9

Specifications

N-11 UMP0067 SKD-11 50 grams Rc 50-60 Min. A-2, D-2

All Die Steels

N-38 UMP0072 HPM38 50 grams Rc 30 Max. 420SS

(Prehardened)

N-39 UMP0073 PD555 50 grams Rc 50-52 STAVAX

N-40 UMP0060 Ni-Cr Alloy 50 grams Rc 36-42 All Mold Steels

N-50 UMP0062 Ni Alloy 50 grams Rc 47-53 All Mold Steels

N-61 UMP0068 SKD61 50 grams Rc 40-53 Max. H-13, 420SS

N-13 UMP0063 Ni Alloy 50 grams Rc 10-15 All Mold Steels

N-90 UMP0061 Ni Alloy 50 grams Rc 16-20 All Mold Steels

SCM, Good Choice

N-14 UMPS017 PHM-2 50 grams Rc 30-35 for P-20

SNCM, Good Choice

N-15 UMPS018 HPM17 50 grams Rc 30-35 for P-20

SNCM, Good Choice

N-16 UMPS019 2767 50 grams Rc 30-35 for P-20

N-55 UMP0071 NAK55 50 grams Rc 38-41 P-21

Welding Material: Fine Powder – Precision Work

Welding D-M-E Japanese Quantity Hardness U.S. Mold Steel

Materials Catalog No. Mold Steel Rockwell C Equivalent

SP-51 UMPS010 SKH-51 50 grams Rc 63 Min. D-2, M-2, S-7

SP-11 UMPS011 SKH-11 50 grams Rc 50 Min. A-2, D-2

SP-61 UMPS012 SKD-61 50 grams Rc 53 Max. H-13

Welding Material: Powder

Welding D-M-E Japanese Quantity Hardness U.S. Mold Steel

Materials Catalog No. Mold Steel Rockwell C Equivalent

Additional Welding Materials for Pro Weld UMW0001

Page 12

10

Specifications

II

Additional Welding Materials for Pro Weld UMW0001

Welding Material:Wire

Welding D-M-E Japanese Hardness U.S. Mold Steel

Materials Catalog No. Mold Steel Quantity / Size Rockwell Equivalent

Welding Material: Sheet

(Dimensions in millimeters)

