DKS Enterprises 9100 User Manual

Owner’s Manual

Model 9100

Vehicular Slide Gate Operator

DoorKing, Inc.

120 Glasgow Avenue

Inglewood, California 90301

U.S.A.

Phone: 310-645-0023

Fax: 310-641-1586

www.doorking.com

P/N 9100-065 REV B, 1/01

Copyright 2000 DoorKing, Inc. All rights reserved.

ii

Use this manual with the following model only.

Model 9100-080 with circuit board 4602-010.

DoorKing, Inc. reserves the right to make changes in the products described in this manual

without notice and without obligation of DoorKing, Inc. to notify any persons of any such revisions

or changes. Additionally, DoorKing, Inc. makes no representations or warranties with respect to

this manual. This manual is copyrighted, all rights reserved. No portion of this manual may be

copied, reproduced, translated, or reduced to any electronic medium without prior written consent

from DoorKing, Inc.

iii

IMPORTANT NOTICES

Vehicular gate systems provide convenience to their users and limit vehicular traffic onto your

property. These systems can produce high levels of force; therefore it is important that you are aware

of possible hazards associated with your gate operating system. These hazards may include pinch

points, entrapment, absence of controlled pedestrian access or traffic backup.

Be sure that the installer has instructed you on the proper operation of the gate and gate operator

system. Be sure that the installer has trained you about the basic functions of the required reversing

systems associated with your gate operating system and how to test them. These include reversing

loops, inherent reversing system, electric edges, photoelectric cells, or other external devices.

• This Owner's Manual is your property. Keep it in a safe place for future reference.

• Loops and loop detectors must be installed with this gate operator to prevent the gate from

closing on vehicular traffic.

• The speed limit for vehicular traffic through the gate area is 5 MPH. Install speed bumps and

signs to keep vehicular traffic from speeding through the gate area. Failure to adhere to

posted speed limits can result in damage to the gate, gate operator, and to the vehicle.

• Be sure that all residents are familiar with the proper use of the gate and gate operator. Be

sure that all residents are familiar with the possible hazards associated with the gate system.

• Be sure that all warning signs are permanently installed on both sides of the gate in an area

where they are fully visible to traffic.

• It is your responsibility to periodically check all reversing devices. If any of these devices are

observed to function improperly, remove the operator from service immediately and contact

your installing or servicing dealer.

• Follow the recommended maintenance schedule.

• Do not allow children to play in the area of the operator or to play with any gate-operating

device.

• Be sure that all activating devices are installed a minimum distance of 10 feet away from the

gate and gate operator, or in such a way that a person cannot touch the gate or gate operator

while using the activating device. If activating devices are installed in violation of these

restrictions, immediately remove the gate operator from service and contact your installing

dealer.

• To remove the gate operator from service, operate the gate to the full open position and then

shut off power to the operator at the service panel.

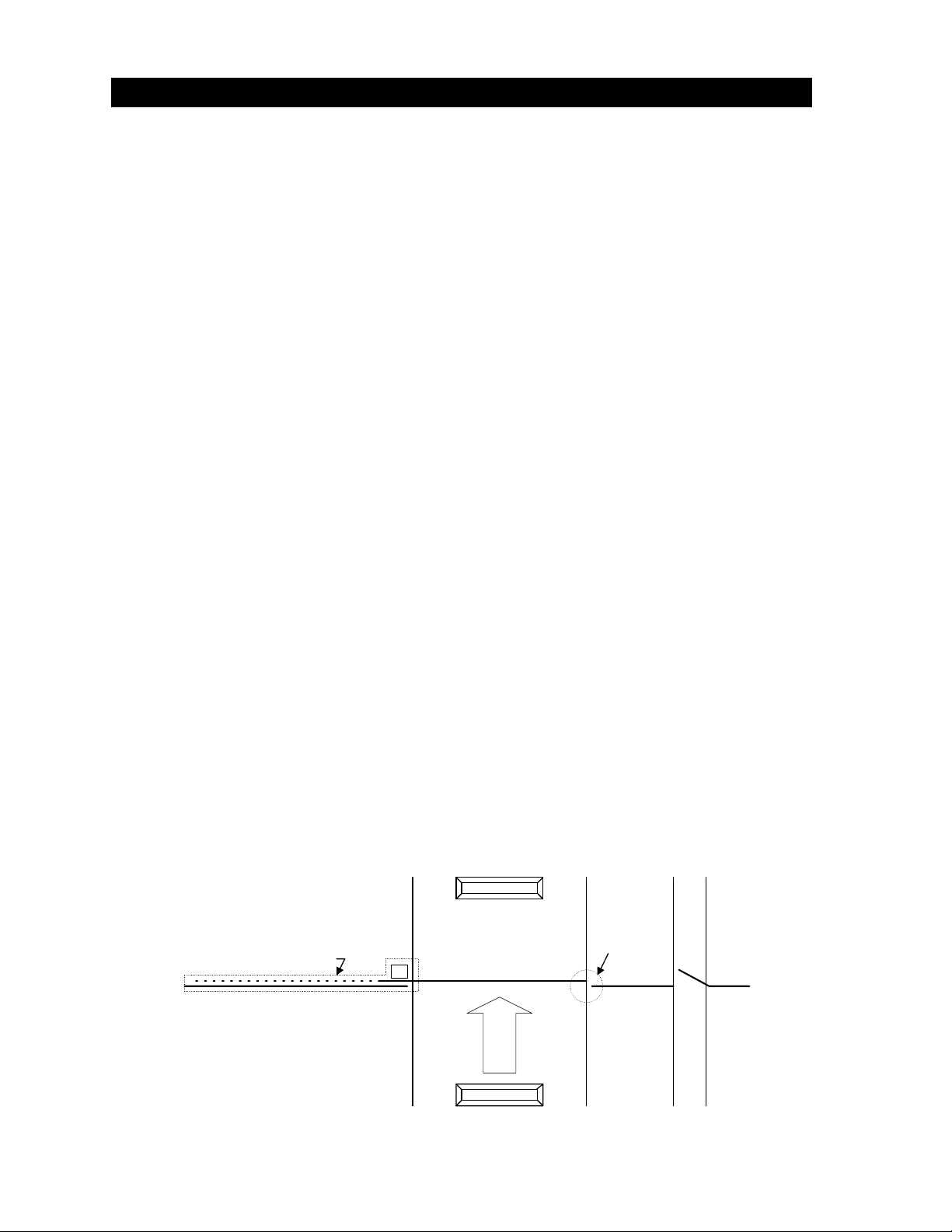

SPEED BUMP

HAZARD AREA

HAZARD AREA

VEHICULAR

SPEED BUMP

iv

TRAFFIC

PEDESTRAINS

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control

away from children.

3. Always keep people and objects away from gate. NO ONE SHOULD CROSS

THE PATH OF THE MOVING GATE.

4. Test the operator monthly. The gate MUST reverse on contact with a rigid object

or stop or reverse when an object activates the non-contact sensors. After

adjusting the force or the limit of travel, retest the gate operator. Failure to adjust

and retest the gate operator properly can increase the risk of injury or death.

