Page 1

1

Maintenance & Operating Instructions

For

BAYCO 5204 A.P.I. VALVES

Part Numbers

USA:

Dixon Bayco USA

Chestertown, Maryland

Phone: 410-778-2000

Fax: 410-778-4702

Toll Free: 800-355-1991

E-mail: dixonbayco@dixonvalve.com

www.dixonbayco.com

Canada:

Dixon Group Canada Limited

Innisfil (Barrie), Ontario

Phone: 705-436-1125

Fax: 705-436-6251

Toll Free: 877-963-4966

E-mail: isales@dixongroupcanada.com

www.dixongroupcanada.com

Mexico:

Dixva, S. de R.L. de C.V.

Monterrey, N.L

Phone: 01-800-00-DIXON (34966)

Fax: 01-81-8354-8197

E-mail: contactenos@dixonvalve.com.mx

www.dixonvalve.com

Europe:

Dixon Group Europe Ltd

Preston, England

Phone: +44 (0)1772 323529

Fax: +44 (0)1772 314664

E-mail: enquiries@dixoneurope.co.uk

www.dixoneurope.co.uk

Asia Pacific:

Dixon (Asia Pacific) Pty Ltd

Wingfield, South Australia

Phone: +61 8 8202 6000

Fax: +61 8 8202 6099

E-mail: enquiries@dixonvalve.com.au

www.dixonvalve.com.au

For Sales & Service Contact

5204L ........................ ‘load only’, with sight glass

5204LNG................... ‘load only’, no sight glass

5204LNGV ................ ‘load only’, no sight glass, Poppet O-ring, for B100

Load / Unload

Load only

5204 ....................... fixed handle, with sight glass

5204C .................... detachable handle, with sight glass

5204NG ................. fixed handle, no sight glass

5204NGC .............. detachable handle, no sight glass

5204T .................... fixed handle, with sight glass, PTFE seals, SS spring

5204TC .................. detachable handle, with sight glass, PTFE seals, SS spring

5204NGT............... fixed handle, no sight glass, PTFE seals, SS spring

5204NGTC ............ detachable handle, no sight glass, PTFE seals, SS spring

5204B .................... fixed handle, sight glass, Bayloy nose ring

5204BC ................. detachable handle, with sight glass, Bayloy nose ring

5204BNG .............. fixed handle, no sight glass, Bayloy nose ring

5204BNGC ............ detachable handle, no sight glass, Bayloy nose ring

5204SNG……… …fixed handle, no sight glass, stainless steel main spring

5204NGV…………fixed handle, no sight glass, Poppet O-ring, for B100

5204NGCV ........... detachable handle, no sight glass, Poppet O-ring, for B100

5204BNGV ......... fixed handle, no sight glass, Bayloy nose ring, Poppet O-ring, for B100

5204BNGCV ...... detachable handle, no sight glass, Bayloy nose ring, Poppet O-ring, for B100

5204SNGV …… …fixed handle, no sight glass, stainless steel main spring, Poppet O-ring, for B100

