DK-LOK Tube Fittings User Manual

DK-Lok Tube Fittings

No.01-6

June 2015

Tube Fittings

Technical Information

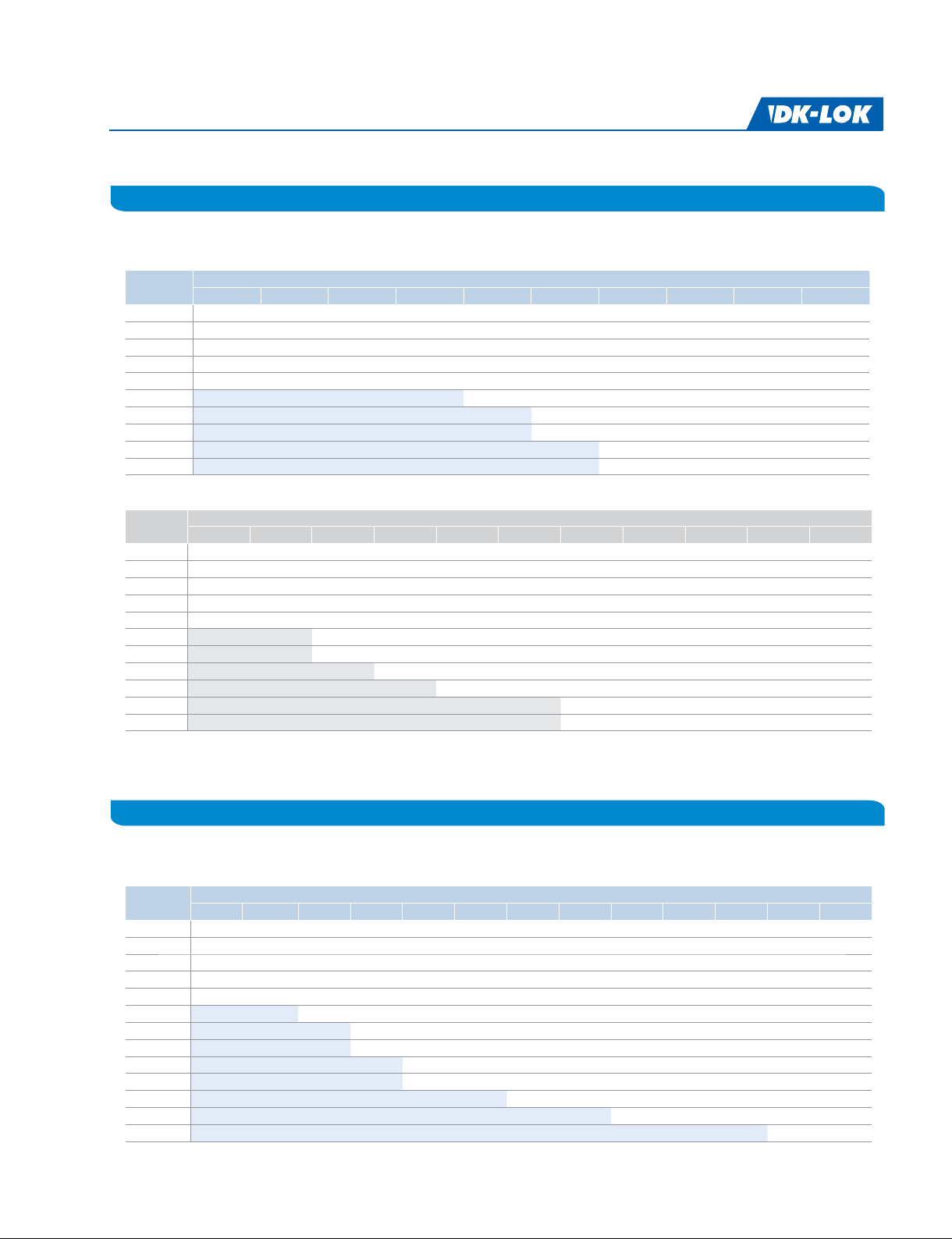

Tube to Tube Union

Union

DU

Union Elbow

DL

Union Tee

DT

Union Cross

DX

Bulkhead Union

DUB

Bulkhead Retainer

DBR

Bulkhead Elbow

Union

DBL

Reducing Union

DUR

Reducing Union

Elbow

DLR

Reducing Union

Cross

DXR

Reducing Union

Tee

DTR

Tube to Male Pipe

Male Connector

DMC-N

Male Connector

DMC-R

Thermocouple

Connector

DMCT

Male Connector for

Bonded Gasket Seal

DMC-G

11

Male Connector

for Metal Gasket

12

DMC-GB, -G

Bulkhead Male

Connector

13

DMCB-N

45° Male Elbow

14

DLBM

Male Elbow

15

DLM-N

Male Elbow

16

DLM-R

Male Run Tee

DTRM-N

16

Male Run Tee

DTRM-R

17

Male Branch Tee

DTBM-N, -R

Male Branch Tee

18

DTBM-N

Male Branch Tee

18

DTBM-R

19

Tube to Female Pipe

20

Female Connector

DCF-N

Female Connector

21

DCF-R

22

Gauge Connector

23

DCF-GG

24

Bulkhead

Female Connector

DCBF-N

23

Female Elbow

DLF-N

Female Run Tee

25

DTRF-N

Female Branch Tee

25

DTBF-N

26

Tube Stub Connector

28

Reducer

29

DR

29

Bulkhead Adapter

DAB

30

Male Adapter

31

DAM-N

32

Male Adapter

33

DAM-R

34

Male Adapter

DAM-G

35

Male Adapter

DAM-U

36

Male Adapter

DAM-UO

37

Female Adapter

DAF-N

38

Female Adapter

DAF-R

Female Adapter

DAF-GR

39

Female Gauge

40

Adapter

DAF-GG

41

Elbow Adapter

DLA

42

Run Tee Adapter

DTRA

43

Branch Tee Adapter

DTBA

44

45

46

47

48

49

49

50

51

52

53

53

54

55

55

56

57

57

57

1

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Port Connector

DCP/DCPZ

Reducing Port

Connector

DCRP

DK-Lok Flanges

DK-Lok Flanges

DF

Lab Joint

Flange Connector

DLJ

Tube to AN Tube

AN Union

DUA

AN Bulkhead Union

DUBA

Male AN adapter

DMAA

AN Adapter

DAA

Tube to Non-Positionable O-Seal

O-Seal Straight

Thread Connector

DMC-UO

O-Seal Pipe

Thread Connector

DMC-NO

Non-Positionable

SAE Male Connector

DMCS-U

Tube to Positionable

Straight Thread

Posiotanable SAE

Male Elbow

DLS-UP

Positionable

45° SAE Male Elbow

58

DLBS-UP

Positionable

59

SAE Male Run Tee

DTRS-UP

Positionable

SAE Male Branch Tee

DTBS-UP

59

60

Positionable Male Elbow

ISO Parallel thread

DLM-GP

60

Tube To Weld End

Male Pipe

Weld Connector

DCW

61

Male Pipe

Weld Elbow

61

DLW

Tube Socket

Weld Connector

62

DCSW

Tube Socket

62

Weld Elbow

DLSW

Welding Bulkhead

Union

DBUW

63

Plug, Cap, Insert

Plug

63

DP

Cap

64

DC

Tube Insert

DI

65

AdditionalProducts

66

Fuse Plug

DFA

Vent Protector

66

DMD

Calibration Fittings

66

DPCM

Dielectric Fittings

67

DEU

Spare Parts

Gasket

DGV/DGB

68

DGC/DGG

Nut

69

DN

Ferrule Set

DFS

69

Nut-Ferrule Set

DFSN

Front Ferrule

70

DFF

Back Ferrule

70

DFB

Tools

Preswaging Tool

70

DPS

Gap Gauge

71

DIG

Tube Depth

Marking Tool

72

DTM

Pre-Swaging Unit

DHS-2A

Pre-Swaging Unit

DES-1A

72

73

73

74

27

75

75

75

76

76

76

77

77

77

77

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

2

Tube Fittings

Technical Information

The Premium Quality DK-Lok Tube Fittings

DK-Lok Tube Fitting is designed using industrial codes and

specications with additional Cutting-Edge Engineering on

swaging action and sealing integrity. DK-Lok provides excellent

leak-free sealing on high pressure gas, vacuum, impulse, thermal

shock, heavy vibration, and many other stringent applications.

DK-Lok brings you truly excellent quality, outstanding customer

service, and availability.

Enjoy DK-Lok tube tting working on your application!

Construction of DK-Lok Tube Fittings

DK-Lok Tube Fitting consists of body, front ferrule, back ferrule and

nut. The features include;

tExcellent product range up to 2 in. and 50 mm OD.

t Additional engineering on sealing integrity and swaging action.

tRe-usable and predictable quality.

tGaugable.

t Excellent leak-free sealing integrity on heavy vibration, vacuum

and impulse.

tHeat-Code Traceability.

t No torque transferring to connective tubing during installation.

DK-Lok Material Standards

DK-Lok tube tting are supplied in various materials to satisfy the

needs of various applications including on shore oil& gas, renery,

oshore oil& gas, chemical, petrochemical, analytical instrumentation,

steel mill, power plant, shipbuilding, pharmaceutical, and alternative

fuel.

Material Bar stock Forging

ASTM A276

Stainless Steel316

Brass

Carbon Steel

Duplex

Super Duplex ASTM A479 S32750 ASTM A182 F51

Aluminum ASTM B211 Alloy 2024 T6 ASTM B247

Alloy 20 ASTM B473 UNS N08020 ASTM B462 UNS N08020

Hastelloy C276 ASTM B574 UNS N10276 ASTM B564 UNS N10276

Alloy 400 ASTM B164 UNS N04400 ASTM B564 UNS N04400

Alloy 600 ASTM B166 UNS N06600 ASTM B564 UNS N06600

Alloy 625 ASTM B446 UNS N06625 ASTM B564 UNS N06625

Alloy 825 ASTM B425 UNS N08825 ASTM B564 UNS N08825

Titanium Gr. 2 ASTM B348 Gr.2 ASTM B381 F3

PTFE ASTM D1710 ASTM D3293

ASTM A479

ASME SA479

JIS G4303

ASTM B16 UNS C36000

JIS H3250 Alloy C3604

ASTM A675 Gr.60-90

JIS G4051 S20C - S48C

ASTM A276 S31803

ASTM A479 S31803

ASTM A182

ASME SA182

JIS G3214

ASTM B283 UNS C37700

JIS H3250 Alloy C3771ASTM B453 UNS C35300

ASTM A105

JIS G4051 S20C - S48C

ASTM A182 F51

Identication of Metric DK-Lok Tube Fitting

Metric DK-Lok tube tting has stepped shoulder on body and nut

hex. Shaped tting such as tee, elbow, and cross forging has such

step on body as well.

Product Cleaning

Every DK-Lok tube tting is cleaned to remove surface contamination,

iron particles from cutting tools, oil from cutting uid, and loose particles.

For further information refer to DK cleaning standard DC-01.

Specialcleaning for oxygen service application is available on request.

Refer to specialcleaning standard DC-11.

Carbon Steel DK-Lok Tube Fittings

Carbon steel ttings are white zinc plated.

Every carbon steel tting is supplied with

SS316 back ferrule and Carbon Steel front

ferrule with black fast plated.

O-ring

DK-Lok tting pipe end with O-ring is supplied; 70 durometer NBR

O-ring on Brass and Carbon steel ttings, 90 durometer FKM O-ring

on Stainless steel tting.

Other O-ring is available on request.

DK-Lok Port Dimension

Dimensions on DK-Lok Port in the catalog are approximate gures

and shown in nger-tight position.

Alternative Fuels

Stainless steel316 DK-Lok Tube Fittings are tested to the requirements

of ECE R110, EIHP Draft, ECE R67 and certied by TUV.

3

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Tubing

For safe, reliable and leak-free DK-Lok tting

system, tubing should be considered as one

of tting components.

t Tubing is assembled by simple wrench

make-up on DK-Lok fitting. This results in

less assembly and maintenance costs.

tTubing assembly on DK-Lok fitting is re-usable.

t Tubing is bendable. It allows lower pressure drop with fewer

connections. This in turn reduces system costs because of less

fabricating manpower.

t Pipe threading or welding is difficult to disassemble and

re-assemble

t Piping requires skilled worker for welding & threading

DK-Lok Tube Fitting Pressure Rating

t The pressure rating of DK-Lok Tube Fitting is rated to the working

pressure of connective tubing.

t The allowable working pressure of tubing in various materials is

listed in the table 2 to 13.

Material

Using like tubing and tting materialis essential for leak-free sealing

Material

system.

Unlike material may have dierent mechanical properties that may adversely aect the tting seal on tubing.

The only exception is copper tubing with brass DK-Lok tting.

Tubing Selection

Hardness

t Tubing must be softer than fitting material. The metal tubing

must be fully annealed and suitable for bending and flaring.

t Tubing hardness must be selected according to the information

in the table 2 to 13.

Surface

t Tubing must have a surface free from scratches, draw mark, dirt,

dust and flat spots.

Ovality

t Tubing in oval or out-of-roundness way not fit into the fitting.

Do not force the tubing into the fitting; it may damage the fitting

sealing system on nut, ferrules, and body.

Wallthickness

t The table 2 to 13 list tubing working pressure ratings in a wide

range of wall thickness. A too thin wall may collapse and a too

thick wall may not properly be deformed by the ferrule action.

t Do not use tubing wall thickness not listed in the table 2 to 13.

Weld tubing

t Welded tubing should have a not measurable bead on its outside

diameter.

Tubing Handling

Careful handling and storage practices will protect tubing from

unnecessary scratches, nicks, or degrading the good tubing surface

nish.

t Tubing ends should be capped so any foreign materials will not

fall inside during transportation and storage.

t Do not drag across tubing rack, cement, gravel or any rough

surface.

t Do use correct tube cutter for tube material. The wrong cutter

may result in excessive deformation of the tube end.

t Do not cut deep with each turn of cutting.

tTube cutters and hacksaws should be sharp enough.

tHacksaw blades should have at least 32 teeth per inch.

tDo deburr tube ends before inserting in fittings.

Gas Application

DK-Lok tube tting is designed for a wide range of leak-free application

including gas leak proof and vacuum tight service.

Gases (helium, hydrogen, nitrogen, air, etc.) can escape even the most

minute leak-path due to their very small molecules.

Tube therefore must be handled not to have scratches, draw mark,

nicks, at spots, dirt, and dust

Use NOT thin wall tubing for gas applications.

Heavier wall tubing resists the ferrule action whereas thin walltubing

may collapse with little resistance to ferrule action.

For Gas service, use the tubing wall listed on un-shadowed section in

table 2 to 13.

Vacuum Application

DK-Lok Tube Fittings have been proved to be excellent vacuum tight

seal in many applications including analytical industry.

DK-Lok Tube Fittings comply with the leakage requirements of TA-LUFT

2002.

Cryogenic Application

DK-Lok Fittings in SS316 Stainless Steel provide highly reliable

performance on cryogenic application.

Cryogenic temperature is considered to be temperatures below

-100℉ (-73℃).

High Pressure Application

Pressure 500 psig (34.5 bar) or higher is considered generally high

pressure. In the high pressure system scratches, draw mark, nicks,

at spots, and dirt on tubing may cause leakage

t For gas application, select the gas applicable tubing wall

thickness from Table 2 to 13.

t Follow the suggestion on tubing selection, handling, and

installation.

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

4

Technical Information

Tube Fittings

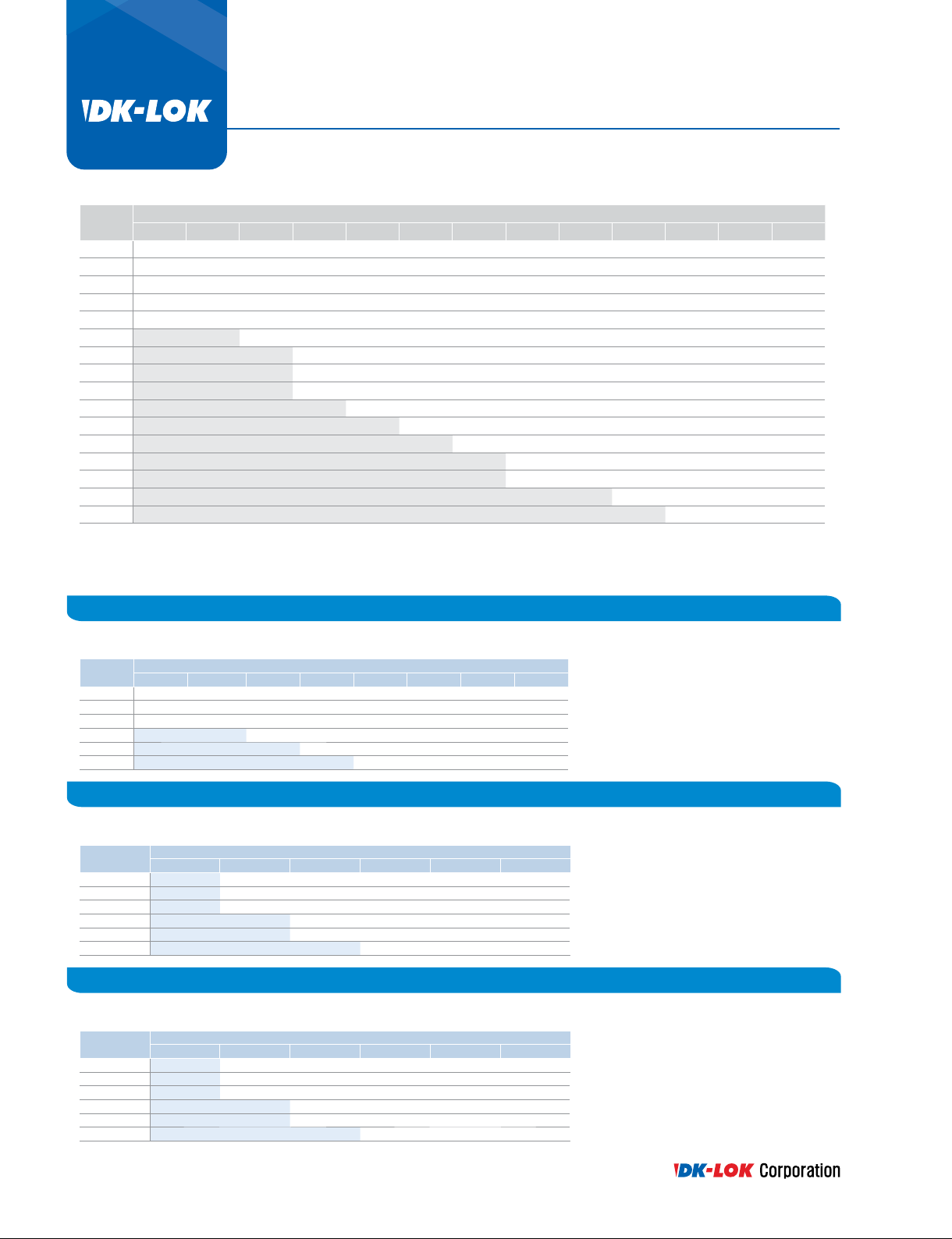

Stainless Steel Tubing

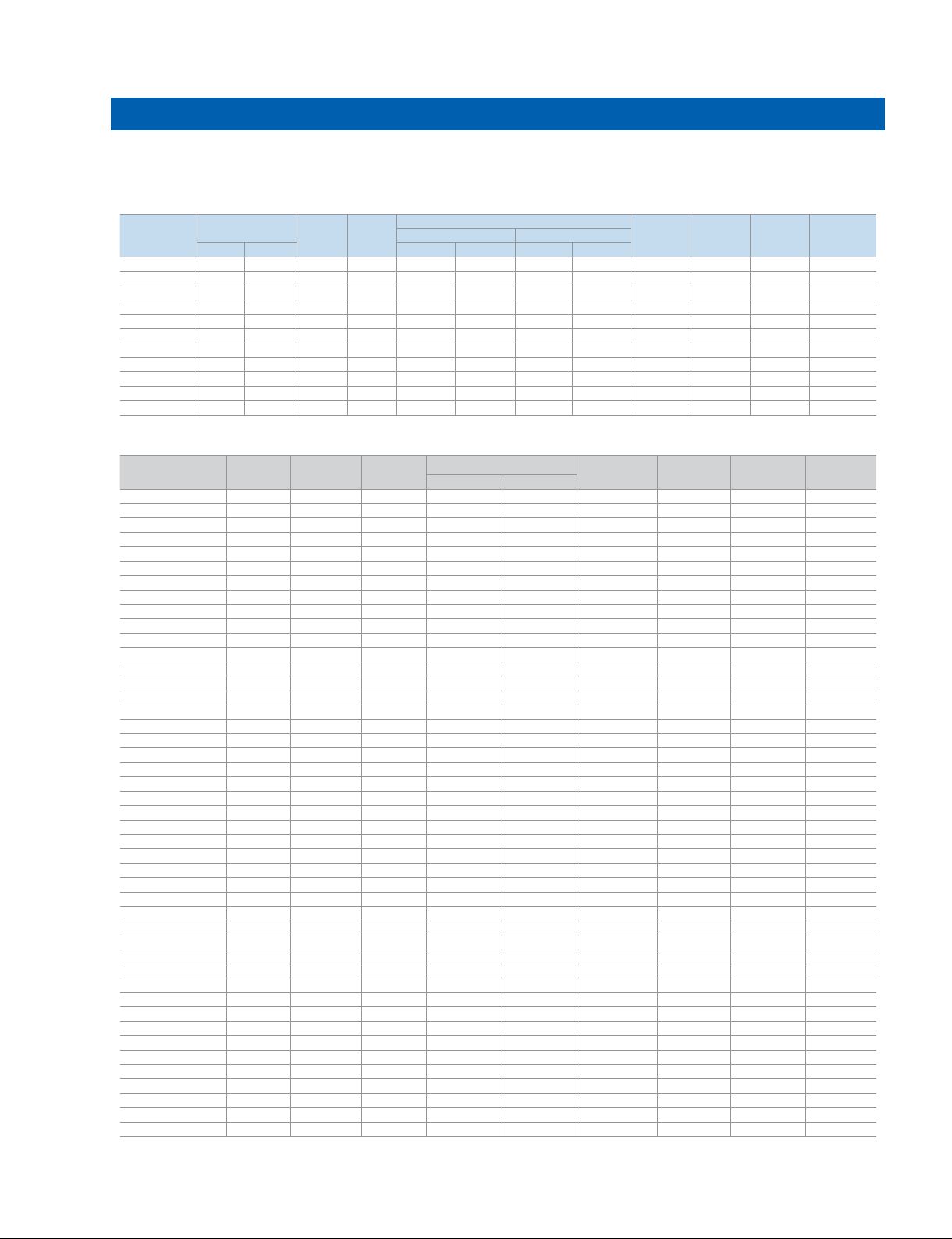

Table 2. Fractional Seamless Stainless Steel Tubing

Fully annealed austenitic Type 304 or 316 seamless tubing ASTM A269 or ASTM A213, or equivalent. Tubing to be free from scratches, draw mark,

dirt, dust, at spots, and suitable for bending and aring. Recommended hardness : 80 HRB or less.