5. KEEP GATES PROPERLY MAINTAINED. Read the owner's manual. Have a

qualified service person make repairs to gate hardware.

6. The entrance is for vehicles only. Pedestrians must use separate entrance.

7. SAVE THESE INSTRUCTIONS!

v

RESTRICTIONS AND WARNINGS

Install The Gate Operator Only If:

• The operator is appropriate for the usage Class of the application and the gate is within the

weight and length limitations specified for the operator.

• All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to

a minimum of 4 feet (1.2 m) above the ground to prevent a 2 ¼ inch (57.15 mm) diameter

sphere from passing through the openings anywhere in the gate, and in that portion of the

adjacent fence that the gate covers in the open position.

• All exposed pinch points are eliminated or guarded.

• This operator is intended for installation only on slide gates used to control vehicular traffic.

Pedestrians must be provided with a separate access opening.

• The gate must be installed in a location so that sufficient clearance is provided between the

gate and adjacent structures when opening and closing to reduce the risk of entrapment (see

diagram). Sliding gates should not open into public access areas.

• The gate must be properly installed and work freely in both directions prior to the installation

of the gate operator. Do not over-tighten the operator clutch to compensate for a damaged

gate.

• Controls must be far enough from the gate so that the user is prevented from coming in

contact with the gate while operating the controls. Outdoor or easily accessible controls

should have a security feature to prevent unauthorized use.

• All warning signs and placards must be installed where visible in the area of the gate.

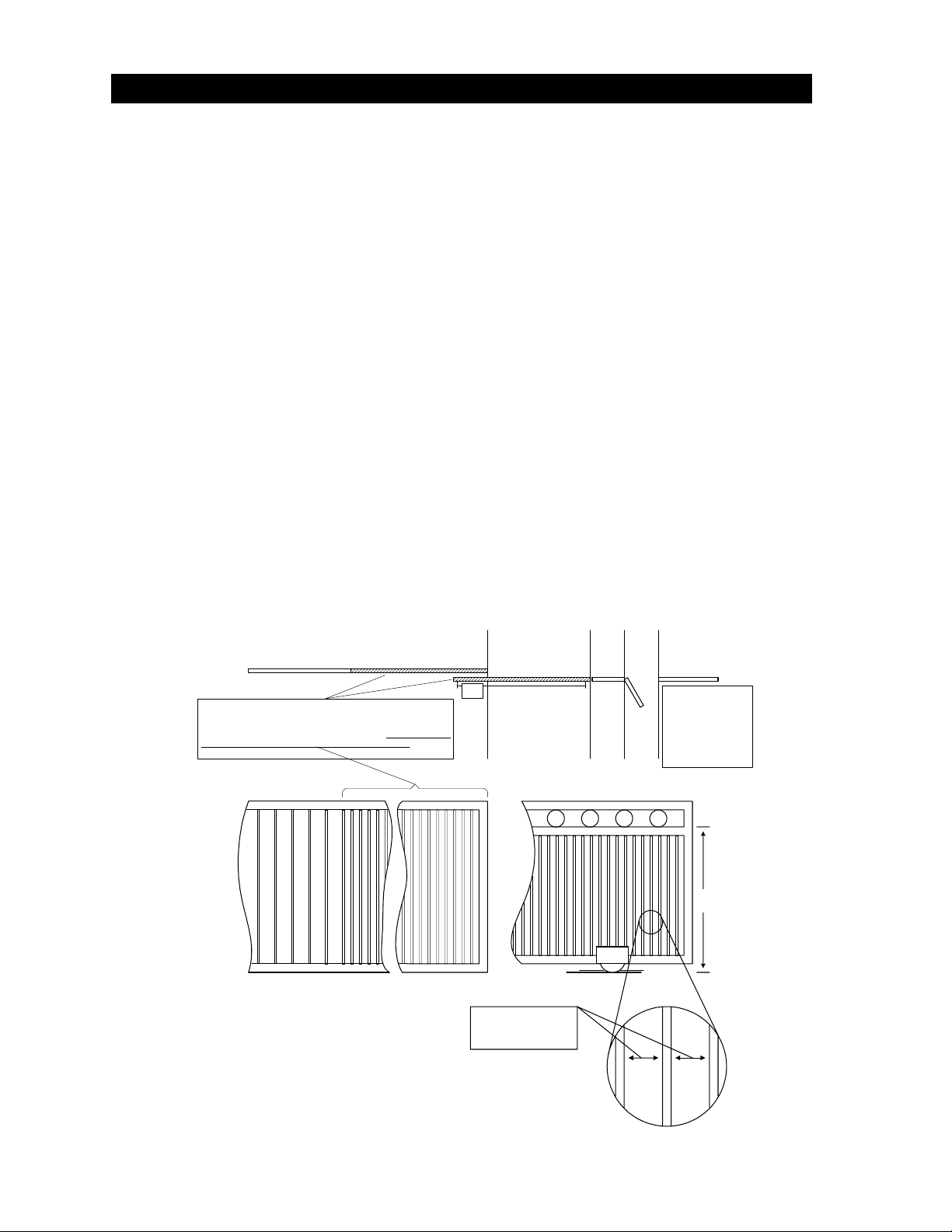

Fence

All openings of a horizontal slide gate are guarded or screened from the

bottom of the gate to a minimum of four (4) feet (1.2 m) above the

ground to prevent a 2 1/4 inch (57.15 mm) diameter sphere from passing

through the openings anywhere in the gate and in that portion of the

adjacent fence that the gate c overs in the open position. (ref. UL325

51.8.4.a.2)

Fence

Vehicular Gate

Gate Operator

Spacing must be such

that a 2 1/4 inch sphere

cannot pass through.

Roadway

Gate

V-Track

Fence

Pedestrian

Access

The operator is

intended for installation

only on gates used for

vehicles. Pedestrians

must be supplied with a

seperate access

opening. (ref. UL325

Sidewalk

51.8.4.b)

4 ft.

min

vi

ENTRAPMENT PROTECTION

This vehicular gate operator is equipped with an inherent (Type A) entrapment sensing system. This

system will sense an obstruction in both the opening and closing gate cycles, and will cause the gate

to reverse direction should an obstruction be encountered. If the system detects a second obstruction

before reaching the full open or close limit after the initial reversal, an alarm will activate and the

operator will require a reset before resuming normal operation. See Section 4 for more information.

EXTERNAL ENTRAPMENT PROTECTION

Non-contact and/or contact sensors must be installed individually or in combination with each other to

provide external entrapment protection. For gate operators utilizing a non-contact sensor:

• See diagram below for placement of non-contact sensors.

• Care should be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips

the sensor while the gate is still moving, and

• One or more non-contact sensors shall be located where the risk of entrapment or

obstruction exists, such as the perimeter reachable by a moving gate or barrier.

Open beam protects area

between the gate and

adjacent fence during the

Fence

open cycle.

