Page 1

Holedall

Equipment and Products

1877.963.4966 • www.dixonvalve.com

Page 2

Equipment

Equipment

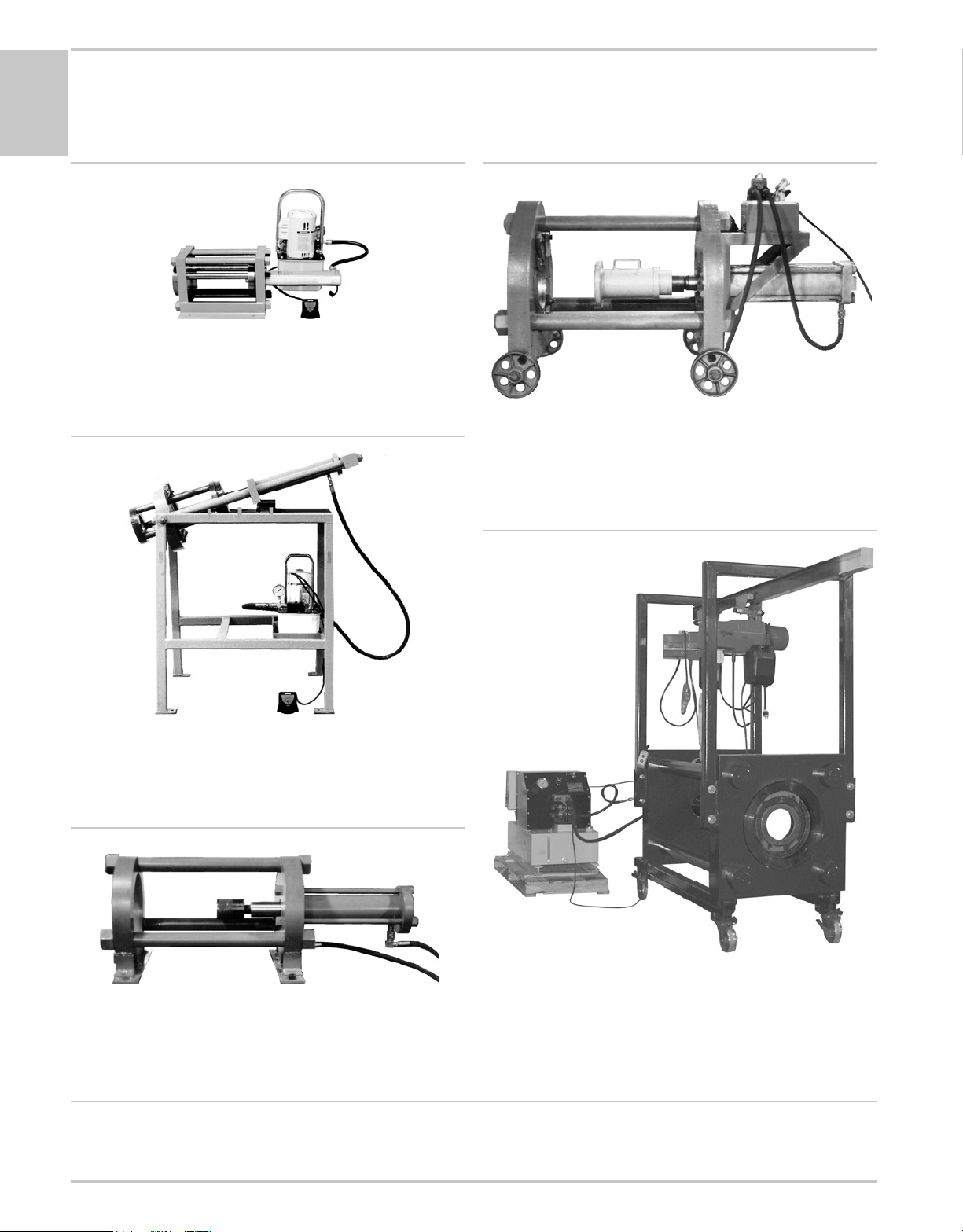

Holedall Coupling Machines

Rams securely attach Holedall couplings to hose. Five machines meet every hose service requirement.

Rams, are powerful nely engineered machines designed specically to swage and internally expand Holedall couplings by

hydraulic pressure. Since each ram generates all the hydraulic pressure required to attach the Holedall coupling, one person can

easily operate the equipment.

15 Ton Ram

Specially designed ram for internally expanded couplings only.

Bench mounted model (optional stand available), producing

up to 10,000 PSI, for up to 15 tons of ram force. Capable of

expanding 1" through 3" steel ttings and ¾" through 4" brass

Holedall Petroleum ttings. The motor is ½ h.p., 115 volt 60

cycle, single phase with foot pedal.

25 Ton Ram

100 Ton Ram

Used for swaging Holedall ttings to hose from 1¼" through

10" ID With optional accessories, this ram may be used for

internally expanded couplings on hose from 1¼" through 6".

This machine is capable of producing up to 100 tons of ram

force. A 1-1/8 h.p., 115 volt, 60 cycle, single phase motor is

standard with remote, (220/440 volt motors are available).

350 Ton Ram

Free standing model producing up to 10,000 PSI of line

pressure for up to 25 tons of ram force. Capable of external

swaging ¼" through 4" ID hose and internal expanding

5/8" through 4" ID hose, with proper equipment. The motor is

½ h.p., 115 volt 60 cycle, single phase with foot pedal. High

speed pump kit option is available.

50 Ton Ram

Used for swaging Holedall and Rotary ttings. This ram is

capable of producing up to 354 tons of ram force for swaging.

Bench mounted model (optional stand available),

producing up to 10,000 PSI, for up to 50 tons of ram force.

Capable of external swaging 1¼" through 6" ID hose and

internal expanding 5/8" through 6" ID hose, with proper

equipment. A 1-1/8 h.p., 115 volt, 60 cycle, single phase motor

is standard with remote, (220/440 volt motors are available).

All Rams require dies of the proper size to reduce the ferrule to the proper diameter for a good grip on the hose. Pushers of the

proper size must be used on the end of the Ram to push the Holedall tting through the die. Die and pusher selection depends

on the sizes and types of hoses being coupled. Ferrule recommendations and a Die Chart binder are available upon request.

Consult your Dixon representative for specic details.

A 14" 150 lb. ange will t through the bed plate. This ram

has 36" of stroke. A 12.5 h.p., 230 volt, 60Hz, 3 phase motor is

standard with remote.

2 877.963.4966 • www.dixonvalve.com

Page 3

• Master die I.D. (standard): 145 mm

• Crimping force: 265 tons

• Maximum hose diameter: 4" I.D.

• Maximum die travel: 2.36"

• Maximum die opening without dies: 7.16"

Length: 29"

Width: 20"

Height: 32"

Weight: 579 lbs.

• Electrical power (standard): 230V 3Ph

• Optional:

Electrical power: 440V 3 Ph

Electrical power: 220V 1 Ph

Pump HP: 7.5 HP

• Manual / fully automatic crimping

• Inch / metric settings

• Approximate crimps per hour: 1415

Equipment

Holedall Crimp Machine

CM400

Equipment

Complete Crimp System Contains:

• 1 - Crimp 400 machine

• 1 - Digital control panel

• 1 - Mechanical stop

• 1 - Stand with foot pedal and die holder panel

• 11 - Small die sets from 1.02" - 3.07"

• 8 - Large die sets from 3.31" - 4.96"

Note: large dies are not stored on the stand

• Quick change die tool

3877.963.4966 • www.dixonvalve.com

Page 4

Holedall

Recommended Working Pressures

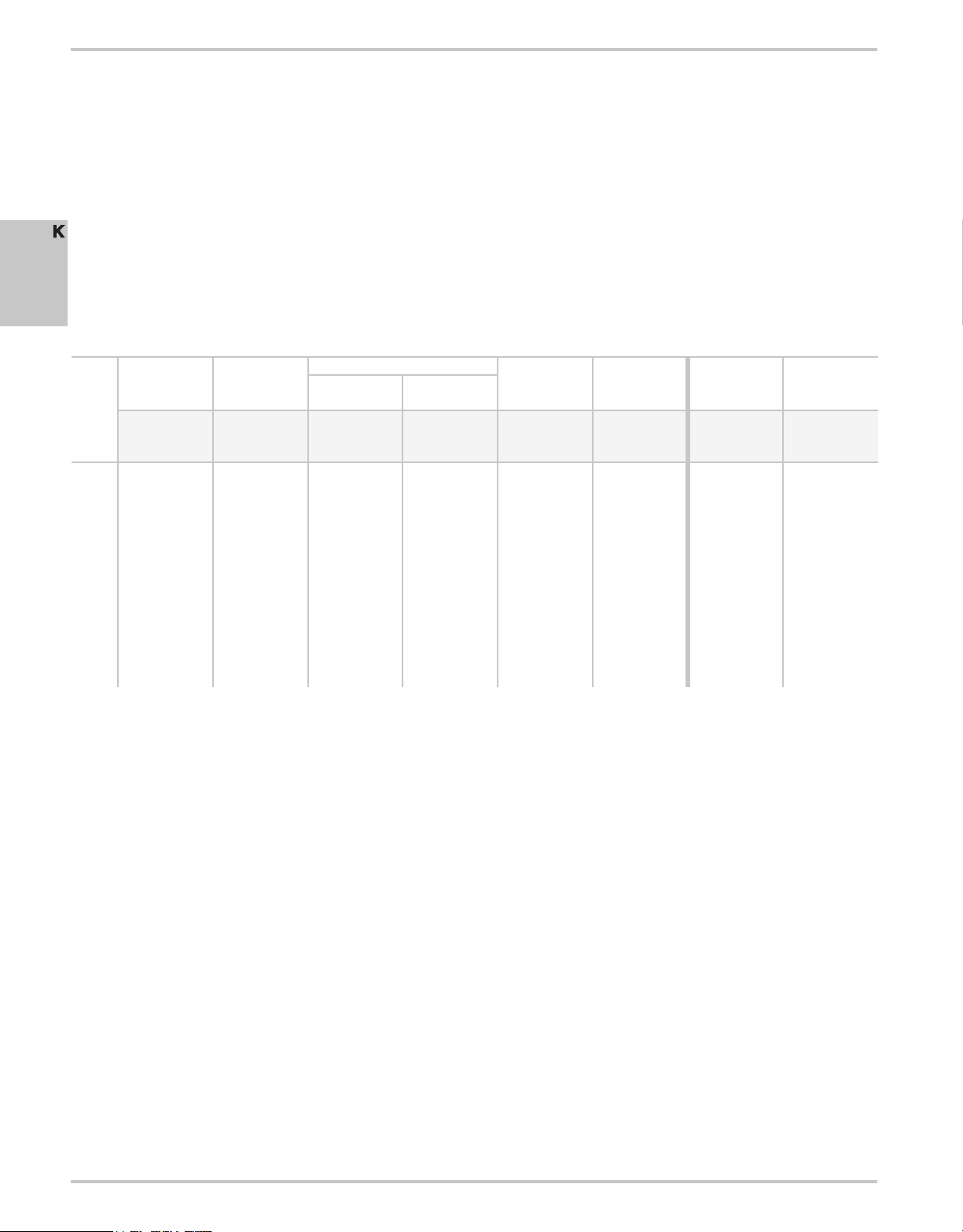

Holedall couplings, regardless of coupling style, are never to be used for steam service at any pressure. Holedall ttings listed

below are not to be used with cable reinforced high-pressure hose, 4 or 6 braid wire hydraulic hose or any other service not

listed in recommendations. Consult factory for recommendations on usage.

Holedall couplings, to perform satisfactorily, must be applied properly in accordance with Dixon's assembly procedures, using

correct die and ferrule for that particular hose end OD Dixon's Die and Ferrule Recommendation Guide is to be used to select

correct dies and ferrules. If you do not have the updated Die and Ferrule Recommendation Guide, consult the factory.

K

Note: Hose service working pressure (including surges and spikes) is never to exceed the maximum recommended working

pressure for the tting (reference chart below)*. King safety cables are recommended. Media being transported through the

hose should be compatible with the stem material and ferrule material. Consult Compatibility Chart on pages 548-553 or the

factory for material compatibility. For applications other than the ones listed, please consult Dixon factory.

