© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

802.15.4 Family of RF Modules

High Performance and Long Range

802.15.4 STM32W RF Modules

Quickly add wireless capability with these high performance ZigBee compliant modules

READY TO USE SoC RF MODULES

Quickly add wireless networking capabilities to your

products with these ready-to-use DiZiC 802.15.4 RF

Modules. Simple to operate and available in a wide range of

configurations, these ZigBee compliant RF modules are

ideal for industrial sensors, consumer remote controls,

home appliances, and more.

Based on the STM32W108 wireless System-on-Chip

(SoC) from STMicroelectronics, this family of modules offer

outstanding RF performance with a -99 dBm normal RX

sensitivity (configurable to -100 dBm) and +3 dBm

normal mode output power (configurable up to +7 dBm).

With a small form factor and pin-to-pin compatible, DiZiC

802.15.4 RF Modules are available with several software

stack options, including EmberZNet PRO, RF4CE stack, or

proprietary low level MAC / PHY stack.

VERSATILE CONFIGURATIONS

With several possible configurations, select from 3 power

level options, 3 output options, 3 software stack options

and 2 EMI options:

Power Level Options - Choose from a standard power

level (+7 dBm), and two versions of RF front end (PA and

LNA, +20 dBm).

RF Output Options - Choose from a chip antenna, a U.FL

connector, or a single port 50 Ohm RF pad.

The U.FL connector allows, amongst other uses, for

connecting an external antenna, for connecting to an

application board that provides additional filters, or for

connecting to another 50 Ohm coaxial cable TX line. The

single port 50 Ohm RF pad allows for a direct connection

to another board, application module, or external antenna.

Software Stack Options - Choose from EmberZNet

PRO, RF4CE, or a low level PHY / MAC stack.

EmberZNet PRO is an easy to use ZigBee platform for

complex mesh networks. RF4CE (Radio Frequency for

Consumer Electronics) is a new protocol for consumer

remote controlled equipment. Custom applications can be

developed on top of a simple to use and low footprint

PHY/MAC API library.

EMI Options – Choose metal shielding protection where

enhanced electromagnetic interference immunity is

required otherwise standard version without metal

shielding is advisable.

D/Z/C 802.15.4 STM32WRF Module with

RF front end and antenna

Key Features

• STM32W108 ZigBee / IEEE 802.15.4 SoC

• 32-bit ARM Cortex-M3 processor

• 128 kB of Flash and 8 kB of SRAM

• JTAG / SWD (programming and debugging)

• 2.4 GHz ISM supporting 16 channels

• Data rate up to 250 kbit/s

• 128-bit AES encryption

• Peripherals

• 24 GPIOs, SPI, USART, and I2C

• 12-bit ADC with up to 6 inputs

• 2x 16-bit timers

• DMA controller

• Standard module

• RX Sensitivity -99 dBm (-100 dBm Boost)

• TX Power 3 dBm (+7 dBm Boost)

• RF front end options

• Two Front End options

• Both with RX Sensitivity -105 dBm

• Both with TX Power +20 dBm

• RF Options

• Chip antenna, U.FL connector, or single port 50 Ohm

RF pad

• Shielding option for enhanced EMI protection

Ordering Information

DZ_ZB_[P] [O] [S] [E], where:

[P] Power level options, one of: S (standard +7 dBm), R (Front End

with Power Level Detect +20 dBm), or T (Front End +20 dBm)

[O] Output options, one of: A (Embedded SMD antenna assembled on

module), P (Single ended 50 Ohm. RF Pad), or U (50 Ohm U.FL

coaxial connector)

[S] Stack options, one of: F (RF4CE stack), X (Proprietary stack), or

Z (EmberZNet PRO stack)

[E] EMI protection options, one of: S (standard, no shielding), or

M (enhanced, with metal shield)

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

TABLE OF CONTENT

1 FEATURE LIST....................................................................................................................................... 3

2 MODULE VARIANTS............................................................................................................................... 4

2.1 INTRODUCTION ............................................................................................................................ 4

2.2 DIZIC 802.15.4 RF MODULE: OUTPUT OPTIONS ...................................................................... 4

2.3 DIZIC 802.15.4 RF MODULE: POWER LEVEL OPTIONS ............................................................ 5

2.4 DIZIC 802.15.4 RF MODULE: STACK OPTIONS ........................................................................ 5

2.5 DIZIC 802.15.4 RF MODULE: EMI PROTECTION OPTIONS ...................................................... 5

3 COMPONENTS OVERVIEW .................................................................................................................... 6

3.1 STM32W108 – SYSTEM-ON-CHIP ............................................................................................ 6

3.2 RF FRONT END WITH RF OUTPUT POWER LEVEL DETECTOR ................................................. 7

3.3 RF FRONT END ........................................................................................................................... 8

3.4 ZIGBEE STACKS .......................................................................................................................... 8

4 ELECTRICAL CHARACTERISTICS ........................................................................................................... 9

4.1 PARAMETER CONDITIONS ........................................................................................................... 9

4.1.1 Minimum and maximum values ............................................................................................ 9

4.1.2 Typical values .......................................................................................................................... 9

4.2 ABSOLUTE MAXIMUM RATINGS .................................................................................................... 9

4.3 OPERATING CONDITIONS .......................................................................................................... 10

4.3.1 General operating conditions .............................................................................................. 10

4.3.2 Electrostatic discharge (ESD) ............................................................................................. 10

4.4 DC CHARACTERISTICS ............................................................................................................. 11

4.5 RF CHARACTERISTIC ................................................................................................................ 13

4.5.1 Receiver ................................................................................................................................. 13

4.5.2 Transmitter ............................................................................................................................. 13

5 MECHANICAL CHARACTERISTICS ........................................................................................................ 14

5.1 MODULE PAD DIAGRAM ............................................................................................................ 14

5.2 MODULE PAD DESCRIPTION ..................................................................................................... 15

5.3 PACKAGE MECHANICAL DIMENSIONS ....................................................................................... 20

6 SOLDERING ........................................................................................................................................ 21

6.1 SOLDER TEMPERATURE PROFILE ........................................................................................... 21

6.2 PROFILE PARAMETERS ............................................................................................................ 21

6.3 RECOMMENDED FOOTPRINT .................................................................................................... 22

7 ORDERING INFORMATION ................................................................................................................... 23

8 LIST OF ACRONYMS ............................................................................................................................ 24

9 REFERENCES & REVISION HISTORY ................................................................................................... 25

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

DIZIC 802.15.4 RF MODULE DZ-ZB-[P]-[O]-[S]-[E] DATA SHEET

POWER LEVEL OPTIONS

STANDARD FRONT END FRONT END WITH

RF POWER LEVEL DETECTOR

1 FEATURE LIST

Complete System-on-Chip

• 32-bit ARM® Cortex-M3 processor

• 2.4 GHz IEEE 802.15.4 transceiver & lower MAC

• 128 kB flash, 8kB RAM memory

• AES128 encryption accelerator

• Flexible ADC, SPI/UART/TWI serial communications, and

general purpose timers

• 24 highly configurable GPIO with Schmitt trigger inputs

Industry-leading ARM Cortex-M3 processor

• Leading 32-bit processing performance

• Highly efficient Thumb-2 instruction set

• Operation at 6, 12 or 24 MHz

• Flexible Nested Vectored Interrupt Controller

Low power consumption, advanced management

• RX Current (w/ CPU): 27 mA

• TX Current (w/ CPU, +3 dBm TX): 31 mA

• Low deep sleep current, with retained RAM and GPIO:

400 nA/800 nA with/without sleep timer

• Low-frequency internal RC oscillator for low-power sleep

timing

• High-frequency internal RC oscillator for fast (100 µsec)

processor start-up from sleep

Innovative network and processor debug

• Serial Wire/JTAG interface

• Standard ARM debug capabilities: Flash Patch &

Breakpoint; Data Watch-point & Trace; Instrumentation

Trace Macrocell

Exceptional RF Performance

• Normal mode Link Budget up to 102 dB; configurable up

to107dB

• -99 dBm normal RX sensitivity; configurable to -100 dBm

(1%PER, 20 byte packet)

• +3 dB normal mode output power; configurable up to +7

dBm

• Robust WiFi and Bluetooth coexistence

Application Flexibility

• Single voltage operation: 2.1-3.6 V

• Optional 32.768 kHz crystal for higher timer accuracy

• Low external component count with single 24 MHz crystal

• External power amplifier versions

Target applications for the Modules

include:

• Smart Energy

• Building automation and control (HVAC)

• Home automation and control

• Security and monitoring

• AMR/AMI

• Logistic & Asset tracking

• Medical

• General ZigBee wireless sensor networking

• Active RFID

• Wireless handheld terminals

• Industry telemetry and automatic data collection system

• Temperature and humidity control system

• Traffic and control for street lamp

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

2 MODULE VARIANTS

2.1 INTRODUCTION

The DZ-ZB is low-power, high sensitivity IEEE 802.15.4 / ZigBee-compliant module. This multi-functional device based on

STMicroelectronics STM32W108 fully integrated System-on-Chip [1]. The STM32W108 integrates a 2.4 GHz, IEEE 802.15.4compliant transceiver, 32-bit ARM® Cortex™-M3 microprocessor, Flash and RAM memory, and peripherals of use to