5204P .................... fixed handle, with sight glass, drain plug

090085 Rev 23

Page 2

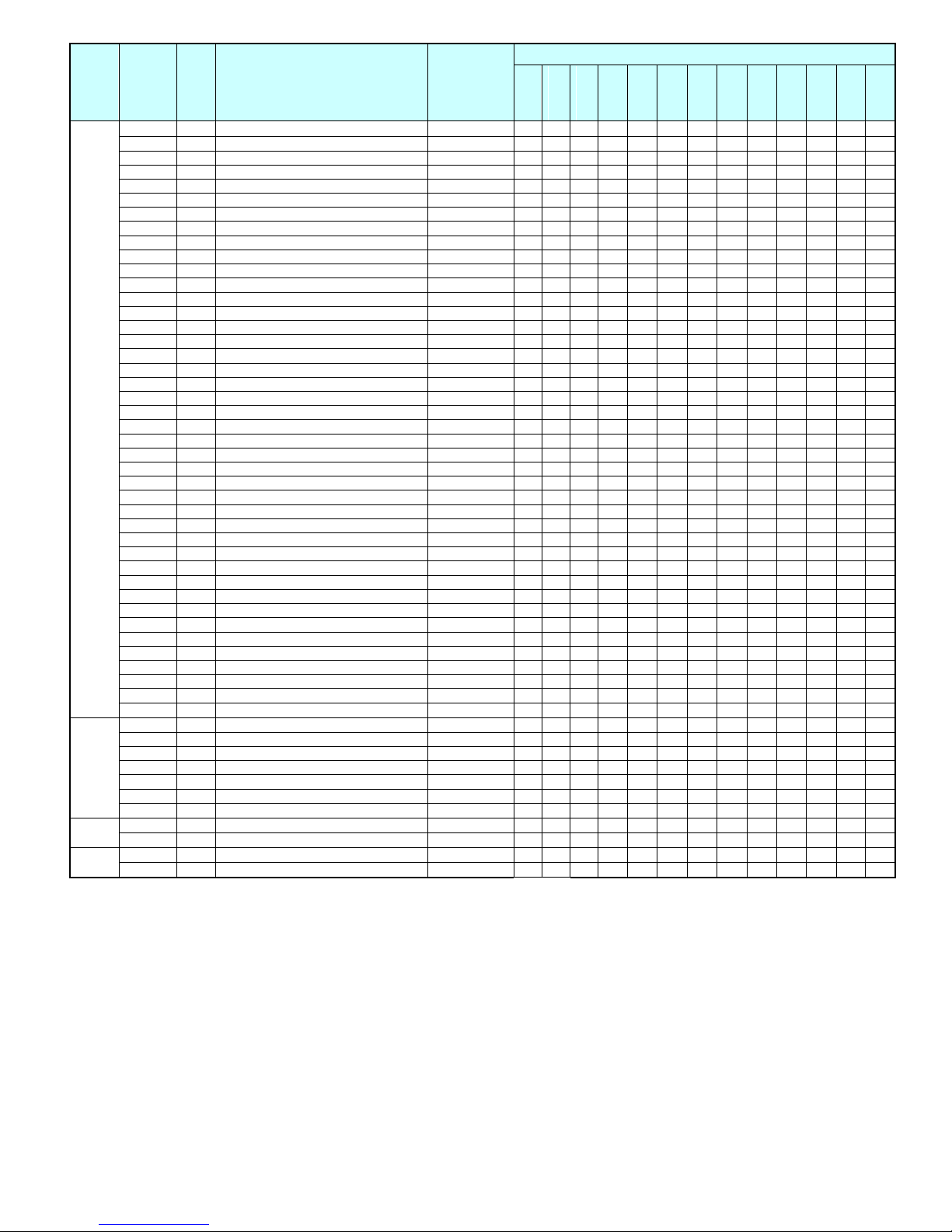

IMAGE

ITEM

QTY.

DESCRIPTION

PART NO.

REPAIR KITS

5204K1

5204K2

5204K3

5204K4

5204K5

5204K6

5204K7

5204K8

5204K9

5204K11

5204K12

5204KV1

5204KV2

1

1

1

Body - Pipe End

Body w/ Sight Glass

341614

Body w/ No Sight Glass

341634

Body Load Only w/ S/G

341649

Body Load Only w/ No S/G

341650

2

1

Nose Ring

*

Y

3

1

Shaft

390812

4 1

Handle Pin

*

Y 5 1

Shaft Spacer

390813

6 1

Shaft Bearing

*

Y

Y 7

1

Stop Pin

390814

8

1

Handle * Y

9

1

Poppet Subassembly

341617

Poppet, Subassembly - Load Only

341651

Poppet Subassembly with PTFE

400624

10

1

-Poppet Bearing

*

Y

Y 11

1

Cam

111550

12

1

Sight Glass

*

Y 13

1

-Poppet Roller

*

Y Y

14

1

-Poppet Roller Bearing

*

Y Y

15

1

Retaining Ring

111560

16

1

-O-Ring

*

Y Y Y

Y Y 17

1

O-Ring

111554

Y Y

Y Y Y 18

1

O-Ring * Y Y

Y 19

2

Roll Pin

111567

20

1

-Pin

111566

21

1

Grease Fitting

111561

22

6

Screw

111570

Y 23

8

Screw * Y Y

Y 24

1

O-Ring * Y Y

Y Y 25

5

Washer * Y Y (2) Y

26

1

Cotter Pin

*

Y

27A

1

Main Spring

111564

27B

1

Main Spring – Stainless (for 5204SNG)

111542

28

1

Handle Spring

*

Y

29

1

O-ring * Y

Y 30

14

Lock Washer

111569

Y

Y Y Y 31

1

Washer *

Y Y

Y

32

1

Washer

111574

33

1

Back-up Ring

111579

34

1

U-Cup * Y

Y 36

1

Float Ball

*

Y

2 37

1

Detachable Handle

*

Y

38

1

Bracket * Y

39

1

Clevis Pin

*

Y

40

1

Flat washer

*

Y

41

1

Cotter Pin

*

Y

42

1

Torsion Spring

*

Y

43

1

Pin * Y

3 44

1

Threaded Nose Ring

*

Y

45

1

Wear Ring

*

Y

4 46

1

Sight Glass Delete Kit – Blank Plate

*

Y 47

1

Sight Glass Delete Kit – Gasket

*

Y

*Use Relevant Repair Kit

Repair kit 5204K1: Poppet o-ring

Repair kit 5204K2: Complete rebuild kit; all o-rings and bearings

Repair kit 5204K3: Anodized nose ring with screws

Repair kit 5204K4: Bayloy nose ring with screws

Repair kit 5204K5: Detachable handle assembly

Repair kit 5204K6: PTFE encapsulated seals

Repair kit 5204K7: Fixed handle repair kit

Repair kit 5204K8: Sight glass repair kit

Repair kit 5204K9: Sightglass delete kit

Repair kit 5204K11: Nose ring hardware kit

Repair kit 5204K12: Sight glass hardware kit

Repair kit 5204KV1: Poppet o-ring rebuild-kit for B100

Repair kit 5204KV2: Complete rebuild kit; (including poppet o-rings and bearings for B100)