Gate

Entrapment area exist between the gate

and the adjacent fence when the gate is in

the opening cycle.

Close beam prevents gate

from hitting obstructions

during the close cycle.

For gate operators utilizing a contact sensor:

• A hardwired contact sensor shall be located and it’s wiring arranged so that the

communication between the sensor and the gate operator is not subjected to mechanical

damage.

• A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate

operator for entrapment protection functions shall be located where the transmission of the

signals are not obstructed or impeded by building structures, natural landscaping or similar

obstruction. A wireless contact sensor shall function under the intended end-use conditions.

Fence

Trailing Edge

Entrapment area exist between the gate

and the adjacent fence when the gate is in

the opening cycle.

Outside

Inside

Gate

Leading Edge

vii

GLOSSARY

GATE – A moving barrier such as a swinging, sliding, raising, lowering, or the like, barrier, that is a

stand-alone passage barrier or is that portion of a wall or fence system that controls entrance and/or

egress by persons or vehicles and completes the perimeter of a defined area.

RESIDENTIAL VEHICULAR GATE OPERATOR-CLASS I - A vehicular gate operator (or system)

intended for use in a home of one-to four single family dwelling, or garage or parking area associated

therewith.

COMMERCIAL / GENERAL ACCESS VEHICULAR GATE OPERATOR-CLASS II - A vehicular gate

operator (or system) intended for use in a commercial location or building such as a multi-family

housing unit (five or more single family units), hotels, garages, retail store, or other building servicing

the general public.

INDUSTRIAL / LIMITED ACCESS VEHICULAR GATE OPERATOR-CLASS III - A vehicular gate

operator (or system) intended for use in an industrial location or building such as a factory or loading

dock area or other locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR-CLASS IV - A vehicular gate operator (or

system) intended for use in a guarded industrial location or building such as an airport security area

or other restricted access locations not servicing the general public, in which unauthorized access is

prevented via supervision by security personnel.

SYSTEM - In the context of these requirements, a system refers to a group of interacting devices

intended to perform a common function.

WIRED CONTROL - A control implemented in a form of fixed physical interconnections between the

control, the associated devices, and an operator to perform predetermined functions in response to

input signals.

WIRELESS CONTROL - A control implemented in means other than fixed physical interconnections

(such as radio waves or infrared beams) between the control, the associated devices, and an

operator to perform predetermined functions in response to input signals.

INHERENT ENTRAPMENT SENSOR SYSTEM - An automatic sensor system, which senses

entrapment of a solid object and is incorporated as a permanent and integral part of the operator.

ENTRAPMENT – The condition when an object is caught or held in a position that increases the risk

of injury.

viii

TABLE OF CONTENTS

Section 1 – Installation

1.1 Specifications ...........................................................................................................................................1

1.2 Mounting Positions

1.2.1 Front Position Pad Mount.........................................................................................................2

1.2.2 Front Position Post Mount........................................................................................................2

1.2.3 Rear Position Pad or Post Mount.............................................................................................3

1.2.4 Center Position Post Mount .....................................................................................................3

1.3 Mounting Options

1.3.1 Pad Mounted Operators...........................................................................................................4

1.3.2 Post Mounted Operators ..........................................................................................................5

1.4 Operator Installation

1.4.1 Pad Mounted Operators...........................................................................................................6

1.4.2 Post Mounted Operators ..........................................................................................................6

1.5 Chain Installation

1.5.1 Front – Pad Mount ...................................................................................................................7

1.5.2 Front – Post Mount...................................................................................................................8

1.5.3 Rear – Pad or Post Mount........................................................................................................9

1.5.4 Center – Post Mount ................................................................................................................10

1.6 Warning Sign Installation..........................................................................................................................11

Section 2 – Wiring

Conduits ...................................................................................................................................................13

2.1 High Voltage Connections........................................................................................................................14

2.2 Control Wiring...........................................................................................................................................15

2.3 Secondary Entrapment Protection Device Wiring

2.3.1 Non-Contact Sensors ...............................................................................................................16

2.3.2 Contact Sensors.......................................................................................................................17

2.4 Loop Detector Wiring................................................................................................................................18

2.5 Gate Tracker™ Connections....................................................................................................................19

2.6 Auxiliary Devices

2.6.1 Alarm Reset Switch..................................................................................................................20

2.6.2 Auxiliary Stop Switch................................................................................................................20

2.7 Master / Slave Wiring

2.7.1 Operator Interface ....................................................................................................................21

2.7.2 Secondary Entrapment Protection Device Wiring ....................................................................22

2.8 Terminal Identification and Description

2.8.1 Main Terminals.........................................................................................................................23

2.8.2 Auxiliary Terminals...................................................................................................................24

Section 3 – Adjustments

3.1 Circuit Board Adjustments........................................................................................................................25

3.2 Switch Settings.........................................................................................................................................26

3.2.1 SW 1 (Left Switch) Description and Function...........................................................................27

3.2.2 SW 2 (Right Switch) Description and Function ........................................................................27

3.3 Limit Adjustment.......................................................................................................................................28

3.4 Inherent Reverse Adjustment

3.4.1 Reverse Sensitivity Adjustment................................................................................................29

3.4.2 Clutch Adjustment ....................................................................................................................30

ix

Section 4 – Operating Instructions

4.1 Power and Reset Switches.......................................................................................................................31

4.2 Shutdown Conditions

4.2.1 Soft Shutdown ..........................................................................................................................32

4.2.2 Resetting a Soft Shutdown.......................................................................................................32

4.2.3 Hard Shutdown.........................................................................................................................33

4.2.4 Resetting a Hard Shutdown .....................................................................................................33

4.3 Manual / Emergency Gate Operation

4.3.1 Emergency Vehicle Access Conditions....................................................................................34

4.3.2 Fail-Safe Manual Operation .....................................................................................................34

4.3.3 Fail-Secure Manual Operation .................................................................................................35

Section 5 – Maintenance and Troubleshooting

5.1 Maintenance Schedule .............................................................................................................................37

5.2 Trouble Shooting ......................................................................................................................................38

5.3 Accessories ..............................................................................................................................................41

Wire Diagram............................................................................................................................................42

Illustrated Parts Breakdown......................................................................................................................43

x

SECTION 1 - INSTALLATION

Prior to beginning the installation of the slide gate operator, we suggest that you become familiar with

the instructions, illustrations, and wiring guide-lines in this manual. This will help insure that your

installation is performed in an efficient and professional manner.

The proper installation of the vehicular slide gate operator is an extremely important and integral part

of the overall access control system. Check all local building ordinances and building codes prior to

installing this operator. Be sure your installation is in compliance with local codes.

1.1 SPECIFICATIONS

Class of Operation: Class I, II, III, IV

Type of Gate: Vehicular Slide Gates Only

Horsepower: 1/2 H.P.

Voltage / Phase: 115 VAC Single-phase only

Current: 5.4 amps

Max Gate Weight: 1000 Lbs.