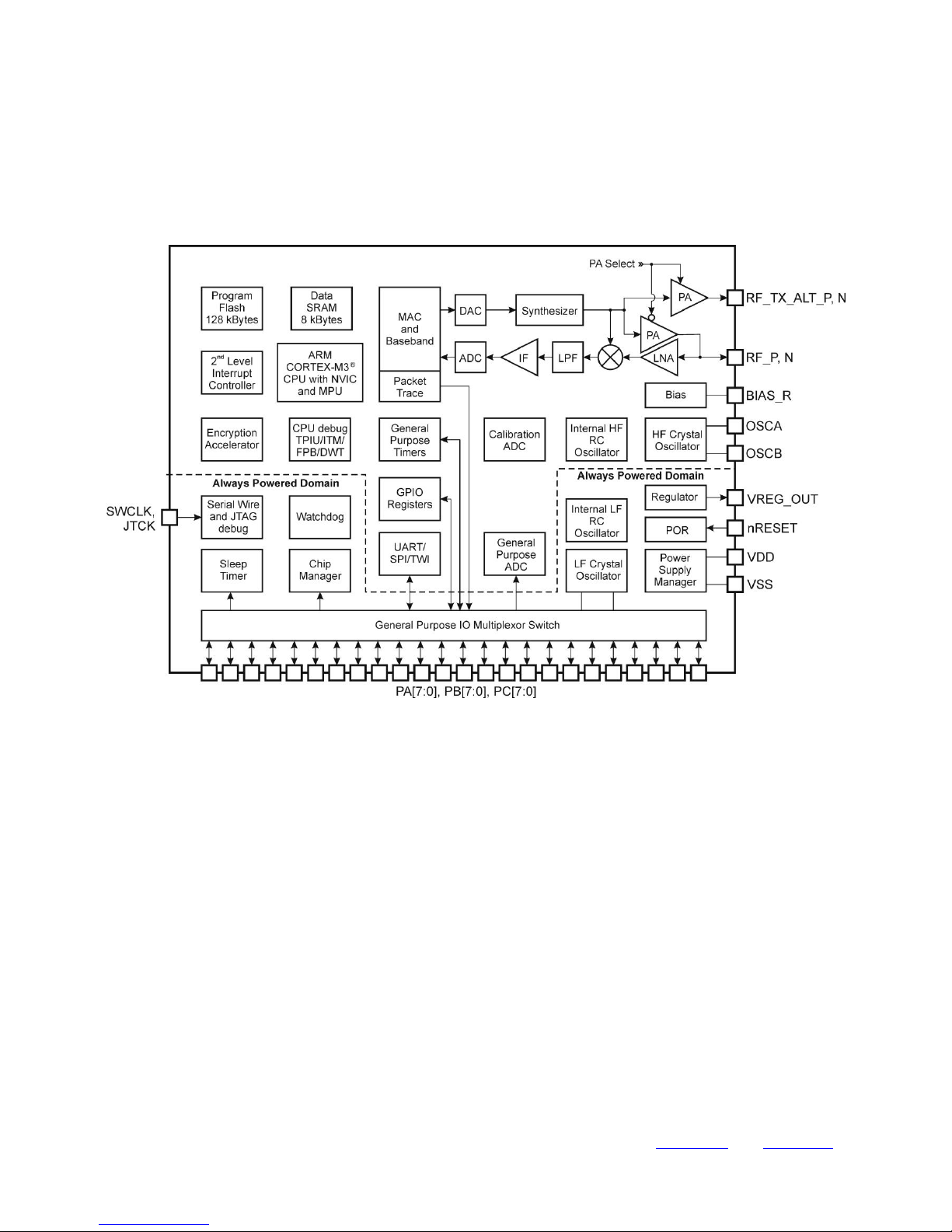

designers of ZigBee-based systems [2]. Block diagrams of DZ-ZB Module is show on Figure 2.1 and utilizes

STM32W108CBU6x version of the high performance, IEEE 802.15.4 compliant, wireless system-on-chip STM32W108 family.

Fig. 2.1 Block diagram of DZ-ZB Modules

DZ-ZB modules are available in two different product lines: without/with PA/LNA Front-End (FE). Both product lines

offering three ZigBee stack configurations. The first decision you need to make is if you want the Output option. The

following options are available:

A - Embedded SMD Antenna

P - Single ended 50 Ohm RF Pad

U - U.FL 50 Ohm coaxial connector

The second decision you need to make is Power level option. The following options are available:

S - Standard + 7dBm

R - Front End (PA and LNA) with RF output power level detector + 20 dBm

T - Front End (PA and LNA) + 20 dBm

The third decision you need to make ZigBee stack. The following options are available:

F - RF4CE stack

X - Proprietary stack

Z - EmberZnet PRO stack

The final decision is level of electromagnetic immunity (EMI) protection. The following options are available:

M - Metal cap shielding enabling enhanced level of electromagnetic immunity (EMI) protection

S - Standard, without metal shielding cap

The next chapters will explain each of all options.

2.2 DIZIC 802.15.4 RF MODULE: OUTPUT OPTIONS

The following Output Options are available:

A - Embedded SMD Antenna

P - Single ended 50 Ohm RF Pad

U - U.FL 50 Ohm coaxial connector

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

2.3 DIZIC 802.15.4 RF MODULE: POWER LEVEL OPTIONS

The following Power Level Options are available:

Option S - Standard + 7dBm

STM32W chip: System on Chip - where radio, microcontroller, program/user memory, RAM, ZigBee protocols stack are

integrated in one chip.

Option R - Front End (PA and LNA) with RF output power level detector + 20 dBm

STM32W chip: System on Chip - where radio, microcontroller, program/user memory, RAM, ZigBee protocols stack are

integrated in one chip.

Option T - Front End (PA and LNA) + 20 dBm

STM32W chip: System on Chip - where radio, microcontroller, program/user memory, RAM, ZigBee protocols stack are

integrated in one chip.

2.4 DIZIC 802.15.4 RF MODULE: STACK OPTIONS

The following ZigBee stack options are available:

Option F - RF4CE stack

Option X - Proprietary stack

Option Z - EmberZnet PRO stack

Instructions concerning to programming ST32W108 you will find at [7] and examples of Application at [6].

2.5 DIZIC 802.15.4 RF MODULE: EMI PROTECTION OPTIONS

The following EMI protection options are available:

Option M - Metal shield cap enabling enhanced level of electromagnetic immunity (EMI) protection

Option S - Standard module without metal shielding

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

3 COMPONENTS OVERVIEW

3.1 STM32W108 – SYSTEM-ON-CHIP

The is a fully The is a fully integrated System-on-Chip that integrates a 2.4 GHz, IEEE 802.15.4-compliant transceiver, 32-bit

ARM® Cortex™-M3 microprocessor, Flash and RAM memory, and peripherals of use to designers of ZigBee-based systems.

Block diagram of STM32W108 is show on Fig. 3.1 below:

Fig. 3.1 Block diagram of System-on-Chip STM32W108

The transceiver utilizes an efficient architecture that exceeds the dynamic range requirements imposed by the IEEE 802.15.42003 standard by over 15 dB. The integrated receive channel filtering allows for robust co-existence with other communication

standards in the 2.4 GHz spectrum, such as IEEE 802.11 and Bluetooth. The integrated regulator, VCO, loop filter, and power

amplifier keep the external component count low. An optional high performance radio mode (boost mode) is softwareselectable to boost dynamic range.

The integrated 32-bit ARM® Cortex™-M3 microprocessor is highly optimized for high performance, low power consumption,

and efficient memory utilization. Including an integrated MPU, it supports two different modes of operation: System mode and

Application mode. The networking stack software runs in System mode with full access to all areas of the chip. Application

code runs in Application mode with limited access to the STM32W108 resources; this allows for the scheduling of events by

the application developer while preventing modification of restricted areas of memory and registers. This architecture results in

increased stability and reliability of deployed solutions.

The STM32W108 has 128 Kbytes of embedded Flash memory and 8 Kbytes of integrated RAM for data and program storage.

The STM32W108 HAL software employs an effective wear-levelling algorithm that optimizes the lifetime of the embedded

Flash.

To maintain the strict timing requirements imposed by the ZigBee and IEEE 802.15.4-2003 standards, the STM32W108

integrates a number of MAC functions into the hardware. The MAC hardware handles automatic ACK transmission and

reception, automatic back off delay, and clear channel assessment for transmission, as well as automatic filtering of received

packets. A packet trace interface is also integrated with the MAC, allowing complete, non-intrusive capture of all packets to

and from the STM32W108.

The STM32W108 offers a number of advanced power management features that enable long battery life. A high-frequency

internal RC oscillator allows the processor core to begin code execution quickly upon waking. Various deep sleep modes are

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

available with less than 1 μsec a power consumption while retaining RAM contents. To support user-defined applications, onchip peripherals include UART, SPI, TWI, ADC and general-purpose timers, as well as up to 24 GPIOs. Additionally, an

integrated voltage regulator, power-on-reset circuit, and sleep timer are available.

Finally, the STM32W utilizes standard Serial Wire and JTAG interfaces for powerful software debugging and programming of

the ARM Cortex-M3 core. The STM32W integrates the standard ARM system debug components: Flash Patch and Breakpoint

(FPB), Data Watch-point and Trace (DWT), and Instrumentation Trace Macrocell (ITM).

