Dixon Bradford BC114, Bradford BC218, Bradford BC318, Bradford BC328, Bradford BC214 Instruction & Operation Manual

...Page 1

Instruction & Operation Manual

BC-Series Centrifugal Pump

Read and understand this manual prior to

installing, operating or servicing this equipment

Updated March 2012

Page 2

Table of Contents

Safety .......................................................2

Care of Stainless Steel .............................3

Introduction ...............................................4

Mechanical Specications ........................5

Dimensions ............................................6-7

Installation ...........................................8-14

Unpacking ..........................................8

Tools needed .....................................8

'D' seal pump assembly ..................8-9

'DG' seal pump assembly ...........10-11

Location ........................................... 11

Leveling ........................................... 11

Piping guidelines.........................12-14

General .....................................12

Suction .................................12-13

Discharge ..................................13

Valve location ............................14

Electrical .................................................14

Operation ...........................................15-17

Priming the Pump .......................15-16

Starting the Pump ............................17

Stopping the Pump ..........................17

Maintenance ......................................17-19

Scheduled Maintenance ..................17

Disassembly & Inspection................18

Seal Maintenance & Repair .............19

Troubleshooting .................................20-21

Model No.s & Part No.s .....................22-25

Pump model No.s ............................22

Motor model No.s ............................23

Part number key ..............................24

Common parts .................................24

Variable parts ...................................25

Repair Kits ..................................26-27

Warranty .................................................28

Safety Information

The following DANGER, WARNING and CAUTION signs are contained in this manual.

To avoid serious injury and/or possible damage to equipment, pay attention to these

messages.

Hazards or unsafe practices which could result in severe personal injury or

death. The word DANGER is used in the most extreme cases.

Hazards or unsafe practices which could result in minor or moderate injury.

May also be used to alert against an unsafe operating or maintenance

practice.

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

Use only replacement parts and devices recommended by the manufacturer to maintain the

integrity of the equipment. Make sure the parts are properly matched to the equipment series,

model, serial number and revision level of the equipment.

Safety labels are placed on every pump. Do not remove any labeling on any BC-series pump.

Replace any label that is missing.

DO NOT modify any Bradford™ product. Non-factory modications could create hazardous

conditions and voids all warranties. DO NOT attempt to use a Bradford™ product in any

application that exceeds the product rating.

2 Instruction & Operation Manual800.789.1718

Page 3

PUMP

Care of Stainless Steel

The stainless steel components in Dixon Sanitary equipment are machined, welded and assembled by skilled craftsmen using

manufacturing methods that preserve the corrosion-resistant quality of the stainless steel.

Retention of corrosion-resistant qualities under processing conditions requires regular attention to the precautions listed below.

1. Regularly check all electrical devices connected to the equipment for stray currents caused by

improper grounding, damaged insulation or other defects. Corrosion: Pitting often occurs when

stray currents come in contact with moist stainless steel.

2. Never leave rubber mats, ttings, wrenches, etc. in contact with stainless steel. Corrosion: Pitting or galvanic action.

Objects retard complete drying, preventing air from reforming the protective oxide lm. Galvanic corrosion occurs when

two dissimilar metals touch when wet.

3. Immediately rinse equipment after use with warm water until the rinse water is clear. Clean the equipment (manual or

CIP) as soon as possible after rinsing. Corrosion: discoloration, deposits, pitting. Product deposits often cause pitting

beneath the particles.

4. Use only recommended cleaning compounds. Purchase chemicals from reputable and responsible chemical

manufacturers familiar with stainless steel processing equipment, they continuously check the effects of their products

on stainless steel.

5. Use cleaning chemicals exactly as specied by the manufacturer. Do not use excessive concentrations, temperatures

or exposure times. Corrosion: Pitting, discoloration, stress cracks. Permanent damage often occurs from excessive

chemical concentrations, temperatures or exposure times.

6. For manual cleaning, use only soft non-metallic brushes, sponges or pads. Brush with the grain on polished surfaces,

avoid scratching the surface. Corrosion: Pitting, scratches. Metal brushes or sponges will scratch the surface and

promote corrosion over a period of time. Metal particles allowed to remain on a stainless steel surface will cause pitting.

7. Use chemical bactericides exactly as prescribed by the chemical manufacturer in concurrence with local health

authority. Use the lowest permissible concentration, temperature and exposure time possible. Flush immediately after

bacterial treatment. In no case should the solution be in contact with stainless steel more then 20 minutes. Corrosion:

Protective lm destroyed. Chlorine and other halogen bactericides can destroy the protective lm. A few degrees

increase in temperature greatly increases chemical activity and accelerates corrosion.

8. Regularly inspect the joints in pipelines. Be sure all connections are tight tting without binding. Corrosion: Crevice

corrosion. Small crevices caused by improperly seated gaskets will promote crevice corrosion. Stainless steel under

stress will develop stress cracking especially in the presence of bactericides containing chlorine.

9. Regularly inspect equipment for surface corrosion (i.e. pitting deposits, stress cracks, etc.). If deposit or color corrosion

is detected, remove it immediately using mild scouring powder and detergents. Rinse thoroughly and allow to air dry.

Review production and cleaning procedures to determine the cause. Note: If corrosion is not removed, the protective

lm cannot be restored and corrosion will continue at an accelerated rate.

3Instruction & Operation Manual 800.789.1718

Page 4

Introduction

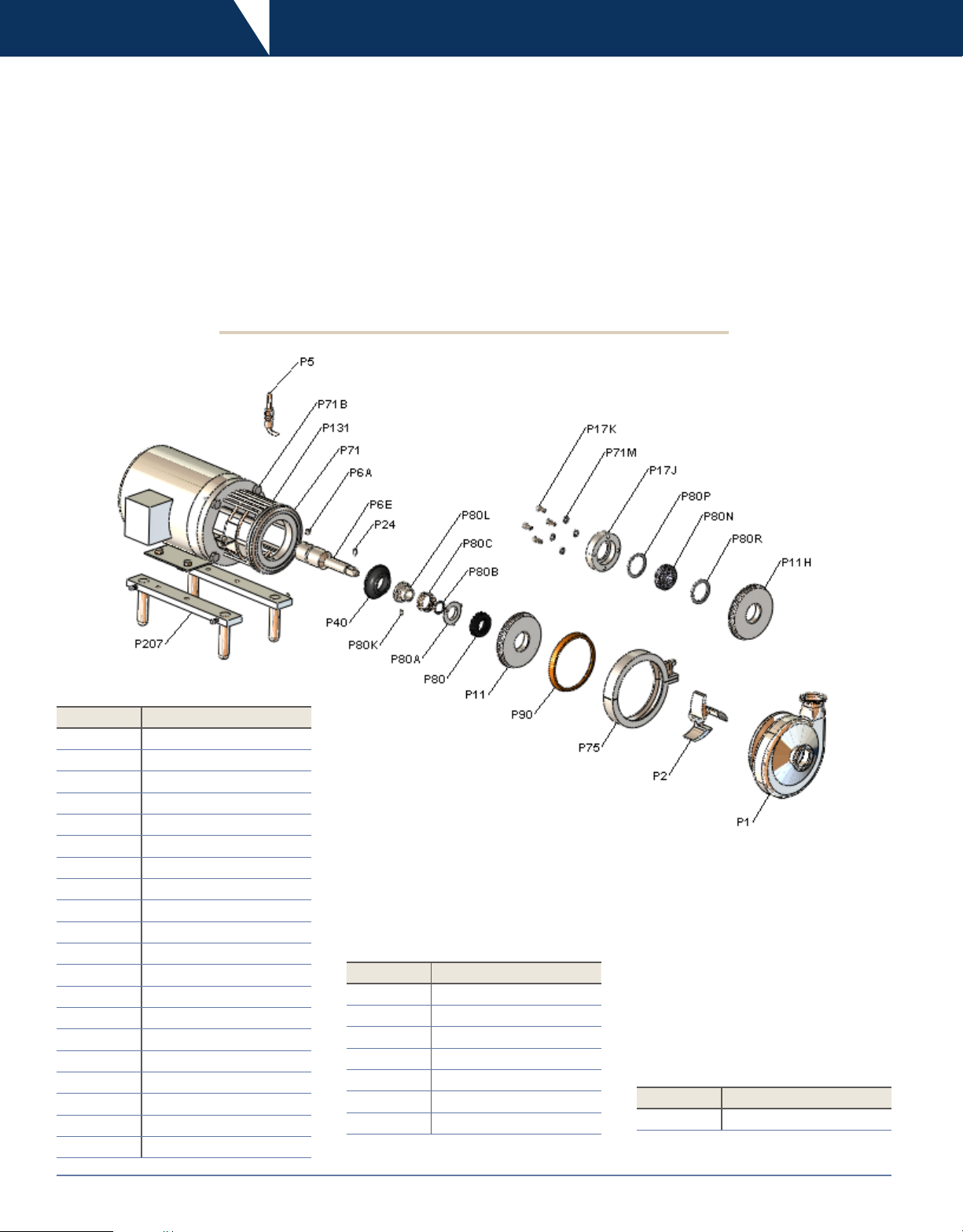

This manual contains installation, operation, cleaning, repair instructions, model numbering structure and parts list for the

Bradford™ BC-Series centrifugal pumps.