NT-6 UMA0001 10 / 0.2T x 5w x 100L Rc 30 All Mold Steels

NS-1 UMA0054 SS Alloy 10 / 0.1T x 30w x 70L Rb 90 All Mold Steels

NS-2 UMA0055 SS Alloy 10 / 0.2T x 30w x 70L Rb 90 All Mold Steels

HPM-50 UMD0102 HPM50 10 / 0.2T x 5w x 100L Rc 38-40 P-21 Improved

HPM-38 UMD0107 HPM38 10 / 0.2T x 5w x 100L Rc 30-33 420SS

STAVAX UMD0104 STAVAX 10 / 0.2T x 5w x 100L Rc 50-52 STAVAX,420SS

SCM440,

HPM-2 UMD0101 IMPAX, 10 / 0.2T x 5w x 100L Rc 30-50 P-20

HPM-2

MAS1 UMD0103 10 / 0.2T x 5w x 100L Rc 50-53 P-20

NAK-55 UMD0106 NAK55 10 / 0.2T x 5w x 100L Rc 38-40 P-21

Welding D-M-E Japanese Hardness U.S. Mold Steel

Materials Catalog No. Mold Steel Quantity / Size Rockwell Equivalent

S2 UMA0056 SS Alloy 1 / 0.2 dia. x 5m Rb 90 All Mold Steels

S3 UMA0057 SS Alloy 1 / 0.3 dia. x 5m Rb 90 All Mold Steels

S4 UMA0058 SS Alloy 1 / 0.4 dia. x 5m Rb 90 All Mold Steels

S5 UMA0059 SS Alloy 1 / 0.5 dia. x 5m Rb 90 All Mold Steels

Page 13

11

III

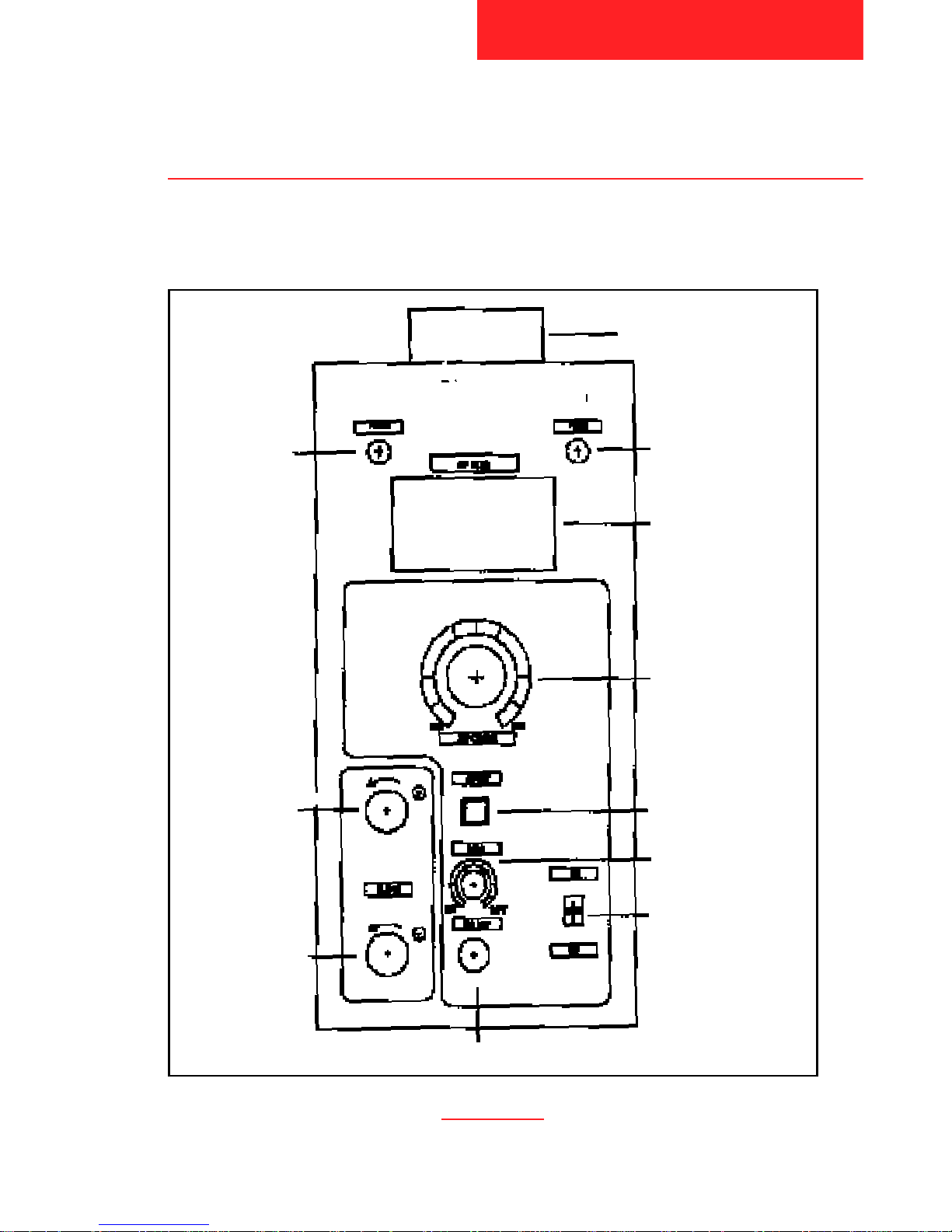

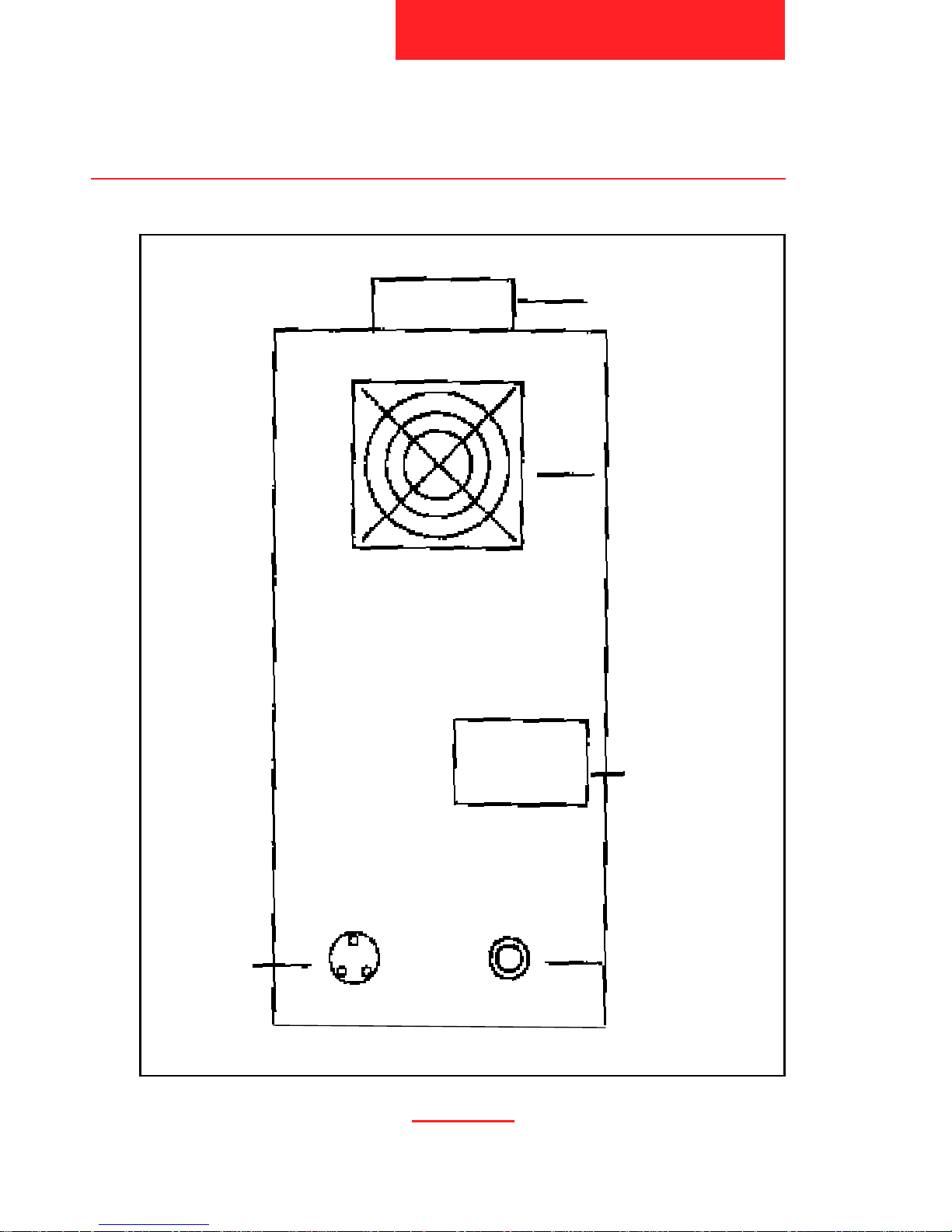

III. Parts Nomenclature for Pro Weld™ UMW0001

Parts Nomenclature for

Pro Weld™ UMW0001

D-M-E Pro Weld

™

Carrying Handle

Amp Output Meter

Slidac Amp

Output Control

Automatic/Manual

Function

Main Power

Switch

Output for

Grounding

Cord

Output for

Electrode

Holder Cord

Power Indicator

Lamp

Timer

Input for Foot Switch

Operation

Mode Lamp

Page 14

III

12

Parts Nomenclature for

Pro Weld™ UMW0001

Carrying Handle

Fan

Specifications and

Serial Number

Plate

Fuse Holder/Fuse

Input Power

Socket

Pro Weld UMW0001 Back Panel

Page 15

13

IV

IV. General Description of Use

IV.1 Function

Electric power is supplied from an AC120V source. As a resistancetype micro-welding machine, Pro Weld stores current in a

capacitance circuit. Current is released by the foot switch and sent

to the electrode in the electrode holder. This release of current

causes the welding material to melt and fuse with the base metal.

IV.2 Attachment of Electrodes to the Electrode Holder

Electrodes are fixed in the Electrode Holders.To use the opposite

end of an Electrode or to replace an Electrode, use the supplied

Allen Head Wrenches. Do not over-tighten;leave approximately

25mm of the Electrode exposed.

IV.3 Usage of Electrodes

Electrodes are of two types: Magnetic Electrodes and Nonmagnetic Electrodes. Magnetic Electrodes are pre-mounted in the

brown Electrode Holders. Use these Electrodes to pick up metal

welding powders and for tacking powders on the mold repair area.

Non-magnetic Electrodes are fixed in the black Electrode Holders.

Use these to tack welding sheet and wire and to weld in place

powders, sheet and wire.

General Description of Use

Page 16

IV

Operational Tip

When using Magnetic Electrodes apply less pressure to

the workpiece. Do not exceed the Amp output guidelines

(see VI.4). To do so could cause the Electrode to demagnetize.

Apply more pressure to the work surface when using

non-magnetic Electrodes. Again, follow the Amp output

guidelines.

Use only Pro Weld Electrodes.The manufacturer does

not accept liability for other manufacturers’ electrodes.

Do not use welding rods in the Electrode Holders

because they may weld to the work surface.

IV.4 Start-Up Procedure

♦ Connect the Electrode Holder Cord to (+) Output, the Grounding

Cord to (-) Output, and Foot Switch to Foot Switch Input on the

Pro Weld according to Parts Nomenclature diagrams (see III).