OD

in.

0.012 0.014 0.016 0.02 0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.12 0.134 0.156 0.188

1/16 6800 8100 9400 12000

1/8 8500 10900

3/16 5400 7000 10200

1/4 4000 5100 7500 10200 Working Pressure in psig

5/16 4000 5800 8000

3/8 3300 4800 6500 8600

1/2 2400 3500 4700 6200

5/8 2900 4000 5200 6000

3/4 2400 3300 4200 4900 5800 6400

7/8 2000 2800 3600 4200 4800 5400 6100

1 2400 3100 3600 4200 4700 5300

1 1/4 2400 2800 3300 3600 4100 4900

1 1/2 2300 2700 3000 3400 4000 4900

2 2000 2200 2500 2900 3600

Wall Thickness (in.)

Table 3. Metric Seamless Stainless Steel Tubing

OD

mm

3 710

6 330 420 520 670

8 310 380 490

10 240 300 380

12 200 240 310 380 430 Working Pressure in bar

14 180 220 280 340 390 430

15 170 200 260 320 360 400

16 190 240 300 330 370

18 170 210 260 290 320 370

20 150 190 230 260 290 330 380

22 130 170 210 230 260 300 340

25 180 200 230 260 300 320

28 180 200 230 260 280 330

30 170 190 210 240 260 310

32 160 170 200 230 240 290 330

38 140 170 190 200 240 280 310

50 150 180 210 240

•

According to the requirements of ASME B31.3 Process Piping Code and ASME B31.1 Power Piping Code, allowable working pressure

0.8 1.0 1.2 1.5 1.8 2.0 2.2 2.5 2.8 3.0 3.5 4.0 4.5

Wall Thickness (mm)

calculated at -20 to 100℉ (-28 to 37℃) using S value of 20,000 psi.

t Pressure calculations are based on maximum O.D. and minimum wallthickness and no allowance is made for corrosion and erosion.

i.e., ASTM A269 1/2 in. OD x 0.035 in.WT: OD tolerance ± 0.005 in., WT tolerance ± 15%.

Calculations are based on 0.505 in.OD x 0.0298 in. WT.

t Safety Factor is 3.75 to 1, considering ultimate tensile strength of 75,000 psi.

Weld Stainless Steel Tubing Allowable Working Pressure

To determine the working pressure of weld tubing to the requirements of ASME B31.3 Code, de-rating factors below must be applied. For single

weld tubing multiply by 0.80, and for double weld tubing multiply by 0.85:

Example: SS316 seamless 1/2 in. O.D. x 0.065 in. WT allowable working pressure: 4700 psi.

5

To determine the work pressure of the single weld tubing, multiply 4700 psi by 0.80.

4700 psig x 0.80 = 3760 psig at -20 to 100℉ (-28 to 37℃).

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Copper Tubing

Table 4. Fractional Seamless Copper Tubing

Soft annealed seamless copper tubing ASME B75 or equivalent. Soft annealed (Temper 0) copper water tube, type K or Type LASTM B88.

Recommended hardness: 60 HRB or less.

OD

in.

1/8 2700 3600

3/16 1800 2300 3400 Working Pressure in psig

1/4 1300 1600 2500 3500

5/16 1300 1900 2700

3/8 1000 1600 2200

1/2 800 1100 1600 2100

5/8 900 1200 1600 1900

3/4 700 1000 1300 1500 1800

7/8 600 800 1100 1300 1500

1 500 700 900 1100 1300 1500

Table 5. Metric Seamless Copper Tubing

OD

mm

3 225 260

4 165 191 244 295 Working Pressure in bar

6 122 157 192 245 263

8 89 114 140 179 193

10 70 89 109 140 150 172 193

12 58 73 89 114 123 140 158

14 62 76 96 103 118 133 148 171 209

16 54 66 83 89 102 114 127 147 180

18 48 58 74 79 90 101 112 129 159

22 39 47 59 64 72 81 90 103 126

25 34 41 52 56 63 71 78 90 110

0.010 0.012 0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.120

0.7 0.8 1.0 1.2 1.5 1.6 1.8 2.0 2.2 2.5 3.0

t According to the requirements of ASME B31.3 Process Piping Code and ASME B31.1 Power Piping Code, allowable working pressure

calculated at -20 to 100℉ (-28 to 37℃) using S value of 6000 psi.

tSafety Factor is 5 to 1, considering ultimate tensile strength of 30,000 psi.

Wall Thickness (in.)

Wall Thickness (mm)

Carbon Steel Tubing

Table 6. Fractional Seamless Carbon Steel Tubing

Soft annealed seamless carbon steel hydraulic tubing ASTM A179 or equivalent. Tubing to be free from scratches, draw mark, dirt, durst, at spots,

and suitable for bending and aring. Recommended hardness: 72 HRB or less.

OD

in.

1/8 8000 10200

3/16 5100 6600 9600

1/4 3700 3700 7000 9600 Working Pressure in psig

5/16 3800 5500 7600

3/8 3100 4500 6200

1/2 2300 3300 4500 5900

5/8 1800 2600 3500 4600 5300

3/4 2100 2900 3700 4300 5100

7/8 1800 2400 3200 3700 4300

1 1500 2100 2700 3200 3700 4100

1 1/4 1600 2100 2500 2900 3200 3600 4000 4600 5000

1 1/2 1800 2000 2400 2600 3000 3300 3700 4100 5100

2 1500 1700 1900 2200 2400 2700 3000 3700

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.120 0.134 0.148 0.165 0.180 0.220

Wall Thickness (in.)

www.dklok.com

6

Technical Information

Tube Fittings

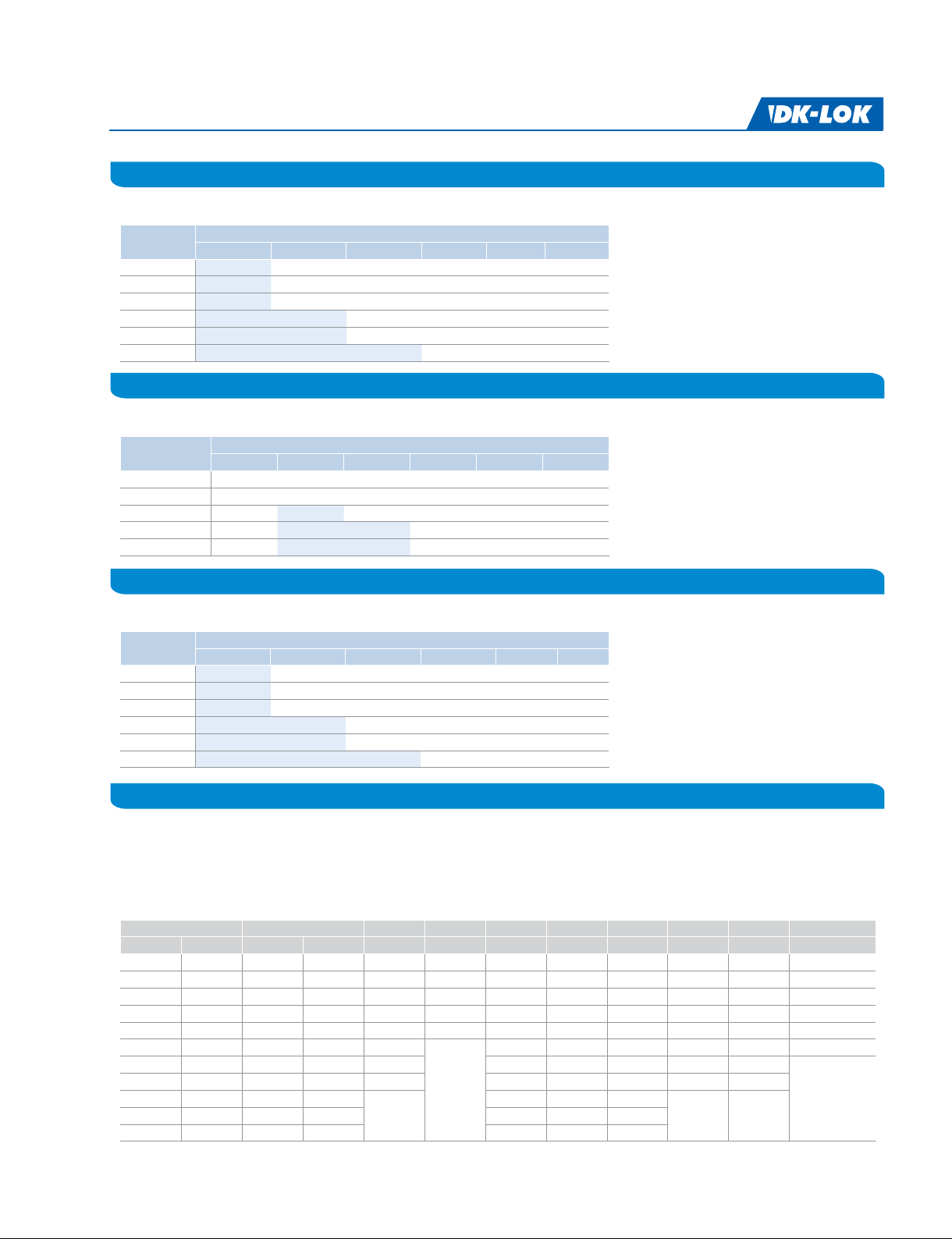

Table 7. Metric Seamless Carbon Steel Tubing

OD

mm

3 670 830

6 310 400 490 630

8 290 360 460

10 230 280 360 Working Pressure in bar

12 190 230 290 360 410 450

14 160 190 250 300 340 380

15 150 180 230 280 320 350

16 170 210 260 290 330 380

18 150 190 230 260 290 330

20 130 170 200 230 250 290 330

22 120 150 180 210 230 260 300

25 160 180 200 230 260 280

28 160 180 200 230 250 290

30 150 160 190 210 230 270

32 140 150 170 200 210 250 290

38 130 140 160 180 210 240 280

0.8 1.0 1.2 1.5 1.8 2.0 2.2 2.5 2.8 3.0 3.5 4.0 4.5

t Allowable working pressure calculated at -20 to 100℉ (-28 to 37℃) using S value of 15,700 psi according to ASME B31.3 Process Piping Code.

tSafety Factor is 3 to 1, considering ultimate tensile strength of 47,000 psi.

tTo determine working pressure of ASME B31.1 Power Piping Code, multiply the ASME B31.3 rating by 0.85

Wall Thickness (mm)

Table 8. Fractional Seamless Alloy 400 Tubing

Fully annealed seamless Alloy 400 tubing ASTM B165 or equivalent. Tubing to be free from scratches, draw mark, dirt, dust, at spots, and suitable

for bending and aring. Recommended hardness: 75 HRB or less.

OD

in.

1/8 7900 10200

1/4 3700 4800 7000 9600 Working Pressure in psig

3/8 3100 4400 6100

1/2 2300 3300 4400

3/4 2200 3000 4000 4600

Table 9. Fractional Seamless Alloy C276 Tubing

0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.120

1 2200 2900 3400 3900 4300

Wall Thickness (in.)

t According to the requirements of ASME B31.3

Process Piping Code and ASME B31.1 Power Piping

Code, allowable working pressure calculated at

-20 to 100℉ (-28 to 37℃) using S value of 18,700 psi.

t Safety Factor is 3.74 to 1, considering ultimate

tensile strength of 70,000 psi.

Fully annealed seamless alloy 825 tubing ASTM B423 or equivalent. Tubing to be free from scratches, draw mark, dirt, dust, at spots, and suitable

for bending and aring. Recommended hardness: 95 HRB or less.

OD

in.

1/8 8200 12000 15300 Working Pressure in psig

3/16 5300 7700 9900 14400

1/4 5600 7200 10600 14400

5/16 5700 8200 11300

3/8 4700 6700 9200

1/2 3400 4900 6700 8800

Table 10. Fractional Seamless Alloy 825 Tubing

0.02 0.028 0.035 0.049 0.065 0.083

Wall Thickness (in.)

t According to the requirements of ASME B31.3

Process Piping Code and ASME B31.1 Power

Piping Code, allowable working pressure

calculated at ambient temperature using S value

of 27,300 psi.

t Safety Factor is 3.66 to 1, considering ultimate

tensile strength of 100,000 psi.

Fully annealed seamless alloy 825 tubing ASTM B423 or equivalent. Tubing to be free from scratches, draw mark, dirt, dust, at spots, and suitable

for bending and aring. Recommended hardness: 100 HRB or less.

OD

In

1/8 7500 11000 14000 Working Pressure in psig

3/16 4800 7000 9000 13000

1/4 5100 6500 9500 13000

5/16 5100 7400 10100

3/8 4100 6000 8300

1/2 3000 4400 6000 7900

0.02 0.028 0.035 0.049 0.065 0.083

Wall Thickness (in.)

t According to the requirements of ASME B31.3

Process Piping Code and ASME B31.1 Power

Piping Code, allowable working pressure

calculated at ambient temperature using S value

of 23,300 psi.

t Safety Factor is 3.64 to 1, considering ultimate

tensile strength of 85,000 psi.

7

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Table 11. Fractional Seamless Alloy 625 Tubing

Fully annealed seamless alloy 625 tubing ASTM B444 Grade 1 or equivalent.

Tubing to be free from scratches, draw mark, dirt, dust, at spots, and suitable for bending and aring.

OD

in.

1/8 12500 18200 23100 Working Pressure in psig

3/16 8000 11600 14900 21500

1/4 8400 10800 15700 21400

5/16 8400 12200 16800

3/8 6900 10000 13700

1/2 4200 6000 8200 10700

Table 12. Fractional Seamless Super Duplex Tubing

0.020 0.028 0.035 0.049 0.065 0.083

Wall Thickness (in.)

t Allowable working pressure is calculated at ambient

temperature using S value of 40,000 psi according

to ASME B31.3 Code.

t Safety Factor is 3 to 1, considering ultimate tensile

strength of 120,000 psi.

t To determine working pressure of ASME B31.1

Power Piping Code, multiply the ASME B31.3

rating by 0.86.

Fully annealed Super Duplex tubing ASTM A789 S32750 or equivalent. Tubing to be free from scratches, draw mark, dirt, dust, at spots, and suitable

for bending and aring. Recommended hardness: 32 HRC or less.

OD

in.

1/4 7700 9900 15000 Working Pressure in psig

3/8 6400 9200 12700

1/2 5000 7200 10000 12900

5/8 5700 7700 10100

3/4 4700 6300 8200 10000

Table 13. Fractional Seamless Alloy 20 Tubing

0.028 0.035 0.049 0.065 0.083 0.095

Wall Thickness (in.)

t Allowable working pressure calculated at ambient

temperature using S value of 38,700 psi according

to ASME B31.3 Code.

t Safety Factor is 3 to 1, considering ultimate tensile

strength of 116,000 psi.

Fully annealed seamless alloy 20 tubing ASTM B729 or equivalent. Tubing to be free from scratches, draw mark, dirt, dust, at spots, and suitable for

bending and aring. Recommended hardness: 95 HRB or less.

OD

in

1/8 8400 12200 15400 Working Pressure in psig

3/16 5300 7700 9900 14400

1/4 5600 7200 10500 14300

5/16 5600 8200 11200

3/8 4600 6600 9100

1/2 2800 4000 5400 7200

0.020 0.028 0.035 0.049 0.065 0.083

Wall Thickness (in.)

t Allowable working pressure calculated at ambient

temperature using S value of 23,300 psi according

to ASME B31.3 Process Piping Code.

t To determine working pressure of ASME B31.1

Power Piping Code, multiply the ASME B31.3 rating

by 0.98.

Temperature De-rating Factors

The pressure rating of DK-Lok port is governed by the connective tubing pressure rating.

To determine allowable working pressure at elevated temperature, multiply working pressure by applicable factor shown in table 14.

Example: SS316 seamless tubing 1/2 in. O.D. x 0.065 in.WT at 700 °F. 4700 psig x 0.82 = 3854 psi.

Allowable working pressure of SS316 seamless 1/2 in. O.D. x 0.065 in. WT is 3854 psi at 700 °F.

Table 14.

Temp. Stainless C.steel Copper 825 C276 625 20 400 Super Duplex

°F °C 304 316 A179 B75 B423 B622 B444 B729 B165 A789

10038111111111 1

200 93 1 1 0.96 0.8 0.92 1 1 0.9 0.88 0.9

300 149 1 1 0.9 0.78 0.87 1 1 0.86 0.79 0.85

400 204 0.94 0.97 0.86 0.5 0.83 1 1 0.83 0.79 0.82

500 260 0.88 0.9 0.82 0.13 0.79 0.98 0.97 0.79 0.79 0.81

600 316 0.82 0.85 0.77 0.76 0.93 0.95 0.77 0.79 0.8

700 371 0.8 0.82 0.73 0.74 0.87 0.93 0.76 0.79

800 427 0.76 0.8 0.59 0.73 0.84 0.93 0.73 0.76

900 482 0.73 0.78 0.73 0.81 0.93

1000 538 0.69 0.77 0.71 0.79 0.93

1200 649 0.3 0.37 0.35 0.33

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

8

Technical Information

Tube Fittings

DK-Lok Pipe End Pressure Rating

Pressure ratings of DK-Lok tube port is governed by the connective tubing pressure rating. The allowable working pressure of those ttings with

both DK-Lok port and pipe end port are determined by the lower pressure port.

Table 15. DK-Lok Pipe Thread Designator

Legends •DK: DK-Lok pipe thread designator. •E: Equivalent.

DK

ASME B1.20.1 (NPT)

N

SAE AS71051

ISO 7-1

BS EN 10226-1 (BSPT)

R

DIN 2999 (male thread only)

JIS B0203 (PT)

Tapered Pipe ThreadParallel Pipe ThreadParallel Pipe ThreadSAE Straight Thread

ISO 228-1

BS 2779 (BSPP)

G

JIS B0202 (PF)

DIN 3852 FORM A

ISO 228-1

BS 2779 (BSPP)

GB

JIS B0202 (PF)

DIN 3852 FORM B

ISO 228-1

BS 2779 (BSPP)

GP

JIS B0202 (PF)

SAE J475 SAE J1926

ISO 228-1

BS 2779 (BSPP)

GG

JIS B0202 (PF)

EN 837-1& EN 837-3

ISO 228-1

BS 2779 (BSPP)

GR

JIS B0202 (PF)

DIN 3852 FORM Z

ISO 228-1

BS 2779 (BSPP)

GY

JIS B0202 (PF)

DIN 3852 FORM Y

ASME B1.1

ISO R725

U

SAE J475

SAE J514

ASME B1.1

ISO R725

UO

SAE J475

SAE J514

ASME B1.1,

ISO R725

UP

SAE J475

SAE J514

ASME B1.20.1,

NO

SAE AS71051

SAE J514

Reference

Specication

Thread Conguration E

RT

RS

RP

PR

RG

RP

RJ

SR

OR

ST

OR

Pipe Thread Sealants

Pipe thread sealant for tapered pipe thread assembly is essential to

ensure leak-free thread sealing. Sealant usually contains a lubricant.

Thread sealant lls the voids between the threads and prevents

thread galling.

Wrap PTFE tape clockwise from rst thread. Do not overhang the rst

thread; the tape may get into the uid system.

Pressure Equivalents:

1 bar = 100 kPa = 14.503 psi 1 kPa = 0.01 bar = 0.145 psi

1 psi = 0.069 bar = 6.89 kPa 1 kg/cm = 0.98 bar = 14.22 psi

Table 16. Tapered Pipe Thread Pressure Ratings

Applicable to DK-Lok thread designator: N and R

ISO/NPT

Pipe

Size

S value 20ksi 10ksi

1/16 14000 965 6600 455 7400 510 3300 227

1/8 10000 689 6400 441 5000 345 3200 220

1/4 8300 572 6500 448 4100 282 3200 220

3/8 8000 551 5200 358 4000 275 2600 179

1/2 7800 537 4800 331 3900 269 2400 165

3/4 7500 517 4600 317 3700 255 2300 158

1 5300 365 4400 303 2600 179 2200 152

1 1/4 6200 427 5000 345 3100 214 2500 172

1 1/2 5100 351 4500 310 2500 172 2200 152

2 4000 276 3900 269 2000 138 1900 131

SS316 and Carbon Steel Brass

Male Female Male Female

psig bar psig bar psig bar psig bar

Allowable Working Pressure

DK-Lok ISO Parallel Male Pipe Thread End

Applicable to DK-Lok thread designator: G, GB, and GP.

