Dixon Kodiak SE 6125 KOH, Kodiak 965884701, Kodiak 965871801, Kodiak SE 5223 VAN BF, Kodiak 965884601 User Manual

...Page 1

Operator Manual

KODIAK SE 5223 VAN / 965871801

KODIAK SE 6125 KOH / 965871802

KODIAK SE 5223 VAN BF / 965884601

KODIAK SE 6125 KOH BF / 965884701

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

Page 2

©2008 HTC. All rights reserved.

Beatrice, NE. Printed in U.S.A.

Page 3

CONTENTS

INTRODUCTION ............................................................... 5

Driving and Transport on Public Roads ...................... 5

Towing......................................................................... 5

Operating .................................................................... 5

Good Service .............................................................. 6

SYMBOLS AND DECALS ................................................. 7

SAFETY ............................................................................ 9

Safety Instructions ...................................................... 9

Personal Safety Equipment ...................................... 11

Slope Operation ........................................................ 11

Safe Handling of Gasoline ........................................ 13

General Maintenance ...............................................14

Transport ..................................................................16

Rollover Protection system (ROPS) .........................17

CONTROLS .................................................................... 18

Control Locations ...................................................... 18

Steering Control Levers ............................................ 19

Parking Brake ........................................................... 20

Throttle Control ......................................................... 20

Blade Switch ............................................................. 20

Ignition Switch........................................................... 21

Choke Control ........................................................... 21

Fuses ........................................................................ 21

Fuel Tank ..................................................................22

Fuel Shut Off Valve ................................................... 23

Cutting Height Adjuster ............................................. 23

Hour Meter ................................................................ 24

OPERATION ................................................................... 25

Training ..................................................................... 25

Steering ....................................................................25

Before Starting .......................................................... 26

Starting the Engine ................................................... 26

Weak Battery ............................................................ 28

Jumper Cables................................................ 28

Running ....................................................................29

Operating On Hills ....................................................30

Mowing Tips ............................................................. 31

Stopping the Engine .................................................32

Manually Moving Unit ...............................................33

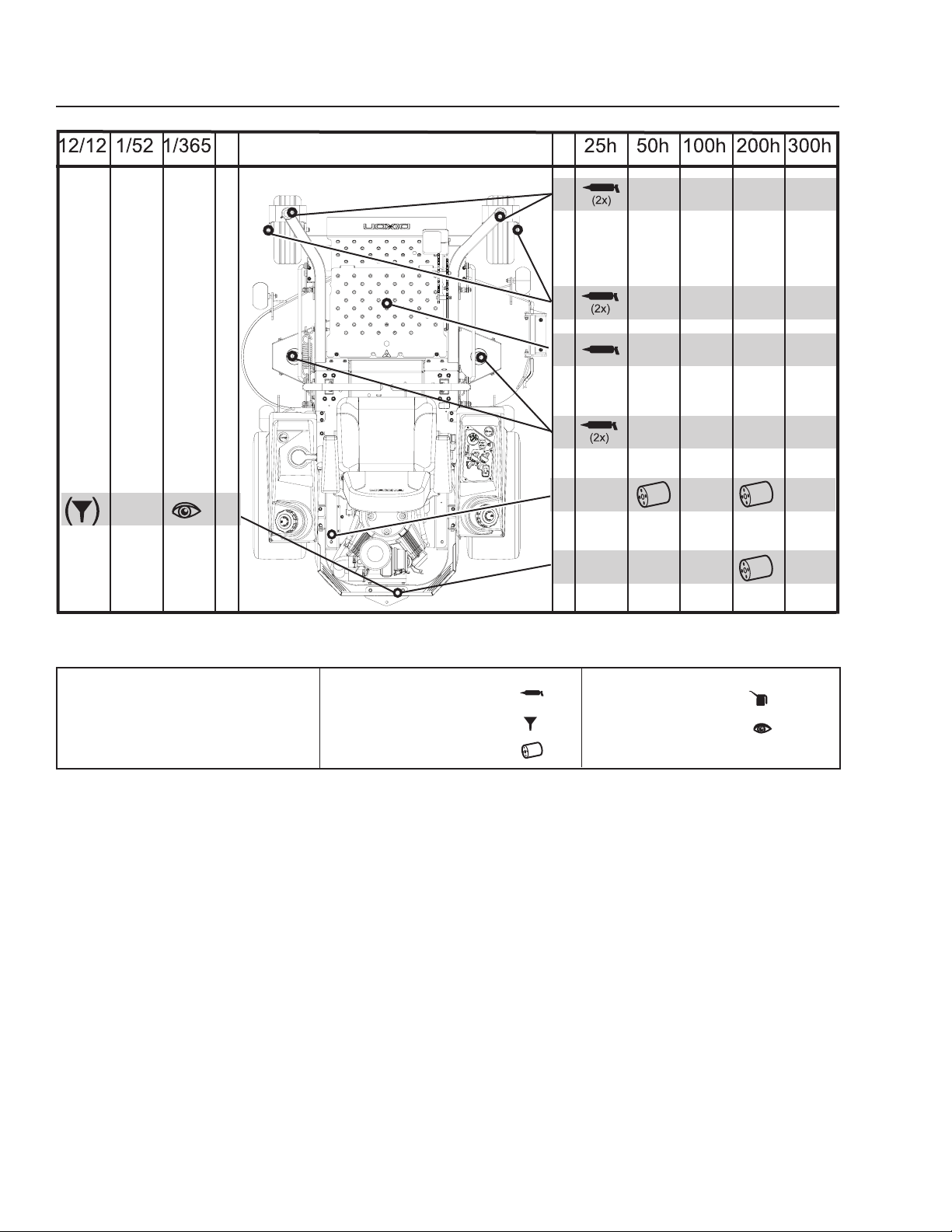

MAINTENANCE .............................................................. 34

Maintenance Schedule ............................................. 34

Battery ......................................................................36

Ignition System ......................................................... 37

Safety System........................................................... 37

Engine Cooling Air Intake ......................................... 38

Throttle Cable ........................................................... 38

Choke Cable ............................................................ 38

Air Filter ....................................................................39

Heavy Duty Air Filter ....................................... 39

Dust cap.......................................................... 39

Fuel Filter .................................................................. 40

Tire Pressures ..........................................................41

Parking Brake ........................................................... 41

V-belts ....................................................................... 42

Deck Belt ........................................................42

Pump Belt ....................................................... 43

Cutting Blades ..........................................................44

Blade replacement .......................................... 44

Adjusting the Mower Deck ........................................ 45

Leveling deck .................................................. 45

Anti-scalp rollers ............................................. 46

Cleaning.................................................................... 47

Caster Wheels .......................................................... 47

Hardware .................................................................. 47

LUBRICATION ................................................................ 48

Cables....................................................................... 49

Front Wheel Mount ................................................... 49

Front Wheel Bearings ............................................... 49

Deck Spindle............................................................. 49

Deck Outer Spindle................................................... 50

Engine Oil ................................................................. 50

Engine Oil Levels ............................................ 51

Changing the Engine Oil ................................. 51

Hydraulic Pump .......................................................52

Fluid Change ..................................................52

Purging ..........................................................52

TROUBLESHOOTING .................................................... 53

STORAGE ....................................................................... 55

Winter Storage .......................................................... 55

Service ...................................................................... 55

SCHEMATICS ................................................................. 56

TECHNICAL DATA .......................................................... 57

Accessories ..............................................................59

Torque Specications................................................ 59

CONFORMITY CERTIFICATES ..................................... 60

SERVICE JOURNAL ....................................................... 61

English-3

Page 4

WARNING!

Failure to follow cautious operating practices can result in serious injury to the

operator or other persons. The owner must understand these instructions, and must

allow only trained persons who understand these instructions to operate the mower.

Each person operating the mower must be of sound mind and body and must not be

under the inuence of any mind altering substance.

WARNING!

Engine exhaust, some of its constituents, and certain vehicle components contain

or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm.

WARNING!

Battery posts, terminals and related accessories contain lead and lead compounds,

chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

English-4

Page 5

INTRODUCTION

Congratulations

Thank you for purchasing a Dixon ride-on mower. This

machine is built for superior efciency to rapidly mow

primarily large areas. A control panel easily accessible

to the operator and a hydrostatic transmission

regulated by steering controls both contribute to the

machine’s performance.

This manual is a valuable document. Read the

contents carefully before using or servicing the

machine. The following of instructions (use, service,

maintenance) by all who operate this machine is

important for the safety of the operator and others.

It can also considerably increase the life span of the

machine and increase its resale value.

If you sell your machine, be sure to give the operator’s

manual to the new owner.

The nal chapter of this operator’s manual provides a

Service Journal. Ensure that service and repair work

are documented. A well-kept service journal reduces

service costs for the maintenance and affects the

machine’s resale value. Please contact your dealer for

more information. Take the operator’s manual along

when the machine is taken to your dealer for service.

General

In this operator’s manual, left and right, backward and

forward are used in relation to the machine’s normal

driving direction.

Continuous dedication to improve our products require

that specications and design are subject to change

without notice.

Driving and Transport on Public Roads

Check applicable road trafc regulations before

transporting on public roads. If the machine is

transported, you must always use approved fastening

equipment and ensure that the machine is well

anchored. DO NOT operate this machine on public

roadways.

Towing

If machine is equipped with a tow hitch, use extreme

caution when towing. Never allow children or others in

or on the towed equipment. Make wide turns to avoid

jack-kning. Travel slowly and allow extra distance to

stop.

Do not tow on sloped ground. The weight of the towed

equipment may cause loss of traction and loss of

control.