♦ Check to ensure correct single phase voltage available is the

same as that marked on the specifications plate located on the

rear panel. Connect the power cable to the Main supply and put

Main power switch ON. In the ON position, the Power Indicator

Lamp will illuminate. Once the equipment has been connected as

directed, your Pro Weld is ready to operate.

♦ In the Main ON position, you may select an amperage (power)

output setting. Amperage output setting will be displayed on the

Amp meter. Use the Slidac Amp Output Control knob to

increase/decrease amperage according to the type and size of

14

General Description of Use

Page 17

Electrode selected and by the type of repair to be perfor med

(see Amp output guidelines, VI.4).

♦ With the amperage output selected, connect an Electrode Holder

with Electrode fixed to the Electrode Holder Cord by sliding it on

to the end of the cord until snug (it need not be perfectly flush).

♦ Release of amperage to the Electrode is accomplished by

depressing the Foot Switch on either the Manual or Auto

setting (10).

♦ Welding material is bonded to the base metal by pressing down

firmly on the repair area with the Electrode, then triggering the

Pro Weld with the Foot Switch, in either the Manual or Auto

setting, while slowly rolling the Electrode across the repair area.

All of the welding material must be covered

by the Electrode to ensure a 100% bond.

♦ Rolling the Electrode slowly over the welding material forms

interconnecting scallop-shaped weld spots approximately 1 to

2mm (0.04"-0.08") in diameter. This is the type of weld needed

to ensure complete bonding.

♦ If greater build-up is desired, repeat the process over the initial

build-up area, by applying another layer of powder, sheet or wire.

Pro Weld will weld 0.3mm thick metal sheet but best results are

achieved if the sheet is welded in 0.1mm thick increments.

♦ No finishing is required between applied layers; an unlimited

number of layers can be applied.

♦ Finishing of any repair area can be done by standard methods

including EDM, grinding, machining, plating, ultrasonic polishing,

or hand stoning and lapping. Diamond laps work well as all

repairs are in the hardened state.

15

IV

General Description of Use

Page 18

Operational Tip

Be sure the Electrode Holder Cord and Grounding

Cord are fully tightened in their respective sockets. If

not completely tight, conductivity will be lost resulting

in bad welding.

16

General Description of Use

IV

Page 19

17

V

V. Operation

V.1 Cautions In Welding W ork

Each Pro Weld has a caution sticker applied to the top of the unit.

Please follow these guidelines before operation:

♦ Wear the supplied goggles during operation.

♦ Both the Pro Weld and its associated cables create strong mag-

netic fields around them.To avoid any problems, please ensure

that neither the mold welder or machine cables are used in close

proximity to:

–People with medical devices like Pacemakers.

– Magnetic products such as magnetic cards, floppy discs,

audio and video tapes.

– Electromechanical devices such as watches, clocks

and televisions.

♦ Do not remove the mold welder cover.The unit’s transfor mer

carries high voltage.

♦ Ensure the welder is properly grounded.

♦ Main voltage must not exceed + or – 10% from the voltage stated

on the Specifications Plate on back panel.

♦ Unit must be cooled for 20 minutes following 60 minutes of

continuous operation. Leave the unit ON while fan is running.