3.2 RF FRONT END WITH RF OUTPUT POWER LEVEL DETECTOR

The Front End (FE) is a fully integrated, single-chip, single-die microwave IC which incorporates all the RF functionality

needed for today’s wireless communications. The FE architecture integrates the PA, LNA, Transmit and Receive switching

circuitry, the associated matching network, and the harmonic filter -- all in a BiCMOS single-chip device. Combining superior

performance, high sensitivity and efficiency, low noise, small form factor, and low cost, is the perfect solution for applications

requiring extended range and bandwidth and can result in a potential 10x range increase. The RF power level (at PA output)

detect circuit is also integrated. Block diagram of the module with this FE is shown below:

Fig. 3.2 Block diagram of the module with front end incorporating RF power level detector (Power level option “R”)

Functional description of the signals controlling front end are summarized in table 3.1 below

Table 3.1 Functional description of the Front End signals

FE Signal name

Direction

Description

STM32W108 port name

TX_ON

Digital input to FE

When RX_ON = 1:

TX_ON = 1: Transmit Mode

TX_ON = 0: Receive Mode

PC5, TX_ACTIVE

RX_ON

Digital input to FE

RX_ON = 0: FE in shut down mode

RX_ON = 1: FE enabled

Transmit / Receive function is determined by

TX_ON signal

PC6, nTX_ACTIVE

PA_DETECT

Analog output from FE

PA_DETECT voltage is proportional to

generated RF power at FE output pin.

For RF output power between:

+5 dBm to +20 dBm

PA_DETECT voltage is between

20 mV to 1200 mV respectively

PB5, ADC0

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

3.3 RF FRONT END

This is a cost-effective and high performance RF Front End for low-power and low-voltage 2.4-GHz wireless applications. It is

a range extender for all existing and future 2.4-GHz low-power RF transceivers, transmitters and System-on-Chip products. It

increases the link budget by providing a power amplifier for increased output power, and an LNA with low noise figure for

improved receiver sensitivity. This FE consists of PA, LNA, RF switches, RF impedance matching, and balun for high

performance wireless applications. Module Block diagram with this Front End is shown below:

Fig. 3.3 Block diagram of the module with front end (Power level option “T”)

Functional description of the signals controlling front end are summarized in table 3.2 below

Table 3.2 Functional description of the Front End signals

FE Signal name

Direction

Description

STM32W108 port name

TxRx

Digital input to FE

When ENABLE = 1:

TxRx = 1: Transmit Mode

TxRx = 0: Receive Mode

PC5, TX_ACTIVE

HIGH_GAIN

Digital input to FE

Receive only (ENABLE = 1, TxRx = 0):

HIGH_GAIN = 1: LNA is in High Gain Mode.

LNA Gain = approx. 11dB

HIGH_GAIN = 0: LNA is in Lo Gain Mode.

LNA Gain = approx. 1 dB

PB5, ADC0

ENABLE

Digital input to FE

ENABLE = 1: FE Enabled

ENABLE = 0: FE in power down mode

PC6, nTX_ACTIVE

3.4 ZIGBEE STACKS

The three stacks are available (see block diagram below depicted on Fig. 3.4):

RF4CE stack

Proprietary stack

EmberZNet PRO stack

Fig. 3.4 Available stacks: Left. Proprietary stack, Centre. RF4CE stack, Right. EmberZNet PRO

For more details regarding stacks please consult [3], [4] [5]. Instruction concerning to programming ST32W108 you will find at

[7].

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

4 ELECTRICAL CHARACTERISTICS

4.1 PARAMETER CONDITIONS

Unless otherwise specified, all voltages are referenced to VSS.

4.1.1 Minimum and maximum values

Unless otherwise specified the minimum and maximum values are guaranteed in the worst conditions of ambient temperature,

supply voltage and frequencies by tests in production on 100% of the devices with an ambient temperature at TA = 25 °C and

TA = TAmax (given by the selected temperature range). Data based on characterization results, design simulation and/or

technology characteristics are indicated in the table footnotes and are not tested in production. Based on characterization, the

minimum and maximum values refer to sample tests and represent the mean value plus or minus three times the standard

deviation (mean ±3σ).

4.1.2 Typical values

are given only as design guidelines and are not tested. Typical ADC accuracy values are determined by characterization of a

batch of samples from a standard diffusion lot over the full temperature range.

4.2 ABSOLUTE MAXIMUM RATINGS

Stresses above the absolute maximum ratings listed in Table 4.1: Voltage characteristics, Table 4.2: Current characteristics

and Table 4.3: Thermal characteristics may cause permanent damage to the device. These are stress ratings only and

functional operation of the device at these conditions is not implied. Exposure to maximum rating conditions for extended

periods may affect device reliability.

Table 4.1 Voltage characteristics

Ratings

Min.

Max.

Unit

Regulator input voltage (VDD_PADS)

-0.3

+3.6

V

RF Input Power (for max level for correct packet reception Receive characteristics)

RX signal into a lossless balun

15

dBm

Voltage on any GPIO (PA[7:0], PB[7:0], PC[7:0]), SWCLK, nRESET, VREG_OUT

-0.3

VDD_PADS +0.3

V

Table 4.2 Current characteristics

Symbol

Ratings

Max.

Unit

IVDD

Total current into VDD/VDDA power lines (source)

150

mA

IVSS

Total current out of VSS ground lines (sink)

150

mA

IIO

Output current sunk by any I/O and control pin

25

mA

Table 4.3 Thermal characteristics

Symbol

Ratings

Value

Unit

TSTG

Storage temperature range

–40 to +140

°C

TJ

Maximum junction temperature

150

°C

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

4.3 OPERATING CONDITIONS

4.3.1 General operating conditions

Table 4.4 Operating conditions

Symbol

Parameter

Min.

Typ.

Max.

Unit

VDD_PADS

Regulator input voltage (VDD_PADS)

2,1 3,6

V

TOP

Operating temperature range

-40 85

°C

4.3.2 Electrostatic discharge (ESD)

Electrostatic discharges (a positive then a negative pulse separated by 1 second) are applied to the pins of each sample

according to each pin combination. The sample size depends on the number of supply pins in the device (3 parts × (n+1)

supply pins). This test conforms to the JESD22-A114/C101 standard.

Table 4.5 ESD absolute maximum ratings

Symbol

Ratings

Conditions

Class

Maximum value

Unit

VESD (HBM)

Electrostatic discharge voltage (Human

Body Model)

TA = +25 °C conforming

to JESD22-A114

2

±2000

V

VESD (CDM)

Electrostatic discharge voltage (Charge

Device Model) for non-RF pins

TA = +25 °C conforming

to JESD22-C101

II

±400

Electrostatic discharge voltage (Charge

Device Model) for RF pins

±225

MSL

Moisture sensitivity level

MSL3

–

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

4.4 DC CHARACTERISTICS

Table 4.6 DC electrical characteristics

Parameter

Conditions

Typical value for module

(Power Level Option)

Unit

"S"

Standard

"R"

Front End

"T"

Front End

Regulator input voltage (VDD_PADS)

2,0 - 3,6

V

Deep Sleep Current

Quiescent current, internal RC

oscillator disabled

-40°C, VDD_PADS = 3,6 V

0,4

μA

+25°C, VDD_PADS = 3,6 V

0,4

5,4

0,7

μA

+85°C, VDD_PADS = 3,6 V

0,6

μA

Quiescent current, including internal

RC oscillator

-40°C, VDD_PADS = 3.6 V

0,7

μA

+25°C, VDD_PADS = 3.6 V

0,8

5,8

1,1

μA

+85°C, VDD_PADS = 3.6 V

1,2

μA

Quiescent current, including 32.768

kHz oscillator

-40°C, VDD_PADS = 3.6V

1,2

μA

+25°C, VDD_PADS = 3.6 V

1,3

6,3

1,6

μA

+85°C, VDD_PADS = 3.6 V

1,7

μA

Quiescent current, including internal

RC oscillator and 32.768 kHz oscillator

-40°C, VDD_PADS = 3.6V

1,4

μA

+25°C, VDD_PADS = 3.6V

1,5

6,5

1,8

μA

+85°C, VDD_PADS = 3.6 V

2

μA

Simulated deep sleep (debug mode)

current

With no debugger activity

200

μA

Reset current

Quiescent current, nRESET asserted

Typical at 25°C/3 V Max at 85°C/3.6 V

1,2

1,2

1,2

mA

Processor and peripheral currents

ARM® Cortex-M3, RAM, and flash

memory

25°C, 1.8 V memory and 1.25 V core

ARM® Cortex-M3 running at 12 MHz

from crystal oscillator Radio and all

peripherals off

8.0

8.0

8.0

mA

ARM® Cortex-M3, RAM, and flash

memory

25°C, 1.8 V memory and 1.25 V core

ARM® Cortex-M3 running at 24 MHz

from crystal oscillator Radio and all

peripherals off

9.0

9.0

9.0

mA

ARM® Cortex-M3, RAM, and flash

memory sleep current

25°C, 1.8 V memory and 1.25 V core

ARM® Cortex-M3 clocked at 12 MHz

from the crystal oscillator Radio and all

peripherals off

4.0

4.0

4.0

mA

ARM® Cortex-M3, RAM, and flash

memory sleep current

25°C, 1.8 V memory and 1.25 V core

ARM® Cortex-M3 clocked at 6 MHz

from the high frequency RC oscillator

Radio and all peripherals off

2.0

2.0

2.0

mA

Serial controller current

For each controller at maximum data

rate

0.2

0.2

0.2

mA

General purpose timer current

For each timer at maximum clock rate

0.1

0.1

0.1

mA

General purpose ADC current

At maximum sample rate, DMA

enabled

1,1

1,1

1,1

mA

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

Table 4.6 DC electrical characteristics (cont)

Rx current

Radio receiver, MAC, and baseband

ARM® Cortex-M3 sleeping

20

27

24

mA

Total RX current (Radio receiver,

MAC and baseband, CPU + IRAM,

and Flash memory)

VDD_PADS = 3,0 V, 25°C, ARM®

Cortex-M3 running at 12 MHz

27

34

31

mA

VDD_PADS = 3,0 V, 25°C, ARM®

Cortex-M3 running at 24 MHz

28

35

32

mA

Boost mode total RX current (Radio

receiver, MAC and baseband, CPU+

IRAM, and Flash memory )

