Page 1

ME-0725-PS-216-B AFIP/ID

09-08

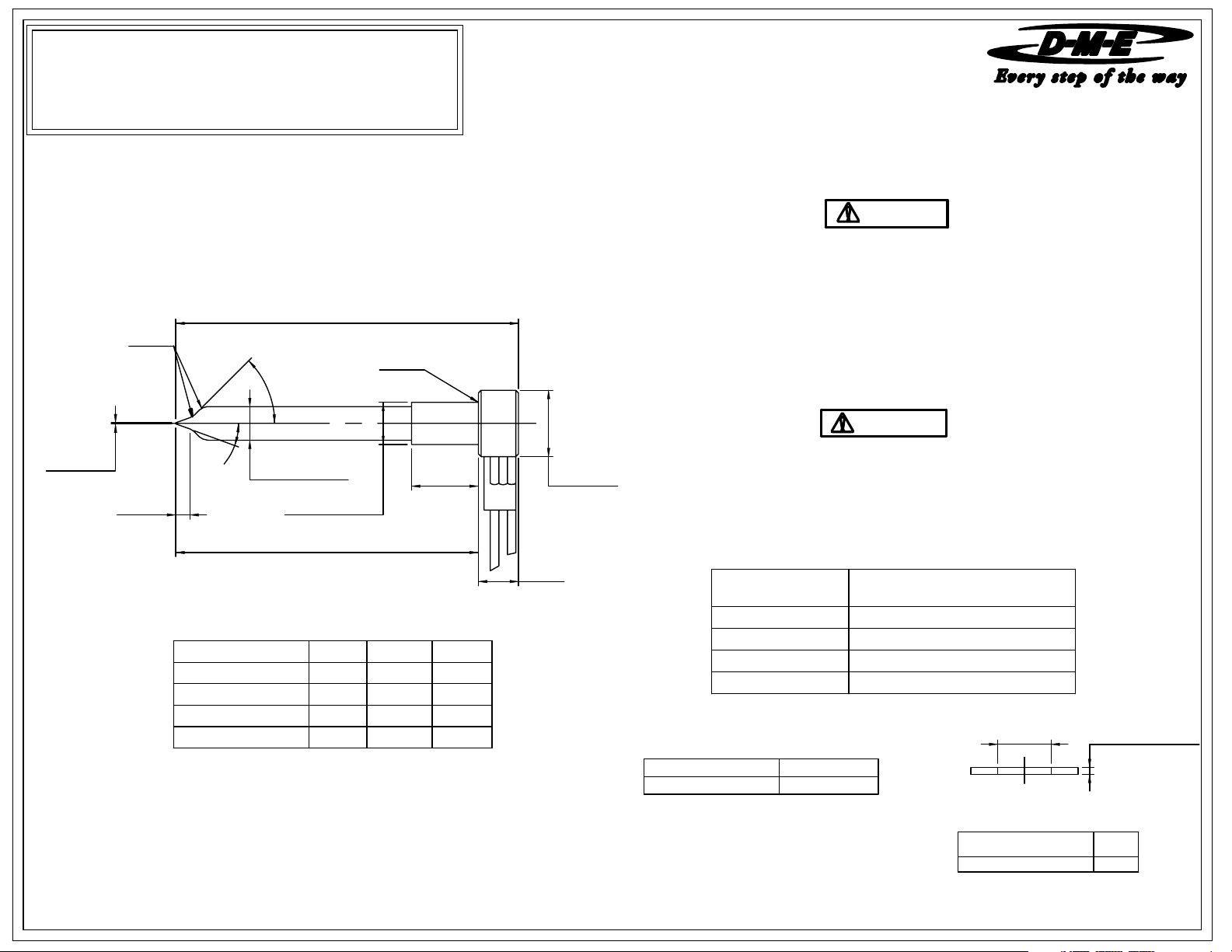

AUTO-FIXED INTEGRAL HEATER

MICRO PROBES

Please read carefully before installing probes

REFER TO : MINI PRINT # 1700

NOTE: PROBE DISCOLORATION

Each Integral Heater probe sold by D-M-E is pretested.

This procedure discolors the outer surface of the probe,

but in no way alters its performance or dimensions

AUTO-FIXED " INTEGRAL HEATER" MICRO PROBES

(240 VAC, T/C TYPE J, 48" LEADS)

MATERIAL, AISI D-2 STEEL OR EQUIVALENT HARDNESS, 50-55 RC

A

0.125 R.

0.030 R.

0.625

DIA.

