Page 1

SCH9997 ME-X741-PS-253-E

09-08

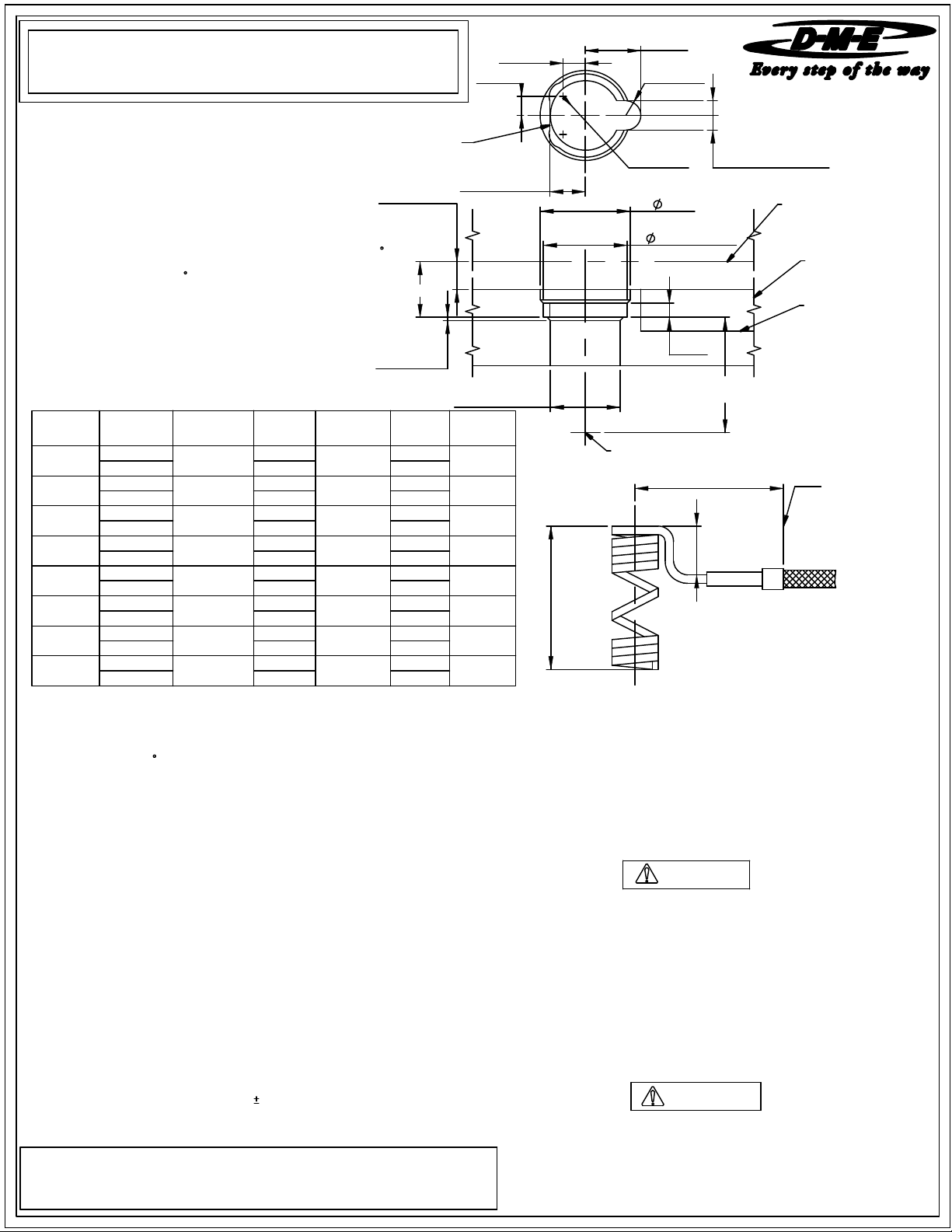

375 SERIES FRONT LOAD HEATER

INSTALLATION DATA

Note: Dimensions are shown in inches.

NOTE: The expansion factor must be taken into consideration

prior to machining for and installing nozzle. This factor

(BE) must then be added to the nominal "A" dimension.