Max Gate Length: 30 Ft.1

Cycles / Hr: 60/Hr

Speed: Approximately 1 Ft./Sec.

Entrapment Protection: Primary – Inherent (Type A)

Secondary – Provision for connection of a non-contact

sensor (Type B1) and/or a contact sensor (Type B2).

Secondary entrapment protection devices are not supplied

with the operator and must be ordered separately.

Note 1: Assumes gate is in good working condition installed on a

level surface.

1

12

24

14.75 11.5

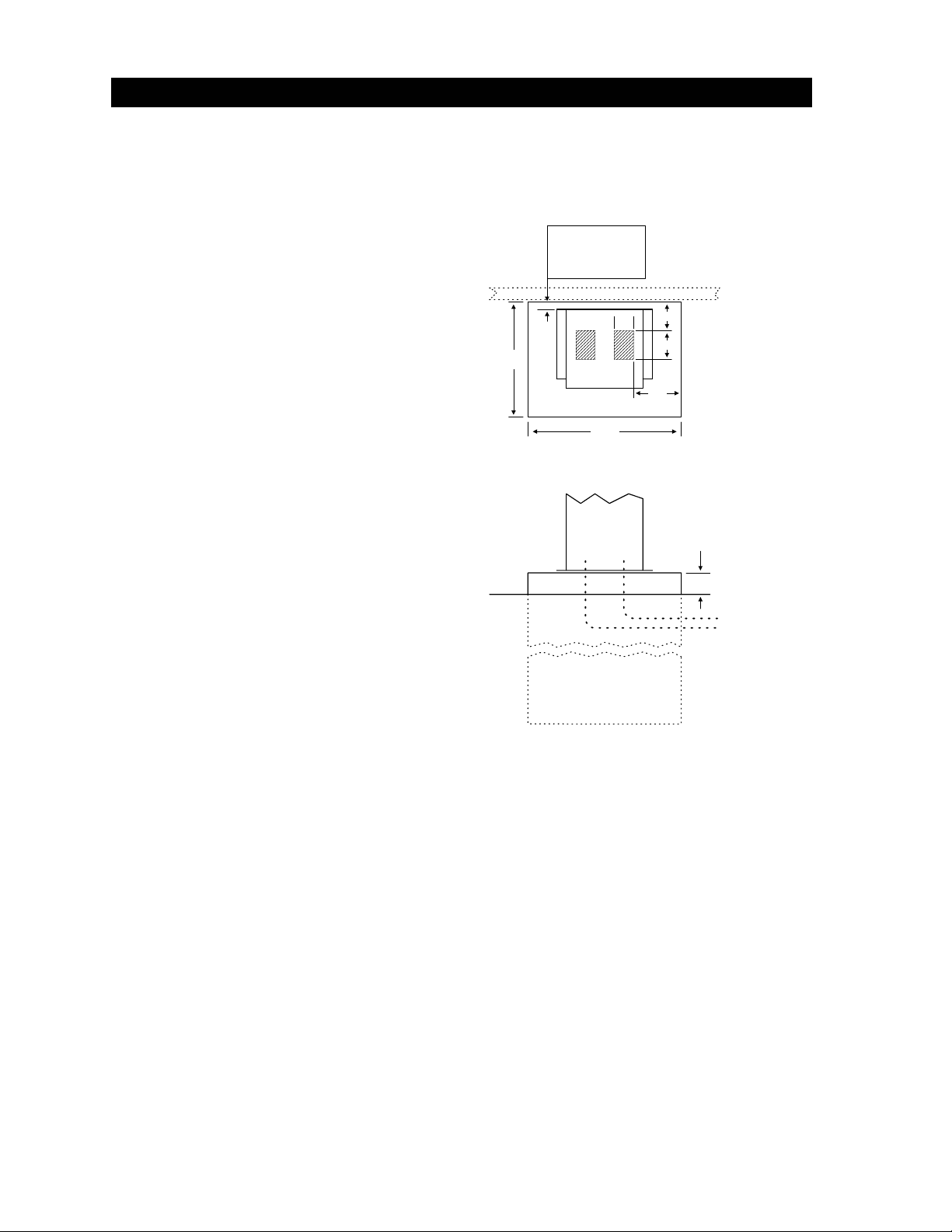

Figure 1

1

1.2 MOUNTING POSITIONS

The Model 9100 operator is designed so that it can be installed in any of the mounting positions

shown below. Once the mounting position has been determined, the chain idlers must be adjusted to

accommodate the mounting position chosen before the operator is mounted to the pad or post. The

idlers are factory set for the front, pad mount position. (Note: Rear and center position, and postmounted operators require additional hardware not supplied with the operator).