Follow the manufacturer's recommendation for weight

limits for towed equipment. Do not tow near ditches,

canals, and other hazards.

Operating

This machine is constructed only for mowing grass

on lawns and even ground without obstacles such

as stones, tree stumps, etc. The machine can also

be used for other tasks when equipped with special

accessories provided by the manufacturer. Operating

instructions for the accessories are provided with

delivery. All other types of uses are incorrect. The

manufacturer’s directions concerning operation,

maintenance, and repairs must be carefully followed.

Lawn mowers and all power equipment, can be

potentially dangerous if used improperly. Safety

requires good judgement, careful use in accordance

with these instructions and common sense.

The machine must only be operated, maintained, and

repaired by persons familiar with the machine’s special

characteristics and who are also knowledgeable about

the safety instructions. Use only approved repair parts

to maintain this machine.

Accident prevention regulations, other general safety

regulations, occupational safety rules, and trafc

regulations must be followed without fail.

Unauthorized modications to the design of the

machine may absolve the manufacturer from liability

for any resulting personal injury or property damage.

Dixon-5

Page 6

INTRODUCTION

Good Service

Dixon’s products are sold all over the world and only in specialized retail stores with complete service. This

ensures that you as a customer receive only the best support and service. Before the product is delivered, the

machine has, for example, been inspected and adjusted by your retailer. See the certicate in the Service Journal

in this operator’s manual.

When you need spare parts or support in service questions, warranty issues, etc., please consult the following

professional:

This Operator’s Manual belongs to the machine with

the manufacturing number:

Manufacturing Number

The machine’s manufacturing number can be found on the printed plate afxed to the left in the engine

compartment. Stated on the plate, from the top are:

The machine’s type designation (I.D.).1.

The manufacturer’s type number (Model).2.

The machine’s serial number (Serial no.)3.

Please have the type designation and serial number available when ordering spare parts.

The engine’s manufacturing number is stamped on one of the valve covers.

The plate states:

The engine’s model.4.

The engine’s type.5.

Code6.

Please have these available when ordering spare parts.

The wheel motors and hydrostatic pumps have a barcode decal afxed at the rear.

Engine

Transmission

6-Dixon

Page 7

SYMBOLS AND DECALS

These symbols are found on the machine and in the operator’s manual.

Study them carefully so that you know what they mean.

WARNING!

Xxxx xxxxxx xxxxx xxxx

xxxxxxxxx xxxxxx xxxxxxxxx. xx

xxxxxxxx xxxx xxxxxx.

Used in this publication to notify the reader of a risk of personal injury or death, particularly if the reader should

neglect to follow instructions given in the manual.

IMPORTANT INFORMATION

Xxxx xxxxxx xxxxx xxxx xxxxxxxxx xxxxxx

xxxxxxxxx. xx xxxxxxxx xxxx xxxxxx.

Used in this publication to notify the reader of a risk of material damage, particularly if the reader should neglect

to follow instructions given in the manual. Used also when there is a potential for misuse or misassembly.

R N

Reverse Neutral Fast Slow Choke Fuel

Warning! Parking Brake CE conformity Warning! Rotating blades, Do not touch parts

marking. Only for keep away from the

European market discharge deck

Battery acid is corrosive, explosive and ammable Do not stand here

Noise emissions to the

surroundings in accordance

with the European Union’s

directive. The machine’s

emission is stated in the

chapter TECHNICAL DATA

and on the decals.

Use protective glasses Use protective gloves

Only machines for European

market

Dixon-7

Page 8

SYMBOLS AND DECALS

Read Shut off engine and Keep a safe Use on slopes No passengers

Operator’s remove key before distance from no greater

Manual performing any the machine than 10°

maintenance or repair work

Whole body Severing of ngers Do not open or Careful backing up, Careful going

exposure to and toes remove safety watch for other forward, watch for

thrown objects shields while people other people

engine is running

Moving sharp blades under cover

8-Dixon

Page 9

SAFETY

Safety Instructions

These instructions are for your safety. Read them carefully.

WARNING!

This symbol means that important safety instructions need to be emphasized. It concerns

your safety.

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING

OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR DEATH.

General Operation

Read, understand, and follow all instructions 1.

on the machine and in the manual before

starting.

Do not put hands or feet near rotating parts 2.

or under the machine. Keep clear of the

discharge opening at all times.

Only allow responsible adults, who are familiar 3.

with the instructions, to operate the machine.

Clear the area of objects such as rocks, toys, 4.

wire, etc., which could be picked up and

thrown by the blades.

Be sure the area is clear of bystanders before 5.

operating. Stop machine if anyone enters the

area.

Never carry passengers. The machine is only 6.

intended for use by one person.

Do not mow in reverse unless absolutely 7.

necessary. Always look down and behind

before and while backing.

Never direct discharged material toward 8.

anyone. Avoid discharging material against a

wall or obstruction. Material may ricochet back

toward the operator. Stop the blades when

crossing gravel surfaces.

Do not operate machine without the entire 9.

grass catcher, discharge guard, or other safety

devices in place and working

Slow down before turning.10.

Never leave a running machine unattended. 11.

Always turn off blades, set parking brake, stop

engine, and remove keys before dismounting.

Disengage blades when not mowing. Shut 12.

off engine and wait for all parts to come to a

complete stop before cleaning the machine,

removing the grass catcher, or unclogging the

discharge guard.

Operate machine only in daylight or good 13.

articial light.

Read the operator’s manual before starting the machine

Clear the area of objects before mowing

8011-512

8011-513

Dixon-9

Page 10

SAFETY

Do not operate the machine while under the 14.

inuence of alcohol or drugs.

Watch for trafc when operating near or 15.

crossing roadways.

Use extra care when loading or unloading the 16.

machine into a trailer or truck.

Always wear eye protection when operating 17.

machine.

Data indicates that operators age 60 years and 18.

above are involved in a large percentage of

riding mower-related injuries. These operators

should evaluate their ability to operate

the riding mower safely enough to protect

themselves and others from serious injury.

Follow the manufacturer’s recommendation for 19.

wheel weights or counterweights.

Anyone who operates this machine must rst 20.

read and understand this Operation Manual.

Local laws may regulate the age of the user.

Keep machine free of grass, leaves or other 21.

debris buildup which can touch the hot exhaust

or engine parts and burn. Do not allow the

mower deck to plow leaves or other debris,

causing buildup to occur.

Clean any oil or fuel spillage before operating 22.

or storing the machine.

Allow machine to cool before storage.23.

8011-520

Never take passengers

WARNING!

Engine exhaust and certain vehicle

components contain or emit

chemicals considered to cause

cancer, birth defects, or other

reproductive system damage. The

engine exhaust contains carbon

monoxide, which is a odorless,

colorless, poisonous gas. Do not use

the machine in enclosed spaces.

10-Dixon

Page 11

Personal Safety Equipment

WARNING!

When using the machine, approved personal protective equipment (shown in illustrations)

shall be used. Personal protective equipment cannot eliminate the risk of injury but it

will reduce the degree of injury if an accident does happen. Ask your retailer for help in

choosing the right equipment.

Make sure that you have rst aid equipment •

close at hand when using the machine.

Never use the machine when barefoot. •

Always wear protective shoes or boots, •

preferably with steel toe caps.

Always wear approved protective glasses or a •

full visor when assembling or driving.

Always wear gloves when handling the blades.•

Never wear loose clothing that can get caught •

in moving parts.

Use ear protectors to avoid damage to •

hearing.

SAFETY

Slope Operation

Slopes are a major factor related to loss of control and

tip-over accidents, which can result in severe injury or

death. Operation on all slopes requires extra caution. If

you cannot back up the slope or if you feel uneasy on

it, do not mow it.

Mow up and down slopes (10 degrees •

maximum), not across.

Watch for holes, ruts, bumps, rocks, or other •

hidden objects. Uneven terrain could overturn

the machine. Tall grass can hide obstacles.

Choose a low ground speed so that you will •

not have to stop while on the slope.

Do not mow on wet grass. Tires may lose •

traction.

Avoid starting, stopping, or turning on a slope. •

If the tires lose traction, disengage the blades

and proceed slowly straight down the slope.

Keep all movement on the slopes slow and •

gradual. Do not make sudden changes in

speed or direction, which could cause the

machine to roll over.

Use extra care while operating machine with •

grass catchers or other attachments; they can

affect the stability of the machine.

Do not use on steep slopes.•

8011-670a

Personal protective equipment

6003-004

Mow up and down, not side to side

WARNING!

Do not drive up or down hills with

slopes greater than 10 degrees. And

do not drive across any slopes.

Dixon-11

Page 12

SAFETY

Do not try to stabilize the machine by putting •

your foot on the ground.

Do not mow near drop-offs, ditches, or •

embankments. The machine could suddenly

roll over if a wheel is over the edge or if the

edge caves in.

Children

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you last

saw them.

Keep children out of the mowing area and in •

the watchful care of a responsible adult other

than the operator.

Be alert and turn machine off if a child enters •

the area.

Before and while backing, look behind and •

down for small children.

Never carry children, even with the blades •

shut off. They may fall off and be seriously

injured or interfere with safe machine

operation. Children who have been given

rides in the past may suddenly appear in the

mowing area for another ride and be run over

or backed over by the machine.

Never allow children to operate the machine.•

Use extra care when approaching blind •

corners, shrubs, trees, or other objects that

may block your view of a child.

8011-509

Be extra cautious when driving on slopes

12-Dixon

8011-517

Never allow children to operate the machine

8011-518

Keep children away from work area

Page 13

SAFETY

WARNING!

The engine must not be started when the driver’s oor plate or any protective plate for the

mower deck’s drive belt is removed.