2 090085 Rev 23

Page 3

Image 3

Threaded nose ring

* Fixed-handle version only

Image 2

Detachable handle

Image 4

Sight Glass Delete

Kit

3 090085 Rev 23

Page 4

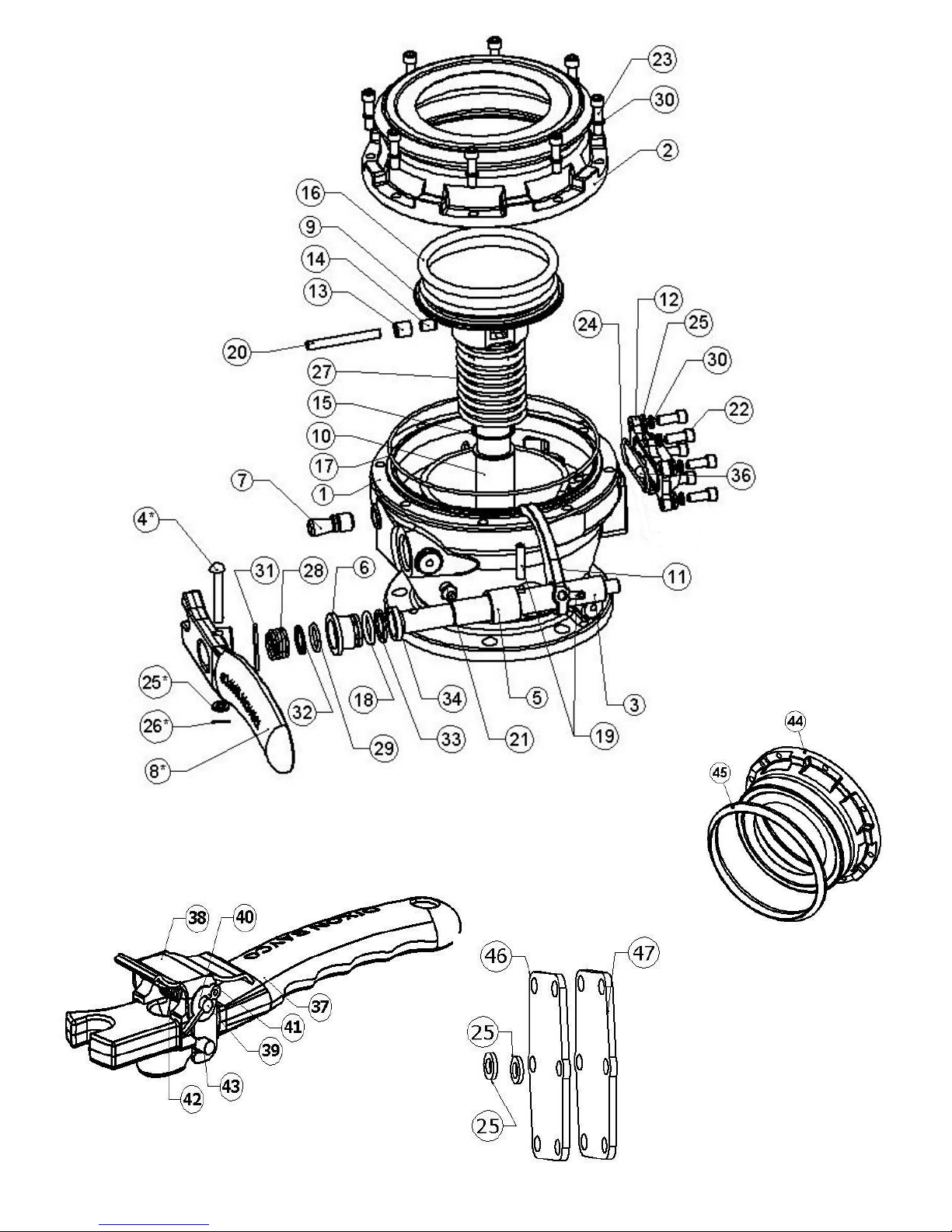

These instructions and recommendations are provided to ensure proper operation and long service life

of Bayco 5204 API. Parts are identified by the item number on the assembly drawing and part list.

MAINTENANCE AND PART REPLACEMENT FOR BAYCO 5204 API

The following instructions cover both the load/unload and load only API valves. For the load only

versions, please disregard items in italics.

I. SEMI-ANNUAL INSPECTION

1. Visual inspection of the valve operation can be done while the valve is still attached to the tank. All

safety precautions that apply to the use of the valve must be followed and all the lines must be

empty.

Visually examine 5204 API for worn or damaged parts, or any other condition that may affect the

operation of the valve.

Visually examine nose ring (2) for cavities, scratches, or other deformation of the sealing surface.

Visually examine shaft (3) for significant dirt accumulation that could cause shaft seal leakage.

Check that the handle (8) automatically positions at an angle to the valve body (1) with detent end

away from the stop pin (7).

Visually examine stop pin (7) for signs of wear and deformation. When the handle is moved to open

position, it should remain firmly latched on the stop pin (7). If the handle cannot stay securely in the

latched open position due to stop pin (7) wear, stop pin (7) should be replaced. Locking pliers can

be used to unscrew the stop pin (7).

2. To check the handle performance, open and close the API valve a few times. The handle should

move unobstructed and smoothly.

