Page 1

Parts & Owner’s Manual

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337

620.251.2000 • www.dixon-ztr.com

Congratulations on the purchase of your new

Dixon mower.

Before any warranty service can be authorized you

must register this product with the manufacturer.

© Dixon Industries Inc.

36” & 48” Commercial

Belt-Drive Mowers

Page 2

TABLE OF CONTENTS

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Information

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Before Use of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operation Of the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety Information Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating The Mower

Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Going Forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Turning The Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Stopping The Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Going In Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Mowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Height Of Cut

Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Adjusting Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Adjusting Front Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Service And Maintenance Of The Mower

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cleaning The Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Service Adjustments

Wheel Brake Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Wheel Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Engine To Blade Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Blade To Blade Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Engine To Transmission Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Safety Interlock System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337

620.251.2000 • www.dixon-ztr.com

Commercial Belt-Drive Mowers

Owner’s Manual For Dixon 36” & 48”

Page 3

3

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

NOTES

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

Page 4

4

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

About This Manual

This owner’s manual is considered a permanent part of the mower. It must be available to all of

the operators and/or person(s) servicing the mower. Should the mower be resold, this manual

must remain with the mower.

All information, illustrations, and specifications contained in this manual were in effect at the

time of publication. Dixon Industries, Inc. reserves the right to change, modify, and/or discontinue specifications and/or design without notice. If there is a change that has been made to

your mower which is not shown or reflected in this manual, please see your authorized Bradley

Mower dealer before operating and/or servicing the equipment.

Congratulations on the purchase of your new Dixon commercial mower. We at Dixon

Industries, Inc. are confident that this mower will provide you with years of excellent performance,

durability, and trouble free service when operated and maintained as directed in this manual.

Should you ever have any questions regarding the operation, maintenance, or safety of your

mower, please contact your authorized Dixon Mower dealer who has been specially trained on

operation and service of Dixon Mowers.

A space has been provided below to record information about your new Dixon Mower. Please

take time to record such information for future reference, especially when you contact an

authorized Dixon Mower dealer with questions.

Date Purchased: ____________________________________________________

Model Number: ____________________________________________________

Serial Number: ____________________________________________________

Purchased From: ____________________________________________________

____________________________________________________

Page 5

5

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

DIXON®LIMITED WARRANTY POLICY

WalkAbout™ Mowers

DIXON® WALKABOUT™ MOWERS ARE WARRANTED AGAINST DEFECTS IN MATERIALS AND WORKMANSHIP AND PROVIDES FOR REPLACEMENT OR REPAIR OF PARTS INCLUDING LABOR COSTS.

THIS WARRANTY IS SUBJECT TO THE FOLLOWING CONDITIONS AND LIMITATIONS.

1. Dixon

® WalkAbout™ mowers are warranted for one (1) year from date of purchase for residential or

commercial use.

2. Warranty applies only to original retail purchase of new and unused mowers and accessories.

3. All Dixon

® warranty must be accomplished by authorized Dixon

® dealers and in accordance with

Dixon

® warranty policy and allowances. All warranty claims must be approved by Dixon Industries, Inc.

4. Warranty does not apply to damage in transit or incidents of misuse, negligence, accidents, or

alteration. The use of parts or components other than those supplied by Dixon Industries VOIDS ALL

WARRANTY.

5. The following items are not covered by this warranty policy:

(a) Pick up and delivery charges for transportation of mower to and from an authorized Dixon

® dealer’s

place of business.

(b) Routine maintenance or adjustments.

(c) Belts, blades, tilters or tires.

(d) Engines - all engines used on Dixon®

WalkAbout™ mowers are warranted by each individual

engine manufacturer.

(e) Transmission - All transmissions used on Dixon

® WalkAbout™ mowers are warranted by the

transmission manufacturer.

(f) Any costs or expense of providing substitute equipment while repair work is being performed on a

warranted mower.

6. There is no other express warranty. Implied warranties, including those of merchantability and fitness

for a particular purpose are limited to the same duration if the express warranty and to the extent

permitted by law any and all implied warranties are excluded. Liabilities for consequential damages

under any and all warranties are excluded.

Page 6

6

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

SAFETY INFORMATION

Read This Manual Carefully And Thoroughly Before Operating The Mower!

Training

1. Carefully and thoroughly read the owner’s manual. Allow adequate time to fully understand the controls and

operation of the equipment.

2. Never allow anyone to operate the mower that has not read and fully understood the owner’s manual.

3. Do not carry passengers. Avoid mowing while people, especially children and pets are nearby, since rotating

blades can throw rocks and other items with enough force to cause serious injury.

Before Use of Equipment

Operator:

Wear protective clothing while mowing. Long trousers and safety glasses will help reduce the risk of injury from

thrown objects. It is recommended that steel toe shoes with aggressive soles or some other type of substantial

footwear be worn to help protect your feet and maintain traction on slopes or uneven ground. Always wear hearing protection.

Mowing Area:

Thoroughly inspect the area where the equipment is to be used. Look for items such as stones, sticks, wire and

other foreign objects. When struck by the mower, these and other objects my become projectiles that could lead

to serous injury and/or death.

Mower:

For your safety and the long life of your mower, always inspect the mower before each use. Before inspection,

make sure it is on a flat and level surface, the blades are disengaged, the ignition switch off with the key

removed, and the spark plug wire is off of the spark plug(s) and hidden so that accidental contact can not be

made,

General Condition:

· Walk around the mower looking for any fluid spills or leaks on or underneath the mower. Remove any

and all excessive debris, dirt, and/or fluids.

· Look for signs of damage or excessive wear. Check the tightness of all nuts, bolts, pins, and screws.

Tighten any that may be loose and replace any that may have been lost during use.

· Be sure the safety interlock controls are operating properly so that the engine can not be started unless

the ground speed control lever is in neutral and the blades disengaged.

· Check the mower blades for any damage or abnormal wear and replace in sets so that they are balanced.

· Check the tire pressure on all four tires. See page 15 for details.

· Check all belts for proper wear and correct tension. See pages 17-19 for details.

· Check engine oil and air filters as recommended in the engine manufacturers’ operators manual.

Page 7

7

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Operation of Equipment

DANGER: GASOLINE IS HIGHLY FLAMMABLE AND EXPLOSIVE. DO NOT ADD FUEL WHILE THE

ENGINE IS RUNNING OR IS HOT. KEEP OPEN FLAMES, SPARKS, AND HEAT AWAY FROM THE

FUEL AND STORE FUEL IN CONTAINERS SPECIFICALLY DESIGNED FOR THAT PURPOSE. ADD

FUEL OUTDOORS ONLY AND IF THE FUEL IS SPILLED, DO NOT START THE ENGINE. MANUALLY

PUSH THE MOWER AWAY FROM THE SPILL AND IMMEDIATELY WIPE UP.

Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect.

Carbon monoxide is odorless, tasteless, and can be fatal.

Mow only in daylight.

Do not park on hills without the use of wheel blocks.

Make sure the mower is in neutral and the blades are disengaged before attempting to start the engine.

Do not stop or start suddenly when going uphill. Never use riding attachments on slopes since there is an

increase risk that they might roll over.

Avoid steep slopes and use extreme caution when changing directions or speed when operating on a slope.

Be extremely careful when operating on a slope or when the grass is damp or wet. Reduced traction could

cause sliding. Never mow by pulling the mower back towards you...you might slip.

Watch for traffic when crossing surfaces other than grass. (i.e. transporting,) loading a trailer or vehicle, or

when the mower is not in use.

Never operate the mower with defective guards, shields, or without the safety devices securely mounted in

place.

Never direct discharge of material toward bystanders nor allow anyone near the mower while in operation.

Do not change the governor settings or over speed the engine.

Always stop the engine whenever you leave the mower, even for a moment.

To help reduce the risk of a fire hazard, keep the engine and the area around the engine free of grass,

leaves, or any other type of foreign material.

Beware of cutting edges. Always wear gloves for safety when performing blade maintenance activities.

Beware on multiple blades units since the rotation of one blade may cause the rotation of the other blade.

Do not store or operate the mower with the grass chute deflector in raised position. Serious injury could

occur.

!

Page 8

8

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

SAFETY INFORMATION DECALS

The following labels are intended to aler t you to potential hazards and to pr ovide

you with important safety information. Should these decals become difficult to

read or are missing from the mower, contact your Dixon® WalkAbout™ Mower

dealer for a replacement.

Page 9

9

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

OPERATING THE MOWER

It is recommended that before you operate the mower, you allow adequate time to fully understand

the controls and operation of the equipment. When reading this manual, it is recommended that you

do so with the equipment nearby for quick orientation, reference of controls and maintenance

adjustments.

