Page 1

Machining &

Installation

Instructions

Please carefully read instructions before installing interlocks.

D-M-E IN2 INnovative INterlocks

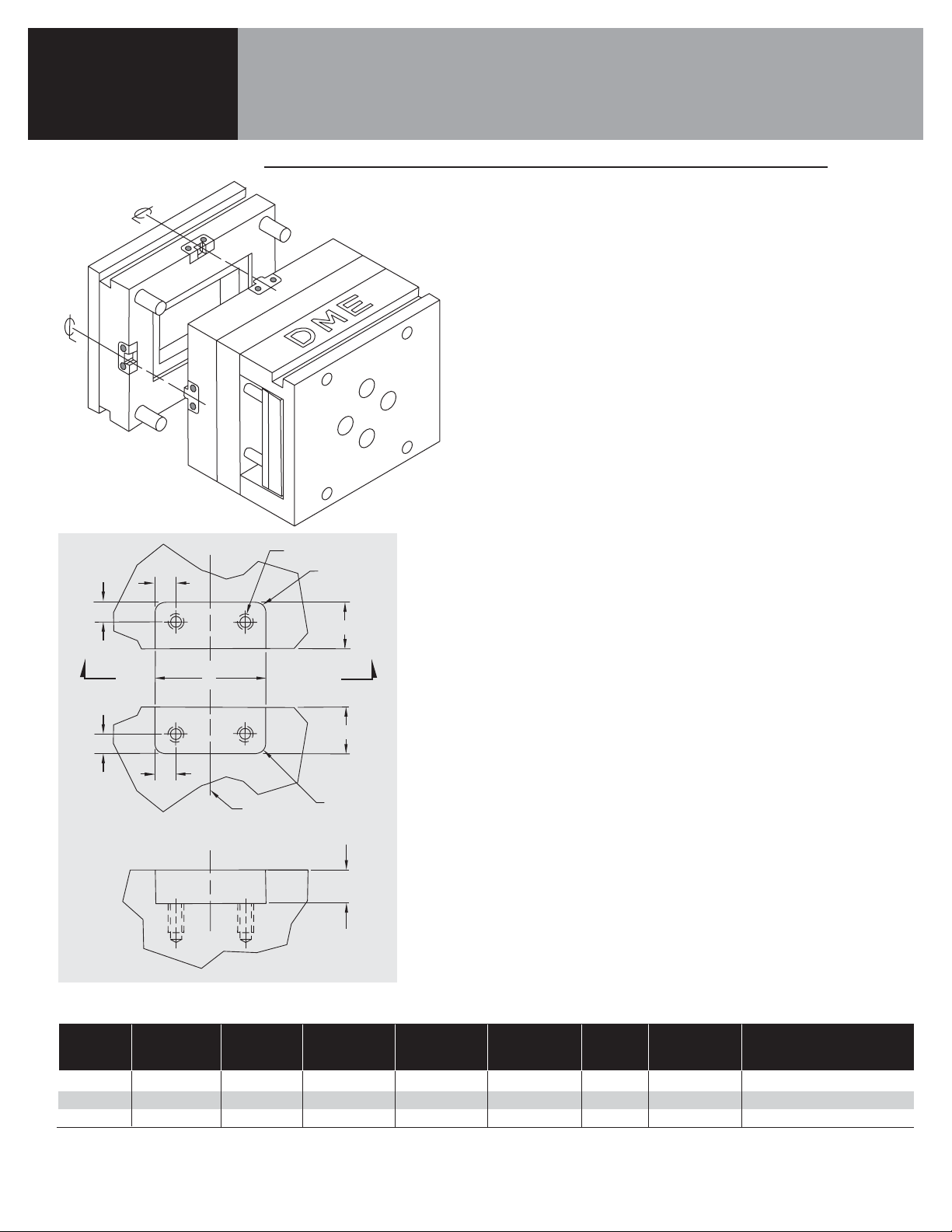

MOLD BASE MACHINING

1. Four (4) D-M-E IN2 INnovative INterlocks must

be used on each mold. When in operation, the

interlocks contact the edges of the machined

pocket to maintain parting line alignment. The

socket head cap screws are only used to retain

the interlocks to the mold base.

2. It is recommended that the mold base assembly

be clamped together and machined as an

assembly to insure proper parting line alignment.

3. Machine the interlock pockets accurately in

assembly. Locate each interlock pocket on the

centerline of the mold. The centerline location

is critical to avoid misalignment problems

which could result from uneven thermal

expansion of the separate mold halves.

4. Mark the mating interlocks to insure that the

interlocks remain as sets.

