Page 1

ME-0738-PS-006-B HNL/PKS

09-08

HEATED NOZZLE LOCATOR

INSTALLATION DATA

Please read carefully before installing components.

A requirement for D-M-E split-plate designs,

and recommended for all D-M-E runnerless

molds, the new heated nozzle locator

improves both the performance and structural

integrity of D-M-E runnerless systems.

It provides uniform temperature control of

resin from the machine nozzle to the distributor

channel. The thermocouple-equipped coil

heater features a square (or flat) cross section

to improve heat tranfer to the core's 0.312

diameter feed channel.The heated nozzle

locator provides quicker and easier systems

start-ups, minimizes preesure loss and

eliminates cold slugs in the feed channel.

Available in two lengths with choice of 1/2"

or3/4" spherical radius, the assemblies can

be installed using either a clamp style or bolt

thru style method for added design and

construction versatility.

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

DANGER

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

WARNING

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn. This product

has heated surfaces. Use caution when operating and servicing the system

to avoid severe burns. Proper protective equipment should be worn.

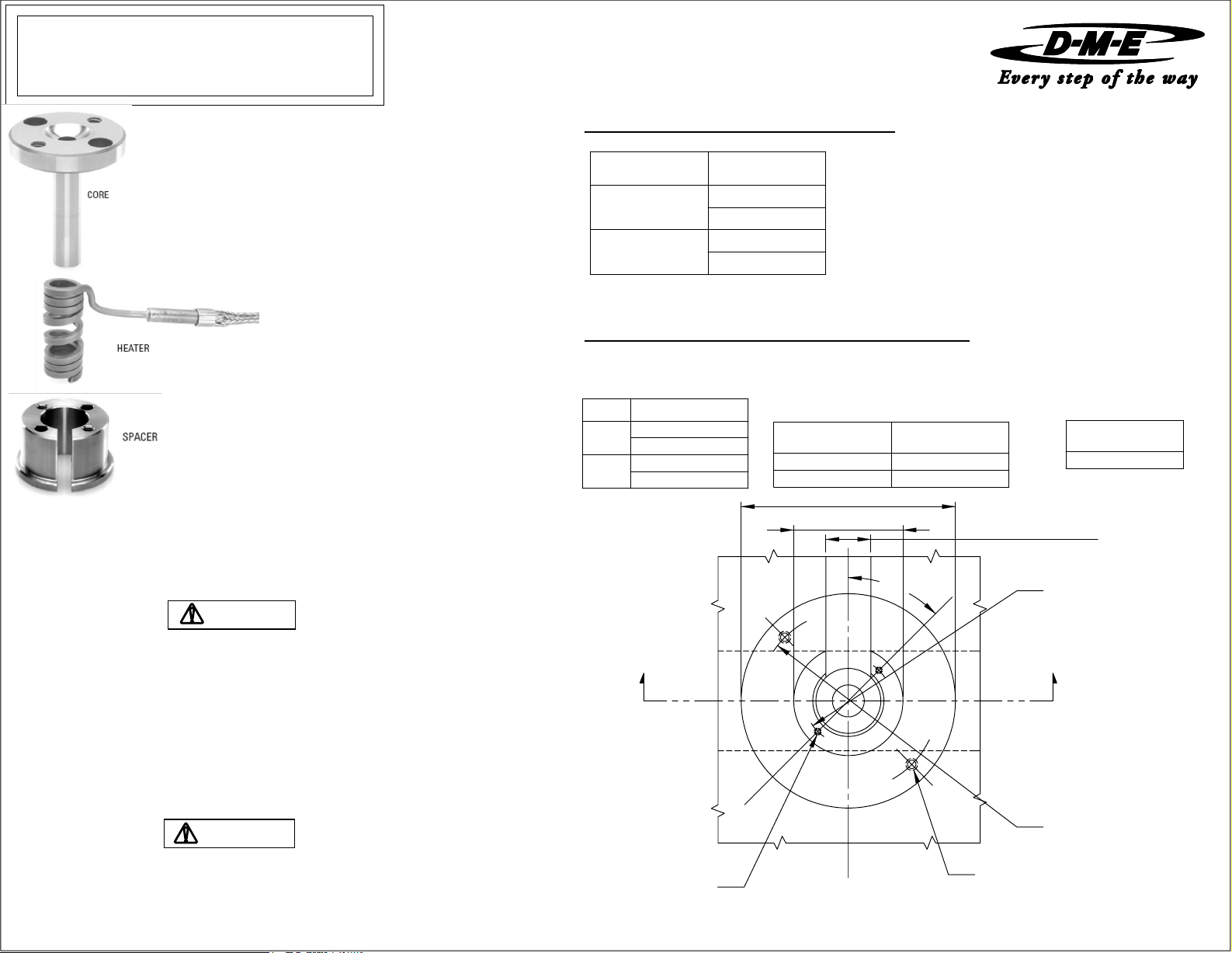

HEATED NOZZLE LOCATOR ASSEMBLIES

R

1/2

3/4

CATALOG

NUMBER

HNL-462

HNL-472

HNL-662

HNL-672

HNL-462 and HNL-662 assemblies include:

•

HNC-46 or HNC-66 core, respectively

•

SSTC-62-90 heater

HNS-67 spacer•

HNL-472 and HNL-672 assemblies include:

HNC-47 or HNC-67 core, respectively

•

SSTC-72-90 heater

•

HNS-67 spacer

•

HEATED NOZZLE LOCATOR REPLACEMENT PARTS

Note: Dimensions shown in Inches.

CORES

CAT. NO.R

1/2

3/4

A

1/4-20 TAP 0.38 DEEP

(2) HOLES FOR BOLT

THRU STYLE SPACER

OMIT HOLES FOR CLAMP

STYLE SPACER

* APPLIES TO BOLT THRU

STYLE APPLICATION ONLY.

HNC-46

HNC-47

HNC-66

HNC-67

THERMOCOUPLE HEATERS

(240 VAC, T/C type J grounded, 34" leads)

CATLOG

NUMBER

SSTC-62-90 HNC-46&66

SSTC-72-90 HNC-47&67

4.000 DIA.

2.000 DIA. *

45°

USED WITH

CORES

.375 WIRE GROOVE

1.437

BOLT CIRCLE

3.312

BOLT CIRCLE

5/16-18 TAP

(2) HOLES

SECTION A-A ON REVERSE SIDE

(FIGURE 3)

SPACERS

CATALOG

NUMBER

HNS-67

A

Page 2

ME-0738-PS-006-B HNL/PKS

08-09

HEATED NOZZLE LOCATOR

INSTALLATION DATA

Please read carefully before installing components.

Note: Dimensions shown in Inches.