SS316 and carbon steel tting thread ends up to 1 in. are rated to

5900 psi (406 bar)

DK-Lok SAE Straight Thread End

Applicable to DK-Lok thread designator: U, UO, and UP.

SS316 and carbon steel tting thread ends up to 16U (1 5/16-12)

are rated to 6000 psi (413 bar)

DK-Lok Tube Socket Weld End

Applicable to DK-Lok tube tting part number: DCSW and DLSW.

SS316 and carbon steel tting tube socket ends up to 1/2 in. (-8)

are rated to 7,000 psi (482 bar)

DK-Lok Pipe Butt Weld End

Applicable to DK-Lok tube tting part number: DCW and DLW.

SS316 and carbon steel tting pipe butt weld ends up to 3/4 in.

(-12P) are rated to 6,000 psi (413 bar)

t Pressure ratings are based on ASME B31.3 Process Piping Code, at

ambient temperature.

t For further information about each size end rating, contact the

authorized DK-Lok distributor in your region.

Table 17. Elastomer seal temperature ratings

Elastomer O-ring Rating

NBR -40 to 110℃ (-40 to 230℉)

FKM -28 to 204℃(-18 to 400℉)

FFKM (Kalrez®) -30 to 275℃(-22 to 527℉)

Care must be taken as tting with elastomer O-ring sealmay have

lower temperature rating.

Kalrez®: DupPont™

9

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

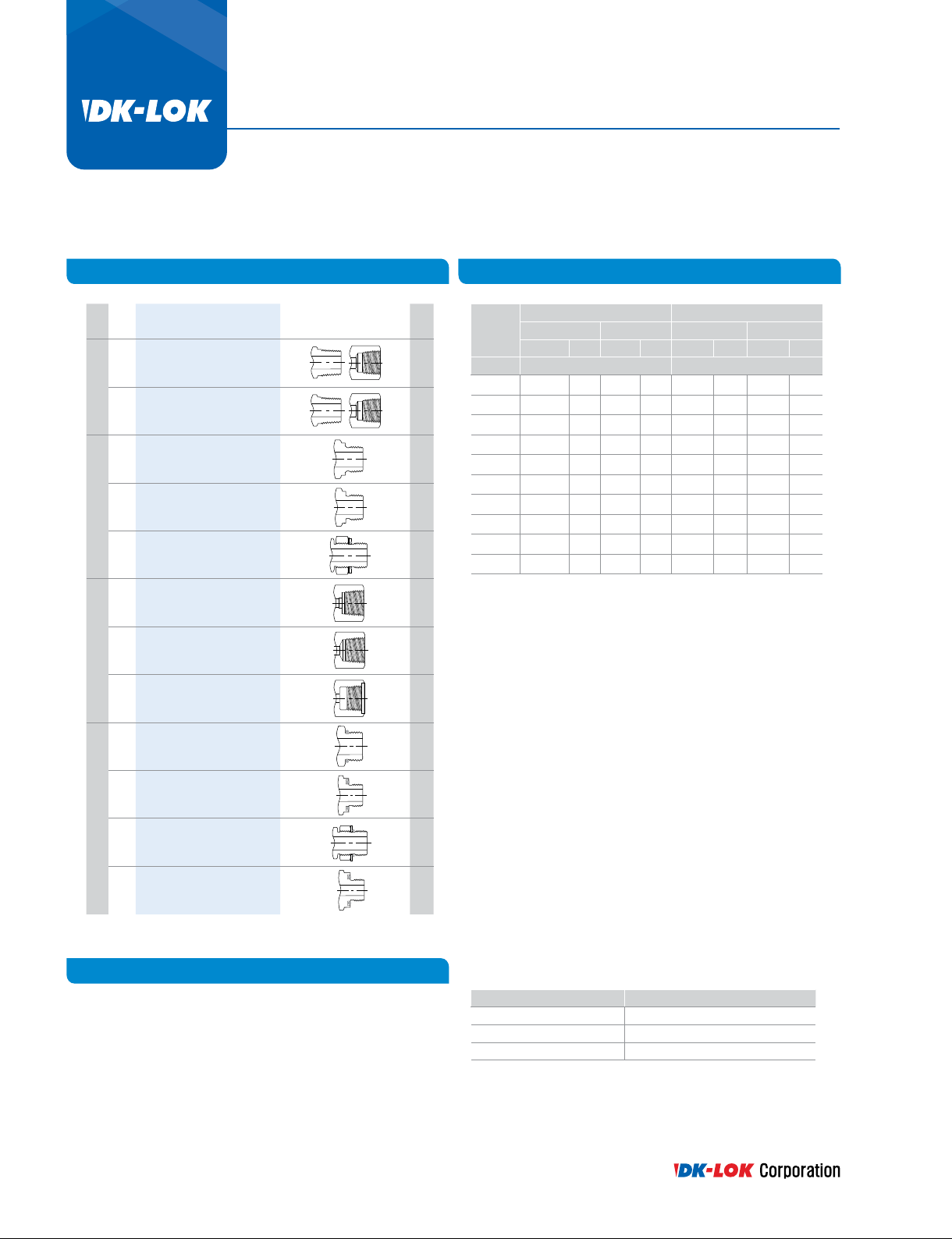

Ordering Information

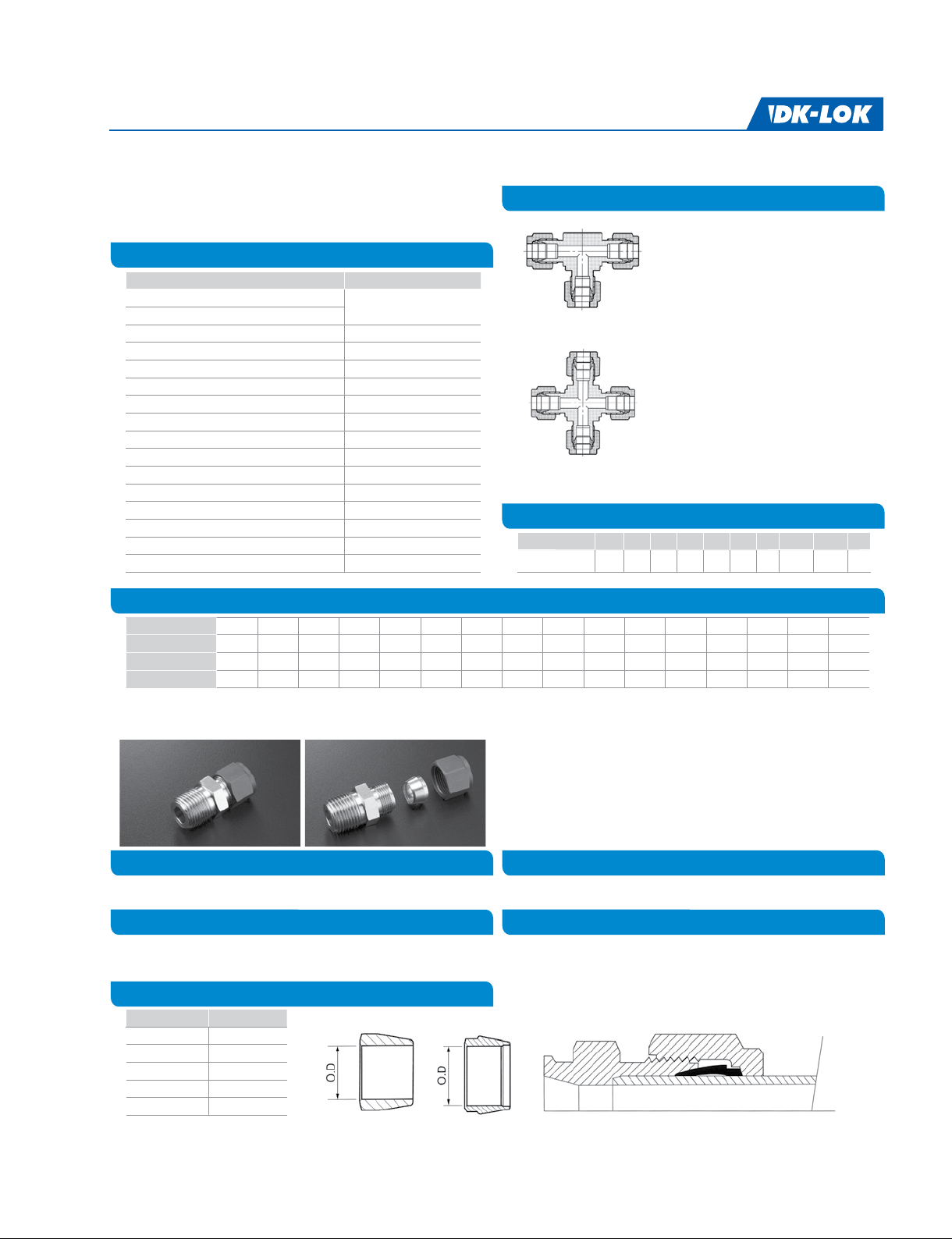

Tee and Cross Fittings

Sux the material designator to the part number. Example: DU-8-S

Table 18. Material Designator

Material Designator

Stainless Steel316

Dual Grade

Brass B

Carbon Steel C

Stainless 310 310

Duplex D

Super Duplex SD

Aluminum AL

Alloy 20 L20

Hastelloy C276 HC

Alloy 400 M

Alloy 600 IN

Alloy 625 L625

Alloy 825 L825

Titanium Gr. 2 TI

PTFE PE

Table 20. Tube O.D. Designator

OD in.

Designator

OD mm

Designator

1/16 1/8 3/16 1/4 5/16 3/8 1/2 5/8 3/4 7/8 1 1 1/4 1 1/2 2

123456810121416202432

2mm 3 mm 4 mm 6 mm 8mm 10 mm 12 mm 16 mm 20 mm 22 mm 25 mm 28 mm 32 mm 38 mm 42 mm 50 mm

2M 3 M 4 M 6 M 8 M 10 M 12 M 16 M 20 M 22 M 25 M 28 M 32 M 38 M 42 M 50 M

S

12

3

4

12

3

Table 19. Pipe Thread Size Designator

Nom. Size in. 1/16 1/8 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Designator 1 2468121620 2432

Tee tting part number is described

by rst the run (1 and 2) and next the

branch (3).

Cross tting part number is described

by rst the run (1 and 2) and next the

branch (3 and 4)

Z series DK-Lok

DK-Lok Z Series single ferrule tube tting is designed and manufactured

to the highest quality standards.

This tting includes single ferrule with standard DK-Lok tting body

and nut.

To help identify DK-Lok Z series from DK-Lok Tube tting, nut is black

Molybdenum Disulde (MoS) coated.

Material

DK-Lok Z Series single ferrule tube tting is manufactured in stainless

steel316.

Pressure and Temperature Ratings

DK-Lok Z Series ttings are identical to DK-Lok Tube Fittings in

pressure and temperature ratings.

Z Series Ferrule

Part No. Tube O.D.

DFZ-4-S 1/4

DFZ-6-S 3/8

DFZ-8-S 1/2

DFZ-12-S 3/4

DFZ-16-S 1

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Dimensions

DK-Lok Z Series ttings are dimensionally identical to DK-Lok Tube

Fittings.

Ordering Information

To order Z series, insert Z in the standard DK-Lok tube tting part

number.

Examples: DUZ-8-S, DMCZ8-8N-S, DNZ-4-S

www.dklok.com

10

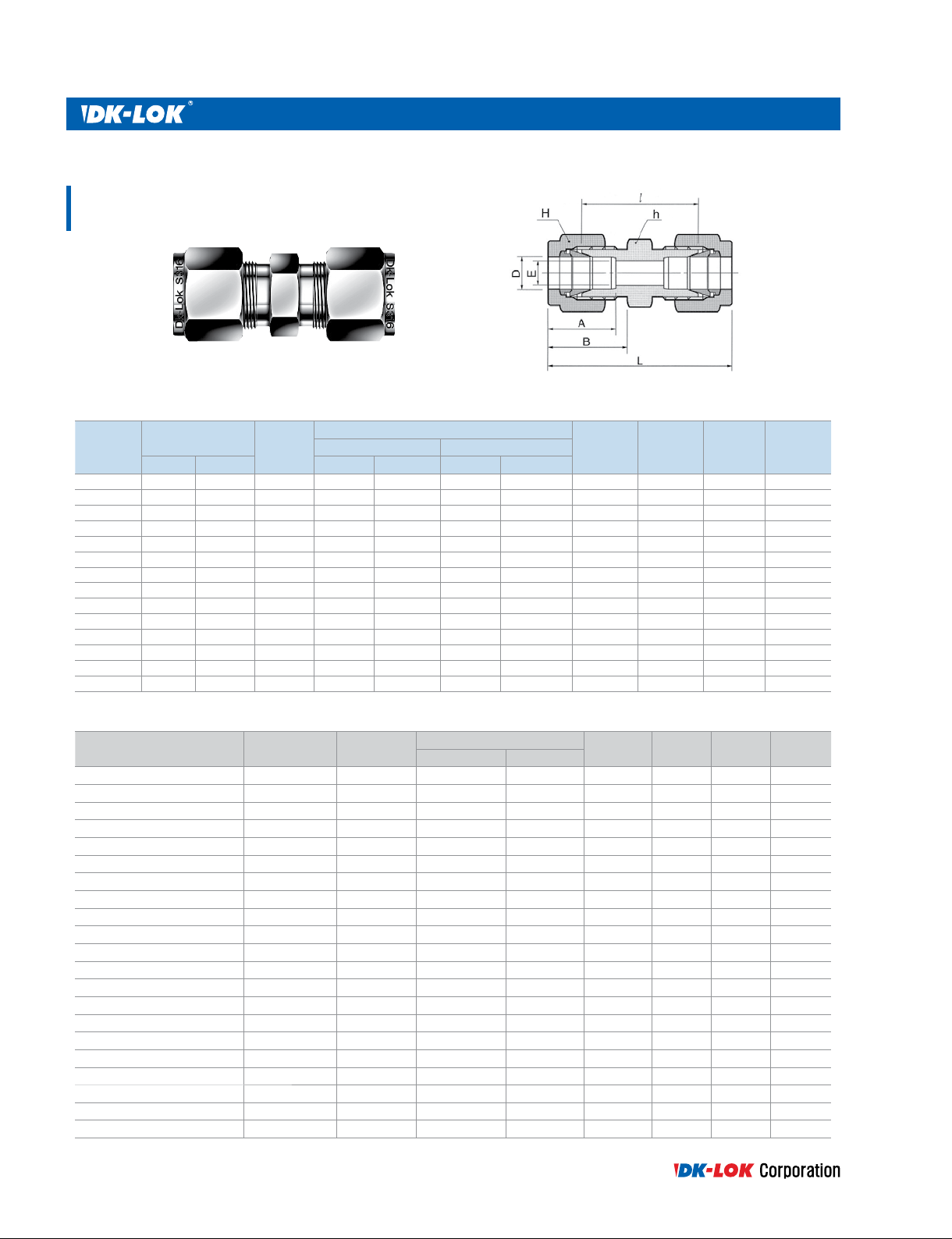

Union

DU

Connects fractional tube

Tube O.D.

Part No.

DU-1 1/16 1.59 1.27 5/16 7.93 5/16 7.93 8.63 10.92 17.50 25.15

DU-2 1/8 3.17 2.28 7/16 11.11 7/16 11.11 12.70 15.24 22.35 35.56

DU-3 3/16 4.76 3.04 7/16 11.11 1/2 12.70 13.71 16.00 24.13 37.33

DU-4 1/4 6.35 4.82 1/2 12.70 9/16 14.28 15.24 17.78 26.16 40.89

DU-5 5/16 7.93 6.35 9/16 14.28 5/8 15.87 16.25 18.54 28.19 42.92

DU-6 3/8 9.52 7.11 5/8 15.87 11/16 17.46 16.76 19.30 30.22 44.95

DU-8 1/2 12.70 10.41 13/16 20.64 7/8 22.22 22.86 21.84 30.98 51.30

DU-10 5/8 15.87 12.70 15/16 23.81 1 25.40 24.38 21.84 31.75 52.07

DU-12 3/4 19.05 15.74 1-1/16 26.98 1-1/8 28.58 24.38 21.84 33.27 53.59

DU-14 7/8 22.22 18.28 1-3/16 30.16 1-1/4 31.75 25.90 21.84 35.05 55.37

DU-16 1 25.40 22.35 1-3/8 34.92 1-1/2 38.10 31.24 26.41 40.38 64.77

DU-20 1-1/4 31.75 27.68 1-3/4 44.45 1-7/8 47.63 41.14 38.86 48.00 92.20

DU-24 1-1/2 38.10 33.90 2-1/8 53.97 2-1/4 57.15 50.03 45.21 53.60 107.95

DU-32 2 50.80 45.97 2-3/4 69.85 3 76.20 67.56 62.73 74.70 149.35

D

in. mm in. mm in. mm

E

Min.

Width across at

AB

NJ

LhH

Connects metric tube

Part No.

DU-2M 2 1.7 12 12 12.9 15.3 22.4 35.6

DU-3M 3 2.4 12 12 12.9 15.3 22.1 35.3

DU-4M 4 2.4 12 12 13.7 16.1 24.1 37.3

DU-6M 6 4.8 14 14 15.3 17.7 26.2 41.0

DU-8M 8 6.4 15 16 16.2 18.6 28.2 43.2

DU-10M 10 7.9 18 19 17.2 19.5 31.0 46.2

DU-12M 12 9.5 22 22 22.8 22.0 31.0 51.2

DU-14M 14 11.1 24 25 24.4 22.0 31.8 52.0

DU-15M 15 11.9 24 25 24.4 22.0 31.8 52.0

DU-16M 16 12.7 24 25 24.4 22.0 31.8 52.0

DU-18M 18 15.1 27 30 24.4 22.0 33.3 53.5

DU-20M 20 15.9 30 32 26.0 22.0 34.8 55.0

DU-22M 22 18.3 30 32 26.0 22.0 34.8 55.0

DU-25M 25 21.8 35 38 31.3 26.5 40.4 65.0

DU-28M 28 21.8 41 46 36.6 36.6 43.4 85.0

DU-30M 30 26.2 46 50 39.7 39.3 49.5 92.9

DU-32M 32 28.6 46 50 42.0 41.6 51.3 97.3

DU-35M 35 31.5 50 55 42.1 41.7 51.3 97.6

DU-38M 38 33.7 55 60 49.4 47.9 58.4 113.6

DU-42M 42 36.8 60 65 49.3 47.8 58.4 113.4

DU-50M 50 45.2 70 76 67.2 62.5 74.7 149

11

Tube O.D.

D

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

E

Min.

