Page 1

DIXON INDUSTRIES, INC. A

FAX 316 251 4117

BLOUNT COMPANY AIRPORT

INDUSTRIAL PARK

PO BOX 1569

COFFEYVILLE KS 673370945

316 251 2000

TECHNICAL DATA BROCHURE

Model 3301

IMPORTANT - READ OPERATOR'S MANUAL BEFORE OPERATING OR MAKING ADJUSTMENTS

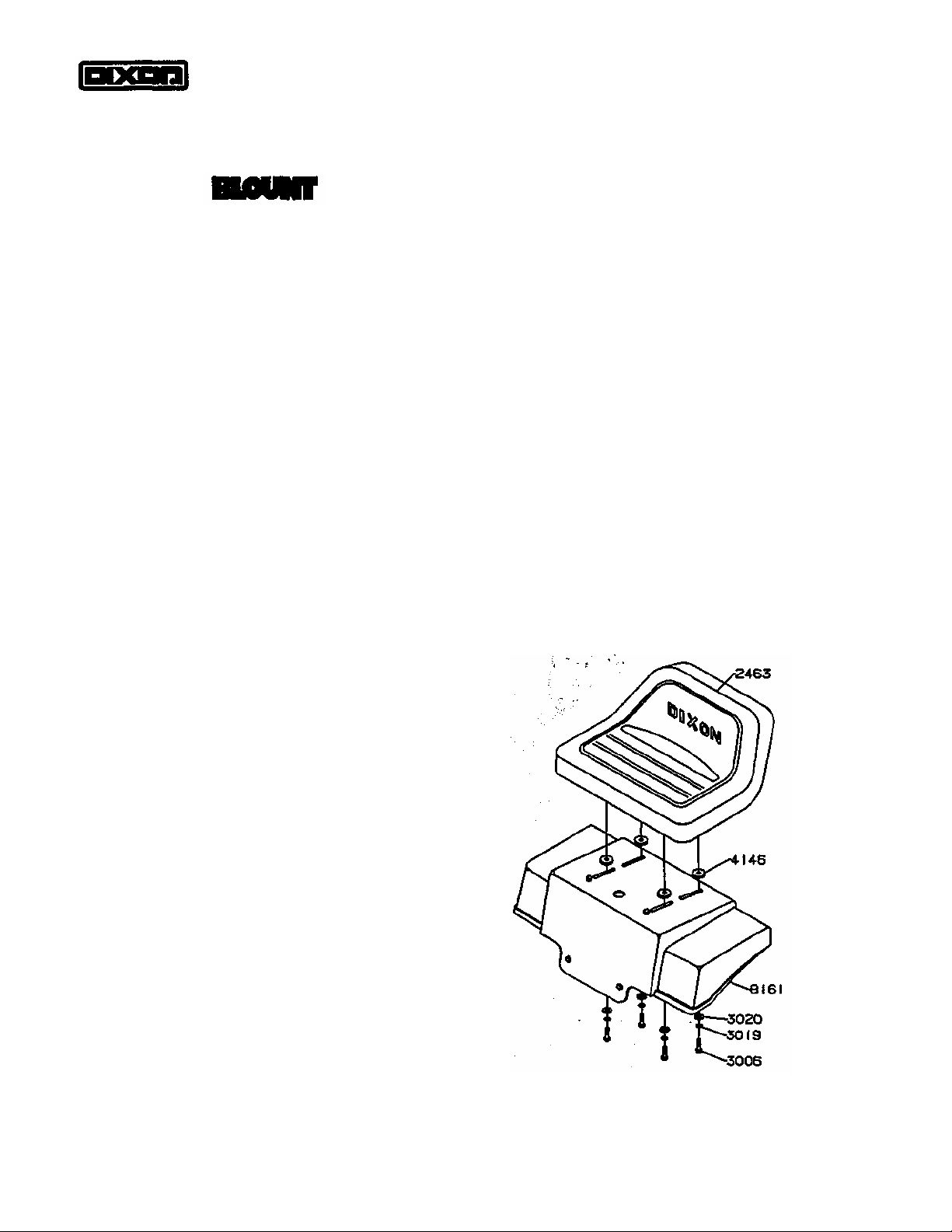

SEAT ADJUSTMENT

1. Pull or lift body retention latch P/N 3954

from transaxle backing plate, raise and

push body and seat assembly forward.

