Page 1

REFERENCE SERIES

8

8

SUBWOOFERS

W610, W612,

W710, W712

MW10, MW12,

MW110, MW112

WELCOME

Thank you for buying a DLS REFERENCE subwoofer.

The subwoofer must be installed correctly in order to work

well. This manual will show you how to install it like a pro.

Please read the entire manual before beginning the installation.

Install the subwoofer yourself if you feel confident with

our instructions and if you have the proper tools. However

if you feel unsure, turn over the installation job to someone

better suited to it.

The speakers are designed for enclosure mounting. In

"open air" installations the power handling capacity is

reduced by 30% from the nominal value. We dont

recommend ”open air” installations for Reference

subwooers.

IMPORTANT!

The speaker cone of MW10/110, MW12/112 is made of

magnesium, a material of low weight with excellent

acoustic qualitys.

We recommend you NEVER to touch the cone body with

you fingers. Remaining deformation of the cone body will

occour if you push it with your fingers.

Also think of the speaker weight when you mount it. If you

don´t mount it properly it can get loose.

SUBWOOFER ENCLOSURES, GENERAL

Build your enclosure in a stable and airtight material. The

best is MDF-board, 19 mm, or particle board, 22 mm.

Larger enclosures must have bracing inside to avoid

vibrations. The enclosure must be completely airtight. Use

sealing compound in all joints, also around the cable

terminals. The size of the enclosure is decided by the speaker data.

SEALED ENCLOSURES

Sealed enclosures are easy to build. The size is not critical,

but it can´t be too small. The speaker data such as Fs,

Qts, V as and X-max decides the size of the enclosure.

Large speakers need larger boxes. T wo speakers need a

box of the double size etc. The enclosure must be

completely airtight.

A sealed enclosure should be filled with acoustic wool up

to 75 - 100%.

A sealed enclosure has a lower efficiency than vented

enclosures but they can handle high power and are easy

to build.

A subwoofer in a sealed enclosure creates a tight bass

suitable for the audiophiles listening to classical music,

jazz and soft rock. All the Reference subwoofers are

recommended NOT to use in sealed enclosures.