Width across at

hH

AB

NJ

L

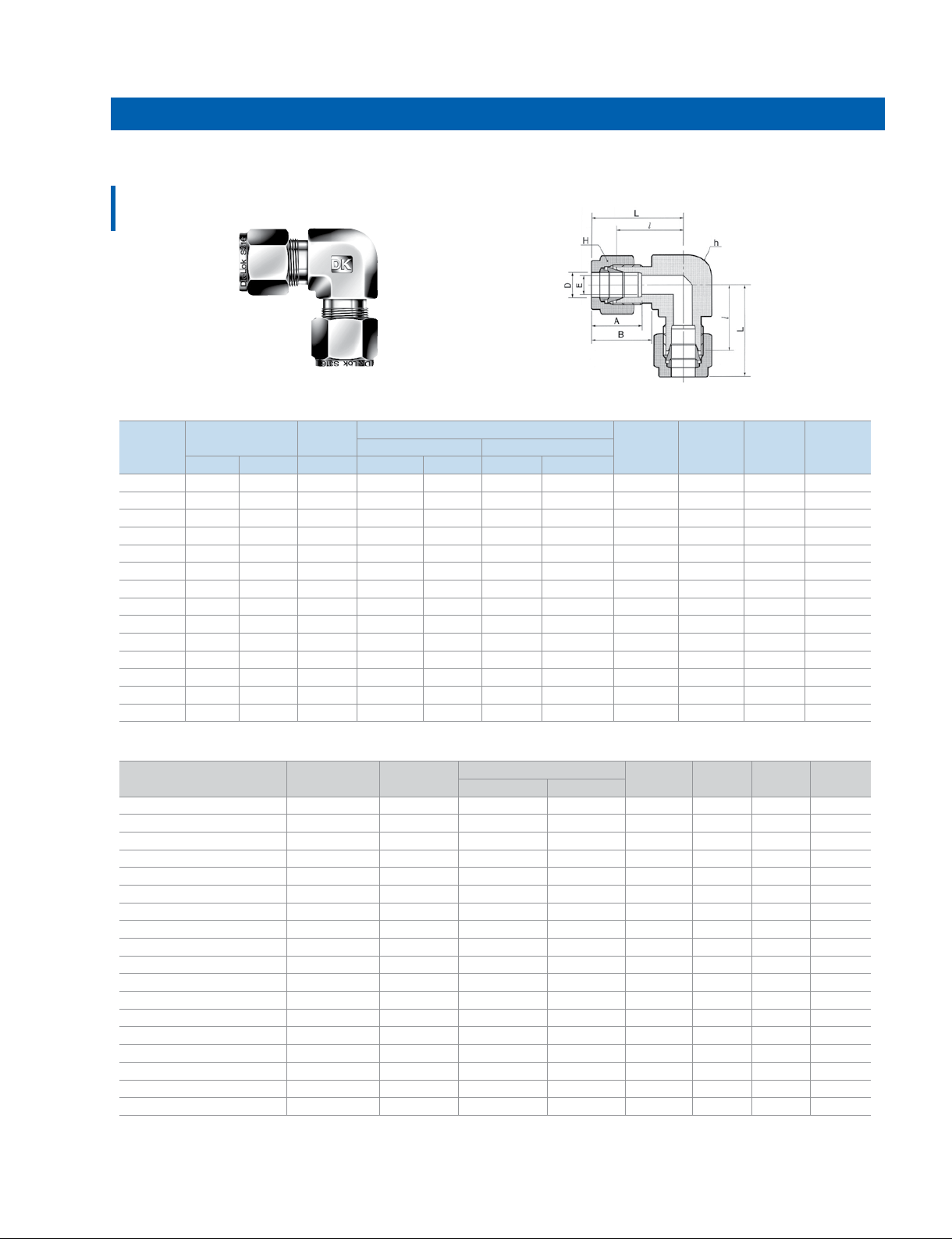

DK-Lok Tube Fitting

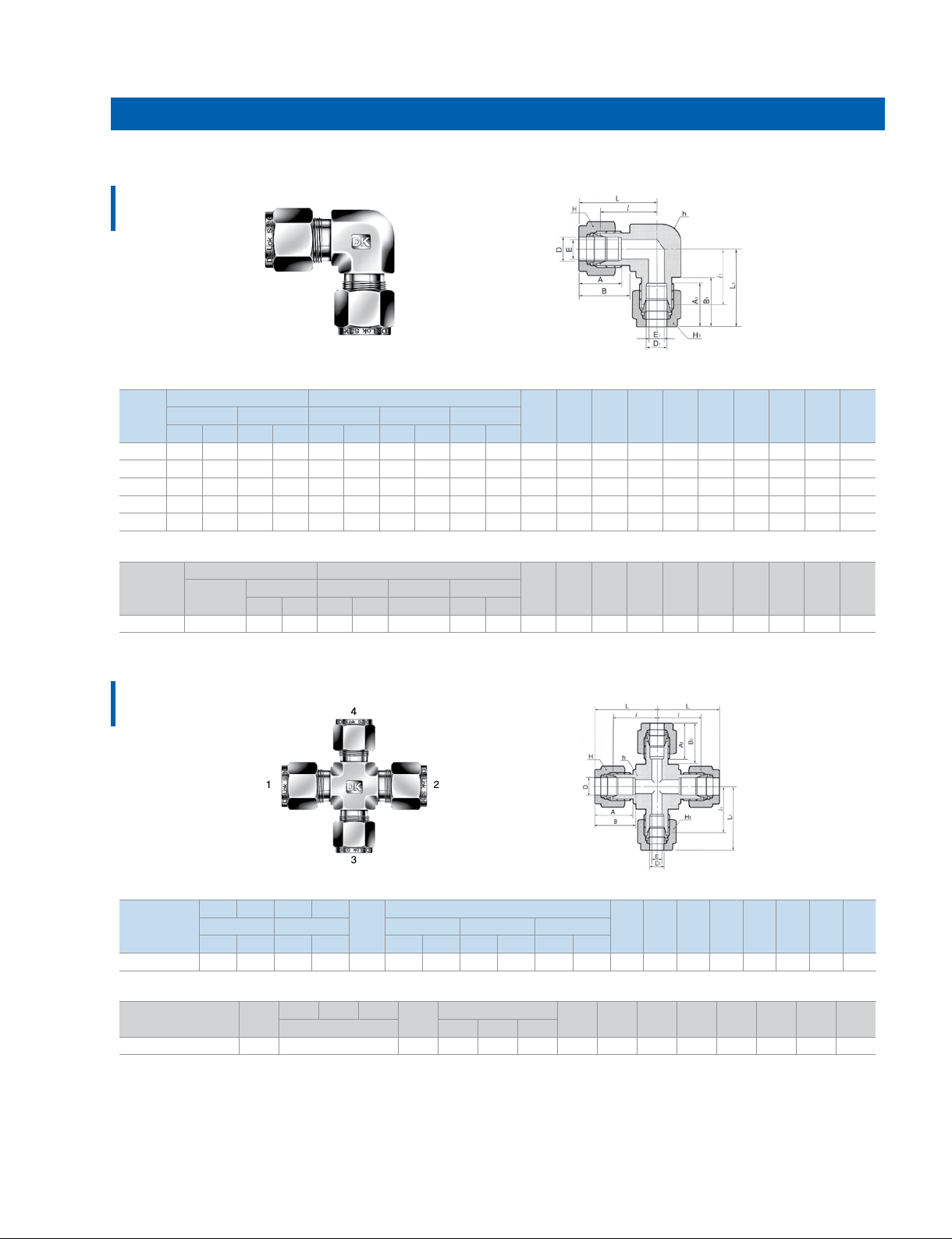

Union Elbow

DL

Connects fractional tube

Tube O.D.

Part No.

DL-1 1/16 1.59 1.27 3/8 9.52 5/16 7.93 8.63 10.92 14.00 17.88

DL-2 1/8 3.17 2.28 3/8 9.52 7/16 11.11 12.70 15.24 15.74 22.35

DL-3 3/16 4.76 3.04 1/2 12.70 1/2 12.70 13.71 16.00 17.78 24.38

DL-4 1/4 6.35 4.82 1/2 12.70 9/16 14.28 15.24 17.78 19.55 26.92

DL-5 5/16 7.93 6.35 9/16 14.28 5/8 15.87 16.25 18.54 21.33 28.70

DL-6 3/8 9.52 7.11 5/8 15.87 11/16 17.46 16.76 19.30 23.11 30.48

DL-8 1/2 12.70 10.41 13/16 20.64 7/8 22.22 22.86 21.84 25.90 36.06

DL-10 5/8 15.87 12.70 15/16 23.81 1 25.40 24.38 21.84 28.70 38.80

DL-12 3/4 19.05 15.74 1-1/16 26.98 1-1/8 28.58 24.38 21.84 29.71 39.87

DL-14 7/8 22.22 18.28 1-3/8 34.92 1-1/4 31.75 25.90 21.84 34.54 44.70

DL-16 1 25.40 22.35 1-3/8 34.92 1-1/2 38.10 31.24 26.41 36.83 49.02

DL-20 1-1/4 31.75 27.68 1-11/16 42.86 1-7/8 47.63 41.14 38.86 44.50 66.54

DL-24 1-1/2 38.10 33.90 2 50.80 2-1/4 57.15 50.03 45.21 50.80 77.97

DL-32 2 50.80 45.97 2-3/4 69.85 3 76.20 67.56 62.73 69.80 107.18

D

in. mm Min. in. mm in. mm

E

Width across at

AB

NJ

LhH

Connects metric tube

Part No.

DL-2M 2 1.7 9.5 12 12.9 15.3 15.7 22.3

DL-3M 3 2.4 9.5 12 12.9 15.3 15.7 22.3

DL-4M 4 2.4 12.7 12 13.7 16.1 18.8 25.4

DL-6M 6 4.8 12.7 14 15.3 17.7 19.6 27.0

DL-8M 8 6.4 14.3 16 16.2 18.6 21.3 28.8

DL-10M 10 7.9 17.5 19 17.2 19.5 23.9 31.5

DL-12M 12 9.5 20.6 22 22.8 22.0 25.9 36.0

DL-15M 15 11.9 25.4 25 24.4 22.0 28.7 38.8

DL-16M 16 12.7 25.4 25 24.4 22.0 28.7 38.8

DL-18M 18 15.1 27.0 30 24.4 22.0 29.7 39.8

DL-20M 20 15.9 34.92 32 26.0 22.0 32.5 42.6

DL-22M 22 18.3 34.92 32 26.0 22.0 32.5 42.6

DL-25M 25 21.8 34.92 38 31.3 26.5 36.8 49.1

DL-28M 28 21.8 41.0 46 36.6 36.6 43.2 64.0

DL-32M 32 28.6 46.0 50 42.0 41.6 49.3 72.3

DL-38M 38 33.7 50.8 60 49.4 47.9 56.4 84.0

DL-42M 42 36.8 60 65 49.3 47.8 55 82.5

DL-50M 50 45.2 70 76 67.2 62.5 69.9 107

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Tube O.D.

D

E

Min.

Width across at

hH

AB

www.dklok.com

NJ

L

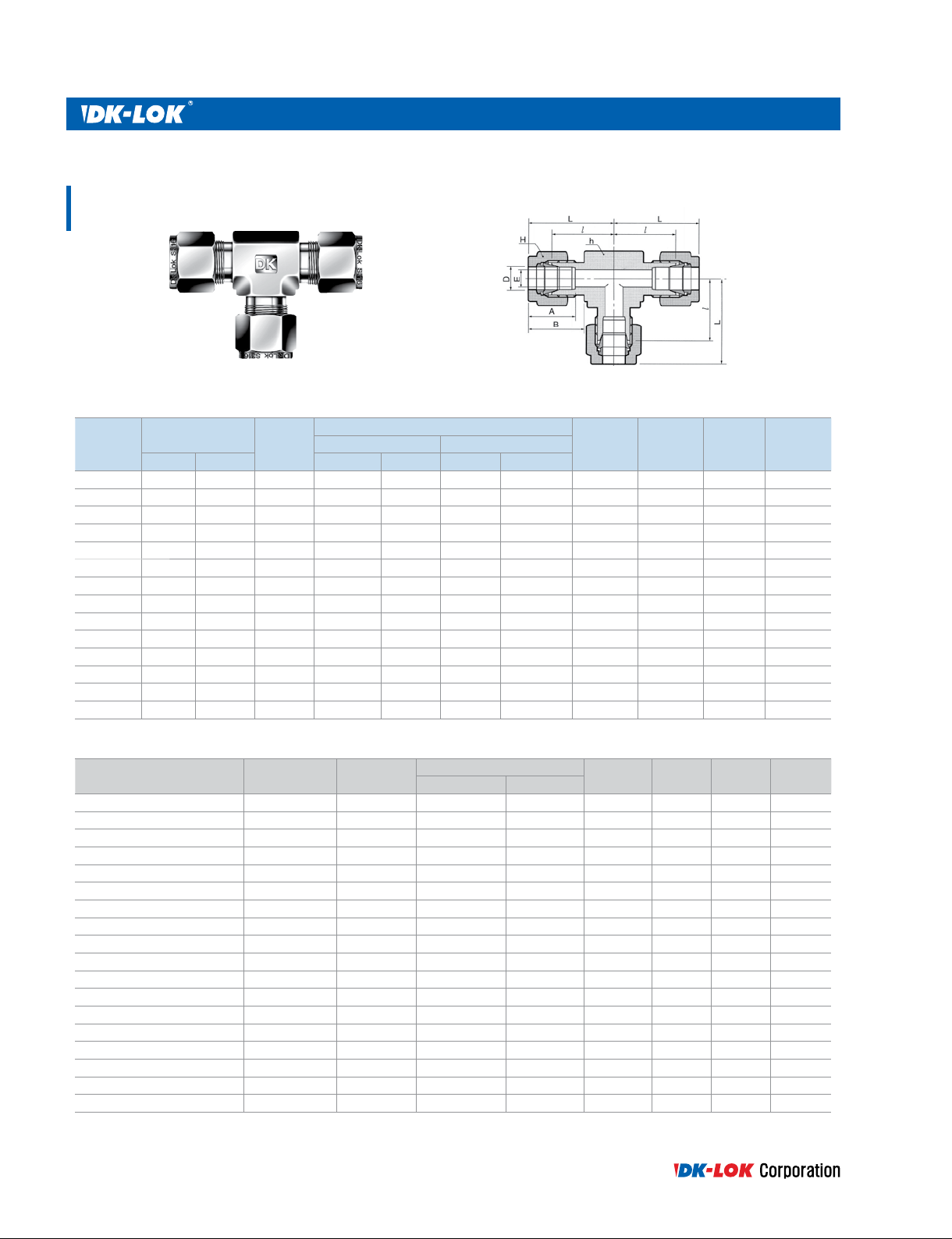

12

Union Tee

DT

Connects fractional tube

Tube O.D.

Part No.

DT-1 1/16 1.59 1.27 3/8 9.52 5/16 7.93 8.63 10.92 14.00 17.88

DT-2 1/8 3.17 2.28 3/8 9.52 7/16 11.11 12.70 15.24 15.74 22.35

DT-3 3/16 4.76 3.04 1/2 12.70 1/2 12.70 13.71 16.00 17.78 24.38

DT-4 1/4 6.35 4.82 1/2 12.70 9/16 14.28 15.24 17.78 19.55 26.92

DT-5 5/16 7.93 6.35 9/16 14.28 5/8 15.87 16.25 18.54 21.33 28.70

DT-6 3/8 9.52 7.11 5/8 15.87 11/16 17.46 16.76 19.30 23.11 30.48

DT-8 1/2 12.70 10.41 13/16 20.64 7/8 22.22 22.86 21.84 25.90 36.06

DT-10 5/8 15.87 12.70 15/16 23.81 1 25.40 24.38 21.84 28.70 38.80

DT-12 3/4 19.05 15.74 1-1/16 26.98 1-1/8 28.58 24.38 21.84 29.71 39.87

DT-14 7/8 22.22 18.28 1-3/8 34.92 1-1/4 31.75 25.90 21.84 34.54 44.70

DT-16 1 25.40 22.35 1-3/8 34.92 1-1/2 38.10 31.24 26.41 36.83 49.02

DT-20 1-1/4 31.75 27.68 1-11/16 42.86 1-7/8 47.63 41.14 38.86 44.50 66.54

DT-24 1-1/2 38.10 33.90 2 50.80 2-1/4 57.15 50.03 45.21 50.80 77.97

DT-32 2 50.80 45.97 2-3/4 69.85 3 76.20 67.56 62.73 69.80 107.18

D

in. mm in. mm in. mm

E

Min.

Width across at

AB

NJ

LhH

Connects metric tube

Part No.

DT-2M 2 1.7 9.5 12 12.9 15.3 15.7 22.3

DT-3M 3 2.4 9.5 12 12.9 15.3 15.7 22.3

DT-4M 4 2.4 12.7 12 13.7 16.1 18.8 25.4

DT-6M 6 4.8 12.7 14 15.3 17.7 19.6 27.0

DT-8M 8 6.4 14.3 16 16.2 18.6 21.3 28.8

DT-10M 10 7.9 17.5 19 17.2 19.5 23.9 31.5

DT-12M 12 9.5 20.6 22 22.8 22.0 25.9 36.0

DT-15M 15 11.9 25.4 25 24.4 22.0 28.7 38.8

DT-16M 16 12.7 25.4 25 24.4 22.0 28.7 38.8

DT-18M 18 15.1 27.0 30 24.4 22.0 29.7 39.8

DT-20M 20 15.9 34.92 32 26.0 22.0 32.5 42.6

DT-22M 22 18.3 34.92 32 26.0 22.0 32.5 42.6

DT-25M 25 21.8 34.92 38 31.3 26.5 36.8 49.1

DT-28M 28 21.8 41.0 46 36.6 36.6 43.2 64.0

DT-32M 32 28.6 46.0 50 42.0 41.6 49.3 72.3

DT-38M 38 33.7 50.8 60 49.4 47.9 56.4 84.0

DT-42M 42 36.8 60 65 49.3 47.2 55 82.5

DT-50M 50 45.2 70 76 67.2 62.5 69.9 107

13

Tube O.D.

D

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

E

Min.

Width across at

hH

AB

NJ

L

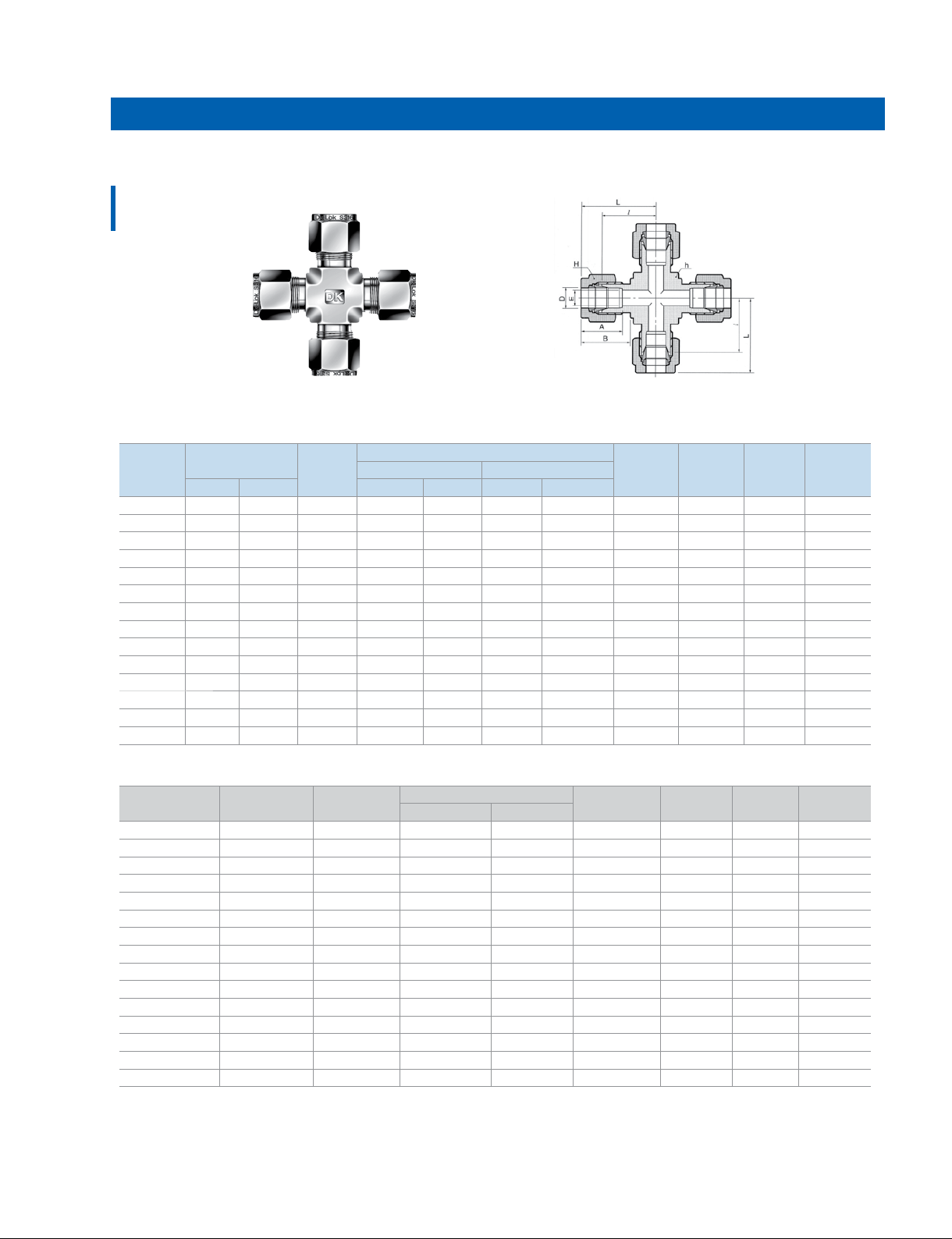

DK-Lok Tube Fitting

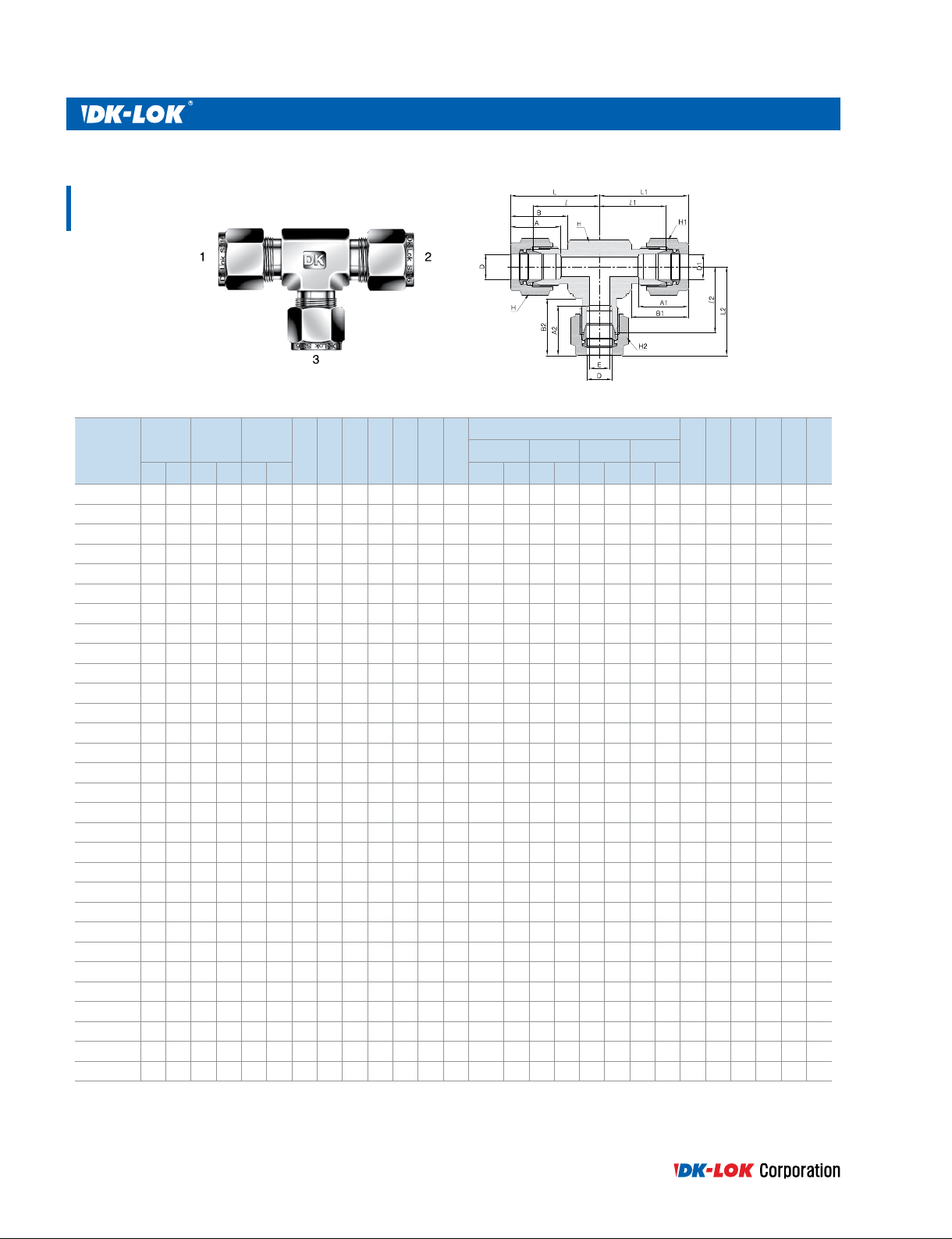

Union Cross

DX

Note : Cross may be made out of bar stock.