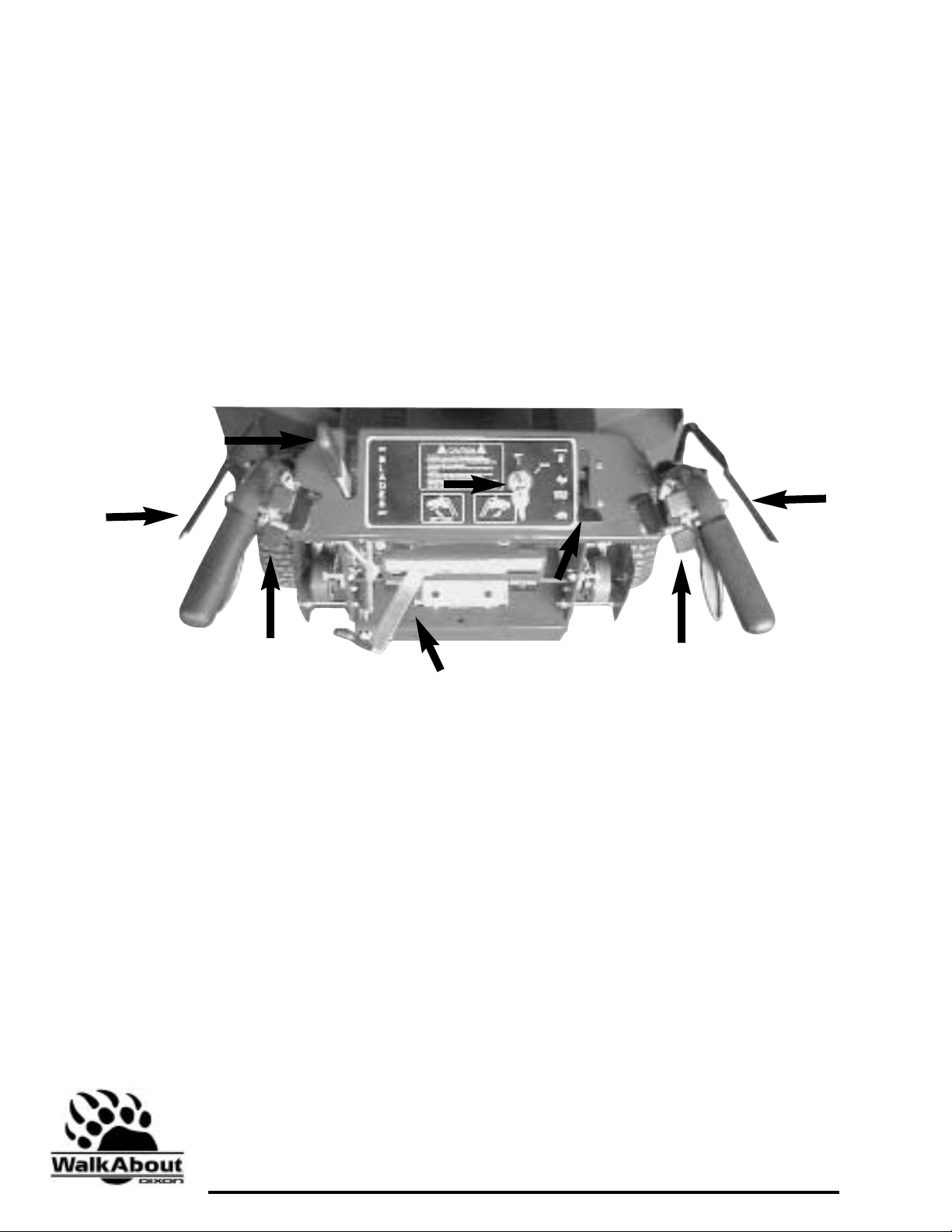

Operating Controls

Before continuing to read the manual, it is recommended that you take adequate time to identify the

controls of the mower.

“A” Traction Lever Locks “D” Key Switch

“B” Operator Presence Controls “E” Throttle/Choke Control

“C” Blade Control Lever “F” Gear Shift Lever

C

A

B

B

D

F

A

E

Page 10

10

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Starting T he Engine:

DANGER: DO NOT OPERATE THE ENGINE IN A CONFINED SPACE

WHERE DANGEROUS CARBON MONOXIDE FUMES CAN COLLECT.

CARBON DIOXIDE IS ODORLESS, TASTELESS, AND CAN BE FATAL.

After going through the steps as discussed on pages (6) and (7), you

are now ready to start the engine. NOTE: THIS UNIT WAS SHIPPED

WITHOUT THE GAS, BE SURE TO ADD FRESH GAS AND TO DOUBLE CHECK THE OIL IN THE ENGINE BEFORE ATTEMPTING TO

START THE MOWER.

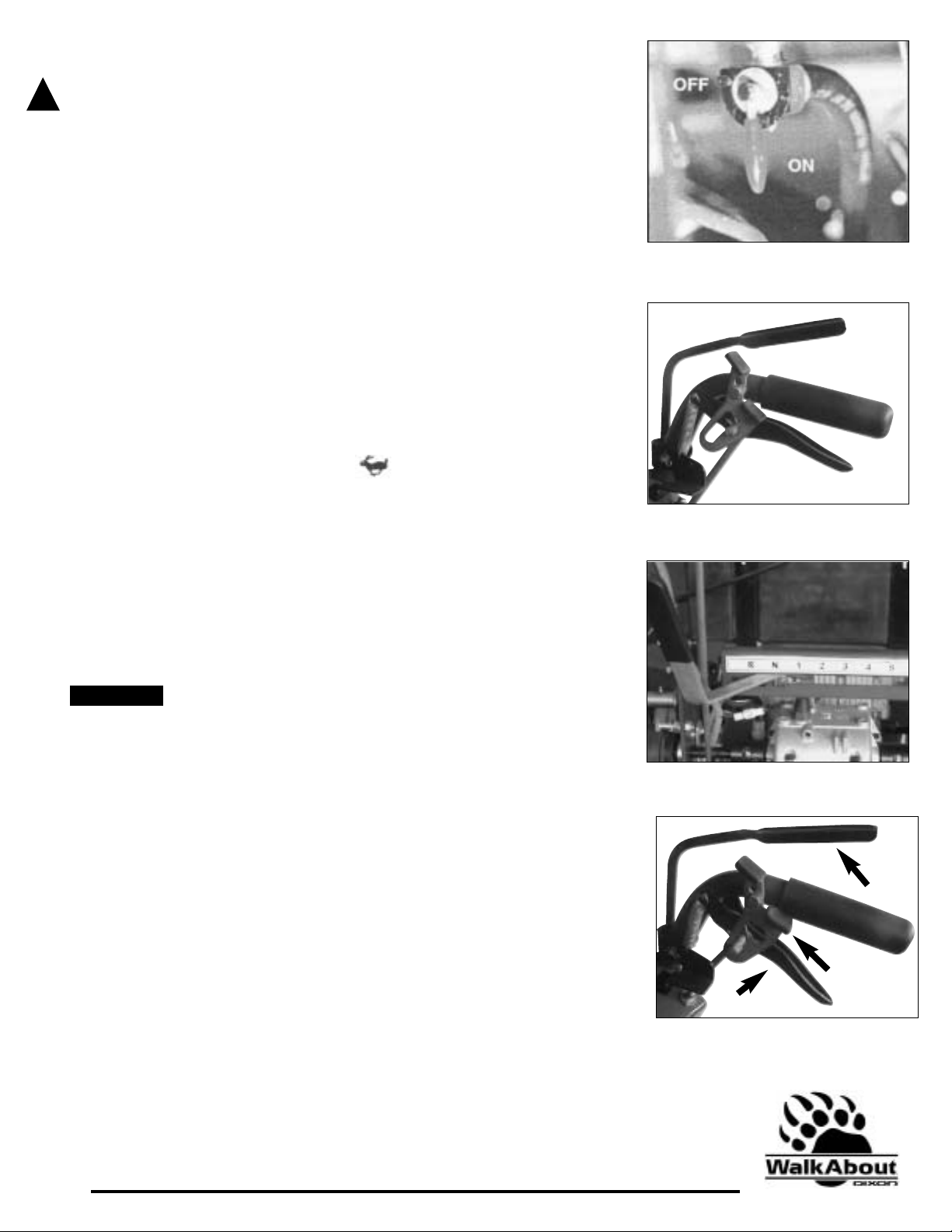

Make sure that the shut off valve, located at the bottom of the fuel tank

is in the “ON” position (figure 2).

Make sure that the traction control lever are in the neutral position(figure 3)