3. When released from the latched (or open) position, the poppet (9) should instantly close and center.

4. Using a non-scratching tool, (piece of wood), push the poppet open without using the operating

handle. Push the poppet to the side and make sure that the poppet reseats and centers itself when

closed slowly.

If any of the checks described above fails, additional maintenance is required.

II. YEARLY INSPECTION AND MAINTENANCE

The 5204 API can be disassembled and the seals may be replaced while the valve is still attached to

the trailer.

It is recommended to draw a line (using a felt-tip pen) across the joint between the pipe end (1) and the

nose ring (2). The line is used later in assembly to rotate the nose ring (2) from the starting position,

which helps balance out wear of the coupling surface.

4 090085 Rev 23

Page 5

DISASSEMBLY – PART I

CAUTION! THE POPPET IS HELD UNDER CONSIDERABLE SPRING TENSION. WHENEVER

THE NOSE RING (2) OR POPPET (9) ARE REMOVED OR REASSEMBLED, THE

VALVE MUST BE LATCHED IN THE OPEN POSITION OR THE POPPET

OTHERWISE RESTRAINED (LOAD ONLY). PERSONAL INJURIES MAY RESULT IF

THIS PRECAUTION IS NOT TAKEN.

ATTENTION! WHERE POLISHING IS INDICATED, USE NOT LESS THAN 600 GRIT POLISHING

CLOTHS.

Inspect nose ring (2) for scratches on sealing surface. If there are any scratches on the sealing

surface, the nose ring (2) should be replaced to avoid valve leakage. Faces without hard coating

should be polished around the bore and only in circumferential direction.

Poppet (9) should be inspected for scoring or raised metal on the stem. Any raised metal on the

poppet stem should be removed with a fine flat file and polished in axial direction.

Inspect poppet bearing (10) for intrusion of any foreign material on the inside diameter. Any foreign

material on the inside diameter should be carefully removed with a sharp tool and polished.

On completion of poppet (9) and poppet bearing (10) inspection, test the bearing (10) on the poppet (9)

without the spring (27) to make sure that the bearing (10) smoothly slides along the poppet (9) stem. If

this is not the case, the bearing should be replaced.

Test rotation of the poppet roller (13) around the pin (20). If the rotation is difficult, the roller bearing

should be replaced. To access the roller bearing, support the poppet (9) and release the pin (20) using

a ¼” pin punch.

Check the handle (8) for free and easy movement of the opening and closing cycle. Operation of the

handle (8) normally requires limited effort. If operating the handle (8) involves stronger force, it implies

the need to clean and possibly replace the shaft bearing (6) and the shaft (3).

Poppet o’ring (16) and main o’ring (17) should be inspected for cracks, scratches, missing material,

unusual hardness, softness, roughness, and other signs of chemical damage. Do not remove poppet

o’ring from the poppet at this stage.

At this point it may be decided to replace the main o’ring (17) and reassemble the valve if the first part

of the inspection did not reveal any damage or malfunction of the parts, or to continue with Part II of

disassembly and replace all the o’rings if there are any additional concerns regarding the performance

of the valve. Steps 5 through 8 of the Assembly section describe how to assemble the valve from this

point.

DISASSEMBLY – PART II

To remove two roll pins (19), turn the handle until the pin is accessible and drive out each pin in turn

using ¼” pin punch. If this is done with the valve attached to the tank, take precautions to ensure that

the pins (19) do not enter upstream piping. To remove the cam arm roll pin (19), ensure that the

handle is rotated to a position such that the roll pin will be clear of the deflector cone (valve body) as it

is driven out. If the roll pin appears not to drive further than approximately ¼”, check for contact

between the roll pin and deflector cone and slightly adjust the rotation of the handle to allow sufficient

clearance.

Take out handle (8) with shaft assembly, shaft spacer (5) and cam (11).

5 090085 Rev 23

Page 6

Remove shaft bearing (6), o’ring (18), back-up ring (33) and u-cup (34) from the pipe end (1) stuffing

box.

Examine stuffing box area of the pipe end (1) for corrosion and, if required, polish in circumferential

direction.

To disassemble handle from shaft assembly, remove cotter pin (28), washer (27), handle pin (4),

washer (31), spring (28), washer (32), and o’ring (29).

Polish sealing surfaces of the shaft (3) in a circumferential direction. Remove any burrs that might

have occurred during pin punching.

Carefully remove poppet o’ring (16) without damaging the sealing surface of the poppet (9). Even the

smallest scratches on the o’ring groove will cause leakage.

CLEANING, INSPECTION AND REPLACEMENT OF DISSASEMBLED PARTS

Clean well and visually examine all the parts of the API. Remove any burrs and sharp edges that could

damage the seals during reassembly. Replace any damaged parts.

ASSEMBLY

1. Before assembly, apply lubricant to the inside diameter of the pipe end stuffing box (1), to the u-cup

(34), back-up ring (33), o’ring (18), and shaft bearing (6). Insert u-cup (34) followed by back-up ring

(33), o’ring (18), and shaft bearing (6) inside pipe end stuffing box (1).

2. Lubricate shaft (3) and install it through the bearing (6) into the body (1) driving it through the shaft

spacer (5) and the cam (11). Insert pins (19) into the shaft holes.

