Page 1

BRASS CRIMPER TOOL

860 and 855 crimpers

for brass ferrules

Professional quality ferrule crimper provides fixed mount production

capability or job-site portability

855 crimper

860 crimper

How To:

Before operating the 855, 855A or 860 Crimper, close the machine and adjust the

screw opposite the end where the handle attaches until the screw just touches the

end stop. Never turn the screw tighter than this. The screw should be looser if

the hose barb fits very tightly and the ferrule ID is close to the hose OD.

A properly placed ferrule will t snugly on to the hose before crimping and will be difcult

to rotate by hand.

1) Place ferrule on the hose.

2) Lubricate the inside of the hose with Dixon

Coupling Lubricant before inserting tting to

make the tting slide in more easily.

3) Insert hose barb.

4) Open hose crimper by raising handle.

5) Place hose into hose crimper, centering the

ferrule on the proper die.

6) Press down on handle until it hits the end

stop. Lift up and rotate hose 90°. Repeat.

•

855 can be used for crimping 31/64" (0.375") to 45/64" (0.710") hose OD range depending on die

• 860 used for crimping 1/2" to 1" ID hoses with larger OD's, from 11/16" to 1-1/2"

• crimps standard brass or aluminum ferrules

• order separate dies for each hose diameter

• weight: 10 lbs.

• 855 crimper with 5 dies for 31/64"

(0.490") to 45/64" (0.710") OD hose

• 855A crimper with 5 dies for 28/64"

(0.447") to 43/64" (0.671") OD hose

• optional dies up to 52/64" die bore

• replacement dies sold separately

• Hose crimper provides "big tool"

crimping advantages at a fraction of

the cost.

• rugged, portable and easy to use

Crimping Dies

Hose OD Range

from to

385" .406"

.447" .468"

.490" .520"

.540" .562"

.590" .625"

.640" .671"

.690" .710"

.760" .781"

.820" .843"

Standard Die

Part Number

856-10

856-7

856-4

856-3

856-2

856-1

856-5

856-8

856-9

Die Bore

.37"

.44"

.48"

.53"

.58"

.63"

.68"

.75"

.81"

Page 2

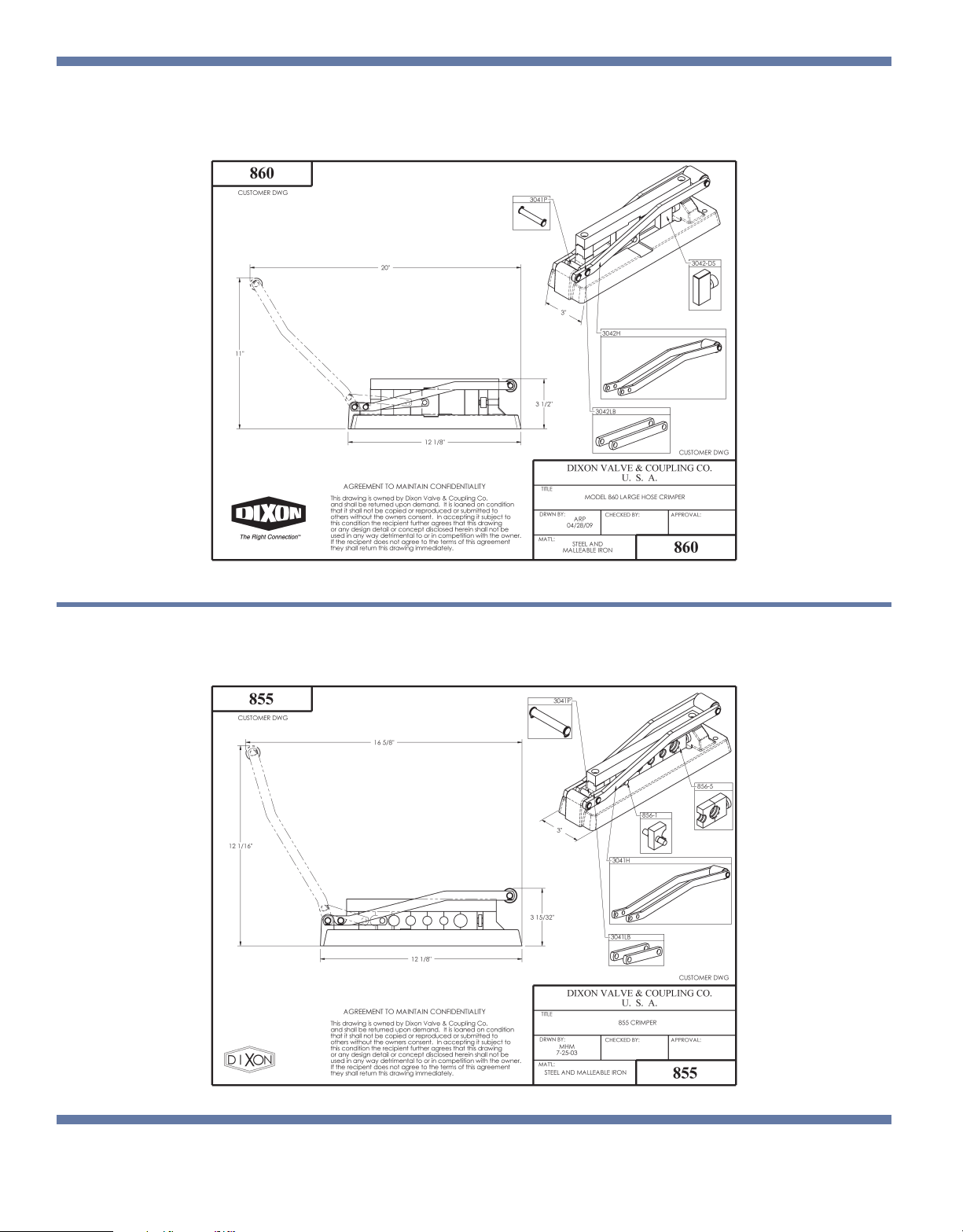

860

parts diagram

855

parts diagram

Dixon

800 High Street

Chestertown, 21620

handcrimp

877.963.4966

dixonvalve.com

Loading...

Loading...