Page 1

D-M-E Integrally Heated Sprue Bushings - .750 SERIES Specification No. ME-M741-PS-999(B)

Part No. INT-HSB-75-99 Page 1 of 2

IMPORTANT SAFETY INFORMATION

1. A hot-runner system includes electrical elements and may contain molten plastic at elevated temperature and pressure. To avoid injury, exercise caution

by reading these instructions before servicing or operating the system.

2. These instructions must be passed on to the end user where they should be read before using this product. Failure to do so can result in serious injury or

death.

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

1. Improper voltages or grounding can result in electrical shock. Use only with proper voltage and a proper earth ground.

2. To avoid electrical shock, do not operate product when wet.

3. Do not operate this equipment with covers or panels removed.

4. To avoid electrical shock, turn off main power disconnect and lockout / tag out before servicing this device. Do not

connect temperature sensors to electrical power. It will damage the product and it can cause fire, severe injuries or even death.

5. Utilizes the direct contact of the bushing, mold plates, and machine platens to establish a path for grounding. There must be a ground present

between the Mold “Hot Half” and the temperature control system or damage may occur to the bushing, thermocouple, and/or temperature control system.

6. Do not rebend rigid leads. Rebending leads might result in damage to circuit.

7. Product might absorb moisture when cool. Use low Voltage or power to drive out residual moisture before applying full power. Failure to do so may

cause damage to this product.

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

1. This product maintains molten plastic at high pressure. Use caution when operating and servicing the system.

2. Physical contact with molten plastic may result in severe burns. Proper protective equipment, including eye protection, must be worn. This product has

heated surfaces. Use caution when operating and servicing the system to avoid severe burns. Proper protective equipment should be worn.

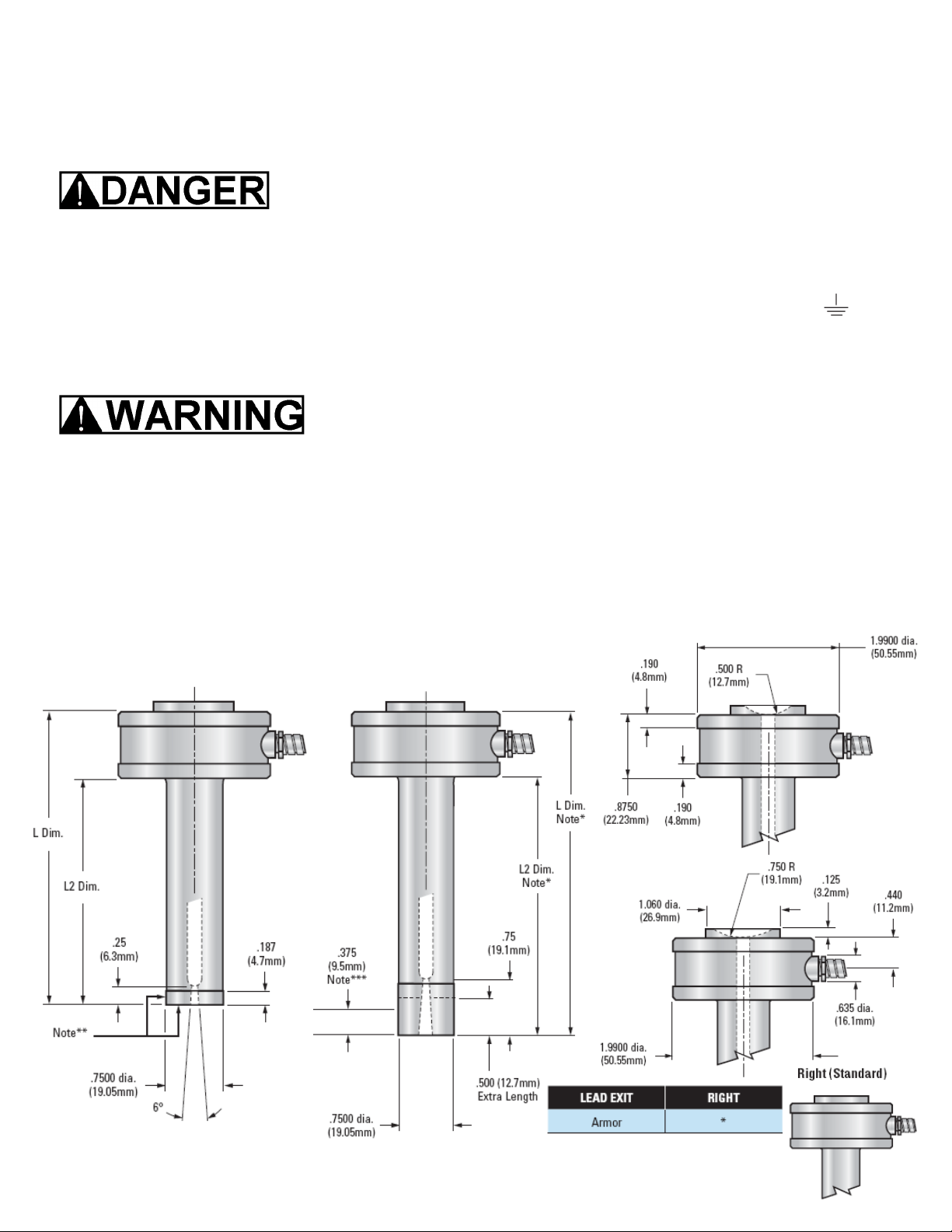

Operating & Servicing Instructions: The D-M-E Integrally Heated Sprue Bushing bodies are identical in design, but differ in length, diameter and head

style. All Sprue Bushings feature: an integrated heater; Type “J” thermocouple; 60” wrapped - 600 Volt leads; right angle lead exit, and 6” stainless steel,

square-lock armor cable. Power requirements: 240 Volts AC - 15 amp fuse.