Holedall

Externally Swaged * Internally Expanded *

Light Duty Fittings

NO Notched

Fittings

TM, TP, TG,

RN•••NO

---

---

350

--350

350

250

250

250

---

---

---

---

NOS Notched

Short Fittings

RST•••NOS,

STC•••NOS,

GAS••••NOS

---

---

---

--250

250

--250

***

---

---

---

---

Holedall II

Fittings

FW

---

---

---

--300

300

250

200

200

---

---

---

---

Cam and

Groove

---

250

---

--250

250

150

125

100

---

---

---

---

Internally

Expanded

IXM,

IXV, IXH

---

--800

--800

800

600

600 **

500 **

--400

---

---

Size

3/4"

1"

1-1/4"

1-3/8"

1-1/2"

2"

2-1/2"

3"

4"

5"

6"

8"

10"

Standard

Fittings

TM, TP,

TG

---

---

600

--600

600

600

600

500

450

400

350

300

Long Style

Fittings

TML, TPL,

TGL

---

---

1,000

--1,000

1,000

1,000

1,000

850

750

700

600

550

Flow Chief /

Crimp Sanitary

Fittings

IXSE, IXFS,

IXMS, CSSR

---

---

---

--250

250

250

250

200

---

---

---

---

• maximum recommended working pressures, in PSI, at 70°F ambient temperature

• for applications other than the ones listed, please consult Dixon factory

* The assembly's (hose + coupling) maximum working pressure is the lesser of:

1) The hose rated working pressure, or

2) The coupling rated working pressure

** For hoses which use IXF48-3 to IXF48-5 and IXF64-2 to IXF64-5, consult the factory for working pressures.

See notes below for specic recommendations.

Standard Fittings

Recommended for use on most one and two wire braid reinforced hoses, ber braided and helical wire reinforced hose, such as:

oil suction and discharge hose, barge and dock loading and unloading hose, L.P. gas hose (consult Dixon for NFPA56 compliant

products), anhydrous ammonia hose, aircraft fueling hose and acid chemical hose.

Long Style Fittings

Recommended for use on hose as listed under standard ttings where additional retention is required due to higher working

pressures or end pull. Consult maximum working pressure chart or call factory.

Holedall II Fittings

Recommended for Royalex P1193 and P1196 hose or hoses with similar construction, having helical wire for a given O.D.

range.

Light Duty Fittings

Recommended for use in the same applications as standard ttings above except that hose rated working pressure is never to

exceed the maximum recommended working pressure listed in chart above.

4 877.963.4966 • www.dixonvalve.com

Page 5

Holedall

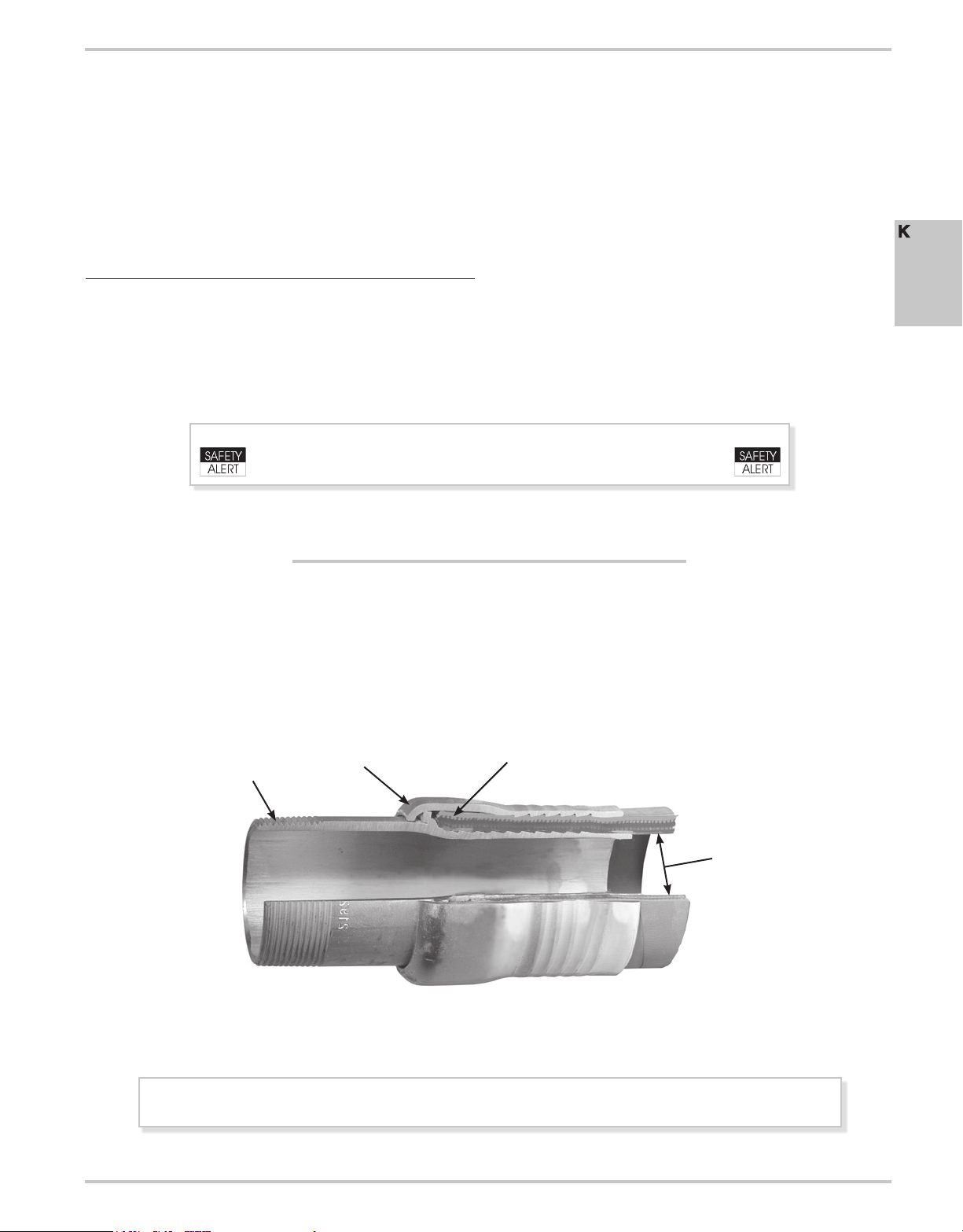

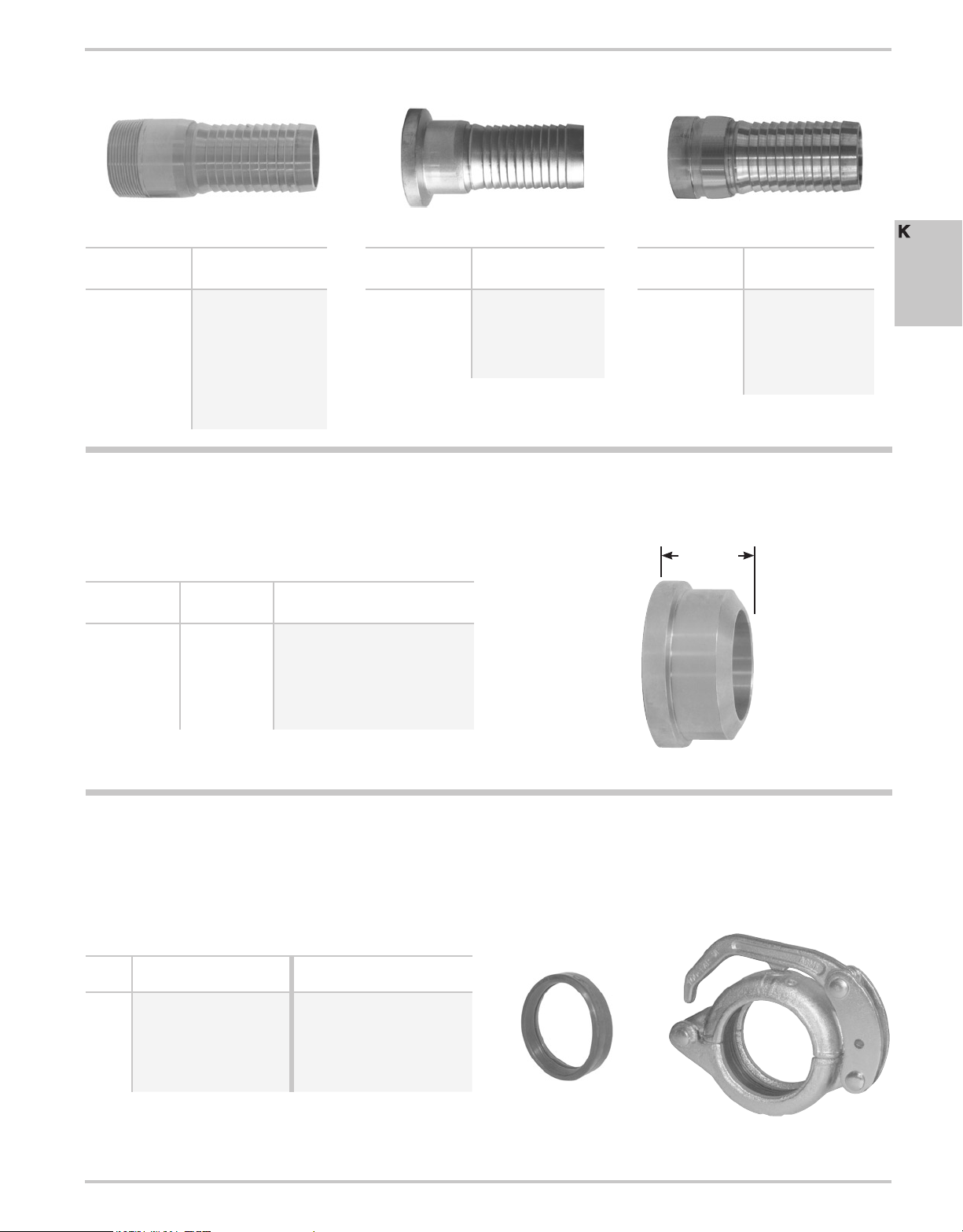

Holedall External Swage Coupling System

The Holedall coupling system provides outstanding strength, durability and safety.

The Holedall system is a method of attaching couplings to hose utilizing a progressive swage. The patented Holedall

couplings include a Holedall stem and a specially engineered ferrule. The hydraulic swaging of the coupling to the hose is

accomplished by pushing the ferrule through a die which reduces the ferrule OD The ferrule penetrates the hose wall, providing

a 360° uninterrupted compression band around the hose.

A hydraulic ram is the only piece of machinery necessary to accomplish the coupling. Available in ve different sizes - 15, 25,

50, 100 and 350 ton - these rams will accommodate dies and pushers of various sizes so that hoses up to 10" in diameter may

be coupled.

This multi-purpose, high pressure coupling system requires no bolts and results in a clean coupling with no protrusions. The

swaging operation is fast and hose of various lengths and different styles can be coupled. Ease of operation, exibility and

economy make the Holedall method an unequalled assembly system.

The Holedall coupling - the most adaptable coupling available.

For almost half a century, Holedall couplings have provided long-lasting efciency and safety unmatched by any other

industrial hose tting.

Couplings are available in stainless steel and carbon steel.

Couplings are furnished with pipe thread, plain end, victaulic grooved or anged ends.

Dixon Holedall stems and ferrules are specically designed to be used together as a coupling system.

Due to differences in dimensions and tolerances, for safety reasons,

do not use other manufacturer's stems or ferrules with Dixon Holedall products.

K

Holedall

stem

Streamlined, lightweight coupling consisting of ferrule and stem.

No protrusions to snag on equipment.