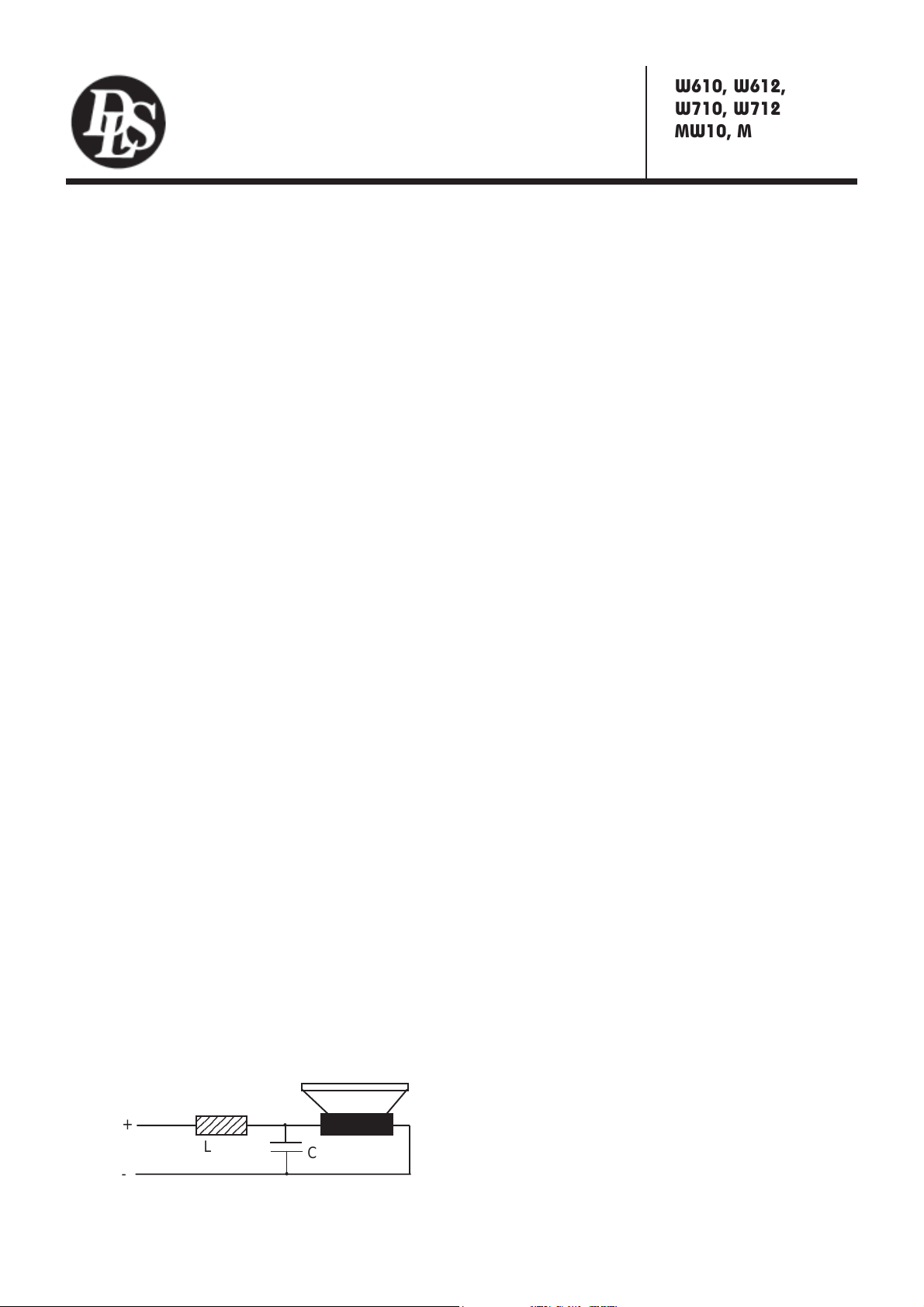

CONNECTION OF SUBWOOFER

How to connect depends on what type of amplifier you

use. The best is to follow the instructions given in the

manual for the amplifier. Most amplifiers today have builtin lowpass crossover and possibilities to connect your

subwoofer in bridge mode.

Two 4 ohm subwoofers are often connected in stereo mode

since most amplifiers can´t handle bridge mode loads

below 4 ohms. If you have a DLS Ultimate amplifier it´s

possible to connect two 4 ohm subs in bridge mode, these

ampliers are 1 ohm stable.

We also recommend the use of a subsonic highpass filter. This gives a better bass reproduction with less

"rumble". In most DLS amplifiers this feature is already

built-in.

For wiring use high class speaker wires, min A WG13 (2.5

mm2). For example DLS SC 2x2,5.

If you have an amplifier without built-in crossover you must

use a passive crossover between amplifier and subwoofer

like in this example:

234567

+

Connected with a 12 dB passive low-pass x-over = 10

mH coil in series and a bipolar capacitor of 300 microFarad

in parallel. Crossover frequency is 95 Hz.

234567

L

C

VENTED ENCLOSURES

A speaker in a vented enclosure has a higher ef ficiency (3

dB) and higher power handling capacity than in a sealed

enclosure. In a vented enclosure the sound from the speaker and the port work together creating a higher sound

level. The sound from the port must come out in the same

phase as from the speaker otherwise the result is bad.

The size of the vented enclosure is decided by the speaker data just as for the sealed one.

The size of the vehicle often decides the practical size of

the enclosure. A smaller enclosure has a higher resonant

frequency than the larger one. The size of the enclosure

should not be so big that the speaker plays below it´s own

free air resonance (Fs), then it looses in power handling

capacity.

The port does not have to be fully inside the enclosure as

long as the area and length are correct.

Sometimes you need two or more ports in an enclosure.

Y ou can convert from one to two or more ports as long as

the total port area is the same.

All DLS subwoofers works well in vented boxes.

BANDPASS ENCLOSURES

In all bandpass enclosures the speakers are hidden inside the enclosure, all sound is coming out through the

ports. There are different types of bandpass enclosures

and they have in common that they are a bit more difficult

to build. Most DLS subwoofers can be used in bandpass

enclosures.