The Bradford™ BC-Series centrifugal pump is made up of two sections, the pump components (uid end) and the motor

assembly. The pump is mounted on the drive motor with an adapter and is coupled to the motor with a stainless steel stub

shaft. The pump impeller is mounted on the stub shaft and is secured with a oating impeller retainer pin.

The casing is joined to the adapter by a heavy duty cast clamp. This design allows the volute outlet to be rotated to various

positions.

An adjustable leg kit is an option for mounting the drive motor and is designed to meet sanitary requirements. This

conguration simplies the installation and ease of leveling.

Part No. Description

P1 Casing

P2 Impeller

P6A Shaft Set Screws

P6E Stub Shaft

P11 'D' Back Plate

P11F Back Plate Pins*

P24 Impeller Retainer

P40 Deector

P71 Adapter

P71A Adapter Pins*

P75 Clamp Assembly

P80 Carbon Seal

P80A Seal Cup

P80B Seal O'Ring

P80C Spring

P80K Seat Screw

P80L Drive Collar

P90 Casing Gasket

P131 Guard Assembly

P207 Leg Kit

*not used on BC114/214 Models

4 Instruction & Operation Manual800.789.1718

Part No. Description

P11H 'DG' Back Plate

P17J Gland Ring

P17K Gland Bolt

P17M Washers

P80N Seal Seat

P80P Outboard Gasket

P80R Inboard Gasket

DG Seal

F Seal

Part No. Description

P5 'DG' Back Plate

Page 5

Mechanical Specications

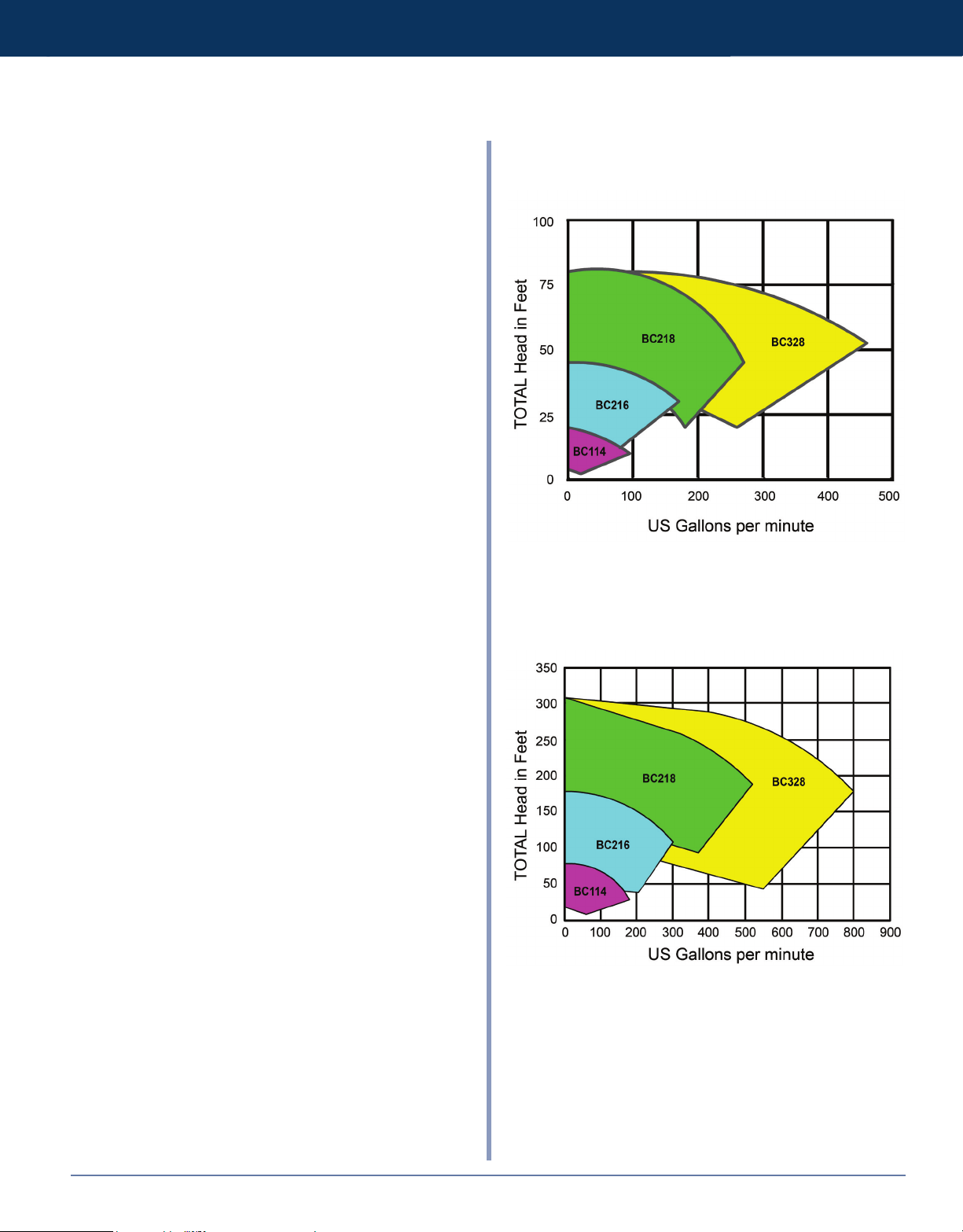

Standard Construction 1750 RPM

• Volute: 316L stainless steel

• Impeller: CF8M (316) stainless steel

• Backplate: 316L stainless steel

• Stub Shaft: 316L stainless steel

• Adapter: 304 stainless steel

• Optional Leg Kit: 304 stainless steel

• Seal Types: externally balanced 'D','DG', and 'F' with

clamped in seat

• Rotary Seal Material: carbon and silicon carbide

• 'DG' Seal Seat Material: silicon carbide, ceramic and

tungsten carbide

• Elastomers: Buna, EPDM, silicone and FKM

• Finish: sanitary polish 32RA

PUMP

Performance Characteristics

• Nominal Capacity: up to 780 GPM

• Temperature: 32°F to 212°F, consult factory for other

temperatures

• Nominal speed: up to 3500 RPM - 60 Hz

Motors and Mounting

• Motor: standard C-face, 1750 and 3450 RPM, TEFC and