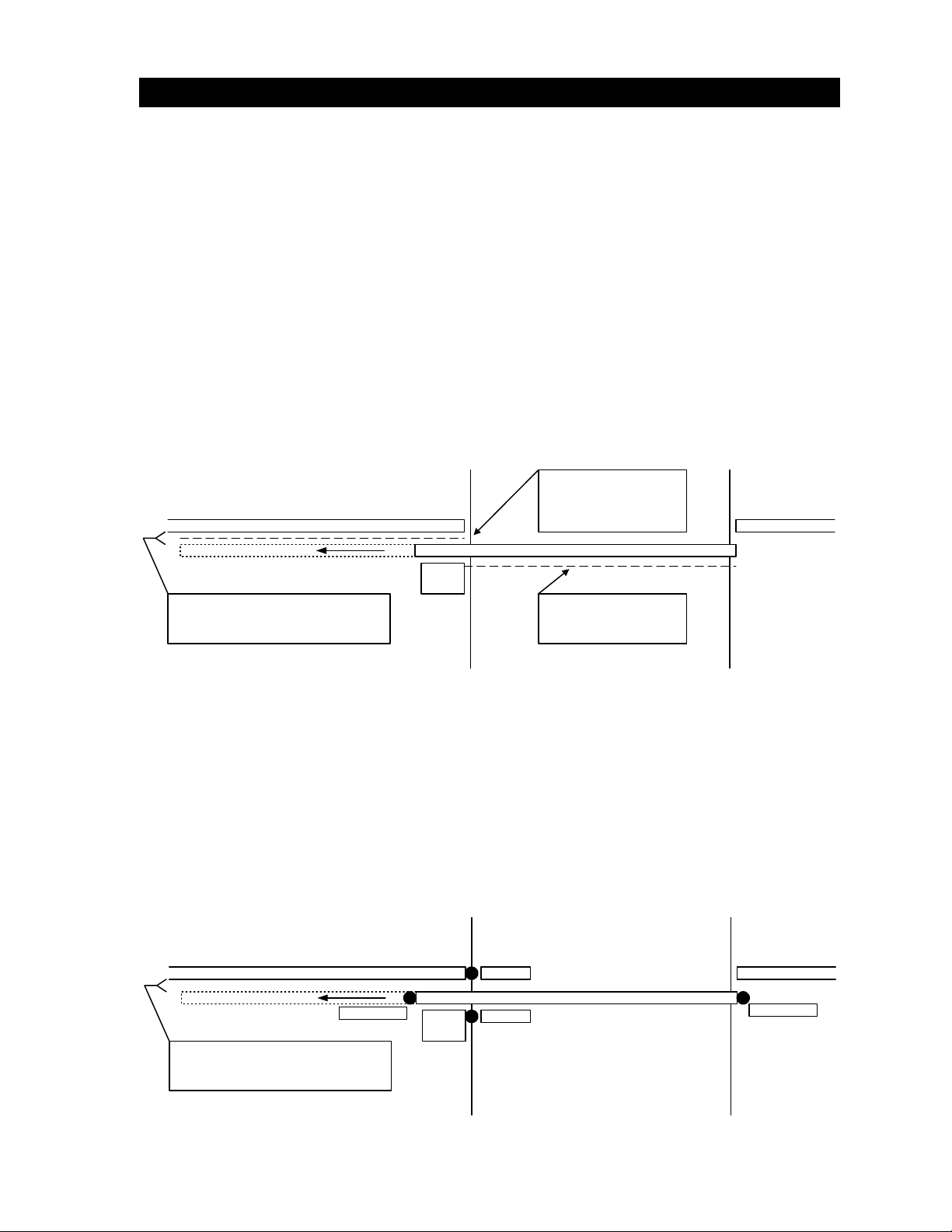

1.2.1 FRONT POSITION PAD MOUNT

• This is considered the standard

method of installing slide gate

operators.

• Set both chain idlers in the top

position (factory setting).

• Remove the TOP chain knockouts

from each side of the operator.

• Chain passes through the

operator and is attached to each

end of the gate.

1.2.2 FRONT POSITION POST MOUNT

• Set both chain idlers in the

bottom position.

• DO NOT remove chain

knockouts. Using this mounting

method, the chain enters and

exits the operator from the

bottom.

• Chain passes through the

operator and is attached to each

end of the gate.

• This mounting method allows for

the use of chain support

attached to the gate. This is useful with long gates and helps prevent chain “stretching.”

Figure 2

Figure 3

• ADDITIONAL HARDWARE REQUIRED: Post Mount Base Plate P/N 2600-418 and two (2)

4” x 4” steel mounting post at least three feet in length. Mounting post are not available from

DoorKing.

