DMC PH1005 Operation Manual

PH1005

POWER CRIMP TOOL

INTRODUCTION

The PH1005Power Crimp Tool is a pneumatic / hydraulic powered version of the Tyco®49935 hand crimp tool. The

basic system consists of a hand held tool (PHMT1005) and the PHRPU4 Remote Power Unit. The Remote Power

Unit contains cycle control logic that assures the tool completes the crimp cycle without operator intervention.

IMPORTANT SAFETY INSTRUCTIONS / USER’S RESPONSIBILITIES

When connected together, the PHMT1005 along with the remote power unit, constitute an integrated operating

system. Under no circumstances should the crimping tool be attached to any control box or power system other than

the control unit provided (PHRPU4). It is imperative that operators using this tool system follow the noted Safety

Precautions, be alert at all times and observe the highest level of operator safety.

1. Disconnect from air supply when tool is not in use or when changing dies.

2. Keep all body parts clear of the crimping area while loading and operating the tool.

3. Restrict operation of the PH1005 system to a single operator and follow the directions on the warning labels.

4. Do not alter the tool or operate outside the guidelines specified in this data sheet.

Itis the user’s responsibility to properly train andinstruct alltool operatorsinthe proper use of this tool.

The operator must be made aware of the danger of the moving parts, the possibility of serious injury to

fingers and other body parts in inserted into the crimp area; and the need to be alert and attentive at all

times while using this tool.