3. Lubricate o’ring (29) and install it on the shaft (3). Continue installing washer (32), spring (28),

washer (31), and handle (8). Insert handle pin (4). Position handle with detent end away from the

stop pin and then install washer (25) and cotter pin (26).

4. Liberally lubricate poppet o’ring (16) and install it on the poppet (9) preventing torsion of the o’ring

during assembly as it may cause leakage. It is recommended to press on the full edge of the o’ring

(16) until it snaps around the poppet (9), and then push it into the o’ring groove from opposite sides.

5. Install spring (27) and poppet (9) into the pipe end (1). Lead the cam (11) over poppet roller (13)

and latch the handle (8) in the open position.

6. With lock washers (30) installed on each of the eight screws (23), apply ‘never-seize’ on the screw

threads.

7. Liberally grease o’ring (17) and install it on the nose ring (2). Use the radial line drawn in the step 1

of disassembly and starting from the initial alignment, rotate the nose ring (2) one bolt hole

clockwise. Bolt screws with washers and ‘anti-seize’ applied to the screw threads. Tighten using a

criss-cross flange torquing sequence.

8. To ensure proper operation of the valve, repeat the steps of the Semi-annual inspection.

6 090085 Rev 23

Page 7

FLUID LEVEL INDICATOR

If no liquid is visible, fluid

level in valve is below level

of adapter outlet.

Fluid level in the valve

is above adapter

outlet.

7 090085 Rev 23

Page 8

Valve closed

Valve semi-open

Valve fully open

HANDLE OPERATING POSITIONS

DIXON BAYCO WARRANTY:

For Warranty Information, please refer to the inside back cover of the latest Dixon

Catalogue.

8 090085 Rev 23

Page 9

1

Entretien & Mode d’emploi

pour

VALVES A.P.I 5204 BAYCO

Numéro des pièces

E-U:

Dixon Bayco USA

Chestertown, Maryland

Téléphone: 410-778-2000

Fax: 410-778-4702

Sans frais: 800-355-1991

E-mail: dixonbayco@dixonvalve.com

www.dixonbayco.com

Canada:

Dixon Group Canada Limited

Innisfil (Barrie), Ontario

Téléphone: 705-436-1125

Fax: 705-436-6251

Sans frais: 877-963-4966

E-mail: isales@dixongroupcanada.com

www.dixongroupcanada.com

Mexique:

Dixva, S. de R.L. de C.V.

Monterrey, N.L

Téléphone: 01-800-00-DIXON (34966)

Fax: 01-81-8354-8197

E-mail: contactenos@dixonvalve.com.mx

www.dixonvalve.com

Europe:

Dixon Group Europe Ltd

Preston, England

Téléphone: +44 (0)1772 323529

Fax: +44 (0)1772 314664

E-mail: enquiries@dixoneurope.co.uk

www.dixoneurope.co.uk

Asie et Pacifique:

Dixon (Asia Pacific) Pty Ltd

Wingfield, South Australia

Phone: +61 8 8202 6000

Fax: +61 8 8202 6099

E-mail: enquiries@dixonvalve.com.au

www.dixonvalve.com.au

Pour vente & service contactez

5204L ........................ Modèle de chargement (load only), avec vitre transparente

5204LNG................... Modèle de chargement (load only), sans vitre transparente

5204LNGV ................ Modèle de charg. (load only),sans vitre transp. joint torique du clapet pour B100

Modèles de chargement/

déchargement

”Load/ Unload”

Modèle de chargement

”Load only”

5204 ....................... manche fixe avec vitre transparente

5204C .................... manche détachable avec vitre transparente

5204NG ................. manche fixe sans vitre transparente

5204NGC .............. manche détachable sans vitre transparente

5204T .................... manche fixe avec vitre transparente, sceau de PTFE, ressort d’acier inoxydable

5204TC .................. manche détachable avec vitre transparente, sceau de PTFE, ressort d’acier inox.

5204NGT............... manche fixe sans vitre transparente, sceau de PTFE, ressort d’acier inox.

5204NGTC ............ manche détachable sans vitre transparente, sceau de PTFE, ressort d’acier inox.

5204B .................... manche fixe avec vitre transparente, anneau du nez de Bayloy

5204BC ................. manche détachable avec vitre transparente, anneau du nez de Bayloy

5204BNG .............. manche fixe sans vitre transparente, anneau du nez de Bayloy

5204BNGC ............ manche détachable sans vitre transparente, anneau du nez de Bayloy

5204SNG……… …manche fixe sans vitre transparente, ressort principal d’acier inoxydable

5204NGV…………manche fixe sans vitre transparente, joint torique du clapet pour B100

5204NGCV ........... manche détachable sans vitre transparente, joint torique du clapet pour B100

5204BNGV ......... manche fixe sans vitre transparente, anneau du nez de Bayloy, joint

torique du clapet pour B100

5204BNGCV ...... manche détachable sans vitre transparente, anneau du nez de Bayloy, joint

torique du clapet pour B100

5204SNGV …… …manche fixe sans vitre transparente, ressort d’acier inox. Joint torique de clapet

pour B100

5204P .................... manche fixé avec vitre transparente avec bouchon

090085(fr) Rev 23

Page 10

IMAGE

PIÈCE

QTÉ.