0.005 DIA.

0.157

20°

4

5

°

0.000

0.312 -0.001

0.394

DIA.

0.000

-0.001

B

0.620 DIA.

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

DANGER

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

WARNING

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn. This product

has heated surfaces. Use caution when operating and servicing the system

to avoid severe burns. Proper protective equipment should be worn.

CATALOG NUMBER A DIM. B DIM.

AFIP3-310-90

AFIP3-360-90

AFIP3-410-90 4.095

3.095 2.720 110

3.595

3.220 130

Note: Dimensions shown in Inches.

WATTS

1503.720

1704.2204.595AFIP3-460-90

0.375

ITEM

ADJUSTMENT RING

REGISTER RING

GATE INSERT

THERMOCOUPLE

(Installed in probe)

LEAD LENGTHCATALOG NUMBER

AFIP3-310-90 THRU AFIP3-460-90

48"TC-9900

USED WITH

TC-9900THERMOCOUPLE

RAF3-062

AFRR-03N

AFGI-03N

ADJUSTMENT RINGS

(Packaged with all probes)

I.D.

0.062

(GRIND TO SUIT)

I.D.CATALOG NUMBER

0.456RAF3-062

Page 2

ME-0725-PS-216-B AFIP/ID

09-08

AUTO-FIXED INTEGRAL HEATER

MICRO PROBES

Please read carefully before installing probes

REFER TO : MINI PRINT # 1700

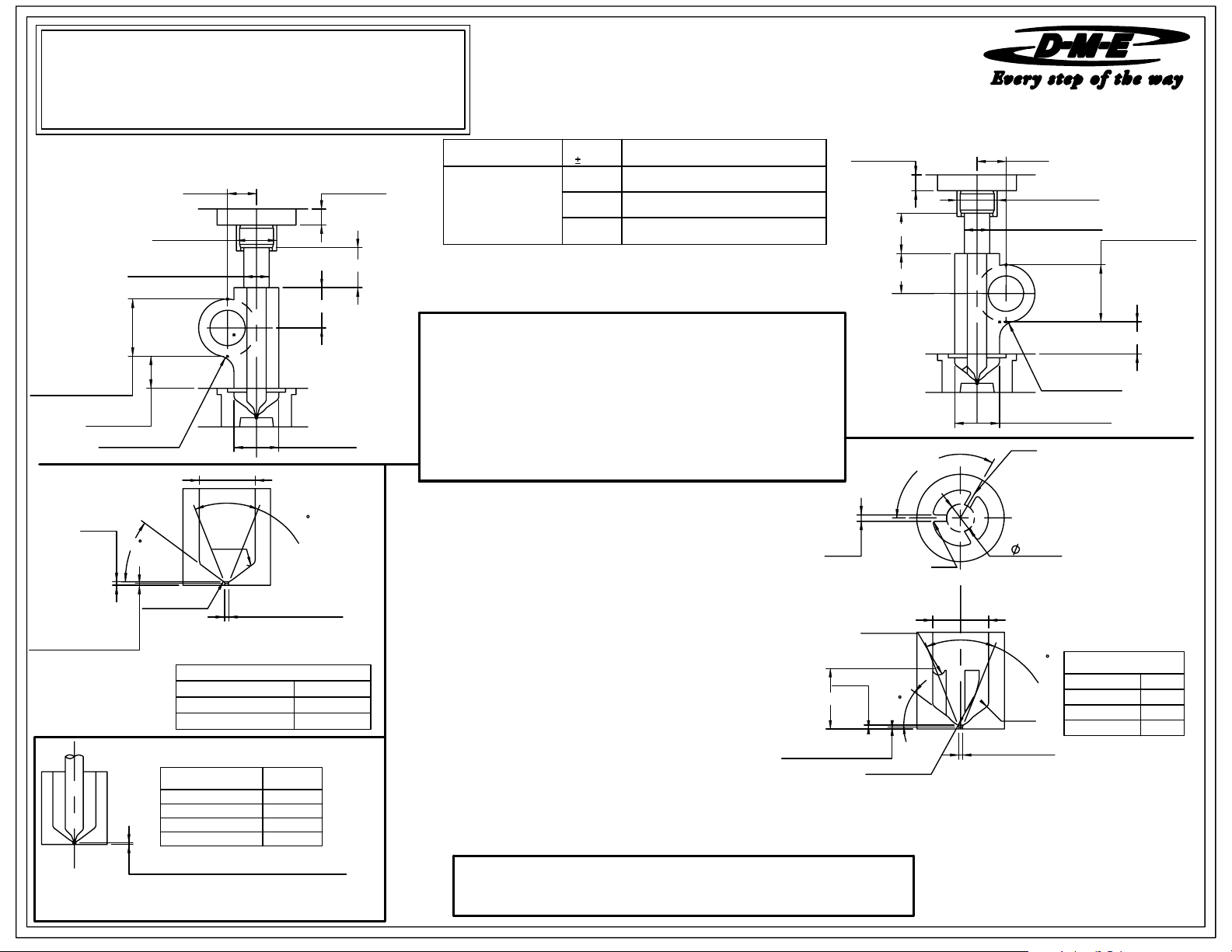

PROBE MACHINING DIMENSIONS - SOLID BLOCK DESIGN

0.625 MIN.

0.812 DIA.

8

0

C

L

.

0.812D DIA.

0.375

0.25 MIN.

0.625 MIN.

WIRING INFORMATION

Probe Heaters are supplied with 48" long leads.

Heaters are 240 VAC.

2 power leads are Multi Color.

Thermocouple is "J" Type.

Thermocouple is supplied with 48"/ 24 Gage leads.

1 T/C lead is WHITE and negative (-)

constantan (non-magnetic).

1 T/C lead is BLACK and positive (+)

iron (magnetic).

A

0.630 DIA.

+0.001

0.395

0.875/1.125 DIA.

DISTRIBUTOR

BORE

(SOLID BLOCK)

0.50 MIN.

0.25 RAD.

0.03

45

0.005 MAX. LAND

X DIMENSION (PROBE TIP SETTING

NOTE: X Dimension is for initial probe set up and may require

further adjustment. Final position of probe tip will be

determined by gate cosmetics and flow requirements.