washdown, foot mounted

• Additional motor types available upon request

• Mounting: pump head mounted to a C-Face motor

3500 RPM

5Instruction & Operation Manual 800.789.1718

Page 6

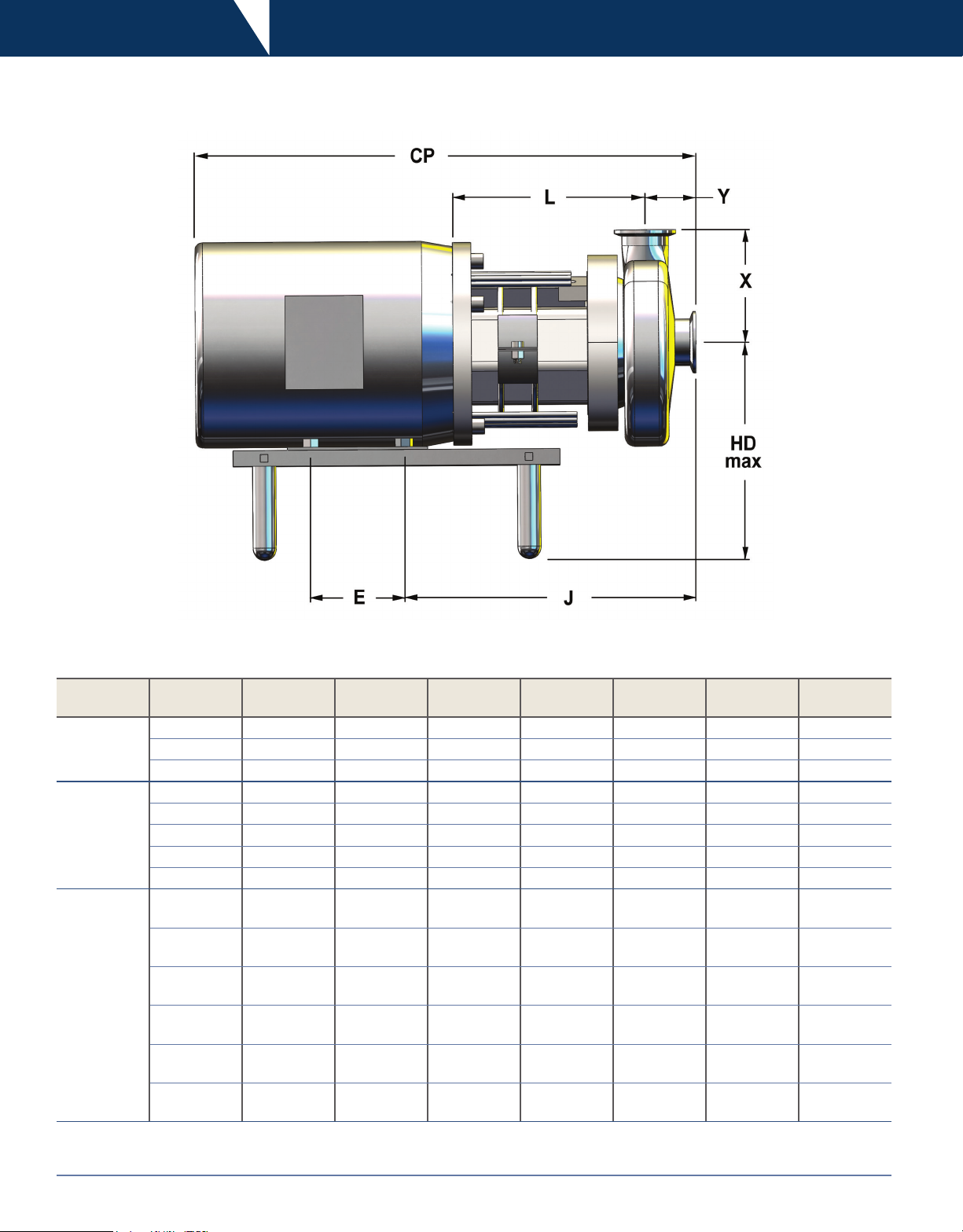

Dimensions

All dimensions are given in inches

Pump

Model

BC114

BC216

BC218

&

BC328

* only applies to the BC328

Frame

Size

56C 3.63 1.63 18.00 3.00 7.00 10.60 6.22

140TC 3.63 1.63 18.20 4.00 7.00 10.80 6.22

180TC 3.63 1.63 18.80 4.50 8.00 11.00 6.78

56C 4.50 1.94 16.26 3.00 7.00 8.81 6.06

140TC 4.50 1.94 18.70 4.00 7.00 11.25 6.06

180TC 4.50 1.94 22.00 4.50 8.00 12.00 6.69

210TC 4.50 1.94 25.70 5.50 8.75 13.90 7.81

250TC 4.50 1.94 31.40 10.00 9.75 15.70 8.50

140TC 5.50

180TC 5.50

210TC 5.50

250TC 5.50

280TC 5.50

320TC 5.50

X Y CP E HDmax J L

1.94

2.25 *

1.94

2.25 *

1.94

2.25 *

1.94

2.25 *

1.94

2.25 *

1.94

2.25 *

18.50 4.00 7.00 11.10 6.31

22.50 4.50 8.00 12.00 6.94

26.30 5.50 8.75 14.50 7.31

31.20 10.00 9.75 15.50 8.19

33.80 11.00 10.50 15.60 8.81

36.70 12.00 11.50 17.90 9.69

6 Instruction & Operation Manual800.789.1718

Page 7

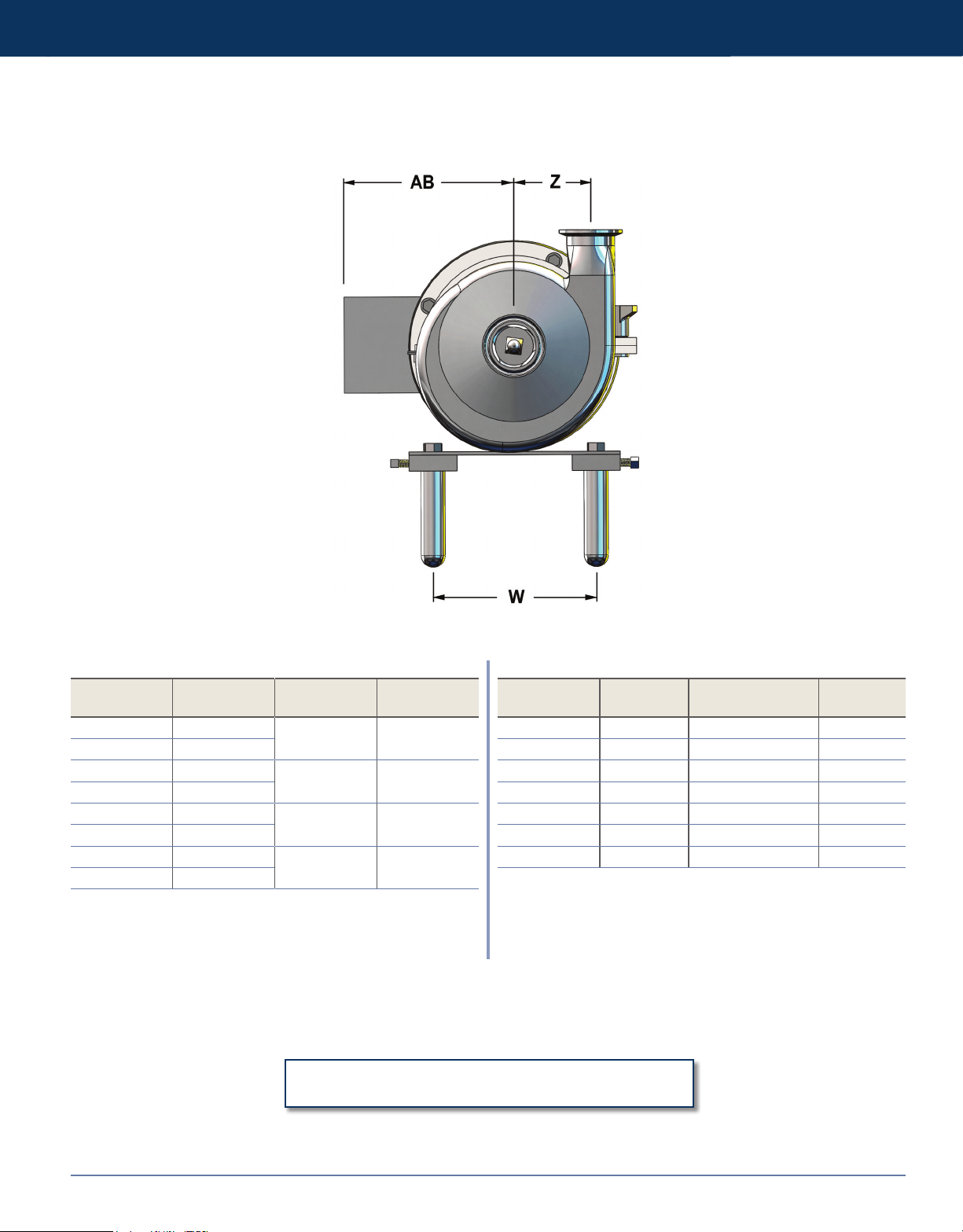

Dimensions

All dimensions are given in inches

PUMP

Pump

Model

BC114 1.5

BC214 2

BC216 2

BC516 2.5

BC218 2

BC318 3

BC328 3

BC428 4

INLET OUTLET Z

Frame

Size

1.5 2.63

1.5 3.69

1.5 4.75

2 4.75

All dimensions are approximate;

for exact dimensions contact Dixon Sanitary

56C 5.53 0.87 4.85

140TC 5.53 0.87 5.50

180TC 7.00 0.87 7.50

210TC 7.62 0.87 8.50

250TC 10.80 2.05 10.00

280TSC 13.40 2.36 11.00

320TSC 14.37 2.36 12.50

AB

Conduit Entry

diameter

W

7Instruction & Operation Manual 800.789.1718

Page 8

Installation

Unpacking

Carefully unpack all parts of the pump and inspect for damages that may have occurred during shipment. Report any

damages to the carrier immediately.

The ports on the pump are protected with a plastic cover. If any covers are missing or damaged, inspect the ports on the

pump thoroughly for any damage.

Tools Needed

If you have purchased a uid end and will be assembling the pump to a motor the following tools will most likely be used:

• Flat head screw driver

• Allen wrenches

• Open ended wrenches

• Feeler gauge

• Calipers

• Pliers

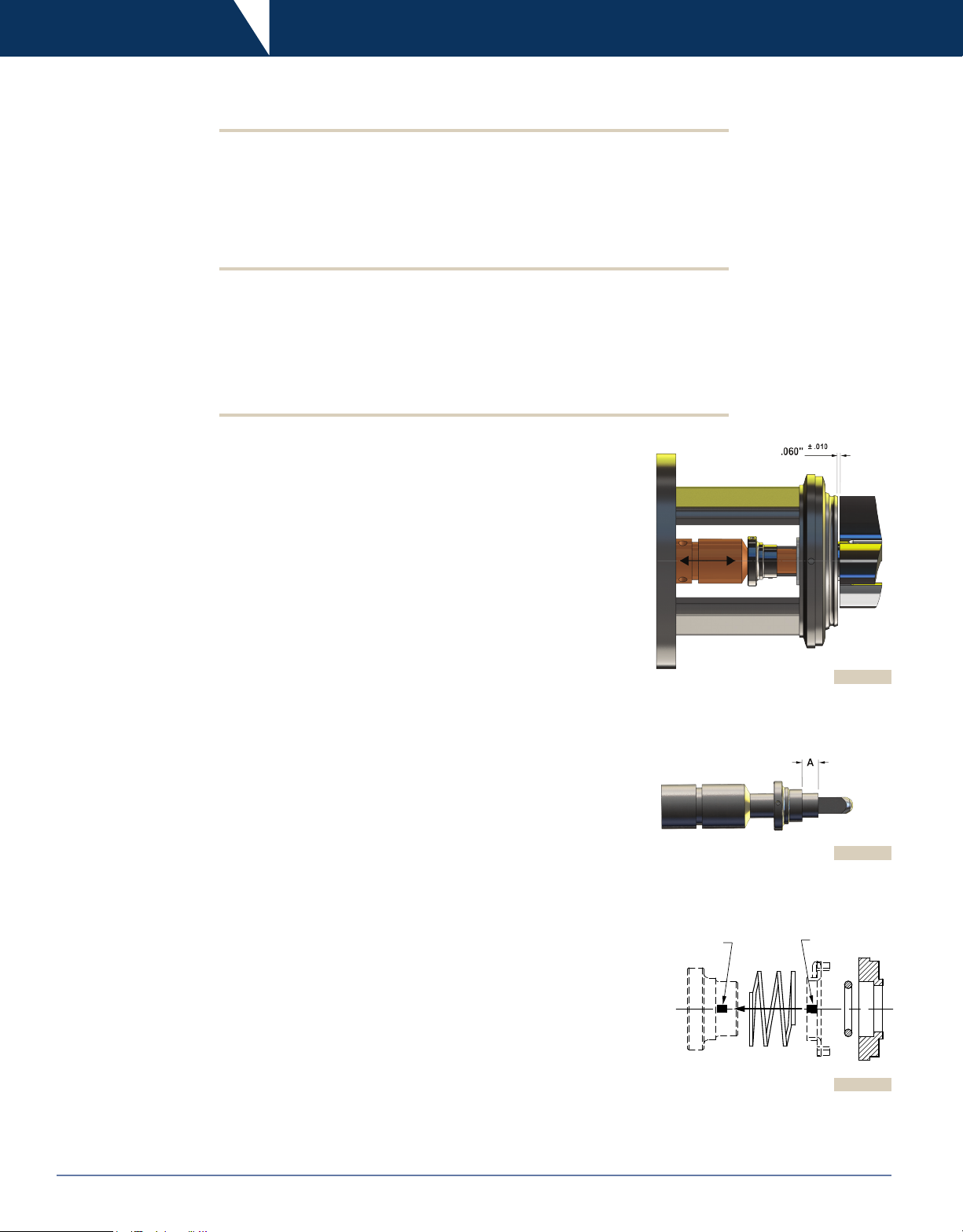

'D' Seal Pump Assembly

1. Install the adapter onto the motor using (4) bolts and (4) lock washers. Position

the adapter such that the threaded seal ush adapter hole is located on the top.

2. Install adapter pins by tapping the knurled end into the holes until ush with the

outside diameter of the adapter face.

3. Stub shaft alignment:

a. Make sure that the key is in the motor shaft, then slide stub shaft onto motor

shaft. Do not tighten set screws.

b. Set back plate on adapter face.

c. Slide impeller onto stub shaft end.

d. Using feeler gauge between back plate and impeller position stub shaft so

that the gap is equal to .060"

e. Tighten set screws on stub shaft.

f. Remove impeller and back plate.

4. Slide deector over shaft large end rst until it locks into position at the base of

the stub shaft.

± .010

. (see gure no.1)

• Rubber mallet

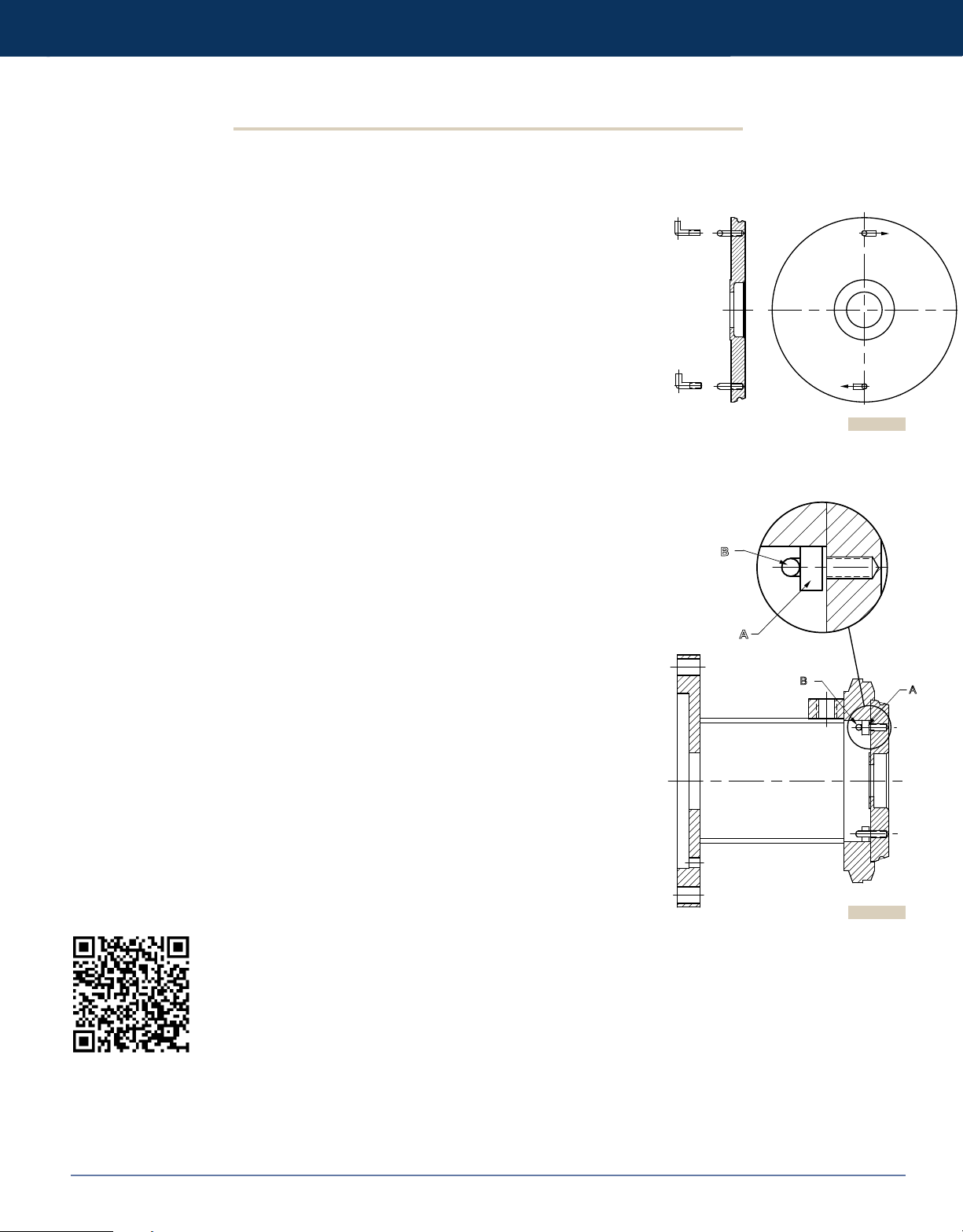

Figure No. 1

5. Slide drive collar large end rst over the stub shaft. Position collar and set

dimension 'A' to 0.6". (see gure no.2)

6. Tighten collar set screws.

a. Place seal spring over stub shaft and down onto the drive collar.

b. Place cup on top of the spring with slot lining up with extrusion on drive collar.

c. Place seal o-ring into the back of the carbon seal and slide the seal o-ring

assembly onto stub shaft, lining the notches in the carbon seal up with the

pins on the cup.

d. Check to make sure that slot in cup is still aligned with the extrusion in the

drive collar. (see gure no.3)

continued on next page ...

8 Instruction & Operation Manual800.789.1718

COLLAR

EXTRUSION

Figure No. 2

CUP

SLOT

Figure No. 3

Page 9

Installation

'D' Seal Pump Assembly

... continued from previous page

7. Screw back plate pins into back plate. (see gure no.4)

8. Position casing gasket on circumference of the back plate.

9. Check that both the seal face on the back plate and the seal face of the carbon seal

are completely clean. Even the oils from your skin are not acceptable on these two

surfaces. Clean faces thoroughly with a clean, lint free cloth.

10. Assemble back plate to adapter.

a. Place the back plate assembly onto the adapter. Put even pressure down on the

back plate until it is completely seated on the adapter. (see gure no.5)

b. Check that the drive collar extrusion is fully engaged in the slot on the cup.

c. Rotate the back plate so that the back plate pins engage the adapter pins, holding

it in place.

d. With black plate depressed completely to the adapter, inspect the spring to

insure there is some space between the coils. If the coil is too tight, repeat step

5 and add 0.05" to dimension 'A' and re-check spring coil. Repeat if necessary.

PUMP

Figure No. 4

11. Install the impeller.

a. Insert the impeller retainer into the hole near the end of the stub shaft so that it is

centered in the shaft.

b. Slide the impeller onto the stub shaft.

c. Using a small hex key or screw driver push the impeller retainer so that it is

sticking out one end as far as it will allow, thus locking the impeller into place.