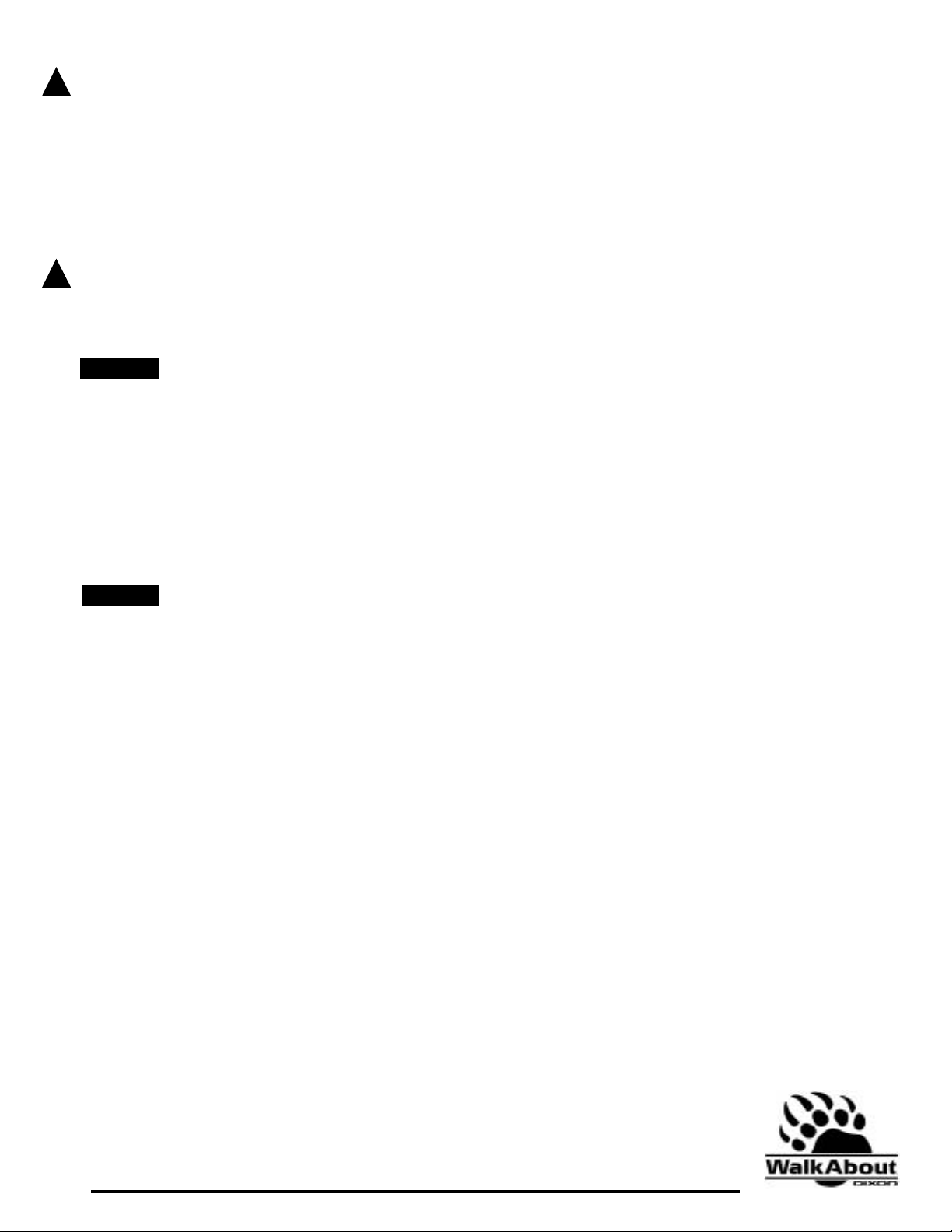

Make sure that the gear shift lever is in the neutral “N” position (figure 4)

Make sure that the blade control lever is in the “OFF” position. NOTE: The

safety interlock system will prevent the engine from being started if the

blade control lever is not in the “OFF” position and the gear shift lever is

not in the neutral “N” position.

Slide the engine speed control to the “ “ position, or to “CHOKE” if the

engine is cold.

Turn the key clockwise to the “RUN” position.

Slowly pull the start cord on the engine until just past compression. STOP!

Return the start cord and then pull firmly with a smooth, steady motion to

start the engine.

When the engine starts to run, slowly return the engine speed control out

of “CHOKE” to the desired engine speed.

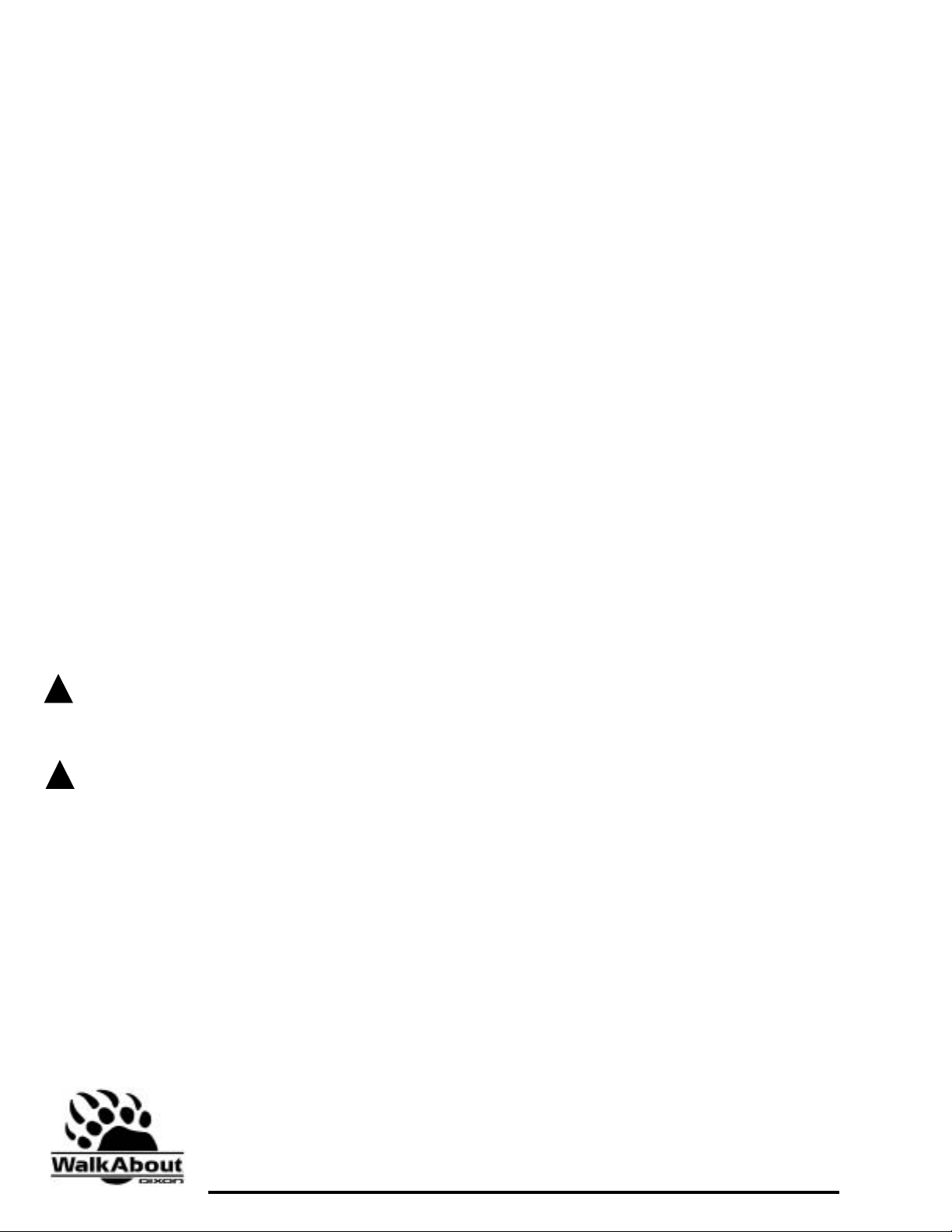

Going Forward:

CAUTION Become totally familiar with the operation and characteris-

tics of the mower before attempting to actually mow with it.

Making sure that the traction control levers are in the neutral position, push

down and hold the operator presence control lever “A” on the handle grips

with one hand (Figure 5).

With the other hand, move the gear shift lever to the desired speed. “1” is

slow and “5” is for transporting the mower between mowing areas (Figure

4). It is recommended that you start out in “1” and then increase your

ground speed to match the mowing conditions.

Release the traction control lever locks by squeezing up both traction control levers “C” only as much as needed while at the same time applying forward pressure in the traction control lever locks “B” with your thumbs.

Slowly and evenly, let both traction control levers down simultaneously and

the mower will start to go forward (Figure 5). NOTE: If the operator lets go

of both operator presence control levers while either the blade control lever

is in “ON”, and/or the gear shift control lever is out of the neutral position

the safety interlock system will stop the engine. To restart the mower, reset

all controls to the “OFF” position and neutral “N” positions.

!

1.

2.

3.

4.

5.

6.

7.

8.

1.

2.

3.

4.

Figure 2

Figure 3

Figure 4

Figure 5

A

B

C

Page 11

11

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Turning The Mower

To turn the mower in the direction you want to go, gently squeeze the side’s traction control lever (i.e. to go right,

squeeze the right traction control lever; to go left, squeeze the left traction control lever). The more a particular

traction control lever is squeezed, the sharper a turn the mower will make.

Stopping The Mower

To stop the mower, gently and evenly squeeze up on both of the traction control levers until the mower comes to a

complete stop. Then with your thumbs, push down on the traction lever locks until the levers are securely locked

in the neutral position. While still holding down with one hand the operator presence controls, move the gear shift

lever to the “N” position with the other hand. If the operator is leaving the operator’s position behind the mower for

any reason, disengage the blades, shut the engine off, and remove the key.

If you are leaving the operator’s position, try to park the mower on level ground. If it is not possible to do

such, be sure to block the wheels to prevent the mower from rolling away.

Using The Reverse Assist

Slowly and evenly squeeze up on both control levers until the mower comes to a complete stop and then with

your thumbs, push down on the traction lever locks until the levers are securely locked in the neutral position.

While still holding down the operator presence control with one hand, use the other and pull the blade control

lever to the “OFF” position.

Shift the gear shift lever to the reverse “R” position.

Release the traction control lever locks by squeezing by both traction control levers only as much as needed

while at the same time, applying forward pressure on the traction control lever locks with your thumbs.

Slowly and evenly, let both traction control levers down simultaneously and the mower will start to go in

reverse. Always use extreme caution when moving the mower backwards and never move the mower

downhill backwards.

To stop the mower, slowly and evenly squeeze up on both control levers until the mower comes to a complete

stop and then with your thumbs, push down on the traction lever locks until the levers are securely locked in

the neutral position and return the gear shift lever to neutral “N”.

Mowing

DANGER: THOROUGHLY INSPECT THE AREA WHERE THE EQUIPMENT IS TO BE USED. LOOK FOR

ITEMS SUCH AS STONES, STICKS, WIRE, AND OTHER FOREIGN OBJECTS. WHEN STRUCK BY THE

MOWER, THESE AND OTHER OBJECTS MAY BECOME PROJECTILES THAT COULD LEAD TO SERIOUS INJURYAND OR DEATH. CLEAR AREA OF ALL DEBRIS AND KEEP PEOPLE AND PETS AWAY.

DANGER: DO NOT OPERATE THE MOWER WITH DEFECTIVE GUARDS, SHIELDS, OR WITHOUT THE

SAFETY DEVICES SECURELY IN PLACE.

For the highest quality of cut and performance, always mow with the engine at full throttle. Quality of cut may

be determined by the ground speed and speed of the mower. Generally, the slower the mower travels across

the terrain, the better the cut.

With the mower at the beginning of the area to be mowed and traction control levers in the neutral position,

hold down with one hand the operator presence control.