Start-up/Operating Procedures: If the temperature controller does not utilize “soft-start” technology, set the controller to 200ºF (93.3ºC) in automatic or 10%

in manual. Allow bushing to “soak” for 15 minutes before increasing to processing temperature. This step will allow the unit to dissipate any moisture and

prolong heater life.

Gating Options / Bushing Dimensions Head Options

Sprue Gate Extra Stock Sprue Gate

.750 Radius Style

.500 Radius Style

* Dimensions include extra length.

** This surface cannot be machined, modified or altered.

*** Maximum machining stock, only this area can be machined.

*Standard Lead exit —

60” (1.52m) wrapped — 600 Volt leads;

right angle lead exit; and 6” (15.2cm)

stainless steel, square-lock armor cable

Page 2

D-M-E Integrally Heated Sprue Bushings - .750 SERIES Specification No. ME-M741-PS-999(B)

Part No. INT-HSB-75-99 Page 2 of 2

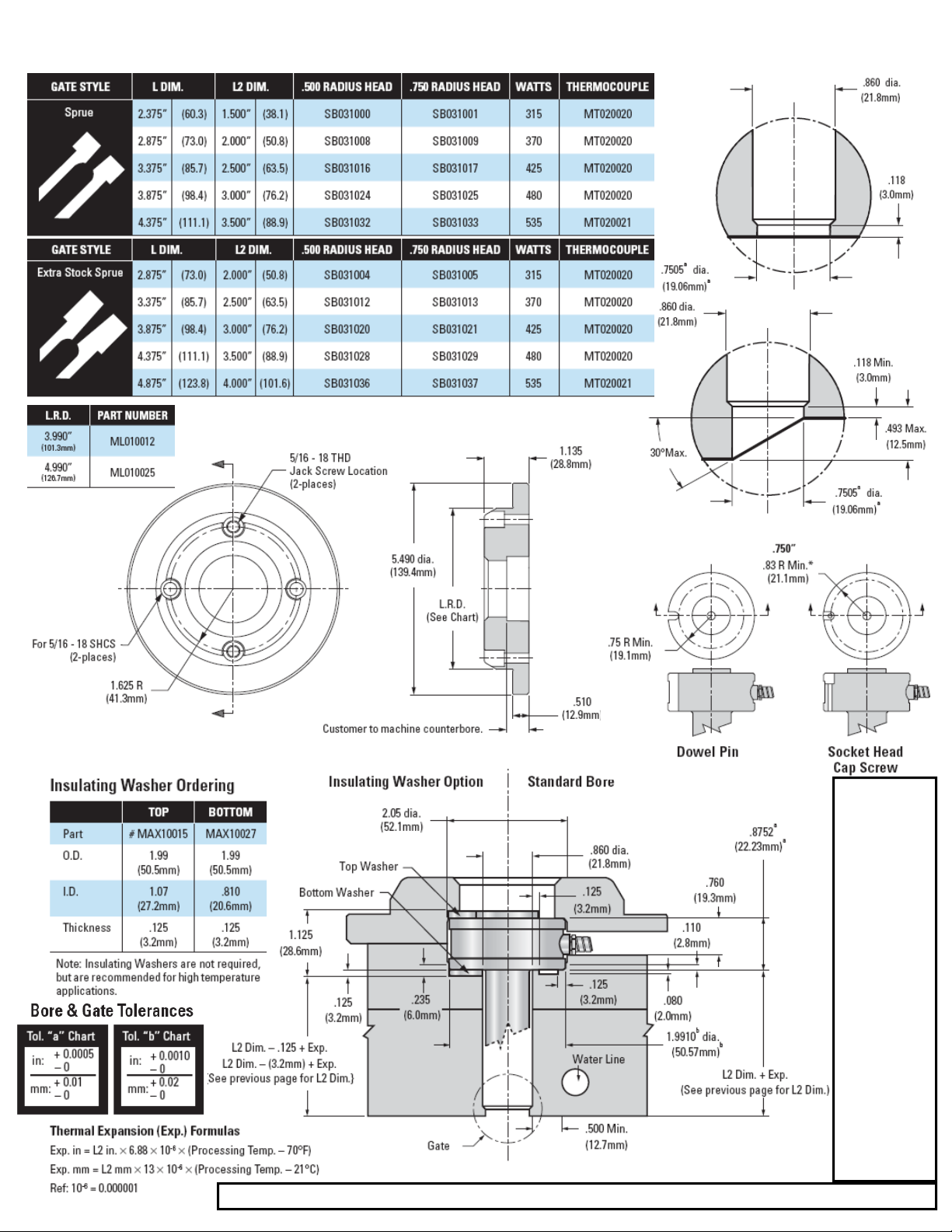

Locating Ring Dimensions/Chart

Sprue Gate

Extra Stock

Sprue Gate

.750 “ Series Bore Dimensions

Machining Options for Keying

NOTICE:

D-M-E shall not

be liable for

misuse or

failure to follow

the enclosed

instructions

and

specifications.

D-M-E hereby

disclaims all

implied

warranties,

including

merchantability

and fitness for

a particular

purpose. In no

event shall

D-M-E be

responsible

for loss of use,

revenue or

profit, or for

incidental or

consequential

damages.

For contact information or more information on our products, please visit our website at www.dme.net

Loading...

Loading...