12. Close and seal the pump.

a. Place volute onto assembly with discharge outlet pointing in the desired position.

b. While applying sufcient pressure to bring adapter and volute together put on and

tighten clamp.

13. Attach and tighten guard assembly making sure that the seal ush tab on the adapter

lines up with the indent on the corresponding side of the guard.

Scan this code on

your smart phone to

visit the YouTube

video for detailed

Click here to visit the YouTube

assembly video for D Seal

Pumps

assembly instructions

B

A

B

Figure No. 5

A

9Instruction & Operation Manual 800.789.1718

Page 10

Installation

'DG' Seal Pump Assembly

1. Install the adapter onto the motor using (4) bolts and (4) lock washers. Position

the adapter such that the treaded seal ush adapter hole is located on the top.

2. Stub shaft alignment:

a. Make sure that the key is in the motor shaft, then slide stub shaft onto motor

shaft. Do not tighten set screws.

b. Set back plate on adapter face.

c. Slide impeller onto stub shaft end.

d. Using feeler gauge between back plate and impeller position stub shaft so

that the gap is equal to .060"

e. Tighten set screws on stub shaft.

f. Remove impeller and back plate.

3. Slide deector over shaft large end rst until it locks into position at the base of

the stub shaft.

4. Slide drive collar large end rst over stub shaft until it will not slide any further.

± .010

. (see gure no.6)

Figure No. 6

5. Tighten collar set screws.

a. Place seal spring over stub shaft and down onto the drive collar.

b. Place cup on top of the spring with slot lining up with extrusion on drive collar.

(see gure no.7)

c. Place seal o-ring into the back of the carbon seal and slide the seal o-ring

assembly onto stub shaft, lining the notches in the carbon seal up with the

pins on the cup.

d. Check to make sure that slot in cup is still aligned with the extrusion in the

drive collar. (see gure no.7)

6. Assemble 'DG' seal back plate. (see gure no.8)

7. Position casing gasket on circumference of the back plate.

8. Check that both the seal face on the back plate and the seal face of the carbon

seal are completely clean. Even the oils from your skin are not acceptable on

these two surfaces. Clean faces thoroughly with a clean, lint free cloth.

9. Assemble back plate to adapter.

a. Place the back plate assembly onto the adapter. Put even pressure down on

the back plate until it is completely seated on the adapter.

b. Check that the drive collar extrusion is fully engaged in the slot on the cup.

10. Install the impeller.

a. Insert the impeller retainer into the hole near the end of the stub shaft so that

it is centered in the shaft.

b. Slide the impeller onto the stub shaft.

c. Using a small hex key or screw driver push the impeller retainer so that it is

sticking out one end as far as it will allow, thus locking the impeller into place.

COLLAR

EXTRUSION

CUP

SLOT

Figure No. 7

Figure No. 8

11. Close and seal the pump.

a. Place volute onto assembly with discharge outlet pointing in the desired

position.

b. While applying sufcient pressure to bring adapter and volute together put on

and tighten clamp.

10 Instruction & Operation Manual800.789.1718

continued on next page ...

Page 11

Installation

PUMP

... continued from previous page

12. Attach and tighten guard assembly making sure that the seal ush tab on the adapter

lines up with the indent on the corresponding side of the guard.

Scan this code on

your smart phone to

visit the YouTube

video for detailed

assembly instructions

'DG' Seal Pump Assembly

Click here to visit the YouTube

assembly video for BC series

pumps with DG seals

Optional Leg Kit Installation and Leveling

The pump can be easily leveled by installing the optional leg

kit. Loosen the set screws and adjust the leg to the proper

level, then tighten the set screws when level. (see the

diagram to the right)

Scan this code on

your smart phone to

visit the YouTube

video for detailed

assembly instructions

Click here to visit the YouTube

installation video for the BC Series

pump optional leg kit

Location

• Pump will perform at its best when located as close as possible to the liquid supply.

• Supply piping should be short and straight to insure the pump has an adequate supply of liquid to it at all times.

• The pump should be located in an area where it is easy to inspect, do preventative maintenance or repair.

• Motor must be in area where it will not be ooded.

11Instruction & Operation Manual 800.789.1718

Page 12

Installation

Piping: General Guidelines

Improper piping can lead to a number of problems

with pump performance which will lead to increased

maintenance costs.

• Insure piping is independently supported at both the

suction and discharge ports of the pump.

(see the diagram to the right)

• Piping must be properly aligned to prevent any strain on

pump volute.

• Try to have as few bends as possible in all piping.

Piping: Suction Guidelines

PROXIMITY

TO

VOLUTE

TUBING

HANGER

TUBING

HANGER

• Make sure line sizes used are equal to or larger than suction side (supply side) port connections on pump.

• Suction side needs to be short and straight as possible. Any restrictions will affect the NPSHa. Adequate NPSHa must be

insured.

• Maintain a straight length of pipe at a minimum of 8 x diameters long at the pump inlet.

(see the diagram below)

MINIMUM LENGTH = 8 x DIAMETER

DIAMETER

• To prevent air leaks, insure all joints in suction line are well sealed.

continued on next page ...

12 Instruction & Operation Manual800.789.1718

Page 13

Installation

Piping: Suction Guidelines

... continued from previous page

• Use an eccentric reducer with straight side up to prevent

air pockets from forming which will result in a decrease in

pump efciency.

(see the diagram to the right)

• To prevent a high point in the suction line resulting

in an air pocket being formed affecting proper pump

performance, horizontal suction pipes must have a

gradual rise to the pump.

Piping: Discharge Guidelines

• Discharge side should be short and direct. Use a minimal number of restrictions.

(see the diagram to the right)

PUMP

CONCENTRIC

REDUCER

ECCENTRIC

REDUCER

DIAMETER

• Vertical or top horizontal pump discharge position is preferred.

(see the diagram at the bottom)

• While increasing the discharge side line size is recommended, please note:

> Using too large of a line size will lead to pump overload.

> Using a smaller than recommend line size will increase the pump head but lower the

ow.

• Types of reducers to use:

> If vertical discharge – concentric

> If horizontal discharge – eccentric with straight side down

MINIMUM LENGTH

= 10 x DIAMETER

BETWEEN

0° & 90°

13Instruction & Operation Manual 800.789.1718

Page 14

• An isolation valve should be installed at both

the suction and discharge sides of the pump.

This will allow you to remove the pump for

preventative maintenance or repair without the

need to drain your system.

(see the diagram to the right)

• If pump is not in a ooded suction condition,

install either a foot valve or system check valve

to insure pump volute is ooded for priming.

• In order to provide pump ow rate control,

a control valve should be installed in the

discharge piping to prevent motor overload.

Installation

Piping: Valve location

CONTROL

VALV E

CHECK

VALVE

DIAMETER

MINIMUM LENGTH

= 10 X DIAMETER

PSI

MINIMUM LENGTH = 8 X DIAMETER

DIAMETER

ISOLATION

VALVE

Electrical

All power must be off and locked out during the installation process.

Only registered electricians should do the electrical installation.

• Follow motor manufacturer’s installation procedures.

• Verify motor nameplate data is compatible with existing

electrical supply.

• Verify pump rotation. An arrow sticker is supplied

with every pump to show correct pump rotation. If the

arrow stickers are missing, contact Dixon Sanitary for a

replacement.

• Correct rotation is counter clockwise when facing pump

inlet connection.

14 Instruction & Operation Manual800.789.1718

Page 15

Operation

Priming the Pump

To avoid damage to the pump, the pump casing must be ooded with

liquid BEFORE starting the pump.

Note: This is not a self priming pump. Other means must be installed to prime the pump.

Fluid supply above the pump:

1. Open supply line isolation valve.

2. Vent any entrapped air by opening the discharge valve.

3. After volute is ooded, start pump.

If the uid supply is below the pump see page 16.

PUMP

CONTROL

VALV E

CHECK

VALVE

SUPPLY SOURCE

ABOVE PUMP LEVEL

ISOLATION

VALVE

15Instruction & Operation Manual 800.789.1718

Page 16

CONTROL

VALV E

Operation

Priming the Pump

Fluid supply below the pump:

1. Close discharge valve and open air vents.

2. Open valve in external priming supply line. Close once

liquid ows from vent valves.

3. Close vent valves.

4. Turn off priming supply line.

5. Start pump.

If the uid supply is above the pump see page 15.

CHECK

VALVE

EXTERNAL PRIMING

SUPPLY LINE

ISOLATION

VALVE

FOOT

VALV E

Note: It is recommended to use a foot/check valve system to keep the pump primed. Otherwise the pump must be primed

before each operation.

16 Instruction & Operation Manual800.789.1718

Page 17

Operation

Starting the Pump

1. Insure pump suction is ooded using either method as explained in the previous priming section.

2. Check for any closed valves or obstructions in the suction and discharge lines.

3. Start the motor.

4. Verify liquid is owing and there is no piping connection or mechanical seal leaks.

5. Adjust throttling valve on discharge line to desired ow.

Stopping the Pump

1. Shut off power to motor.

2. Suction and discharge valves are to be shut off.

Be advised the pump does not act as a shut off valve. The liquid will ow freely though the pump.

