Maintenance & Operating

Instructions

For

Dixon Bayco

5204SFI API Valves

Canada:

Dixon Group Canada Limited

Innisfil (Barrie), Ontario

Phone: 705-436-1125

Fax: 705-436-6251

Toll Free: 877-963-4966

E-mail: isales@dixongroupcanada.com

USA:

Dixon Bayco USA

Chestertown, Maryland

Phone: 410-778-2000

Fax: 410-778-4702

Toll Free: 800-355-1991

E-mail: dixonbayco@dixonvalve.com

Mexico:

Dixva, S. de R.L. de C.V.

Monterrey, N.L

Phone: 01-800-00-DIXON (34966)

Fax: 01-81-8354-8197

E-mail: contactenos@dixonvalve.com.mx

Europe:

Dixon Group Europe Ltd

Preston, England

Phone: +44 (0)1772 323529

Fax: +44 (0)1772 314664

E-mail: enquiries@dixoneurope.co.uk

Asia Pacific:

Dixon (Asia Pacific) Pty Ltd Wingfield,

South Australia

Phone: +61 8 8202 6000

Fax: +61 8 8202 6099

E-mail: enquiries@dixonvalve.com.au

dixonvalve.com

For Sales and Service Contact

5204SFI API Valves

2 090112 REV 3 5204SFI

5204SFI API Valves

5204SFI 090112 REV 3 3

5204SFI API Valves

4 090112 REV 3 5204SFI

These instructions and recommendations are provided to ensure

proper operation and long service life of Dixon Bayco 5204SFI API.