Displacement of hose carcass

ferrule

Cross-section of holedall externally swaged assembly

into ared portion of coupling

traps and seals hose end.

hose ID

Unless specied

consult the Dixon Swage/Crimp Recommendation Guide

5877.963.4966 • www.dixonvalve.com

Page 6

Holedall

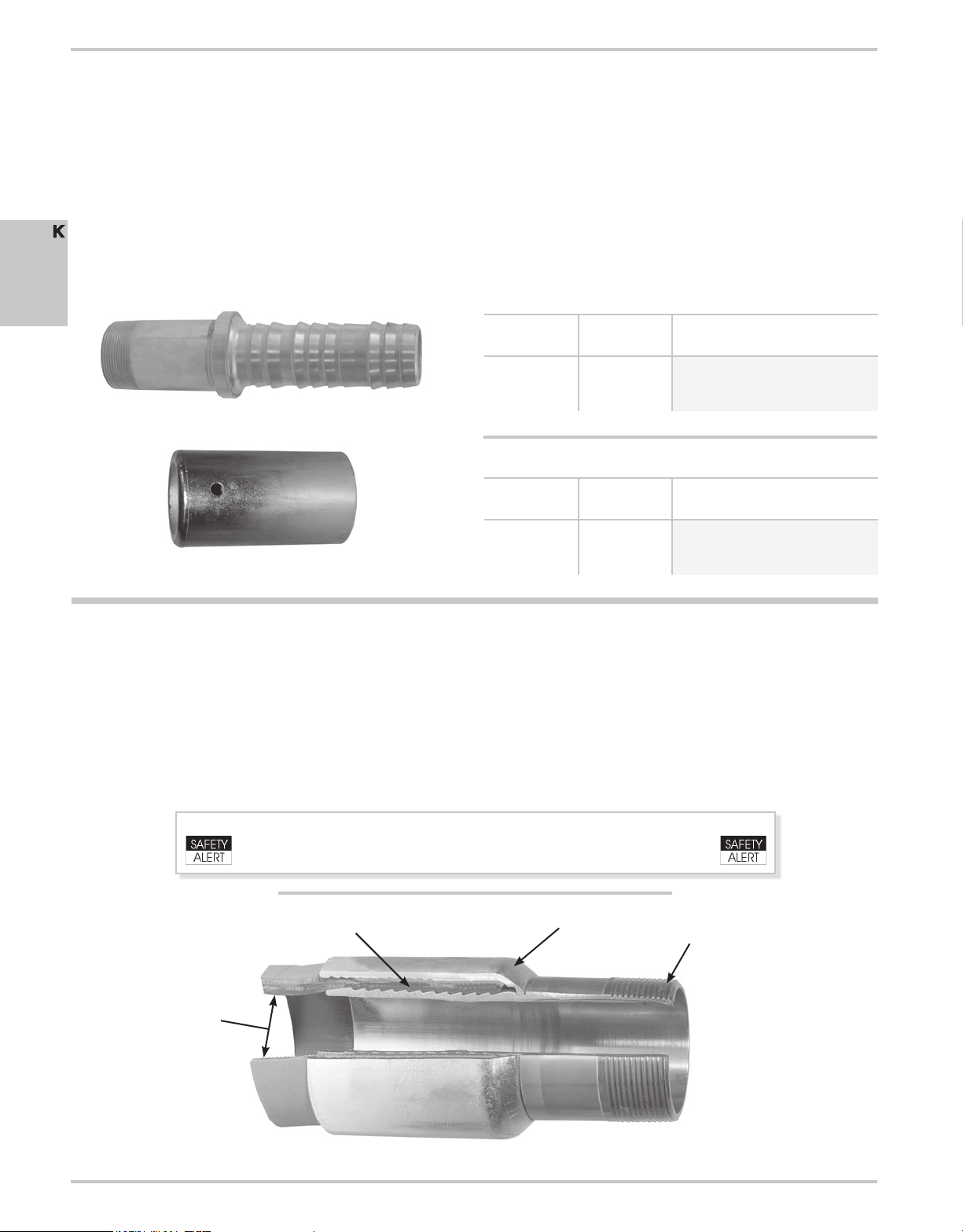

External Swage Stems

• designed and machined for hydraulic suction line applications using SAE100R4 hydraulic hose

• Barbs provide easy assembly and maximum gripping action.

• for higher working pressure applications use long style stems and ferrules

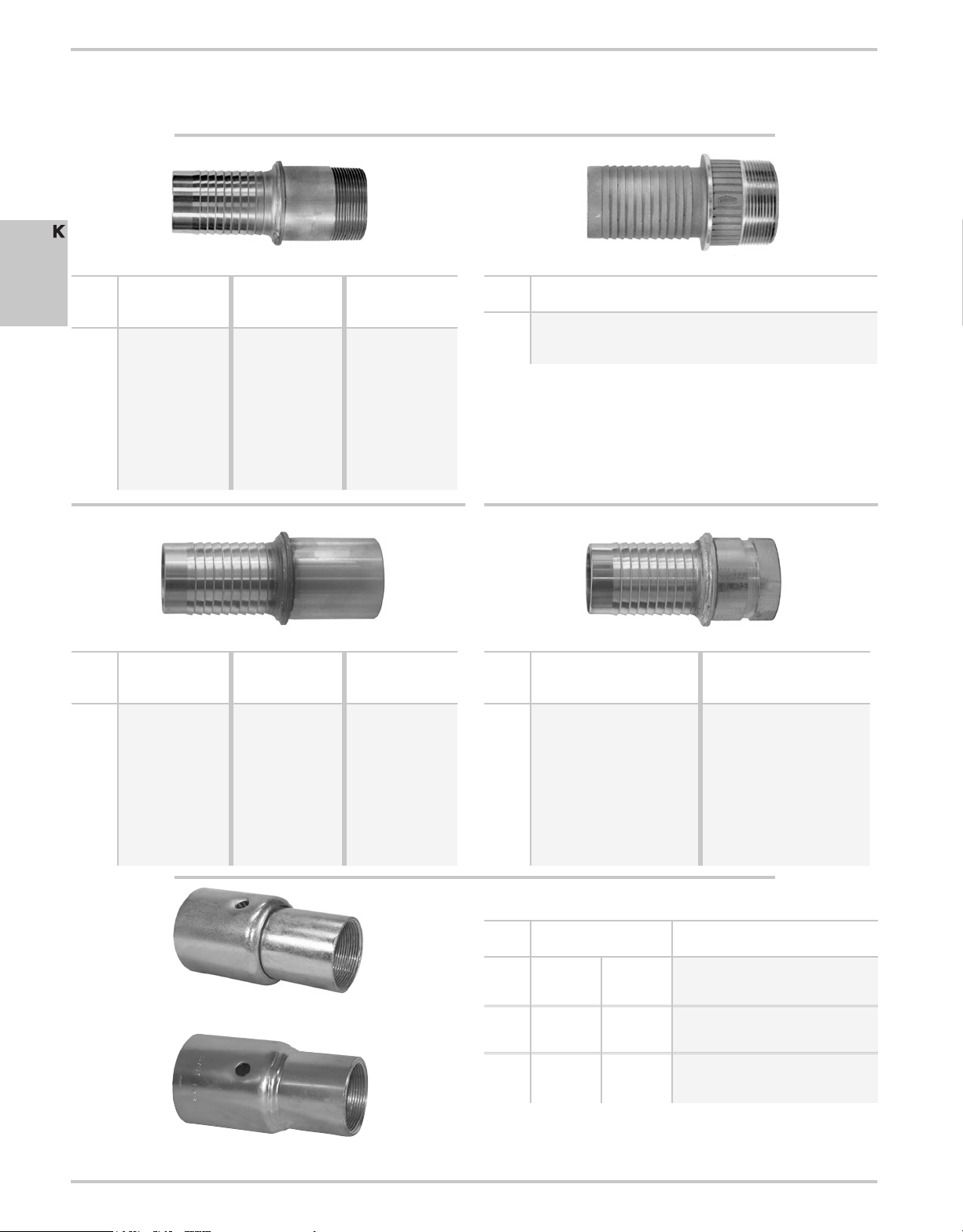

Male Pipe Threaded (NPT) End

K

Holedall

Hose

ID

1¼"

1½"

2"

2½"

3"

4"

5"

6"

8"

10"

Hose

ID

1¼"

1½"

2"

2½"

3"

4"

5"

6"

8"

10"

tubular type

Carbon Steel

Long Style

Carbon Steel

Part # Part # Part #

TM20

TM24

TM32

TM40

TM48

TM64

TM80

TM96

TM128

TM160

TML20

TML24

TML32

TML40

TML48

TML64

TML80

TML96

TML128

TML160

Stainless Steel

tubular type

Carbon Steel

Long Style

Carbon Steel

Part # Part # Part #

TP20

TP24

TP32

TP40

TP48

TP64

TP80

TP96

TP128

TP160

TPL20

TPL24

TPL32

TPL40

TPL48

TPL64

TPL80

TPL96

TPL128

TPL160

Stainless Steel

TMR20

TMR24

TMR32

TMR40

TMR48

TMR64

--TMR96

---

---

---

--TPR32

--TPR48

TPR64

---

---

---

---

Hose

ID

1½"

2"

3"

Hose

ID

1¼"

1½"

2"

2½"

3"

4"

5"

6"

8"

10"

investment cast design

Stainless Steel

Part #

TMR24C

TMR32C

TMR48C

Grooved End (Victaulic)Beveled End for Welding

tubular type

Carbon Steel

Part # Part #

TG20

TG24

TG32

TG40

TG48

TG64

TG80

TG96

TG128

TG160

Long Style

Carbon Steel

TGL20

TGL24

TGL32

TGL40

TGL48

TGL64

TGL80

TGL96

TGL128

TGL160

Female End

Hose

ID

1"

stem & ferrule - two piece design

1" sizes

1¼"

2"

1

Special pushers required for 1¼" and 2" sizes:

1¼" 25PUSH125-MOD

stem & ferrule - one piece design

2" 25PUSH200-MOD

1¼" - 2" sizes

6 877.963.4966 • www.dixonvalve.com

from to Part #

1-30/64"

1-34/64"

1-35/64"

1-44/64"

1-49/64"

1-57/64"

2-36/64"

2-41/64"

2-49/64"

tubular type

Hose OD Carbon Steel

1-34/64"

1-38/64"

1-42/64"

1-48/64"

1-56/64"

2"

2-40/64"

2-48/64"

2-56/64"