VDD_PADS = 3,0 V, 25°C, ARM®

Cortex-M3 running at 12 MHz

28

35

32

mA

VDD_PADS = 3,0 V, 25°C, ARM®

Cortex-M3 running at 24 MHz

29

36

33

mA

Tx current

Radio transmitter, MAC, and

baseband

25°C and 1.8 V core; max. power out (+3

dBm typical) ARM® Cortex-M3 sleeping

26

136

138

mA

Total Tx current (Radio transmitter,

MAC and baseband, CPU + IRAM,

and Flash memory )

VDD_PADS = 3.0 V, 25°C; maximum

power setting (+7dBm); running at 24 MHz

40

150

152

mA

VDD_PADS = 3.0 V, 25°C; +3 dBm power

setting; ARM® Cortex-M3 running at 24

MHz

32

142

144

mA

VDD_PADS = 3.0 V, 25°C; 0dBm power

setting; ARM® Cortex-M3 running at 24

MHz

30

140

142

mA

VDD_PADS = 3.0 V, 25°C; minimum

power setting; ARM® Cortex-M3 running

at 24 MHz

24

134

136

mA

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

4.5 RF CHARACTERISTIC

4.5.1 Receiver

Table 4.7 Receiver characteristics

Parameter

Conditions

Typical value for module

(Power Level Option)

Unit

"S"

Standard

"R"

Front End

"T"

Front End

Frequency range

2400 - 2500

MHz

Sensitivity (boost mode)

1% PER, 20 byte packet defined by

IEEE 802.15.4-2003

-100

TBD

-105

dBm

Sensitivity

1% PER, 20 byte packet defined by

IEEE 802.15.4-2003

-99

TBD

-104

dBm

Co-channel rejection

IEEE 802.15.4 signal at -82 dBm

-6

dBc

Relative frequency error (2 x 40 ppm

required by IEEE 802.15.4)

-120 … +120

ppm

Relative timing error (2 x 40 ppm

required by IEEE 802.15.4)

-120 … +120

ppm

Linear RSSI range

As defined by IEEE 802.15.4

40

dB

RSSI Range

-90 … -30

dBm

4.5.2 Transmitter

Table 4.8 Transmitter characteristics

Parameter

Conditions

Typical value for module

(Power Level Option)

Unit

"S"

Standard

"R"

Front End

"T"

Front End

Maximum output power (boost mode)

At highest power setting

7

20

20

dBm

Maximum output power

At highest power setting

3

20

20

dBm

Minimum output power

At lowest power setting

-32

-9

-9

dBm

Error vector magnitude

As defined by IEEE 802.15.4, which

sets a 35% maximum

5 … 15

%

Carrier frequency error

-40 … +40

ppm

PSD mask relative

3,5 MHz away

-20

dB

PSD mask absolute

3,5 MHz away

-30

dBm

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

5 MECHANICAL CHARACTERISTICS

5.1 MODULE PAD DIAGRAM

Module pad connection diagram is depicted below (top view):

Fig. 5.1 Pad connection diagram for modules (top view)

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

5.2 MODULE PAD DESCRIPTION

The following table describes the pads of the module.

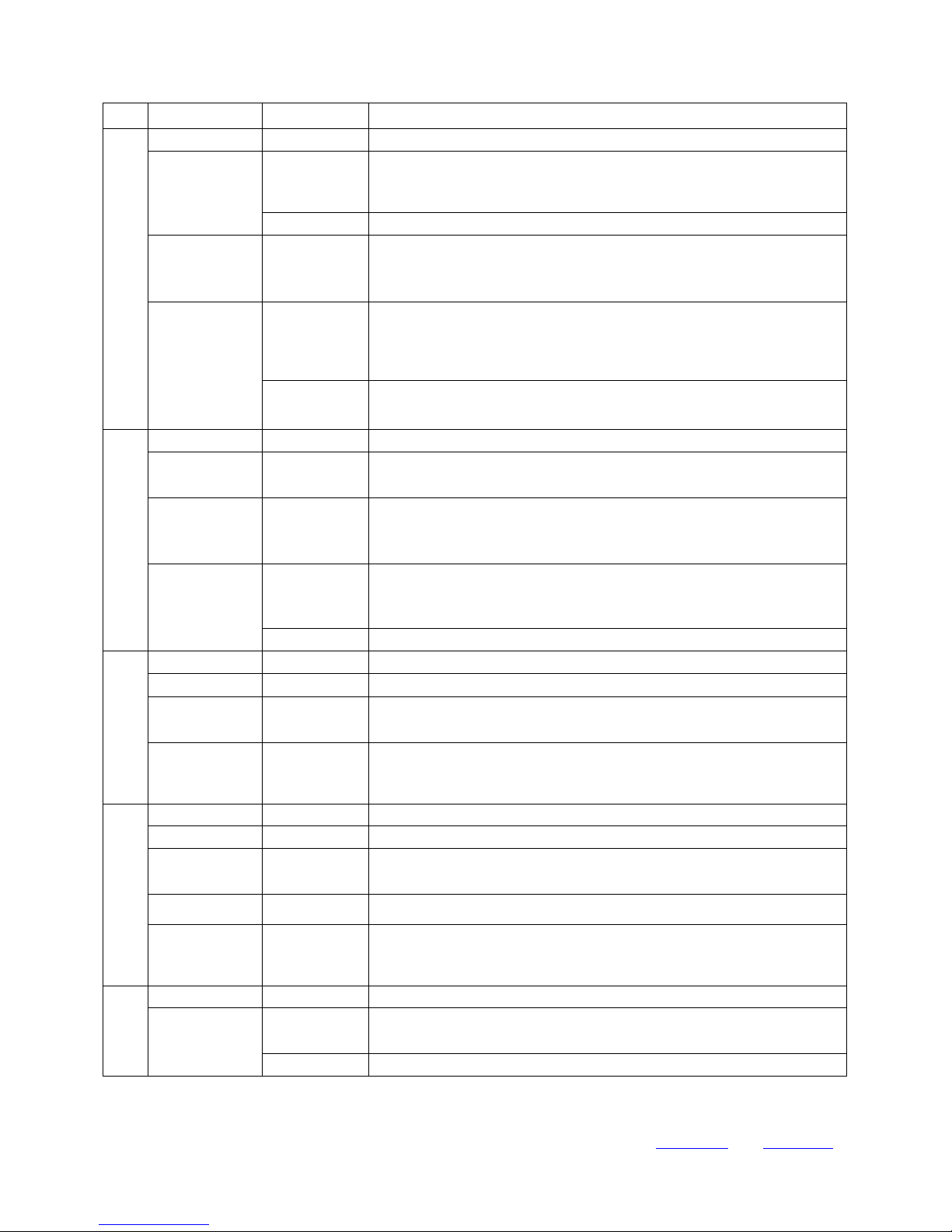

Table 5.1: Pad Description

Pad#

Signal

Direction

Description

1

GND

Power

Ground supply pad

2

GND

Power

Ground supply pad

3

VCC

Power

Power supply pad

4

VCC

Power

Power supply pad

5

nRESET

I

Active low chip reset (internal pull-up)

6

PC5

I/O

Digital I/O

TX_ACTIVE

O

Logic-level control for external Rx/Tx switch. The STM32W108 baseband

controls TX_ACTIVE and drives it high (VDD_PADS) when in Tx mode.

Select alternate output function with GPIO_PCCFGH[7:4]

7

PC6

I/O

Digital I/O

OSC32B

I/O

32.768 kHz crystal oscillator.

Select analogue function with GPIO_PCCFGH[11 :8]

nTX_ACTIVE

O

Inverted TX_ACTIVE signal (see PC5)

Select alternate output function with GPIO_PCCFGH[11:8]

8

PC7

I/O

Digital I/O

OSC32A

I/O

32.768 kHz crystal oscillator.

Select analogue function with GPIO_PCCFGH[15:12]

OSC32_EXT

I

Digital 32 kHz clock input source

9

PA7

I/O High current

Digital I/O Disable REG_EN with GPIO_DBGCFG[4]

TIM1CH4

O

Timer 1 Channel 4 output

Enable timer output with TIM1_CCER

Select alternate output function with GPIO_PACFGH[15:12]

Disable REG_EN with GPIO_DBGCFG[4]

I

Timer 1 Channel 4 input. Cannot be remapped

REG_EN

O

External regulator open drain output. (Enabled after reset).