Connects fractional tube

Tube O.D.

Part No.

DX-1 1/6 1.59 1.27 3/8 9.52 5/16 7.93 8.63 10.92 14.00 17.88

DX-2 1/8 3.17 2.28 3/8 9.52 7/16 11.11 12.70 15.24 15.74 22.35

DX-3 3/16 4.76 3.04 1/2 12.70 1/2 12.70 13.71 16.00 17.78 24.38

DX-4 1/4 6.35 4.82 1/2 12.70 9/16 14.28 15.24 17.78 19.55 26.92

DX-5 5/16 7.93 6.35 9/16 14.28 5/8 15.87 16.25 18.54 21.33 28.70

DX-6 3/8 9.52 7.11 5/8 15.87 11/16 17.46 16.76 19.30 23.11 30.48

DX-8 1/2 12.70 10.41 13/16 20.64 7/8 22.22 22.86 21.84 25.90 36.06

DX-10 5/8 15.87 12.70 15/16 23.81 1 25.40 24.38 21.84 28.70 38.80

DX-12 3/4 19.05 15.74 1-1/16 26.98 1-1/8 28.58 24.38 21.84 29.71 39.87

DX-14 7/8 22.22 18.28 1-3/8 34.92 1-1/4 31.75 25.90 21.84 34.54 44.70

DX-16 1 25.40 22.35 1-3/8 34.92 1-1/2 38.10 31.24 26.41 36.83 49.02

DX-20 1-1/4 31.75 27.68 1-11/16 42.86 1-7/8 47.63 41.14 38.86 44.50 66.54

DX-24 1-1/2 38.10 33.90 2 50.80 2-1/4 57.15 50.03 45.21 50.80 77.97

DX-32 2 50.80 45.97 2-3/4 69.85 3 76.20 67.56 62.73 69.80 107.18

D

in. mm in. mm in. mm

E

Min.

Width across at

AB

NJ

LhH

Connects metric tube

Part No.

DX-3M 3 2.4 9.5 12 12.9 15.3 15.7 22.3

DX-4M 4 2.4 12.7 12 13.7 16.1 18.8 25.4

DX-6M 6 4.8 12.7 14 15.3 17.7 19.6 27.0

DX-8M 8 6.4 14.3 16 16.2 18.6 21.3 28.8

DX-10M 10 7.9 17.5 19 17.2 19.5 23.9 31.5

DX-12M 12 9.5 20.6 22 22.8 22.0 25.9 36.0

DX-15M 15 11.9 25.4 25 24.4 22.0 28.7 38.8

DX-16M 16 12.7 25.4 25 24.4 22.0 28.7 38.8

DX-18M 18 15.1 27.0 30 24.4 22.0 29.7 39.8

DX-20M 20 15.9 34.92 32 26.0 22.0 32.5 42.6

DX-22M 22 18.3 34.92 32 26.0 22.0 32.5 42.6

DX-25M 25 21.8 34.92 38 31.3 26.5 36.8 49.1

DX-28M 28 21.8 41.0 46 36.6 36.6 43.2 64.0

DX-32M 32 28.6 46.0 50 42.0 41.6 49.3 72.3

DX-38M 38 33.7 50.8 60 49.4 47.9 56.4 84.0

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Tube O.D.

D

E

Min.

Width across at

hH

www.dklok.com

AB

NJ

L

14

Bulkhead Union

DUB

Connects fractional tube

Tube O.D.

Part No.

DUB-1 1/16 1.59 1.27 5/16 7.93 5/16 7.93 8.63 10.92 23.87 13.46 31.50 17.27 5.16 3.05

DUB-2 1/8 3.17 2.28 1/2 12.70 7/16 11.11 12.70 15.24 38.10 24.63 51.30 31.24 8.33 12.70

DUB-3 3/16 4.76 3.04 9/16 14.28 1/2 12.70 13.71 16.00 40.38 25.40 53.59 32.00 9.92 12.70

DUB-4 1/4 6.35 4.82 5/8 15.87 9/16 14.28 15.24 17.78 42.92 26.16 57.65 33.52 11.50 10.16

DUB-5 5/16 7.93 6.35 11/16 17.46 5/8 15.87 16.25 18.54 45.97 28.44 60.70 35.81 13.09 11.17

DUB-6 3/8 9.52 7.11 3/4 19.05 11/16 17.46 16.76 19.30 47.49 29.46 62.23 36.83 14.68 11.17

DUB-8 1/2 12.70 10.41 15/16 23.81 7/8 22.22 22.86 21.84 50.80 31.75 71.12 41.91 19.44 12.70

DUB-10 5/8 15.87 12.70 1-1/16 26.98 1 25.40 24.38 21.84 52.32 32.51 72.64 42.67 22.62 12.70

DUB-12 3/4 19.05 15.74 1-3/16 30.16 1-1/8 28.58 24.38 21.84 58.67 37.33 78.99 47.49 25.79 16.76

DUB-14 7/8 22.22 18.28 1-3/8 34.92 1-1/4 31.75 25.90 21.84 64.26 42.92 84.58 53.08 28.97 19.05

DUB-16 1 25.40 22.35 1-5/8 41.27 1-1/2 38.10 31.24 26.41 71.37 45.21 95.75 57.40 33.73 19.05

DUB-20 1-1/4 31.75 27.68 1-7/8 47.63 1-7/8 47.63 41.14 38.86 78.99 47.75 123.19 69.85 41.67 19.05

DUB-24 1-1/2 38.10 33.90 2-1/4 57.15 2-1/4 57.15 50.03 45.21 84.83 49.27 139.19 76.45 49.61 19.05

DUB-32 2 50.80 45.97 2-3/4 69.85 3 76.20 67.56 62.73 105.66 56.38 180.34 93.72 57.94 19.05

D

in. mm Min. in. mm in. mm

E

Width across at

hH

AB

NJNJ1

LL1

Panel

Hole

Drill size

Thickness

Panel

Max

Connects metric tube

Part No.

DUB-3M 3 2.4 14 12 12.9 15.3 38.1 24.6 51.3 31.2 8.3 12.7

DUB-4M 4 2.4 14 12 13.7 16.1 40.4 25.4 53.6 32.0 9.9 12.7

DUB-6M 6 4.8 16 14 15.3 17.7 42.9 26.2 57.7 33.6 11.5 10.2

DUB-8M 8 6.4 18 16 16.2 18.6 46.0 28.6 61.0 36.1 13.1 11.2

DUB-10M 10 7.9 22 19 17.2 19.5 48.5 29.4 63.7 37.0 16.2 11.2

DUB-12M 12 9.5 24 22 22.8 22.0 50.8 31.8 71.0 41.9 19.5 12.7

DUB-15M 15 11.9 27 25 24.4 22.0 52.3 32.5 72.5 42.6 22.8 12.7

DUB-16M 16 12.7 27 25 24.4 22.0 52.3 32.5 72.5 42.6 22.8 12.7

DUB-18M 18 15.1 30 30 24.4 22.0 58.7 37.3 78.9 47.4 26.0 16.8

DUB-20M 20 15.9 35 32 26.0 22.0 64.3 42.9 84.5 53.0 29.0 17.0

DUB-22M 22 18.3 35 32 26.0 22.0 64.3 42.9 84.5 53.0 29.0 19.0

DUB-25M 25 21.8 41.3 38 31.3 26.5 71.4 45.2 95.9 57.5 33.7 19.0

DUB-32M 32 28.6 50 50 42.0 41.6 82.3 49.5 128.3 72.5 42.5 19.0

DUB-38M 38 33.7 60 60 49.4 47.9 89.4 51.5 144.6 79.1 50.5 19.0

15

Tube O.D.DE

Min.

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Width across at

hH

AB

NJNJ1

LL1

Panel

Hole

Drill size

Panel

Max

Thickness

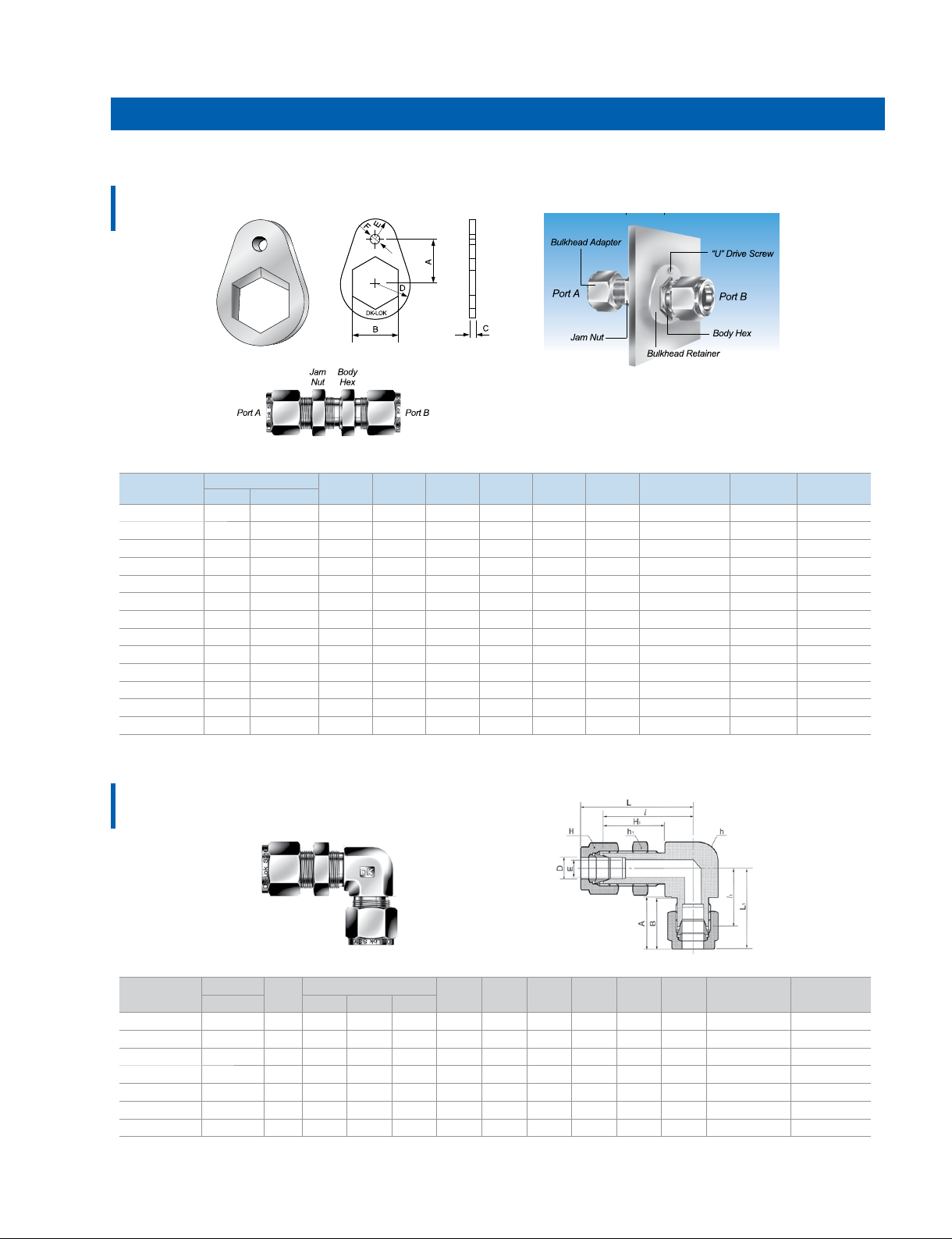

DK-Lok Tube Fitting

Bulkhead Retainer

DBR

Bulkhead retainer acts as a backup wrench on panel construction.

This allows one person to tighten the jam nut on port A side and

following tubing connection on port A and B without a backup

wrench.

Connects fractional tube

Part No.

DBR-1-S 1/6 9.52 7.94 3.18 7.94 3.97 3.97 #6-3/8 31 3.05

DBR-2-S 1/8 12.7 12.7 3.18 10.31 5.55 3.97 #6-3/8 31 3.05

DBR-3-S 3/16 3M,4M 14.28 14.28 3.18 11.90 6.35 3.97 #6-3/8 31 3.05

DBR-4-S 1/4 6M 15.87 15.87 3.18 12.7 7.14 3.97 #6-3/8 31 3.05

DBR-5-S 5/16 17.46 17.46 3.18 14.28 7.94 3.97 #6-3/8 31 3.05

DBR-8M-S 8M 17.46 18.0 3.18 14.28 7.94 3.97 #6-3/8 31 3.05

DBR-6-S 3/8 19.05 19.05 3.18 15.87 8.73 3.97 #6-3/8 31 3.05

DBR-10M-S 10M 23.81 22.0 3.18 19.05 10.31 5.55 #10-1/2 27 3.66

DBR-8-S 1/2 12M 23.81 23.81 3.18 19.05 10.31 5.55 #10-1/2 27 3.66

DBR-10-S 5/8 15M,16M 25.4 26.98 3.18 20.64 10.31 5.55 #10-1/2 27 3.66

DBR-12-S 3/4 18M 26.98 30.16 3.18 23.02 11.90 5.55 #10-1/2 27 3.66

DBR-14-S 7/8 28.57 33.33 3.18 26.19 13.49 5.55 #10-1/2 27 3.66

DBR-16-S 1 32.54 41.27 3.18 29.37 14.28 5.55 #10-1/2 27 3.66

DK-Lok O.D.

in. mm

A B C D E F “U” Drive Screw

Drill

Number

Drill Holl

Dia

Bulkhead Elbow Union

DBL

Connects Metic tube

Part No.

DBL-6M 6 4.8 15.8 14.2 14.0 15.3 17.7 36.5 20.6 43.9 30.0 11.5 10.2

DBL-8M 8 6.4 17.4 17.4 16.0 18.6 46.0 40.9 23.2 48.4 30.7 13.1 11.2

DBL-10M 10 7.9 22.0 22.0 19.0 19.5 48.5 44.5 26.9 52.1 34.5 16.2 11.2

DBL-12M 12 9.5 24.0 23.8 22.0 22.0 50.8 46.9 26.9 57.0 37.0 19.5 12.7

DBL-16M 16 13.5 27.0 27.0 25.0 22.0 52.3 53.5 34.1 63.7 44.5 22.8 12.7

DBL-20M 20 15.9 34.9 35.0 32.0 26.0 22.0 68.4 39.0 78.2 48.7 29.0 17.0

DBL-25M 25 21.8 41.0 41.0 38.0 31.3 26.5 74.2 46.1 86.5 58.4 33.7 19.1

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

Tube O.D.

mm h h

Min.

E

Width across at

1 H

AB

NJNJ1

www.dklok.com

LL1

Panel Hole

Drill size

Panel Max

Thickness

16

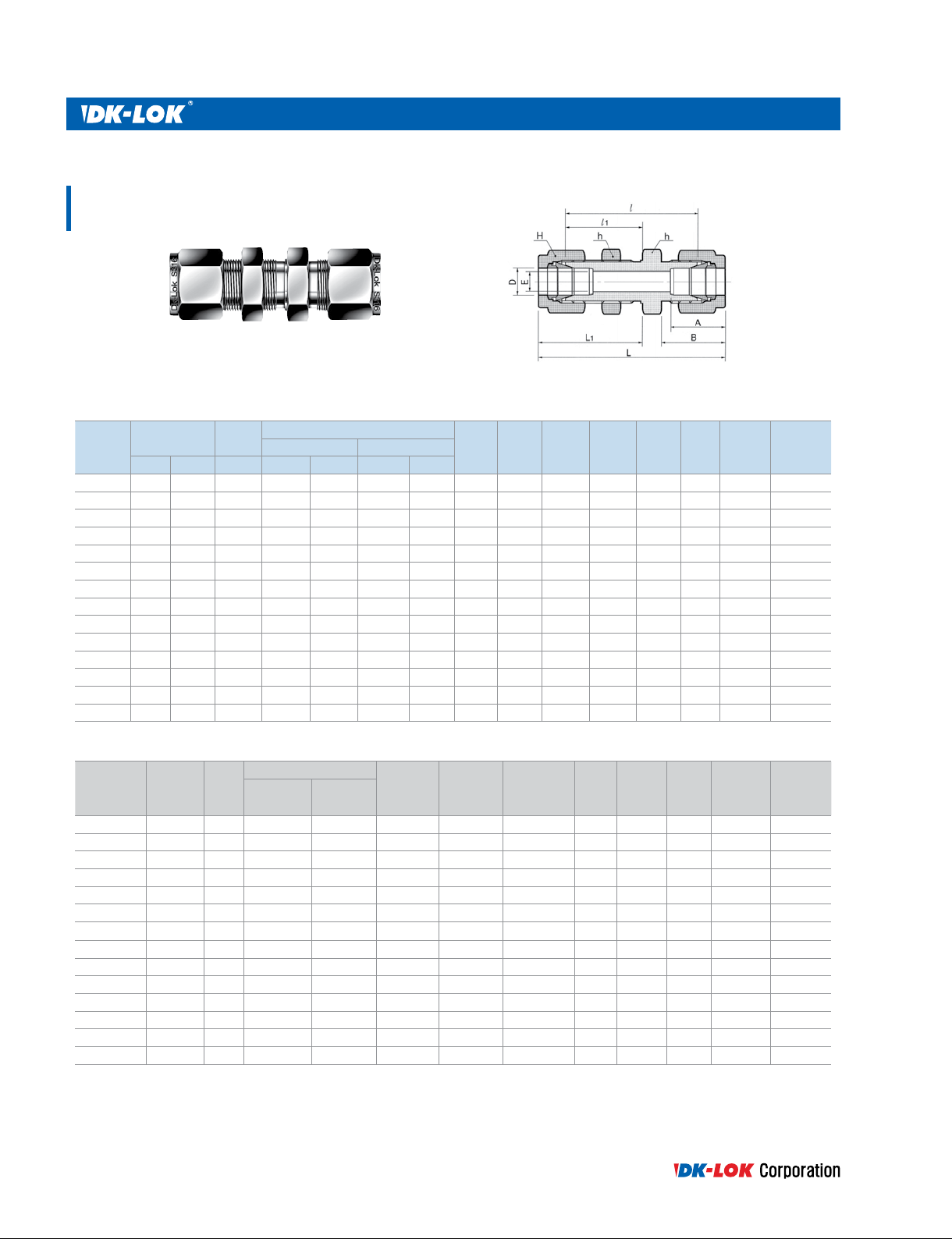

Reducing Union

DUR

Connects fractional tube

Part No.