TF16WF1-80

TF16WF2-80

TF16WF3-80

TF20WF1-80

TF20WF2-80

TF20WF3-80

TF32WF1-80

TF32WF2-80

TF32WF3-80

1

1

1

1

1

1

Page 7

Holedall

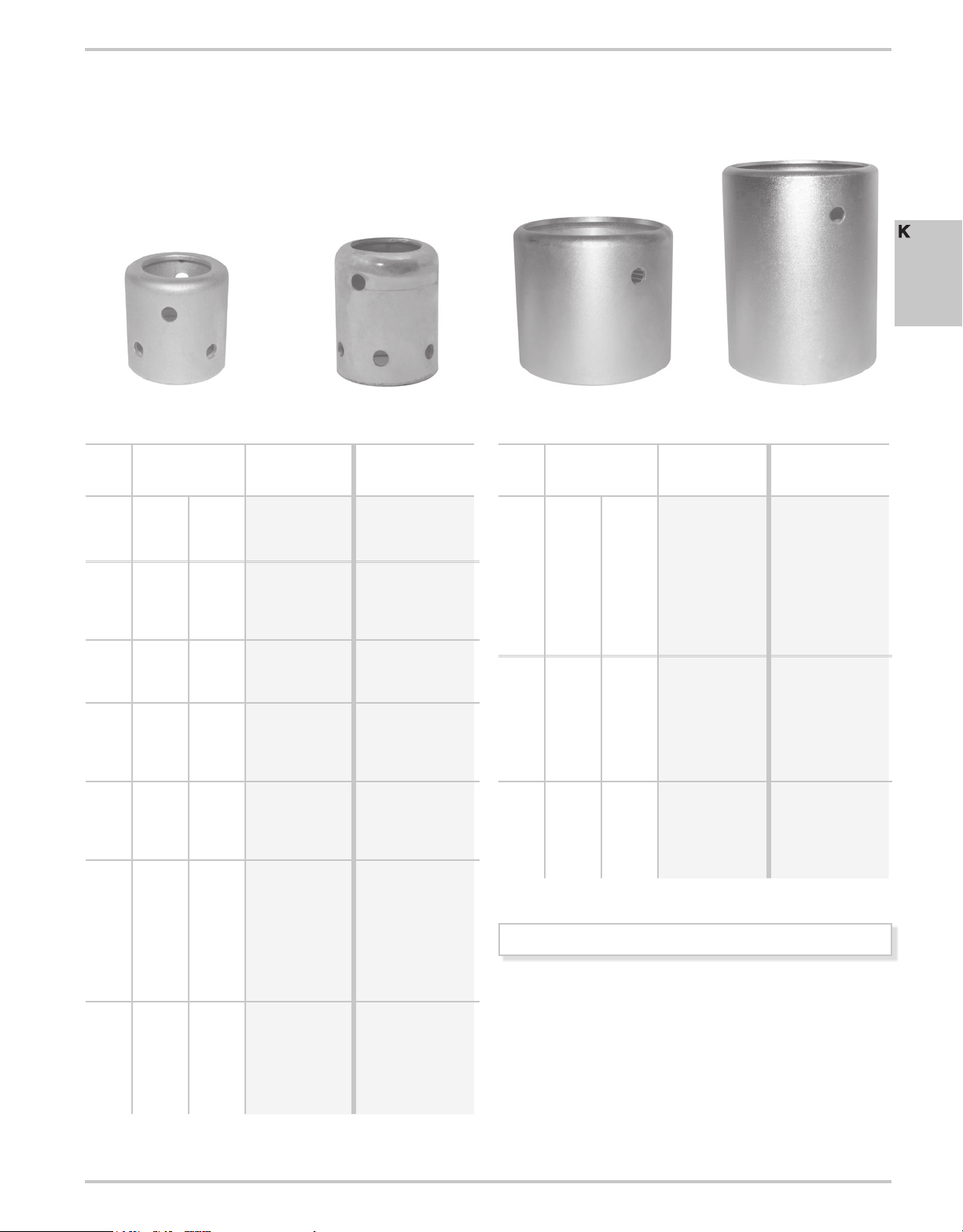

External Swage Ferrules

The selection of ferrules is very important to achieve the proper coupling-to-hose assembly.

• ferrules are plated carbon steel

• style F ferrules are used with all standard length male stems

• style FL ferrules are extra long and are used with all long style stems

K

Holedall

6-hole design

Hose

ID

1¼"

1½"

2"

2½"

3"

4"

5"

1

requires special stem: TM64-42

2

requires special stem: TML64-42

Hose OD

from to Part # Part #

1-44/64"

1-49/64"

1-57/64"

2-1/64"

1-58/64"

2-1/64"

2-9/64"

2-17/64"

2-25/64"

2-28/64"

2-41/64"

2-49/64"

2-57/64"

2-62/64"

3-9/64"

3-17/64"

3-25/64"

3-33/64"

3-30/64"

3-41/64"

3-49/64"

3-57/64"

4-1/64"

4-30/64"

4-40/64"

4-45/64"

4-53/64"

4-61/64"

5-5/64"

5-13/64"

5-21/64

5-29/64"

5-56/64"

5-61/64"

6-5/64"

6-13/64"

6-21/64"

6-29/64"

6-37/64"

1-48/64"

1-56/64"

2"

2-8/64"

2"

2-8/64"

2-16/64"

2-24/64"

2-32/64"

2-40/64"

2-48/64"

2-56/64"

3-2/64"

3-8/64"

3-16/64"

3-24/64"

3-32/64

3-40/64"

3-40/64"

3-48/64"

3-56/64"

4"

4-8/64"

4-39/64"

4-44/64"

4-52/64"

4-60/64"

5-4/64"

5-12/64"

5-20/64"

5-28/64"

5-36/64"

5-60/64"

6-4/64"

6-12/64"

6-20/64"

6-28/64"

6-38/64"

6-44/64"

Plated

Carbon Steel

F20-1

F20-2

F20-3

F20-4

F24-1

F24-2

F24-3

F24-4

F24-5

F32-1

F32-2

F32-3

F32-4

F40-1

F40-2

F40-3

F40-4

F40-5

F48-1

F48-2

F48-3

F48-4

F48-5

F64-Z

F64-1

F64-2

F64-3

F64-4

F64-5

F64-6

F64-7

F64-8

F80-1

F80-2

F80-3

F80-4

F80-5

F80-6

F80-7

Long Style

Plated Carbon Stl.

1

FL20-1

FL20-2

FL20-3

FL20-4

FL24-1

FL24-2

FL24-3

FL24-4

FL24-5

FL32-1

FL32-2

FL32-3

FL32-4

FL40-1

FL40-2

FL40-3

FL40-4

FL40-5

FL48-1

FL48-2

FL48-3

FL48-4

FL48-5

FL64-Z

FL64-1

FL64-2

FL64-3

FL64-4

FL64-5

FL64-6

FL64-7

FL64-8

FL80-1

FL80-2

FL80-3

FL80-4

FL80-5

FL80-6

FL80-7

2-hole design

Hose

ID

6"

8"

10"

2

Hose OD

from to Part # Part #

7"

9"

6-63/64"

7-4/64"

7-12/64"

7-20/64"

7-28/64"

7-36/64"

7-44/64"

7-52/64"

7-60/64"

8"

9-9/64"

9-24/64"

9-32/64"

9-40/64"

9-48/64"

9-56/64"

10"

10-4/64"

11-44/64"

11-60/64"

12-12/64"

12-28/64"

12-44/64"

12-60/64"

6-44/64"

7-5/64"

7-13/64"

7-21/64"

7-29/64"

7-37/64"

7-45/64"

7-53/64"

7-61/64"

9-20/64"

9-25/64"

9-33/64"

9-41/64"

9-49/64"

9-57/64"

10-1/64"

11-32/64"

11-45/64"

11-61/64"

12-13/64"

12-29/64"

12-45/64"

Plated

Carbon Steel

F96-Z

F96-1

F96-2

F96-3

F96-4

F96-5

F96-6

F96-7

F96-8

F96-9

F128-Y

F128-1

F128-2

F128-3

F128-4

F128-5

F128-6

F128-7

F160-1

F160-2

F160-3

F160-4

F160-5

F160-6

For applications with hose OD ranges not listed, call the factory.

Long Style

Plated Carbon Stl.

FL96-Z

FL96-1

FL96-2

FL96-3

FL96-4

FL96-5

FL96-6

FL96-7

FL96-8

FL96-9

FL128-Y

FL128-1

FL128-2

FL128-3

FL128-4

FL128-5

FL128-6

FL128-7

FL160-1

FL160-2

FL160-3

FL160-4

FL160-5

FL160-6

7877.963.4966 • www.dixonvalve.com

Page 8

Holedall

Holedall II External Swage Ferrules

For use with Royal-Flex™ thin wall hose. These specially

designed carbon steel ferrules have serrations on the outside

and should be used with stem styles TM, TP and TG stems on

page 6.

Hose

ID

1½"

K

2"

3"

4"

1

4" takes special stem; TM64-42

Hose OD Carbon Steel

from to Part #

1-58/64"

2-28/64"

3-30/64"

4-30/64"

2-2/64"

2-34/64"

3-38/64"

4-42/64"

FW24

FW32

FW48

FW64

1

Holedall

Stainless External Swage Ferrules

Light duty 304 stainless ferrules for use with standard length

stems such as the TMR series. Consult Dixon for die

recommendations. Refer to the Dixon Pressure Slide Chart

for specic pressure recommendations.

Hose

ID

1½"

2"

3"

4"

Hose OD 304 Stainless Steel

from to Part #

1-60/64"

2-4/64"

2-30-64"

2-42/64"

3-30/64"

3-47/64"

4-40/64"

2-12/64"

2-22/64"

2-44/64"

2-54/64"

3-46/64"

3-54/64"

4-47/64"

GAS2334TO

GAS2370TO

GAS2709TO

GAS2885TO

GAS3760TO

GAS3885TO

GAS5010TO

External Swage Notched NOS Stems and Ferrules

• The largest advantage of the notched design is that the coupling can be removed from a damaged hose by cutting away the

ferrule, without necessarily damaging the tting. After inspection of the tting to determine its suitability for reuse, it can be

reinstalled into another hose by using a new ferrule.

• The notched system allows you to better manage your inventories. You can stock one stem and two ferrules, and cover the

same hose range with less inventory. You must purchase a stem and the matching ferrule to create an assembly.

• For hose outside diameters of 2-4/64" and below, the couplings are crimp only.

• For hose outside diameters of 2-5/64" and above, the couplings can be crimped or swaged.

• See page 22 for cam and groove style notched NOS ttings.

Only use the NOS shank with the NOS ferrules.

Due to differences in dimensions and tolerances for safety reasons, do not use other

manufacturer's stems or ferrules with Dixon Holedall products.

Hose

ID

1½"

2"

3"

4"

with wrench ats

Hose

ID

1½"

2"

3"

4"

8 877.963.4966 • www.dixonvalve.com

from to Part #

1-60/64"

2-4/64"

2-30-64"

2-42/64"

3-30/64"

3-47/64"

4-40/64"

male NPT stems

316 Stainless Steel

Part #

RST150NOS

RST200NOS

RST300NOS

RST400NOS

ferrules

Hose OD 304 Stainless Steel

2-12/64"

2-22/64"

2-44/64"

2-54/64"

3-46/64"

3-54/64"

4-47/64"

GAS2334NOS

GAS2370NOS

GAS2709NOS

GAS2885NOS

GAS3760NOS

GAS3885NOS

GAS5010NOS

Page 9

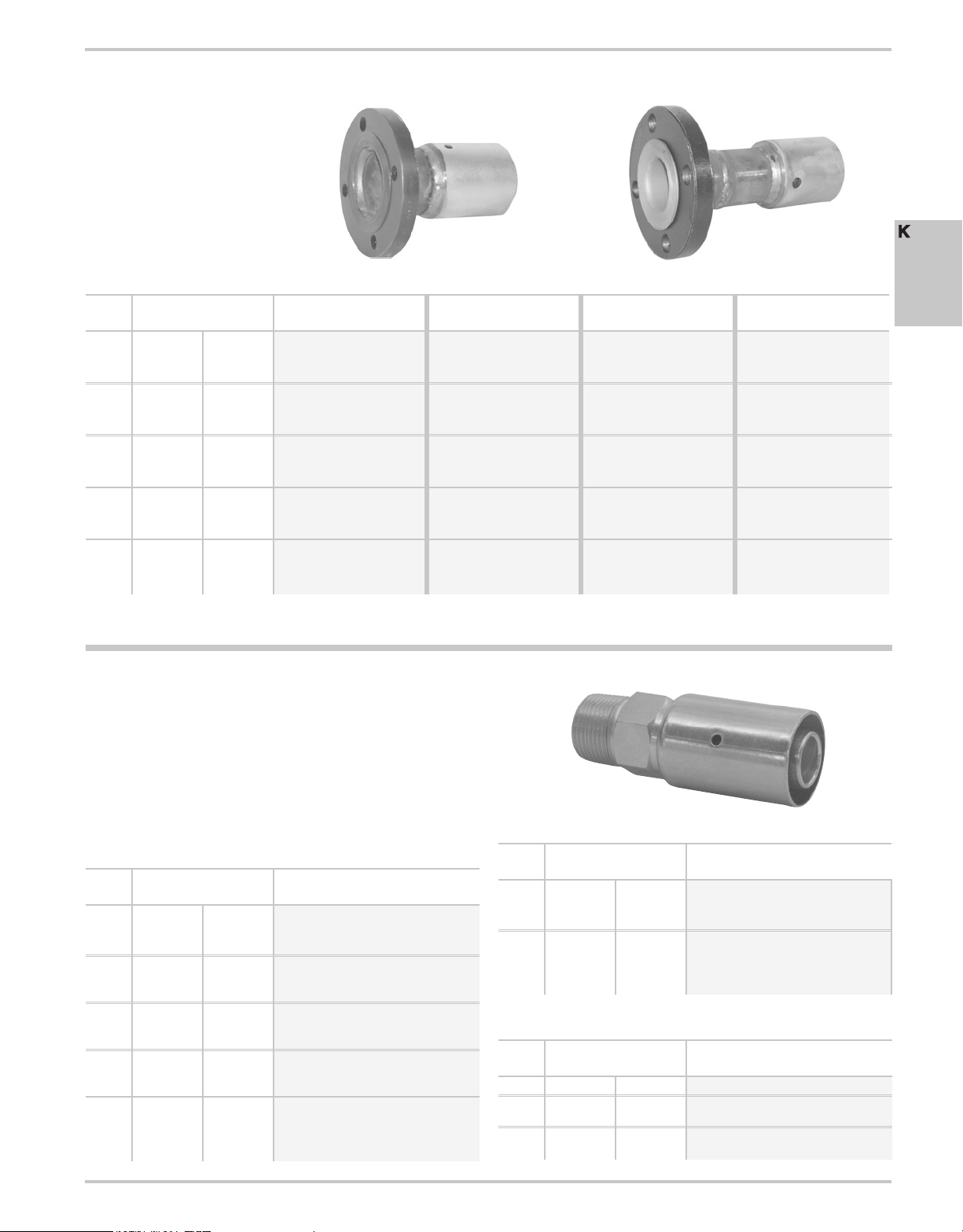

• 150# ASA ange drilling

available with carbon steel

stem, ferrule and ange,

or 316 stainless steel

stem, ange and carbon

steel ferrule

• available in other sizes,

consult the factory for

pricing

Holedall

External Swage Flanged Assemblies

K

xed ange

Hose

ID

2"