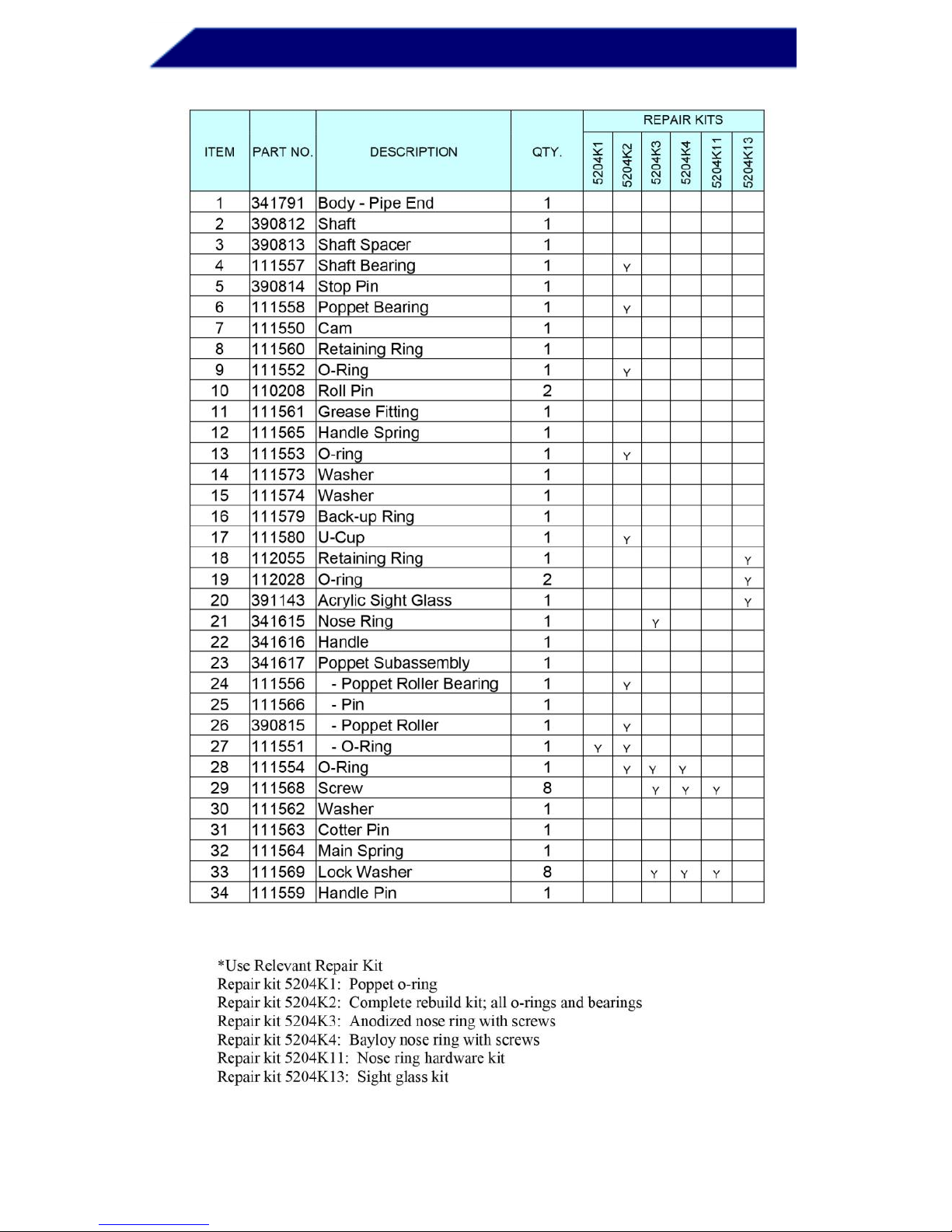

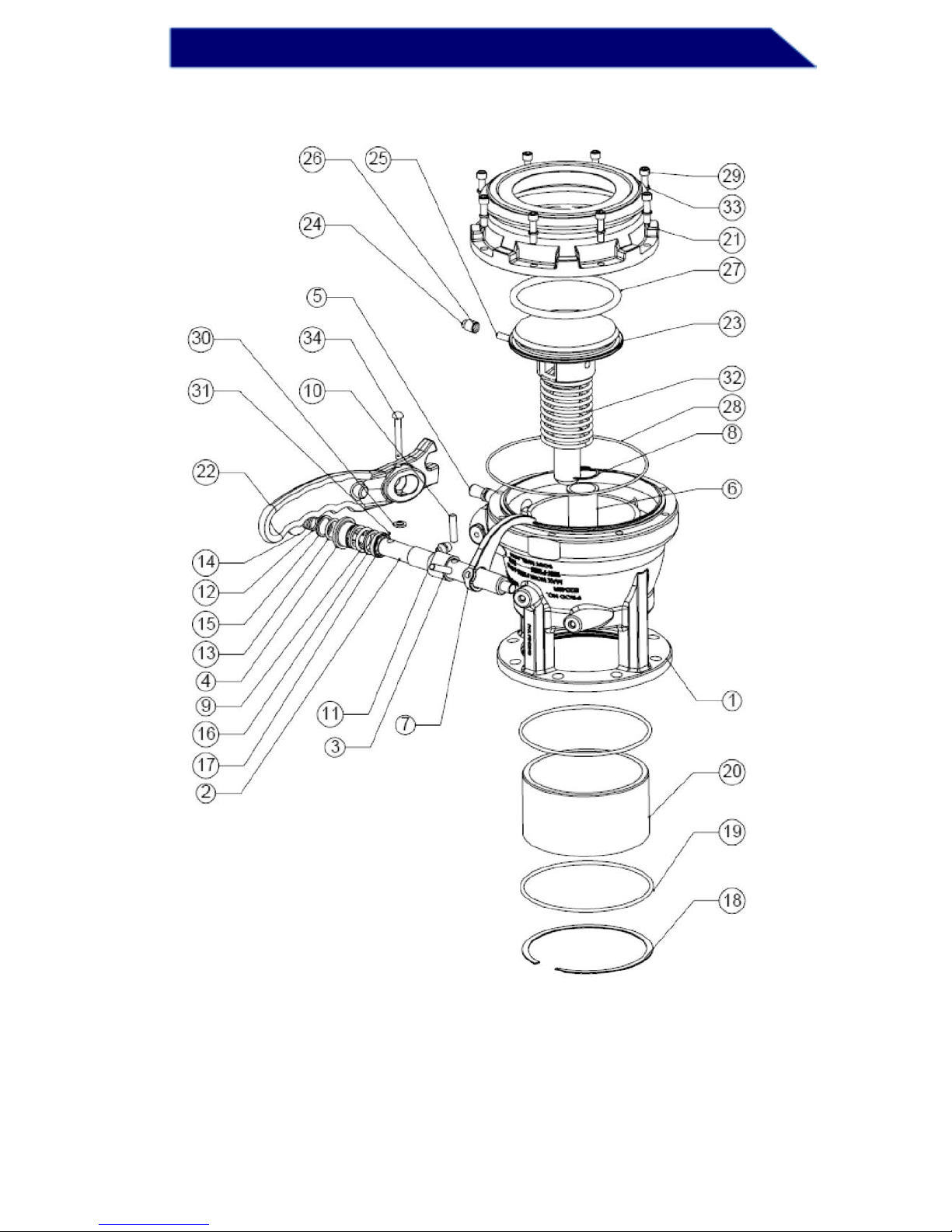

Parts are identified by the item number on the assembly drawing and

part list.

Maintenance and Part Replacement

Semi-Annual Inspection

Visual inspection of the valve operation can be done while the valve

is still attached to the tank. All safety precautions that apply to the

use of the valve must be followed and all the lines must be empty.

1. Visually examine 5204SFI API for worn or damaged parts, or any

other condition that may affect the operation of the valve.

2. Visually examine nose ring (21) for cavities, scratches, or other

deformation of the sealing surface.

3. Visually examine shaft (2) for significant dirt accumulation that

could cause shaft seal leakage.