Tube O.D.

in. mm in. mm in. mm in. mm in. mm

DUR2-1 1/8 3.18 1/16 1.59 1.27 7/16 11.11 7/16 11.11 5/16 7.93 12.70 8.63 15.24 10.92 20.60 30.91

DUR3-1 3/16 4.76 1/16 1.59 1.27 7/16 11.11 1/2 12.70 5/16 7.93 13.71 8.63 16.00 10.92 21.84 32.25

DUR3-2 3/16 4.76 1/8 3.17 2.28 7/16 11.11 1/2 12.70 7/16 11.11 13.71 12.70 16.00 15.24 23.36 36.57

DUR4-1 1/4 6.35 1/16 1.59 1.27 1/2 12.70 9/16 14.28 5/16 7.93 15.24 8.63 17.78 10.92 23.11 34.29

DUR4-2 1/4 6.35 1/8 3.17 2.28 1/2 12.70 9/16 14.28 7/16 11.11 15.24 12.70 17.78 15.24 24.63 38.60

DUR4-3 1/4 6.35 3/16 4.76 3.04 1/2 12.70 9/16 14.28 1/2 12.70 15.24 13.71 17.78 16.00 25.40 39.37

DUR5-2 5/16 7.93 1/8 3.17 2.28 9/16 14.28 5/8 15.87 7/16 11.11 16.25 12.70 18.54 15.24 25.90 39.87

DUR5-4 5/16 7.93 1/4 6.35 4.82 9/16 14.28 5/8 15.87 9/16 14.28 16.25 15.24 18.54 17.78 27.43 42.16

DUR6-1 3/8 9.52 1/16 1.59 1.27 5/8 15.87 11/16 17.46 5/16 7.93 16.76 8.63 19.30 10.92 25.40 36.57

DUR6-2 3/8 9.52 1/8 3.17 2.28 5/8 15.87 11/16 17.46 7/16 11.11 16.76 12.70 19.30 15.24 26.92 40.89

DUR6-4 3/8 9.52 1/4 6.35 4.82 5/8 15.87 11/16 17.46 9/16 14.28 16.76 15.24 19.30 17.78 28.44 43.18

DUR6-5 3/8 9.52 5/16 7.93 6.35 5/8 15.87 11/16 17.46 5/8 15.87 16.76 16.25 19.30 18.54 29.46 44.19

DUR8-2 1/2 12.70 1/8 3.17 2.28 13/16 20.64 7/8 22.22 7/16 11.11 22.86 12.70 21.84 15.24 28.44 45.21

DUR8-4 1/2 12.70 1/4 6.35 4.82 13/16 20.64 7/8 22.22 9/16 14.28 22.86 15.24 21.84 17.78 29.46 46.99

DUR8-6 1/2 12.70 3/8 9.52 7.11 13/16 20.64 7/8 22.22 11/16 17.46 22.86 16.76 21.84 19.30 30.98 48.51

DUR10-6 5/8 15.87 3/8 9.52 7.11 15/16 23.81 1 25.40 11/16 17.46 24.38 16.76 21.84 19.30 31.75 49.27

DUR10-8 5/8 15.87 1/2 12.70 10.41 15/16 23.81 1 25.40 7/8 22.22 24.38 22.86 21.84 21.84 31.75 52.07

DUR12-4 3/4 19.05 1/4 6.35 4.82 1-1/16 26.98 1-1/8 28.57 9/16 14.48 24.38 15.24 21.84 17.78 31.75 49.27

DUR12-6 3/4 19.05 3/8 9.52 7.11 1-1/16 26.98 1-1/8 28.57 11/16 17.46 24.38 16.76 21.84 19.30 33.27 50.80

DUR12-8 3/4 19.05 1/2 12.70 10.41 1-1/16 26.98 1-1/8 28.57 7/8 22.22 24.38 22.86 21.84 21.84 33.27 53.59

DUR12-10 3/4 19.05 5/8 15.87 12.70 1-1/16 26.98 1-1/8 28.57 1 25.40 24.38 24.38 21.84 21.84 33.27 53.59

DUR16-8 1 25.40 1/2 12.70 10.41 1-3/8 34.92 1-1/2 38.10 7/8 22.22 31.24 22.86 26.41 21.84 40.89 63.24

DUR16-12 1 25.40 3/4 19.05 15.74 1-3/8 34.92 1-1/2 38.10 1-1/8 28.58 31.24 24.38 26.41 21.84 40.38 62.73

E

Min.

Connects metric tube

Part No.

DUR3M-2M 3 2 1.7 12 12 12 12.9 12.9 15.3 15.3 22.1 35.3

DUR6M-2M 6 2 1.7 14 14 12 15.3 12.9 17.7 15.3 24.6 38.6

DUR6M-3M 6 3 2.4 14 14 12 15.3 12.9 17.7 15.3 24.6 38.6

DUR6M-4M 6 4 2.4 14 14 12 15.3 13.7 17.7 16.1 25.4 39.4

DUR8M-6M 8 6 4.8 15 16 14 16.2 15.3 18.6 17.7 27.4 42.3

DUR10M-3M 10 3 2.4 18 19 12 17.2 12.9 19.5 15.3 27.7 41.9

DUR10M-4M 10 4 2.4 18 19 12 17.2 13.7 19.5 16.1 28.7 42.9

DUR10M-6M 10 6 4.8 18 19 14 17.2 15.3 19.5 17.7 29.5 44.5

DUR10M-8M 10 8 6.4 18 19 16 17.2 16.2 19.5 18.6 30.0 45.1

DUR12M-6M 12 6 4.8 22 22 14 22.8 15.3 22.0 17.7 29.5 47.0

DUR12M-8M 12 8 6.4 22 22 16 22.8 16.2 22.0 18.6 30.2 47.8

DUR12M-10M 12 10 7.9 22 22 19 22.8 17.2 22.0 19.5 31.0 48.7

DUR15M-12M 15 12 9.8 24 25 22 24.4 17.2 22.0 19.5 31.8 52.5

DUR16M-10M 16 10 7.9 24 25 19 24.4 17.2 22.0 19.5 31.8 49.5

DUR16M-12M 16 12 9.5 24 25 22 24.4 22.8 22.0 22.0 31.8 52.0

DUR18M-10M 18 10 7.9 27 30 19 24.4 17.2 22.0 19.5 33.0 51.0

DUR18M-12M 18 12 9.5 27 30 22 24.4 22.8 22.0 22.0 33.3 53.5

DUR25M-18M 25 18 15.1 35 38 30 31.3 24.4 26.5 22.0 38.6 61.0

DUR25M-20M 25 20 15.9 35 38 32 31.3 26.0 26.5 22.0 39.9 62.3

DUR30M-18M 30 18 15.1 46 50 30 39.7 24.4 39.3 22.0 43.7 75.4

DUR30M-20M 30 20 15.9 46 50 32 39.7 26.0 39.3 22.0 43.7 75.4

DUR30M-25M 30 25 21.8 46 50 38 39.7 31.3 39.3 26.5 46.2 80.1

DUR32M-18M 32 18 15.1 46 50 30 42.0 24.4 41.6 22.0 44.7 77.8

DUR32M-20M 32 20 15.9 46 50 32 42.0 26.0 41.6 22.0 44.7 77.8

DUR32M-25M 32 25 21.8 46 50 38 42.0 31.3 41.6 26.5 47.0 82.3

DUR38M-20M 38 20 15.9 55 60 32 49.4 26.0 47.9 22.0 49.8 87.5

DUR38M-25M 38 25 21.8 55 60 38 49.4 31.3 47.9 26.5 52.1 92.0

DUR38M-30M 30 30 26.2 55 60 50 49.4 39.7 47.9 39.3 55.4 104.6

Tube O.D.

DD

1 hHH1

E

Min.

Width across at

Width across at

1 BB1

AA

AA1 BB1

NJ

NJ

LDD1 hHH1

L

17

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

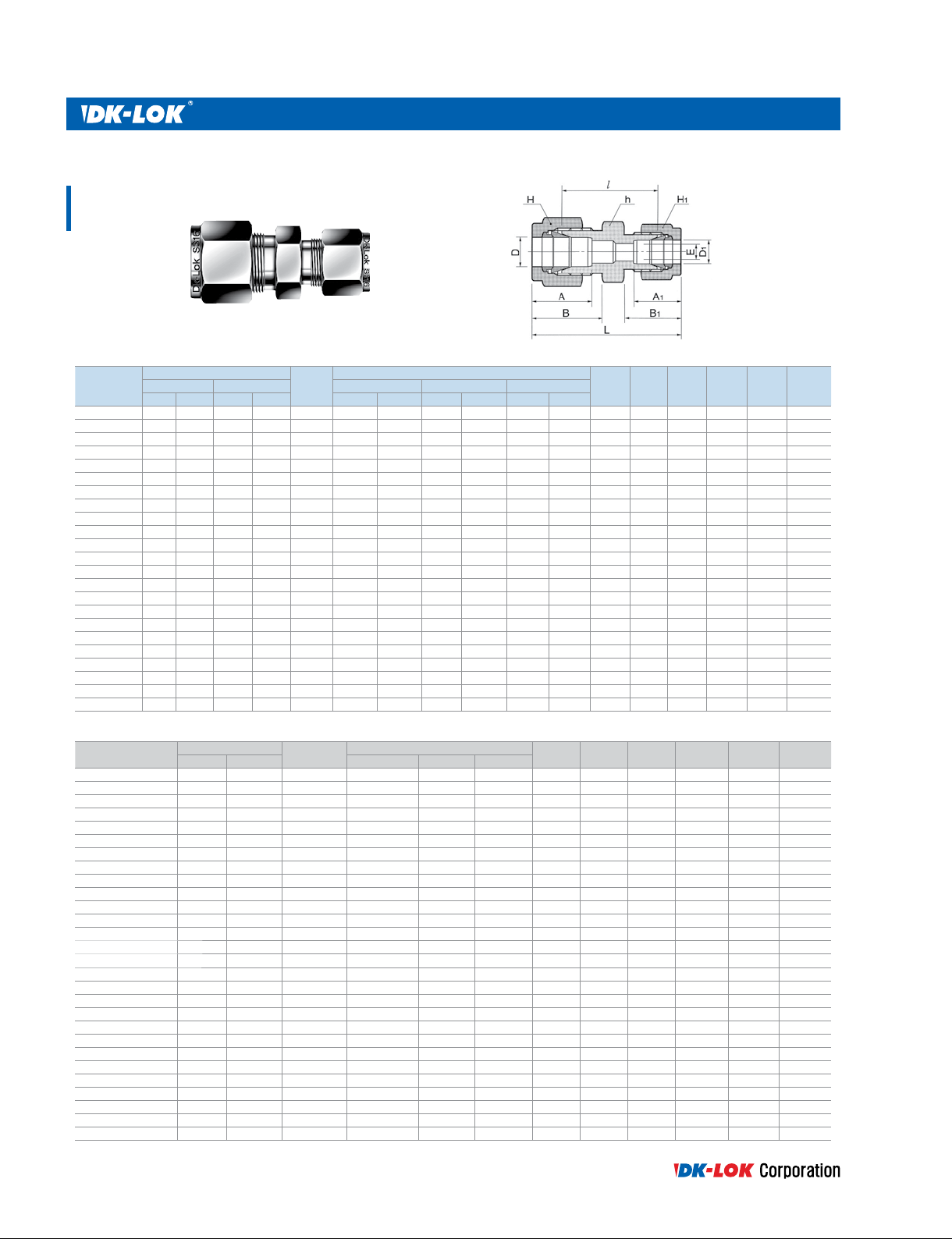

DK-Lok Tube Fitting

Reducing Union Elbow

DLR

Connects fractional tube

Tube O.D. Width across at

Part No.

in. mm in. mm in. mm in. mm in. mm

DLR2-1 1/8 3.17 1/16 1.59 3/8 9.52 7/6 11.11 5/16 7.93 2.4 1.3 12.7 8.63 15.24 10.93 15.74 14.2 22.35 18.0

DLR4-2 1/4 635 1/8 3.17 1/2 12.7 9/16 14.28 7/6 11.11 4.8 2.4 15.24 12.7 17.78 15.24 19.55 17.9 26.92 24.5

DLR6-4 3/8 9.52 1/4 6.35 5/8 15.87 11/16 17.46 9/16 14.28 7.1 4.8 16.76 15.24 19.3 17.78 23.1 21.92 30.47 29.29

DLR8-4 1/2 12.7 1/4 6.35 13/16 20.64 7/8 22.22 9/16 14.28 10.41 4.8 22.86 15.24 21.84 17.78 25.9 24.4 36.06 31.77

DLR8-6 1/2 12.7 3/8 9.52 13/16 20.64 7/8 22.22 11/16 17.46 10.41 7.1 22.86 16.76 21.84 19.30 25.9 25.9 36.06 33.27

Connects metric tube

Tube O.D. Width across at

Part No.

DLR8M-4 8 1/4 6.35 9/16 14.28 16 9/16 14.28

D

D

1 hHH1

in. mm in. mm mm in. mm

EE1 AA1 BB1

EE1 AA1 BB1

6.4 4.8 16.2 15.24 18.6 17.78 21.3 20.6 28.7 28.0

NJNJ1

NJNJ1

LL1DD1 hHH1

LL1

Reducing Union Cross

DXR

Connects fractional tube

Port 1 Por t 2 Port3 Port4

Part No.

in. mm in. mm in. mm in. mm in. mm

DXR12-12-6-6 3/4 19.05 3/8 9.52 7.1 1-1/16 26.98 1-1/8 28.57 11/16 17.46 24.38 16.76 21.84 19.3 29.71 29.71 39.87 37.07

E

Min.

Connects metric tube

Port 2 Port3 Port4

Part No.

DXR16M-6M-6M-6M 16 6 4.8 25.4 25 14 24.4 15.3 22.0 17.7 28.7 27.2 38.8 34.6

Port 1

D

D1 hHH1

E

Min.

Width across at

Width across at

AA1 BB1

1 BB1

AA

NJNJ1

NJNJ1

LL1DD1 hHH1

LL1

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

18

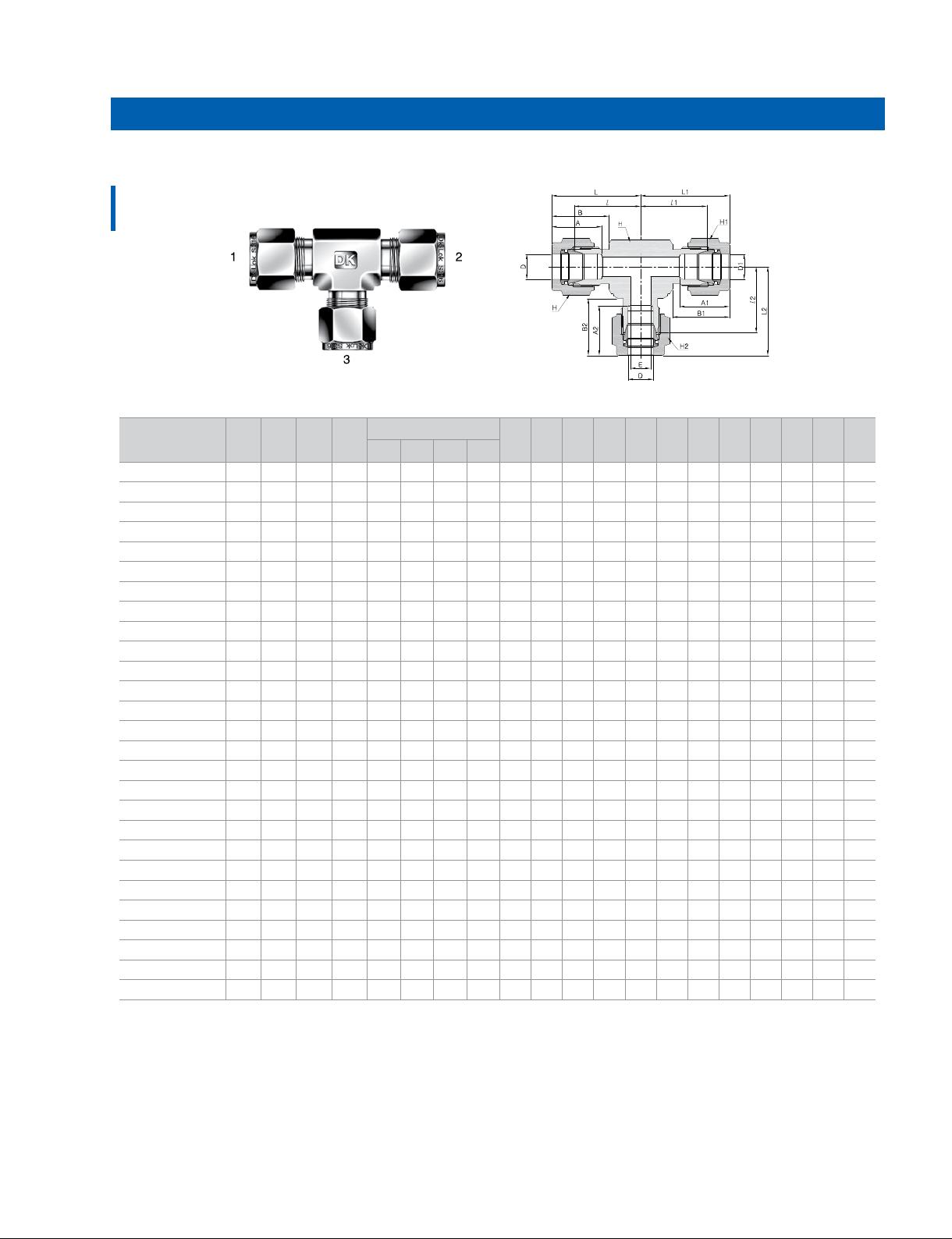

Reducing Union Tee

DTR

Connects fractional tube

Part No

DTR4-4-2

DTR4-4-6

DTR4-8-8

DTR6-4-6

DTR6-6-4

DTR6-6-8

DTR8-4-6

DTR8-4-8

DTR8-6-6

DTR8-8-4

DTR8-8-6

DTR10-10-6

DTR12-8-12

DTR12-12-4

DTR12-12-6

DTR12-12-8

DTR12-12-16

DTR12-12-20

DTR14-14-8

DTR16-12-12

DTR16-16-4

DTR16-16-6

DTR16-16-8

DTR16-16-12

DTR20-12-12

DTR20-20-12

DTR24-20-20

DTR24-24-8

DTR24-24-12

DTR24-24-16

Port 1 DPort 2

in. mm in. mm in. mm in. mm in. mm in. mm in. mm

1/4 6.35 1/4 6.35 1/8 3.17 2.4 15.24 15.24 12.7 17.78 17.78 15.24 1/2 12.7 9/16 14.28 9/16 14.28 7/16 11.11 19.55 19.55 17.9 26.91 26.91 24.5

1/4 6.35 1/4 6.35 3/8 9.52 4.8 15.24 15.24 16.76 17.78 17.78 19.3 5/8 15.87 9/16 14.28 9/16 14.28 11/16 17.46 21.92 21.92 23.1 29.28 29.28 30.46

1/4 6.35 1/2 12.7 1/2 12.7 4.8 15.24 22.86 22.86 17.78 21.84 21.84 13/16 20.64 9/16 14.28 7/8 22.22 7/8 22.22 24.4 25.9 25.9 31.76 36.06 36.06

3/8 9.52 1/4 6.35 3/8 9.52 4.8 16.76 15.24 16.76 19.3 17.78 19.3 5/8 15.87 11/16 17.46 9/16 14.28 11/16 17.46 23.1 21.92 23.1 30.46 29.28 30.46

3/8 9.52 3/8 9.52 1/4 6.35 4.8 16.76 16.76 15.24 19.3 19.3 17.78 5/8 15.87 11/16 17.46 11/16 17.46 9/16 14.28 23.1 23.1 21.92 30.46 30.46 29.28

3/8 9.52 3/8 9.52 1/2 12.7 7.1 16.76 16.76 22.86 19.3 19.3 21.84 13/16 20.64 11/16 17.46 11/16 17.46 7/8 22.22 25.9 25.9 25.9 33.26 33.26 36.06

1/2 12.7 1/4 6.35 3/8 9.52 4.8 22.86 15.24 16.76 21.84 17.78 19.3 13/16 20.64 7/8 22.22 9/16 14.28 11/16 17.46 25.9 25.9 25.9 36.06 33.26 33.26

1/2 12.7 1/4 6.35 1/2 12.7 7.1 22.86 15.24 22.86 21.84 17.78 21.84 13/16 20.64 7/8 22.22 9/16 14.28 7/8 22.22 25.9 24.4 25.9 36.06 31.76 36.06

1/2 12.7 3/8 9.52 3/8 9.52 7.1 22.86 16.76 16.76 21.84 19.3 19.3 13/16 20.64 7/8 22.22 11/16 17.46 11/16 17.46 25.9 25.9 25.9 36.06 33.26 33.26

1/2 12.7 1/2 12.7 1/4 6.35 4.8 22.86 22.86 15.24 21.84 21.84 17.78 13/16 20.64 7/8 22.22 7/8 22.22 9/16 14.28 25.9 25.9 24.4 36.06 36.06 31.76

1/2 12.7 1/2 12.7 3/8 9.52 7.1 22.86 22.86 16.76 21.84 21.84 19.3 13/16 20.64 7/8 22.22 7/8 22.22 11/16 17.46 25.9 25.9 25.9 36.06 36.06 33.26

5/8 15.87 5/8 15.87 3/8 9.52 7.1 24.38 24.38 16.76 21.84 21.84 19.3 15/16 23.81 1 25.4 1 25.4 11/16 17.46 28.7 28.7 28.7 38.86 38.86 36.06

3/4 19.05 1/2 12.7 3/4 19.05 10.41 24.38 22.86 24.38 21.84 21.84 21.84 1-1/16 26.98 1-1/8 28.57 7/8 22.22 1-1/8 28.57 29.71 29.71 29.71 39.87 39.87 39.87

3/4 19.05 3/4 19.05 1/4 6.35 4.8 24.38 24.38 15.24 21.84 21.84 17.78 1-1/16 26.98 1-1/8 28.57 1-1/8 28.57 9/16 14.28 29.71 29.71 28.21 39.87 39.87 35.57

3/4 19.05 3/4 19.05 3/8 9.52 7.1 24.38 24.38 16.76 21.84 21.84 19.3 1-1/16 26.98 1-1/8 28.57 1-1/8 28.57 11/16 17.46 29.71 29.71 29.71 39.87 39.87 35.57

3/4 19.05 3/4 19.05 1/2 12.7 10.41 24.38 24.38 22.86 21.84 21.84 21.84 1-1/16 26.98 1-1/8 28.57 1-1/8 28.57 7/8 22.22 29.71 29.71 29.71 39.87 39.87 38.37

3/4 19.05 3/4 19.05 1 25.4 16.0 24.38 24.38 31.24 21.84 21.84 26.41 1-3/8 34.92 1-1/8 28.57 1-1/8 28.57 1-1/2 38.10 34.43 34.43 36.83 49.02 49.02 45.7

3/4 19.05 3/4 19.05 1-1/4 31.75 16.0 24.38 24.38 41.14 21.84 21.84 38.86 1-11/16 42.86 1-1/8 28.57 1-1/8 28.57 1-7/8 47.63 39.41 39.41 44.45 49.57 49.57 66.55