3"

4"

6"

8"

Hose OD Carbon Steel Stainless Steel Carbon Steel Stainless Steel

from to Part # Part # Part # Part #

2-36/64"

2-41/64"

2-49/64"

3-36/64"

3-41/64"

3-49/64"

4-40/64"

4-45/64"

4-53/64"

7"

7-5/64"

7-13/64"

9-20/64"

9-25/64"

9-33/64"

2-40/64"

2-48/64"

2-56/64"

3-40/64"

3-48/64"

3-56/64"

4-44/64"

4-52/64"

4-60/64"

7-4/64"

7-12/64"

7-20/64"

9-24/64"

9-32/64"

9-40/64"

32P1SO15

32P2SO15

32P3SO15

48P1SO15

48P2SO15

48P3SO15

64P1SO15

64P2SO15

64P3SO15

96P1SO15

96P2SO15

96P3SO15

128P1SO15

128P2SO15

128P3SO15

External Swage Uni-Range Male Couplings

Designed for smaller hose systems, these couplings may be

used for hose ID's of ¼" - 1" and come complete with factory

assembled stem and ferrule combination.

• can be swaged or crimped

• other hose OD's available, consult the factory

• stainless steel stems are investment cast

• plated carbon steel stem and ferrule

Hose

ID

1/4"

3/8"

1/2"

3/4"

1"

Hose OD Plated Carbon Steel

from to Part #

34/64"

38/64"

42/64"

46/64"

50/64"

54/64"

54/64"

58/64"

62/64"

1-10/64"

1-14/64"

1-18/64"

1-30/64"

1-34/64"

1-38/64"

1-42/64"

38/64"

42/64"

46/64"

50/64"

54/64"

58/64"

58/64"

62/64"

1-2/64"

1-14/64"

1-18/64"

1-22/64"

1-34/64"

1-38/64"

1-42/64"

1-46/64"

4P1

4P2

4P3

6P1

6P2

6P3

8P1

8P2

8P3

12P1

12P2

12P3

16P1

16P2

16P3

16P4

oating ange

R32P1SOR15

R32P2SOR15

R32P3SOR15

R48P1SOR15

R48P2SOR15

R48P3SOR15

R64P1SOR15

R64P2SOR15

R64P3SOR15

R96P1SOR15

R96P2SOR15

R96P3SOR15

---

---

---

• 316 stainless steel stem, plated carbon steel ferrule

Hose

ID

3/4"

1"

• 316 stainless steel stem, 304 stainless steel ferrule

Hose

ID

1/2"

3/4"

1"

from to Part #

1-10/64"

1-14/64"

1-18/64"

1-30/64"

1-34/64"

1-38/64"

1-42/64"

from to Part #

58/64"

1-6/64"

1-13/64"

1-30/64"

1-38/64"

32P1LJ15

32P2LJ15

32P3LJ15

48P1LJ15

48P2LJ15

48P3LJ15

64P1LJ15

64P2LJ15

64P3LJ15

96P1LJ15

96P2LJ15

96P3LJ15

128P1LJ15

128P2LJ15

128P3LJ15

Hose OD Stainless/Carbon Steel

1-14/64"

1-18/64"

1-22/64"

1-34/64"

1-38/64"

1-42/64"

1-46/64"

Hose OD Stainless Steel

58/64"

1-6/64"

1-13/64"

1-30/64"

1-38/64"

Holedall

R32P1LJR15

R32P2LJR15

R32P3LJR15

R48P1LJR15

R48P2LJR15

R48P3LJR15

R64P1LJR15

R64P2LJR15

R64P3LJR15

R96P1LJR15

R96P2LJR15

R96P3LJR15

---

---

---

R12P1

R12P2

R12P3

R16P1

R16P2

R16P3

R16P4

R8P2SS

R12P1250

R12P1370

R16P1620

R16P1770

9877.963.4966 • www.dixonvalve.com

Page 10

Holedall

External Swage High Pressure Couplings

These couplings are for services requiring a tting which will withstand extremely high pressures (up to 3,000 PSI) and severe

operating conditions, such as on small and medium size drilling rigs, used for slim hole, core drill, workover, seismograph, water

well, blast or shot holes, etc. These long, rugged ttings are machined from seamless pipe and tubing with specially designed

serrations. The mating ferrules are machined from heavy wall material incorporating matching serrations. These couplings are

shipped with matching ferrules. Please provide hose OD when ordering for properly sized ferrule. Make sure both ends of the

hose are measured for OD. Must be swaged with 50 Ton or 100 Ton Ram.

* An accurate hose OD must be provided to complete the part # and to ensure proper retention.

• The LM ttings are sold as a complete coupling, including stem and ferrule.

K

• API and NPT sizes are interchangeable

Stem and Ferrule Complete Assemblies

Holedall

Hose

ID

2"

2½"

3"

NPT

Size

2"

2½"

3"

Zinc Plated Steel

Part #

LM32-*

LM40-*

LM48-*

API Male Threaded Couplings

NPT Male Threaded Couplings

Hose

ID

2"

2½"

3"

API

Size

2½"

3"

4"

Zinc Plated Steel

Part #

LM3240- *

LM4048- *

LM4864- *

Holedall Internal Expansion Couplings

The Dixon Internally Expanded Couplings are essential when maximum ow is important. Only one expansion tool is needed for

each hose ID Some recommended applications of these ttings are: concrete pump hose, plaster and grout hose, oil suction and

discharge hose, multi-purpose heavy duty air hose, jetting hose, barge loading hose and bottom loading hose.

Benets of Internal Expansion Fittings:

• maximum ow of media

• reduction of turbulence through hose

• excellent sealing and retention characteristics

• outperforms band clamps

• easy and consistent installation

End Congurations Available:

• male NPT

• raised California

• victaulic

• others available on request

Dixon Holedall stems and ferrules are specically designed to be used together as a coupling system.

Due to differences in dimensions and tolerances, for safety reasons,

do not use other manufacturer's stems or ferrules with Dixon Holedall products.

excellent hose retention

hose ID

Cross-section of Holedall internally expanded assembly

10 877.963.4966 • www.dixonvalve.com

Ferrule

Stem

Page 11

Holedall

Internal Expansion Stems

Size

1¼"

1½"

2"

2½"

3"

4"

grooved end

Carbon Steel

Part #

IXV20

IXV24

IXV32

IXV40

IXV48

IXV64

male pipe end

Size

1"

1¼"

1½"

2"

2½"

3"

4"

6"

Carbon Steel

Part #

IXM16

IXM20

IXM24

IXM32

IXM40

IXM48

IXM64

IXM96

heavy duty raised end

Size

1½"

2"

2½"

3"

4"

Carbon Steel

Part #

IXH24

IXH32

IXH40

IXH48

IXH64

Butt Weld x Heavy Duty Raised End (California Style)

Beveled design for welding to Schedule 40 pipe allows connection to a heavy duty raised end (California style) hose tting or

similar style end.

California style end

Size Length

1½"

2"

2½"

3"

4"

5"

1½"

1½"

1½"

1½"

1½"

1½"

Carbon Steel

Part #

HDE24

HDE32

HDE40

HDE48

HDE64

HDE80

Length

K

Holedall

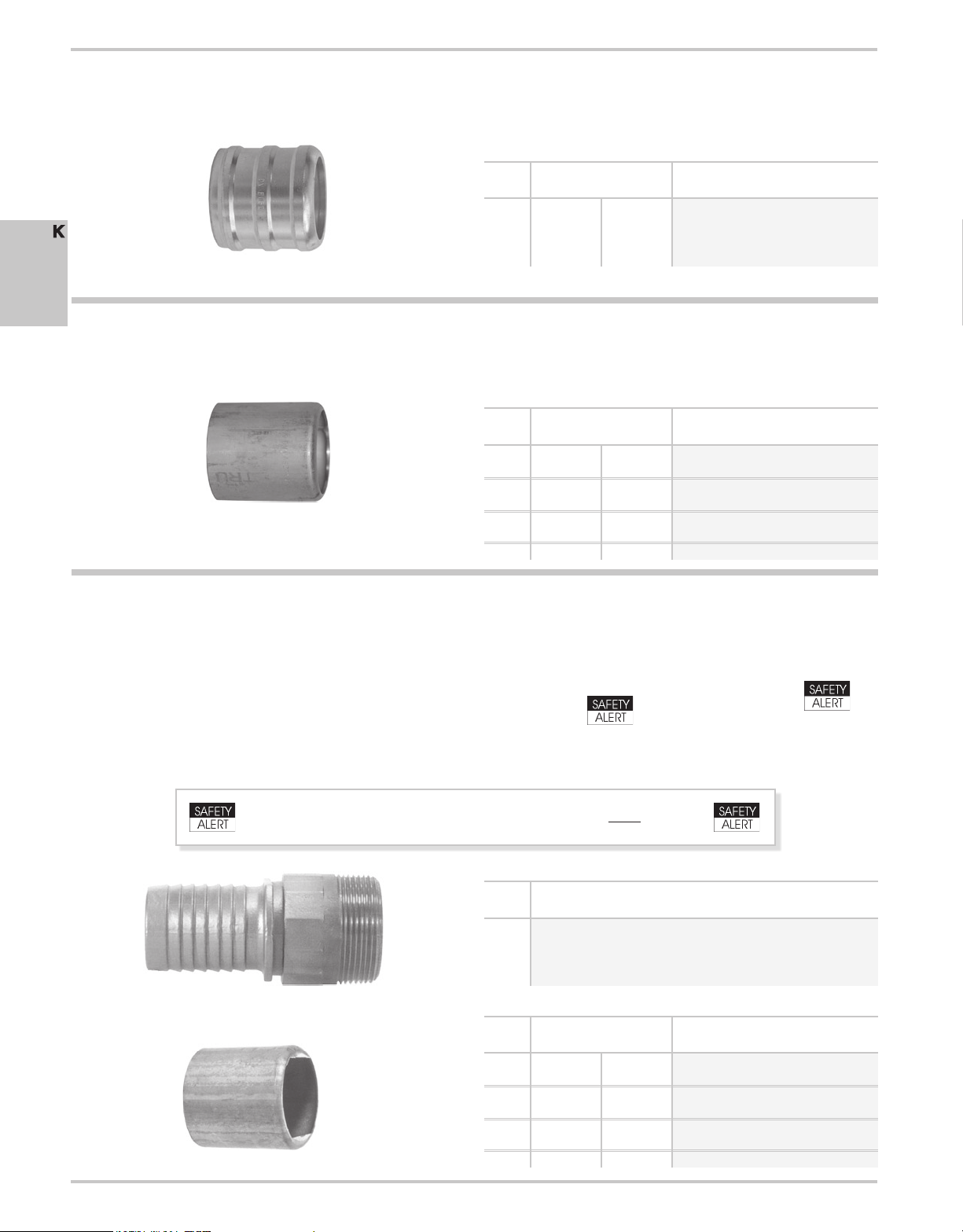

Clamps for IXH Raised End (California Style) Stems

Drop-forged steel clamps for fast assembly when connecting heavy-duty raised end ttings used for concrete. These clamps can

be used to connect the ends of pipes or hoses which use the Raised End or California style ttings listed above. Shipped with

double lipped gasket and safety pin. 1½" through 3" are galvanized; 4" and 5" are painted green. Clamp should only be used with

safety pin in place.