DESCRIPTION

PARTIE.

TROUSSES DE REPARATIONS

5204K1

5204K2

5204K3

5204K4

5204K5

5204K6

5204K7

5204K8

5204K9

5204K11

5204K12

5204KV1

5204KV2

1

1

1

Corps – entrée du tuyau

Corps avec vitre transparente

341614

Corps sans vitre transparente

341634

Corps avec modèle de chargement

(load only) et vitre transparente

341649

Corps avec modèle de chargement

(load only) sans vitre transparente

341650

2 1 Anneau du nez

* O

3

1

Arbre

390812

4 1

Goupille du manche

* O

5 1 Entretoise de l’arbre

390813

6 1

Roulement de l’arbre

* O O 7 1 Goupille d’arrêt

390814

8 1

Manche

* O

9 1 Sous-ensemble du clapet

341617

Sous-ensemble du clapet- modèle

De chargement (load only)

341651

Sous-ensemble avec PTFE

400624

10 1 -Roulement du clapet

* O

O

11

1

Came

111550

12 1 Vitre transparente

* O

13 1 -Rouleau du clapet

* O O 14 1 -Rouleau de roulement du clapet

* O O 15 1 Anneau de retenu

111560

16 1 -Joint torique

* O O O O

O

17

1

Joint torique

111554

O O O O O

18 1 Joint torique

* O O

O

19 2 Goupille cylindrique

111567

20 1 -Goupille

111566

21 1 Graisseur

111561

22 6 Vis

111570

O

23

8

Vis

* O O O 24 1 Joint torique

* O O O

O

25 5 Rondelle

* O

O (2) O

26 1 Goupille

* O 27A 1 Ressort principal

111564

27B 1 Ressort principal-acier inoxydable (pour 5204SNG)

111542

28

1

Ressort du manche

* O 29 1 Joint torique

* O

O

30

14

Rondelle de verrouillage

111569

O O O O

31 1 Rondelle

* O O O 32 1 Rondelle

111574

33 1 Anneau supplémentaire

111579

34

1

U-Cup

* O O 36

1

Flotteur

* O

2 37

1

Manche détachable

* O 38

1

Support

* O

39 1 Axe de chape

* O 40 1 Rondelle plate

* O 41 1 Goupille

* O 42 1 Ressort de torsion

* O 43 1 Goupille

* O

3 44 1 Anneau du nez fileté

* O

45

1

Bague d’usure

* O

4

46

1

Trousse d’enlèvement pour vitre transparente –

Plaque vide

* O

47

1

Trousse d’enlèvement pour vitre transparente-

Joint d’étanchéité

* O

*Utilisent une trousse de réparation appropriée O: OUI

Trousse de réparation 5204K1: Joint torique du clapet

Trousse de réparation 5204K2: Trousse complète de reconstruction; Tous les joints torique et les roulements

Trousse de réparation 5204K3: Anneau du nez anodisé avec vis

Trousse de réparation 5204K4: Anneau du nez de Bayloy avec vis

Trousse de réparation 5204K5: Assemblée de manche détachable

Trousse de réparation 5204K6: Sceau de PTFE encapsulé

Trousse de réparation 5204K7: Trousse de réparation pour manche fixe

Trousse de réparation 5204K8: Trousse de réparation pour vitre transparente

Trousse de réparation 5204K9: Trousse d’enlèvement pour vitre transparente

Trousse de réparation 5204K11: Trousse de quincaillerie pour l’anneau du nez

Trousse de réparation 5204K12: Trousse de quincaillerie pour la vitre transparente

Trousse de réparation 5204KV1: Trousse de reconstruction pour joint torique du clapet pour B100

Trousse de réparation 5204KV2: Trousse complète de reconstruction; (incluant joint torique du clapet et les roulements pour B100)

2 090085(fr) Rev 23

Page 11

* Version avec manche fixé

Image 2

Manche détachable

Image 3

Anneau du nez fileté

Image 4

Trousse

d’enlèvement de la

vitre transparente

3 090085(fr) Rev 23

Page 12

Ces instructions et ces recommandations sont fournies pour assurer un bon fonctionnement et un long

service du 5204 API Bayco. Les parties sont identifiées par des numéros de pièces sur le dessin

d’assemblement et la liste des pièces.

ENTRETIEN ET REMPLACEMENT DES PIÈCES POUR LES 5204 API BAYCO

Les instructions suivantes couvrent les deux modèles : valve à modèle chargement/déchargement

(load/unload) API et valve à modèle de chargement (load only) API. Pour la version de chargement ne

porter pas attention aux pièces en italiques.

I. INSPECTION SEMI-ANNUELLE

1. Une inspection visuelle de fonctionnement de la valve d’opération est possible lorsque la valve est

installée sur le réservoir. Toutes les mesures de sécurités qui sont en place pour l’usage de la valve

doivent être appliquées et tous les conduits doivent être vidés.

Inspectez visuellement le 5204 API pour l’usure ou des pièces endommagées ou n’importe quelle

condition qui pourrait affecter le fonctionnement de la valve.

Inspectez visuellement l’anneau du nez (2) des cavités, des égratignures ou n’importe quelle

déformation de la surface d’étanchéité.