Formula for determining this expansion is as follows:

BE= "A" dimension x 0.00000633 x (nozzle setpoint - 68

EXAMPLE: Given a 2.500 Inch "A" dimension, with a nozzle

setpoint temperature of 500

BE= 2.500 x 0.00000633 x (500 - 68) = 0.0068....

thus "A" + BE will be 2.5068.

Please note that the above information is given as an example.

Variations may occur based on mold configuration and cooling

factor. In some instances it may be necessary to obtain an

empirical factor.

"A"

2.000

2.500

3.000

3.500

4.000

5.000

6.000

7.000

OPERATING PROCEDURE

The nozzles are supplied with a Square (Flat) Coil Heater equipped with Type J

thermocouple. It is recommended to use a D-M-E closed loop Temperature

Controller for optimum Temperature Control.

When starting the nozzle, set the temperature to 10% voltage if using in open loop

manual type or to 200

procedure will allow the heater to dissipate any moisture.

Be certain to maintain this start-up setting for 15 minutes.

Controller equipped with Step Smart ® , Smart Step ®

or other heater warm-up circuitry will change automatically.

It is essential to use controllers with the proper voltage and wattage capabilities.

The voltage and wattage of each heater is clearly marked on the heater tag.

Step Smart ®, Smart Start ® and DME ® are all registered trademarks

of DME Company.

DISASSEMBLY PROCEDURE

1. Nozzle has been designed to have the tip removed in the press. See

recommendations and guidelines Note # 2 for keying nozzle to keep from rotating.

2. Careful attention should be taken to the heater / thermocouple leads as

damage could occur when working on nozzle assembly.

3. For removal of tip from nozzle, a six point deep well socket is recommended. The

nozzle must be at processing temperature and the heater should be turned off

when removing tip counter-clockwise from the nozzle.

4. For removal of heater recommendations and guidelines Note # 4.

ASSEMBLY PROCEDURE

1. Tip and nozzle threaded area must be clean of any material before reassembling.

2. Apply an anti-seize compound on the tip threads.

3. Firmly screw the tip into the shank of the nozzle body. Tighten and untighten two

or three times making sure there is a good contact between the tip and the nozzle.

Torque the tip into the nozzle using 30

point deep well socket is recommended.

4. For removal of heater recommendations and guidelines Note # 4.

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

SUB-ASS'Y

CAT.NO.

EHA1008

EHA2008 SCH2088 1.375

EHA1009

EHA2009 SCH2089 1.375

EHA1010

EHA2010 SCH2090 1.375

EHA1011

EHA2011 SCH2091 1.375

EHA1012

EHA2012 SCH2092 1.375

EHA1013

EHA2013 SCH2093 1.375

EHA1014

EHA2014 SCH2094 1.375

EHA1015

EHA2015 SCH2095

F if using closed loop automatic type. In either case this

F.

NOZZLE

BODY

CAT.NO

CIB1366

CIB1367

CIB1368

CIB1369

CIB1370

CIB1371

CIB1372

CIB1373

installing and/or removing heaterPlease read carefully before

0.250 MIN.

0.750 MAX.

F).

0.03

HEATER

CAT.NO.

SCH1088

SCH1089

SCH1090

SCH1091

SCH1092

SCH1093

SCH1094

SCH1095

5 ft-lbs. For protection of the tip, a six

WATTAGE "B" "L"

400

450

550

700

800

900

1000

1100

CIRCLE

INTERPOLATION

1.0000

X 45°

0.875

0.875

0.875

0.875

0.875

0.875

0.875

0.875

1.375

0.433

0.885

1.437 MIN.

1.625 MAX.

2.125

2.625

3.125

3.625

4.125

5.125

6.125

7.125

GATE

1.250

R0.25

R0.25

2.06

2.001

0.531 WIRE SLOT

+0.001

0.000

0.25

"A" + BE

SEE NOTE

2.875

"B"

MANIFOLD

LINE

NOZZLE

PLATE

WIRE

SLOT

FLEXIBLE LEADS

AFTER THIS AREA

0.643

0.001

+

0.000

"L"

5. Seal ring for nozzle body must be replaced each time nozzle body and / or

manifold are removed to ensure seal-off.