Hose

1½"

2½"

Forged Steel Clamps Buna-N Gaskets

ID

2"

3"

4"

5"

Part # Part #

IXHC150

IXHC200

IXHC250

IXHC300

IXHC400

IXHC500

IXHCG150

IXHCG200

IXHCG250

IXHCG300

IXHCG400

IXHCG500

11877.963.4966 • www.dixonvalve.com

Page 12

Holedall

Holedall

Internal Expansion Ferrules

K

Hose

ID

1"

1¼"

1½"

2"

2½"

Hose OD

from to Part #

1-24/64"

1-28/64"

1-32/64"

1-40/64"

1-44/64"

1-48/64"

1-52/64"

1-56/64"

1-60/64"

1-56/64"

1-60/64"

2-4/64"

2-8/64"

2-12/64"

2-16/64"

2-20/64"

2-32/64"

2-36/64"

2-40/64"

2-44/64"

2-48/64"

2-52/64"

2-56/64"

2-60/64"

3-4/64"

3-8/64"

3-12/64"

3-16/64"

3-20/64"

3-24/64"

3-28/64"

1-28/64"

1-32/64"

1-36/64"

1-44/64"

1-48/64"

1-52/64"

1-56/64"

1-60/64"

2"

2"

2-4/64"

1-60/64"

2"

2"

2-4/64"

2-8/64"

2-12/64"

2-16/64"

2-20/64"

2-24/64"

2-36/64"

2-40/64"

2-44/64"

2-48/64"

2-52/64"

2-56/64"

2-60/64"

3"

3"

3-4/64"

3"

3-4/64"

3-8/64"

3-12/64"

3-16/64"

3-20/64"

3-24/64"

3-28/64"

3-32/64"

Ferrule

Size

1-7/16"

1-1/2"

1-9/16"

1-11/16"

1-3/4"

1-13/16"

1-7/8"

1-15/16"

2"

2-1/16"

1-15/16"

2"

2-1/16"

2-1/8"

2-3/16"

2-1/4"

2-5/16”

2-3/8"

2-9/16"

2-5/8"

2-11/16"

2-3/4"

2-13/16"

2-7/8"

2-15/16"

3"

3-1/16"

3-1/16"

3-1/8"

3-3/16"

3-1/4"

3-5/16"

3-3/8"

3-7/16"

3-1/2"

Plated Carbon Steel

IXF16-1

IXF16-2

IXF16-3

IXF20-Z

IXF20-1

IXF20-2

IXF20-3

IXF20-4

IXF20-5

IXF20-6

IXF24-Z

IXF24-1

IXF24-2

IXF24-3

IXF24-4

IXF24-5

IXF24-6

IXF24-7

IXF32-Y

IXF32-Z

IXF32-1

IXF32-2

IXF32-3

IXF32-4

IXF32-5

IXF32-6

IXF32-7

IXF40-1

IXF40-2

IXF40-3

IXF40-4

IXF40-5

IXF40-6

IXF40-7

IXF40-8

Hose

ID

3"

4"

6"

Hose OD

from to Part #

3-32/64"

3-36/64"

3-40/64"

3-44/64"

3-48/64"

3-52/64"

3-56/64"

3-60/64"

4-4/64"

4-8/64"

4-12/64"

4-36/64"

4-40/64"

4-44/64"

4-48/64"

4-52/64"

4-56/64"

4-60/64"

5-4/64"

5-8/64"

5-12/64"

5-16/64"

6-40/64"

6-44/64"

6-46/64"

6-48/64"

6-52/64"

6-56/64"

6-60/64"

7-4/64"

7-8/64"

7-12/64"

7-16/64"

7-18/64"

7-20/64"

3-36/64"

3-40/64"

3-44/64"

3-48/64"

3-52/64"

3-56/64"

3-60/64"

4"

4"

4-4/64"

4-8/64"

4-12/64"

4-16/64"

4-40/64"

4-44/64"

4-48/64"

4-52/64"

4-56/64"

4-60/64"

5"

5"

5-4/64"

5-8/64"

5-12/64"

5-16/64"

5-20/64"

6-44/64"

6-48/64"

6-50/64"

6-52/64"

6-56/64"

6-60/64"

7"

7"

7-4/64"

7-8/64"

7-12/64"

7-16/64"

7-20/64"

7-22/64"

7-24/64"

Ferrule

Size

3-9/16"

3-5/8"

3-11/16"

3-3/4"

3-13/16"

3-7/8"

3-15/16"

4"

4-1/16"

4-1/8"

4-3/16"

4-1/4"

4 -5/8"

4-11/16"

4-3/4"

4-13/16"

4-7/8"

4-15/16"

5"

5-1/16"

5-1/8"

5-3/16"

5-1/4"

5-5/16"

6-11/16"

6-3/4"

6-25/32"

6-13/16"

6-7/8"

6-15/16"

7"

7-1/16"

7-1/8"

7-3/16"

7-1/4"

7-5/16"

7-11/32"

7-3/8"

Plated Carbon Steel

IXF48-T

IXF48-U

IXF48-V

IXF48-W

IXF48-X

IXF48-Y

IXF48-Z

IXF48-1

IXF48-2

IXF48-3

IXF48-4

IXF48-5

1

1

1

IXF64-T

IXF64-U

IXF64-V

IXF64-W

IXF64-X

IXF64-Y

IXF64-Z

IXF64-1

IXF64-2

IXF64-3

IXF64-4

IXF64-5

1

1

1

1

IXF96-1

IXF96-2

IXF96-3

IXF96-4

IXF96-5

IXF96-6

IXF96-7

IXF96-8

IXF96-9

IXF96-10

IXF96-11

IXF96-12

IXF96-13

IXF96-14

1 For hoses using ferrule sizes IXF48-3 thru IXF48-5 and IXF64-2 thru IXF64-5, consult the factory for working pressures.

12 877.963.4966 • www.dixonvalve.com

Page 13

Holedall

Internally Expanded Permanent Couplings - Scovill Style

Do not interchange with other manufacturer's ttings.

Brass internally expanded permanent coupling are recommended for discharge and suction service. Commonly used in the

transfer of fuel in industry to homes, airplanes, ships, etc. The working pressure of the 520-H tting varies with the size of the

tting, the size and construction of the hose and the media being conveyed. Consult the factory for recommendations. Dixon

Holedall stems and ferrules are specically designed to be used together as a coupling system.

Both the male and female have octagonal facets for tightening with a wrench. The female in 1½" and larger sizes has special

lugs for tightening. The stem is expanded to nominal ID of hose for a rigid, uniform, full-ow area.

• Male and female stems are machined from bar stock or

solid brass forgings; ferrules are available in brass and

stainless steel.

• Couplings are compact, light and streamlined to eliminate

• The H520 ttings are designed for internal expansion only.

• Couplings are pre-lubricated for assembly.

• Hand and electrically operated installation equipment is

available. Consult factory for pricing and availability.

catching on curbs and shrubs.

male NPT male NST female NPSH female NST victaulic groove

Hose

ID

3/4"

1"

1-1/4"

1-3/8"

1-1/2"

2"

2-1/2"

3"

1

1-3/8" stem has 1½" thread

2

1½" NST requires special adapter, part # H5231NSTADT

3

2½" and 3" female parts have NPSM thread

Brass Brass Brass Brass Brass

Part # Part # Part # Part # Part #

H5192

H5212-A

H5222-A

H5272

H5232-A

H5242

H5252

H5262

1

--H5212NST

---

--H5232NST

---

---

---

H5191-BU

H5211-A-BU

H5221-A-BU

2

H5271-BU

H5231-A-BU

H5241-BU

H5251

H5261

1

3

3

--H5211NST

---

--H5231NST

---

---

---

--G5212

---

2

--G5232

G5242

---

---

Note: The ttings on this page are intended for fuel delivery

service. See page 12 for information on API 1529

certication.

K

Holedall

520-H Ferrules

A wide range of 520-H ferrules permits a perfect assembly of a coupling to a corresponding size

of hose within commercial tolerances regardless of wall thickness. Eliminates need for large

stock of coupling bodies. Consult Dixon for other hose OD's.

Hose

ID

¾"

1"

1¼"

1

1", 1¼" and 1½" ferrules will be replaced by API ferrules on page 14 as inventory is depleted.

Hose OD Brass

from to Part #

1-8/64"

1-12/64"

1-15/64"

1-18/64"

1-24/64"

1-27/64"

1-30/64"

1-33/64"

1-36/64"

1-39/64"

1-42/64"

1-39/64"

1-43/64"

1-47/64"

1-51/64"

1-55/64"

1-59/64"

1-11/64"

1-14/64"

1-17/64"

1-20/64"

1-26/64"

1-29/64"

1-32/64"

1-35/64"

1-38/64"

1-41/64"

1-44/64"

1-42/64"

1-46/64"

1-50/64"

1-54/64"

1-58/64"

1-62/64"

R75AAS

R75AS

R75BS

R75CS

R1AAAS-A

R1AAS-A

R1AS-A

R1BS-A

R1CS-A

R1DS-A

R1ES-A

R125AAS-A

R125AS-A

R125BS-A

R125CS-A

R125DS-A

R125ES

Hose

ID

1-3/8"

1½"

Hose OD Brass

from to Part #

2-3/64"

2-7/64"

1-50/64"

1-54/64"

1-58/64"

1-62/64"

1-57/64"

1-62/64"

2-2/64"

2-6/64"

2-11/64"

2-14/64"

2-19/64"

2-24/64"

2-28/64"

R1375BS

R1375CS

R1375DS

R1375ES

R15AAAS-A

R15AAS-A

R15AS-A

R15BS-A

R15CS-A

R15DS-A

R15ES-A

R15FS

R15GS

1-47/64"

1-51/64"

1-55/64"

1-59/64"

1-54/64"

1-58/64"

1-63/64"

2-12/64"

2-15/64"

2-20/64"

2-25/64"

Hose

ID

2"

2½"

3"

Hose OD Brass

from to Part #

3-2/64"

3-7/64"

2-30/64"

2-34/64"

2-38/64"

2-42/64"

2-46/64"

2-50/64"

2-54/64"

3-1/64"

3-6/64"

3-11/64"

3-16/64"

3-21/64"

3-26/64"

3-34/64"

3-39/64"

3-45/64"

3-50/64"

3-54/64"

R2AAS

R2AS

R2BS

R2CS

R2DS

R2ES

R2FS

R25AS

R25BS

R25CS

R25DS

R25ES

R25FS

R3AAAS

R3AAS

R3AS

R3BS

R3CS

2-27/64"

2-31/64"

2-35/64"

2-39/64"

2-43/64"

2-47/64"

2-51/64"

2-62/64"

3-12/64"

3-17/64"

3-22/64"

3-30/64"

3-35/64"

3-40/64"

3-46/64"

3-51/64"

13877.963.4966 • www.dixonvalve.com

Page 14

Holedall

API Certied Permanently Attached Petroleum Couplings

The following ttings have been tested and are compliant with API 1529 6th edition. Coupling procedures, ferrule

recommendations and API test data are available upon request, please contact the factory.