SAFETY OPERATION MANUAL

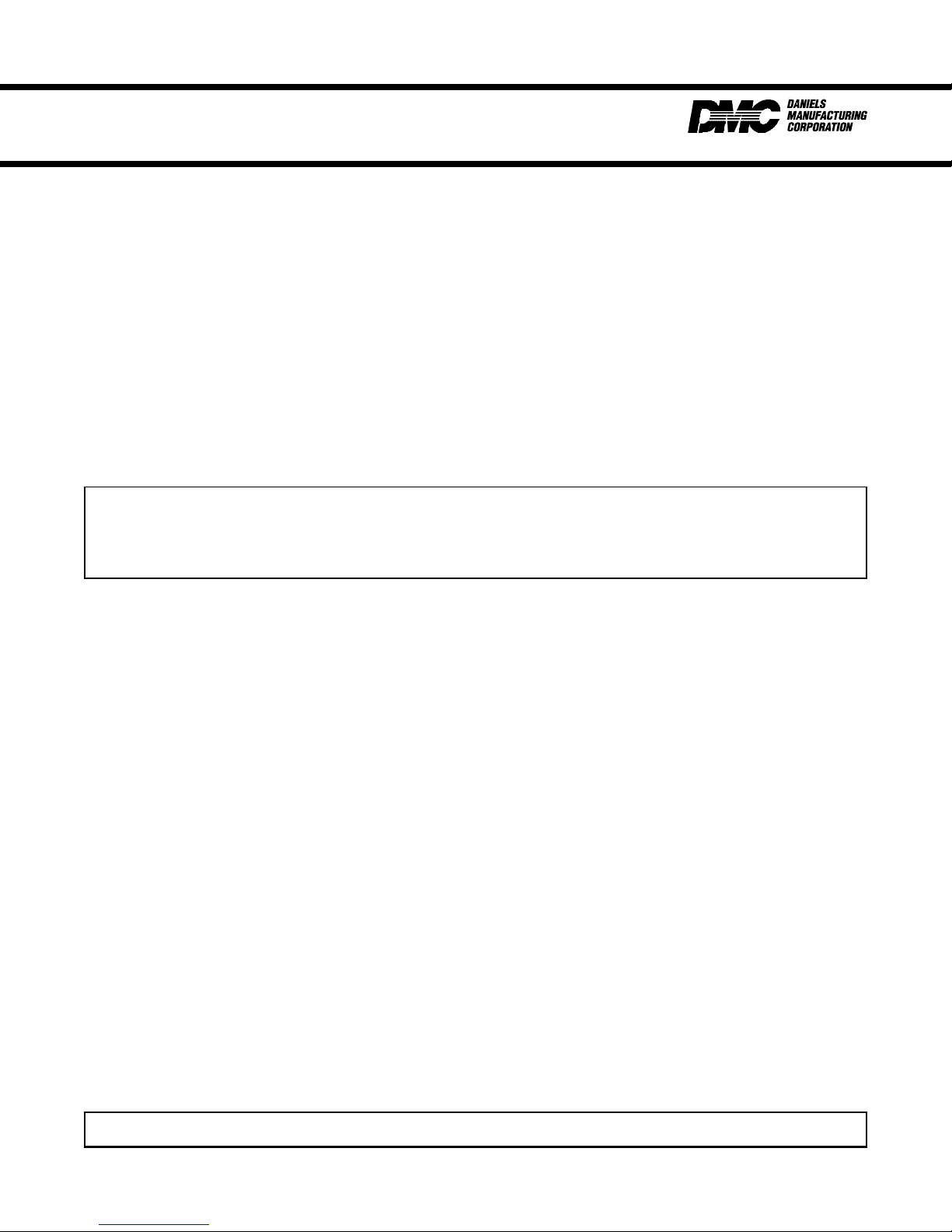

PREPARING TOOL FOR OPERATION (see Figure 1)

The PH1005 Power Crimp Toolconsists of the PHMT1005 CrimpingTool, PHRPU4 Remote Power Unit, PHFV3 Foot Press (optional), and the BM-2 Bench Mount (optional). Four features used for operation or control can be

seen on the front panel of the PHRPU4 Remote Power Unit, they include the Hydraulic Quick Disconnect, Dual

Coupling Control, Single Coupling Control, and the Input Air Quick Disconnect. Use the following steps to assemble the separate parts:

1. Connectthe hydraulic hose from the PHMT1005 Crimping Tool into the hydraulic quick disconnect on thefront

panelof the PHRPU4 Remote Power Unit by pushing back on the lockingringofthehydraulic quick disconnect

andpluggingthe male part of the hydraulic hose into the provided area. Theoperator will realize the connection

has been made when the locking ring snaps into place.

2. Connect the small tool control hose from the PHMT1005 Crimping Tool to the single coupling control on the

front panel of the PHRPU4 Remote Power Unit by pushing the connecting end of hose into the fitting until the

spring clip locks into place.

3. Connecttheshop air supply to the air quick disconnect by pulling back on the air hose coupling and inserting the

hose into the fitting on the PHRPU4 Remote Power Unit.

4. If PHFV-3 Foot Press is supplied, connect it to the dual coupling control by orienting the connector on the hose

so the side marked "TOP" is up, then press inward until the spring clips lock into place.

5. IfBM-2 Bench Mount is supplied, attach ittothe PHMT1005 Crimping Tool by threading themalethreadof the

benchmount into the female thread on the tool. Adjust toolto appropriate working position, and lock handle on

bench mount.

EMERGENCY STOP BUTTON

ThePHRPU4 Remote Power Unit is configured with an Emergency Stop Button. Bypressingthisbuttonat any time

during the crimp cycle, the forward motion on the crimp tool will stop and retract to the open position. Further

operation of the system will be inhibited until this Emergency Stop Button is rotated in a clockwise direction and

DANIELS MANUFACTURINGCORP. 526 THORPEROAD, ORLANDO, FL 32824, USA

PHONE (407)855-6161 • FAX (407) 855-6884• WWW.DMCTOOLS.COM • E-MAIL: DMC@DMCTOOLS.COM

COPYRIGHT© 2001 ALL RIGHTS RESERVED

1of6

12/01 REV. A FILE #: SOM0021 DOC. #: PH1005-SOM

PHMT1005

AIR BLEED

(ACTUATOR)

PHFV-3

(OPTIONAL)

DUAL COUPLING CONTROL

HYDRAULIC QUICK

DISCONNECT

BM-2

(OPTIONAL)

FIGURE 1

SAFETY OPERATION MANUAL

PHRPU4

EMERGENCY STOP

BUTTON

INPUT AIR

QUICK DISCONNECT

SINGLE COUPLING CONTROL

allowed to release.