10

PB3

I/O

Digital I/O

TIM2_CH3 (see

also Pad 13)

O

Timer 2 channel 3 output

Enable remap with TIM2_OR[6]

Enable timer output in TIM2_CCER

Select alternate output function with GPIO_PBCFGL[15:12]

I

Timer 2 channel 3 input Enable remap with TIM2_OR[6]

UART_CTS

I

UART CTS handshake of Serial Controller 1

Enable with SC1_UARTCFG[5]

Select UART with SC1_MODE

SC1SCLK

O

SPI master clock of Serial Controller 1 Either disable timer output in

TIM2_CCER, or disable remap with TIM2_OR[6] Enable master with

SC1_SPICFG[4] Select SPI with SC1_MODE

Select alternate output function with GPIO_PBCFGL[15:12]

I

SPI slave clock of Serial Controller 1

Enable slave with SC1_SPICFG[4]

Select SPI with SC1_MODE

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

Table 5.1: Pad Description (cont)

Pad#

Signal

Direction

Description

11

PB4

I/O

Digital I/O

TIM2_CH4 (see

also Pad 15)

O

Timer 2 channel 4 output

Enable remap with TIM2_OR[7]

Enable timer output in TIM2_CCER

Select alternate output function with GPIO_PBCFGH[3:0]

I

Timer 2 channel 4 input Enable remap with TIM2_OR[7]

UART_RTS

O

UART RTS handshake of Serial Controller 1

Either disable timer output in TIM2_CCER, or disable remap with

TIM2_OR[7]

Enable with SC1_UARTCFG[5] Select UART with SC1_MODE

Select alternate output function with GPIO_PBCFGH[3:0]

SC1nSSEL

I

SPI slave select of Serial Controller 1

Enable slave with SC1_SPICFG[4]

Select SPI with SC1_MODE

12

PA0

I/O

Digital I/O

TIM2_CH1 (see

also Pad 20)

O

Timer 2 channel 1 output

Disable remap with TIM2_OR[4]

Enable timer output in TIM2_CCER

Select alternate output function with GPIO_PACFGL[3:0]

I

Timer 2 channel 1 input

Disable remap with TIM2_OR[4]

SC2MOSI

O

SPI master data out of Serial Controller 2 Either disable timer output in

TIM2_CCER, or enable remap with TIM2_OR[4]

Enable master with SC2_SPICFG[4]

Select SPI with SC2_MODE

Select alternate output function with GPIO_PACFGL[3:0]

I

SPI slave data in of Serial Controller 2

Enable slave with SC2_SPICFG[4] Select

SPI with SC2_MODE

13

PA1

I/O

Digital I/O

TIM2_CH3 (see

also Pad 10)

O

Timer 2 channel 3 output

Disable remap with TIM2_OR[6]

Enable timer output in TIM2_CCER

Select alternate output function with GPIO_PACFGL[7:4]

I

Timer 2 channel 3 input Disable remap with TIM2_OR[6]

SC2SDA

I/O

TWI data of Serial Controller 2 Either disable timer output in TIM2_CCER, or

enable remap with TIM2_OR[6] Select TWI with SC2_MODE

Select alternate open-drain output function with GPIO_PACFGL[7:4]

SC2MISO

O

SPI slave data out of Serial Controller 2

Either disable timer output in TIM2_CCER, or enable remap with TIM2_OR[6]

Enable slave with SC2_SPICFG[4] Select SPI with SC2_MODE

Select alternate output function with GPIO_PACFGL[7:4]

I

SPI master data in of Serial Controller 2

Enable slave with SC2_SPICFG[4]

14

GND

Power

Ground supply pad.

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

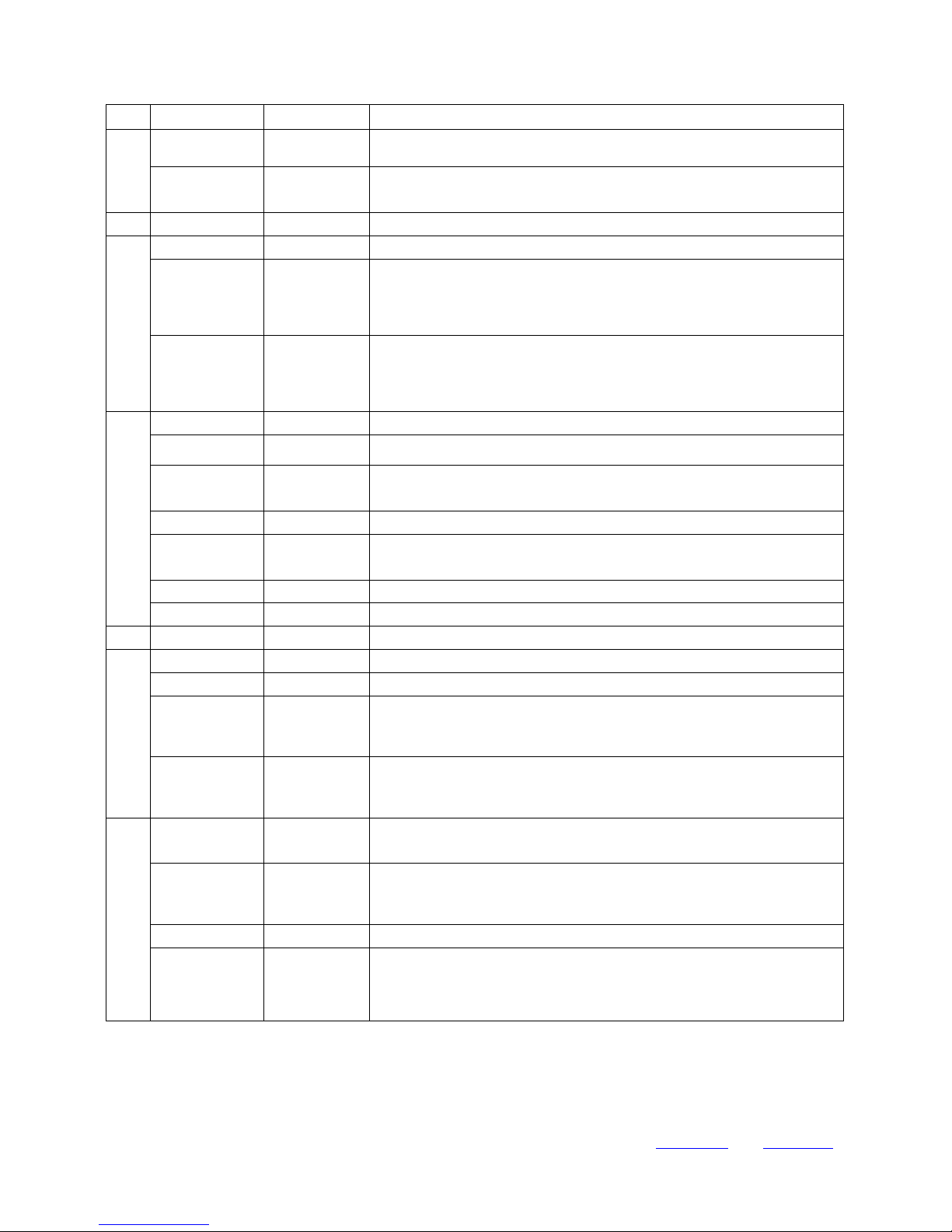

Table 5.1: Pad Description (cont)

Pad#

Signal

Direction

Description

15

PA2

I/O

Digital I/O.

TIM2_CH4 (see

also Pad 11)

O

Timer 2 channel 4 output.

Disable remap with TIM2_OR[7].

Enable timer output in TIM2_CCER .

Select alternate output function with GPIO_PACFGL[11:8].

I

Timer 2 channel 4 input Disable remap with TIM2_OR[7].

SC2SCL

I/O

TWI clock of Serial Controller 2.

Either disable timer output in TIM2_CCER, or enable remap with TIM2_OR[7].

Select TWI with SC2_MODE.

Select alternate open-drain output function with GPIO_PACFGL[11:8].

SC2SCLK

O

SPI master clock of Serial Controller 2.

Either disable timer output in TIM2_CCER, or enable remap with TIM2_OR[7].

Enable master with SC2_SPICFG[4].

Select SPI with SC2_MODE.

Select alternate output function with GPIO_PACFGL[11:8].

I

SPI slave clock of Serial Controller 2.

Enable slave with SC2_SPICFG[4].

Select SPI with SC2_MODE.

16

PA3

I/O

Digital I/O

SC2nSSEL

I

SPI slave select of Serial Controller 2

Enable slave with SC2_SPICFG[4]

Select SPI with SC2_MODE

TRACECLK (see

also Pad 27)

O

Synchronous CPU trace clock .

Either disable timer output in TIM2_CCER, or enable remap with TIM2_OR[5].

Enable trace interface in ARM core.

Select alternate output function with GPIO_PACFGL[15:12].

TIM2_CH2 (see

also Pad 21)

O

Timer 2 channel 2 output.

Disable remap with TIM2_OR[5].

Enable timer output in TIM2_CCER.

Select alternate output function with GPIO_PACFGL[15:12].

I

Timer 2 channel 2 input Disable remap with TIM2_OR[5].

17

PA4

I/O

Digital I/O.

ADC4

Analog

ADC Input 4 Select analogue function with GPIO_PACFGH[3:0].

PTI_EN

O

Frame signal of Packet Trace Interface (PTI).

Disable trace interface in ARM core.

Select alternate output function with GPIO_PACFGH[3:0].

TRACEDATA2

O

Synchronous CPU trace data bit 2.

Select 4-wire synchronous trace interface in ARM core.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PACFGH[3:0].

18

PA5

I/O

Digital I/O.

ADC5

Analog

ADC Inputs Select analog function with GPIO_PACFGH[7:4].

PTI_DATA

O

Data signal of Packet Trace Interface (PTI).

Disable trace interface in ARM core.

Select alternate output function with GPIO_PACFGH[7:4].

nBOOTMODE

I

Embedded serial boot-loader activation out of reset Signal is active during

and immediately after a reset on nRESET.

TRACEDATA3

O

Synchronous CPU trace data bit 3.

Select 4-wire synchronous trace interface in ARM core.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PACFGH[7:4].

19

PA6

I/O High current

Digital I/O.

TIM1_CH3

O

Timer 1 channel 3 output.

Enable timer output in TIM1_CCER.

Select alternate output function with GPIO_PACFGH[11 :8].

I

Timer 1 channel 3 input Cannot be remapped.

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

Table 5.1: Pad Description (cont)

Pad#

Signal

Direction

Description

20

PB1

I/O

Digital I/O.

SC1MISO

O

SPI slave data out of Serial Controller 1.