DIA.

0.000

D DIA.

I

N

R

SPH.R.

GATE MACHINING DIMENSIONS

(SOLID BLOCK DESIGN)

AFIP3 SERIES PROBE

SPH. R. 0.187

INITIAL PROBE SET-UP DIMENSIONS

PROBE

CATALOG NUMBER

AFIP3-310-90

AFIP3-360-90 0.000-0.004

AFIP3-410-90 0.000-0.004

AFIP3-460-90

AT ROOM TEMPERATURE)

0.030/0.125

R

X DIM.

0.000-0.003

0.000-0.005

PROBE

CATALOG NUMBER

AFIP3

SERIES

NOTE: THE S SYMBOL INDICATES THE SPLIT

LINE FOR SPLIT PLATE DESIGNS.

INSTALLATION CHECK LIST

1) Insure that 0.630 diameter counterbore has been machined for probe head.

2) Check the hold down plate thickness and machined channel to

insure contact with probe and fit against adjustment ring.

3) Measure all probe machining dimensions the 0.395 diameter probe bore

must be with in the tolerance specified.

4) Double check that the probe "X" dimension is correct.

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

A DIMN.

0.010

0.428

0.544

0.550

L

USED WITH

0.394 DIA. DISTRIBUTOR PROBE

(0.875 DIA. CHANNEL OR BORE)

0.625 DIA. DISTRIBUTOR PROBE

(1.125 DIA. CHANNEL OR BORE)

0.628 DIA. DISTRIBUTOR TUBE

(1.125 DIA. CHANNEL OR BORE)

0.005 MAX. LAND

0.06 T DIA.

0.03

0.378

PROBE MACHINING DIMENSIONS - SPLIT PLATE DESIGN

0.25 MIN.

0.625 MIN.

0.625 MIN.

S

L

0.06 R

R0.06

SPH.R.

120.00°

D DIA.

5

4

0.030 / 0.125

REFER TO MINI PRINT 1700

FOR GUIDELINES OTHER THAN THOSE SHOWN

A

0.630 DIA.

+0.001

0.395

IMPORTANT: When using a single

Locator, the primary locator must

be positioned directly opposite the

distributor channel feeding the drop.

GATE MACHINING DIMENSIONS

I

N

R

DIA.

0.000

0.25 RAD.

0.812 DIA.

OPTIONAL LOCATIONS

(SPLIT PLATE DESIGN)

8

0

C

L

.

0.875/1.125

DISTRIBUTOR

CHANNEL

(SPLIT PLATE)

0.812 MIN.

AFIP3 SERIES

PROBE

D DIA.

T DIA. 0.313

SPH. R. 0.187

R0.375

0.812

D-M-E COMPANY

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6656

CANADA 800-387-6600

www.dme.net

Loading...

Loading...