Safe Handling of Gasoline

To avoid personal injury or property damage, use

extreme care in handling gasoline. Gasoline is

extremely ammable and the vapors are explosive.

Extinguish all cigarettes, cigars, pipes, and •

other sources of ignition.

Use only approved gasoline container.•

Never remove gas cap or add fuel with the •

engine running. Allow engine to cool at least

two (2) minutes before refueling.

Never fuel the machine indoors.•

Never store the machine or fuel container •

where there is an open ame, spark, or pilot

light such as on a water heater or other

appliance.

Before you begin refueling, minimize the risk of •

static electricity by touching a metal surface.

Never ll containers inside a vehicle or on a •

truck or trailer bed with plastic liner. Always

place containers on the ground away from the

vehicle when lling.

Remove gas-powered equipment from the •

truck or trailer and refuel it on the ground. If

this is not possible, refuel such equipment

with a portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the •

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lockopen device.

If fuel is spilled on clothing, change clothing •

immediately.

Never overll fuel tank. Replace gas cap and •

tighten securely.

Do not start the engine near spilled fuel.•

Never use gasoline as a cleaning agent.•

If leaks arise in fuel system, engine must not •

be started until problem has been resolved.

Check the fuel level before each use and leave •

space for the fuel to expand, as the heat from

the engine and the sun may otherwise cause

the fuel to expand and overow.

8011-516

Never ll the fuel tank indoors

WARNING!

The engine and the exhaust system

become very hot during operation.

There is risk for burns if touched.

Allow engine and exhaust system to

cool at least two (2) minutes before

refueling.

Dixon-13

Page 14

General Maintenance

Never operate machine in a closed area.•

Keep all nuts and bolts tight to be sure the •

equipment is in safe working condition.

Never tamper with safety devices. Check their •

proper operation regularly.

Keep machine free of grass, leaves, or other •

debris buildup. Clean oil or fuel spillage and

remove any fuel-soaked debris. Allow machine

to cool before storing.

If you strike a foreign object, stop and inspect •

the machine. Repair, if necessary, before

restarting.

Never make any adjustments or repairs with •

the engine running.

Check grass catcher components and the •

discharge guard frequently and replace with

manufacturer’s recommended parts, when

necessary.

Mower blades are sharp. Wrap the blade or •

wear gloves, and use extra caution when

servicing them.

Check brake operation frequently. Adjust and •

service as required.

Maintain or replace safety and instruction •

labels, as necessary.

Do not modify safety equipment. Check •

regularly to be sure it works properly. The

machine must not be driven with defective

or unmounted protective plates, protective

cowlings, safety switches, or other protective

devices.

Do not change the settings of governors and •

avoid running the engine with overly high

engine speeds. If you run the engine too fast,

you risk damaging the machine components.

Be very careful when handling battery acid. •

Acid on skin can cause serious corrosive

burns. If you spill battery acid on your skin,

rinse immediately with water.

Acid in the eyes can cause blindness, contact •

a doctor immediately.

Be careful when servicing the battery. •

Explosive gases form in the battery. Never

perform maintenance on the battery when

smoking or near open ames or sparks.

The battery can explode and cause serious •

injury/damage.

SAFETY

8011-515

Never drive the machine in an enclosed space

WARNING!

Use protective glasses for

maintenance work.

WARNING!

The battery contains lead and lead

compounds, chemicals that are

considered to cause cancer, birth

defects, and other reproductive

system damage. Wash your hands

after handling the battery.

14-Dixon

Page 15

SAFETY

Ensure that nuts and bolts, especially the •

fastening bolts for the blade attachments,

are properly tightened, torqued and that the

equipment is in good condition.

Do not modify safety equipment. Check •

regularly to be sure it works properly. The

machine must not be driven with defective

or unmounted protective plates, protective

cowlings, safety switches, or other protective

devices.

Do not change the settings of governors and •

avoid running the engine with overly high

engine speeds. If you run the engine too fast,

you risk damaging the machine components.

Sparking can occur when working with the •

battery and the heavy cables of the starter

circuit. This can cause battery explosion, re or

eye injury. Sparking in this circuit can not occur

after the chassis cable (normally negative,

black) is removed from the battery.

6003-009

Do not smoke when performing maintenance on the battery.

The battery can explode and cause serious injury/damage.

WARNING!

Avoid electrical sparking and its

consequences by the following

routines:

Use protective goggles.•

Ensure that the fuel ller cap is mounted tightly •

and no ammable substances are stored in an

open vessel.

Never work with the starter circuit if there is •

spilled fuel.

Disconnect the chassis cable from the battery •

rst and reconnect it last.

Do not make a bridge short circuit across the •

starter relay to run the starter.

Never use the machine indoors or in spaces •

lacking proper ventilation. The exhaust fumes

contain carbon monoxide, an odorless,

poisonous, and lethal gas.

Stop and inspect the equipment if you run over •

or into anything. If necessary, make repairs

before starting.

Never make adjustments with the engine •

running.

The machine is tested and approved only •

with the equipment originally provided or

recommended by the manufacturer. Only use

approved repair parts for the machine.

8009-728

Risk of sparking

Dixon-15

Page 16

The blades are sharp and can cause cuts and •

gashes. Wrap the blades or use protective

gloves when handling them.

Check the parking brake’s functionality •

regularly. Adjust and service as necessary.

The mulch blades should only be used in •

familiar areas when higher quality mowing is

desired.

Reduce the risk of re by removing grass, •

leaves, and other debris that may have

accumulated on the machine. Allow the

machine to cool before putting it in storage.

Regularly clean deck and underside of •

deck, avoid spraying engine and electrical

components with water.

Transport

The machine is heavy and can cause serious •

crushing injuries. Be extra cautious when it is

loaded on or unloaded from a vehicle or trailer.

Use an approved trailer to transport the •

machine. Activate the parking brake, turn off

the fuel supply, and fasten the machine with

approved fastening devices, such as bands,

chains, or straps, when transporting.

Do not operate this machine on public •

roadways.

Check and abide by local trafc regulations •

before transporting the machine on any road.

Do not tow this machine, it may cause damage •

to the drive system.

Do not tow with this mower. They may •

jackknife or overturn causing damage to the

mower and possibly serious injury to the

operator.

Load the unit onto truck or trailer by driving up •

ramps of suitable strength using a slow speed.

Do not lift! The machine is not intended to be

lifted by hand.

SAFETY

8011-514

Regularly clean deck

WARNING!

Escaping hydraulic oil under

pressure can have sufcient force

to penetrate the skin, causing

serious injury. If injured by escaping

uid, see a doctor at once. Serious

infection or reaction can develop

if proper medical treatment is not

administered immediately.

IMPORTANT INFORMATION

The parking brake is not sufcient to lock the

machine in place during transport. Ensure that

the machine is well fastened to the transport

vehicle. Always reverse the machine onto the

transport vehicle to avoid tipping it over.

16-Dixon

Page 17

SAFETY

Rollover Protection system (ROPS)

The ROPS increases the basic weight of the unit by

88 lbs / 40 kg. The ROPS is an accessory.

Do not use ROPS as a lifting, attaching or •

anchoring point.

Do not use ROPS for wrecking or towing.•

Do not exceed Max GVW: 2822 lbs/1283 kg.•

Read machine operator´s manual before each •

use.

Securely fasten the seat belt when using the •

unit with the ROPS in the upright position.

When operating with the ROPS in the folded •

position, the seat belt should not be worn.

Where possible, avoid operating the unit near •

ditches, embankments and holes.

Reduce speed when turning, crossing slopes •

and on rough, slick or muddy surfaces.

Stay off slopes too steep for safe operation.•

Watch where you are going, especially at row •

ends, on roads and around trees.

Do not permit others to ride.•

Operate the mower smoothly without jerky •

turns, starts or stops.

When mower is stopped, set brakes securely •

and use park brake.

If any part of ROPS is damaged, the entire •

ROPS must be replaced.

Check all bolts including seat belt for correct •

torque before each use.

Check ROPS structure for damage before •

each use.

ROPS bar is NOT intended for use in sub zero •

temperatures.

WARNING!

The rollover protection system's

capabilities may be impaired by

damage if the mower is overturned

or if alteration to the ROPS occurs. If

these conditions take place, the total

structure MUST be replaced.

WARNING!

This mower is equipped with an

internal combustion engine and

should not be used on or near any

unimproved forested, bush covered

or grassy lands unless the engine's

system is equipped with a spark

arrester meeting applicable local or

state laws (if any). If a spark arrester

is used, it should be maintained

in effective working order by the

operator.

Dixon-17

Page 18

CONTROLS

This operator’s manual describes the Dixon Zero

Turn Rider. The rider is tted with either a Kohler or

Briggs & Stratton four-stroke overhead valve engine

developing 23-25 horse power*.

Control Locations

9

8

7

Transmission from the engine is made via a belt-driven

hydraulic pumps. Using the left and right steering

controls, the ow is regulated and thereby the direction

and speed.

2

1

10

8

6

*As rated by the engine manufacturer.

12

3

Motion control levers1.

Parking brake2.

Throttle control3.

Blade switch4.

Ignition switch5.

Choke control6.

11

45

Fuses7.

Fuel tank cap8.

Fuel shut off valve9.

Deck lift10.

Seat adjustment lever11.

Hour meter12.

18-Dixon

Page 19

CONTROLS

Steering Control Levers

The machine’s speed and direction are continuously

variable using the two steering controls. The steering

controls can be moved forward or backward about

a neutral position. Furthermore, there is a neutral

position, which is locked if the steering controls are

moved outward.