♦ If the Electrodes become too warm while welding, use the

supplied gloves to protect fingers.

Operation

Page 20

18

V

V.2 Discharge of Stored Energy

Resistance type micro welding machines store voltage in condensers. It is impor tant to discharge the stored voltage when the unit is

not in use to avoid any danger and to save energy. Except at the

time of welding (which is done by the discharge of stored voltage),

Pro Weld has a special circuit which discharges the stored voltage

automatically 10 minutes after the machine’s Main Power Switch is

turned OFF.

Operation

Page 21

19

VI

VI. Welding

In welding work using a Pro Weld unit, only the duration of each

pulse (current discharge) is a constant.The variable factors are:

♦ the welding current

♦ electrode-applied pressure

♦ surface condition of the base metal, and

♦ selection of welding materials

VI.1 Workpiece, Electrode,Welding Materials

♦ Clean the mold surface of oil contamination. Remove oil on the

workpiece with acetone or some other alcohol absorbent. With a

brass or steel brush, remove any oxidation.

♦ Clean and smooth the Electrode surface with a fine emery cloth

before welding unless the Electrode is new (previously unused).

♦ Use fine emery cloth on the Copper Grounding Plate to ensure

good contact with the mold surface.

♦ Clean the welding material of oil with acetone or some other

alcohol absorbent and remove oxidation with a fine emer y cloth.

♦ Place the mold on top of the Grounding Plate. Better power

transfer and welding will be achieved if the Grounding Plate

is fixed close to the area to be repaired. Fix in place with a tension bolt, magnet or clamps. Small molds and inser ts should be

Welding

Page 22

20

VI

secured in a vise with the Grounding Plate close to the repair

area. (FIG. 1)

♦ Cut the welding material to the proper size of the area to

be repaired with supplied sheet metal shears. Place on

workpiece. (FIG. 2)

VI.2 Pro Weld Control Features

Manual Function

1. Select the Manual Function by pushing the Automatic/Manual

Function (10) so that the push button light does not illuminate.

If this button light is illuminated, the unit is in the Automatic

welding mode.

2. The manual mode is used for tack welding metal powder in

place with a magnetic electrode or metal strip or wire in place

with a standard (non-magnetic) electrode.

Welding

FIG. 1

GoodGood

GoodBad

Good

Bad

Page 23

21

VI

Operational Tip

It is important when using the Manual Function to

depress the Foot Switch correctly and in a timely fashion.

Each time the Foot Switch is depressed, current is discharged to the Electrode. If the Foot Switch is repeatedly

depressed too fast (in quick succession), the unit will not

produce a good weld.

Automatic Function

♦ Select the Automatic Function by pushing the Automatic/Manual

Function (10) so that the push button is illuminated.

♦ The Automatic mode is used for “roll-welding” weld material that

has been tacked in place. Roll welding can be done with either

magnetic or standard electrodes.

♦ In the Automatic mode, Pro Weld discharges current in constant

intervals according to the Timer Function setting.For constant

current discharges, depress the Foot Switch and leave depressed

until a new wrist position must be started in the roll welding process (see VI.7 Roll Welding Technique). Lift your foot from the Foot

Switch each time you finish a roll and before lifting the Electrode

off the weld surface to prevent excessive spar king.

Operational Tip

After roll welding powder welding material with a

magnetic Electrode, use a bare (without additional

welding material) standard Electrode with a slightly

stronger output current setting and re-roll weld the

repair area. Using this technique will create a stronger

weld. Be sure the entire repair area is covered while

re-roll welding (see Current Settings Chart VI.4).

Welding

Page 24

22

VI

Timer

1. The Timer will adjust the inter vals at which the current is

discharged.

2. The duration of each Pro Weld pulse (discharge) is 0.0040

second.

3. Tur ning the Timer knob from Slow to Fast will increase the

frequency at which each pulse is released.

4. Generally, the “Slow” settings are used when the Pro Weld unit

will be used to weld for a long time. The “Fast” settings are for

short-ter m welding lasting for several minutes.

5. As an operator becomes more accomplished, he may prefer

to operate the unit using only the Fast settings.

Fast – 300 pulses per minute

Moderate – 200 pulses per minute

Slow – 150 pulses per minute

Note: The Pro Weld’s thermal protection mechanism automatically reduces pulse rate

when the unit’s optimal internal operating temperature is exceeded. The unit will

automatically resume selected pulse rate when the unit senses it is again operating within its optimal internal temperature range. Pro Weld’s thermal protection

mechanism will not adversely affect welding results.

VI.3

Shaping of Standard (Non-magnetic) Electrodes

Although the original shapes of the Pro Weld Standard Electrodes

can do all the welding, it is recommended that the tips be shaped to

conform to the mold surfaces to be repaired.* This will improve the

efficiency of the welding process.The ver y tip of an Electrode

should have a small round curve (0.2 to 0.5mm).See FIG. 3. When

the tip is too sharp, the flow of current will concentrate to the tip and

Welding

*Magnetic Electrodes cannot be shaped without their losing magnetism.

Page 25

cause excessive spar king. Standard Electrodes are made of a silver

alloy and can be easily shaped using diamond hard tools and

emery paper.

Shape examples of the Flat Electrode, Fig.4

VI.4 Recommended Current Output Levels

Amperage output levels used during welding will vary according to:

– The type of mold repair to be welded.

– The type of welding material used for a repair.

– The type and diameter of the Electrode used for a repair.

To obtain a good strong weld, it is impor tant to acquire optimal

current values.Use the following chart as a guide to amperage

settings.While welding, keep a note pad handy and note the

optional current values used after obtaining a good weld.Amperage

output is adjusted by turning the Slidac Amp Output Control.Turning

to the right increases Amp output. Amperage levels are

indicated digitally on the Amp Meter.