K

Holedall

Hose

Size

1¼"

1½"

2½"

1

requires a special thrust plate

1"

2"

3"

4"

Thread

Type

NPT

NPT

NPT

NPT

NPT

NPT

NPT

2" 25000HTL24

2½" 25000HTL25

3" 25000HTL26

520-H series male thread

Brass Aluminum

Part # Part #

H5212-A

H5222-A

H5232-A

H5242L-A

H5252L-A

H5262L-A

H5282L-A

API 520-H Series Ferrules

---

---

--A5242L-A

A5252L-A

A5262L-A

---

520-H series female thread

Hose

Size

1"

1¼"

1

1

1

1½"

2"

2½"

3"

4"

Thread

Type

NPSH

NPSH

NPSH

NPSH

NPSM

NPSM

NPSM

Brass

Part #

H5211-A-BU

H5221-A-BU

H5231-A-BU

H5241L-A-BU

H5251L-A-BU

H5261L-A-BU

H5281L-A-BU

Hose

ID

1"

1¼"

1½"

Hose OD Brass

from to Part #

1-24/64"

1-27/64"

1-30/64"

1-33/64"

1-36/64"

1-39/64"

1-42/64"

1-39/64"

1-43/64"

1-47/64"

1-51/64"

1-55/64"

1-59/64"

1-54/64"

1-58/64"

1-63/64"

2-3/64"

2-7/64"

2-12/64"

2-15/64"

1-26/64"

1-29/64"

1-32/64"

1-35/64"

1-38/64"

1-41/64"

1-44/64"

1-42/64"

1-46/64"

1-50/64"

1-54/64"

1-58/64"

1-62/64"

1-57/64"

1-62/64"

2-2/64"

2-6/64"

2-11/64"

2-14/64"

2-19/64"

R1AAAS-A

R1AAS-A

R1AS-A

R1BS-A

R1CS-A

R1DS-A

R1ES-A

R125AAS-A

R125AS-A

R125BS-A

R125CS-A

R125DS-A

R125ES-A

R15AAAS-A

R15AAS-A

R15AS-A

R15BS-A

R15CS-A

R15DS-A

R15ES-A

Hose

ID

2"

2½"

3"

4"

Hose OD

from to Part # Part #

2-31/64"

2-35/64"

2-39/64"

2-43/64"

2-47/64"

2-62/64"

3-2/64"

3-7/64"

3-12/64"

3-17/64"

3-35/64"

3-40/64"

3-46/64"

3-51/64"

3-55/64"

4-46/64"

4-49/64"

4-52/64"

4-55/64"

4-58/64"

4-60/64"

4-63/64"

14 877.963.4966 • www.dixonvalve.com

2-34/64"

2-38/64"

2-42/64"

2-46/64"

2-50/64"

3-1/64"

3-6/64"

3-11/64"

3-16/64"

3-21/64"

3-39/64"

3-45/64"

3-50/64"

3-54/64"

3-59/64"

4-48/64"

4-51/64"

4-54/64"

4-57/64"

4-59/64"

4-62/64"

5"

304 Stainless Steel Aluminum

R2ASS-A

R2BSS-A

R2CSS-A

R2DSS-A

R2ESS-A

R25ASS-A

R25BSS-A

R25CSS-A

R25DSS-A

R25ESS-A

R3AASS-A

R3ASS-A

R3BSS-A

R3CSS-A

R3DSS-A

R4ESS-A

R4FSS-A

R4GSS-A

R4HSS-A

R4KSS-A

R4LSS-A

R4MSS-A

R2AAL-A

R2BAL-A

R2CAL-A

R2DAL-A

R2EAL-A

R25AAL-A

R25BAL-A

R25CAL-A

R25DAL-A

R25EAL-A

R3AAAL-A

R3AAL-A

R3BAL-A

R3CAL-A

R3DAL-A

---

---

---

---

---

---

---

Page 15

Holedall

CIP Internal Expansion (IX) Sanitary Style Hose Couplings

• Clean-In-Place (CIP) compliant

• Flow Chief internal expansion (IX) ttings are only to be used with Flow Chief stainless steel ferrules.

• Flow Chief Sanitary ttings are used in the food, dairy and beverage industries.

Sanitary Clamp End Stems

• see the current Dixon Price List for sanitary style gaskets

• see the current Dixon Price List for sanitary style clamps

• special plug is required to expand CIP compliant ttings

• special adapter plate is required to expand 1½" CIP

compliant ttings

• 3A compliant when assembled by 3A authorized hose shop

Size

1½"

2"

3"

• special plug is required to expand CIP compliant ttings

304 Stainless Steel

Part #

IXSE24-3A

IXSE32-3A

IXSE48-3A

Tube Weld End Stem

K

Holedall

Size

304 Stainless Steel

Part #

2" IXPE32-3A

Special Expansion Plug for CIP Compliant IX Fittings

Hose Size Part #

1½"

2"

3"

IXFDPLG137

IXFDPLG187

IXFDPLG287

Flow Chief Ferrules

• the ferrule ID's are designed in increments of 1/16"

Hose

ID

1½"

2"

2½"

1

1

Hose OD 304 stainless steel

from to Part #

1-56/64"

1-60/64"

2"

2-4/64"

2-8/64"

2-12/64"

2-16/64"

2-28/64"

2-32/64"

2-36/64"

2-40/64"

2-44/64"

2-48/64"

2-52/64"

2-56/64"

3"

3-4/64"

3-8/64"

3-12/64"

3-16/64"

3-20/64"

3-28/64"

1-59/64"

1-63/64"

2-3/64"

2-7/64"

2-11/64"

2-15/64"

2-19/64"

2-31/64"

2-35/64"

2-39/64"

2-43/64"

2-47/64"

2-51/64"

2-55/64"

2-59/64"

3-3/64"

3-7/64"

3-11/64"

3-15/64"

3-19/64"

3-23/64"

3-31/64"

24PFX1.937

24PFX2.000

24PFX2.062

24PFX2.125

24PFX2.187

24PFX2.250

24PFX2.312

32PFX2.500

32PFX2.562

32PFX2.625

32PFX2.687

32PFX2.750

32PFX2.812

32PFX2.875

32PFX2.937

40PFX3.062

40PFX3.125

40PFX3.187

40PFX3.250

40PFX3.312

40PFX3.375

40PFX3.500

Hose

ID

2

3"

4"

1

1½" and 2" ferrules are not serrated

2

consult the factory for working pressure

Hose OD 304 stainless steel

from to Part #

3-32/64"

3-36/64"

3-40/64"

3-44/64"

3-48/64"

3-52/64"

3-56/64"

3-60/64"

4"

4-4/64"

4-36/64"

4-40/64"

4-44/64"

4-48/64"

4-52/64"

4-56/64"

3-35/64"

3-39/64"

3-43/64"

3-47/64"

3-51/64"

3-55/64"

3-59/64"

3-63/64"

4-3/64"

4-7/64"

4-39/64"

4-43/64"

4-47/64"

4-51/64"

4-55/64"

4-59/64"

48PFX3.562

48PFX3.625

48PFX3.687

48PFX3.750

48PFX3.812

48PFX3.875

48PFX3.937

48PFX4.000

48PFX4.062

48PFX4.125

64PFX4.625

64PFX4.687

64PFX4.750

64PFX4.812

64PFX4.875

64PFX4.937

15877.963.4966 • www.dixonvalve.com

Page 16

Holedall

Internal Expansion (IX) Sanitary Style Hose Couplings

• sanitary style end

• Flow Chief internal expansion (IX) ttings are only to be

used with Flow Chief stainless steel ferrules, see page 15

• see the current Dixon Price List for sanitary style gaskets

• see the current Dixon Price List for sanitary style clamps

Holedall

K

Size

1½"

2"

2½"

3"

4"

304 Stainless Steel

Part #

IXSE24

IXSE32

IXSE40

IXSE48

IXSE64

Internal Expansion (IX) Male NPT Stems

• Flow Chief internal expansion (IX) ttings are only to be

used with Flow Chief stainless steel ferrules, see page 15

Size

1½"

2"

2½"

3"

4"

304 Stainless Steel

Part #

IXMS24

IXMS32

IXMS40

IXMS48

IXMS64

Internal Expansion (IX) Bevel Seat Hose Couplings

• Flow Chief internal expansion (IX) ttings are only to be used with Flow Chief stainless steel ferrules, see page 15

• see the current Dixon Price List for bevel seat gaskets

Female Shank

• only use with the IXAN nuts shown below

Size

1½"

2"

2½"

3"

4"

Threaded Hex Nuts

series 13H (modied)

Size

1½"

2"

2½"

3"

4"

304 Stainless Steel

Part #

IXFS24

IXFS32

IXFS40

IXFS48

IXFS64

304 Stainless Steel

Part #

IXAN24

IXAN32

IXAN40

IXAN48

IXAN64

16 877.963.4966 • www.dixonvalve.com

Page 17

Dixon Sanitary Style Crimp Stems

Sanitary End x Hose Shank

• sanitary style end

• Dixon sanitary crimp stems are only to be used with

Dixon stainless steel crimp ferrules

• reference pages 18-19 for crimp recommendations

Size

1"

1½"

2"

3"

4"

316 Stainless Steel

Part #

CSSR100

CSSR150

CSSR200

CSSR300

CSSR400

Female Bevel Seat End x Hose Shank

Holedall

K

Holedall

Size

1"

1½"

2"

3"

4"

1

only use with IXAN nut on page 14

2

only use with IXAN300 nut

Size

1½"

2"

3"

4"

Size

1½"

2"

3"

4"

316 Stainless Steel

Part #

CBSR100

CBSR150

CBSR200

CBSR300

CBSR400

1

1

1

2

1

Female I-Line End x Hose Shank

316 Stainless Steel

Part #

CILR150

CILR200

CILR300

CILR400

Tube Weld End x Hose Shank

316 Stainless Steel

Part #

CTER150

CTER200

CTER300

CTER400

Dixon Sanitary Crimp Ferrules

• manufactured in AISI 304 stainless steel

• ferrules have a surface nish of 63 or better

Hose

ID

1"

1½"

2"

Hose OD 304 stainless steel

from to Part #

1-26/64"

1-29/64"

1-32/64"

1-35/64"

1-38/64"

1-58/64"

1-62/64"

2-2/64"

2-6/64"

2-30/64"

2-34/64"

2-38/64"

2-42/64"

1-28/64"

1-31/64"

1-34/64"

1-37/64"

1-40/64"

1-61/64"

2-1/64"

2-5/64"

2-9/64"

2-33/64"

2-37/64"

2-41/64"

2-45/64"

F16G-1453

F16G-1500

F16G-1547

F16G-1594

F16G-1641

F24G-1969

F24G-2031

F24G-2094

F24G-2156

F32G-2531

F32G-2594

F32G-2656

F32G-2719

Hose

ID

3"

4"

Hose OD 304 stainless steel

from to Part #

3-39/64"

3-40/64"

3-44/64"

3-48/64"

3-52/64"

3-56/64"

4-40/64"

4-44/64"

4-48/64"

4-52/64"

4-56/64"

3-42/64"

3-43/64"

3-47/64"

3-51/64"

3-55/64"

3-59/64"

4-43/64"

4-47/64"

4-51/64"

4-55/64"

4-59/64"

F48G-3625

F48G-3688

F48G-3750

F48G-3813

F48G-3875

F48G-3938

F64G-4688

F64G-4750

F64G-4813

F64G-4875

F64G-4938

17877.963.4966 • www.dixonvalve.com

Page 18

Holedall

Crimped Sanitary Recommendation Guide

See page 17 for Crimp Sanitary products.