When both controls are in the neutral position (N), the

machine stands still.

By moving both controls an equal amount forward

or backward, the machine moves in a straight line

forward or backward respectively.

In order, for example, to turn right while moving

forward, move the right control towards the neutral

position. The rotation of the right wheel is reduced and

the machine turns to the right.

Zero turn can be achieved by moving one control

backward (behind the neutral position) and carefully

moving the other steering control forward from its

neutral position. The rotation direction when zero

turning is determined by which steering control is

moved backward behind the neutral position. If the left

steering control is pulled backward, the machine turns

to the left. Use extra care when using this maneuver.

If the steering controls are in uneven positions when

standing still or do not t in the slots for moving the

controls outward, they can be adjusted.

8050-827

Steering controls

WARNING!

The machine can turn very rapidly if

one steering control is moved much

further forward than the other.

1. Forward

2. Neutral

3. Neutral slot, Neutral lock

4. Reverse

Motion control lever, right side

8011-7912

Dixon-19

Page 20

CONTROLS

Parking Brake

IMPORTANT INFORMATION

The machine must stand absolutely still when

applying the parking brake. Always set the

parking brake before dismounting. Release the

parking brake before moving the mower.

The parking brake is found on the left of the machine.

Pull the lever backward to activate the brake and

forward to release it.

Throttle Control

The throttle control regulates the engine speed and

thereby the rate of rotation of the blades, assuming the

blade switch is pulled out, see Engaging the Mower

Deck.

In order to increase or decrease the engine speed, the

control is moved forward or back respectively.

Avoid idling the engine for long periods, as there is a

risk of fouling the spark plugs.

USE FULL THROTTLE WHEN MOWING, for best

mower performance and battery charging.

8061-019

Parking brake released

Blade Switch

In order to engage the mower deck, pull the knob out;

the mower blades are disengaged when the knob is

depressed.

20-Dixon

8061-017

Throttle control

8061-017

Blade switch

Page 21

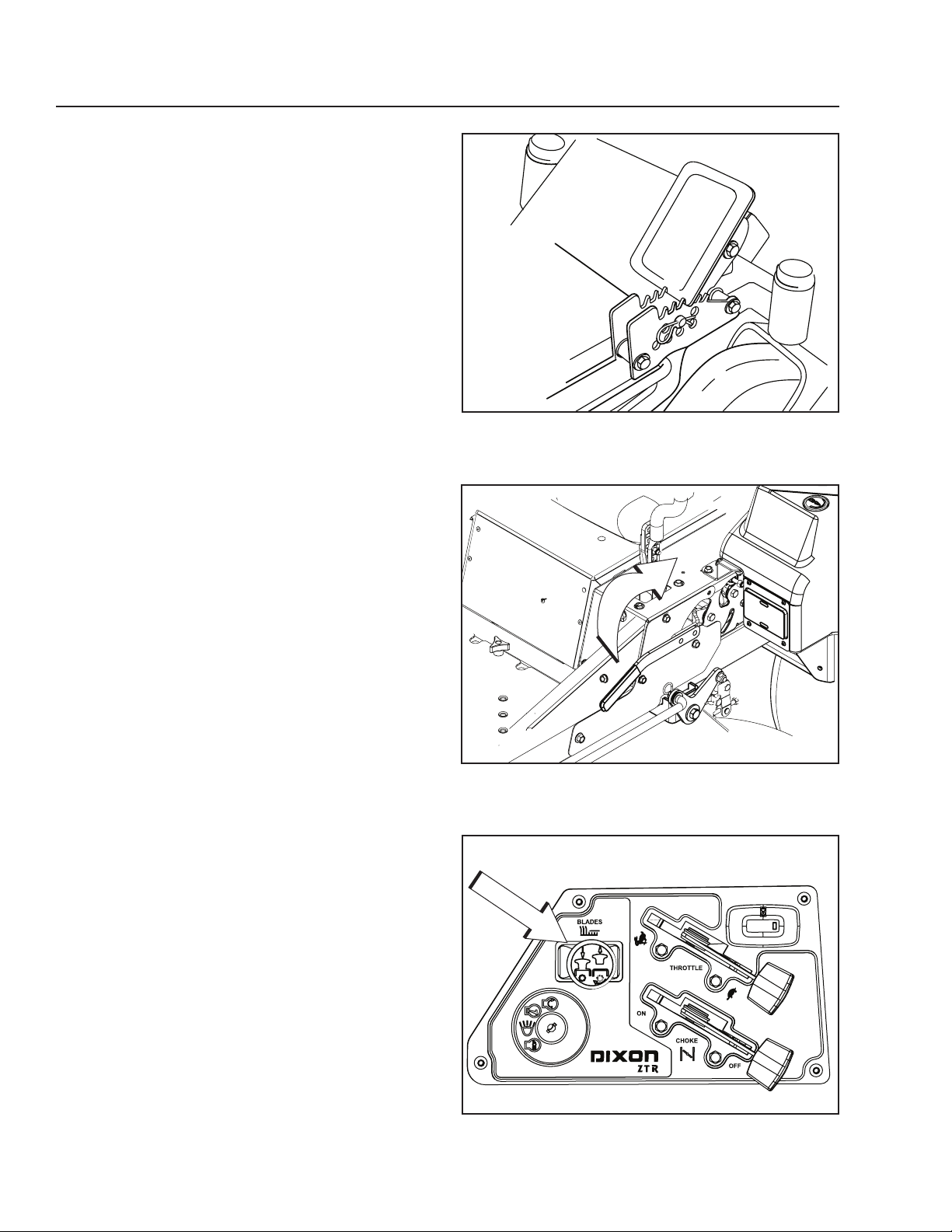

CONTROLS

Ignition Switch

The ignition key is placed on the control panel and is

used to start and stop the engine.

Choke Control

The choke control is used for cold starts in order to

provide the engine with a richer fuel mixture.

For cold starts the control should be pushed to the ON

position.

8061-017

Ignition switch

Fuses

Fuses are located on the left hand side of the machine.

They are accessed by tilting the seat forward. They are

at pin fuses of the same type used in automobiles.

There are two fuses with ratings and functions:

20 Amp Primary fuse1.

7.5 Amp Mower deck coupling2.

8061-017

Choke control

8011-420

Fuses

Dixon-21

Page 22

CONTROLS

Fuel Tank

Read the safety instructions before refueling. The

machine has two fuel tanks, just behind the seat. Each

tank capacity is 5.7 gallons (22 liters).

Make sure the fuel caps are properly tightened and the

cap gaskets are not damaged.

The engine will run on a minimum of 85-octane

unleaded gasoline (no oil mix). Environmentally

adapted alkylate gasoline can be used. See also

Technical Data concerning ethanol fuel. Methanol fuel

is not allowed. Do not use E85 alcohol based fuel.

Damage to engine and components may occur.

WARNING!

Gasoline is highly ammable.

Observe caution and ll the tank

outdoors (see the safety instruction).

WARNING!

The engine and the exhaust system,

become very hot during operation.

Risk for burns if touched.

Allow engine and exhaust system to

cool at least two (2) minutes before

refueling.

WARNING!

Fill to bottom of ller neck. Do not

overll. Wipe off any spilled oil

or fuel. Do not store, spill or use

gasoline near an open ame.

8050-828

Fuel tank

IMPORTANT INFORMATION

Experience indicates that alcohol blended

fuels (called gasohol, ethanol or methanol) can

attract moisture which leads to separation and

formation of acids during storage. Acidic gas

can damage the fuel system of an engine while

in storage. To avoid engine problems, the fuel

system should be emptied before storage of

30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and

carburetor are empty. Use fresh fuel the next

season. See Storage Instructions for additional

information. Never use engine or carburetor

cleaners in the fuel tank or permanent damage

may occur.

When operating in temperatures below 32° F. (0° C.),

use fresh, clean winter grade gasoline to insure good

cold weather starting.

22-Dixon

Page 23

CONTROLS

Fuel Shut Off Valve

The fuel shut off valve is located at the left rear of the

seat. The valve is off when the handle tab is turned

perpendicular to the fuel line.

IMPORTANT INFORMATION

In order to obtain an even cutting height, it is

important that the air pressure in all tires is 15

psi / 103 kPa / 1 bar.

IMPORTANT INFORMATION

Always raise the deck to the highest position

for transport.

8011-419

Fuel shut off valve in the CLOSED position

Cutting Height Adjuster

The deck cutting height is obtained by pressing the

foot pedal forward to lift the deck. To lower the deck,

apply pressure to the top side of the foot pedal and

allow it to pivot while the lift arm rotates to the rear of

the unit. To stop in the desired cutting position, rotate

the foot pedal down into the notch in the height plate.

The cutting height range is from 1½" (38mm) to 4½"

(114mm) in ¼ (6mm) increments. The heights are

measured from the ground up to the blade tip with the

engine not running.

8050-117

The mower deck’s lifting lever

Dixon-23

Page 24

CONTROLS

Seat Adjustment Lever

The seat can be adjusted lengthways. When making

adjustments, the lever under the front edge of the

seat is moved to the left (as seen by the driver in the

seat), after which the seat can be moved backward or

forward.

Hour Meter

The hour meter displays the total operating time.

It will ash CHG OIL (Change Oil) at 50 hour intervals.

The ash duration is one hour before and one hour

after the interval. The CHG OIL icon will come on

and shut off automatically. The hour meter cannot be

manually reset.

8011-441

Lengthways adjustment

24-Dixon

8061-017

Hour meter

Page 25

OPERATION

Read “Safety Instructions” section and following

pages, if you are unfamiliar with the machine.