Either disable timer output in TIM2_CCER, or disable remap with TIM2_OR[4].

Select SPI with SC1_MODE.

Select slave with SC1_SPICR.

Select alternate output function with GPIO_PBCFGL[7:4].

SC1MOSI

O

SPI master data out of Serial Controller 1.

Either disable timer output in TIM2_CCER, or disable remap with TIM2_OR[4].

Select SPI with SC1_MODE.

Select master with SC1_SPICR.

Select alternate output function with GPIO_PBCFGL[7:4]

SC1SDA

I/O

TWI data of Serial Controller 1.

Either disable timer output in TIM2_CCER, or disable remap with TIM2_OR[4].

Select TWI with SC1_MODE.

Select alternate open-drain output function with GPIO_PBCFGL[7:4].

SC1TXD

O

UART transmit data of Serial Controller 1.

Either disable timer output in TIM2_CCER, or disable remap

with TIM2_OR[4].

Select UART with SC1_MODE.

Select alternate output function with GPIO_PBCFGL[7:4].

TIM2_CH1 (see

also Pad 12)

O

Timer 2 channel 1 output.

Enable remap with TIM2_OR[4].

Enable timer output in TIM2_CCER.

Select alternate output function with GPIO_PACFGL[7:4].

I

Timer 2 channel 1 input Disable remap with TIM2_OR[4].

21

PB2

I/O

Digital I/O

SC1MISO

I

SPI master data in of Serial Controller 1.

Select SPI with SC1_MODE.

Select master with SC1_SPICR.

SC1MOSI

I

SPI slave data in of Serial Controller 1.

Select SPI with SC1_MODE.

Select slave with SC1_SPICR

SC1SCL

I/O

TWI clock of Serial Controller 1.

Either disable timer output in TIM2_CCER, or disable remap with TIM2_OR[5].

Select TWI with SC1_MODE.

Select alternate open-drain output function with GPIO_PBCFGL[11 :8].

SC1RXD

I

UART receive data of Serial Controller 1.

Select UART with SC1_MODE.

TIM2_CH2 (see

also Pad 16)

O

Timer 2 channel 2 output.

Enable remap with TIM2_OR[5].

Enable timer output in TIM2_CCER.

Select alternate output function with GPIO_PBCFGL[11 :8].

I

Timer 2 channel 2 input.

Enable remap with TIM2_OR[5].

22

SWCLK

I/O

Serial Wire clock input/output with debugger.

Selected when in Serial Wire mode (see JTMS description, Pad 26)

JTCK

1

JTAG clock input from debugger.

Selected when in JTAG mode (default mode, see JTMS description,

Pad 26) Internal pull-down is enabled.

23

PC2

I/O

Digital I/O.

Enable with GPIO_DBGCFG[5].

JTDO

O

JTAG data out to debugger.

Selected when in JTAG mode (default mode, see JTMS description,

Pad 26).

SWO

O

Serial Wire Output asynchronous trace output to debugger.

Select asynchronous trace interface in ARM core.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PCCFGL[11:8].

Enable Serial Wire mode (see JTMS description, Pad 26).

Internal pull-up is enabled.

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

Table 5.1: Pad Description (cont)

Pad#

Signal

Direction

Description

24

PC3

I/O

Digital I/O Either Enable with GPIO_DBGCFG[5], or enable Serial Wire mode

(see JTMS description, Pad 26)

JTDI

1

JTAG data in from debugger Selected when in JTAG mode (default

mode, see JTMS description, Pad 26).

Internal pull-up is enabled.

25

GND

Power

Ground supply pad.

26

PC4

I/O

Digital I/O Enable with GPIO_DBGCFG[5]

JTMS

I

JTAG mode select from debugger.

Selected when in JTAG mode (default mode).

JTAG mode is enabled after power-up or by forcing nRESET low.

Select Serial Wire mode using the ARM-defined protocol through a debugger.

Internal pull-up is enabled.

SWDIO

I/O

Serial Wire bidirectional data to/from debugger.

Enable Serial Wire mode (see JTMS description).

Select Serial Wire mode using the ARM-defined protocol through a

debugger.

Internal pull-up is enabled.

27

PB0

I/O

Digital I/O

VREF

Analog O

ADC reference output.

Enable analog function with GPIO_PBCFGL[3:0]

VREF

Analog I

ADC reference input.

Enable analog function with GPIO_PBCFGL[3:0].

Enable reference output with an STM system function

IRQA

I

External interrupt source A.

TRACECLK (see

also Pad 16)

O

Synchronous CPU trace clock.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PBCFGL[3:0].

TIM1CLK

I

Timer 1 external clock input

TIM2MSK

I

Timer 2 external clock mask input

28

GND

Power

Ground supply pad.

29

PC1

I/O

Digital I/O

ADC3

Analog

ADC Inputs Enable analog function with GPIO_PCCFGL[7:4]

SWO (see also

Pad 23)

O

Serial Wire Output asynchronous trace output to debugger.

Select asynchronous trace interface in ARM core.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PCCFGL[7:4].

TRACEDATA0

O

Synchronous CPU trace data bit 0.

Select 1-, 2- or 4-wire synchronous trace interface in ARM core.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PCCFGL[7:4].

30

PC0

I/O High current

Digital I/O.

Either enable with GPIO_DBGCFG[5], or enable Serial Wire mode (see

JTMS description, Pad 26) and disable TRACEDATA1.

JRST

I

JTAG reset input from debugger.

Selected when in JTAG mode (default mode, see JTMS description) and

TRACEDATA1 is disabled.

Internal pull-up is enabled.

IRQD1

I

Default external interrupt source D

TRACEDATA1

O

Synchronous CPU trace data bit 1.

Select 2- or 4-wire synchronous trace interface in ARM core.

Enable trace interface in ARM core.

Select alternate output function with GPIO_PCCFGL[3:0].

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

Table 5.1: Pad Description (cont)

Pad#

Signal

Direction

Description

31

PB7

I/O High current

Digital I/O

ADC2

Analog

ADC Input 2

Enable analog function with GPIO_PBCFGH[15:12]

IRQC1

I

Default external interrupt source C

TIM1_CH2

O

Timer 1 channel 2 output.

Enable timer output in TIM1_CCER.

Select alternate output function with GPIO_PBCFGH[15:12].

I

Timer 1 channel 2 input .(Cannot be remapped).

32

PB6

I/O High current

Digital I/O.

ADC1

Analog

ADC Input 1.

Enable analog function with GPIO_PBCFGH[11:8].

IRQB

I

External interrupt source B.

TIM1_CH1

O

Timer 1 channel 1 output.

Enable timer output in TIM1_CCER.

Select alternate output function with GPIO_PBCFGH[11:8].

I

Timer 1 channel 1 input. (Cannot be remapped).

33

PB5

I/O

Digital I/O

ADC0

Analog

ADC Input 0.

Enable analog function with GPIO_PBCFGH[7:4].

TIM2CLK

I

Timer 2 external clock input.

TIM1MSK

I

Timer 2 external clock mask input.

34

GND

Power

Ground supply pad.

35

GNDRF

RF Ground

Ground pad for RF port.

36

RF

Analog

RF port with 50 Ohm impedance.

37

GNDRF

RF Ground

Ground pad for RF port.