2

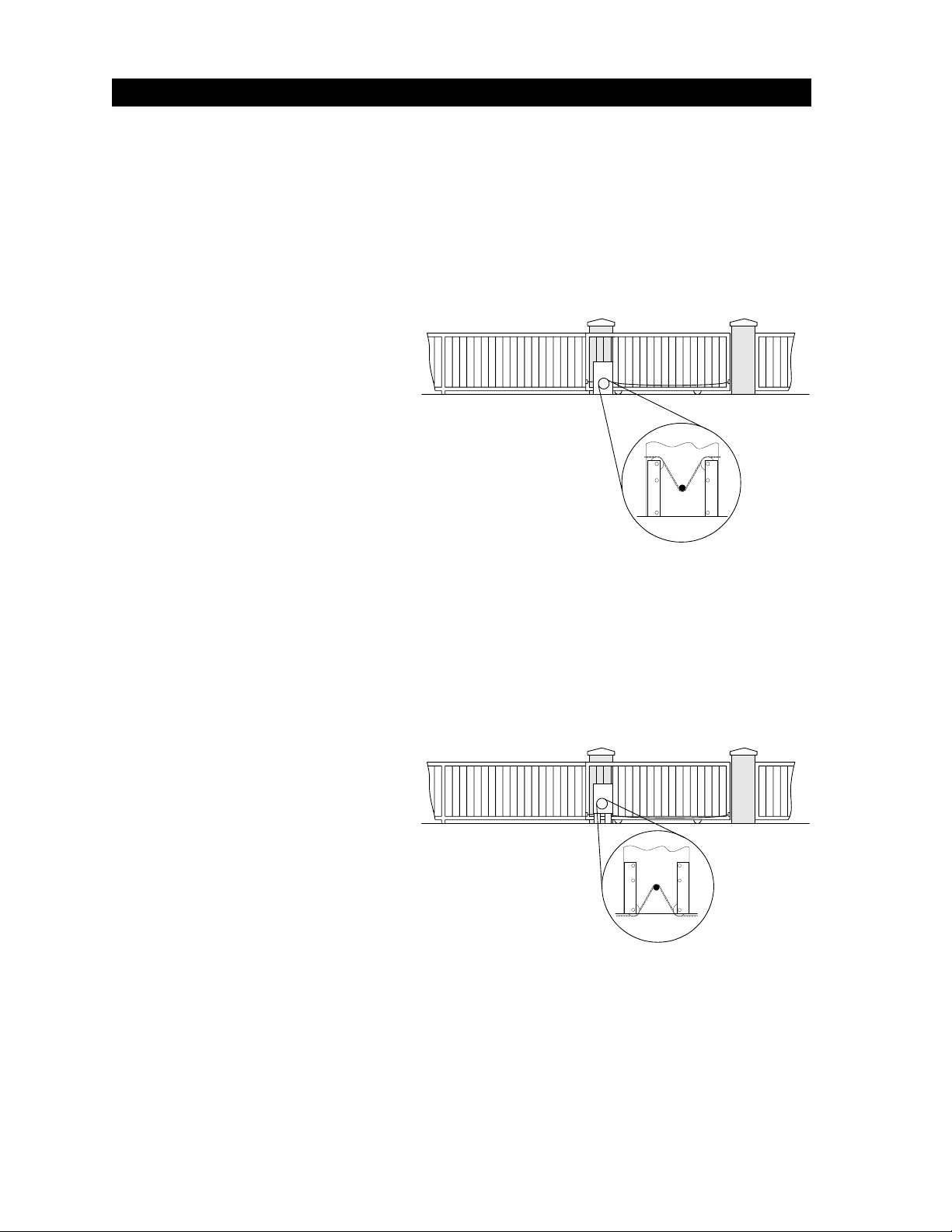

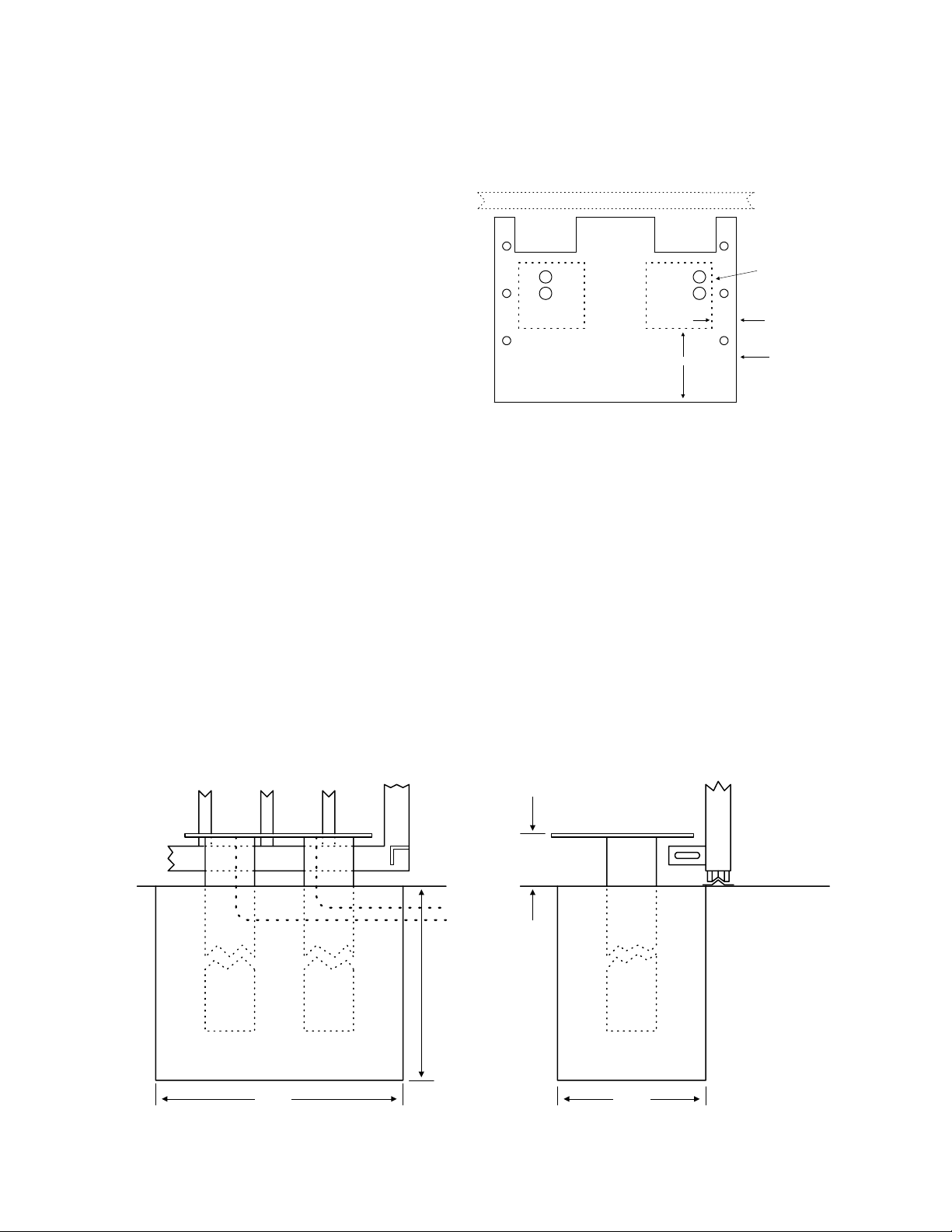

1.2.3 REAR POSITION PAD OR POST MOUNT

• Set one chain idler at the top

position and one chain idler at

the center position on the same

side of the operator.

• Remove the top and bottom

chain knockouts from the side of

the operator.

• Chain enters and exits the

operator from the same side.

Chain is attached to one end of

the gate.

• This mounting method hides the

Figure 4

chain when looking at the gate

from the front.

• ADDITIONAL HARDWARE REQUIRED: Endless Idler Assembly P/N 2600-818. Additional

length of #41 Chain P/N 2600-441 (20 ft.). Note: additional chain may be required depending

on the length of the gate.

• If operator is post mounted: Post Mount Base Plate P/N 2600-418 and two (2) 4” x 4” steel

mounting post at least three feet in length. Mounting post are not available from DoorKing.

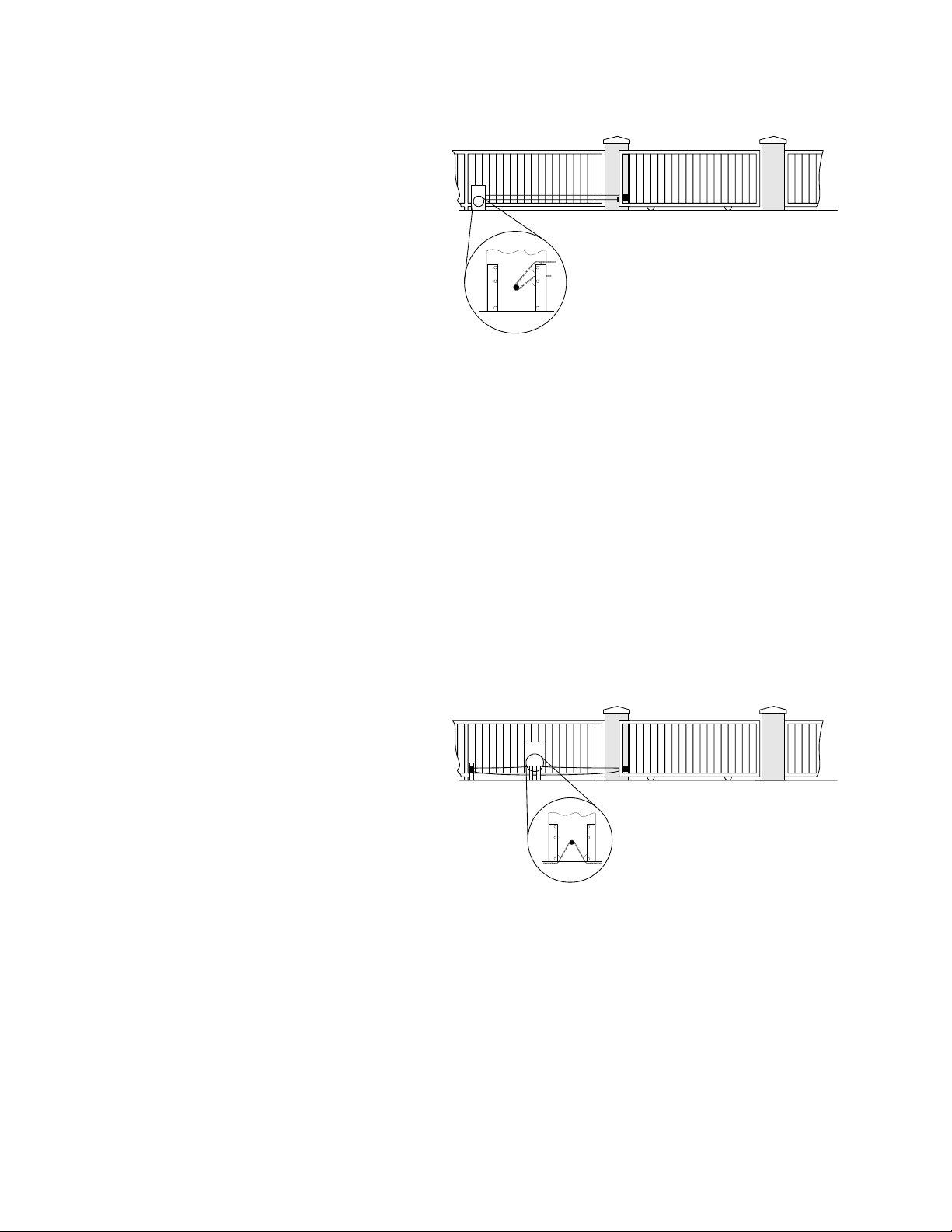

1.2.4 CENTER POSITION POST MOUNT

• Set both chain idlers in the bottom

position.