5. Mount the IN2 female interlock on the

half of the mold which will have the highest

operating temperature. Normally, this will

be the “A” side of the mold. This is important

to insure that the male interlock does not

grow larger than the female interlock if

uneven mold temperatures occur.

6. Torque the socket head cap screws to:

4.5 ft.lbs for #8-32 socket head cap screws

7.5 ft.lbs for #10-32 socket head cap screws

16.5 ft.lbs for 1/4-20 socket head cap screws

7. After installation, open and close the mold

on the bench and check to insure proper

alignment has been achieved.

8. Always maintain lubrication on the interlocks

to prevent galling.

9. Please carefully read instructions on other side

regarding installation of the inserts for IN2

INnovative INterlocks.

SIS-9999-3/05

ME-E09-0199-A

IN2 INnovative INterlock Dimensions

INTERLOCK

AB S

REPLACEMENT

SET*

W

HEIGHT HEIGHT

TR

SCREW THREAD INTERCHANGEABLE INSERTS**

ITEM NO. WIDTH FEMALE MALE DEPTH RADII LOCATIONS SIZE ITEM NO.

SIS150023 1.500 .875 .875 .500 .25 .250 #8-32 x .38 Deep SII15003

SIS200023 2.000 1.375 .875 .500 .25 .312 #10-32 x .44 Deep SII20003

SIS300023 3.000 1.875 .875 .750 .375 .375 1/4-20 x .50 Deep SII30003

*Sets include one (1) male,

one (1) female, two (2) inserts,

four (4) SHCS.

**Replacement Interchangeable Inserts

are sold in pairs.