With the other hand, slowly push the blade control lever forward to the “ON” position.

Move the gear shift lever to the desired speed. Always begin at a slow ground speed and increase only as the

condition of the terrain warrants.

Slowly and evenly, engage the traction control levers and begin mowing.

To stop mowing, slowly and evenly squeeze up on both traction control levers until the mower comes to a com-

plete stop and then with your thumbs, push down on the traction lever locks until the levers are securely locked

in the neutral position. Return the gear shift lever to the neutral “N” position.

Pull the blade control lever back to the “OFF” position.

1.

2.

3.

4.

5.

6.

!

!

Page 12

12

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Changing The Height Of Cut:

DANGER: BEFORE MAKING ANY ADJUSTMENTS AND/OR SERVICING YOUR MOWER, MAKE SURE

THE MOWER IS ON LEVEL GROUND, BLADES DISENGAGED, KEYS REMOVED, AND THE ENGINE OFF

WITH THE SPARK PLUG WIRE(S) REMOVED FROM THE SPARK PLUGS(S) TO PREVENT ACCIDENTAL

CONTACT.

When your Dixon walkabout mower is shipped from the factory, the mowing height is set at 2-1/2”. The mowing

height may be raised or lowered using a combination of front wheel spacers and blade bolt assembly spacers.

It is recommended that you first set your height of cut to the highest level using the blade spacers and then

lower the height of cut using the front wheel spacers.

Measuring The Height Of Cut:

DANGER: BEFORE MAKING ANY ADJUSTMENTS AND/OR SERVICING YOUR MOWER, MAKE SURE

THE MOWER IS ON LEVEL GROUND, BLADES DISENGAGED, KEYS REMOVED, AND THE ENGINE OFF

WITH THE SPARK PLUG WIRE(S) REMOVED FROM THE SPARK PLUGS(S) TO PREVENT ACCIDENTAL

CONTACT.

CAUTION Beware of the cutting edges on the blades. The rotation of one blade may cause the other

blade(s) to rotate. Always wear work gloves when handling blades.

Park the mower on level ground.

With the blade control lever in the “OFF” position, the engine off with the key removed, and the spark

plug wire (s) removed from the spark plug(s), reach through the discharge chute and slowly rotate the blade

so that the length of the blade is going from the front of the mower towards the rear.

Using a tape measure or small ruler, measure the distance from the front tip of the blade’s cutting edge to the

ground. As a general rule, if measuring the cutting height on a hard surface such as concrete, the mower will

usually mow about 1/4” lower in grass due to the weight of the machine.

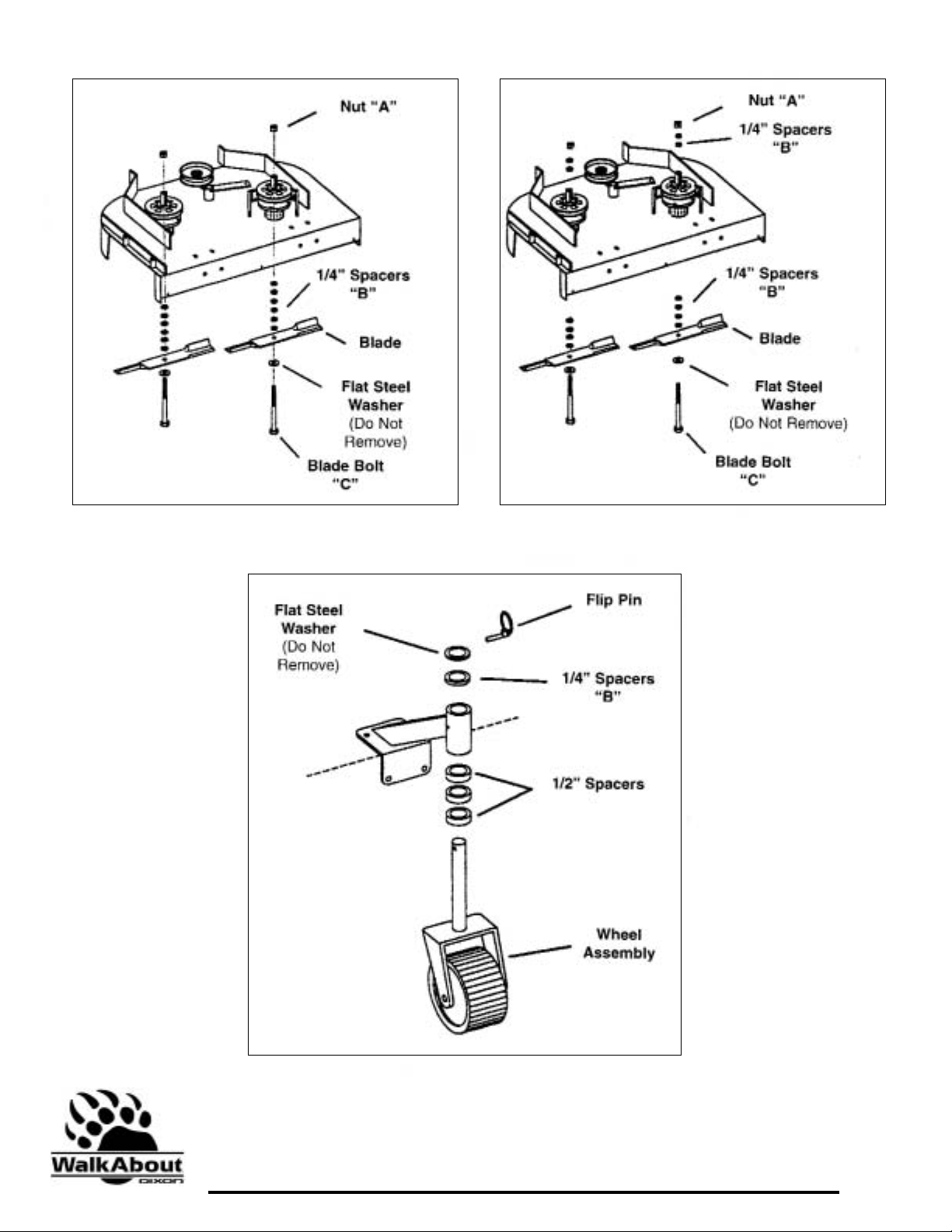

Removing And Adjusting T he Blades:

CAUTION Beware of the cutting edges on the blades. The rotation of one blade may cause the other

blade(s) to rotate. Always wear work gloves when handling blades.

Park the mower on level ground and block the rear wheels to prevent accidental rollback.

Raise the front end of the mower using a jackstand

Using two (2) 15/16” box end wrenches, use one wrench to loosen nut “A” while holding blade bolt “C” with the

other wrench (Figure 6).

Slide the blade bolt down through the mower deck and out.

To raise the blades to the height desired, remove the appropriate amount of spacers from the blade bolt.

Example: If the height of cut needs to be raised 1/2”, move two (2) of the 1/4” spacers “B” on each blade from

underneath the mower (Figure 6) to the top of the mower (Figure 7).

Reinsert the blade bolt through the cutting deck.

Install the blade spacers that were removed, back onto the blade bolt followed by the nut and tighten (Figure 6).

IMPORT ANT: The amount of spacers should always be the same on each blade bolt. Never put the spacers

below the blade.

Adjusting The Front Wheels: (refer to Figure 8)

Raise and support the front of the mower with a jackstand.

While supporting the front wheel with one hand, remove the flip pin from the wheel shaft.

Remove the wheel from the front wheel support arm being careful not to loose the spacers.

Remove the amount of spacers desired to lower the height of cut.

Reinsert the wheel through the support arm.

Reinstall the spacers on the top that were removed from the bottom and then secure with the flip pin.

To raise the height, repeat steps 1-3, but take the spacers from the top of the wheel support arm, and put

them on the bottom.

!

!

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

1.

2.

3.

4.

5.

6.

7.

Page 13

13

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Figure 6 Figure 7

Figure 8

Page 14

14

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

GENERAL MAINTENANCE

Proper maintenance and adjustment of your Dixon® WalkAbout™mower is necessary to keep the mower in good

and safe condition. The maintenance of the mower is the responsibility of the owner/operator and must be performed

at regular intervals. When replacing any parts of servicing your mower, be sure to use only genuine Dixon

®

WalkAbout™ mower replacement parts to assure quality and performance of your mower.

DANGER: BEFORE MAKING ANY ADJUSTMENTS AND/OR SERVICING YOUR MOWER, MAKE

SURE THE MOWER IS ON LEVEL GROUND, BLADES DISENGAGED, KEY REMOVED, AND THE

ENGINE OFF WITH THE SPARK PLUG WIRE(S) REMOVED FROM THE SPARK PLUGS(S) TO PREVENT ACCIDENTAL CONTACT. IF ADJUSTMENT OR MAINTENANCE IS BEING PERFORMED

AFTER OPERATION OF THE MOWER, ALLOW THE UNIT TO COOL SINCE HEAT BUILD UP

COULD CAUSE SEVERE BURNS.