• DO NOT remove chain knockouts.

Using this mounting method, the

chain enters and exits the

operator from the bottom.

• Chain passes through the

operator and is attached to one

end of the gate.

• This mounting method allows for

Figure 5

the use of chain support

attached to the gate. This is useful with long gates and helps prevent chain “stretching.”

• ADDITIONAL HARDWARE REQUIRED: Two (2) Endless Idler Assemblies P/N 2600-818.

Additional length of #41 Chain P/N 2600-441 (20 ft.). Note: additional chain may be required

depending on the length of the gate. Post Mount Base Plate P/N 2600-418 and two (2) 4” x

4” steel mounting post at least three feet in length. Mounting post are not available from

DoorKing.

3

1.3 MOUNTING OPTIONS

Pad mounting can be used when the operator will be installed using either the front or rear mounting

position. If the operator is to be center mounted, the post mounting method must be used.

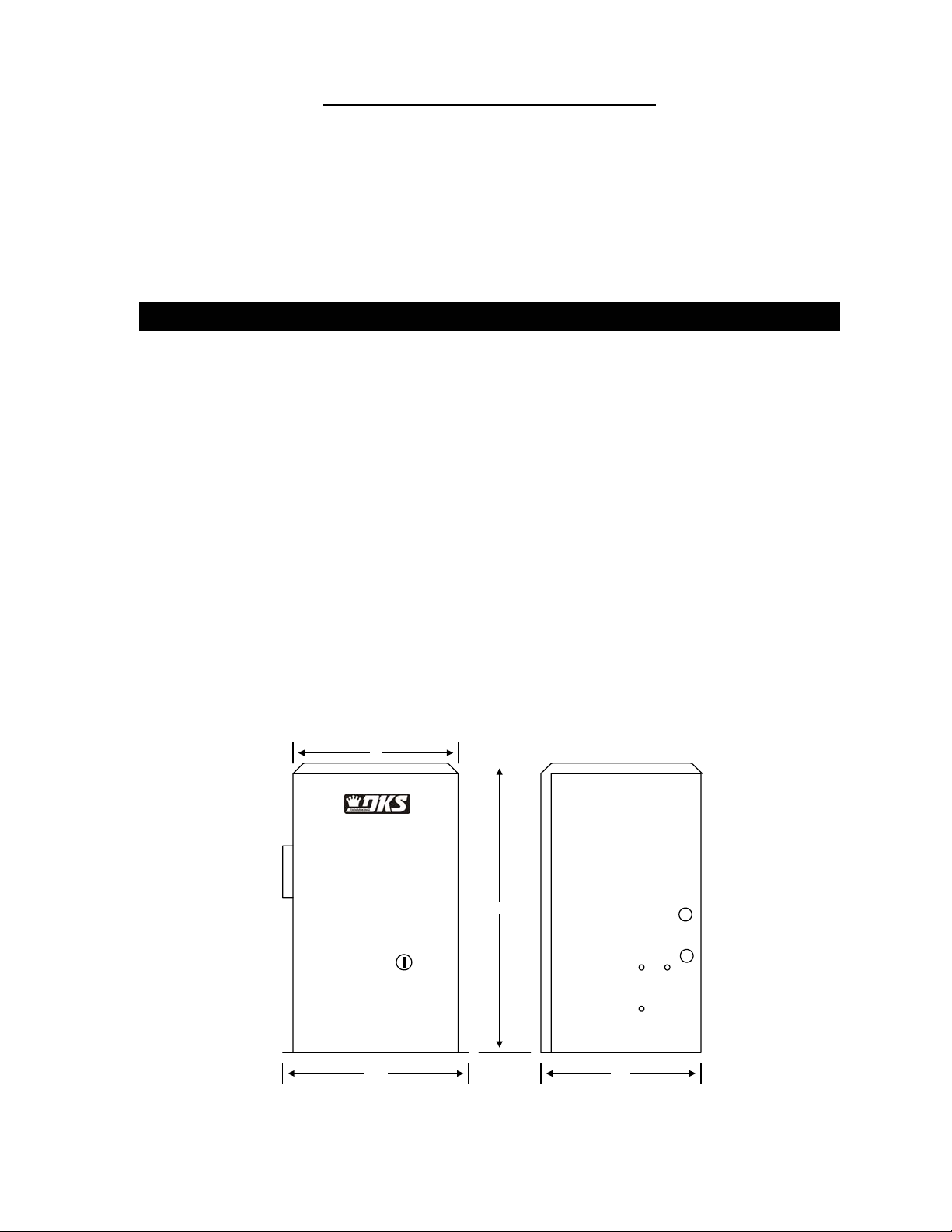

1.3.1 PAD MOUNTED OPERATORS

1. Construct a form for the mounting pad

according to the specifications shown in

figure 6. Be sure to level the top edge of

the form and that the top of the form is a

minimum of four (4) inches above ground

level. We suggest that you contact the

local building department to determine

the required depth of the pad since soil

conditions and code requirements vary

from city to city.

2. Set conduits, reinforcing bars and/or wire

mesh if required. The number of conduits

is determined by the application

requirements. We suggest using a

minimum of four (4) conduits. 1-High

voltage power lines; 2-Low voltage

control lines; 3-Loop lead-in wires (open

loop); 4-Loop lead-in wires (reverse

loops). See SECTION 2. Set additional

conduits as required for your application.

NOTE: If conduits are not set in the pad,

they can be routed to a J box where

connections to the operator can be made

after it is installed. There are three (3) ½inch knockouts and one (1) ¾-inch

knockout on each side of the operator for

this purpose.

3. Mix the concrete according to the

manufacturers instructions. Pour the

mixture into the form and tamp. Level

and finish the surface after pouring is

complete. Do not set anchor bolts in the

concrete. Sleeve anchors should be

used to secure the operator to the pad.

This allows greater flexibility in

positioning the operator on the pad.

4. Allow the pad to cure for 48 hours before

removing the forms or mounting the

operator.

18

Minimum 1"

clearance between

gate and back of

operator.

3.5

24

Figure 6

2.5

6.5

Conduits can

be located in

shaded areas.

7

4" minimum above

ground level

Ground Level

Depth of pad

determined by

soil conditions

and local code

Gate

Conduits

4

1.3.2 POST MOUNTED OPERATORS

Post mounting can be used when the operator will be installed in any of the three mounting positions,

and must be used if the operator is to be center mounted.

1. Post mounting the operator requires

the use of an operator base plate

(P/N 2600-418) and two (2) 4 X 4

steel post (not supplied) welded to

the base plate as shown in figure 7.