Training

Zero turn mowers are far more maneuverable than

typical riding mowers due to their unique steering

capabilities.

We suggest that this section be reviewed in its entirety

prior to attempting to move the mower under its own

power. Additionally, we suggest when rst operating

the mower, use a reduced throttle speed and reduced

ground speed by NOT moving control levers to the

furthest forward or reverse positions during initial

operation, or until operator becomes comfortable with

controls. We also suggest rst time users, or new

users to Zero Turn mowers to become familiar with

the mower’s movement on a hard surface, such as

concrete or blacktop PRIOR to attempting to operate

on turf. Until operator becomes comfortable with

mower controls and zero turning capability, they may

damage turf due to overly aggressive maneuvers.

IMPORTANT INFORMATION

When control levers are in the reverse position

they return to neutral when released. This may

cause the mower to suddenly stop.

Steering

To move forward and backward

The direction and speed of the mower’s movements

is effected by the movement of the control lever(s)

on each side of mower. The left control lever controls

the left wheel. The right control lever controls the right

wheel.

First time users should push mower (see “Moving by

Hand” in the Operation section) to an open, at area,

without other people or vehicles/obstacles nearby. In

order to move unit under its own power, the operator

must be in the seat, start engine (see “Before Starting”

in Operation section), adjust engine speed to idle,

disengage parking brake, do not engage blades at

this time, rotate control levers inward. As long as

the control levers have not been moved forward or

backwards, mower will not move. Slowly move both

control levers forward slightly. This will allow mower

to start moving forward in a straight line. Pull back on

control levers to the neutral position and mower should

stop moving. Pull back slightly on control levers, this

will allow mower to start moving backwards. Push

forward on control levers to the neutral position and

mower should stop moving.

To turn to the right

While moving in a forward direction, pull the right lever

back towards the neutral position while maintaining the

position of the left lever, this will slow the rotation of

the right wheel and cause the machine to turn in that

direction.

To turn to the left

While moving in a forward direction pull the left lever

back towards the neutral position while maintaining

the position of the right lever, this will slow the rotation

of the left wheel and cause the machine to turn in that

direction.

To zero turn

While moving in a forward direction, rst pull both

control levers back until the mower stops or slows

dramatically.

Then by alternating one lever slightly to the forward

position and the other in the reverse position.

Dixon-25

Page 26

OPERATION

Before Starting

Read the sections Safety Instructions and •

Controls before starting the machine.

Perform the daily maintenance before •

starting (see Maintenance Schedule in the

Maintenance section).

Check that there is sufcient fuel in the fuel •

tank.

Adjust the seat to the desired position.•

The following conditions must be fullled before the

engine can be started:

The driver must be seated on the seat.•

The blade switch for engaging the mower •

blades must be depressed.

The parking brake must be on.•

Both steering controls must be in the locked •

(outer) neutral position.

Starting the Engine

Sit on the seat. 1.

Raise the mower deck by pulling the lifting 2.

lever backward to the locked position

(transport position).

Activate the parking brake.3.

8050-117

Mower deck lifting lever

Disengage the mower blades by pressing the blade

switch downwards.

26-Dixon

8061-019

Pull parking brake upwards to activate.

8061-017

Blade switch

Page 27

OPERATION

Move the steering controls outward to the locked

(outer) neutral position.

Move the throttle to the middle position.

8061-020

Place controls in neutral position

WARNING!

Engine exhaust and certain vehicle

components contain or emit

chemicals considered to cause

cancer, birth defects or other

reproductive system damage. The

engine exhaust contains carbon

monoxide, which is a odorless,

colorless, poisonous gas. Do not use

the machine in enclosed spaces.

If the engine is cold, the choke lever should be pushed

to the ON position.

8061-017

Set the throttle

Set the choke control

8061-017

Dixon-27

Page 28

OPERATION

Weak Battery

WARNING!

Lead-acid batteries generate

explosive gases. Keep sparks, ame

and smoking materials away from

batteries. Always wear eye protection

when around batteries.

IMPORTANT INFORMATION

Your mower is equipped with a 12-volt

negative grounded system. The other vehicle

must also be a 12-volt negative grounded

system. Do not use your mower to start other

vehicles.

If your battery is too weak to start the engine, it should

be recharged. (See “Battery” in the Maintenance

Section.)

If “jumper cables” are used for emergency starting,

follow this procedure:

Jumper Cables

Connect each end of the RED cable to the 1.

POSITIVE (+) terminal on each battery, taking

care not to short against chassis.

Connect one end of the BLACK cable to the 2.

NEGATIVE (-) terminal of the fully charged

battery.

Connect the other end of the BLACK cable to 3.

a good CHASSIS GROUND on the mower with

the discharged battery, away from the fuel tank

and battery.

To remove cables, reverse order

Remove BLACK cable rst from chassis and 1.

then from the fully charged battery.

Remove RED cable last from both batteries.2.

8011-642

Jumper cable connection

28-Dixon

Page 29

Running

Release the parking brake by moving the lever 1.

downward.

NOTE: The mower is equipped with an

operator presence system. When the engine is

running, any attempt by the operator to leave

the seat without rst setting the parking brake

will shut off the engine.

Move the steering controls to the neutral 2.

position (N).

Select the cutting height with the cutting height 3.

adjustment pedal.

Make sure the work area is free from objects 4.

that could be thrown by the rotating blades.

Engage the mower deck by pulling out the 5.

blade switch.

OPERATION

8061-019

Parking brake released

WARNING!

Ensure that no one is near mower

when engaging blade switch.

Move throttle control to full throttle. 6.

The machine’s speed and direction are

continuously variable using the two steering

controls. When both controls are in the neutral

position, the machine stands still.

By moving both controls an equal amount

forward or backward, the machine moves in a

straight line forward or backward respectively.

In order, for example, to turn right while moving

forward, move the right control towards the

neutral position. The rotation of the right wheel

is reduced and the machine turns to the right.

Turning on the spot (zero turn) can be

achieved by moving one control backward

(behind the neutral position) and carefully

moving the other steering control forward from

its neutral position.

8050-117

Mower deck lifting lever

Set blade engagement and throttle control

8061-017

Dixon-29

Page 30

OPERATION

Operating On Hills

Read the Safety Instructions “Driving on Slopes” in the

“Safety Instructions”.

WARNING!

Do not drive up or down hills with

slopes greater than 10 degrees. Do

not drive across slopes.

The slowest speed possible should be used •

before starting up or down hills.

Avoid stopping or changing speed on hills.•

If stopping is absolutely necessary, pull drive •

levers into the neutral position and push to

the outside of the unit and engage the parking

brake.

IMPORTANT INFORMATION

8061-020

Place controls in neutral position

Control levers return to neutral when released.

This may cause the mower to suddenly stop.

To restart movement, release the parking •

brake.

Pull the control levers back to the center of the •

mower and press forward to regain forward

motion.

Make all turns slowly.•

8061-019

Parking brake released

30-Dixon

Page 31

OPERATION

Mowing Tips

Observe and ag rocks and other xed objects •

to avoid collisions.

Begin with a high cutting height and reduce it •

until the desired mowing result is attained.

The average lawn should be cut to 2½"

(64 mm) during the cool season and over

3" (76 mm) during the hot months. For

healthier and better looking lawns, mow

often after moderate growth. For best cutting

performance, grass over 6" (15 cm) in height

should be mowed twice. Make the rst cut

relatively high, the second to the desired

height.

The mowing result will be best with a high •

engine speed (the blades rotate rapidly) and

low speed (the rider moves slowly). If the

grass is not too long and dense, the driving

speed can be increased without negatively

affecting the mowing result.

The nest lawns are obtained by mowing •

often. The lawn becomes more even and the

grass clippings more evenly distributed over

the mown area. The total time taken is not

increased as a higher operating speed can be

used without poor mowing results.

Avoid mowing wet lawns. The mowing result •

is poorer because the wheels sink into the soft

lawn, clumps build, and the grass clippings

fasten under the cowling.

Hose the mower deck underside with water •

after each use. When cleaning, the mower

deck shall be raised into the transport position.

Make sure the mower is cooled and the

engine is off.

Use compressed air to clean top surface of •

the deck. Avoid ooding water on top surface,

engine and electrical components.

When the mulching kit is used, it is important •

that the mowing interval is frequent.

WARNING!

Clear the lawn of stones and other

objects that can be thrown out by the

blades.

8011-603

Mowing pattern

WARNING!

Never drive the rider on terrain that

slopes more than 10 degrees. Mow

slopes up and down, never side

to side. Avoid sudden directional

changes.

Dixon-31

Page 32

OPERATION

Stopping the Engine

Allow the engine to idle a minute in order to attain

normal operating temperature before stopping it, if

it has been worked hard. Avoid idling the engine for

longer periods, as there is a risk of the spark plugs

fouling.

Disengage the mower deck by depressing the •

blade switch.

Raise the mower deck by pressing the foot •

pedal forward to the transport position.

When the machine is standing still, activate the •

parking brake by pulling the lever upward.

Move the throttle to the minimum position •

(tortoise symbol). Turn the ignition key to the

stop position.

Move the steering controls outward.•

8061-017

Disengage the mower deck and move throttle to minimum

Remove key. Always remove key when leaving •

the mower to prevent unauthorized use.

IMPORTANT INFORMATION

Leaving the ignition switch in any other

position than “OFF” will cause the battery to

be discharged.

32-Dixon

The mower deck’s lifting lever

Place controls in neutral position to stop

8050-117

8061-020

Page 33

OPERATION

Manually Moving Unit

Pump release valves

Pump release valves are located at the front and rear

of the pump. They are used to release the system

so the machine may be moved by hand when not

running. Tilt seat forward to gain access to the pump.