PATENT PENDING

S

Y

S

THREAD SIZE

S

+.0002

-.0000

W

S

CENTERLINE

OF MOLD

R

+.005

-.000

A

Y

+.005

-.000

B

R

+.005

-.000

T

VIEW Y-Y

Page 2

Machining &

Installation

Instructions

D-M-E IN2 INnovative INterlocks

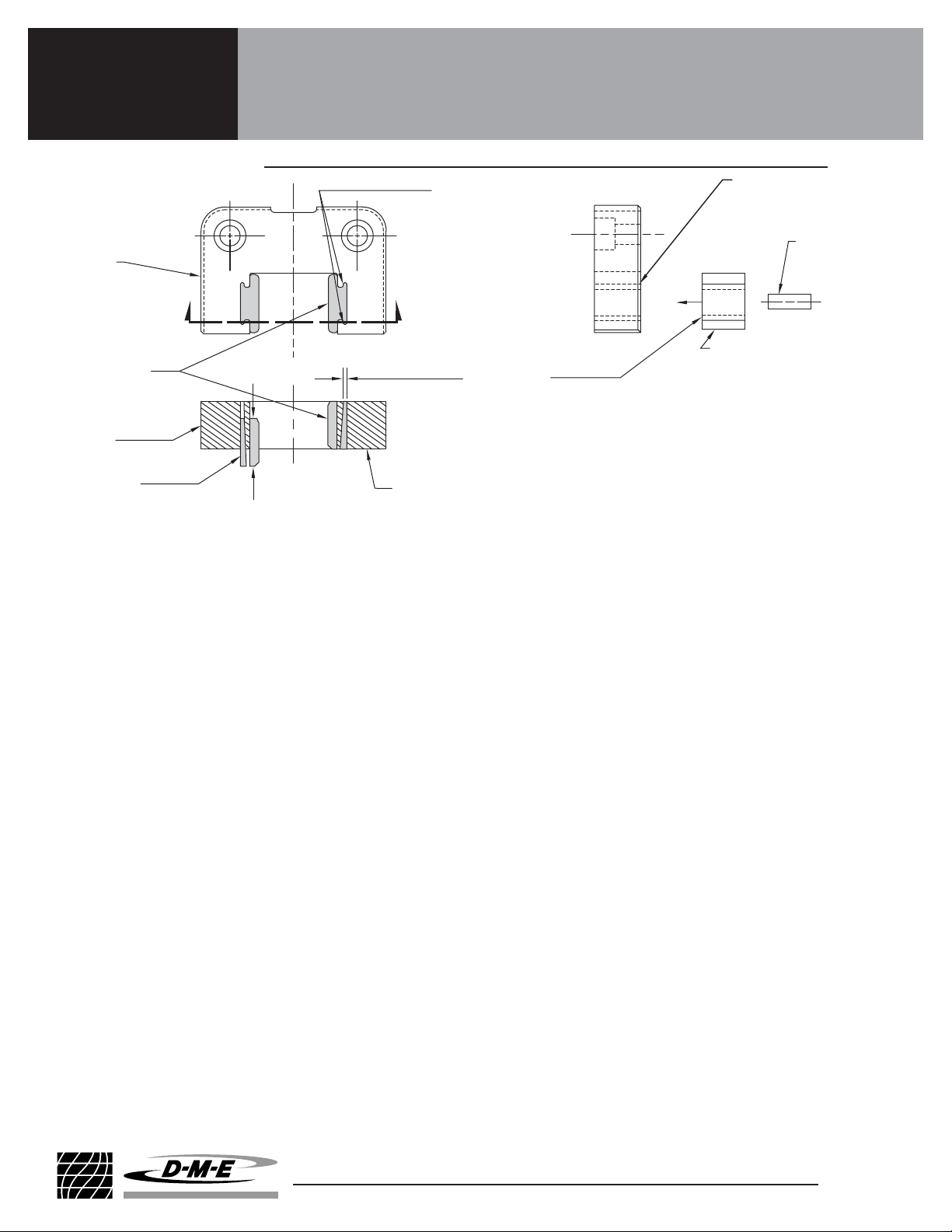

INSERT INSTALLATION

INSERT INSTALLATION

D-M-E INterchangeable INserts can only be installed from

the back of the female IN2 INnovative INterlock. The back of

the female interlock mounts against the mold (and is the side

opposite the counterbores for the socket head cap screws).

When the Interchangeable Inserts are properly inserted into

the female interlock they will be retained by the tapered

wedge of the Interchangeable Insert and the retaining taper

of the female interlock. Once installed in a mold, the mold will

insure that Interchangeable Inserts will be securely retained.

1. First, place the female interlock face down on a flat

surface with the back facing up.

2. Next, select a pair of IN2 INterchangeable INserts for

the appropriate size interlock for insertion into the female

interlock. Interchangeable Inserts of the same size are

truly interchangeable; any Interchangeable Insert of the

proper size can be inserted into the female interlock.

3. Inspect the tapered wedge on the Interchangeable

Insert to determine which end of the Interchangeable

Insert is the thin end of tapered wedge. The thin end

of the tapered wedge will be inserted into the female

interlock first (refer to above drawings for clarification).

4. Insert the thin end of the tapered wedge into the female

interlock from the back and slide the Interchangeable

Insert firmly into the female interlock. The Interchangeable

Insert should seat most of the way into the female interlock

by hand. The tapered wedge of the Interchangeable Insert

provides a slight interference fit with the retaining

wedge of the female interlock.

SIS-9999-3/05

ME-E09-0199-A

5. Now, place an aluminum rod against the Interchangeable

Insert and use a hammer to tap on the aluminum rod to

move the Interchangeable Insert until it is flush with the back

of the female interlock. Properly seated Interchangeable

Inserts will be .000 to .005 below the back surface of the

female interlock. Use an aluminum rod whose diameter is

small enough to make contact with only the Interchangeable

Insert and does NOT contact the small retaining wedges

on the female interlock.

6. Repeat this procedure for each insert.

7. The D-M-E IN2 INnovative INterlock is now ready

for installation on your mold. Please carefully read

instructions on other side regarding installation of

IN2 INnovative INterlocks on your mold.

INSERT REMOVAL

To remove an Interchangeable Insert from an IN2 INnovative

INterlock, the female interlock must be removed from the mold.

1. Place the female interlock on two aluminum blocks with

the front facing up. (The front face of the female interlock

is the side with the counterbores.) Position the two aluminum

blocks under the outer edges of the female interlock but

not under the Interchangeable Insert being removed.

2. Place an aluminum rod on the Interchangeable Insert and

use a hammer to tap on the aluminum rod. The Interchangeable

Insert has a tapered wedge which will release from the

retaining taper of the female interlock as the insert moves

down, allowing the Interchangeable Insert to drop free

from the female interlock. As previously indicated, use

an aluminum rod whose diameter is small enough to make

contact with only the Interchangeable Insert and does NOT

contact the small retaining wedges on the female interlock.

3. Repeat this procedure for each insert.

Please carefully read instructions before installing inserts.

PATENT PENDING

D-M-E Company World Headquarters 29111 Stephenson Highway, Madison Heights, MI 48071

U.S. 800-626-6653 • Canada 800-387-6600 • www.dme.net

FEMALE

INTERLOCK

TAPERED

WEDGE OF

INTERCHANGEABLE

INSERT

BACK OF

INTERLOCK

FEMALE

ALUMINUM

ROD

INSERT

INSTALLED

FEMALE

INTERLOCK

INSERT

PARTIALLY

INSTALLED

Z

REMOVE

INSERT

SECTION Z-Z

INSTALL

INSERT

Z

BACK OF

FEMALE

INTERLOCK

INSERT BEING

ALIGNED FOR

THIN END OF

TAPERED WEDGE

GOES IN FIRST

INSTALLATION

Loading...

Loading...