6. Wait a minimum of 5 minutes after set point has been achieved for sufficient

heat to transfer into the tip before molding.

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

DANGER

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it could cause fire,

severe injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

WARNING

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn.

This product has heated surfaces. Use caution when operating and servicing

the system to avoid severe burns. Proper protective equipment should be worn.

Page 2

SCH9997 ME-X741-PS-253-E

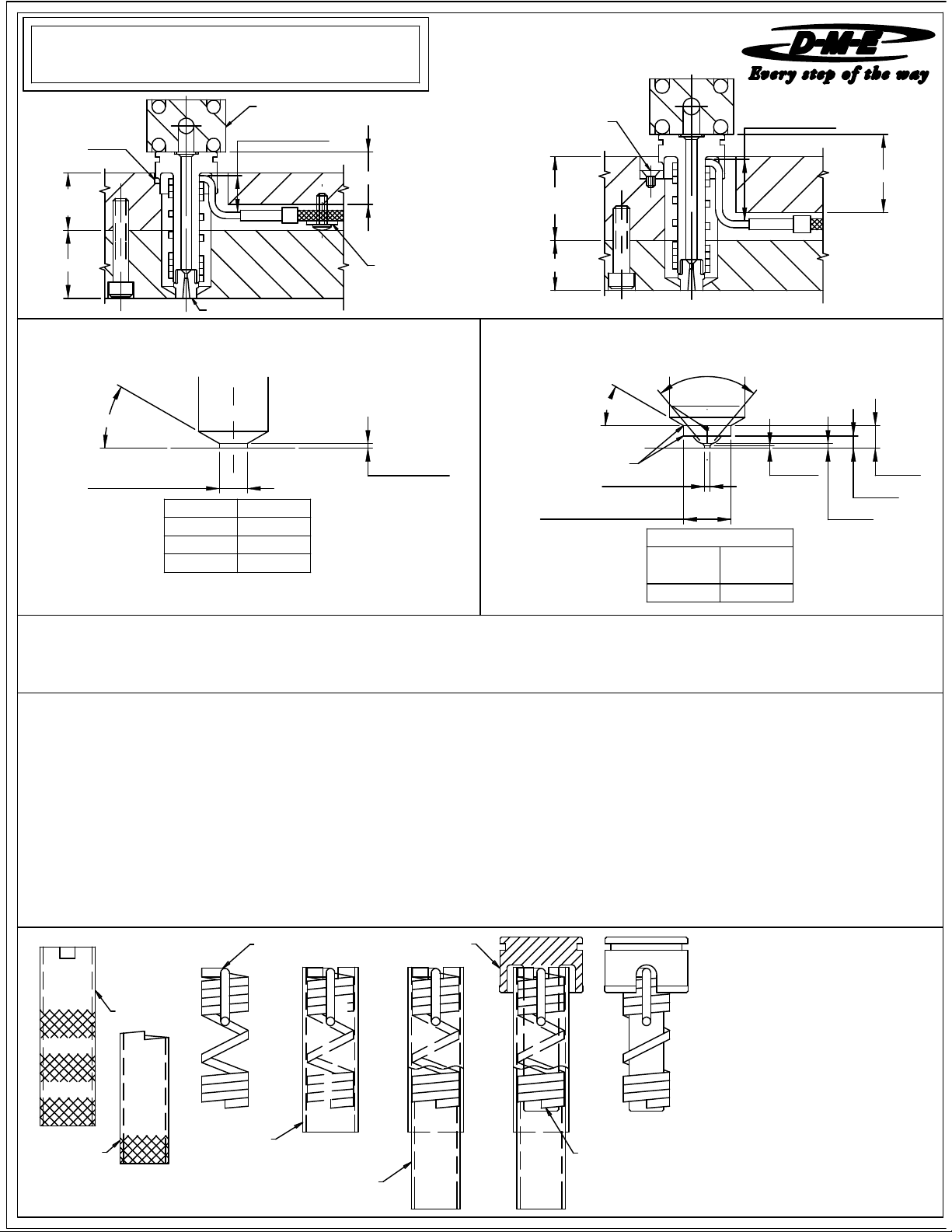

375 SERIES FRONT LOAD HEATER

CIRCLE

INTERPOLATION

1.375

NOZZLE PLT

INSTALLATION DATA

installing and/or removing heaterPlease read carefully before

0.875 "B" DIM

TUBULAR HEATED

MANIFOLD

1.125

09-08

OPTIONAL KEY

MOLDER TO

SUPPLY

1.875

NOZZLE PLT

1.375 "B" DIM

1.625

"A" PLT

SPRUE GATE TIP SHOWN

DME WIRE

COVER

SPRUE AND RING GATE

MACHINING DIMENSIONS

30.0°

0.0005

+

0.0000

"S"

For selection of tips and gate diameters it is important to take into consideration the materials flow characteristic, shear rate of resin, molding conditions, fill time

requirements, gate vestiage, wall thickness and configuration of part to be molded. Situations requiring high injections velocities must be considered when selecting

small gate diameters. High injection rates may require larger gates due to shear heat build up (e.g. high weight thin wall applications). See material manufactures

literature for further information regarding material to be molded.

DIA

"S" DIA."T" DIA.

.5005.500

.7505.750

1.000 1.0005

0.080

LAND

RECOMMENDATIONS AND GUIDELINES

1. Front Load Coil Heaters are designed to be used with 375 Series

Nozzles.

2. The nozzle head must be held in such a manner to keep it from

rotating upon installation of the Front Load Heater. This may

be done by making a key for the head to match the flat on the

nozzle's head or by circle interpolation.

3. Nozzle plate must be designed so that the heads of the socket