The rear bypass valve sits directly opposite the front

valve, below the seat support. It is not visible in the

illustration.

Use a 17 mm open end wrench or socket and ratchet.

Turn the outer locknut 2-3 turns. Using an 8mm

wrench or socket, turn the inner nut one turn.

Reverse the procedure to reset the pump, makng sure

the outer locknut is tightened.

IMPORTANT INFORMATION

Tighten the valve moderately.

Do not overtighten the valve when closing.

That can damage the valve seat.

8011-507

Pump release valves

English-33

Dixon-33

Page 34

MAINTENANCE

Maintenance Schedule

The following is a list of maintenance procedures that must be performed on the machine. For those points not

described in this manual, visit an authorized service workshop. An annual service carried out by an authorized

service workshop is recommended to maintain your machine in the best possible condition and to ensure safe

operation.

Read “Maintenance” in the Safety Instructions section.

1)

First change after 5-8 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

replacement are required more often.

3)

For daily use, the machine should be lubricated twice weekly.

4)

Performed by authorized service workshop.

● = Described in this manual

♦ = Not described in this manual

2)

In dusty conditions, cleaning and

Daily Weekly At

Maintenance Before After

Check the parking brake

Check the engine’s oil level (every refueling)

Check the safety system

Check for fuel and oil leakages

Check/clean the engine’s cooling air intake

Check the mower deck

Check for loose hardware (screws, nuts)

Clean under the mower deck

Start the engine and blades, listen for unusual sounds

Check for damage

Thoroughly clean around the engine

Clean around belts, belt pulleys

Check the tire pressures

Check battery

Sharpen/Replace mower blades

Clean the engine’s cooling air intake 2)

Clean the air cleaner’s pre-lter 2) (foam)

Clean the air cleaner’s lter cartridge 2) (paper lter)

Check/adjust the parking brake

Inspect mufer/Spark arrester

●

●

●

♦

●

●

●

●

♦

♦

♦

♦

Maintenance interval

least

once

each

year

in hours

25 50 100 300

●

●

●

● ●

● ●

● ●

♦ ♦

♦ ♦

34-Dixon

Page 35

MAINTENANCE

Daily Weekly At

Maintenance Before After

Check/adjust throttle cable

Check the condition of belts, belt pulleys

Change the engine oil

Replace the engine oil lter

Clean/replace the spark plugs

Replace the fuel lter

Replace the air lter (paper lter)

Check the caster wheels (every 200 hours)

Replace the air cleaner’s pre-lter 2) (foam)

Check/adjust the mower deck

Check the engine valve clearance

Perform the 300-hour service

Lubricate according to Lubrication Schedule

Check hydraulic oil at reservoir

Change hydraulic oil & lter (200 hours)

1)

2)

3)

3)

●

Maintenance interval

least

once

each

year

in hours

25 50 100 300

●

● ●

● ●

● ●

● ●

● ●

● ●

●

●

● ●

♦ ♦

♦ ♦

● ● ● ● ●

● ●

1)

First change after 5-8 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

conditions, cleaning and replacement are required more often.

3)

Performed by authorized service workshop.

● = Described in this manual

♦ = Not described in this manual

WARNING!

Before performing any service or adjustment checklist

• Engage the parking brake.

• Place the Blade-switch in the disengaged position.

• Turn the ignition switch to “OFF” position and remove the key.

• Make sure the blades and all moving parts have completely stopped.

• Disconnect the spark plug wire from all spark plugs and place the wire where it

cannot come in contact with the plug.

2)

In dusty

Dixon-35

Page 36

MAINTENANCE

Battery

Your mower is equipped with a maintenance free

battery and does not need servicing. However,

periodic charging of the battery with an automotive

type battery charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Recharge at 6-10 amperes for 1 hour

STANDARD

BATTERY

12.6V 100%

12.4V 75% 20 min. 35 min. 48 min. 90 min.

12.2V 50% 45 min. 75 min. 95 min. 180 min.

12.0V 25% 65 min. 115 min. 145 min. 280 min.

11.8V 0% 85 min. 150 min. 195 min. 370 min.

STATE

CHARGE

*Charging time depends on battery capacity,

condition, age, temperature and efciency of charger

Cleaning battery and terminals

Corrosion and dirt on the battery and terminals can

cause the battery to “leak” power.

Open the terminal access doors.1.

Disconnect BLACK battery cable rst, then 2.

the RED battery cable and remove the battery

from the machine.

Rinse the battery with plain water and dry.3.

Clean terminals and battery cable ends with 4.

wire brush until shiny.

Coat terminals with grease or petroleum jelly5.

Reinstall battery.6.

APPROXIMATE BATTERY CHARGING TIME*

OF

TO FULL CHARGE AT 80

Maximum Rate at:

50 Amps 30 Amps 20 Amps 10 Amps

- FULL CHARGE -

O

F / 27OC

WARNING!

Always wear eye protection when

around batteries.

IMPORTANT INFORMATION

Do not attempt to open or remove caps or

covers. Adding or checking level of electrolyte

is not necessary.

Always use two wrenches for the terminal

screws.

WARNING!

Do not short battery terminals by

allowing a wrench or any other

object to contact both terminals at

the same time. Before connecting

battery, remove metal bracelets,

wristwatch bands, rings, etc.

Positive terminal must be connected

rst to prevent sparks from

accidental grounding.

Replacing battery

Lift seat and rotate forward.1.

Open terminal access doors2.

Using two ½" wrenches disconnect BLACK 3.

battery cable then RED battery cable.

Using a 4.

7

/16 wrench, remove the bolts on either

side of the terminal guard and lift off guard.

Carefully remove the battery from the mower.5.

Install new battery with terminals in the same 6.

position as the old battery.

Reinstall battery terminal guard.7.

First connect RED battery cable to positive (+) 8.

battery terminal with hex bolt and hex nut.

Connect BLACK grounding cable to negative 9.

(-) battery terminal with remaining hex bolt and

hex nut.

Close access doors.10.

36-Dixon

2

1

CZ-22

1. Terminal guard

2. Access doors

Battery cleaning and installation

Page 37

MAINTENANCE

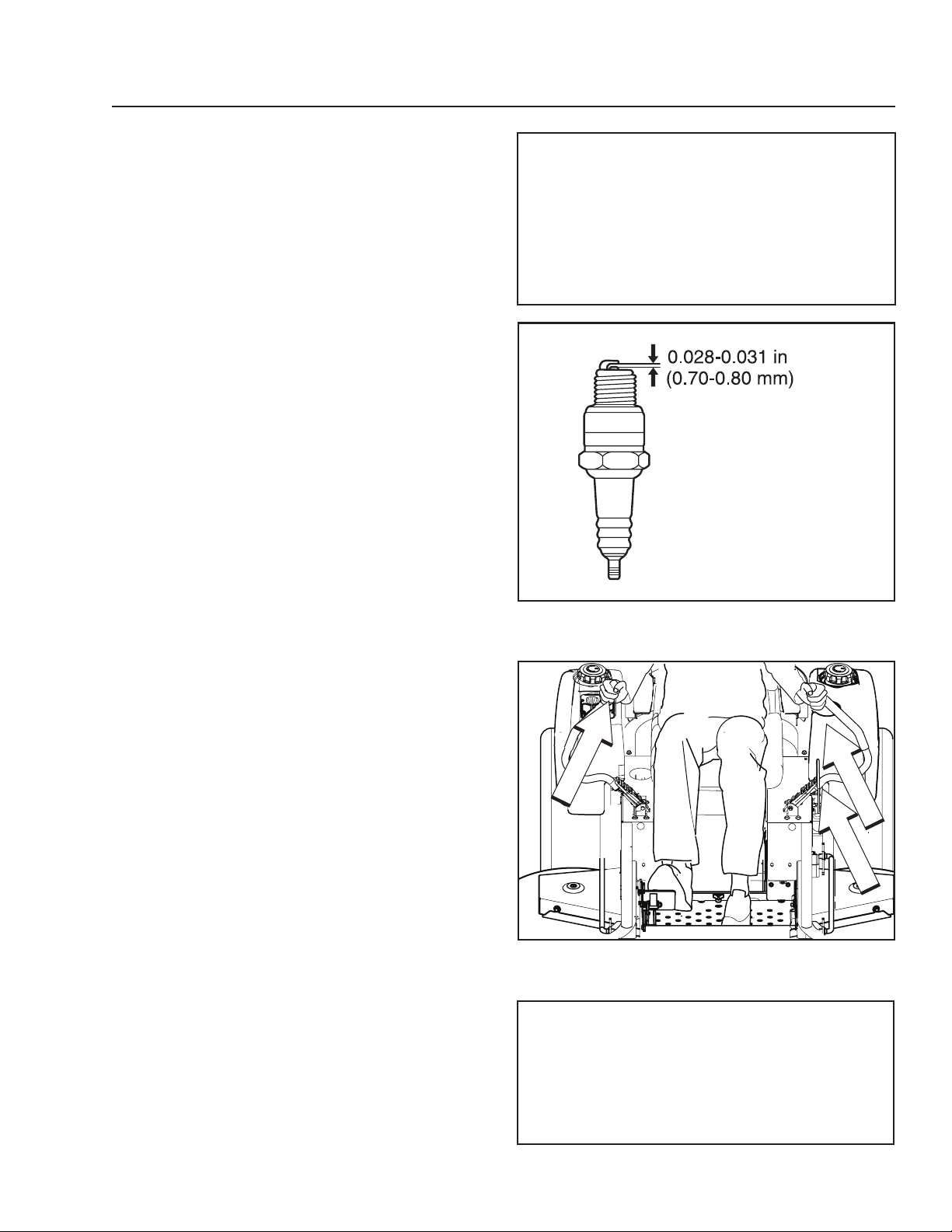

Ignition System

The engine is equipped with an electronic ignition

system. Only the spark plugs require maintenance.