7/8 22.22 7/8 22.22 1/2 12.7 10.41 25.9 25.9 22.86 21.84 21.84 21.84 1-1/4 31.75 1-1/4 31.75 1-1/4 31.75 7/8 22.22 34.54 34.54 34.54 44.7 44.7 44.7

1 25.4 3/4 19.05 3/4 19.05 16.0 31.24 24.38 24.38 26.41 21.84 21.84 1-3/8 34.92 1-1/2 38.10 1-1/8 28.57 1-1/8 28.57 36.83 35.54 35.54 49.02 45.7 45.7

1 25.4 1 25.4 1/4 6.35 4.8 31.24 31.24 15.24 26.41 26.41 17.78 1-3/8 34.92 1-1/2 38.10 1-1/2 38.10 9/16 14.28 36.83 36.83 33.04 49.02 49.02 40.4

1 25.4 1 25.4 3/8 9.52 7.1 31.24 31.24 16.76 26.41 26.41 19.3 1-3/8 34.92 1-1/2 38.10 1-1/2 38.10 11/16 17.46 36.83 36.83 34.54 49.02 49.02 41.9

1 25.4 1 25.4 1/2 12.7 10.41 31.24 31.24 22.86 26.41 26.41 21.84 1-3/8 34.92 1-1/2 38.10 1-1/2 38.10 7/8 22.22 36.83 36.83 34.54 49.02 49.02 44.7

1 25.4 1 25.4 3/4 19.05 16.0 31.24 31.24 24.38 26.41 26.41 21.84 1-3/8 34.92 1-1/2 38.10 1-1/2 38.10 1-1/8 28.57 36.83 36.83 35.54 49.02 49.02 45.7

1 1/4 31.75 3/4 19.05 3/4 19.05 16.0 41.14 24.38 24.38 38.86 21.84 21.84 1-11/16 42.86 1-7/8 47.63 1-1/8 28.57 1-1/8 28.57 44.45 39.41 39.41 66.55 49.57 49.57

1 1/4 31.75 1 1/4 31.75 3/4 19.05 16.0 41.14 41.14 24.38 38.86 38.86 21.84 1-11/16 42.86 1-7/8 47.63 1-7/8 47.63 1-1/8 28.57 44.45 44.45 39.41 66.55 66.55 49.57

1 1/2 38.10 1 1/4 31.75 1 1/4 31.75 27.69 50.03 41.14 41.14 45.21 38.86 38.86 2 50.8 2-1/4 57.15 1-7/8 47.63 1-7/8 47.63 50.8 49.62 49.62 77.97 71.72 71.72

1 1/2 38.10 1 1/2 38.10 1/2 12.7 10.41 50.03 50.03 22.86 45.21 45.21 21.84 2 50.8 2-1/4 57.15 2-1/4 57.15 7/8 22.22 50.8 50.8 44.58 77.97 77.97 54.74

1 1/2 38.10 1 1/2 38.10 3/4 19.05 16.0 50.03 50.03 24.38 45.21 45.21 21.84 2 50.8 2-1/4 57.15 2-1/4 57.15 1-1/8 28.57 50.8 50.8 44.58 77.97 77.97 54.74

1 1/2 38.10 1 1/2 38.10 1 25.4 22.3 50.03 50.03 31.24 45.21 45.21 26.41 2 50.8 2-1/4 57.15 2-1/4 57.15 1-1/2 38.10 50.8 50.8 47.75 77.97 77.97 59.94

D

1

Port 3

2

D

E

Min.

1 A2 BB1 B2

AA

Width across at

NJNJ1 NJ2

LL1 L2hHH1 H2

19

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

DK-Lok Tube Fitting

Reducing Union Tee

DTR

Connects metric tube

Port 3

Part No.

DTR3M-3M-6M 3 3 6 2.4 12.7 12 12 14 12.9 12.9 15.3 15.3 15.3 17.7 18.0 18.0 19.6 24.6 24.6 27.0

DTR8M-8M-6M 8 8 6 4.8 15 16 16 14 16.2 16.2 15.3 18.6 18.6 17.7 21.3 21.3 20.5 28.8 28.8 28.0

DTR10M-10M-6M 10 10 6 4.8 17.4 19 19 14 17.2 17.2 15.3 19.5 19.5 17.7 23.9 23.9 22.4 31.5 31.5 29.8

DTR10M-10M-12M 10 10 12 7.9 20.6 19 19 22 17.2 17.2 22.8 19.5 19.5 22.0 25.9 25.9 25.9 33.5 33.5 36.0

DTR12M-6M-10M 12 6 10 4.8 20.6 22 14 19 22.8 15.3 17.2 22.0 17.7 19.5 25.9 24.4 25.9 36.0 31.8 33.5

DTR12M-6M-12M 12 6 12 4.8 20.6 22 14 22 22.8 15.3 22.8 22.0 17.7 22.0 25.9 24.4 25.9 36.0 31.8 36.0

DTR12M-10M-10M 12 10 10 7.9 20.6 22 19 19 22.8 17.2 17.2 22.0 19.5 19.5 25.9 25.9 25.9 36.0 33.5 33.5

DTR12M-12M-10M 12 12 10 7.9 20.6 22 22 19 22.8 22.8 17.2 22.0 22.0 19.5 25.9 25.9 25.9 36.0 36.0 33.5

DTR12M-12M-6M 12 12 6 4.8 20.6 22 22 14 22.8 22.8 15.3 22.0 22.0 17.7 25.9 25.9 24.4 36.0 36.0 31.8

DTR15M-15M-12M 15 15 12 9.8 25.4 25 25 22 24.4 24.4 22.8 22.0 22.0 22.0 28.7 28.7 28.7 38.8 38.8 38.8

DTR16M-16M-12M 16 16 12 9.8 25.4 25 25 22 24.4 24.4 22.8 22.0 22.0 22.0 28.7 28.7 28.7 38.8 38.8 38.8

DTR18M-18M-12M 18 18 12 9.8 27 30 30 22 24.4 24.4 22.8 22.0 22.0 22.0 29.7 29.7 28.2 39.8 39.8 38.3

DTR20M-12M-20M 20 12 20 9.8 34.9 32 22 32 26.0 22.8 26.0 22.0 22.0 22.0 32.5 32.5 32.5 42.6 42.6 42.6

DTR20M-20M-6M 20 20 6 4.8 34.9 32 32 14 26.0 26.0 15.3 22.0 22.0 17.7 32.5 32.5 31.0 42.6 42.6 38.4

DTR20M-20M-10M 20 20 10 7.9 34.9 32 32 19 26.0 26.0 17.2 22.0 22.0 19.5 32.5 32.5 32.5 42.6 42.6 40.1

DTR20M-20M-12M 20 20 12 9.8 34.9 32 32 22 26.0 26.0 22.8 22.0 22.0 22.0 32.5 32.5 32.5 42.6 42.6 42.6

DTR20M-20M-25M 20 20 25 15.9 34.9 32 32 38 26.0 26.0 31.3 22.0 22.0 26.5 34.3 34.3 36.8 44.4 44.4 49.1

DTR20M-20M-32M 20 20 32 15.9

DTR22M-22M-12M 22 22 12 9.8 34.9 32 32 22 26.0 26.0 22.8 22.0 22.0 22.0 32.5 32.5 32.5 42.6 42.6 42.6

DTR25M-20M-20M 25 20 20 15.9 34.9 38 32 32 31.3 26.0 26.0 26.5 22.0 22.0 36.8 34.3 34.3 49.1 44.4 44.4

DTR25M-25M-10M 25 25 10 7.9 34.9 38 38 19 31.3 31.3 17.2 26.5 26.5 19.5 36.8 36.8 34.3 49.1 49.1 38.9

DTR25M-25M-12M 25 25 12 9.8 34.9 38 38 22 31.3 31.3 22.8 26.5 26.5 22.0 36.8 36.8 34.3 49.1 49.1 44.4

DTR25M-25M-20M 25 25 20 15.9 34.9 38 38 32 31.3 31.3 26.0 26.5 26.5 22.0 36.8 36.8 34.3 49.1 49.1 44.4

DTR32M-32M-20M 32 32 20 15.9 46 38 38 32 42.0 42.0 26.0 41.6 41.6 22.0 49.3 49.3 42.5 72.3 72.3 52.6

DTR38M-32M-32M 38 32 32 28.6 50.8 60 38 38 49.4 42.0 42.0 47.9 41.6 41.6 56.4 54.7 54.7 84.0 77.7 77.7

DTR38M-38M-20M 38 38 20 15.9 50.8 60 60 32 49.4 49.4 26.0 47.9 47.9 22.0 56.4 56.4 47.9 84.0 84.0 58.0

DTR38M-38M-25M 38 38 25 21.8 50.8 60 60 38 49.4 49.4 31.3 47.9 47.9 26.5 56.4 56.4 50.4 84.0 84.0 62.7

Port 1DPort 2

1

D

E

2

D

Min.

Width across at

hHH1 H2

46 32 32 50 26.0 26.0 42.0 22.0 22.0 41.6 42.5 42.5 49.3 52.6 52.6 72.3

AA

1 A2 BB1 B2

NJNJ1 NJ2

LL1 L2

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

20

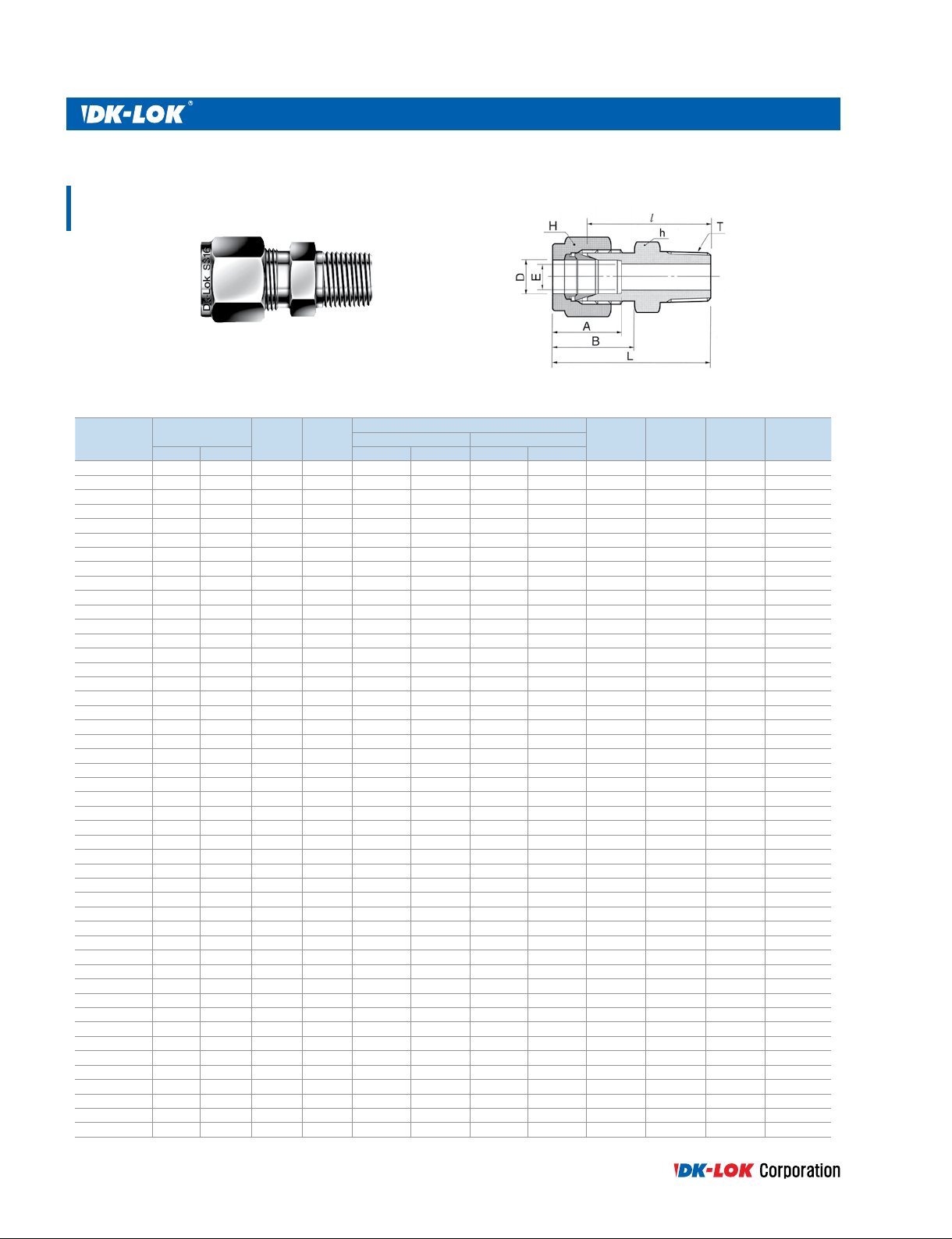

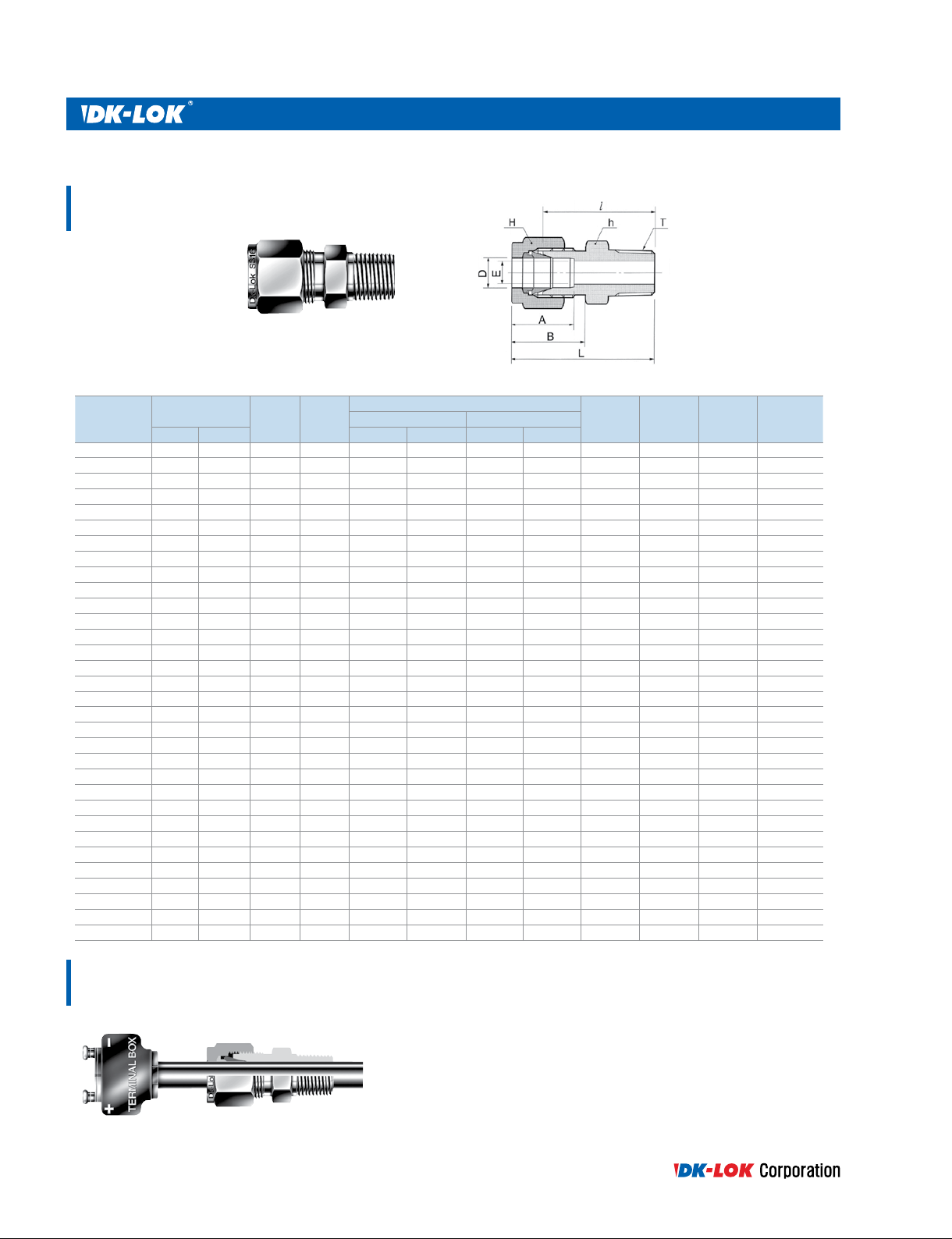

Male Connector

DMC-N

Connects fractional tube to female NPT thread

Tube O.D.

Part No.

DMC1-1N 1/16 1.59 1/16 1.27 5/16 7.93 5/16 7.93 8.63 10.92 20.00 23.83

DMC1-2N 1/16 1.59 1/8 1.27 7/16 11.11 5/16 7.93 8.63 10.92 22.35 26.23

DMC1-4N 1/16 1.59 1/4 1.27 9/16 14.28 5/16 7.93 8.63 10.92 27.17 30.98

DMC2-1N 1/8 3.17 1/16 2.28 7/16 11.11 7/16 11.11 12.70 15.24 23.11 29.71

DMC2-2N 1/8 3.17 1/8 2.28 7/16 11.11 7/16 11.11 12.70 15.24 23.87 30.48

DMC2-4N 1/8 3.17 1/4 2.28 9/16 14.28 7/16 11.11 12.70 15.24 28.95 35.56

DMC2-6N 1/8 3.17 3/8 2.28 11/16 17.46 7/16 11.11 12.70 15.24 29.21 35.81

DMC2-8N 1/8 3.17 1/2 2.28 7/8 22.22 7/16 11.11 12.70 15.24 35.56 42.16

DMC3-2N 3/16 4.76 1/8 3.04 7/16 11.11 1/2 12.70 13.71 16.00 24.63 31.24

DMC3-4N 3/16 4.76 1/4 3.04 9/16 14.28 1/2 12.70 13.71 16.00 29.71 36.32

DMC4-1N 1/4 6.35 1/16 4.82 1/2 12.70 9/16 14.28 15.24 17.78 25.40 32.76

DMC4-2N 1/4 6.35 1/8 4.82 1/2 12.70 9/16 14.28 15.24 17.78 25.40 32.76

DMC4-4N 1/4 6.35 1/4 4.82 9/16 14.28 9/16 14.28 15.24 17.78 30.48 37.84

DMC4-6N 1/4 6.35 3/8 4.82 11/16 17.46 9/16 14.28 15.24 17.78 30.98 38.35

DMC4-8N 1/4 6.35 1/2 4.82 7/8 22.22 9/16 14.28 15.24 17.78 37.33 44.70

DMC4-12N 1/4 6.35 3/4 4.82 1-1/16 26.98 9/16 14.28 15.24 17.78 38.86 46.22

DMC5-2N 5/16 7.93 1/8 4.82 9/16 14.28 5/8 15.87 16.25 18.54 26.67 34.03

DMC5-4N 5/16 7.93 1/4 6.35 9/16 14.28 5/8 15.87 16.25 18.54 31.24 38.60

DMC5-6N 5/16 7.93 3/8 6.35 11/16 17.46 5/8 15.87 16.25 18.54 31.75 39.11

DMC5-8N 5/16 7.93 1/2 6.35 7/8 22.22 5/8 15.87 16.25 18.54 38.11 45.60

DMC6-2N 3/8 9.52 1/8 4.82 5/8 15.87 11/16 17.46 16.76 19.30 27.94 35.30

DMC6-4N 3/8 9.52 1/4 7.11 5/8 15.87 11/16 17.46 16.76 19.30 32.51 39.87

DMC6-6N 3/8 9.52 3/8 7.11 11/16 17.46 11/16 17.46 16.76 19.30 32.51 39.87

DMC6-8N 3/8 9.52 1/2 7.11 7/8 22.22 11/16 17.46 16.76 19.30 38.86 46.22

DMC6-12N 3/8 9.52 3/4 7.11 1-1/16 26.98 11/16 17.46 16.76 19.30 40.38 47.75

DMC6-16N 3/8 9.52 1 7.11 1-3/8 34.92 11/16 17.46 16.76 19.30 47.0 54.37

DMC8-2N 1/2 12.70 1/8 4.82 13/16 20.64 7/8 22.22 22.86 21.84 28.70 38.86

DMC8-4N 1/2 12.70 1/4 7.11 13/16 20.64 7/8 22.22 22.86 21.84 33.27 43.43

DMC8-6N 1/2 12.70 3/8 9.65 13/16 20.64 7/8 22.22 22.86 21.84 33.27 43.43

DMC8-8N 1/2 12.70

DMC8-12N 1/2 12.70 3/4 10.41 1-1/16 26.98 7/8 22.22 22.86 21.84 40.38 50.54

DMC8-16N 1/2 12.70 1 10.41 1-3/8 34.92 7/8 22.22 22.86 21.84 46.99 57.15

DMC10-4N 5/8 15.87 1/4 6.35 15/16 23.81 1 25.40 24.38 21.84 33.80 43.96

DMC10-6N 5/8 15.87 3/8 9.65 15/16 23.81 1 25.40 24.38 21.84 34.03 44.19

DMC10-8N 5/8 15.87 1/2 11.93 15/16 23.81 1 25.40 24.38 21.84 38.86 49.02

DMC10-12N 5/8 15.87 3/4 12.70 1-1/16 26.98 1 25.40 24.38 21.84 40.38 50.54

DMC12-6N 3/4 19.05 3/8 9.65 1-1/16 26.98 1-1/8 28.58 24.38 21.84 34.03 44.19

DMC12-8N 3/4 19.05 1/2 11.93 1-1/16 26.98 1-1/8 28.58 24.38 21.84 40.38 50.54

DMC12-12N 3/4 19.05 3/4 15.74 1-1/16 26.98 1-1/8 28.58 24.38 21.84 40.38 50.54

DMC12-16N 3/4 19.05 1 15.74 1-3/8 34.92 1-1/8 28.58 24.38 21.84 46.99 57.15

DMC14-8N 7/8 22.22 1/2 11.9 1-3/16 30.16 1-1/4 31.75 25.90 21.84 40.38 50.54

DMC14-12N 7/8 22.22 3/4 15.74 1-3/16 30.16 1-1/4 31.75 25.90 21.84 40.38 50.54

DMC14-16N 7/8 22.22 1 18.28 1-3/8 34.92 1-1/4 31.75 25.90 21.84 46.99 57.15

DMC16-6N 1 25.40 3/8 9.65 1-3/8 34.92 1-1/2 38.10 31.24 26.41 40.30 52.49

DMC16-8N 1 25.40 1/2 11.93 1-3/8 34.92 1-1/2 38.10 31.24 26.41 45.21 57.40

DMC16-12N 1 25.40 3/4 15.74 1-3/8 34.92 1-1/2 38.10 31.24 26.41 45.21 57.40

DMC16-16N 1 25.40 1 22.35 1-3/8 34.62 1-1/2 38.10 31.24 26.41 50.03 62.23

D

in. mm in. mm in. mm

T

NPTEMin.

