Page 1

MAINTENANCE GUIDE

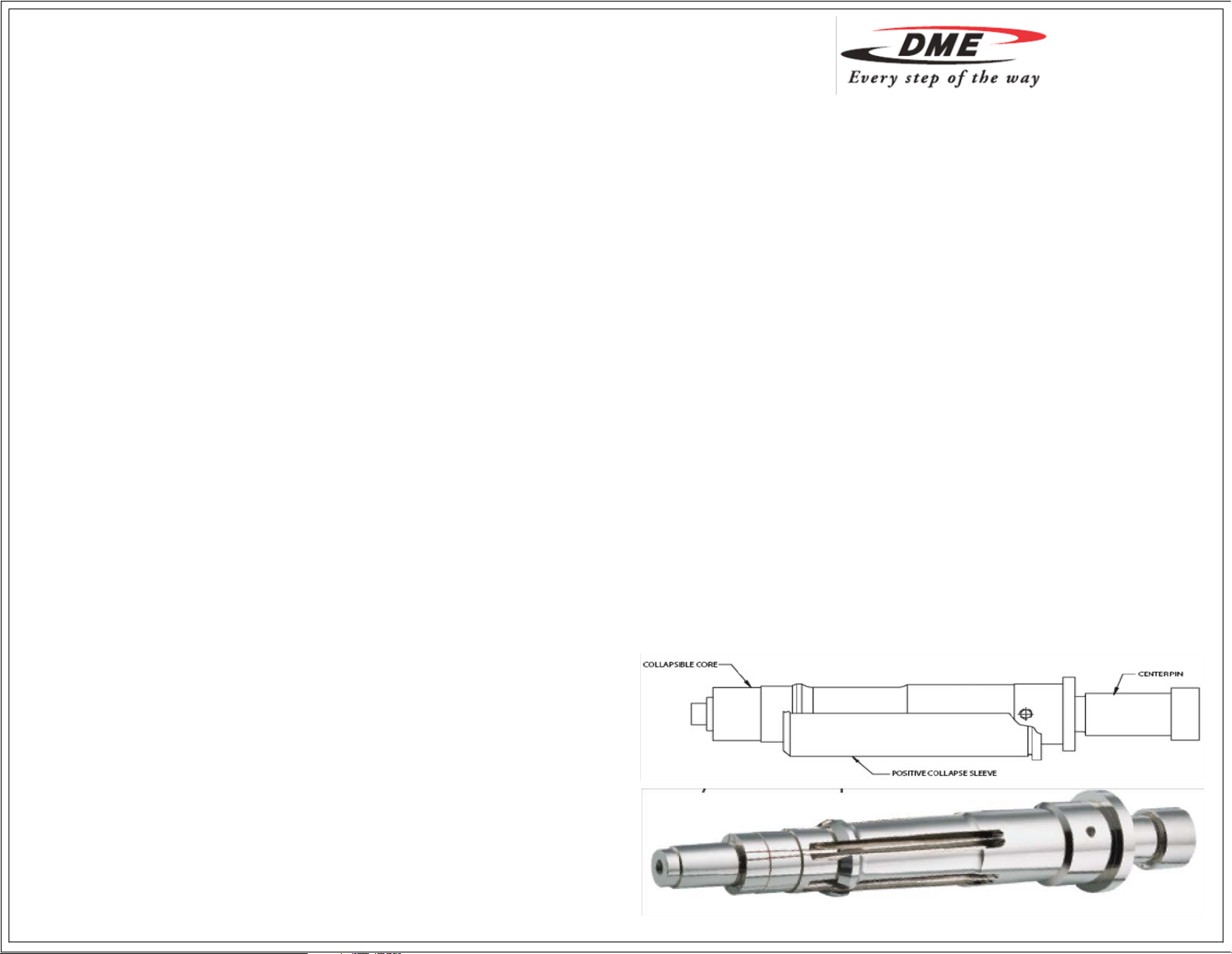

CC SERIES COLLAPSIBLE CORES

ME-0502-PS-021(A) CCMG01

To ensure trouble free operation and minimal maintenance

requirements, please adhere to the following mold design guidelines.

For additional information, including 2D and 3D CAD geometry, mold

base machining information and grinding instructions, please visit our

website at www.dme.net

Core Installation

MECHANICAL ENGINEERING

29111 STEPHENSON HWY.

MADISON HEIGHTS

MICHIGAN 48071

U.S.A.

PH: +1-248-398-6000

FX: +1-248-544-5707

Things to Look For

1. Center Pin protrusion when the ejector and stripper plates are in the

back position. Lack of pin protrusion could be a sign of a bent plate

or something restricting the complete return of the ejector system.

2. Any amount of flash on the inside of the part in the core segment

areas that could prevent the segments from collapsing.

1. Ensure that all cores are numbered to their corresponding mold plate

locations and that the serial number on the center pin matches the

serial number on the C-Core.

Pins and cores are not interchangeable.

2. Ensure that the Positive Collapse Sleeve is free to travel through

the mold plates. Apply grease where indicated in the mold design

guidelines. Check for free movement when the mold is up to normal

operating temperature.

3. Ensure that the mounted core is free to rotate in the ejector plate

assembly. If keyed for positive feature orientation, the core must not

be held rigid.

4. Check that the Center Pin is concentric with the stripper insert and

that the pin tip protrudes beyond the core face and has the proper

edge radius when the mold is assembled.

Mold Set-Up

1. Care must be taken when the mold is set and dry cycled so that the

proper mold sequence is followed: Mold opens, ejector & stripper

plates move forward together the entire ejection stroke, the stripper

plate is pushed forward and then returned, the ejector plate and

stripper plate return together.

3. Gassing or burns on the inside of the part. The mold cavities should

be well vented at the parting line away from the cores.

4. Any cocking or bouncing of the mold plates and audible sounds of

friction or misalignment.

Maintenance

1. The collapsing segments have a “Self Cleaning” action and will

tend to carry any dirt deposits to the outer surface.

Although designed to be capable of operating without lubrication,

a spray-on, PTFE-based lubricant is recommended.

2. Prior to the assembly of the mold, the cores should be thoroughly

cleaned and degreased. Inserting a small section of polypropylene

rod into the base of the core, up into the molding area will help

separate the segments for complete cleaning.

3. Periodically lubricate the outside surface of the Positive Collapse

Sleeve with a general purpose mold grease so that it continues to

move freely in the mold plate bores.

2. Heat the mold evenly to maintain bore alignment.

Avoid looping water from one end of the mold to the other.

3. Lightly lubricate the tapered end of the Center Pin during new

mold break-in.

4. Be aware of any short shots. Remove any from the cores prior to

closing the mold.

Closing on parts is the No.1 cause of C-Core damage.

Loading...

Loading...