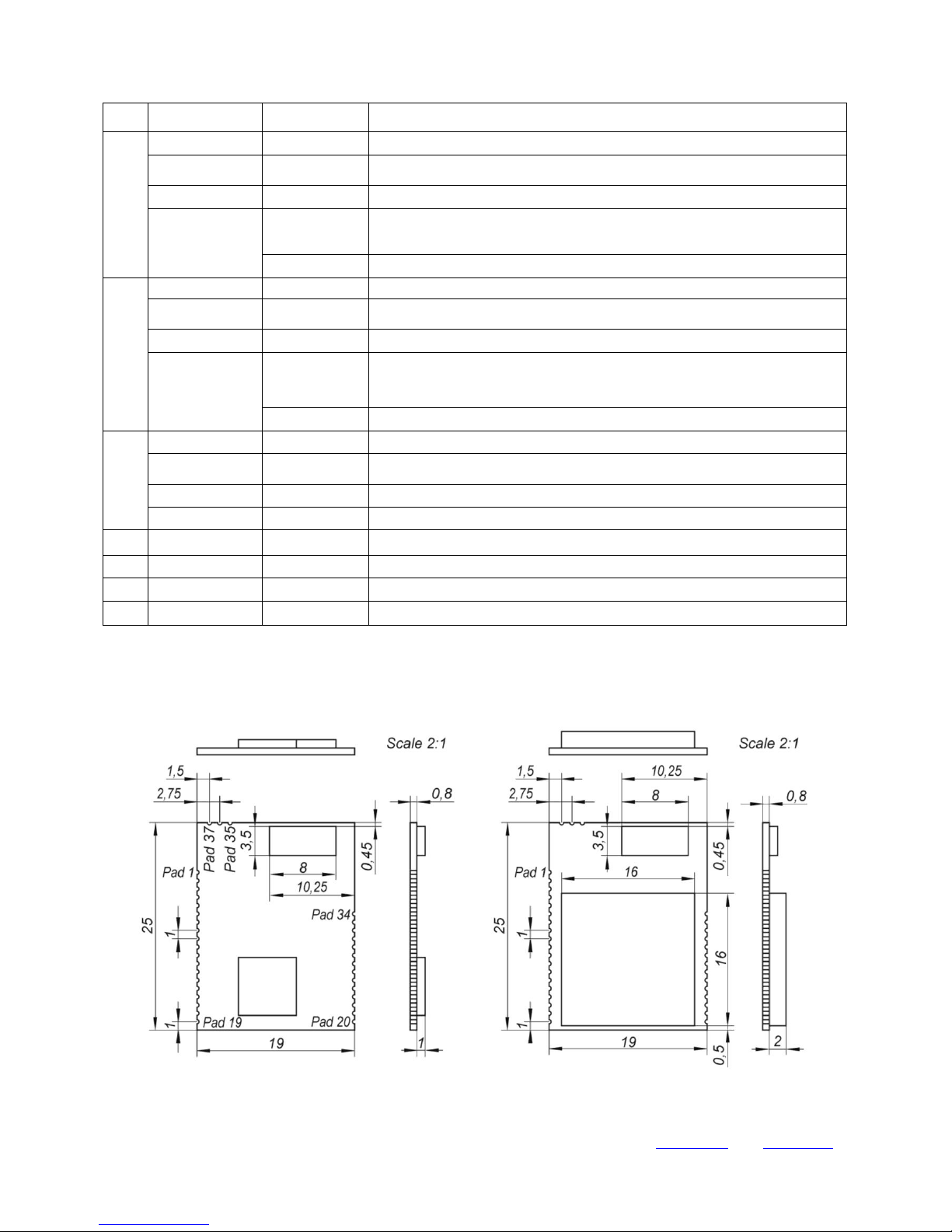

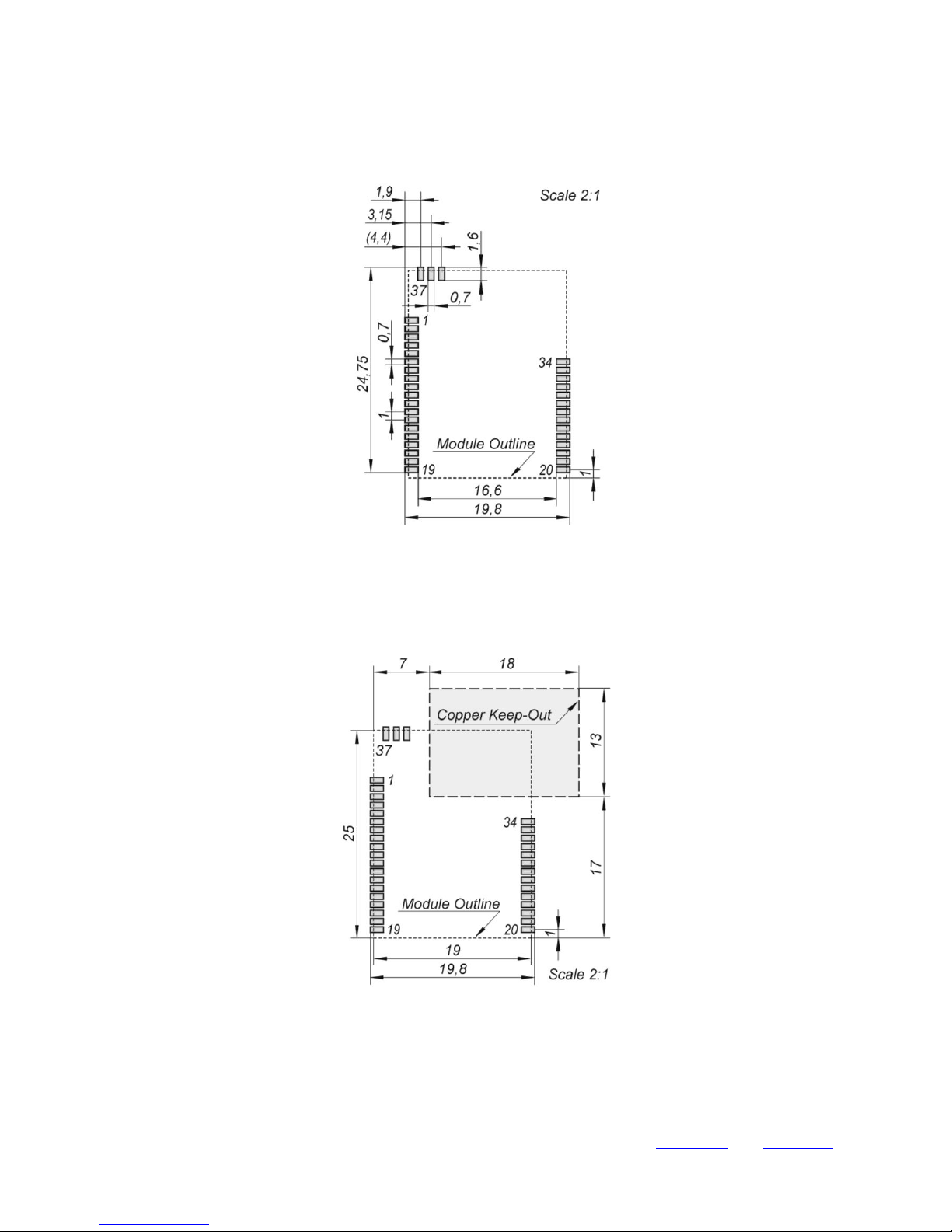

5.3 PACKAGE MECHANICAL DIMENSIONS

Module dimensions are 25 mm x 19 mm x 2 mm and detailed drawing is shown below on Fig. 5.2.

Fig. 5.2 Dimensions of the module. Left: EMI Option “S” -- without shielding; Right: Option “M” – with metal shielding

(Enhanced EMI protection)