23

VI

Welding

FIG. 3

FIG. 4

Good

Bad

Ra

Ra = 0.2-0.5mm

Page 26

Sheet

Mold Electrode Powder Material Wire

Repair Type Diameter 1-0.2mm 1-0.1mm Material

Tack Welding 2 200-300 300-500

Roll Welding with electrode 2

angled at 45° 3 200-400 400-600

4

5 300-500 500-700 700-900

Roll Welding with round 2

electrode angled at 10° 3 300-500 500-700

4

5 400-600 600-800 800-1000

Roll Welding to a flat 2

surface inclined at 45° 3 300-500 400-600

4

5 400-600 500-700 900-1200

Spot Welding to a flat surface 2

3 200-400 400-600 900-1100

Re-Welding powder

material. After welding

2 300-500 300-500

powder, re-weld with a

bare standard electrode

4 400-600 400-600 900-1200

for a stronger weld period.

5

Current (Amperage) Settings for Welding

24

VI

Welding

Page 27

VI.5 Mold Material/Welding Material

Pro Weld welding materials are in powder, sheet metal and wire

form. Each has a different hardness and metal mold application.

Generally, the powders, and sheets supplied standard with

Pro Weld produce a strong homogenous weld on most large

and small molds. Molds producing small par ts and made of harder

alloys should be welded using UMW0002 powder (supplied with

Pro Weld) or harder sheet material (see Welding Materials Chart

below).

Matching the base metal hardness to the welding material hardness

will produce the ideal weld but using the above described procedure

produces very good weld results.

The following charts list all the welding materials available for

Pro Weld.

25

VI

Welding

SP-51 UMPS010 SKH51 50 grams Rc 63 Min. D-2, M-2, S-7

SP-11 UMPS011 SKH-11 50 grams Rc 50 Min. A-2, D-2

SP-61 UMPS012 SKD-61 50 grams Rc 53 Max. H-13

Welding Material: Fine Powder - Precision Work

Welding D-M-E Japanese Hardness U.S. Mold Steel

MaterialsCatalog No. Mold Steel Quantity Rockwell C Equivalent

Page 28

26

VI

Welding

Welding D-M-E Japanese Hardness U.S. Mold Steel

MaterialsCatalog No. Mold Steel Quantity Rockwell C Equivalent

N-11 UMP0067 SKD11 50 grams Rc 50-60 Min. A-2, D-2

All Die Steels

N-38 UMP0072 HPM38 50 grams Rc 30 Max. 420SS

(Prehardened)

N-39 UMP0073 PD555 50 grams Rc 50-52 STAVAX

N-40 UMP0060 Ni-Cr Alloy 50 grams Rc 36-42 All Mold Steels

N-51* UMW0002 SKH51 50 grams Rc 63 Min. D-2, M-2, S-7

N-50 UMP0062 Ni Alloy 50 grams Rc 47-53 All Mold Steels

N-61 UMP0068 SKD61 50 grams Rc 40-53 Max. H-13, 420SS

N-13 UMP0063 Ni Alloy 50 grams Rc 10-15 All Mold Steels

N-80* UMW0003 NAK80 50 grams Rc 38-40 P-20, P-21

N-90 UMP0061 Ni Alloy 50 grams Rc 16-20 All Mold Steels

SCM, Good Choice

N-14 UMPS017 PHM-2 50 grams Rc 30-35 for P-20

SNCM, Good Choice

N-15 UMPS018 HPM17 50 grams Rc 30-35 for P-20

SNCM, Good Choice

N-16 UMPS019 2767 50 grams Rc 30-35 for P-20

N-55 UMP0071 NAK55 50 grams Rc 38-41 P-21

Welding Material: Powder

Welding D-M-E Japanese Hardness U.S. Mold Steel

Materials Catalog No. Mold Steel Quantity / Size Rockwell Equivalent

S2 UMA0056 SS Alloy 1 / 0.2 dia. x 5m Rb 90 All Mold Steels

S3 UMA0057 SS Alloy 1 / 0.3 dia. x 5m Rb 90 All Mold Steels

S4 UMA0058 SS Alloy 1 / 0.4 dia. x 5m Rb 90 All Mold Steels

S5 UMA0059 SS Alloy 1 / 0.5 dia. x 5m Rb 90 All Mold Steels

Welding Material:Wire

*Supplied with Pro Weld unit.

Page 29

27

VI

VI.6 Pro W eld Welding Process

A. Having selected an Electrode Holder with Electrode and

set the Amperage Control Knob to the desired output level

(see IV.4), tack (fix) the weld material to the workpiece using

the Manual (single pulse) setting. Firmly push the Electrode

onto the weld material and trigger the current discharge by

depressing the Foot Switch. Lift your foot from the Foot Switch

and move the Electrode to another spot on the

weld material. Depress the

Foot Switch

to tack the material down.

Repeat this process to tack at each end of

the weld material and at other points as needed

according to the length of the weld sheet.