The length of the steel post and the

depth of the pad are determined by

soil conditions and local code

requirements. We suggest that you

contact the local building department

to determine the required depth of

4.5

the pad since soil conditions and

code requirements vary from city to

city.

Figure 7

2. After the posts have been welded to

the base plate to form the mounting plate assembly, construct a form for the assembly

according to the specifications in figure 8.

3. Position the mounting plate assembly into the form. Be sure that the base plate is a

minimum of four (4) inches above ground level. Set conduits, reinforcing bars and/or wire

mesh if required. The number of conduits is determined by the application requirements.

We suggest using a minimum of four (4) conduits. 1-High voltage power lines; 2-Low

voltage control lines; 3-Loop lead-in wires (open loop); 4-Loop lead-in wires (reverse

loops). See SECTION 2. Set additional conduits as required for your application.

NOTE: If conduits are not set in the pad, they can be routed to a J box where

connections to the operator can be made after it is installed. There are three (3) ½-inch

knockouts and one (1) ¾-inch knockout on each side of the operator for this purpose.

IMPORTANT!! Be sure that the mounting plate is level and parallel with the gate.

4. Secure the mounting plate assembly in the form. Mix the concrete according to the

manufacturers instructions. Pour the mixture into the form and tamp. Level and finish the

surface after pouring is complete.

5. Allow the pad to cure for 48 hours before removing the forms or mounting the operator.

Gate

4 x 4 Steel Post

(not supplied)

1.5

Base Plate

P/N 2600-418

4 inch

minimum

Conduits

Depth of pad

determined by

soil conditions

and local code.

Figure 8

5

1220

1.4 OPERATOR INSTALLATION

Prior to mounting the gate operator, be sure that the chain knockouts and chain idlers are set for the

mounting position (front, center or rear) and the mounting option chosen (pad or post). Refer back to

SECTION 1.2.

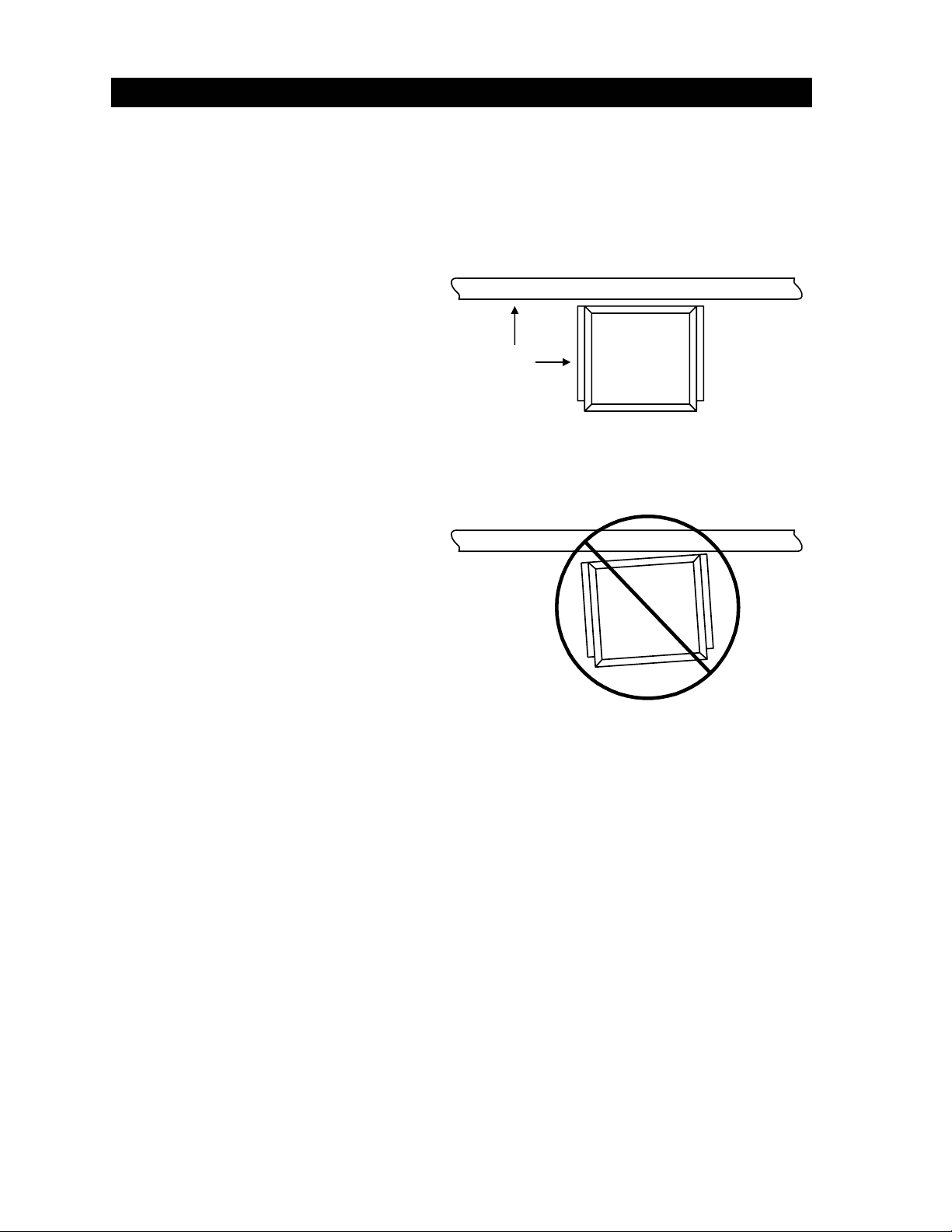

1.4.1 PAD MOUNTED OPERATORS

• Position the operator on the pad

so that there is a minimum

clearance of one (1) inch between

the back of the operator housing

and the gate.

• IMPORTANT!! Be sure that the

operator is parallel to the gate!

Installing the operator in any other

manner will cause excessive

chain noise, chain wear and

stretching, and premature idler

failure.

• Mark the mounting holes on the

mounting pad. Use a concrete

drill bit to drill the mounting holes

to the size and depth required for

the anchors being used. We

recommend minimum 3/8 x 2

sleeve anchors (not supplied).

• After drilling the mounting holes,

clean them out and install the

sleeve anchors. Position the

operator over the anchors and

tighten.

1.4.2 POST MOUNTED OPERATORS

90°

Figure 9

• Position the operator on the mounting plate so that the mounting holes are in alignment. If

the mounting plate/post assembly has been installed correctly, there should be a minimum of

one (1) inch clearance between the back of the operator housing and the gate, and the

operator should be parallel to the gate. If these conditions do not exist, make corrections

now!

• IMPORTANT!! Be sure that the operator is parallel to the gate! Installing the operator in any

other manner will cause excessive chain noise, chain wear and stretching, and premature

idler failure.

• Secure the operator to the mounting plate/post assembly using six (6) ½-13 x 1 ½ bolts, lock

washers and nuts (or equivalent hardware). NOTE: Hardware is not supplied with the

operator or mounting plate.

6

Loading...

Loading...