Inspectez visuellement l’arbre (3) pour l’accumulation de saleté qui pourrait causer à l’étanchéité

de l’arbre d’avoir une fuite.

Vérifiez que le manche (8) de la valve (1) soit positionné automatiquement à un angle où l’entaille

sera dans le sens opposé de la goupille d’arrêt (7).

Inspectez visuellement la goupille d’arrêt (7) pour des signes d’usures ou de déformations. Lorsque

le manche est en position ouverte, il devrait rester accroché à la goupille d’arrêt (7). Si le manche

ne peut pas rester sécurisé au loquet de façon sécuritaire dû à l’usure de la goupille de d’arrêt (7),

la goupille devrait être remplacée. Vous pouvez utilisez des pinces-étaux pour dévisser la goupille

d’arrêt (7).

2. Vérifiez la performance du manche, ouvrez et fermez la valve API une couple de fois. Le manche

devrait bouger sans obstruction et facilement.

3. Lorsque le manche est relâché (ouvert) de la goupille d’arrêt, le clapet (9) devrait se centrer et se

fermer immédiatement.

4. Pour ne pas endommager le clapet (9), appuyez sur le clapet (9) (en utilisant un morceau de bois)

sans utiliser le manche. Pressez le clapet sur le coté en vous assurant qu’il se rassoit et se recentre

lorsqu’il est fermé.

Si l’un des points ci-dessus échoue, un entretien supplémentaire sera nécessaire.

4 090085(fr) Rev 23

Page 13

II. INSPECTION ANNUELLE ET ENTRETIEN

La soupape 5204 API peut être désassemblée et les étanchéités peuvent être remplacées lorsque la

valve est attachée au pétrolier.

Il est recommandé que vous traciez une ligne (avec un marqueur) à travers le joint entre le tuyau (1) et

l’anneau du nez (2). La ligne est utilisée pour tourner la position de l’anneau du nez de sa position

initiale, ceci aide à balancer l’usure de la surface de la valve.

DÉMONTAGE – ÉTAPE 1

ATTENTION! LE CLAPET EST RETENU PAR UNE TENSION DE RESSORT CONSIDERABLE.

AVANT QUE L’ANNEAU DU NEZ (2) OU LE CLAPET (9) SOIENT RETIRÉS OU

RÉSASSEMBLÉS, EN UTILISANT LE MANCHE, LA VALVE DOIT ÊTRE EN

POSITION OUVERTE ET LE MODÈLE SANS MANCHE DOIT AVOIR LE CLAPET

OUVERT. UN ACCIDENT POURRAIT EN RESULTER SI VOUS NE PRENEZ PAS

LES PRÉCAUTIONS NÉCESSAIRES.

ATTENTION! N’UTILISER PAS UN CHIFFON À MOINS DE 600 GRAINS LORS DU POLISSAGE.

Inspectez l’anneau du nez (2) pour des égratignures sur la surface d’étanchéité. S’il y a des

égratignures sur la surface d’étanchéité l’anneau du nez (2) devrait être remplacé pour éviter des

fuites. La surface sans revêtement devrait être polie autour de l’alésage dans une direction

circonférentielle.

Le clapet (9) devrait être inspecté pour des signes d’usures et des dommages à la tige. Toutes

accumulations de métal sur la tige devraient être limé et polie dans la même direction que l’axe.

Inspectez le roulement (10) du clapet pour l’intrusion de matériaux étranger à intérieure du diamètre.

Tout matériel à l’intérieure du diamètre devrait être retiré soigneusement avec un objet pointu et polie.

Lorsque l’inspection du clapet (9) et du roulement du clapet (10) sont complet, testez le roulement du

clapet (10) sans ressort (27) pour vous assurez que le roulement (10) glisse facilement au long de la

tige du clapet (9). Si ce n’est pas le cas le roulement devrait être remplacé.

Testez le rouleau du clapet (13) autour de la goupille (20). Si la rotation est difficile, le rouleau du

clapet devrait être remplacé. Pour avoir accès au rouleau du clapet, supportez le clapet et retirez la

goupille (20) en utilisant un poinçon de ¼”.

Vérifiez le manche (8) pour un mouvement libre et facile durant l’ouverture et la fermeture. L’opération

normale du manche (8) demande un effort limité. Si le fonctionnement du manche (8) demande plus de

force, cela indique le besoin de nettoyer ou possiblement de remplacer le roulement de l’arbre (6) ou

l’arbre (3).

Le joint torique du clapet (16) et le joint torique principal (17) devraient être inspectés pour des

craques, des égratignures, pièces manquantes, la dureté inhabituelle, la mollesse, rugosité et d’autres

dommages causés par des produits chimiques. Ne retirez pas le joint torique du clapet à cette étape.

A ce stade vous pouvez décider de remplacer le joint torique principal (17) et réassembler la valve si la

première partie de l’inspection ne révèle aucun dommage ou un mauvais fonctionnent des pièces ou

de continuer avec la deuxième partie du démontage et remplacez tout les joints toriques s’il y a des

concernes additionnels regardant la performance de la valve. Les étapes de 5 à 8 de la section

d’assemblement décrivent comment assembler la valve à partir de ce point.