Welding

FIG. 5

NT-6 UMA0001 10 / 0.2T x 5w x 100L Rc 30 All Mold Steels

NS-1 UMA0054 SS Alloy 10 / 0.1T x 30w x 70L Rb 90 All Mold Steels

NS-2 UMA0055 SS Alloy 10 / 0.2T x 30w x 70L Rb 90 All Mold Steels

NAK-80* UMW0004 NAK-80 10 / 0.1T x 5w x 100L Rc 38-40 P-20, P-21

NTA-1* UMW0005 Ni Alloy 10 / 0.1T x 30w x 70L HV135 All Mold Steels

NTA-2* UMW0006 Ni Alloy 10 / 0.2T x 30w x 70L HV135 All Mold Steels

HPM-50 UMD0102 HPM50 10 / 0.2T x 5w x 100L Rc 38-40 P-21 Improved

HPM-38 UMD0107 HPM38 10 / 0.2T x 5w x 100L Rc 30-33 420SS

STAVAX UMD0104 STAVAX 10 / 0.2T x 5w x 100L Rc 50-52 STAVAX, 420SS

SCM440,

HPM-2 UMD0101 IMPAX,HPM-2 10 / 0.2T x 5w x 100L Rc 30-50 P-20

MAS1 UMD0103 10 / 0.2T x 5w x 100L Rc 50-53 P-20

NAK-55 UMD0106 NAK55 10 / 0.2T x 5w x 100L Rc 38-40 P-21

Hardness

Welding D-M-E Japanese Roc

kwell U.S. Mold Steel

Materials Catalog No. Mold Steel Quantity / Size Vickers (HV) Equivalent

*Supplied with Pro Weld unit.

Welding Material: Sheet (Dimensions in millimeters)

Page 30

B. Turn the Auto(matic) Function to ON.Firmly push the Electrode

on the weld material. Depress the Foot Switch

and keep it depressed while slowly rolling (see VI.7, Roll Welding Technique) the electrode along the length of the

weld material. Pro Weld will continually discharge and form

overlapping weld spots (FIG. 6).

0.1-0.2mm

FIG. 6

The speed at which you roll across the weld material should be a

constant 0.1~0.2mm ever y discharge. This procedure will ensure

the strongest weld by automatically bonding the weld material to the

mold surface.

Operational Tip

Good conductivity results in a good weld. It is impor tant

to clean the surfaces of the repair area of the mold, the

mold surface in contact with the Grounding Plate, the

Grounding Plate itself, the Electrode and the Weld sheet

material.The copper Grounding Plate should be firmly

against the base metal and the Plate screw firmly tightened.This will promote good welding and reduce the

chance of spark occurring.

28

VI

Welding

Page 31

VI.7 Roll Welding Technique

A. With the Pro Weld micro welder, proper weld padding is

obtained by rolling the Electrode across all surfaces of the

weld material.This technique may take some practice.

B. It will be helpful to hold the Electrode Holder like a pencil with

the forefinger or middle finger touching and pressing on the

Electrode itself.This will ensure that proper pressure is being

applied against the weld material during machine discharge

(welding). Do not apply too much pressure to the Electrode.

Rather, try to develop a feeling with your fingers as if you can

feel the Electrode sink into the welding material upon current

discharge. Holding the Electrode Holder like a pencil will also

help you guide the Electrode across the weld material surface.

Further control can be obtained by using finger(s) from the

other hand also pressed against the Electrode.

C. Control over the “roll-welding” process is important to gain a

strong and homogenous weld. Control will also keep the

Electrode on only the weld material, and with the right amount

of pressure. Failure to use pressure on the weld mater ial

and/or rolling off the weld material onto the base metal while

the Pro Weld is discharging (Foot Switch depressed) will

cause the unit to spark. Spar king can pit the weld material,

causing a pin-hole or minor depression in the base material.

D. While roll welding, if the Electrode becomes uncomfortably

warm (this is a function of the amount of amperage selected

and the length of time the unit is allowed to constantly

discharge this current), use the supplied gloves to insulate

the fingers.

29

VI

Welding

Page 32

30

VI

E. Proper roll welding is accomplished across a strip of weld

material by holding the Electrode Holder as described above.

Then, starting at one end of the weld material, tur n your wrist

as far as comfortable in one direction and roll turning the wrist

as you roll as far as comfor table in the opposite direction. Lift

your foot off the Foot Switch each time you finish a roll and

before lifting the Electrode off the surface. This will prevent the

possibility of sparking. Continue to weld where you stopped

with the Electrode by turning your wrist again and rolling to the

opposite direction. A strong weld is obtained by rolling across

all of the weld material surface to for m overlapping weld spots.

Welding

Page 33

31

VII

VII. Examples of Welding

VII.1 Focalization of Current, Electrode Shape and Formation

of the Weld Spot

Examples of Welding

Good O Bad X

FIG. 8

Electrode Shape

Ra=0.2-0.5mm

FIG. 9

FIG. 7

Current Dispersion

Good O Bad X

Page 34

32

VII

Formation of the Weld Spot

The size of the weld spot for med dur ing roll welding will vary with

amperage output value, the end-shape of an Electrode and the

applied pressure. Generally the spot formed will be 0.2~1.0mm in

diameter per machine current discharge. Progression along the

weld is made so that one spot over laps another by half its diameter.

A second weld line should over lap the first by half in diameter as

should a third line.Welding a second layer should be done in the

same manner.

VII.2 Powder Metal Application

Powder metal is an excellent material for welding on corners,

edges and for repairing pinholes and cracks. Powder metal will

form a stronger weld for these applications than will sheet material. Powder welding is done in two steps. Using a magnetic

Electrode to pick up the powder, tack the powder in place and/or

roll weld the powder along a parting line or edge.The next step is

to re-roll weld the area using a bare standard Electrode.This two

step procedure will create a strong and completely homogeneous

weld.

Examples of Welding

D=0.2-1.0

FIG. 10

Page 35

33

VII

Welding to a 3-point corner, par ting line, edge

Roll the Electrode on a 3-point corner at various angles to ensure

weld build-up at all points of the corner. Re-roll weld with a bare

Electrode after the first layer. If second or third layers are needed,

also re-roll weld between layer applications. This will ensure a

strong weld.

Roll the Electrode along an edge or parting line in a clockwise

and counterclockwise direction to obtain weld build-up. Hold the

Electrode at different angles while rolling to cover all areas of

the repair.