Page 2

TECHNICAL SPECIFICATIONS FOR DLS REFERENCE SUBWOOFERS

W610 W612 W710 W712

Size 25 cm (10") 30 cm (12") 25 cm (10") 30 cm (12")

Impedance 4 ohm 4 ohm 4 ohm 4 ohm

Nom. power (RMS) 180 W (max 360) 210 W (max 400) 200 W (max 400) 250 W (max 480)

Freq. range 20 Hz- 1 kHz 20 Hz-1 kHz 20 Hz- 1 kHz 20 Hz-1 kHz

Sensitivity 89,7 dB 89,2 db 90,8 dB 91 dB

Voice coil diameter 50 mm (2”) 50 mm (2”) 50 mm (2”) 50 mm (2”)

Voice coil height 22 mm (0,87”) 22 mm (0,87”) 22 mm (0,87”) 22 mm (0,87”)

Re 3,6 ohm 3,3 ohm 3,6 ohm 3,24 ohm

Voice coil inductance, 1 kHz 1,58 mH 1,53 mH 1,49 mH 1,43 mH

BL product 15,98 15,98 17,43 16,69

X-max +-9 mm (0,35”) +-9 mm (0,35”) +-9 mm (0,35”) +-9 mm (0,35”)

Suspension compliance CMS 290 271 308 279

SD- Effective piston area 314,6 cm

Resonant freq. (Fs) 32,9 Hz 28,1 Hz 32,4 Hz 28,8 Hz

Vas (liters) 40,3 77,9 42,8 80,2

Vas (ft3) 1,42 2,75 1,51 2,83

Qms 3,63 3,93 3,76 3,13

Qes 0,23 0,32 0,19 0,23

Qts 0,22 0,30 0,18 0,21

Cone material PPC PPC PPC PPC

Magnet weight 40 oz (1,13 kg) 50 oz (1,42 kg) 80 oz (2,27 kg) 100 oz (2,83 kg)

Magnet diameter 5,7" (145 mm) 6,14" (156 mm) 5,7" (145 mm) 6,14" (156 mm)

Installation depth 4,29" (109 mm) 4,72" (120 mm) 5,08" (129 mm) 5,51" (140 mm)

Mounting hole 9,13" (232 mm) 11,18" (284 mm) 9,13" (232 mm) 11,18" (284 mm)

Outer diameter 10,31" (262 mm) 12,2" (310 mm) 10,31" (262 mm) 12,2" (310 mm)

Weigth 8,16 lb (3,7 kg) 10,14 lb (4,6 kg) 11,68 lb (5,3 kg) 13,56 lb (6,15 kg)

2

452,3 cm

2

314,6 cm

2

452,3 cm

2

RECOMMENDED ENCLOSURES FOR W610, W612, W710 & W712

RUNNING-IN PERIOD

Allow the speaker to play for at least

15-20 hours. After this time the

performance is correct.

Subwoofer Volume (liters/ft3) Port Damping F3 Fb

W610 vol: 35,6 / 1,25 4” x 32 cm/12,6” Line inside 43,4 Hz 43,0 Hz

W612 vol: 41,8 / 1,47 4” x 35 cm/ 13,7” Line inside 45,6 Hz 39,1 Hz

W710 vol: 35,4 / 1,25 4” x 29 cm/1 1,4” Line inside 45,4 Hz 45,0 Hz

W712 vol: 45,6 / 1,61 4” x 19,5 cm/7,7” Line inside 50,4 Hz 45,0 Hz

SEALED BANDPASS

The speaker is installed in Vb1

playing into chamber Vb2 where

the port(s) are installed.

Vb1=rear, Vb2=front

W610

Vb1 Vb2 port Vb2

19,0 18,6 1x10,2x19 cm

0,67 ft30,66 ft31x4"x7,5" (US)

F3 Vb1: 45 Hz, Vb2: 108 Hz

VENTED ENCLOSURE

W710

Vb1 Vb2 port Vb2

25,08 18,5 1x10,2x23,5 cm

0,88 ft30,65 ft31x4"x9,25" (US)

F3 Vb1: 40 Hz, Vb2: 106,6 Hz

F3 = approximative lower frequency for

vented boxes in Hz. Often called F-3 dB point

= the point where the power is 50% lower.

Fb = Box resonant frequency

SEALED ENCLOSURE

We don´t recommend the use of

sealed enclosures for these

subwoofers

W612

Vb1 Vb2 port Vb2

31,65 38,61 2x10,2x19 cm

1,12 ft31,36 ft32 x 4" x 7,5" (US)

F3 Vb1: 45 Hz, Vb2: 96,7 Hz

W712

Vb1 Vb2 port Vb2

33,97 19,4 1x10,2x17,5 cm

1,2 ft30,68 ft31 x 4" x 6,9" (US)

F3 Vb1: 40 Hz, Vb2: 120,5 Hz

Page 3

TECHNICAL SPECIFICATIONS FOR DLS REFERENCE SUBWOOFERS

MW110 MW112 MW10 MW12

Size 25 cm (10") 30 cm (12") 25 cm (10") 30 cm (12")