2. Loosen four seat bolts P/N 3006 and

slide seat forward or backward to

desired position.

3. Re-tighten bolts. DO NOT operate

mower without seat retention bolts

properly tightened.

4. Close upper body and push retention

latch P/N 3954 over transaxle backing

plate.

Page 1 of 8

Page 2

BODY REMOVAL

Page 2 of 8

1. The 3301 has a 2-piece polyethylene body. The upper body can be folded forward to expose the

transaxle. In some cases, it may be necessary to remove the upper body to service the

transaxle.

2. To remove the upper body, remove two bolts P/N 3093 from the front of upper body hinge

located on the brake shaft P/N 9283. Disconnect seat switch P/N 4761 at plug-in.

3. Reverse above procedure to reinstall.

ADJUSTMENT OF MOWER DECK DRIVE BELT

1. The mower deck drive belt is tensioned by a spring loaded engagement idler quadrant.

2. This system is designed to maintain the proper belt tension at all times.

3. Belt tension can be adjusted by moving the eng aging rod P/N 7013 into the outside hole of

engagement handle P/N 7020.

4. After belt tension is adjusted, check to assure that the mower blade will not turn freely when the

engaging rod is in the "OFF" position.

5. If the mower blade turns freely, adjust the blade by loosening nut P/N 3205 at the end of the

brake rod P/N 2988.

6. After adjustment is achieved, perform the safety checks listed below.

REMOVING THE MOWER BLADE

Secure blade P/N 2483 from turning. Remove blade bolt from center, P/N 3268 and blade

washer P/N 6260, then blade P/N 2483. To reinstall, reverse above procedure. Tighten blade

bolt to 60 ft. lbs. of torque.

WARNING: Sharp edges on blade can cause injury!

REMOVING MOWER DECK

1. Loosen the belt keepers P/N's 7026 & 7027, located under the engine, by loosening the

mounting bolts, allowing the deck drive belt to come free of the rear pulley.

2. Disconnect the wiring loom at the deck safety switch P/N 4242.

3. Remove the two clevis pins P/N 3072 from the two rear L-rods P/N 1355 and slide from slots.

4. Remove clevis pins P/N 3072, and L-rod attached to lift handle, and slide from slot.

5. Remove clevis pin P/N 3072 from front deck hanger shaft P/N 1332, located at front of mower

deck on slide plates welded at battery box and remove.

6. Lift front of mower chassis and roll free of the deck.

7. To install, reverse the above procedure.

Caution should be exercised when service is required on blade.

Page 3

MOWER BLADE OPERATION

To engage the mower blades, turn lever on floor slowly to the "ON" position. To

disengage mower blades, turn lever slowly to the "OFF" position.

SAFETY CHECKS

IMPORTANT - PERFORM SAFETY CHECKS AFTER MAKING ANY REPAIRS OR ADJUSTMENTS

1. After reassembly, while seated on mower, attempt to start engine with mower deck engaged.

Engine should not start. If engine does start, return the mower to an Authorized Dixon dealer for

adjustment or repair.

2. Disengage mower deck and start engine. With the operator in the normal seated position,

engage mower deck and remove weight from seat. The engine should stop. If the engine does

not stop when operator rises from seat, return the mower to an Authorized Dixon dealer for

adjustment or repair.

3. Engage, then disengage mower blade in each cutting height. Insure that blade disengages

and comes to a stop within (5) seconds in each height position. If blade does nof disengage

properly, contact your Authorized Dixon dealer.

CAUTION: DO NOT OPERATE MOWER IF ANY SAFETY FEATURE IS NOT FUNCTIONING CORRECTLY

PARKING BRAKE ADJUSTMENT

1. Raise upper body to the open position.

2. Tighten nut on brake rod P/N 2533 located in front of the transaxle on each side, just enough to

prevent brake from slipping when engaged.

CAUTION:

Over tightening may cause premature wear on the brake band P/N 5085.

Revised 7/93 P/N

8112

Page 3 of 8

Page 4

Page 4 of 8

Page 5

Page 5

of 8

3301 CHASSIS ASSEMBLY

Page 6

Page 6

of 8

3301 TRANSAXLE ASSEMBLY

Page 7

3301

MOWER DECK

ASSEMBLY

30

”

Page 8

3301 WIRING ASSEMBLY

Page 8 of 8

Loading...

Loading...