Examples of Welding

FIG. 11

FIG. 12

Page 36

Welding to a Flat Surface

♦ Put a small amount of powder onto the part to be welded.

Using a standard Electrode with its end shaped like a ball point

pen (magnetic Electrodes cannot be shaped without their losing

magnetism), weld the powder down spot by spot.

♦ With a round Electrode whose edge has been shaped with a

small radius, roll weld the repair area.This Electrode can also

be used for the bare re-roll welding of the area.

Welding an Inner Corner

34

VII

Examples of Welding

FIG. 13

Page 37

♦ Put a small amount of powder onto an inner corner and use

a flat Electrode shaped like a spatula to weld the first layer

down (FIG. 14a).

♦ To add a second layer of powder material use an Electrode

with its end shaped like a ball point pen and weld spot by spot

(FIG. 14b). Also use this Electrode for bare re-roll welding.

Welding a Pinhole

Put a small amount of powder into the

hole and then for best results add a

small piece of sheet material on top of

the hole.Weld both mater ials with a

tapered Electrode. If the repair is a

deep blowhole caused by argon welding, first hammer a centering punch

into the pinhole.This expanded hole

can now have powder put into it.

Welding a Crack

For repairing cracks, first groove the crack before placing powder or

35

VII

Examples of Welding

FIG. 14

a b

FIG. 15

Page 38

welding.

Fill and weld the crack in approximately 0.15mm thick layers. Weld

one layer and then another and so on. Wire welding material is also

effective in filling and repair ing cracks.

Welding in a Rib

♦ The rib opening can be welded using a 2mm Electrode

36

Examples of Welding

VII

FIG. 16

FIG. 17

3

2

1

Page 39

VII

(UMW0013) or one shaped to a smaller diameter.

♦ For a flaw on the side of a r ib, apply powder onto the area and

use a flat Electrode with its end thinned/dressed as necessary.

♦ For flaws at the bottom of a r ib, apply powder as above and

weld with a flat electrode with its end thinned as needed.

Operational Tip

Magnetic Electrodes cannot be shaped without losing

their magnetism.To wear these Electrodes down as little

as possible, clean them when it becomes necessary

using fine sand paper. Some weld repairs will require

the use of a shaped standard (non-magnetic) Electrode.

To use powder material in a confined space, make a

paste by dipping the shaped Electrode into a drop of

light machine oil and then into the powder material.

Alternately, powder can be placed into a confined

area with, for example, an Ejector Pin that has been

magnetized.

VII.3 Welding of Sheet Material

37

Examples of Welding

FIG. 18

Page 40

Proper Electrode Contact

While welding sheet material, it is important to keep the Electrode

on the sheet to avoid sparking which could cause minor damage

to the base material.

Positioning of the Sheet Material

The sheet material should be slightly larger than the repair area

and extend beyond the edge of the area to be repaired. This is

true whether the repair is an edge, concave surface, v-notched

flaw or pinhole.

Welding to a Flat Surface

♦ Position the sheet mater ial on the repair area to be welded. Set

38

Examples of Welding

VII

FIG. 19

Good Bad

Good Bad

a = -0.5 -1.0mm b = 0 -1.0mm

a b a b

Page 41

VII

the Pro Weld to Manual Function and tack the material in place

(see FIG. 19). Be sure the Electrode end is in a rounded shape.

♦ Using a round Electrode, its edge shaped with a small radius,

include the Electrode and roll weld the sheet material. For best

results, the first layer should be

0.1mmT sheet material.The

second layer can be either 0.1T

or 0.2T. Re-roll welding the area

with slightly higher amperage

setting will strengthen the weld.

Sheet Material Recession

Sheet Material will recess 15~30%

when welded. For example,

in FIG. 21 below, if the sheet mater ial (d) = 0.2mm, after welding

(c) will = 0.15mm.Take this into consideration when doing

build-up repair or design changes.

Repair of a 3-Point Corner Collapse

This repair can be done with either powder or sheet material.

A powder repair is

39

Examples of Welding

FIG. 20

d

FIG. 21

d

c

Page 42

described in VII.2 (see FIG.22).

Repairing a 3-point corner with sheet mater ial, use the profile (side)

of a round Electrode or the side of a flat square shaped Electrode.

Cover all of the weld mater ial moving the Electrode in various

directions (see FIG. 22 and 23 below). Re-roll weld the material

at a slightly higher amperage setting to strengthen the weld. If a

second and third layer is applied, use the same procedure used

with the first layer.

Repair of a Parting Line or Edge

40

Examples of Welding

VII

FIG. 23

Movement of the Electrode in Top View

FIG. 22

Movement of the Electrode in Side View

Page 43

VII

Using the Pro Weld Sheet Metal Shears, cut a strip of sheet material large enough to cover the parting line or

edge. Set the Pro Weld to Manual Function

and tack the strip in place.Then, set Pro

Weld to Auto and, with the profile (side) of

a round Electrode, roll weld the material

ensuring that each weld spot half overlaps

the next.This should also be the case if a

second layer is added and when re-roll

welding.

Weld the strip in the 1 to 4 sequence depicted in FIG.

25 below.

Movement and angles of Electrode in side view

Repair of a Scratch or V-Notched Flaw and Pinhole

41

Examples of Welding

FIG. 24

FIG. 25

Page 44

FIG. 26

If the flaw to be repaired is more that 1mm in width or diameter,

multiple layers of sheet material must be applied in the sequence

shown in FIG. 27 below.

FIG. 27

A pinhole can be repaired using powder, sheet material or a combination of both.When using sheet material, if the hole diameter is

less than 1mm, press weld the material directly into the hole (see

FIG. 28 below).