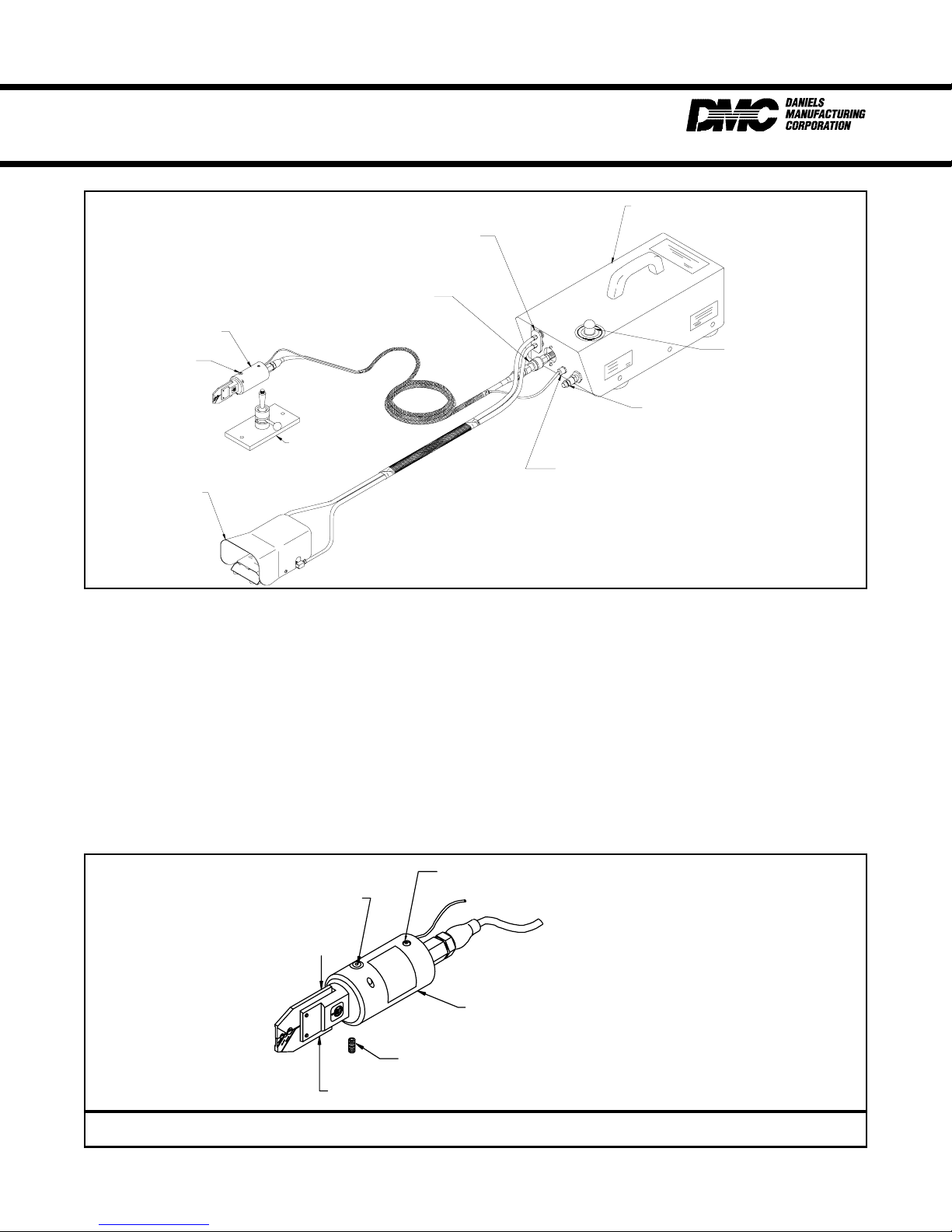

Tool Head Positioning (see Figure 2):

Thetoolheadon the PH1005 Crimping Tool may be rotated to any selectable position relative to the actuator that an

operatormightprefer. Toselect or change the head position, loosenthe headposition holding screwso thehead can

be turned by hand and rotate head to selected position, then tighten screw.

TOOL OPERATION:

After the PH1005 tool has beenassembled with the dies intheir proper location, the tool isready for operation. Use

the following steps to operate the tool properly and safely:

1. Connect the PHRPU4 remote power unit to a standard shop air supply of 80 - 120 psi. (5.5 - 8.3 BAR).

2. Insert component to be crimped in crimp jaws and position properly. The jaws are spring loaded and will hold

the part in place.

HYDRAULIC FLUID

AIR BLEED HOLE (SEAL HOLE

WITH FINGER TO ACTIVATE

TOOL)

FIGURE 2

PRESS HERE TO LOAD AND UNLOAD SPLICE

FILL HOLE

PHMT1005

CRIMP TOOL

HEAD POSITIONING HOLDING SCREW

DANIELS MANUFACTURING CORP. 526 THORPE ROAD, ORLANDO, FL 32824, USA

PHONE (407) 855-6161 • FAX (407) 855-6884 • WWW.DMCTOOLS.COM • E-MAIL: DMC@DMCTOOLS.COM

2of6

12/01 REV. A FILE #: SOM0021 DOC. #: PH1005-SOMCOPYRIGHT© 2001 ALL RIGHTS RESERVED

Loading...

Loading...