PUMP

Maintenance

Scheduled Maintenance

Preventative maintenance will increase the life of your pump. Documentation of any maintenance will help to diagnose

potential problems and help in determining solutions.

Scheduled maintenance will require disassembly of the pump and the following:

1. Inspect casing for:

• Unusual wear

• Damage to ports

2. Inspect casing gasket for

• Wear

• Damage

Monitor pump throughout its use for any of the following problems: see troubleshooting guide on pages 20-21, for possible

solutions.

3. Inspect impeller for

• Unusual wear

• Damage

4. Inspect mechanical seal for wear

5. Inspect shaft for

• Straightness

• Tightly installed

• Unusual pump or motor noise

• Excessive vibration

• Seal leakage

• Piping leaks at ports

• Unexpected change in ow or head

• Temperature changes

• Excessive power consumption

• Overheating motor

17Instruction & Operation Manual 800.789.1718

Page 18

Maintenance

Disassembly & Inspection

1. Turn off and lock out power to pump motor.

2. Isolate pump from system.

3. Relieve system pressure.

4. Remove suction and discharge lines from volute.

5. Remove seal guard assembly.

6. Loosen clamp assembly and remove.

7. Remove casing and inspect for unusual wear or port damage.

8. Push back impeller and center impeller retainer in the stub shaft.

9. Remove impeller and inspect for unusual wear or damage.

10. Remove impeller retainer.

11. Rotate back plate to disengage from adapter pins and remove.

12. See seal removal and inspection instructions on page 19.

13. Inspect shaft to insure straightness and that it is fastened securely to the motor shaft.

14. If stub shaft needs to be removed, remove deector rst.

15. If necessary remove stub shaft by loosening the two (2) set screws. If the shaft does not remove easily, use a pry bar on

the periphery of the base of the shaft.

Scan this code on

your smart phone to

visit the YouTube

video for

BC Series Disassembly D-Seal

Scan this code on

your smart phone to

visit the YouTube

video for

BC Series Disassembly DG-Seal

Click here to visit the YouTube

disassembly video for BC Series

pumps with D seals

Click here to visit the YouTube

disassembly video for BC Series

pumps with DG seals

18 Instruction & Operation Manual800.789.1718

Page 19

Maintenance

Seal Maintenance & Repair

See page 18 for disassembly instructions.

'D' Seal

1. When removing back plate inspect the stationary seal seat area for wear and/or damage.

Depending upon the extent of wear, the back plate may need to be resurfaced or

replaced.

2. Remove the carbon seal, o-ring, cup and spring.

3. Inspect carbon seal. Replace carbon seal if "A" dimension is less than 1/32".

(see the diagram to the right)

4. If carbon seal is replaced, drive collar setting should be veried and adjusted as needed.

'DG' Seal

1. When removing back plate inspect for any nicks or scratches.

2. Remove the four (4) bolts from the gland assembly.

3. Inspect 'DG' seal seat. This is a reversible part and if there is wear on one side you can

ip it to the other side until that side is worn.

4. Inspect gland ring and gaskets. Replace as needed.

5. Remove the carbon seal, o-ring, cup and spring.

6. Inspect carbon seal. Replace carbon seal if "A" dimension is less than 1/32".

(see the diagram to the right)

PUMP

Return to disassembly instructions on page 18.

Scan this code on

your smart phone to

visit the YouTube

video for

BC Series Repair Kit #1

Click here to visit the YouTube

instruction video for the BC Series pump

Repair Kit # 1

Scan this code on

your smart phone to

visit the YouTube

video for

BC Series Repair Kit #4

Click here to visit the YouTube

instruction video for the BC Series pump

Repair Kit #4

Scan this code on

your smart phone to

visit the YouTube

video for

BC Series Repair Kit #3

Click here to visit the YouTube

instruction video for the BC Series pump

Repair Kit #3

Scan this code on

your smart phone to

visit the YouTube

video for

BC Series DG Repair Kit

Click here to visit the YouTube

instruction video for the BC Series pump

DG Repair Kit

19Instruction & Operation Manual 800.789.1718

Page 20

Troubleshooting

Dixon Sanitary BC-Series pumps are manufactured and inspected to meet sanitary standards. Occasional problems may

arise. The following guide will help determine the possible cause and offer suggestions on corrections to maximize the

performance of your pump. In case of any electric motors issues, contact the motor manufacturer directly. If you have any

questions or concerns in regards to your BC-Series pump, we encourage you to contact Dixon Sanitary.

PROBLEM POSSIBLE CAUSE SUGGESTED ACTION

Not enough or no discharge No uid reaching pump. Need to prime pump. Installation of a priming system is

recommended.

Suction or discharge closed or

blocked.

Motor rotation incorrect. Adjust motor electrical wiring to correct rotation.

Speed too slow (low voltage,

wrong frequency, wrong

motor).

Impeller damaged. Replace impeller.

Seal area or supply area has

an air leak.

Excessive air in material. Make any adjustments in system to insure excess air is

Discharge head too high. Adjust system to lower discharge head.

Suction lift too high. Adjust system to lower suction lift.

Insufcient NPSH (Net Positive

Suction Head) available.

Impeller diameter not correct

for application.

Not Enough Pressure Seal area or supply area has

an air leak.

Motor rotation incorrect. Adjust motor electrical wiring to correct rotation.

Speed too slow (low voltage,

wrong frequency, wrong

motor).

Excessive air in material. Make any adjustments in system to insure excess air is

Impeller diameter not correct

for application.

Motor Overload/Excessive

Power Consumption

Discharge is too high. Restrict discharge to lower ow rate.

Impeller is binding. Inspect pump and check for any damage, misalignment or

Seal binding. Inspect pump and replace any damaged or worn parts.

Discharge is too low. Increase discharge head.

Liquid is heavier or more

viscous than rating.

Electrical supply, voltage or

frequency incorrect.

Faulty electrical connections. Check wiring and repair/replace as necessary.

Overload heaters too small. Inspect and replace as necessary.

Defective motor. Contact motor manufacturer for possible warranty or repair.

Open suction. If plugged, shutdown pump and remove

blockage. If closed, check all valves for proper positions.

Adjust voltage and frequency. Change motor if necessary.

Replace seal if needed. Check all other areas for air leaks

and repair.

removed before material reaches the pump.

Adjust system to provide correct NPSHa.

Contact: Dixon Sanitary 800-789-1718

Replace seal if needed. Check all other areas for air leaks

and repair.

Adjust voltage and frequency. Change motor if necessary.

removed before material reaches the pump.

Contact: Dixon Sanitary 800-789-1718

interference. Replace any damaged or worn parts.

Contact: Dixon Sanitary 800-789-1718

Make any adjustments needed up to replacing the motor.

Replace if needed.

20 Instruction & Operation Manual800.789.1718

Page 21

PUMP

Troubleshooting

PROBLEM POSSIBLE CAUSE SUGGESTED ACTION

Excessive Vibration/Pump

is Noisy

Rapid Seal Wear Improper installation of

Pump Leaks Inlet/Outlet Inspect for missing union gaskets, loose connections or

Any Other Issue Contact: Dixon Sanitary 800-789-1718

Pump not level. Inspect installation of pump and correct level.

Non-supported piping. Verify piping support follows recommendations in installation

portion of this manual.

Not enough or no material

reaching pump.

Insufcient NPSH (Net Positive

Suction Head) available.

Impeller and/or shaft worn. Replace worn parts.

Shaft loose or bent. Readjust shaft settings, tighten shaft screws if loose. If bent,

Impeller out of balance. Inspect shaft if loose or bent. If impeller damaged, replace.

Foreign material in pump. Remove any foreign material and replace any worn or

Excessive air in material. Make any adjustments in system to insure excess air is

Motor bearings worn. Replace any worn ports or replace motor if needed.

mechanical seal.

Dry running. Material must be in contact with seal at all times.

Abrasive product. Contact: Dixon Sanitary 800-789-1718

Shaft loose or bent. Readjust shaft settings, tighten shaft screws if loose. If bent,

Water hammer. Correct system to prevent any quick starts and stops.

Improper seal for application. Contact: Dixon Sanitary 800-789-1718

Casing clamp loose. Tighten clamp.

Casing gasket damaged or

worn.

Seal not installed correctly. Reassemble seal properly. Replace any worn or damaged

Carbon seal worn or damaged. Replace any worn or damaged parts.

'D' seal back plate worn. Resurface or replace. "DG" option should be considered.

Inspect pump to verify there is no blockage. Inspect suction

line and shorten or enlarge.

Adjust system to provide correct NPSHa.

replace shaft and inspect impeller hub for uneven wear,

replace impeller if worn.

damaged parts.

removed before material reaches the pump.

Adjust mechanical seal installation. Replace any worn or

damaged parts.

Catastrophic failure will occur.

replace shaft and inspect impeller hub for uneven wear,

replace impeller if worn.

damaged ports. Replace worn gaskets and tighten loose

connections. Damaged ports repair or replace.

Replace gaskets.

parts.

21Instruction & Operation Manual 800.789.1718

Page 22

Model No.'s & Part No.'s

Pump Models

Fluid End

BC

114 M 1

Port Style

M – Clamp

B – Buttweld

Model No.