1/2 10.41 7/8 22.22 7/8 22.22 22.86 21.84 38.86 49.02

Width across at

AB

NJ

LhH

21

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

DK-Lok Tube Fitting

Connects fractional tube to female NPT thread

Tube O.D.

Part No.

DMC20-16N 1-1/4 31.75 1 22.35 1-3/4 44.45 1-7/8 47.63 41.14 38.86 55.11 77.21

DMC20-20N 1-1/4 31.75 1-1/4 27.68 1-3/4 44.45 1-7/8 47.63 41.14 38.86 55.11 77.21

DMC20-24N 1-1/4 31.75 1-1/2 27.68 1-3/4 44.45 1-7/8 47.63 41.14 38.86 60.54 82.64

DMC24-16N 1-1/2 38.10 1 22.30 2-1/8 53.98 2-1/4 57.15 50.03 45.21 59.42 86.60

DMC24-20N 1-1/2 38.10 1-1/4 27.68 2-1/8 53.98 2-1/4 57.15 50.03 45.21 59.42 86.60

DMC24-24N 1-1/2 38.10 1-1/2 33.90 2-1/8 53.98 2-1/4 57.15 50.03 45.21 61.72 88.90

DMC24-32N 1-1/2 38.10 2 33.90 2-3/4 69.85 2-1/4 57.15 50.03 45.21 62.42 99.75

DMC32-8N 2 50.80 1/2 11.93 2-3/4 69.85 3 76.20 67.56 62.73 68.40 105.73

DMC32-20N 2 50.80 1-1/4 45.97 2-3/4 69.85 3 76.20 67.56 62.73 71.40 108.73

DMC32-24N 2 50.80 1-1/2 45.97 2-3/4 69.85 3 76.20 67.56 62.73 75.50 112.83

DMC32-32N 2 50.80 2 45.97 2-3/4 69.85 3 76.20 67.56 62.73 76.20 113.53

D

in. mm in. mm in. mm

T

NPTEMin.

Connects metric tube to female NPT thread

Part No.

DMC2M-2N 2 1/8 1.7 12 12 12.9 15.3 23.9 30.5

DMC3M-2N 3 1/8 2.4 12 12 12.9 15.3 23.1 29.7

DMC3M-4N 3 1/4 2.4 14 12 12.9 15.3 29.0 35.6

DMC4M-2N 4 1/8 2.4 12 12 13.7 16.1 24.6 31.2

DMC4M-4N 4 1/4 2.4 14 12 13.7 16.1 29.7 36.3

DMC6M-2N 6 1/8 4.8 14 14 15.3 17.7 25.4 32.8

DMC6M-4N 6 1/4 4.8 14 14 15.3 17.7 30.2 37.6

DMC6M-6N 6 3/8 4.8 18 14 15.3 17.7 31.0 38.4

DMC6M-8N 6 1/2 4.8 22 14 15.3 17.7 37.3 44.0

DMC8M-2N 8 1/8 4.8 15 16 16.2 18.6 26.7 34.2

DMC8M-4N 8 1/4 6.4 15 16 16.2 18.6 31.2 38.7

DMC8M-6N 8 3/8 6.4 18 16 16.2 18.6 31.8 39.2

DMC8M-8N 8 1/2 6.4 22 16 16.2 18.6 37.3 44.8

DMC10M-2N 10 1/8 4.8 18 19 17.2 19.5 28.7 36.3

DMC10M-4N 10 1/4 7.1 18 19 17.2 19.5 33.3 40.9

DMC10M-6N 10 3/8 7.9 18 19 17.2 19.5 33.3 40.9

DMC10M-8N 10 1/2 7.9 22 19 17.2 19.5 38.1 45.7

DMC10M-12N 10 3/4 7.9 27 19 17.2 19.5 38.9 46.5

DMC12M-2N 12 1/8 4.8 22 22 22.8 22.0 28.7 38.8

DMC12M-4N 12 1/4 7.1 22 22 22.8 22.0 33.3 43.4

DMC12M-6N 12 3/8 9.5 22 22 22.8 22.0 33.3 43.4

DMC12M-8N 12 1/2 9.5 22 22 22.8 22.0 38.1 48.2

DMC12M-12N 12 3/4 9.5 27 22 22.8 22.0 38.9 49.0

DMC14M-4N 14 1/4 6.4 24 25 24.4 22.0 34.0 44.1

DMC14M-6N 14 3/8 9.5 24 25 24.4 22.0 34.0 44.1

DMC14M-8N 14 1/2 11.1 24 25 24.4 22.0 34.0 44.1

DMC15M-8N 15 1/2 11.9 24 25 24.4 22.0 38.9 49.0

DMC16M-4N 16 1/4 7.1 24 25 24.4 22.0 34.0 44.1

DMC16M-6N 16 3/8 9.5 24 25 24.4 22.0 34.0 44.1

DMC16M-8N 16 1/2 11.9 24 25 24.4 22.0 38.9 49.0

DMC16M-12N 16 3/4 12.7 27 25 24.4 22.0 38.9 49.0

DMC18M-8N 18 1/2 11.9 27 30 24.4 22.0 40.4 50.5

DMC18M-12N 18 3/4 15.1 27 30 24.4 22.0 40.4 50.5

DMC20M-8N 20 1/2 11.9 30 32 26.0 22.0 42.2 52.3

DMC20M-12N 20 3/4 15.9 30 32 26.0 22.0 42.2 52.3

DMC22M-12N 22 3/4 15.9 30 32 26.0 22.0 42.2 52.3

DMC22M-16N 22 1 18.3 35 32 26.0 22.0 47.8 57.9

DMC25M-8N 25 1/2 11.9 35 38 31.3 26.5 45.2 57.5

DMC25M-12N 25 3/4 15.9 35 38

DMC25M-16N 25 1 21.8 35 38 31.3 26.5 50.0 62.3

DMC28M-16N 28 1 21.8 41 46 36.6 36.6 51.6 72.4

DMC28M-20N 28 1-1/4 21.8 46 46 36.6 36.6 52.3 73.1

DMC30M-20N 30 1-1/4 26.2 46 50 39.6 39.2 55.6 77.2

DMC32M-20N 32 1-1/4 28.6 46 50 42.0 41.6 56.6 79.6

DMC38M-24N 38 1-1/2 33.7 55 60 49.4 47.9 64.0 91.6

Tube O.D.

D

T

NPT

E

Min.

Width across at

Width across at

hH

AB

AB

31.3 26.5 45.2 57.5

NJ

NJ

LhH

L

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

22

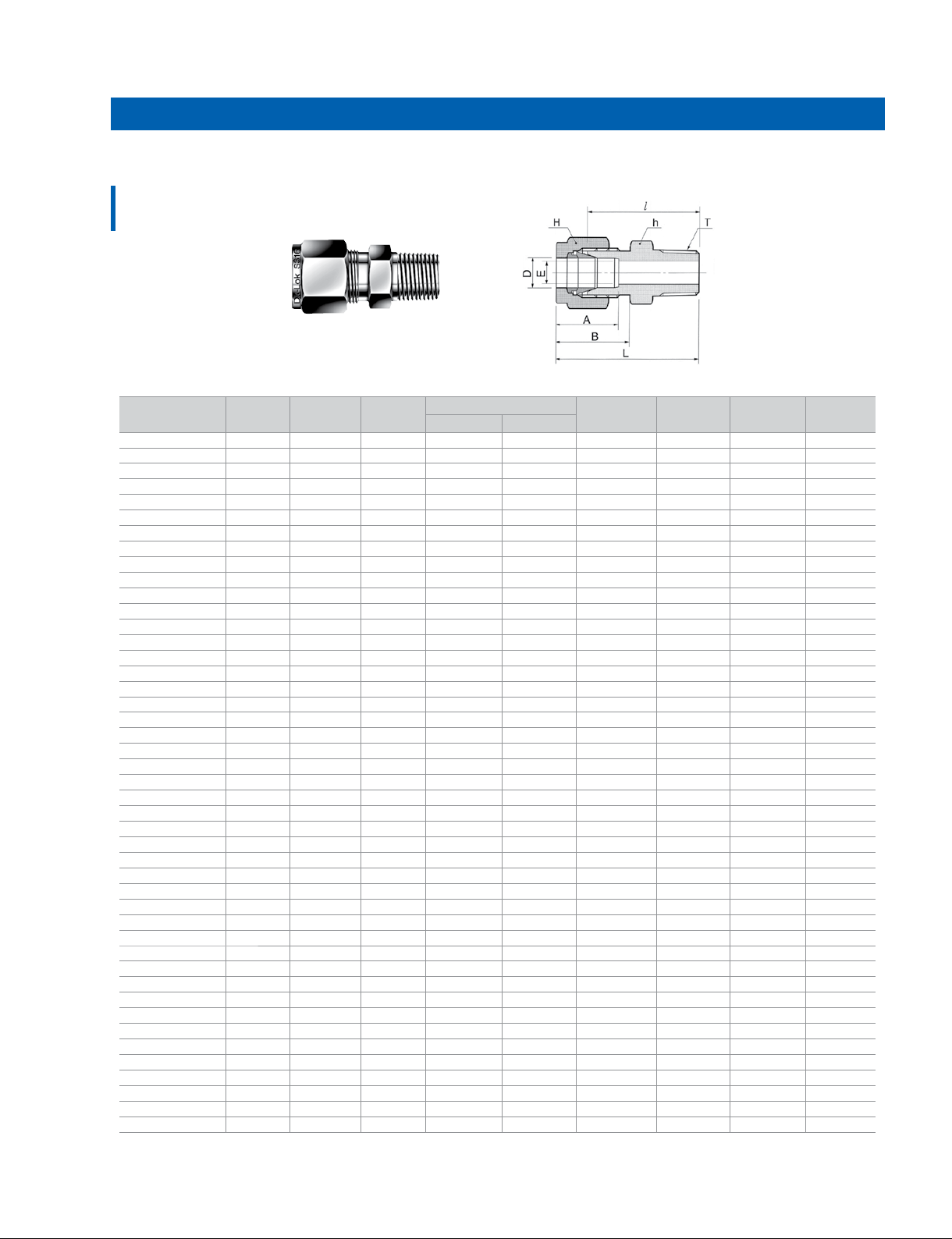

Male Connector

DMC-R

Connects fractional tube to female ISO tapered thread

Tube O.D.

Part No.

DMC2-2R 1/8 3.17 1/8 2.28 7/16 11.11 7/16 11.11 12.70 15.24 23.87 30.48

DMC2-4R 1/8 3.17 1/4 2.28 9/16 14.28 7/16 11.11 12.70 15.24 28.95 35.56

DMC4-2R 1/4 6.35 1/8 4.82 1/2 12.70 9/16 14.28 15.24 17.78 25.40 32.76

DMC4-4R 1/4 6.35 1/4 4.82 9/16 14.28 9/16 14.28 15.24 17.78 30.48 37.84

DMC4-6R 1/4 6.35 3/8 4.82 11/16 17.46 9/16 14.28 15.24 17.78 30.98 38.35

DMC4-8R 1/4 6.35 1/2 4.82 7/8 22.22 9/16 14.28 15.24 17.78 37.33 44.70

DMC5-2R 5/16 7.93 1/8 4.82 9/16 14.28 5/8 15.87 16.25 18.54 26.67 34.03

DMC5-4R 5/16 7.93 1/4 6.35 9/16 14.28 5/8 15.87 16.25 18.54 31.24 38.60

DMC5-16R 5/16 7.93 1 6.35 1-3/8 34.92 5/8 15.87 16.25 18.54 46.2 50.0

DMC6-2R 3/8 9.52 1/8 4.82 5/8 15.87 11/16 17.46 16.76 19.30 27.94 35.30

DMC6-4R 3/8 9.52 1/4 7.11 5/8 15.87 11/16 17.46 16.76 19.30 32.51 39.87

DMC6-6R 3/8 9.52 3/8 7.11 11/16 17.46 11/16 17.46 16.76 19.30 32.51 39.87

DMC6-8R 3/8 9.52 1/2 7.11 7/8 22.22 11/16 17.46 16.76 19.30 38.86 46.22

DMC6-12R 3/8 9.52 3/4 7.11 1-1/16 26.98 11/16 17.46 16.76 19.30 40.38 47.75

DMC8-2R 1/2 12.70 1/8 4.82 13/16 20.64 7/8 22.22 22.86 21.84 28.70 38.86

DMC8-4R 1/2 12.70 1/4 7.11 13/16 20.64 7/8 22.22 22.86 21.84 33.27 43.43

DMC8-6R 1/2 12.70 3/8 9.65 13/16 20.64 7/8 22.22 22.86 21.84 33.27 43.43

DMC8-8R 1/2 12.70 1/2 10.41 7/8 22.22 7/8 22.22 22.86 21.84 38.86 49.02

DMC8-12R 1/2 12.70 3/4 10.41 1-1/16 26.98 7/8 22.22 22.86 21.84 40.38 50.54

DMC8-16R 1/2 12.70 1 10.41 1-3/8 34.92 7/8 22.22 22.86 21.84 46.99 57.15

DMC10-6R 5/8 15.87 3/8 9.65 15/16 23.81 1 25.40 24.38 21.84 34.03 44.19

DMC10-8R 5/8 15.87 1/2 11.93 15/16 23.81 1 25.40 24.38 21.84 38.86 49.02

DMC10-12R 5/8 15.87 3/4 12.70 1-1/16 26.98 1 25.40 24.38 21.84 40.38 50.54

DMC12-8R 3/4 19.05 1/2 11.93 1-1/16 26.98 1-1/8 28.58 24.38 21.84 40.38 50.54

DMC12-12R 3/4 19.05 3/4 15.74 1-1/16 26.98 1-1/8 28.58 24.38 21.84 40.38 50.54

DMC12-16R 3/4 19.05 1 15.74 1-3/8 34.92 1-1/8 28.58 24.38 21.84 46.99 57.15

DMC16-12R 1 25.40 3/4 15.74 1-3/8 34.92 1-1/2 38.10 31.24 26.41 45.21 57.40

DMC16-16R 1 25.40 1 22.35 1-3/8 34.62 1-1/2 38.10 31.24 26.41 50.03 62.23

DMC20-12R 1-1/4 31.75 3/4 15.74 1-3/4 44.45 1-7/8 47.63 41.14 38.86 50.0 72.10

DMC20-16R 1-1/4 31.75

DMC20-20R 1-1/4 31.75 1-1/4 27.68 1-3/4 44.45 1-7/8 47.63 41.14 38.86 55.11 77.21

DMC32-32R 2 50.80 2 45.97 2-3/4 69.85 3 76.20 67.56 62.73 76.20 113.53

D

in. mm in. mm in. mm

T

PTE Min.

1 22.35 1-3/4 44.45 1-7/8 47.63 41.14 38.86 55.11 77.21

Width across at

AB

NJ

LhH

Thermocouple Connector

DMCT

23

Most DK-Lok male connectors can be bored-through thermocouple ttings except

those ttings with small male thread like 1/8 in.

To order, insert T in DMC male connector part number. Example: DMCT8-8N-S

DK-Lok bored-through ttings have no shoulder or sizing angle inside the body. This

allows thermocouples or dip tubes to pass beyond the tting male thread.

Assembly instruction

1. Position the length of thermocouple to pass through tting male thread and hold

it to prevent shifting during assembly.

2. Wrench tightens the nut 1 1/4 turns from nger tight position, keeping the body

steady with backup wrench.

•Tighten the nut 3/4 turn for 1/8, and 3/16; 3, and 4mm Tube Fittings.

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

DK-Lok Tube Fitting

Male Connector

DMC-R

Connects metric tube to female ISO tapered thread

Part No.

DMC2M-2R 2 1/8 1.7 12 12 12.9 15.3 23.9 30.5

DMC3M-2R 3 1/8 2.4 12 12 12.9 15.3 23.1 29.7

DMC3M-4R 3 1/4 2.4 14 12 12.9 15.3 29.0 35.6

DMC4M-2R 4 1/8 2.4 12 12 13.7 16.1 24.6 31.2

DMC4M-4R 4 1/4 2.4 14 12 13.7 16.1 29.7 36.3

DMC6M-2R 6 1/8 4.8 14 14 15.3 17.7 25.4 32.8

DMC6M-4R 6 1/4 4.8 14 14 15.3 17.7 30.2 37.6

DMC6M-6R 6 3/8 4.8 18 14 15.3 17.7 31.0 38.4

DMC6M-8R 6 1/2 4.8 22 14 15.3 17.7 37.3 44.0

DMC8M-2R 8 1/8 4.8 15 16 16.2 18.6 26.7 34.2

DMC8M-4R 8 1/4 6.4 15 16 16.2 18.6 31.2 38.7

DMC8M-6R 8 3/8 6.4 18 16 16.2 18.6 31.8 39.2

DMC8M-8R 8 1/2 6.4 22 16 16.2 18.6 37.3 44.8

DMC10M-2R 10 1/8 4.8 18 19 17.2 19.5 28.7 36.3

DMC10M-4R 10 1/4 7.1 18 19 17.2 19.5 33.3 40.9

DMC10M-6R 10 3/8 7.9 18 19 17.2 19.5 33.3 40.9

DMC10M-8R 10 1/2 7.9 22 19 17.2 19.5 38.1 45.7

DMC10M-12R 10 3/4 7.9 27 19 17.2 19.5 38.9 46.5

DMC12M-4R 12 1/4 7.1 22 22 22.8 22.0 33.3 43.4

DMC12M-6R 12 3/8 9.5 22 22 22.8 22.0 33.3 43.4

DMC12M-8R 12 1/2 9.5 22 22 22.8 22.0 38.1 48.2

DMC12M-12R 12 3/4 9.5 27 22 22.8 22.0 38.9 49.0

DMC14M-6R 14 3/8 9.5 24 25 24.4 22.0 34.0 44.1

DMC14M-8R 14 1/2 11.1 24 25 24.4 22.0 34.0 44.1

DMC15M-6R 15 3/8 9.5 24 25 24.4 22.0 34.0 44.1

DMC15M-8R 15 1/2 11.9 24 25 24.4 22.0 38.9 49.0

DMC16M-4R 16 1/4 7.1 24 25 24.4 22.0 34.0 44.1

DMC16M-6R 16 3/8 9.5 24 25 24.4 22.0 34.0 44.1

DMC16M-8R 16 1/2 11.9 24 25 24.4 22.0 38.9 49.0

DMC16M-12R 16 3/4 12.7 27 25 24.4 22.0 38.9 49.0

DMC18M-8R 18 1/2 11.9 27 30 24.4 22.0 40.4 50.5

DMC18M-12R 18 3/4 15.1 27 30 24.4 22.0 40.4 50.5

DMC20M-8R 20 1/2 11.9 30 32 26.0 22.0 42.2 52.3

DMC20M-12R 20 3/4 15.9 30 32 26.0 22.0 42.2 52.3

DMC22M-8R 22 1/2 11.9 30 32 26.0 22.0 42.2 52.3

DMC22M-12R 22 3/4 15.9 30 32 26.0 22.0 42.2 52.3

DMC22M-16R 22 1 18.3 35 32 26.0 22.0 47.8 57.9

DMC25M-8R 25 1/2 11.9 35 38 31.3 26.5 45.2 57.5

DMC25M-12R 25 3/4 15.9 35

DMC25M-16R 25 1 21.8 35 38 31.3 26.5 50.0 62.3

DMC28M-16R 28 1 21.8 41 46 36.6 36.6 51.6 72.4

DMC28M-20R 28 1-1/4 21.8 46 46 36.6 36.6 52.3 73.1

DMC30M-20R 30 1-1/4 26.2 46 50 39.6 39.2 55.6 77.2

DMC32M-20R 32 1-1/4 28.6 46 50 42.0 41.6 56.6 79.6

DMC38M-24R 38 1-1/2 33.7 55 60 49.4 47.9 64.0 91.6

Tube O.D.

D

PT

T

E

Min.

Width across at

hH

38 31.3 26.5 45.2 57.5

AB

NJ

L

All dimensions are in millimeters unless otherwise specied and only for reference subject to change.

www.dklok.com

24

Loading...

Loading...