Small diameter pinhole

FIG. 28

To repair a pinhole larger than 1mm in diameter, weld in layers. First

42

Examples of Welding

VII

Page 45

weld a small piece of material into the bottom of the pinhole and

then a full-size piece of material over the first weld.

Large diameter pinhole

FIG. 29

An alternate method of pinhole repair is done by hammering a center punch into the pinhole and onto the sheet material at the same

time. Place this material onto the pinhole and with a tapered round

Electrode tack weld the piece in place.Next and with less current,

incline and roll the Electrode around the hole for 5 or 6 discharges

of current. Use the same procedure for a second layer.

Multi-Layer Padding

Proper multi-layer padding will take some time as each layer must

be tack welded at many points and then thoroughly roll welded. Tack

weld with a round Electrode tapered and rounded like a ball point

pen.

For complete welding to the base metal, use 0.1mmT sheet material

in the first layer. Before the second layer is applied, the surface of

the first layer should be evened (flattened) out using a file. Follow

this procedure also before the welding of a third layer.This procedure will ensure a strong weld without any pockets of improperly

welded material.

VII

43

Examples of Welding

Page 46

To ensure a good, strong weld on the first layer, roll weld with a

2mm or 3mm diameter tapered Electrode with its end rounded like

a ball-point pen. For the second layer, roll welding can be done with

a round Electrode, its edge shaped with a small radius.

FIG. 30

When two pieces of sheet material are used on the same metal

face, weld the sheet mater ial par ting line with a narrow strip of

additional material.

FIG. 31

At any time during multi-layer padding or other types of welding

repairs where it is important that surrounding areas to the weld not

be touched by the Electrode, use the supplied Masking Tape and

cover those areas.

FIG. 32

44

Examples of Welding

VII

Page 47

VII

Repair of Base Metal Impurities

If the base metal surface is found to have impurities due to nitriding

etc., grind the surface by 0.1mm and then weld sheet mater ial onto

it. Add another layer as needed.

FIG. 33

Repair of an Inner Corner

To weld at an inner corner, use a length of wire material 0.2~0.4mm

in diameter. Tack the wire in place using an Electrode with its end

shaped like a ball-point pen.Weld the wire in place by using the

same Electrode and welding spot-by-spot or with a flat Electrode

shaped like a spatula with its edge rounded. Roll the Electrode from

its point down onto its side along the wire material.

FIG. 34

45

Examples of Welding

a=0.1mm

a

Page 48

Welding to a Rising Wall

In a confined area where a rising wall needs to have material

build-up, it may not be possible to roll weld. In this case, pressing

onto the weld material and triggering current discharge with the

Manual setting will be sufficient to properly weld the material in

place. Use the Masking Tape to protect any surrounding areas

not to be touched by the Electrode.

FIG. 35

Welding to a Narrow or Concave Mold Section

Using the Pro Weld micro welder, repair welding into ver y small or

very confined areas can be accomplished. It is unlikely welding of

this nature can be done by argon arc, TIG or other types of welders.

In each case, shape the Electrode according to the area to be

welded. Mask tape off any parts of the base metal to be unaffected.

FIG. 36

46

Examples of Welding

VII

Page 49

VIII

VIII. Examples of Bad Welding

VIII.1 Unconnected Weld Spots

The worst kind of welding will result if the weld spots are arranged

with any gap or clearance between them.Each weld spot must

overlap the next by half its diameter. Subsequent weld material

layers must be done in this same manner.

FIG. 37

VIII.2 Improperly Shaped Electrodes

Proper welding can only be done with Electrodes that have a rounded

end or edge with a slight radius. Electrodes with flattened ends or

those that give linear contact will cause a bad weld even if the

contact area is very small.

FIG. 38

47

Examples of Bad Welding

Page 50

VIII.3 Oxidized Base Metal or Electrodes

It is important that the mold surface and Electrode be cleaned

of any type of stain or contamination using sandpaper or alcohol

absorbent. For full details, see VI.1 Workpiece, Electrode,

Welding Materials.

FIG. 39

VIII.4 Bad Conductivity

Bad Conductivity in welding current flow will cause bad welding.

It is important to clean the surface of the mold repair area, the

mold surface in contact with the Grounding Plate, the Grounding

Plate, the Electrode and the weld sheet material. Check to ensure

the Electrode Holder Cord and Grounding Cord are fully tightened

in their sockets. The copper Grounding Plate should be placed

as close to the repair area as possible, firmly anchored against

the base material and the Plate tightening screw fully tightened.

Following all of these precautions will provide good conductivity

and result in a good weld.

48

Examples of Bad Welding

VIII

Page 51

IX

IX. Maintenance Guarantee

D-M-E guarantees the Pro Weld UMW0001 free from defects

in parts and workmanship for a period of one year from date of

shipment of the unit.Within the guarantee period, D-M-E or the

manufacturer will repair or replace defects free of any cost. All

claims must be made in writing to D-M-E stating the date of

purchase and serial number of the unit.

The Manufacturer shall in no way be liable for:

♦ Damages in shipment.

♦ Failures or damages due to misuse, abuse, improper installation

or abnormal conditions of temperature, dirt or corrosives.

♦ Failures due to operation, intentional or otherwise, above rated

capacities.

♦ Non-authorized expenses for removal, inspection, transportation,

repair or rework.

♦ Consequent damages; and

♦ If the unit has been tampered with or dismantled in any way.

49

Maintenance Guarantee

Page 52

D-M-E Company

29111 Stephenson Highway

Madison Heights, MI 48071

Phone:

(800) 626-6653 (248) 398-6000

Fax:

(248) 398-6174

D-M-E Pro Weld

™

User Guide

Loading...

Loading...