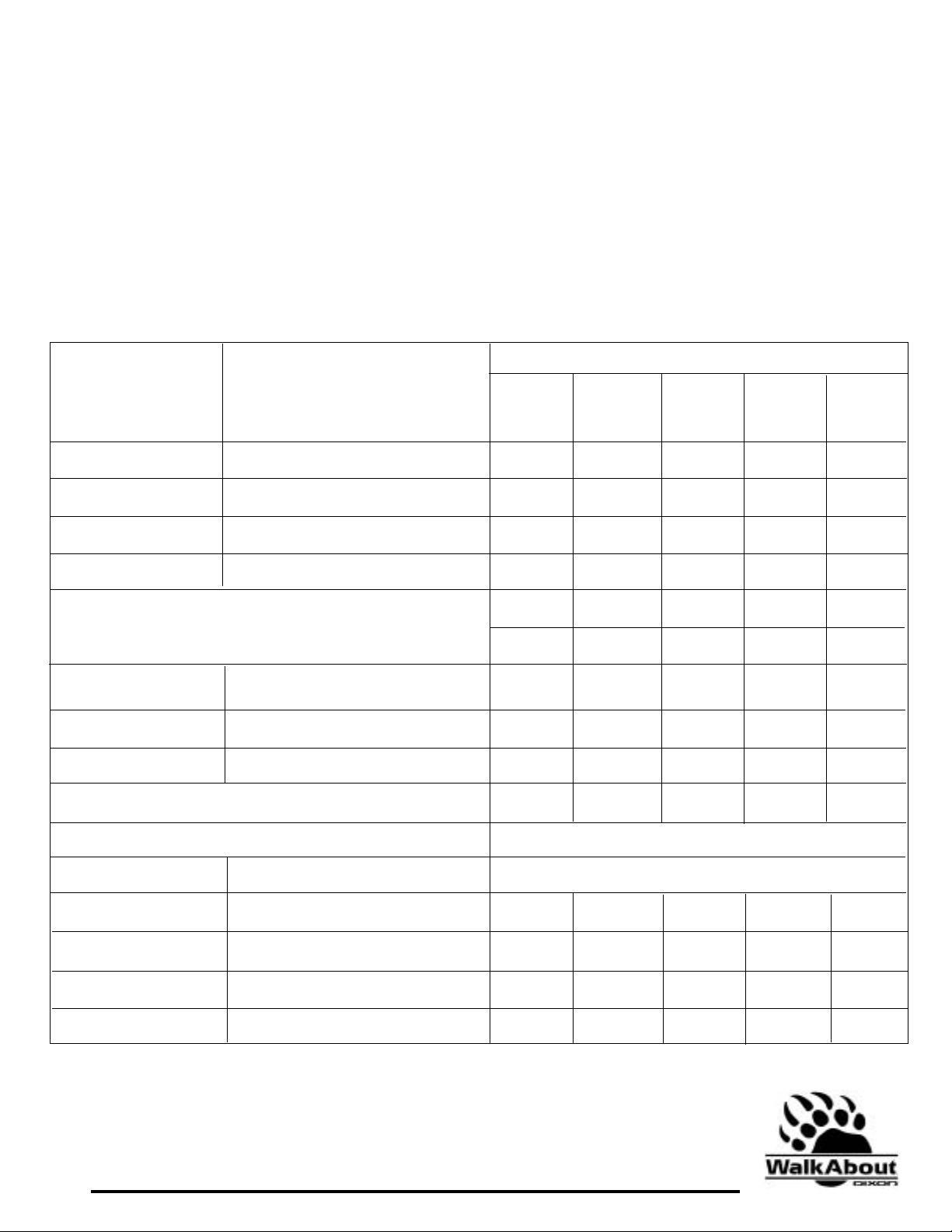

Maintenance Schedule

Time Interval

Item

Procedure

Break-in

(first 5 hrs)

Every 8

hours

(Daily)

Every 40

hours

(Weekly)

Every 100

hours

(Bi-weekly)

Every 200

hours

(Monthly)

Belts Inspect (adjust if needed)

Blades Inspect and Sharpen

Engine Air Filter Inspect

(See Engine Owner’s Manual)

Engine Cooling Areas Clean (See Engine Owner’s Manual)

Engine Oil Check(See Engine Owner’s Manual)

Change (See Engine Owner’s Manual)

Engine Oil Filter Change (See Engine Owner’s Manual)

Engine Spark Plug (s) Inspect (See Engine Owner’s Manual)

Fuel Filter Replace

Fuel Line Check

Replace

Grease Fittings Refer to Page 16

Hardware Check for proper tightness

Mower Main Frame

Remove debris from under belt cover

Safety Interlock System

Check Operation and Switches

Tires Check Air Pressure

••

•

•

•

•

••

••

•

•

•

••

•

•

•

Every 2 years

Page 15

15

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Fuel

DANGER: GASOLINE IS HIGHLY FLAMMABLE AND EXPLOSIVE. DO NOT ADD FUEL WHILE THE ENGINE

IS RUNNING OR IS HOT. KEEP OPEN FLAMES, SPARKS, AND HEAT AWAY FROM THE FUEL AND STORE

FUEL IN CONTAINERS SPECIFICALLY DESIGNED FOR THAT PURPOSE. ADD FUEL OUTDOORS ONLY

AND IF THE FUEL IS SPILLED, DO NOT START THE ENGINE. MANUALLY PUSH THE MOWER AWAY FROM

THE SPILL AND IMMEDIATELY WIPE UP.

Refer to the Engine Owner’s Manual for the type of fuel to use.

A fuel shut off valve is located on the bottom of the fuel tank. (Refer to Figure 2, page 10). It is recommended

that the fuel be shut off when transporting between job sites and when storing the mower for extended periods

of time.

Engine Oil

CHECK THE ENGINE OIL BEFORE EACH USE.

Refer to the Engine Owner’s Manual for the type of oil, oil

change intervals,and the proper procedures to check and change oil.

Air Filter

Refer to the Engine Owner’s Manual for the recommended maintenance.

Tire Pressure

The recommended tire Pressure for all four (4) wheels is 28 P.S.I. Incorrect tire pressure may cause the mower

to pull to one side and/or an uneven cut.

Always use caution when filling the tire and never exceed the rec-

ommended tire pressure.

Blade

DANGER: BEFORE WORKING ON THE BLADES, MAKE SURE THE ENGINE IS OFF, KEY REMOVED, AND

THE SPARK PLUG(S) WIRES REMOVED FROM THE SPARK PLUG (S) TO PREVENT ACCIDENTAL CONTACT.

CAUTION Beware of the cutting edges on the blades. Always wear work gloves when performing blade

maintenance.

Blades should be inspected on a daily basis for nicks, bends, and or excessive wear. If the blades is worn,

cracked, bent, or damaged, replace with a new blade immediately before using the mower. Use only genuine

Dixon

® WalkAbout™ Mowers replacement blades since substitute blades may not meet Dixon®

WalkAbout™ specifications and may be dangerous.

To remove the blades, refer to page 12, section “Removing And Adjusting The Blades.”

When sharpening the blades, sharpen only the cutting edges and try to maintain the original angle of the

blade. Do not make the cutting edge “razor sharp” and remove the same amount from each side of the blade

so that balance is maintained.

Cleaning The Mower

It is recommended that the mower be cleaned in a daily basis. Excessive accumulation of dirt, debris, oil,

etc., causes premature wear on the components and may present a potential safety hazard.

!

!

Page 16

16

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Lubrication Points

To assure proper lubrication on moving parts, it is recommended that you lubricate the following components

with a high-quality EP2 high temperature based grease or equivalent. Should the conditions of operation be

more severe than normal, the lubrication interval may be shorter than recommended. GTR/OPE Grease is the

recommended lubricant.

Transmission Output Shaft

(Left & Ride Sides)

Every 40 hrs./Weekly

Blade Engagement Bellcrank

Every 40 hrs./Weekly

Blade Engagement Pivot

(Left & Right Sides)

Every 40 hrs./Weekly

Cutterhousings

Every 100 hrs./Monthly

Front Caster Wheel

(Left & Right Sides)

Every 40 hrs/Weekly

Front Caster Support

(Left & Right Sides)

Every 40 hrs/Weekly

Drive Wheel

(Left & Right Sides)

Every 40 hrs/Weekly

Wheel Brake Pivot

(Left & Right Sides)

Every 40 hrs/Weekly

Idler Arm Pivot

(Left & Right Sides)

Every 40 hrs/Weekly

Page 17

17

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

SERVICE ADJUSTMENTS

DANGER: BEFORE MAKING ANY ADJUSTMENTS AND/OR SERVICING YOUR MOWER, MAKE SURE

THE MOWER IS ON LEVEL GROUND, BLADES DISENGAGED, KEY REMOVED, AND THE ENGINE OFF

WITH THE SPARK PLUG WIRE(S) REMOVED FROM THE SPARK PLUG(S) TO PREVENT ACCIDENTAL

CONTACT. IF ADJUSTMENTS OR MAINTENANCE IS BEING PERFORMED AFTER OPERATION OF THE

MOWER, ALLOW THE UNIT TO COOL SINCE HEAT BUILD UP COULD CAUSE SEVERE BURNS.

Drive Belt Adjustment: (Refer to Figure 9)

1. Release the right side traction control lever into the engaged

position. Move the gear shift lever into first “1” gear, and

pull the mower backwards until the mower stops.

2. Remove hair pin cotter “A” and the flat washer from swivel “B”.

3. Remove swivel “B” from idler arm “C”.

4. Move traction control rod “D” until there is approximately 1/2”

clearance between the bottom of the traction control rod and

the bottom of the slot in traction control lever lock “A”

(figure 10).

5. While holding the rod in place, rotate swivel “B” on the traction

control rod “D” until the swivel realigns with the hole in idler

arm “C”. Push the swivel through the idler arm hole and secure

with the flat washer and hair pin cotter. Repeat for the other

side.

Wheel Brake Adjustment: (Refer to Figure 11)

1. Release the left side traction control lever into the engaged

position.

2. Remove the hair pin cotter “A” from swivel “B”.

3. Remove swivel “B” from idler arm “C”.

4. To increase the amount of brake, rotate swivel “B” clockwise

approximately 2 to 3 turns and insert swivel “B” back into idler

arm “C”.

5. Check the traction control lever for the proper amount of

brake. Should more brake be necessary, repeat steps 3 and 4.