4. Check that the handle (22) automatically positions at an angle to

the valve body (1) with detent end away from the stop pin (5).

5. Visually examine stop pin (5) for signs of wear and deformation.

When the handle is moved to open position, it should remain firmly

latched on the stop pin (5). If the handle cannot stay securely in the

latched open position due to stop pin (5) wear, stop pin (5) should be

replaced. Locking pliers can be used to unscrew the stop pin (5).

6. Visually examine the sight glass (20) for damage or sign of

leakage, check the sight glass for cracks. If the sight glass is cloudy,

the color of the sight glass changed, or visible cracks are seen, or

leakage can be found from the sight glass or the O-rings (19), replace

the sight glass. See the “REPLACEMENT OF SIGHT GLASS”

section for how to replace the sight glass.

7. To check the handle performance, open and close the API valve a

few times. The handle should move unobstructed and smoothly.

8. When released from the latched (or open) position, the poppet (23)

should instantly close and center.

5204SFI API Valves

5204SFI 090112 REV 3 5

9. Using a non-scratching tool, (piece of wood), push the poppet open

without using the operating handle. Push the poppet to the side and

make sure that the poppet reseats and centers itself when closed

slowly.

If any of the checks described above fails, additional maintenance is

required.

Yearly Inspection and Maintenance

The 5204SFI API can be disassembled and the seals may be

replaced while the valve is still attached to the trailer. The sight glass

(20) and O-rings (19) can only be replaced when the valve is

removed from the trailer. See the “REPLACEMENT OF SIGHT

GLASS” section for how to replace the sight glass.

It is recommended to draw a line (using a felt-tip pen) across the joint

between the pipe end (1) and the nose ring (21). The line is used

later in assembly to rotate the nose ring (21) from the starting

position, which helps balance out wear of the coupling surface.

Disassembly – Part I

THE POPPET IS HELD UNDER CONSIDERABLE SPRING

TENSION. WHENEVER THE NOSE RING (21) OR POPPET (23)

ARE REMOVED OR REASSEMBLED, THE VALVE MUST BE

LATCHED IN THE OPEN POSITION OR THE POPPET

OTHERWISE RESTRAINED (LOAD ONLY). PERSONAL

INJURIES MAY RESULT IF THIS PRECAUTION IS NOT TAKEN.

WHERE POLISHING IS INDICATED, USE NOT LESS THAN 600

GRIT POLISHING CLOTHS.

1. Inspect nose ring (21) for scratches on sealing surface. If there are

any scratches on the sealing surface, the nose ring (21) should be

replaced to avoid valve leakage. Faces without hard coating should

be polished around the bore and only in circumferential direction.

2. Poppet (23) should be inspected for scoring or raised metal on the

stem. Any raised metal on the poppet stem should be removed with

a fine flat file and polished in axial direction.

3. Inspect poppet bearing (6) for intrusion of any foreign material on

the inside diameter. Any foreign material on the inside diameter

should be carefully removed with a sharp tool and polished.

5204SFI API Valves

6 090112 REV 3 5204SFI

4. On completion of poppet (23) and poppet bearing (6) inspection,

test the bearing (6) on the poppet (23) without the spring (32) to

make sure that the bearing (6) smoothly slides along the poppet (23)

stem. If this is not the case, the bearing should be replaced.

5. Test rotation of the poppet roller (26) around the pin (25). If the

rotation is difficult, the roller bearing should be replaced. To access

the roller bearing, support the poppet (23) and release the pin (25)

using a ¼" pin punch.

6. Check the handle (22) for free and easy movement of the opening

and closing cycle. Operation of the handle (22) normally requires

limited effort. If operating the handle (22) involves stronger force, it

implies the need to clean and possibly replace the shaft bearing (4)

and the shaft (2).

7. Poppet O-ring (27) and main O-ring (28) should be inspected for

cracks, scratches, missing material, unusual hardness, softness,

roughness, and other signs of chemical damage. Do not remove

poppet O-ring from the poppet at this stage.

8. At this point it may be decided to replace the main O-ring (28) and

reassemble the valve if the first part of the inspection did not reveal

any damage or malfunction of the parts, or to continue with Part II of

disassembly and replace all the O-rings if there are any additional

concerns regarding the performance of the valve. Steps 5 through 8

of the Assembly section describe how to assemble the valve from this

point.

Disassembly – Part II

1. To remove two roll pins (10), turn the handle until the pin is

accessible and drive out each pin in turn using ¼" pin punch. If this is

done with the valve attached to the tank, take precautions to ensure

that the pins (10) do not enter upstream piping. To remove the cam

arm roll pin (10), ensure that the handle is rotated to a position such

that the roll pin will be clear of the deflector cone (valve body) as it is

driven out. If the roll pin appears not to drive further than

approximately ¼", check for contact between the roll pin and deflector

cone and slightly adjust the rotation of the handle to allow sufficient

clearance.