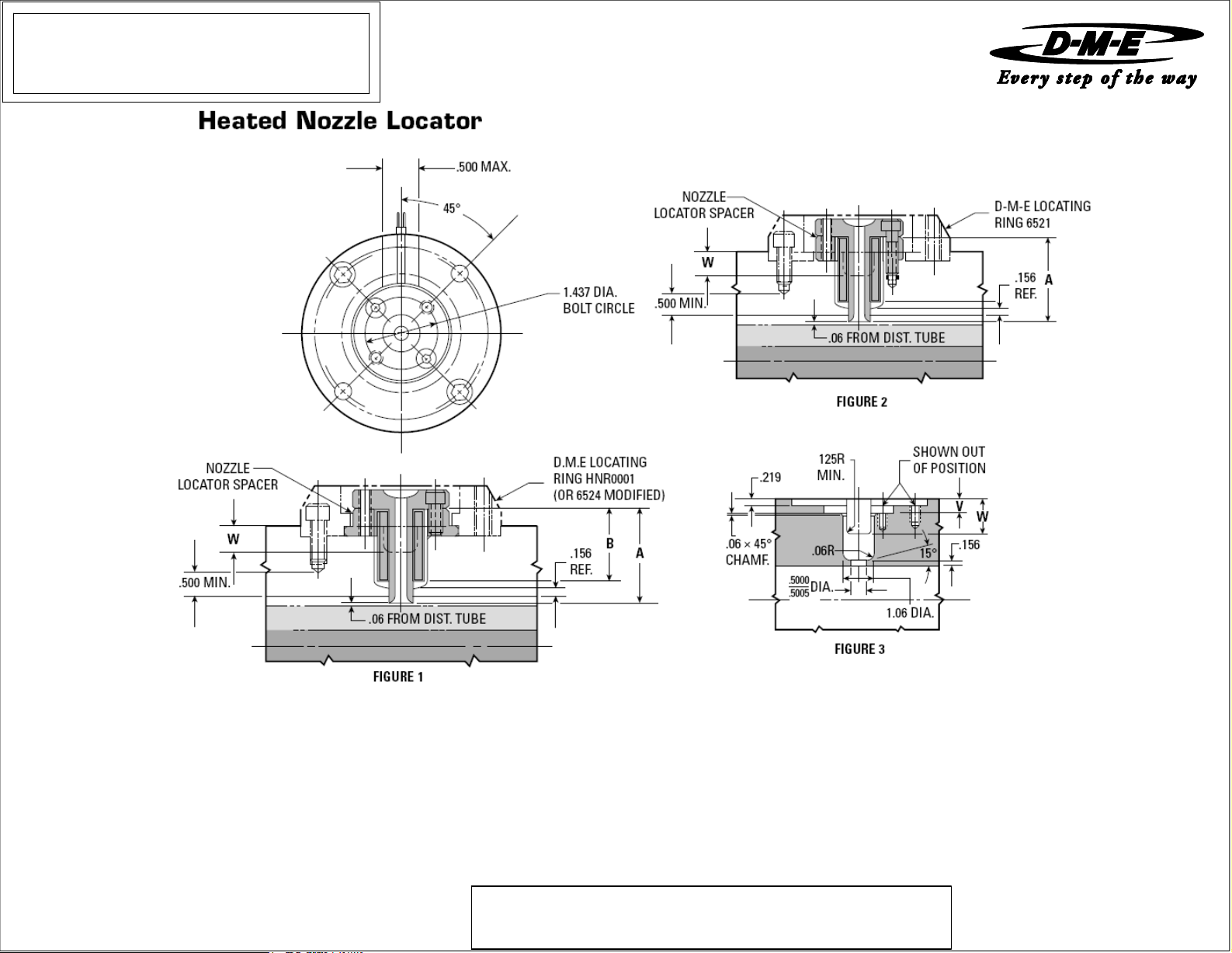

ALL APPLICATIONS

The locator's core tip should be positioned 0.060 from the top of the disributor

tube, establishing the "A" dimension. In most cases, the dimension from the

bottom of the core head to the locating ring counter bore will equal the adjusted

height of the spacer. (The "B" dimension, for reference, is the heater length of

1.450 or 1.950, depending on core length bieng used.)

CLAMP STYLE SPACER APPLICATION (Figure 1)

The spacer is supplied with a flange and a 1.250 height. The flange may be

used in conjuction with amodified D-M-E Model # 6524 locating ring to form

a clamp-style spacer. To modify the locating ring, enlarge its 2.00 diameter

counterbore to 2.281 (0.219 deep) and its 1.75 I.D: to 2.00 . The core is

secured to the spacer with two 1/4-20 S.H.C.S.

BOLT THRU STYLE SPACER APPLICATION (Figure 2)

Another option is to remove the flange and adjust the spacer height to the

desired dimension, then secure the Heated Nozzle Locator through the

spacer with two 1/4-20 S.H.C.S. into the mold plate. Use caution to insure

that the tapped holes are 0.500 minimum from the distributor channel.

Spacer thickness should never be less than 0.250. However, if a condition

results where the spacer would be less than 0.250, counterbore a 2.00

diameter into the pltae to a "V" depth that will accept the 0.250 spacer (see

Figure 3).

ALL APPLICATIONS

In order to maintain plate strength, the depth of the lead wire channel, dimension"W" , must be no deeper than required to contain the heater leads. The

distance from the bottom of the core head to the bottom of the heater leads is

0.800 .Channel depth can be determined accordingly, based on the distance

between the core head and top of the mold.

If a condition occurs where the Heted Nozzle Locator would extend above

the standard locating ring, a special locating ring with extended flange for

protecting the Heated Nozzle should be constructed.

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

WIRING INFORMATION

Probe Heaters are supplied with 34''long leads.

Heaters are 240 VAC.

2 power leads are Multi Color.

1 ground lead is GREEN.

Thermocouple is "J" Type.

Thermocouple is supplied with 34"/ 24 Gage leads.

1 T/C lead is WHITE and negative (-)

constantan (non-magnetic).

1 T/C lead is BLACK and positive (+)

iron (magnetic).

D-M-E COMPANY

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6656

CANADA 800-387-6600

www.dme.net

Loading...

Loading...