6. Once the proper amount of brake has been achieved, be sure

to secure swivel ”B” to idler arm “C” with the flat washer and

hair pin cotter.

7. Repeat for the other side if needed.

!

Figure 9

Figure 10

A

Figure 11

A

C

B

A

B

C

D

Page 18

18

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Figure 12

32” & 36” Gear Drive

48” Gear Drive

Engine To Blade Belt Adjustment (Refer to Figure 12)

DANGER: BEFORE MAKING ANYADJUSTMENTS AND/OR SERVICING YOUR MOWER, MAKE SURE THE

MOWER IS ON LEVEL GROUND, BLADES DISENGAGED, KEY REMOVED, AND THE ENGINE OFF WITH THE

SPARK PLUG WIRE(S) REMOVED FROM THE SPARK PLUG(S) TO PREVENT ACCIDENTAL CONTACT. IF

ADJUSTMENTS OR MAINTENANCE IS BEING PERFORMED AFTER OPERATION OF THE MOWER, ALLOW

THE UNIT TO COOL SINCE HEAT BUILD UP COULD CAUSE SEVERE BURNS.

1. Remove the deck cover and move the blade control lever on the control console to the “ON” position.

2. With approximately 10 lbs. of pressure being applied on the engine to blade belt midway between the pulleys,

(refer to the appropriate figure for your mower) the belt should move approximately 1/2”.

3. If the belt moves more than 1/2”, move the blade control lever back to the “OFF” position.

4. Remove hair pin cotter “A” and the flat washer from swivel “B” and pull the swivel from idler arm “C”.

5. Rotate swivel “B” clockwise, or towards the rear of the mower, approximately 2 to 3 turns. Reinsert swivel “B”

back into idler arm “C” and secure with the flat washer and hair pin cotter.

6. Repeat steps 1 and 2 to check for proper tension. If more tension is needed, repeat steps 3-5 until the proper

amount is achieved.

7. Replace deck cover.

!

Midway Point

Midway Point

B

A

C

Page 19

19

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

48” Blade To Blade Belt Adjustment: (Refer to figure 13)

1. Remove the deck cover.

2. With approximately 10 lbs. of pressure being applied on the blade to blade belt, midway between the

pulleys, the belt should move approximately 1/2”.

3. If the belt moves more than 1/2”, turn nut “A” clockwise approximately1-2 turn.

4. Recheck the tension on the blade to blade belt. If it is still loose repeat step 3. Important: Do not overtighten

the blade to blade belt. Over tension can cause premature wear on belts and blade spindles.

5. Replace deck cover

Figure 13

Figure 14

Engine To Transmission Belt Adjustment: (Refer to figure 14)

1. The engine to transmission belt, located underneath the rear deck, should move 3/16” with 5 lbs. of

pressure applied midway on the belt between the transmission pulley and the engine output shaft pulley.

2. To adjust the belt, loosen nut “A” on idler pulley “B”.

3. Slide idler pulley “B” to tighten or loosen and secure in place by tightening nut “A”.

Figure 15

Safety System Adjustment: (Refer to figure 15)

DANGER: DO NOT BYPASS, MODIFY, ALTER, OR DISCONNECT THE

SAFETY SYSTEM. MAKE SURE THAT THE SAFETY INTERLOCK

SYSTEM IS FULLY OPERATIONAL EACH TIME BEFORE MOWING,

FAILURE TO DO SO COULD PRESENT DANGER TO YOU AND

OTHERS AROUND YOU.

1. Move the blade control lever to “OFF”.

2. Loosen screws “A” until safety switch “B” moves freely.

3. Slide safety switch “B” firmly against blade bellcrank “C”.

4. Tighten screws “A” and check that safety switch “B” does not move.

Midway Point

A

B

C

A

Page 20

20

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

TROUBLE SHOOTING

Problem Possible Cause Solution

Engine Does Not Start Key in the OFF position Turn key to ON

Transmission shift lever not in the Move lever into the neutral

neutral position (Page 10).

Blade control not in the OFF position Move blade control lever to OFF

Fuel tank empty Fill fuel tank

Fuel shut-off valve closed Open fuel shut off (Page 10)

Safety interlock switches out of Adjust switches (Page 19)

adjustment

Throttle control not in the choke Move throttle control to choke

position

Spark plug loose or disconnected Connect spark plug wire

Bad spark plug Replace

Dirty air filter Replace

Clogged fuel filter Replace

Bad fuel Drain and refill with fresh fuel

Engine Starts Hard Or Dirt or water in the fuel tank Drain and clean fuel tank

Loose Power

Clogged or dirty fuel filter Replace

Air filter dirty Replace

Faulty spark plug Replace

Incorrect oil level Check and adjust

Engine Overheats Dirt in fuel line Clean and replace

Dirty grass screen Clean

Incorrect oil level Check and adjust

Dirty air filter Check and adjust

Faulty spark plug Replace

Page 21

21

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

TROUBLE SHOOTING

Problem Possible Cause Solution

Mower Does Not Move Transmission is in neutral Move transmission lever (page 9)

When Traction Levers Engine to transmission belt loose Check and adjust (page 17)

Are Released Incorrect drive wheel belt adjustment Check and adjust (page 17)

Drive belts worn or damaged Check and replace if necessary

Mower Pulls To One Side Drive belt broken or slipping Replace or adjust (page 17)

Blades Do Not Turn Tire pressure not the same in both Check and adjust (page 15)

drive wheels

Uneven Cut Blade belt broken or slipping Replace or adjust

Excessive build-up underneath Check and clean

mowing deck

Rough Cut Unequal space configuration on Check and adjust (page 13)

blades or front casters

Ground speed too fast for Reduce travel speed

mowing conditions

Blades bent Check and replace (page 12)

Tire pressure in wheels not equal Check and adjust (page15)

Unequal spacer configuration on blades Check and adjust (page 13)

or front casters

Blades dull Sharpen or replace (page 15)

Engine not running 3600 r.p.m. Move throttle to fast

Blades installed upside down Remove and replace rightside up

(page 12)