2. Take out handle (22) with shaft assembly, shaft spacer (3) and

cam (7).

5204SFI API Valves

5204SFI 090112 REV 3 7

3. Remove shaft bearing (4), O-ring (9), back-up ring (16) and u-cup

(17) from the pipe end (1) stuffing box.

4. Examine stuffing box area of the pipe end (1) for corrosion and, if

required, polish in circumferential direction.

5. To disassemble handle from shaft assembly, remove cotter pin

(31), washer (30), handle pin (34), washer (14), spring (12), washer

(15), and O-ring (13).

6. Polish sealing surfaces of the shaft (2) in a circumferential

direction. Remove any burrs that might have occurred during pin

punching. Carefully remove poppet O-ring (27) without damaging the

sealing surface of the poppet (23). Even the smallest scratches on

the O-ring groove will cause leakage.

Cleaning, Inspection and Replacement of

Disassembled Parts

Clean well and visually examine all the parts of the API. Remove any

burrs and sharp edges that could damage the seals during

reassembly. Replace any damaged parts.

Assembly

1. Before assembly, apply lubricant to the inside diameter of the pipe

end (1) stuffing box, to the u-cup (17), back-up ring (16), O-ring (9),

and shaft bearing (4). Insert u-cup (17) followed by back-up ring (16),

O-ring (9), and shaft bearing (4) inside pipe end (1) stuffing box.

2. Lubricate shaft (2) and install it through the bearing (4) into the

body (1) driving it through the shaft spacer (3) and the cam (7). Insert

pins (10) into the shaft holes.

3. Lubricate O-ring (13) and install it on the shaft (2). Continue

installing washer (15), spring (12), washer (14), and handle (22).

Insert handle pin (34). Position handle with detent end away from the

stop pin and then install washer (30) and cotter pin (31).

4. Liberally lubricate poppet O-ring (27) and install it on the poppet

(23) preventing torsion of the O-ring during assembly as it may cause

leakage. It is recommended to press on the full edge of the O-ring

(27) until it snaps around the poppet (27), and then push it into the Oring groove from opposite sides.

5204SFI API Valves

8 090112 REV 3 5204SFI

5. Install spring (32) and poppet (23) into the pipe end (1). Lead the

cam (7) over poppet roller (26) and latch the handle (22) in the open

position.

6. With lock washers (33) installed on each of the eight screws (29),

apply ‘never-seize’ on the screw threads.

7. Liberally grease O-ring (28) and install it on the nose ring (21). Use

the radial line drawn in the step 1 of disassembly and starting from

the initial alignment. Rotate the nose ring (21) one bolt hole

clockwise. Bolt screws with washers and ‘anti-seize’ applied to the

screw threads. Tighten using a crisscross flange torqueing sequence.

8. To ensure proper operation of the valve, repeat the steps of the

Semi-annual inspection.

Replacement of Sight Glass

Remove the 5204SFI API from the trailer. Remove the sight glass

(20) from the pipe end (1).

a.) Drill a through hole on the sight glass (20) as shown; make sure

not to damage any other parts. Apply penetrating oil to sight glass

(20) on outside and bottom end for easy removal.

b.) Use screw drivers or any round rod through the hole. Twist the

sight glass by the screw drivers or the rod to loosen the sight glass.

Make sure not to damage the pipe end.

5204SFI API Valves

5204SFI 090112 REV 3 9

c.) Remove the retaining ring (18) from the groove of the pipe end

(1). Push the sight glass out by the screw drivers or the rod. Make

sure not to damage the pipe end.

d.) Once the sight glass passes the inside O-ring, remove the screw

drivers or the rod. Continue to push the sight glass out from the

inside end by the screw drivers or the rod till the sight glass is out.

Make sure not to damage the pipe end.

Remove the O-rings (item 19, 2 pieces) from the grooves of the pipe

end (1). Clean all grooves and the inside of the pipe end (1) to

remove any debris and oil. Make sure not to scratch or damage the

grooves and inside of the pipe end.

Lubricate NEW O-rings (item 19, 2 pieces) and put them into the

grooves in the piped end (1).

Install the NEW sight glass (20) and make sure that the side with a

chamfer gets into the pipe end (1) first. Push the sight glass evenly

into the piped end till the side with a chamfer stops by the pipe end.

Use the old sight glass as a tool to push the new sight glass, if

necessary.

Install the NEW retaining ring (18) into the groove of the pipe end.

5204SFI API Valves

10 090112 REV 3 5204SFI

Handle Operating Positions

Maximum operating temperature is 140ºF. Do not clean the

sight glass by steam! Failure to follow the warning will void the

warranty.

Dixon Bayco Warranty

For complete warranty information, please refer to the latest

Dixon catalog.

Loading...

Loading...