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

6 SOLDERING

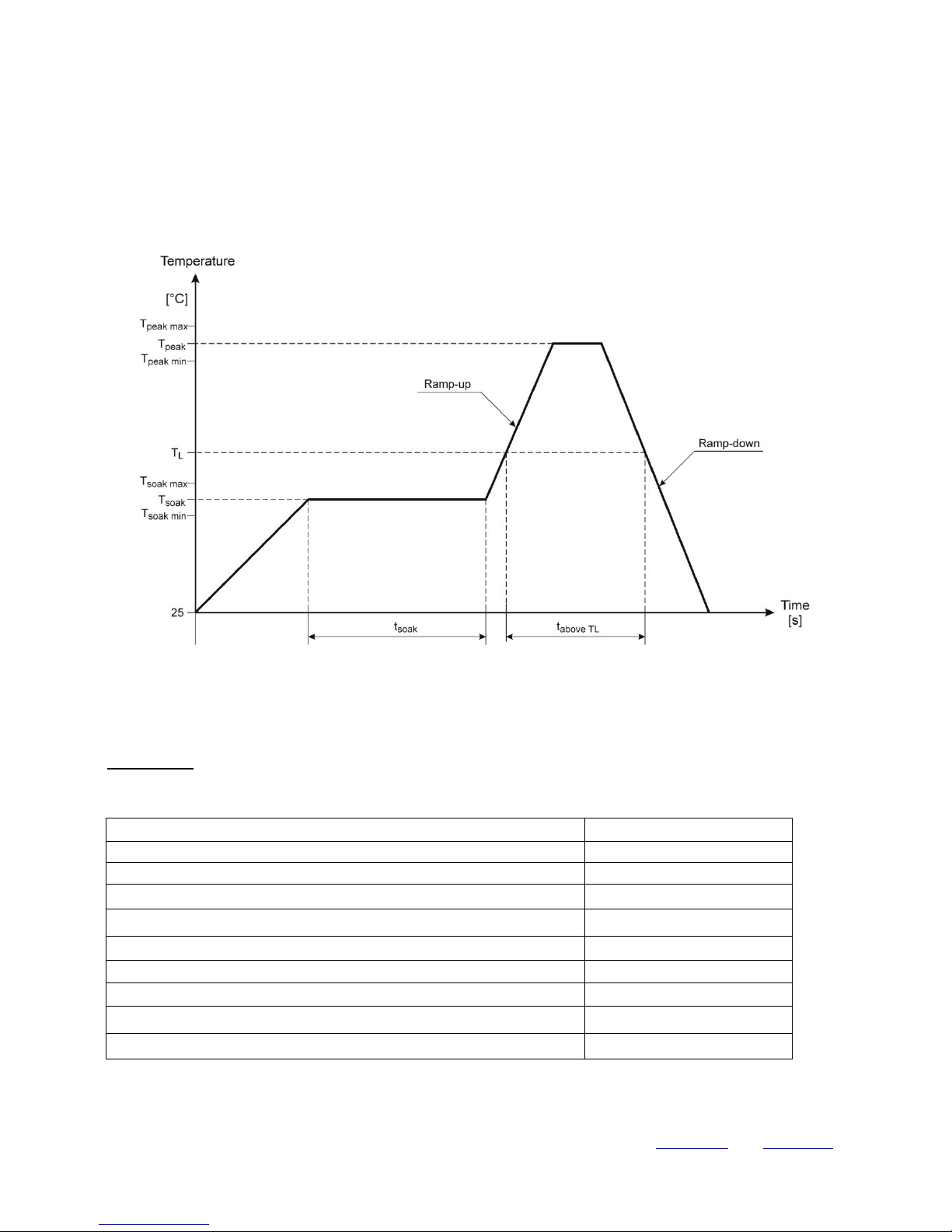

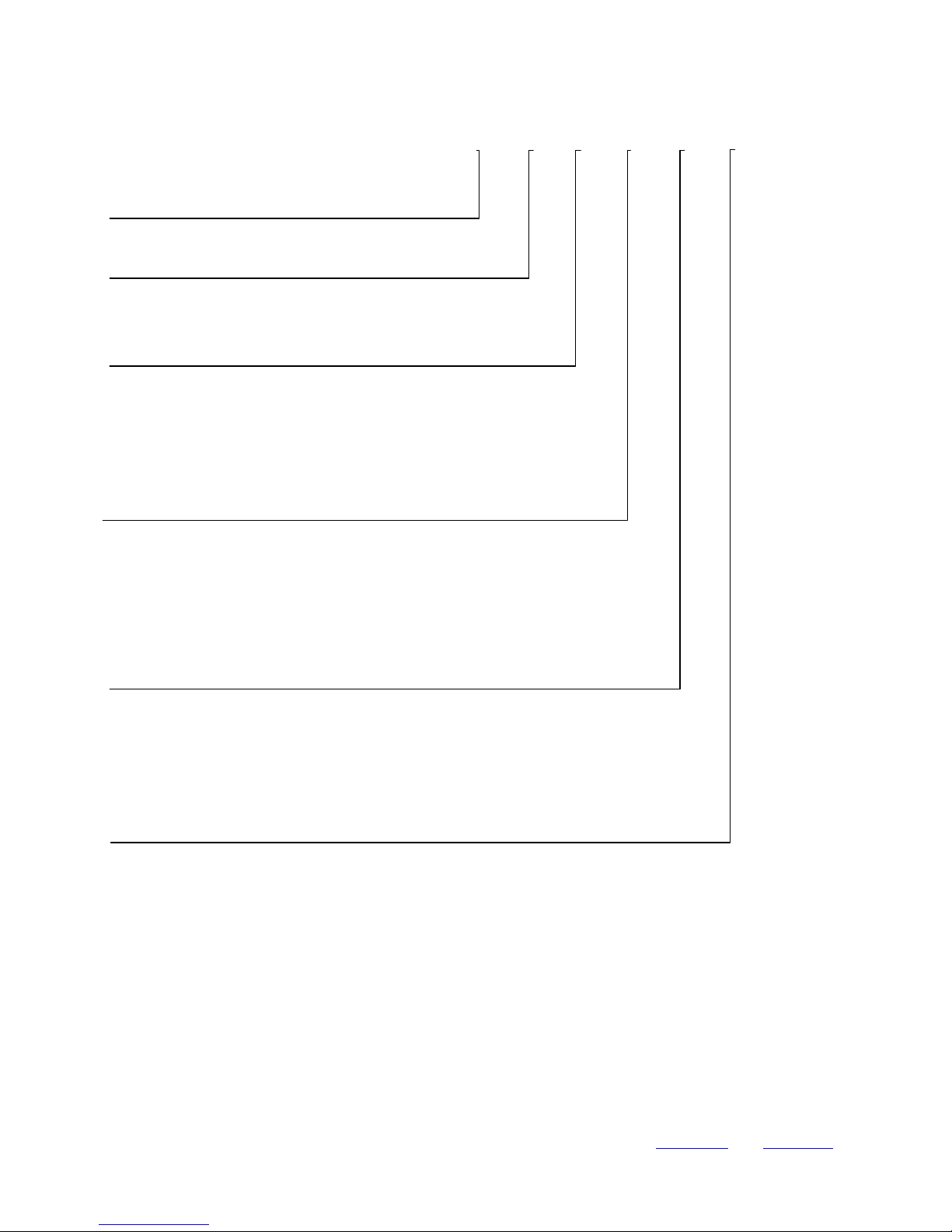

6.1 SOLDER TEMPERATURE PROFILE

The following Fig. 6.1 illustrates the solder temperature profile for the module. This temperature profile is similar for other

RoHS compliant packages, but manufacturing lines should be programmed with this profile in order to guarantee proper solder

connection to the PCB. Please note: module can be soldered only once.

Reflow Profile

Fig. 6.1 Reflow profile

6.2 PROFILE PARAMETERS

The following table 6.1 contains the temperature profile parameters.

Important note: module should be processed according to recommended temperature profile only one time.

Table 6.1 Solder Reflow Parameters

Parameter

Value

Average Ramp Up Rate (from Tsoak

max

to Tpeak)

3°C per second max

Average Ramp Up Rate (from 25°C to Tsoak

min

)

2°C to 4°C per second max

Minimum Soak Temperature (Tsoak

mjn

)

150°C

Maximum Soak Temperature (Tsoak

max

)

200°C

TL

220°C

Time above TL

30 to 60 seconds

Minimum Peak Temperature Tpeak

min

230°C

Maximum Peak Temperature Tpeak

max

250°C

Ramp Down Rate

6°C per second max

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

6.3 RECOMMENDED FOOTPRINT

Top view of recommended footprint for module is shown below on Fig. 6.2:

Fig. 6.2 Recommended footprint for modules (top view)

For the modules with output option “A” (with Embedded SMD Antenna) it is important to prevent presence of any conductive

materials in proximity of the module’s antenna. This requirement is valid for copper traces, ground planes, wires and

connectors too. Recommended “Copper-Keep-Out” area, where presence of copper (and any conductive material too) should

be avoided is depicted on Fig. 6.3 below:

Fig. 6.3 Recommended “Copper-Keep-Out” Area (top view) – only for modules with Output Option “A”

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

7 ORDERING INFORMATION

Example: DZ - ZB - P - O - S - E -

Manufactured by DiZiC

ZigBee Module

Power level options

S -- Standard + 7dBm

R -- Front End with RF Output Power Level Detector + 20 dBm

T -- Front End + 20 dBm

Output options:

A -- Embedded SMD Antenna

P -- Single ended 50 Ohm RF Pad

U -- U.FL 50 Ohm coaxial connector

Stack options:

F -- RF4CE stack

X -- Proprietary stack

Z -- EmberZNet PRO stack

Electromagnetic Interference (EMI) protection options:

S -- Standard, without protective metal shielding

M -- Metal Shield, for enhanced EMI protection

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

8 LIST OF ACRONYMS

This chapter defines a collection of terms that are commonly used when talking about networks in general or ZigBee in

particular.

AC Alternating Current

ACK Acknowledge

ADC Analogue-to-Digital Converter

API Application Programming Interface

ARM Advanced RISC Machines Ltd, now ARM Holdings

BiCMOS Bipolar junction transistors combined with CMOS technology

BER Bit Error Rate

CMOS Complementary Metal–Oxide–Semiconductor

CPU Central Processing Unit

CTS Clear To Send

dB decibel, logarithmic unit of measurement that expresses the magnitude of a physical quantity

dBm Power ratio in decibels of the measured power referenced to one milliwatt (1 mW)

DC Direct Current

DWT Data Watch-point and Trace

EEPROM Electrically Erasable Programmable Read-Only Memory

EMI Electromagnetic Interference

ESD Electrostatic Discharge

FE Front End

FPB Flash Patch and Breakpoint

GPIO General Purpose Input/Output

HAL Hardware Abstraction Layer

HBM Human Body Model

HF High Frequency

HVAC Heating, Ventilating and Air Conditioning

I²C Inter-Integrated Circuit bus

IEEE Institute of Electrical and Electronics Engineers

IRQ Interrupt Request

ISM Industrial, Scientific and Medical radio band

ITM Instrumentation Trace Macrocell

JTAG Joint Test Action Group, digital interface for debugging of embedded device

LNA Low Noise Amplifier

MAC Media Access Control layer

MCU Microcontroller Unit

MPU Multi-core Processing Unit

PA Power Amplifier

PCB Printed Circuit Board

PER Package Error Ratio

PSD Power Spectral Density

PTI Packet Trace Interface

RAM Random Access Memory

RF Radio Frequency

RF4CE Radio Frequency for Consumer Electronics consortium

RSSI Received Signal Strength Indicator

RX Receiver

SMD Surface Mounted Device

SPI Serial Peripheral Interface

STM STMicroelectronics, an Italian-French electronics and semiconductor manufacturer

TWI Two Wire Interface, a variant of I²C

TX Transmitter

UART Universal Asynchronous Receiver/Transmitter

U.FL Miniature coaxial RF connector (up to 6 GHz) manufactured by Hirose Electric Group in Japan

VCO Voltage Controlled Oscillator

ZigBee, ZigBee PRO Wireless networking standards targeted at low-power applications

802.15.4 The IEEE 802.15.4-2003 standard applicable to low-rate wireless Personal Area Network

© 2010 DiZiC Co. Ltd, 3F, N° 4-2 Jin Xi Street Taipei City 104, TAIWAN Email: info@dizic.com | Web: www.dizic.com

All Rights Reserved. All trademarks are property of their respective owners. Subject to change without notice.

Document ID: PB-ZB-MOD-003-20DS

9 REFERENCES & REVISION HISTORY

[1]. STM32W108HB, STM32W108CB, High-performance, 802.15.4 wireless system-on-chip, Data brief, 20-Aug-2009, Rev. 1

[2]. STM32W108HB, STM32W108CB, High-performance, 802.15.4 wireless system-on-chip, Preliminary data, 01-Mar-2010,

Rev. 4

[3]. RN0034, Release notes, STM32W108xx starter and extension kits EmberZNet 4.0.2 GA, Doc ID 16225, 16-Feb-2010,

Rev. 2

[4]. RN0047, Release notes, STM32W108xx starter and extension kits ZigBee RF4CE, Doc ID 17098, 23-Feb-2010, Rev. 1

[5]. RN0046, Release note, STM32W108xx starter and extension kits for Simple MAC library, Doc ID 16996, 04-March-2010,

Rev. 1

[6]. UM0894, User Manual, STM32W-SK and STM32W-EXT starter and extension kits for STM32W108xx, Doc ID 16999, 05-

Feb-2010, Rev. 1

[7]. UM0847, User Manual, IAR customization for STM32W108 system-on-chip, Doc ID 16551, 16-Nov-2009, Rev. 1.

Loading...

Loading...