5 090085(fr) Rev 23

Page 14

DÉMONTAGE – ÉTAPE II

Pour retirez les deux goupilles cylindriques (19), tournez le manche jusqu’à ce que la goupille soit

accessible et retirez les goupilles en utilisant un poinçon de ¼”. Si vous faites ceci avec la valve

attaché au pétrolier, prenez les mesures nécessaires pour que les goupilles (19) n’entrent pas dans la

tuyauterie. Pour retirer la goupille cylindrique (19) du bras de la came, assurez-vous que le manche

soit tourné en position pour que la goupille cylindrique ne soit pas obstruer par le cône déflecteur

(corps de la valve) en la retirant. Si la goupille cylindrique ne sort pas plus que ¼”, vérifiez s’il y a un

contact entre la goupille cylindrique et le cône déflecteur et ajuster la rotation légèrement pour

permettre un dégagement suffisant.

Retirez le manche (8) avec l’assemblé de l’arbre, entretoise d’arbre (5) et la came (11).

Retirez le roulement de l’arbre (6), joint torique (18), l’anneau supplémentaire et capsule en U (34) du

bout du tuyau (1) du presse-étoupe.

Examinez le presse-étoupe au bout du tuyau (1) pour de la corrosion et polissez si nécessaire dans

une direction circonférentielle.

Pour démonter le manche de l’assemblé de l’arbre, enlevez la goupille (26), rondelle (27), goupille du

manche (4), rondelles (31), ressort (28), rondelle (32) et joint torique (29).

Polissez la surface d’étanchéité de l’arbre (3) dans une direction circonférentielle. Retirez toutes les

bavures qu’il aurait pu avoir durant le poinçonnage de la goupille.

Délicatement retirez le joint torique du clapet (16) sans endommager la surface d’étanchéité du clapet

(9). Même la plus petite égratignure de la rainure du joint torique peut causer une fuite.

NETTOYAGE, INSPECTION ET REMPLACEMENT DES PARTIES DÉMONTÉS

Nettoyez bien et examinez visuellement toutes les parties de la valve API. Retirez toutes les bavures et

les bordures aiguisées qui pourraient endommager les joints d’étanchéités durant le réassemblage.

Remplacez toutes les pièces endommagées.

ASSEMBLAGE

1. Avant l’assemblage, lubrifiez le diamètre intérieur du presse-étoupe (1), la capsule en U (34),

l’anneau de réserve (33), joint torique (18) et le roulement de l’arbre (6). Insérez le capsule en U

(34) suivit par l’anneau de réserve (33), joint torique (18) et l’arbre de roulement (6) à l’intérieure du

presse-étoupe(1).

2. Lubrifiez l’arbre (3) et installez-le à travers le roulement (6) à l’intérieur du corps (1) à travers

l’entretoise (5) et la came (11). Insérez les goupilles (19) dans les trous de l’arbre.

3. Lubrifiez le joint torique (29) et installez-le sur l’arbre (3). Continuez à installer la rondelle (32),

ressort (28), rondelle (31) et le manche (8). Insérez la goupille du manche (4). Positionnez la

manche avec l’embouchure dans la direction opposée de la goupille d’arrêt et ensuite installer la

rondelle (25) et le goupille (26).

4. Lubrifiez le joint torique du clapet (16) et installez-le sur le clapet (9) en évitant la torsion du joint

torique durant l’assemblage car une fuite pourrait en résulter. Il est recommandé que vous

appuyez complètement sur le joint torique (16) jusqu’à ce qu’il soit en place autour du clapet (9),

ensuite appuyez sur l’autre coté de la rainure du clapet.

6 090085(fr) Rev 23

Page 15

5. Installez le ressort (27) et le clapet (9) au bout du tuyau (1). Mettez la came (11) sur le rouleau du

clapet (13) et sécurisez le manche (8) dans la position ouverte.

6. Avec une rondelle de verrouillage (30) installé sur chacune des huit vis (23), appliquez un lubrifiant

anti-grippant sur les vis.

7. Lubrifiez le joint torique (17) et installez-le sur l’anneau du nez (2). Servez-vous de la ligne que vous

avez tracez à la première étape du démontage et en commençant par l’alignement initial, tournez

l’anneau du nez (2) d’un trou de boulon au sens des aiguilles d’une montre. Appliquez du lubrifiant

anti-grippant aux boulons et aux rondelles. Serrez les boulons de la bride de façon sillonnée.

8. Pour assurer un bon fonctionnement de la valve, répétez les étapes de l’inspection semi- annuelle

Indicateur du niveau de fluide

S’il n’y a pas de liquide

visible, le niveau du

fluide dans la valve est

inférieur au niveau dans

la sortie pour

Le niveau de fluide dans

la valve est au-dessus

du niveau à sortie pour

l'adaptateur.

l’adaptateur.

7 090085(fr) Rev 23

Page 16

Valve fermée

Valve semi-ouverte

Valve complètement

ouverte

POSITIONS DE FONCTIONNEMENT POUR LE MANCHE

GARANTIE DIXON:

Pour plus d’informations complètes sur la garantie, s’il vous plait se référer à la

couverture intérieure de la dernière page du dernier catalogue Dixon.

8 090085(fr) Rev 23

Loading...

Loading...