head cap screws are exposed when the mold is split on the on

the parting line.

4. After the nozzle has been located and positioned in the nozzle

plate with manifold secured in place and "A" plate removed, the

heater can be installed on the nozzle body as follows:

a. Place heater within Tube "A" so that the bending exit lead

lies within the slot of the tube.

Male Cat. No.: 18RA-251T

Female Cat. No.: 18RA-2577

"A" PLT

POINT GATE

MACHINING DIMENSIONS

80.0°

30.0°

.010-.015 RAD.

0.5000

b. Insert Tube "B" with angle cut within Tube "A" so that the

angle of the tube mates with the last coil of the heater.

c. Rotate Tube "A" counterclockwise while at the same time rotate

Tube "B" clockwise. This action will spring open the coils

enough to slide the heater onto the shaft of the nozzle body.

d. Slide the heater onto the nozzle body shaft aligning the heater

exit lead within the relief slot in the nozzle's head.

e. Position heater so that the end of the last coil is above the

chamfer.

5. The power and thermocouple leads may be spliced in the wiring

channel for ease of heater replacement. Leads may be spliced

using Thomas & Betts nylon insulated disconnects.

6. Secure wires in wire channel with D-M-E Wire Covers before

assembling "A" plate to mold.

"O" DIA.

+

0.0005

0.0000 DIA.

R0.187

"O" DIA.

UNFILLED

RESIN

.028 MIN.

FILLED

RESIN

.060 MIN.

0.180

0.005

LAND

MAX.

0.020

AT TANGENT

0.100

TUBE "A"

TUBE "A"

TUBE "B"

FRONT LOAD COIL HEATER WRENCH

CAT. NO.: WRE0013

FRONT LOAD

HEATER

TUBE "B"

NOZZLE BODY

LAST COIL TO

BE POSITIONED

ABOVE CHAMFER

WIRING INFORMATION

Square Coil Heaters are supplied with 2"

prestripped 36" long leads.

Heaters are 240 VAC

2 power leads are Multi Color.

1 ground lead is GREEN.

Thermocouple is "J" Type.

Thermocouple is supplied with 36" leads.

1 T/C lead is WHITE and negative (-)

constantan (non-magnetic).

1 T/C lead is BLACK and positive (+)

iron (magnetic).

D-M-E COMPANY

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6653

CANADA 800-387-6600

www.dme.net

Loading...

Loading...