Excessive build-up underneath Check and clean mowing deck

Page 22

1

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” Frame Assembly

Page 23

2

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” Frame Assembly

I tem No. MF G Co d e Par t Nu mb er Descri p tio n Qty

1 100-001-Blue 11501 Tank Handle Mount Brack et 1

2 100-002-B l ue 11502 Shi ft Cons ol e 1

3 100-003 11503 Plai n Was her 2*10.5 id *26 od 4

4 100-004 11504 Pivot Tube 2

5 200-001 11701 Nut M10 GB923-88 4

6 100-005-Blue 11505 Fender 2

7 200-002 11702 Double end bolt m 10*120 GB 901-88 2

8 200-003 12808 Hexagon Bol t M10* 25 GB 5783-86 14

9 100-006-B l ue 11506 Rear Deck 1

10 132-001 11621 Ax l e Wel dm ent 1

11 200-004 11704 Hexagon Head Bol t M12*25 G B 5783-86 6

12 200-005 11705 Hexagon Head Bol t M10*240 G B 5782-86 1

13 100-007-B l ue 11507 Chute Deflec tor 1

14 100-008 11508 Tors i on Spring 1

15 200-006 11706 Nylon Nut , M10 GB889-86 (not shown) 17

17 200-007 11707 Nylon Nut , M12 GB889-86 6

18 200-021 3020 P l ai n Washer 8 GB95-85 2

21 100-009 11509 Sauc er Nut 4

22 200-006 11706 Nylon Nut M 10 G B 889-86 2

23 200-008 11708 Hexagon B ol t M 10* 110 GB5782-86 2

24 200-009 11709 Nylon Nut M 6 G B 889-86 4

25 200-010 3057 P l ai n Washer 10 GB95-85 4

26 200-011 11711 Bolt M6*16 G B /T794-93 4

30 100-011 11511 Safety Fl ap 1

31 100-012 11512 Rod Safety F l ap 1

32 200-014 11714 Cott er P i n 2*20 GB91-86 2

33 100-116 11616 Shift P l ate 1

34 200-063 11763 Rivet 2* 5 GB827-86 2

35 136-001-B l ue 11631 Deck 36" 1

36 136-002-B l ue 11632 Hood 36" 1

Page 24

3

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

48” Frame Assembly

Page 25

4

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

48” Frame Assembly

I tem No. MF G Co d e Par t Nu mb er Descri p tio n Qty

1 100-001 11501 Tank Handl e M ount Brac ket 1

2 100-002 11502 Shift Console 1

3 100-003 11503 Plai n Was her 2*10.5 id *26 od 4

4 100-004 11504 Pivot Tube 2

5 200-001 11701 Nut M10 GB923-88 4

6 100-005 11505 Fender 2

7 200-002 11702 Double End B ol t M 10* 120 GB901-88 2

8 200-003 12808 Hexagon Bol t M10* 25 GB 5783-86 10

9 100-006 11506 Rear Deck 1

10 148-001 11641 Ax l e Wel dm ent 48" 1

11 200-004 11704 Hexagon B ol t M 12* 25 GB5783-86 6

12 200-005 11705 Hexagon B ol t M 10* 240 GB5782-86 1

13 100-007 11507 Chute Deflector 1

14 100-008 11508 Tors i on Spring 1

16 148-002 11642 Deck 48" 1

17 200-007 11707 Nylon Nut M 12 G B 889-86 6

18 200-021 3020 P l ai n Washer 8 GB-95-85 2

19 200-015 11715 Hexagon B ol t M 10* 140 GB5783-86 3

20 148-003 11643 Hood 48" 1

21 100-009 11509 Sauc er Nut 3

22 200-006 11706 Nylon Nut M 10 G B 889-86 5

23 200-008 11708 Hexagon B ol t M 10* 110 GB5782-86 2

24 200-009 11709 Nylon Nut M 6 G B 889-86 4

25 200-011 11711 Bolt M6*16 G B /T794-93 4

26 200-006 11706 Nylon Nut M 10 G B 889-86 (Not S hown) 17

27 100-011 11511 Safety Fl ap 1

28 100-012 11512 Rod safety Fl ap 1

29 200-014 11714 Cott er P i n 2*20 GB91-86 2

30 100-010 11510 Shift Lever Stop 1

31 200-012 11712 Bolt M5*15 G B 818-85 2

32 200-013 11713 Nylon Nut M 5 G B 889-86 2

33 100-116 11616 Shift P l ate 1

34 200-063 11763 Rivet 2* 5 GB827-86 2

Page 26

5

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” Front Deck Assembly

Page 27

6

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” Front Deck Assembly

Item No. MFG Code Part Num b er Descri p t ion Qty

1 100-013 11513 Idl er P ul l ey I with F l ange 1

3 200-006 11706 Nylon Nut M 10 GB889-86 17

4 200-016 11716 Nut Flange M 10 G B 6187-86 4

5 100-014 11514 Key 6. 35* 6*50 2

6 200-017 11717 Hexagon Nut M 16* 1. 5 2

7 200-018 11718 Hexagon Bol t M10* 35 GB 5783-86 2

8 200-019 11719 Hexagon Bol t M10* 40 GB 5782-86 1

9 100-015 11515 Plai n Was her 2*26 i d * 38 od 1

10 100-016 11516 Belt Guide, Spi ndl e 4

11 100-017 11517 Blade Rod 1

12 100-018 11518 Swiv el 1

13 200-014 11714 Cott er P i n 2*20 GB91-86 1

14 200-020 3240 Hex agon Bolt M 10* 70 GB782-86 1

15 100-019 11519 Plai n Washer 3*10.5 i d * 38 od 2

16 100-020 11520 Blade Idler A rm Wel dm ent 1

17 200-021 3020 P l ai n Washer 8 GB95-85 1

18 200-022 11722 Hexagon B ol t M 10* 65 GB5782-86 1

19 200-010 3057 P l ai n Washer 10 GB95-85 5

20 200-018 11718 Hexagon B ol t M 10* 35 GB5783-86 8

21 100-021 11521 Cutt i ng Hous e A ss em bl y 2

22 100-022 11522 Spac er 6 10

24 100-023 11523 Plai n Washer 3*16.5 i d * 50 od 2

25 200-023 11723 Bolt M16*1.5*245 2

26 100-024 11524 Pivot Hub 1

27 100-025 11525 Pull ey, S i ngl e 2

28 100-026 11526 H-Bushing 2

29 200-024 3019 Lock Was her 8 GB 93-87 4

30 200-025 7372 Hex agon Bolt M 8* 30 GB5783-86 4

31 200-026 11726 Grease F itt i ng M 6 GB 1152-89 3

32 100-027 11527 Rod End RH 1

33 100-028 11528 Rod End LH 1

34 100-029 11529 Link Idler A rm 1

35 100-030 11530 Turn B uck l e Rod 1

36 100-031 11531 Spac er 12 1

37 100-032 11532 Link B ushing 7*10.5 id*14 od 1

38 200-027 11727 Nut Thin M10 GB 6172-86 1

39 100-033 11533 Belt Guide I 1

40 136-003 11633 Blade 36" 2

41 136-004 11634 Belt 36" Engine t o Blade 1

Page 28

7

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

48” Front Deck Assembly

Page 29

8

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

48” Front Deck Assembly

Item No. M F G Co d e Part Nu mber De scri p tion Qty

1 100-013 11513 Idler P ul ley wit h F l ange 1

2 100-025 11525 P ul l ey, S i ngl e 2

3 148-004 11644 P ul l ey , Double 1

4 100-026 11526 H-Bushing 3

5 100-024 11524 P i vot Hub 2

6 100-021 11521 Cut t i ng Housing A s sembl y 3

7 100-022 11522 S pacer 6 15

8 148-005 11645 B l ade 48" 3

9 100-023 11523 P l ai n Was her 3*16. 5 i d* 50 od 3

10 200-023 11723 B ol t M16*1. 5* 245 3

11 200-017 11717 Hex agon Nut M 16* 1. 5 3

12 200-026 11726 Grease Fit ting M6 G B 1152 89 5

13 148-002 11642 Dec k 48" 1

14 148-006 11646 B el t 48" E ngi ne to Blade 1

15 148-007 11647 B el t 48" B l ade to Blade 1

16 100-028 11528 Rod E nd LH 1

17 100-027 11527 Rod E nd RH 1

18 200-028 11728 Hex agon Bolt M 10*120 GB5782-86 2

19 200-018 11718 Hex agon Bolt M 10*35 GB5783-86 12

20 100-014 11514 K ey 6.35* 6*50 3

21 100-016 11516 B el t Guide, S pi ndl e 4

22 200-014 11714 Cot ter Pin, 2*20 GB91-86 1

23 200-029 11729 Nut F l ange M 8 GB 6187-86 1

24 200-030 11730 Ny l on Nut M 8 G B 889-86 1

25 148-008 11648 Idler P ul l ey IV with Flange 1

26 100-018 11518 Swivel 1

27 100-017 11517 B l ade Rod 1

28 200-006 11706 Ny l on Nut M 10 G B 889-86 22

29 100-020 11520 B l ade Idler A rm Weldm ent 1

30 148-009 11649 Dec k Idler Arm Weldm ent 1

31 148-010 11650 Rod B el t Tensi on Hook 1

32 100-019 11519 P l ai n Was her 3*10.5 id*38 od 4

33 200-010 3057 Pl ain Was her 10 GB95-85 7

34 100-033 11533 B el t Guide I 1

35 100-015 11515 P l ai n Was her 2*26 i d *38 od 2

36 100-031 11531 S pacer 12 1

37 200-020 3240 Hexagon B ol t M10*70 GB 5782-86 2

38 200-022 11722 Hex agon Bolt M 10*65 GB5782-86 2

39 200-025 7372 Hexagon B ol t M8*30 GB 5783 86 6

40 200-024 3019 Lock W asher 8 GB93-87 6

41 200-031 3065 Lock W asher 10 GB93-87 1

42 100-030 11530 Turn Buc kle Rod 1

43 100-032 11532 Li nk Bus hi ng 7* 10. 5 i d* 14 od 1

44 100-029 11529 Li nk Idler Arm 1

45 200-027 11727 Nut Thin M10 GB6172-86 1

46 200-018 11718 Hex agon Bolt M 10*35 GB5783-85 2

47 200-019 11719 Hex agon Bolt M 10*40 GB5782-86 1

48 200-006 11706 Ny l on Nut M 10 G B 889-86 7

49 200-016 11716 Nut F l ange M 10 GB 6187 86 11

50 148-011 11651 S pacer 16 1

Page 30

9

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Brake Assembly

Page 31

10

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Brake Assembly

I tem No. MFG Co d e Part Num b er Descri p tion Qty

1 200-001 11701 Nut M10 GB 923-88 4

2 100-005 11505 Fender 2

3 100-034 11534 Idler A rm RH 1

4 100-035 11535 Idler A rm LH 1

5 200-021 3020 Plai n Was her 8 GB 95-85 2

6 100-036 11536 Brake Rod 2

7 100-037 11537 Brake Lever RH 1

8 100-038 11538 Brake Lever LH 1

9 100-039 11539 F l at Head Rivet I 2

10 200-047 11747 Snap Ring 16 G B 894.1-86 2

11 100-120 11620 Pl ai n Was her 2*16 i d * 26 od 4

12 100-040 11540 Brake Link 4

13 200-032 11732 Hexagon B ol t M10*50 G B 5782-86 2

14 200-016 11716 Nut Fl ange M 10 G B 6187-86 2

16 100-041 11541 Brake Lever Mount 2

19 200-008 11708 Hexagon B ol t M10*110 G B 5782-86 2

20 100-003 11503 Pl ai n Was her 2*10.5 id *26 od 4

21 100-004 11504 Pi vot Tube 2