114 – 1.5 x 1.5

214 – 2 x 1.5

216 – 2 x 1.5

516 – 2.5 x 1.5

218 – 2 x 1.5

318 – 3 x 1.5

328 – 3 x 2

428 – 4 x 2

Shaft Seal

1 – D Type

2 – DG SC

3 – DG CER

4 – DG TC

5 – D/F

6 – DG/SC/SC

7 – DG/SC/F

07

Impeller Size

01 – 2.5"

02 – 2.75"

03 – 3.0"

04 – 3.25"

05 – 3.50"

06 – 3.75"

07 – 4.0"

08 – 4.25"

09 – 4.50"

10 – 4.75"

11 – 5.0"

12 – 5.25"

13 – 5.50"

14 – 5.75"

15 – 6.0"

16 – 6.25"

17 – 6.5"

18 – 6.75"

19 – 7.0"

20 – 7.25"

21 – 7.50"

22 – 7.75"

23 – 8.0"

E A S B 02

Elastomer

B – Buna

E – EPDM/EPDM

V – FKM

S – Silicone/EPDM

Frame

A – 56c

B – 143/145TC

C – 182/184TC

D – 213/215TC

E – 254/256TC

F – 284/286TSC

G – 324/326TSC

Electrical

A – 1 Ph/60 Hz/115/230V

B – 3 Ph/60 Hz/208-230/460V

C – 3 Ph/60 Hz/575V

D – 3 Ph/50 Hz/190/380V

E – 3 Ph/50 Hz/380/460V

F – 3 Ph/50 Hz/220/380/440V

G – 3 Ph/50 Hz/220/380/415V

Motor Type

C – TEFC Cast Iron

I – TENV Cast Iron WD

N – TENV SS WD

Q – TENV Cast Iron

R – TENV Rolled Steel

S –TEFC SS WD

T – TEFC Rolled Steel

V – TENV Rolled Steel WD

W – TEFC Rolled Steel WD

X – TEFC Cast Iron WD

HP - RPM

01 – 1/3 1750

02 – 1/2 1750

03 – 3/4 1750

04 – 1 1750

05 – 1.5 1750

06 – 2 1750

07 – 3 1750

08 – 5 1750

09 – 7.5 1750

10 – 10 1750

11 – 15 1750

12 – 20 1750

13 – 25 1750

14 – 30 1750

15 – 40 1750

16 – 50 1750

17 – 60 1750

18 – 1/3 3450

19 – 1/2 3450

20 – 3/4 3450

21 – 1 3450

22 – 1.5 3450

23 – 2 3450

24 – 3 3450

25 – 5 3450

26 – 7.5 3450

27 – 10 3450

28 – 15 3450

29 – 20 3450

30 – 25 3450

31 – 30 3450

32 – 40 3450

33 – 50 3450

34 – 60 3450

BRADFORD™ CENTRIFUGAL PUMP

Fluid end includes all parts required to assemble to your motor.

Specify adjustable leg kits at time of order. Leg kits will be shipped to match the frame size of motor as

specied by model number. Leg kits will not be assembled.

Please note, if there are options that are not listed above, please contact Dixon Sanitary (800.789.1718) for

availability and pricing.

22 Instruction & Operation Manual800.789.1718

Page 23

Model No.'s & Part No.'s

Motor Models

PUMP

M

010

Horsepower

003 - 1/3

005 - 1/2

007 - 3/4

010 - 1

015 - 1.5

020 - 2

030 - 3

050 - 5

075 - 7.5

100 - 10

150 - 15

200 - 20

300 - 30

400 - 40

500 - 50

600 - 60

A

RPM

A - 1750 RPM

B - 3500 RPM

Phase

1 - 1 Ph

3 - 3 Ph

3

Voltage

A - 115/230V

B - 208-230/460V

C - 575V

D - 190/380V

E - 380/460V

F - 220/380/440V

G - 220/380/415V

B

Frame

A - 56C

B - 143/145TC

C - 182/184TC

D - 213/215TC

E - 254/256TC

F - 284/286TSC

G - 324/326TSC

B

Enclosure

CW - TENV Washdown Cast Iron

NC - TENV Cast Iron

NS - TENV Rolled Steel

NW - TENV Washdown Rolled Steel

SN - S/S Washdown TENV

SW - S/S Washdown TEFC

TC - TEFC Cast Iron

TI - TEFC Washdown Cast Iron

TS - TEFC Rolled Steel

TW - TEFC Washdown Rolled Steel

SW

BC-SERIES MOTOR

23Instruction & Operation Manual 800.789.1718

Page 24

Model No.'s & Part No.'s

Part Number Key

Common Parts

Key No. Description

P1 Casing Clamp P1-114M P1-216M P1-218M P1-328M

P1 Casing Clamp Enlarged P1-214M P1-516M P1-318M P1-428M

P2 Impeller P2-114-400 P2-216-600 P2-218-800 P2-328-800

P6A Stub Shaft Set Screw P6A-114SS P6A-216BSS P6A-216BSS P6A-216BSS

P11 Back Plate (D Seal) P11-114DP P11-216DP P11-218BDP P11-218BDP

P11F Back Plate Pin P11F-114BPP P11F-114BPP P11F-114BPP P11F-114BPP

P11H Back Plate (DG Seal) P11H-114DGP P11H-216DGP P11H-218BDGP P11H-218BDGP

P17J Gland Ring (DG Seal) P17J-114GR P17J-216GR P17J-218BGR P17J-218BGR

P17K Gland Bolt (DG Seal) P17K-114BG P217K-216BGB P217K-216BGB P217K-216BGB

P17M Washers (DG Seal) P17M-114GW P17M-216BGW P17M-216BGW P17M-216BGW

P24 Impeller Retainer P24-114R P24-216R P24-218BR P24-218BR

P71A Adapter Pins P71A-114BAP P71A-114BAP P71A-114BAP P71A-114BAP

P75 Clamp Assembly P75-114CA P75-216CA P75-218BCA P75-218BCA

P80 Carbon Seal P80-114CS P80-216CS P80-218BCS P80-218BCS

P80 Silicon Carbon Seal P80-114SC P80-216SC P80-218BSC P80-218BSC

P80A Seal Cup P80A-114CP P80A-216CP P80A-218BCP P80A-218BCP

P80B Buna Seal O'Ring P80B-114SOB P80B-216SOB P80B-218BSOB P80B-218BSOB

P80B EPDM Seal O'Ring P80B-114SOE P80B-216SOE P80B-218BSOE P80B-218BSOE

P80B Silicone Seal O'Ring P80B-114SOS P80B-216SOS P80B-216BSOS P80B-216BSOS

P80B FKM Seal O'Ring P80B-114SOV P80B-216SOV P80B-218BSOV P80B-218BSOV

P80C Spring P80C-114SG P80C-216SG P80C-218BSG P80C-218BSG

P80K Seat Screw P80K-114DCS P80K-216BDCS P80K-216BDCS P80K-216BDCS

P80L Drive Collar P80L-114DC P80L-216DC P80L-218BDC P80L-218BDC

P80N Silicon Carbide Seat (DG Seal) P80N-114SC P80N-216SC P80N-218BSC P80N-218BSC

P80N Ceramic Seat (DG Seal) P80N-114CER P80N-216CER P80N-218BCER P80N-218BCER

P80N Tungsten Carbide Seat (DG Seal) P80N-114TC P80N-216TC P80N-218BTC P80N-218BTC

P80P Outboard Gasket (DG Seal) P80P-114OB P80P-216OB P80P-218BOG P80P-218BOG

P80R Inboard Gasket (DG Seal) P80R-114IG P80R-216IG P80R-218BIG P80R-218BIG

P90 Buna Casing Gaskets P90-114CGB P90-216CGB P90-218BCGB P90-218BCGB

P90 EPDM Casing Gasket P90-114CGE P90-216CGE P90-218BCGE P90-218BCGE

P90 Silicone Casing Gasket P90-114CGS P90-216CGS P90-218BCGS P90-218BCGS

P90 FKM Casing Gasket P90-114CGV P90-216CGV P90-218BCGV P90-218BCGV

BC114 BC216 BC218 BC328

Part Number Part Number Part Number Part Number

24 Instruction & Operation Manual800.789.1718

Page 25

Model No's & Part No's

Variable Parts

PUMP

BC114

Key

No.

P6E Stub Shaft P6E-114-56SH P6E-114-14SH P6E-114-18SH

P40 Deector P40-114-56D P40-114-56D P40-114-18D

P71 Adapter P71-114-56A P71-114-56A P71-114-18A

P71B Adapter Bolts P71B-114B-56AB P71B-114B-56AB P71B-114B-18AB

P131 Guard

P207 Adjustable

Description Part Number Part Number Part Number

Assembly

Leg Kit

BC216

Key

No.