Impedance 4 ohm 4 ohm 4 ohm 4 ohm

Nom. power (RMS) 350 W (max 550) 350 W (max 550) 400 W (max 600) 400 W (max 600)

Freq. range 25 Hz- 2 kHz 20 Hz-2 kHz 25 Hz- 2 kHz 20 Hz-2 kHz

Sensitivity 87 dB 90 db 89 dB 91 db

Voice coil diameter 75 mm (3”) 75 mm (3”) 75 mm (3”) 75 mm (3”)

Voice coil height 24 mm (0,94”) 24 mm (0,94”) 24 mm (0,94”) 24 mm (0,94”)

Re 3,2 ohm 3,34 ohm 3,23 ohm 3,57 ohm

Voice coil inductance, 1 kHz 1,22 mH 0,99 mH 1,26 mH 0,95 mH

BL product 12,58 16,35 14,20 18,94

X-max +-9 mm (0,35”) +-9 mm (0,35”) +-9 mm (0,35”) +-9 mm (0,35”)

Suspension compliance CMS 197 205 202 210

SD- Effective piston area 314,6 cm

Resonant freq. (Fs) 36,7 Hz 31,8 Hz 35,1 Hz 37,1 Hz

Vas (liters) 27,5 58,8 28 60,2

Vas (ft3) 0,97 2,08 1,51 2,83

Qms 2,34 1,71 2,32 2,14

Qes 0,44 0,31 0,36 0,24

Qts 0,37 0,26 0,31 0,21

Cone material Magnesium Magnesium Magnesium Magnesium

Magnet weight 50 oz (1,42 kg) 70 oz (1,98kg) 100 oz (2,83 kg) 140 oz (3,97 kg)

Magnet diameter 6,14" (156 mm) 7,09" (180 mm) 6,14" (156 mm) 7,09" (180 mm)

Installation depth 4,33" (110 mm) 4,80" (122 mm) 5,11" (130 mm) 5,59" (142 mm)

Mounting hole 9,21" (234 mm) 11,10" (282 mm) 9,21" (234 mm) 11,10" (282 mm)

Outer diameter 10,31" (262 mm) 12,2" (310 mm) 10,31" (262 mm) 12,2" (310 mm)

Weigth 10,6 lb (4,8 kg) 14,3 lb (6,5 kg) 14,77 lb (6,7 kg) 19,6 lb (8,9 kg)

2

452,3 cm

2

314,6 cm

2

452,3 cm

2

RECOMMENDED ENCLOSURES FOR MW10, MW12, MW110 & MW112

RUNNING-IN PERIOD

Allow the speaker to play for at least

15-20 hours. After this time the

performance is correct.

Subwoofer Volume (liters/ft3) Port Damping F3 Fb

MW10 vol: 24 / 0,85 3” x 26 cm/10,2” Line inside 46,3 Hz 40,0 Hz

MW12 vol: 32 / 1,13 4” x 37 cm/ 14,5” Line inside 49,1 Hz 45,0 Hz

MW1 10 vol: 28,8 / 1,01 3” x 22 cm/8,8” Line inside 40,9 Hz 38,2 Hz

MW1 12 vol: 34,5 / 1,22 4” x 33 cm/13” Line inside 45,2 Hz 44,4 Hz

BANDPASS ENCLOSURES

The speaker is installed in Vb1

playing into chamber Vb2 where

the port(s) are installed.

MW10, MW12 & MW112 have

Vb1=rear, Vb2=front

ports also in Vb1.

MW10

Vb1 Vb2 Port Vb2

19,02 10,53 1x10,2x31 cm

0,67 ft30,37 ft31x4"x12,2" (US)

Port Vb1: 1 x 6,8 28 cm (1 x 3"x11" )

F3 Vb1: 47,8 Hz, Vb2: 109,5 Hz

VENTED ENCLOSURE

MW110

Vb1 Vb2 Port Vb2

16,81 13,48 1x10,2x34 cm

0,59 ft30,48 ft31x4"x13,4" (US)

F3 Vb1: 45 Hz, Vb2: 110,9 Hz

F3 = approximative lower frequency for

vented boxes in Hz. Often called F-3 dB point

= the point where the power is 50% lower.