22 200-014 11714 Cott er Pin 2*20 GB91-86 8

23 100-042 11542 Swivel, B rake Rod 2

24 200-026 11726 Grease F i tti ng M 6 G B 1152-89 2

25 200-006 11706 Nyl on Nut M 10 GB889-86 2

26 100-043 11543 Flat Head Rivet II 2

27 200-033 11733 Pl ai n Was her 10 GB95-85 4

28 100-044 11544 Brake Ass em bl y Band 2

Page 32

11

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Transmission Drive Assembly

Page 33

12

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Transmission Drive Assembly

I tem No. MFG Co d e Part Num b er Descri p tion Qty

1 100-045 11545 Fl at Grip 1

2 100-046 11546 Transmi ss i on S hi ft Lever Upper 1

3 100-047 11547 Output Pulley 2

4 200-034 11734 Nut 3/ 8-24 1

5 200-035 11735 S crews M 8* 10 GB 71-85 2

6 100-048 11548 Was her Rubber 1

7 200-011 11711 B ol t M6*16GB/T794-93 4

8 100-049 11549 Fl ange Bearing 2

9 100-050 11550 Tract i on B el t 2

10 200-036 11736 Hexagon B ol t M6*20 G B 5783-86 5

11 100-051 11551 Bel t G ui de II 2

12 200-009 11709 Nyl on Nut M 6 GB889-86 10

13 200-047 11747 Snap Ring 16 G B 894.1-86 2

14 100-052 11552 W oodruff Key 2

15 100-053 11553 Output S haft 2

16 100-054 11554 Coupling 2

17 200-026 11726 Grease F i tti ng M 6 G B 1152-89 2

18 100-055 11555 Neutral Swit ch Transmi s sion 1

20 200-037 11737 Hexagon B ol t 5/ 16-18 4

21 200-024 3019 Lock W asher 8 GB 93-87 4

22 100-057 11557 Tract i on S pri ng 2

23 100-058 11558 Idler Pul ley II 2

24 200-032 11732 Hexagon B ol t M10*50 G B 5782-86 2

25 200-038 3384 Hexagon B ol t M10*60 GB5782-86 2

26 200-010 3057 Plai n washer 10 GB95-85 2

28 200-016 11716 Nut Fl ange M 10 G B 6187-86 2

29 100-059 11559 Transmi ss i on S hi ft Lever Lower 1

30 200-006 11706 Nyl on Nut M 10 GB889-86 2

31 200-031 3065 Lock washer 10 GB93-87 1

32 200-039 11739 Nyl on Nut M 4 GB889-86 2

33 200-040 11740 Pl ai n Was her 4 GB95-85 2

34 200-041 7386 Bolt M4* 30 GB 818-85 2

35 100-060 11560 Switch 1

37 100-061 11561 Compres sion S pri ng 1

38 200-042 3066 Plai n Washer 6 GB95-85 1

39 200-043 11743 Pl ai n Was her 6 GB5287-86 1

41 200-044 11744 Hexagon B ol t M6*40 G B 5782-86 1

Page 34

13

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Rear Deck Assembly

Page 35

14

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Rear Deck Assembly

I tem No. MFG Co d e Part Num b er Descri p tion Qty

2 200-045 11745 B ol t M6*20 GB/T794-93 2

4 100-055 11555 Neut ral Swit ch Transmi s sion 1

5 200-046 11746 B ol t M10*45 GB/T794-93 1

6 200-038 3384 Hex agon B ol t M10*60 G B 5782-86 (for 48") 1

7 100-063 11563 P ul l ey, Transm i ss i on 1

8 100-117 11617 Woodruff Key, Transmi s sion 1

9 200-006 11706 Ny l on Nut M 10 GB889-86 (for 48") 1

10 200-047 11747 Snap Ring 16 G B 894, 1-86 1

11 100-064 11564 Transmi ss i on B el t 1

12 200-010 3057 Plai n Washer 10 GB95-85 2

13 200-006 11706 Nyl on Nut M 10 GB889-86 (for 48") 1

14 100-065 11565 Idler Pul ley III 1

15 100-025 11525 Pul l ey, Singl e 1

16 100-066 11566 Key 6. 35*6*25 2

17 100-067 11567 Pul l ey, Input 1

18 200-016 11716 Nyl on Nut M 10 GB889-86 (for 48") 1

19 200-009 11709 Nyl on Nut M 6 GB889-86 2

20 100-068 11568 Bel t G ui de III 1

21 100-069 11569 Bel t G ui de IV 1

22 200-030 11730 Nyl on Nut M 8 GB889-86 2

23 200-048 11748 Hexagon B ol t M8*20 G B 5782-86 2

24 200-049 11749 Hexagon B ol t M8*40 G B 5783-86 4

25 100-026 11526 H-Bushing 1

26 200-024 3019 Lock W asher 8 GB 93-87 2

27 200-025 7372 Hexagon B ol t M8*30 GB5783-86 2

33 200-021 3020 Plai n Washer 8 GB95-85 4

34 200-024 3019 Lock W asher 8 GB 93-87 4

35 148-014 11654 Bushing, Belt G ui de IV (for 48") 1

Page 36

15

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Handle Control Assembly

Page 37

16

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Handle Control Assembly

Item No. MFG Co d e Part Nu mber Descri p tion Qty

1 100-072 11572 Handle Grip 2

2 200-051 11751 Nut M 6 G B 923-88 2

3 100-073 11573 Tracti on Cont rol Lever 2

4 100-074 11574 Tracti on Rod 1

5 100-075 11575 Clevi s Pi n Traction Cont rol Lever 2

6 100-076 11576 Roll Pin 4

7 100-077 11577 Opc Spring 2

8 200-052 11752 Hexagon Bolt M 10* 45 GB5782-86 4

9 100-018 11518 Swivel 3

14 200-021 3020 Plai n Was her 8 GB 95-85 2

15 200-053 11753 Lock Washer 6 GB93-87 2

16 100-017 11517 Blade Rod 1

17 200-047 11747 Snap-Ring 16 GB 894.1-86 1

18 100-120 11620 Plai n Was her 2*16 i d* 26 od 2

19 200-014 11714 Cotter P i n 2* 20 GB91-86 3

20 100-078 11578 Bell Crank 1

21 200-026 11726 Grease Fi tti ng M 6 GB1152-89 1

22 100-079 11579 Bell Crank M ount Brack et 1

23 100-080 11580 Blade Rod Tract i on Cont rol Lever 1

26 200-054 11754 Hair Pin Cot ter 2 1

28 200-006 11706 Nylon Nut M 10 GB889-86 5

29 200-010 3057 Plai n Was her 10 GB 95-85 4

30 100-081 11581 Compression S pri ng 1

31 200-032 11732 Hexagon Bol t M10*50 G B 5782-86 1

33 100-082 11582 Blade Cont rol Lever 1

34 100-045 11545 Flat Gri p 1

35 100-083 11583 Flange B us hi ng 4

36 100-084 11584 OPC Lever RH 1

37 100-085 11585 OPC Lever LH 1

38 200-055 11755 Hexagon Bol t M6*50 G B 5782-86 2

39 200-014 11714 Cotter P i n 2* 20 GB91-86 2

40 100-086 11586 Clevis Pin, O pc Lever 2

41 100-087 11587 Bus hi ng, Traction Loc k 2

42 100-088 11588 Trac tion Lock wi th Grip, LH 1

43 100-089 11589 Trac tion Lock wi th Grip, RH 1

44 100-090 11590 Top Handle Weldm ent 1

45 200-042 3066 Plai n Was her 6 GB 95-85 (not shown) 2

46 100-091 11591 Throt tle Cont rol 1

47 200-012 11712 Bolt M 5* 20 GB818-85 2

48 200-013 11713 Nylon Nut M 5 GB889-86 2

Page 38

17

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Front Caster Assembly

Page 39

18

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Front Caster Assembly

I tem No. MFG Co d e Part Num b er Descri p tion Qty

1 200-026 11726 Grease Fitti ng M 6 G B 1152-89 4

2 200-003 12808 Hex agon Bolt M 10* 25 GB 5783-86 8

3 200-006 11706 Ny l on Nut M 10 GB889-86 4

4 200-010 3057 P l ai n Was her 10 GB95-85 4

5 200-031 3065 Loc k Was her 10 GB 93-87 (For 36") 2

6 100-092 11592 Cas tor W heel A ss em bl y W 2

7 100-093 11593 P i vot Tube, Castor 2

9 100-015 11515 P l ai n Was her 2*26 i d * 38 od 2

12 200-057 11757 Hexagon B ol t M12*140 G B 5782-86 2

13 100-096 11596 Castor Yoke 2

14 100-097 11597 Lynch P i n 2

15 100-098 11598 Spacer 13 6

16 100-099 11599 Spacer 6.5 2

17 100-100 11600 Bushing, Castor 4

18 100-101 11601 Castor Support 2

19 200-007 11707 Nyl on Nut M 12 GB889-86 2

20 200-006 11706 Nyl on Nut M 10 GB889-86 (For 48") 4

Page 40

19

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Fuel Tank Assembly

Item No. MFG Co d e Part Nu mber De scri p tion Qty

1 100-102 11602 Fuel Tank Cap 1

2 100-103 11603 Fuel Tank Body 1

3 100-104 11604 Fuel Tank Strap 2

4 200-058 11758 Hexagon Bolt M 6* 50 GB5782-86 2

5 200-042 3066 Plain Was her M6 G B 95-85 2

6 200-009 11709 Nyl on Nut M 6 GB889-86 2

7 100-105 11605 Fuel Shut Off Valve 1

8 100-106 11606 Fuel Li ne 1

9 200-059 3649 Fuel Line Clam p 4

10 100-107 11607 Tank Pad 2

11 100-108 11608 Fuel F i l t er 1

12 100-109 11609 Tube Insert 1

Page 41

20

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Traction Wheel Assembly

Item No. MFG Co d e Part Number Descri p tion Qty

2 100-110 11610 Pulley, Tract i on 4

3 100-111 11611 Spacer 11.5 8

4 100-112 11612 Brake Hub 2

5 200-024 3019 Lock Was her 8 GB 93-87 8

6 200-060 11760 Bolt M 8*40 G B 787-86 8

7 200-061 11761 Bearing 6005 2RS 4

8 100-113 11613 Valve 2

9 200-026 11726 Grease Fi t ting M6 GB1152-89 2

11 148-013 11653 Ri m 36" & 48" 2

13 100-019 11519 Plain Was her 3*10.5 id*38 od 2

14 100-119 11619 Bolt M 10 (left ) 1

15 200-003 12808 Hexagon Bol t M 10* 25 GB 5782-86 1

16 100-099 11599 Spacer 6. 5 (for 36" & 48") 2

17 148-012 11652 Tire 13X6.50-6 (for 36" & 48" ) 2

148-015 11655

W heel Assembly for 36", 48" (inc l udes # 7, 8, 9, 11, 17)

2

Page 42

21

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

36” & 48” Electrical Components

Item No. M F G Co de Part Number De scri p tion Qty

1 100-060 11560 Switch 3

2 200-062 11762 Wire Tie 4

3 & 4 100-114 11614 Key Switch & Key 1

5 100-115 11615 Wiring Harness 1

6 100-055 11555 Neut ral S wi t ch Transmiss ion 1

Page 43

22

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

NOTES

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

Page 44

© Dixon Industries, Inc.

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

Loading...

Loading...