P6E Stub Shaft P6E-216-56SH P6E-216-14SH P6E-216-18SH P6E-216-21SH P6E-216-25SH

P40 Deector P40-216-56D P40-216-56D P40-216-56D P40-216-21D P40-216B-25D

P71 Adapter P71-216-56A P71-216-56A P71-216-18A P71-216-21A P71-216-25A

P71B Adapter Bolts P71B-114B-56AB P71B-114B-56AB P71B-114B-18AB P71B-114B-18AB P71B-114B-18AB

P131 Guard

P207 Adjustable

Description Part Number Part Number Part Number Part Number Part Number

Assembly

Leg Kit

56C 140TC 180TC

P131-114-56GA P131-114-56GA P131-114-18GA

P207-56LK P207-14LK P207-18LK

56C 140TC 180TC 210TC 250TC

P131-216-56A P131-216-56A P131-216-18A P131-216-21A P131-216-25A

P207-56LK P207-14LK P207-18LK P207-21LK P207-25LK

BC218/328

Key

No.

P6E Stub Shaft P6E-218-14SH P6E-218B-18SH P6E-218B-21SH P6E-218B-25SH P6E-218B-28SH P6E-328-32SH

P40 Deector P40-218B-14D P40-218B-14D P40-218B-14D P40-218B-14D P40-218B-28D P40-328-32D

P71 Adapter P71-218-14A P71-218B-18A P71-218B-21A P71-218B-25A P71-218B-28A P71-328-32A

P71B Adapter Bolts P71B-114B-56AB P71B-114B-18AB P71B-114B-18AB P71B-114-18AB P71B-114B-18AB P71B-328-32AB

P131 Guard

P207 Adjustable

Description Part Number Part Number Part Number Part Number Part Number Part Number

Assembly

Leg Kit

140TC 180TC 210TC 250TC 280TSC 320TSC

P131-218-14GA P131-218B-18GA P131-218B-21GA P131-218B-25GA P131-218B-28GA P131-328-32GA

P207-14LK P207-18LK P207-21LK P207-25LK P207-28LK P207-32LK

25Instruction & Operation Manual 800.789.1718

Page 26

Repair Kits

BC-Series Repair Kits

Repair Kit # 1

1 - Casing Gasket (P90) 1 - Seal O-Ring (P80B)

1 - Carbon Seal (P80) 1 - Impeller Retainer (P24)

Model Number Buna EPDM Silicone FKM

BC114 PRK1-114B PRK1-114E PRK1-114S PRK1-114V

BC216 PRK1-216B PRK1-216E PRK1-216S PRK1-216V

BC218/BC328 PRK1-218BB PRK1-218BE PRK1-218BS PRK1-218BV

Repair Kit # 2

3 - Casing Gasket (P90) 3 - Seal O-Ring (P80B) 3 - Carbon Seal (P80)

Model Number Buna EPDM Silicone FKM

BC114 PRK2-114B PRK2-114E PRK2-114S PRK2-114V

BC216 PRK2-216B PRK2-216E PRK2-216S PRK2-216V

BC218/BC328 PRK2-218BB PRK2-218BE PRK2-218BS PRK2-218BV

Repair Kit # 3

1 - Carbon Seal (P80) 1 - Seal O-Ring (P80B)

1 - Spring (P80C) 1 - Cup (P80A)

Model Number Buna EPDM Silicone FKM

BC114 PRK3-114B PRK3-114E PRK3-114S PRK3-114V

BC216 PRK3-216B PRK3-216E PRK3-216S PRK3-216V

BC218/BC328 PRK3-218BB PRK3-218BE PRK3-218BS PRK3-218BV

Repair Kit # 4

1 - Casing Gasket (P90) 1 - Seal O-Ring (P80B)

1 - Carbon Seal (P80) 1 - Impeller Retainer (P24)

1 - Seal Cup (P80A) 1 - Spring (P80C)

Model Number Buna EPDM Silicone FKM

BC114 PRK4-114B PRK4-114E PRK4-114S PRK4-114V

BC216 PRK4-216B PRK4-216E PRK4-216S PRK4-216V

BC218/BC328 PRK4-218BB PRK4-218BE PRK4-218BS PRK4-218BV

26 Instruction & Operation Manual800.789.1718

Page 27

Repair Kits

BC-Series DG Repair Kits

DG Repair Kit

1 - Seal Seat (P80N) 1 - Carbon Seal (P80) 1 - Seal Cup (P80A)

1 - Seal O-Ring (P80B) 1 - Spring (P80C) 1 - Casing Gasket (P90)

1 - Impeller Pin (P24) 1 - Inboard Gasket (P80R) 1 - Outboard Gasket (P80P)

Model Number Elastomer Ceramic SC TC

Buna PRKDG-114BCER PRKDG-114BSC PRKDG-114BTC

BC114

BC216

BC218/BC328

EPDM PRKDG-114ECER PRKDG-114ESC PRKDG-114ETC

SILICONE PRKDG-114SCER PRKDG-114SSC PRKDG-114STC

FKM PRKDG-114VCER PRKDG-114VSC PRKDG-114VTC

Buna PRKDG-216BCER PRKDG-216BSC PRKDG-216BTC

EPDM PRKDG-216ECER PRKDG-216ESC PRKDG-216ETC

SILICONE PRKDG-216SCER PRKDG-216SSC PRKDG-216STC

FKM PRKDG-216VCER PRKDG-216VSC PRKDG-216VTC

Buna PRKDG-218BBCER PRKDG-218BBSC PRKDG-218BBTC

EPDM PRKDG-218BECER PRKDG-218BESC PRKDG-218BETC

SILICONE PRKDG-218BSCER PRKDG-218BSSC PRKDG-218BSTC

FKM PRKDG-218BVCER PRKDG-218BVSC PRKDG-218BVTC

PUMP

DG Conversion Kit

1 - DG Backplate (P11H) 1 - Gland Ring (P17J) 4 - Gland Bolts (P17K)

4 - Lock Washers (P17M) 1 - Seal Seat (P80N) 1 - Outboard Gasket (P80P)

1 - Inboard Gasket (P80R)

Model Number Ceramic SC TC

BC114 PCK-114DGCER PCK-114DGSC PCK-114DGTC

BC216 PCK-216DGCER PCK-216DGSC PCK-216DGTC

BC218/BC328 PCK-218BDGCER PCK-218BDGSC PCK-218BDGTC

27Instruction & Operation Manual 800.789.1718

Page 28

Limited Warranty

Dixon Sanitary, a division of Dixon Valve and Coupling Company, (herein called Dixon Sanitary)

warrants the products described herein, and manufactured by Dixon Sanitary to be free from

defects in material and workmanship for a period of one (1) year from date of shipment by Dixon

Sanitary under normal use and service. It's sole obligation under this warranty being limited to

repairing or replacing, as hereinafter provided, at its option any product found to Dixon Sanitary’s

satisfaction to be defective upon examination by it, provided that such product shall be returned

for inspection to Dixon Sanitary within three (3) months after discovery of the defect. The

repair or replacement of defective products will be made without charge for parts or labor. This

warranty shall not apply to: (a) parts or products not manufactured exclusively for Dixon Sanitary,

the warranty of such items being limited to the actual warranty extended to Dixon Sanitary by its

supplier; (b) any product that has been subject to abuse, negligence, accident, or misapplication;

(c) any product altered or repaired by others than Dixon Sanitary; and (d) to normal maintenance

services and the replacement of service items (such as gaskets and seats) made in connection

with such services. To the extent permitted by State law, this limited warranty shall extend only

to the buyer and any other person reasonably expected to use or consume the goods who

is injured in person by any breach of the warranty. No action may be brought against Dixon

Sanitary for an alleged breach of warranty unless such action is instituted within one (1) year

from the date the cause of action accrues. This limited warranty shall be construed and enforced

to the fullest extent allowable by applicable State law.

OTHER THAN THE OBLIGATION OF DIXON SANITARY SET FORTH HEREIN, DIXON

SANITARY DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, AND ANY OTHER OBLIGATION OR LIABILITY. THE FOREGOING

CONSTITUTES BRADFORD'S SOLE OBLIGATION WITH RESPECT TO DAMAGES,

WHETHER DIRECT, INCIDENTAL OR CONSEQUENTIAL, RESULTING FROM THE USE OR

PERFORMANCE OF THE PRODUCT.

Some products and sizes may be discontinued when stock is depleted, or may require a

minimum quantity for ordering.

NOTE: Reasonable care has been taken in preparing this catalog. Dixon Sanitary, a

division of Dixon Valve & Coupling Company, reserves the right to make corrections

and any dimensional changes.

28 Instruction & Operation Manual800.789.1718

Page 29

Notes

PUMP

29Instruction & Operation Manual 800.789.1718

Page 30

Through its divisions and afliated companies, Dixon is

recognized as the premier manufacturer and supplier of hose

ttings and accessories spanning a wide range of industrial

uses. Dixon’s reach includes products for food, dairy

processing, beverage and brewery, mobile tankers, mining,

construction, chemical processing, petroleum, oilelds,

rening, nuclear and manufacturing.

Dixon Sanitary

N25 W23040 Paul Road • Pewaukee, WI 53072

Customer Service: 800.789.1718

Fax: 800.789.4046

www.bradfordttings.com

® 2012 DVCC Printed in the USA DS_IOmanual_PUMP0212-1P5C

Loading...

Loading...