For recommended spark plugs, see Technical Data.

Remove the ignition cable boot and clean 1.

around the spark plug.

Remove the spark plug with a spark plug 2.

socket wrench.

Check the spark plug. Replace the spark plug 3.

if fouled, the electrodes are burned and if

the insulation is cracked or damaged. Clean

the spark plug with a steel brush if it is to be

reused.

Measure the electrode gap with a gapping tool. 4.

The gap should be .030" (0.75 mm). Adjust as

necessary by bending the side electrode.

Reinsert the spark plug, turning by hand to 5.

avoid damaging the threads.

After the spark plug is seated, tighten it using 6.

a spark plug wrench so that the washer is

compressed. A used spark plug should be

turned

new spark plug should be turned a ¼ turn from

the seated position.

Replace the ignition cable.7.

1

/8 of a turn from the seated position. A

IMPORTANT INFORMATION

Fitting the wrong spark plug type can damage

the engine.

Inadequately tightened spark plugs can

cause overheating and damage the engine.

Tightening the spark plugs too hard can

damage the threads in the cylinder head.

8011-054

Measure the electrode gap

Safety System

The machine is equipped with a safety system that

prevents starting or driving under the following

conditions.

The engine can only be started when:

The mower deck is disengaged. 1.

The steering controls are in the outer, locked 2.

neutral position.

The parking brake is on.3.

Make daily inspections to ensure that the safety

system works by attempting to start the engine

when one of the conditions is not met. Change the

conditions and try again.

If the machine starts when one of these conditions

is not met, turn the machine off and repair the safety

system before using the machine again.

Make sure the engine stops when the park brake is not

engaged and the operator leaves the seated position.

Check that the engine stops if the mower blades are

engaged and the driver temporarily moves off the

drivers seat.

8050-827

Conditions for starting

IMPORTANT INFORMATION

In order to be able to drive, the driver must

sit in the seat and release the parking brake

before the steering controls can be moved into

the neutral position, otherwise the engine will

stop.

Dixon-37

Page 38

MAINTENANCE

Engine Cooling Air Intake

Check that the engine’s cooling air intake is free from

leaves, grass, and dirt.

If the cooling air intake is clogged, engine cooling

deteriorates, which can lead to engine damage.

The cooling air intakes rotates when the engine is

running. Keep ngers away.

Throttle Cable

Check that the engine responds to throttle increases

and that a good engine speed is attained at full

throttle.

If doubts arise, contact the service workshop.

If adjustments are necessary, they can be made as

follows for the lower cable:

Loosen the clamping screw for the cable’s 1.

outer casing and move the throttle to the full

throttle position.

Check that the throttle cable is mounted in the 2.

correct hole in the lower lever, see illustration.

Push the throttle cable’s outer casing as far to 3.

the right as possible and tighten the clamping

screw.

8061-014

Check and clean the cooling air intake

8011-554

Adjusting the throttle cable

Choke Cable

If the engine produces black smoke or is difcult

to start, this can be because the choke cable is

incorrectly adjusted (upper cable).

If doubts arise, contact the service workshop.

If adjustments are necessary, they can be made as

follows:

Loosen the clamping screw for the cable’s 1.

outer casing and push the choke control fully

in.

Check that the choke cable is mounted in 2.

the upper lever, see illustration. Push the

choke cable’s outer casing as far to the left as

possible and tighten the clamping screw.

38-Dixon

8011-555

Adjusting the choke cable

Page 39

MAINTENANCE

Air Filter

Heavy Duty Air Filter

If the engine seems weak or runs unevenly, the air

lter may be clogged. If running with a dirty air lter,

the spark plugs can become fouled.

For this reason, it is important to replace the air lter

regularly (see the heading Maintenance Schedule for

the proper service interval).

IMPORTANT INFORMATION

Operating the engine with loose or damaged

air cleaner components could allow unltered

air into the engine causing premature wear

and failure.

Dust cap

Check the dust cap every day by pressing the rubber

valve with two ngers to let out the dirt.

WARNING!

The engine and the exhaust system,

become very hot during operation.

Risk for burns if touched.

Allow engine and exhaust system to

cool at least two (2) minutes before

servicing.

Air Filter Housing And Filter

Remove the end cover of the air lter housing by

unhooking the two retaining clips at each side.

IMPORTANT INFORMATION

Do not use compressed air to clean the air

lter.

Filter should be assembled dry and not be

oiled.

8011-447

Pressing the rubber valve

8011-448

Removing the end cover

Dixon - 39

Page 40

MAINTENANCE

Fuel Filter

Replace the line-mounted fuel lter every 100 hours

(once per season) or more regularly if it is clogged.

Replace the lter as follows:

Move the hose clamps away from the lter. 1.

Use at-nosed pliers.

Pull the lter loose from the hose ends.2.

Push the new lter into the hose ends. Position 3.

the lter with the “FLOW” arrow pointing up

toward the fuel pump. If necessary, a soap

solution can be applied to the lter ends to

ease mounting.

Move the hose clamps back toward the lter.4.

Fuel Pump Air Filter

Regularly check that the fuel pump’s air lter is free

from dirt.

Remove the screws and open the pump, no hoses

need be removed.

The lter can be cleaned with a brush if necessary.

Replace the lter on the console.

8011-468

Fuel lter

40-Dixon

8009-147

Fuel pump air lter

Page 41

MAINTENANCE

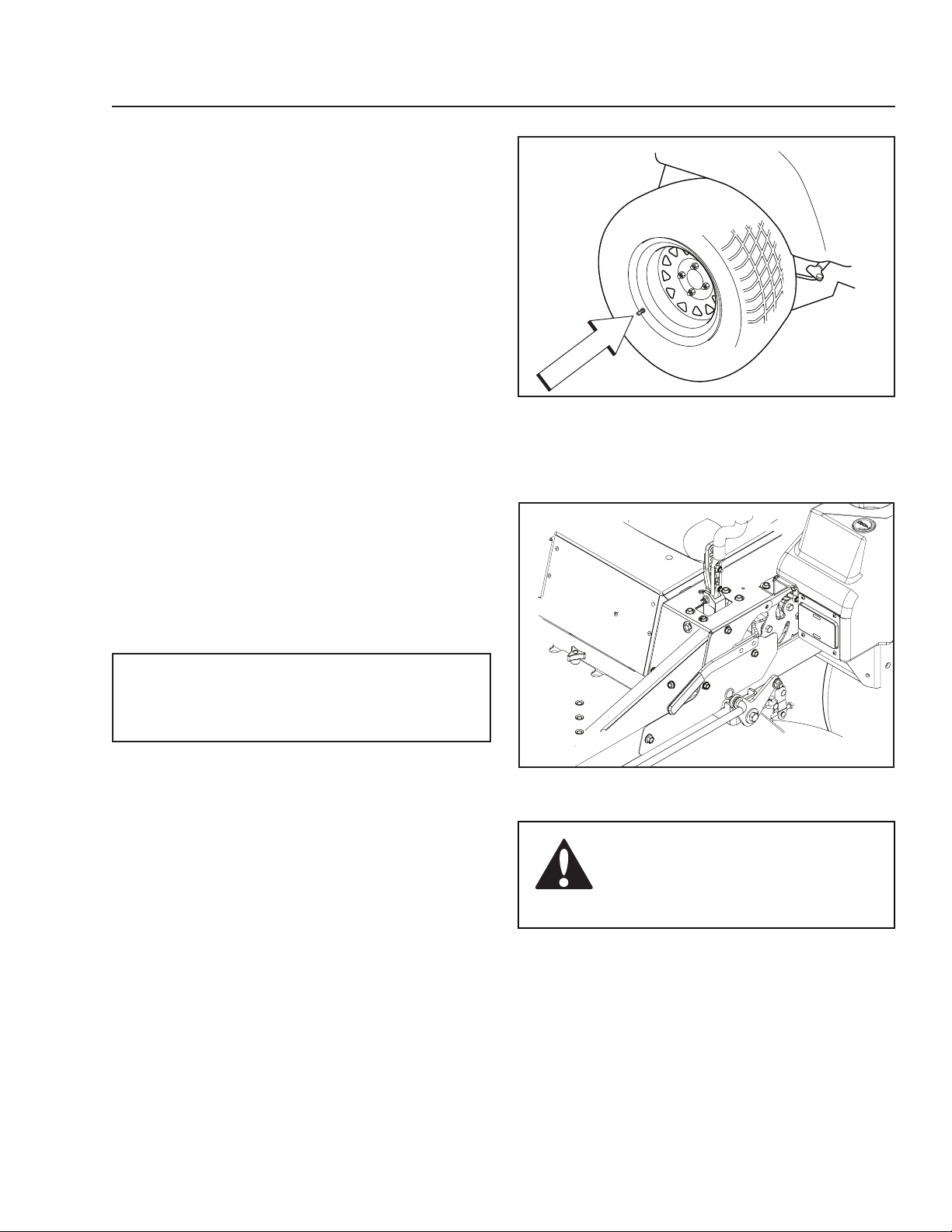

Tire Pressures

All tires should be at 15 psi / 103 kPa / 1 bar.

Parking Brake

Visually check that no damage is found on the lever,

cables, or switch belonging to the parking brake.

Perform a standstill test and check that there is

sufcient braking action.