Fb = Box resonant frequency

SEALED ENCLOSURE

We don´t recommend the use of

sealed enclosures for these

subwoofers

MW12

Vb1 Vb2 Port Vb2

27,02 18,18 3x6,8x20 cm

0,95 ft30,64 ft33 x 3" x 7,8" (US)

Port Vb1: 1x10,2x37 cm (1x4"x14,5")

F3 Vb1: 56 Hz, Vb2: 94 Hz

MW112

Vb1 Vb2 Port Vb2

29,62 17,51 3x6,8x23 cm

1,05 ft30,62 ft33 x 3" x 9" (US)

Port Vb1: 1x6,8x17 cm (1x3"x6,7")

F3 Vb1: 49,7 Hz, Vb2: 98,8 Hz

Page 4

HINTS & TIPS FOR ”DO IT YOURSELF” ENCLOSURE BUILDERS

ABOUT THE RECOMMENDED ENCLOSURES

The performance of these recommended enclosures will

vay from vehicle to vehicle. It is more difficult to get a tight

and well defined bass in a SEDAN vehicle because of the

tightness between trunk and interior of the vehicle. In this

case a bandpass box could be a better choise.

- All volumes are inside measures.

- Volumes occupied by speaker and ports have already

been added to the given enclosure volumes.

- Use conical bass ports for best result. (DLS BP-75 or

BP-1 10). If the ports are too long for the box you can use

a bend. Either cut the tube and glue it together in angle, or

use factory made tube bends. It´s easier to use the factory

made ones. The total length must be the same as for a

straight tube. Make the measure in the center of the tube.

The port opening inside the enclosure must not be closer

to an interior wall than 3” (75 mm), otherwise it will have

negative effects on the airflow .

- The enclosure must be very steady and completely airtight. Use 22 mm particle board or 19 mm MDF-board.

The particle board has a self resonant frequency of 14 Hz

while the MDF has a resonant frequency of approx. 400

Hz. It´s important to do some type of bracing inside the

enclosure to avoid vibrations.

Volume taken up by bracing should be added to the

enclosure volumes.

ENCLOSURE DAMPING

Most enclosures should be damped inside with syntetic

(acoustic) wool or damping mat (line). Attach the damping

material on the wall opposite from the speaker and port. A

sealed enclosure should be filled up to 70-100% with

acoustic wool.

In a vented enclosure the speaker and port should be on

the same side, otherwise a fade-out of some frequencies

can occour. In most vehicles, except for SEDAN cars, the

speaker and port should be directed backwards for best

result.

upper

THE SUBWOOFER

speaker cone

chassis

dust cap

suspension

spider

ENCLOSURE PLACING IN DIFFERENT TYPES OF

VEHICLES

In small vehicles like VW Golf, Peugeot 306 and similar

the bass box should be installed with both speaker and

port directed backwards. Alternatively booth speaker and

port can be directed upwards. This way of mounting is

valid for all types of vehicles where the trunk is

incorporated with the inner compartment.

In sedan vehicles with the passenger compartment

separated from the trunk, the enclosure should be installed

with booth speaker and port directed towards the rear seat.

Some cars have an opening in the middle of the rear seat

for loading skis etc. You can install the enclosure behind

this opening and direct speaker or port through this

opening. There must be some free space in front of the

port, (between the rear seat and the port opening).

In large vehicles like station wagons the best sound is

achieved with the enclosure installed behind the rear seat

with booth speaker and port directed backwards.

Alternatively you can install the enclosure on one side of

the luggage compartment.

CALCULATE YOUR ENCLOSURE

Box volumes:

When caculating the volume of an enclosure you simply

multiply the width (W) x heigth (H) x depth (D).

Use measures in dm and you will get the answer in liters.

A trapezoid box is calulated as below:

Vol=width (W) x heigth (H) x upper depth (UD) + lower depth (LD)

W

UD

H

LD

2

Be sure to measure the

inside dimensions.

WARRANTY SERVICE

This speaker is covered by warranty, depending on the

conditions in the country where it is sold. If the speaker is

returned for service, please include the original dated

receipt with the product.

voice coil

magnet

pole plate

T-yoke

DLS Svenska AB

P.O. Box 13029

SE-40251 Göteborg, Sweden

Tel: +46 31 840060

Fax: +46 31 844021

E-mail: info@dls.se

www.dls.se

Technical Assistance

For technical assistance ask the shop where the product

was sold or the distributor in your very country.You can

always phone the DLS Helpdesk in Sweden + 46 31

840060 or send an e-mail to info@dls.e

Information can also be found on our WEB-site www.dls.se

We follow a policy of continuous advancement in

development. For this reason all or part of specifications

& designs may be changed without prior notice.

Loading...

Loading...