To adjust the parking brake, contact the Dixon service

workshop.

8011-564

Check tire pressures

IMPORTANT INFORMATION

The machine must be absolutely standing still

when applying the parking brake.

8061-019

Parking brake

WARNING!

Faulty adjustment will result in

reduced braking ability and can

cause an accident.

Dixon-41

Page 42

MAINTENANCE

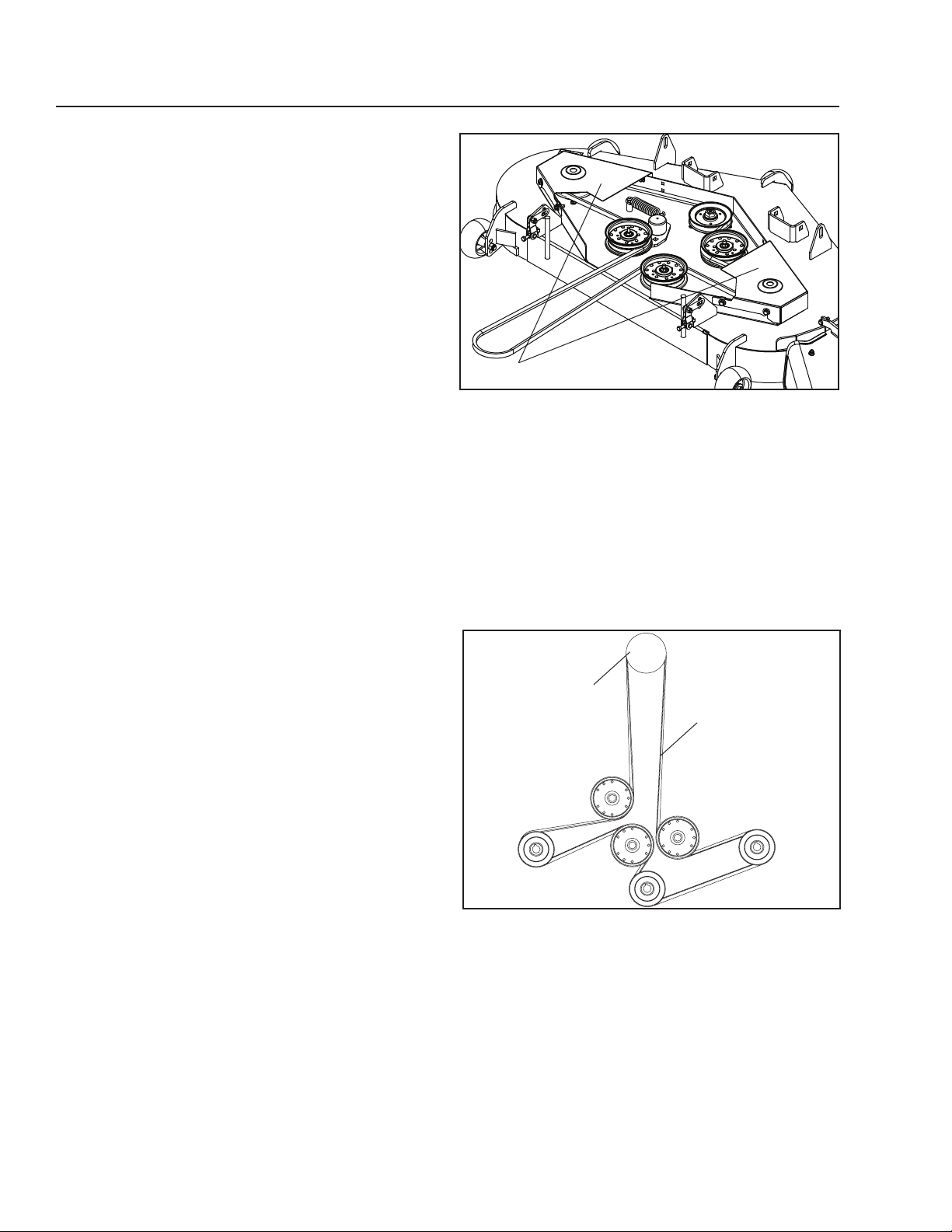

V-belts

Check every 100 hours of operation. Check for severe

cracking and large nicks.

NOTE: The belt will show some small cracks in normal

operation.

The belts are not adjustable. Replace belts if they

begin to slip from wear.

Deck Belt

Park on a level surface. Apply parking brake.1.

Lower the deck into the lowest cutting position.2.

Remove bolts from belt shields and remove 3.

shields.

Remove any dirt or grass that may have 4.

accumulated around the cutter housings and

entire deck surface.

Carefully roll the belt over the top of the cutter 5.

housing pulleys and remove belt.

Belt Shields

Removing deck belt

Deck belt installation

NOTE: For ease in installing the deck belt, refer to

the routing decal on bottom of seat.

Wrap the deck belt around the electric clutch 1.

pulley that is located on the engine shaft.

Route the belt forward and up onto the deck.2.

Place belt around spring loaded idler pulley.3.

Wrap the belt around the stationary idler pulley 4.

and around the mandrel housings.

Push inward on the idler arm and carefully 5.

route belt over stationary idler pulley. Once belt

is properly routed, slowly release idler arm to

tension belt.

Double check belt routing to make sure it 6.

matches the routing decal, and the belt does

not have any twist. Correct as needed.

Replace belt shields on both mandrel housings 7.

and secure with fasteners.

1

2

8011-764

1. Clutch pulley

2. Deck belt

Belt routing, deck belt

42-Dixon

Page 43

MAINTENANCE

Pump Belt

Replacing pump belt

Park the mower on a level surface. Engage the

parking brake.

Belt removal

Remove the deck belt (see Deck Belt 1.

Removal in this section of the manual).

Create slack in the belt by removing the 2.

spring on the pump idler arm.

The belt should now be able to be removed 3.

from the engine pulley and pump pulleys.

Belt installation

Wrap the belt around the pulley1.

Route the belt around the inside of the idler 2.

pulley.

Wrap the belt around the engine pulley.3.

Reattach the spring on the pump idler arm.4.

Reinstall the deck belt. (see Deck Belt 5.

Removal in this section of the manual).

1

2

3

8054-002

Electric clutch1.

Idler spring2.

Clutch stop3.

Pump belt removal

Dixon-43

Page 44

MAINTENANCE

Cutting Blades

In order to attain the best mowing effect, it is important

that the blades are well sharpened and not damaged.

Bent or cracked blades or blades with large nicks

should be replaced.

IMPORTANT INFORMATION

The sharpening of blades should be carried

out by an authorized service workshop.

Damaged blades should be replaced when hitting

obstacles that result in a breakdown. Let the service

workshop decide whether the blade can be repaired/

ground or must be replaced.

Balance the blades after sharpening.

Check the blade mounts.

WARNING!

8011-604-1

Check the blades

Blades are sharp. Protect your hands

with gloves and/or wrap blades with

a heavy cloth when handling.

Blade replacement

• Remove blade bolt by turning counterclockwise.

• Install new or resharpened blade with stamped

“GRASS SIDE” facing towards ground/grass

(down) or “THIS SIDE UP” facing deck and cutter

housing.

• Install and tighten blade bolt securely.

• Torque blade bolt to 90 ft/lbs (122 Nm).

IMPORTANT INFORMATION

Special blade bolt is heat treated.

Replace with a Dixon bolt if required.

3

1

2

Do not use lower grade hardware than

specied.

44-Dixon

1. Blade

2. Blade bolt (special)

3. Cutter housing

Blade attachment

Page 45

MAINTENANCE

Adjusting the Mower Deck

Leveling deck

Adjust the deck while the mower is on a level

surface. Make sure the tires are inated to the correct

pressure. See “Technical Data” under Transmission.

If tires are under or over inated, you cannot properly

adjust your deck.

Four slots control the height and pitch of the mower

deck. The deck should be adjusted slightly higher in

the rear.

NOTE:To insure accuracy of leveling procedure,

mower deck drive belt must be installed prior to

leveling deck.

Wear heavy gloves. Turn each outer blade 1.

tip to align with the deck or in a side-to-side

manner.

Measure from the oor surface up to the 2.

bottom of the blade tip on the discharge side

of the mower deck. Retain this measurement.

Move to the opposite side, check that

measurement is the same. If adjustment

is required, loosen the locknut and move

mounting bolt up or down in slot until both

side-to-side measurements are equal. Retain

measurement.

Turn both outer blades to align with the deck in 3.

front-to-rear manner. Reposition rear mounting

bolts up or down until rear of mower deck is

positioned level to

the side-to-side measurement.

Conrm measurements once again. Blade tips 4.

should be level in a side-to-side manner. In the

rear, blade tips should be level to 1/8" higher

than side-to-side measurement. In the front,

blade tips should be level to 1/8" lower than

side-to-side measurement.

1

/8" higher in the rear than

WARNING!

Before performing any service or

adjustment checklist:

Engage the parking brake.•

Place the Blade switch in the •

disengaged position.

Turn ignition switch to “OFF” •

position and remove the key.

Make sure the blades and all •

moving parts have completely

stopped.

Disconnect the spark plug wire •

from all spark plugs and place

the wire where it cannot come in

contact with the plug.

2

1

2

NOTE: This will place the mower deck in a base

measurement position. Additional adjustment may be

required to achieve desired cut for the type of grass or

conditions being mowed.

8050-829

1. Lift arm

2. Mounting bolts

Leveling the mower deck

Dixon-45

Page 46

MAINTENANCE

Anti-scalp rollers

Anti-scalp rollers are properly adjusted when they

are just slightly off of the ground when the deck is at

the desired cutting height in the operating position.