1", 1½” and 2” Crimped Sanitary Fittings

Holedall

Hose ID Stem Part # Ferrule Part #

1"

K

1½”

CSSR100

CBSR100

CSSR150

CBSR150

CILR150

CTER150

2”

CSSR200

CBSR200

CILR200

CTER200

F16G-1453

F16G-1500

F16G-1547

F16G-1594

F16G-1641

F24G-1969

F24G-2031

F24G-2094

F24G-2156

F32G-2531

F32G-2594

F32G-2656

F32G-2719

Hose OD

Fractional Decimal

1 26/64

1 27/64

1 28/64

1 29/64

1 30/64

1 31/64

1 32/64

1 33/64

1 34/64

1 35/64

1 36/64

1 37/64

1 38/64

1 39/64

1 40/64

1 58/64

1 59/64

1 60/64

1 61/64

1 62/64

1 63/64

2

2 1/64

2 2/64

2 3/64

2 4/64

2 5/64

2 6/64

2 7/64

2 8/64

2 9/64

2 30/64

2 31/64

2 32/64

2 33/64

2 34/64

2 35/64

2 36/64

2 37/64

2 38/64

2 39/64

2 40/64

2 41/64

2 42/64

2 43/64

2 44/64

2 45/64

1.406

1.422

1.438

1.453

1.469

1.484

1.500

1.516

1.531

1.547

1.563

1.578

1.594

1.609

1.625

1.906

1.922

1.938

1.953

1.969

1.984

2.000

2.016

2.031

2.047

2.063

2.078

2.094

2.109

2.125

2.141

2.469

2.484

2.500

2.516

2.531

2.547

2.563

2.578

2.594

2.609

2.625

2.641

2.656

2.672

2.688

2.703

Crimp Diameter

(±0.005)

1.565

1.577

1.589

1.601

1.613

1.625

1.637

1.649

1.661

1.673

1.685

1.697

1.709

1.721

1.733

2.063

2.075

2.087

2.099

2.111

2.123

2.135

2.147

2.159

2.171

2.183

2.195

2.207

2.219

2.231

2.243

2.611

2.623

2.635

2.647

2.659

2.671

2.683

2.695

2.707

2.719

2.731

2.743

2.755

2.767

2.779

2.791

% Reduction

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

18 877.963.4966 • www.dixonvalve.com

Page 19

Holedall

Crimped Sanitary Recommendation Guide

See page 17 for Crimp Sanitary products.

3" and 4" Crimped Sanitary Fittings

Hose ID Stem Part # Ferrule Part #

3"

CSSR300

CBSR300

F24G-1969

F48G-3625

CILR300

CTER300

F48G-3688

F48G-3750

F48G-3813

F48G-3875

F48G-3938

4"

CSSR400

F64G-4688

CBSR400

CILR400

CTER400

F64G-4750

F64G-4813

F64G-4875

F64G-4938

Hose OD

Fractional Decimal

3 36/64

3 37/64

3 38/64

3 39/64

3 40/64

3 41/64

3 42/64

3 43/64

3 44/64

3 45/64

3 46/64

3 47/64

3 48/64

3 49/64

3 50/64

3 51/64

3 52/64

3 53/64

3 54/64

3 55/64

3 56/64

3 57/64

3 58/64

3 59/64

4 40/64

4 41/64

4 42/64

4 43/64

4 44/64

4 45/64

4 46/64

4 47/64

4 48/64

4 49/64

4 50/64

4 51/64

4 52/64

4 53/64

4 54/64

4 55/64

4 56/64

4 57/64

4 58/64

4 59/64

3.563

3.578

3.594

3.609

3.625

3.641

3.656

3.672

3.688

3.703

3.719

3.734

3.750

3.766

3.781

3.797

3.813

3.828

3.844

3.859

3.875

3.891

3.906

3.922

4.625

4.641

4.656

4.672

4.688

4.703

4.719

4.734

4.750

4.766

4.781

4.797

4.813

4.828

4.844

4.859

4.875

4.891

4.906

4.922

Crimp Diameter

(±0.005)

3.683

3.695

3.707

3.719

3.731

3.743

3.755

3.767

3.779

3.791

3.803

3.815

3.828

3.840

3.852

3.864

3.876

3.888

3.900

3.912

3.924

3.936

3.948

3.960

4.857

4.869

4.881

4.893

4.905

4.917

4.929

4.941

4.954

4.966

4.978

4.990

5.002

5.014

5.026

5.038

5.050

5.062

5.074

5.086

% Reduction

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

23%

K

Holedall

19877.963.4966 • www.dixonvalve.com

Page 20

Cam & Groove

Swaged Cam and Groove

• Developed specically for chemical transport hoses having Crosslinked Polyethylene (XLPE) or Ultra High Molecular Weight

Polyethylene (UHMW) tubes. Swaged Boss-Lock provides you with a permanently attached Cam and Groove tting when

superior coupling retention is required.

• In testing tank transport hoses from a wide variety of manufacturers, the swaged Boss-Lock tting proved itself to be the clear

winner in overall performance.

• Fittings are also available on special order for other sizes or hose OD's. Consult the factory for pricing and availability.

• Consult the factory for pricing and availability of the special equipment required for installation or refer to pages 2-3.

EZ Boss-Lock type C Coupler with Ferrule

Hose OD 316 Stainless Steel

from to Part #

1-6/64"

1-29/64"

1-36/64"

1-22/64"

1-35/64"

1-44/64"

RC075EZ-70

RC100EZ-20

RC100EZ-70

coupler x hose shank with ferrule

Size

¾"

1"

1"

A

Cam &

Groove

adapter x hose shank with ferrule

Boss-Lock type E Adapter with Ferrule

Size

¾"

1"

1"

Hose OD 316 Stainless Steel

from to Part #

1-6/64"

1-29/64"

1-36/64"

1-22/64"

1-35/64"

1-44/64"

RE075-1370

RE100-1620

RE100-1770

Crimp Sleeves

• The hose OD ranges for the crimp sleeves are the same as for Dixon’s standard cam and

groove notched ferrules.

• The crimp sleeve is not designed to be used in applications where the assembly is

exposed to high temperatures.

• Carbon steel is also available. Contact the factory for pricing and availability.

Size

2"

3"

Dixon stems and ferrules are specically designed to be used together as a coupling system.

Due to differences in dimensions and tolerances for safety reasons, do not use other

Hose OD 304 Stainless Steel

from to Part #

2-30/64"

3-30/64"

manufacturer's stems or ferrules with Dixon Holedall products.

2-44/64"

3-46/64"

GCS2709

GCS3760

Notched Ferrules

Size

1½"

1½"

2"

2"

3"

3"

4"

Dixon stems and ferrules are specically designed to be used together as a coupling system.

Due to differences in dimensions and tolerances for safety reasons, do not use other

20 877.963.4966 • www.dixonvalve.com

Hose OD 304 Stainless Steel

from to Part #

1-60/64"

2-4/64"

2-30/64"

2-42/64"

3-30/64"

3-47/64"

4-40/64"

manufacturer's stems or ferrules with Dixon Holedall products.

2-12/64"

2-22/64"

2-44/64"

2-54/64"

3-46/64"

3-54/64"

4-47/64"

GAS2334NO

GAS2370NO

GAS2709NO

GAS2885NO

GAS3760NO

GAS3885NO

GAS5010NO

Page 21

Cam & Groove

Notched Cam and Groove

• The largest advantage of the notched EZ Boss-Lock design is that the coupling can be removed from a damaged hose be

cutting away the ferrule, without necessarily damaging the tting. After inspection to of the tting determine its suitability

for reuse, it can be reinstalled into another hose by using a new ferrule.

• The notched EZ Boss-Lock system allows you to better manage your inventories. You can stock one coupling and two

ferrules, and cover the same hose range with less inventory. You must purchase a tting and the matching ferrule to create

an assembly.

Dixon stems and ferrules are specically designed to be used together as a coupling system.

Due to differences in dimensions and tolerances for safety reasons, do not use other

manufacturer's stems or ferrules with Dixon Holedall products.

Couplers

EZ Boss-Lock type C

Size

1½"

2"

3"

4"

316 Stainless Steel

Part #

RC150EZNO

RC200EZNO

RC300EZNO

RC400EZNO

A

Cam &

Groove

Size

1½"

2"

3"

4"

crimped assembly

Size

1½"

2"

3"

4"

Boss-Lock type C

316 Stainless Steel

Part #

RC150BLNO

RC200BLNO

RC300BLNO

RC400BLNO

Contact the factory for swage

and crimp recommendations.

Adapters

Boss-Lock type E

316 Stainless Steel

Part #

RE150NO

RE200NO

RE300NO

RE400NO

female coupler x

notched hose shank

female coupler x

notched hose shank

swaged assembly

swaged assembly

Contact the factory for swage

and crimp recommendations.

male adapter x

notched hose shank

crimped assembly

21877.963.4966 • www.dixonvalve.com

Page 22

Cam & Groove

Dixon Notched NOS Shank Cam and Groove

• For hose outside diameters of 2-4/64" and below, the couplings are crimp only.

• For hose outside diameters of 2-5/64" and above, the couplings can be crimped or swaged.

• See page 34 for male NPT notched NOS ttings.

Only use the NOS shank with the NOS ferrules.

Due to differences in dimensions and tolerances for safety reasons, do not use other

manufacturer's stems or ferrules with Dixon Holedall products.

Couplers

Dixon type C

316 Stainless Steel

Cam &

Groove

Size

1½"

A

2"

3"

Part #

150CNOSSS

200CNOSSS

300CNOSSS

female coupler x

notched NOS hose shank

male adapter x

notched NOS hose shank

crimped assembly

Size

1½"

2"

3"

swaged assembly

Contact the factory for swage

and crimp recommendations.

Adapters

Contact the factory for swage

and crimp recommendations.

swaged assembly

type E

316 Stainless Steel

Part #

150ENOSSS

200ENOSSS

300ENOSSS

crimped assembly

Notched NOS Ferrules

Size

1½"

1½"

2"

2"

3"

3"

22 877.963.4966 • www.dixonvalve.com

Hose OD 304 Stainless Steel

from to Part #

1-60/64"

2-4/64"

2-30/64"

2-42/64"

3-30/64"

3-47/64"

2-12/64"

2-22/64"

2-44/64"

2-54/64"

3-46/64"

3-54/64"

GAS2334NOS

GAS2370NOS

GAS2709NOS

GAS2885NOS

GAS3760NOS

GAS3885NOS

Page 23

Cam & Groove

Interlocking Style External Crimp Ferrules

Dixon’s External Crimp Ferrules are designed for use with Dixon’s Type C and E hose shanks. This design offers 360°

interlocking with approved Dixon hose shanks and can be installed with any Dixon crimper system. For crimp specications

please refer to pages 24-26.

• designed to be used on aluminum Dixon grooved hose

shanks (1½", 2", 3", 4")

• carbon steel for rugged applications

• 1½" – 2" features .063" wall thickness

• 3" – 4" features .125" wall thickness

Size

1½"

2"

3"

4"

Hose OD Carbon Steel Aluminum Aluminum

from to Part # Adapter Part# Coupler Part#

1-49/64"

1-53/64"

1-57/64"

1-61/64"

2-1/64"

2-5/64"

2-9/64"

2-13/64"

2-17/64"

2-21/64"

2-21/64"

2-25/64"

2-29/64"

2-33/64"

2-37/64"

2-41/64"

2-45/64"

2-49/64"

2-53/64"

2-57/64"

3-23/64"

3-27/64"

3-31/64"

3-35/64"

3-39/64"

3-43/64"

3-47/64"

3-51/64"

3-55/64"

3-59/64"

4-23/64"

4-27/64"

4-31/64"

4-35/64"

4-39/64"

4-43/64"

4-47/64"

4-51/64"

4-55/64"

4-59/64"

1-52/64"

1-56/64"

1-60/64"

2"

2-4/64"

2-8/64"

2-12/64"

2-16/64"

2-20/64"

2-24/64"

2-24/64"

2-28/64"

2-32/64"

2-36/64"

2-40/64"

2-44/64"

2-48/64"

2-52/64"

2-56/64"

2-60/64"

3-26/64"

3-30/64"

3-34/64"

3-38/64"

3-42/64"

3-46/64"

3-50/64"

3-54/64"

3-58/64"

3-62/64"

4-26/64"

4-30/64"

4-34/64"

4-38/64"

4-42/64"

4-46/64"

4-50/64"

4-54/64"

4-58/64"

4-62/64"

CF150-1

CF150-2

CF150-3

CF150-4

CF150-5

CF150-6

CF150-7

CF150-8

CF150-9

CF150-10

CF200-1

CF200-2

CF200-3

CF200-4

CF200-5

CF200-6

CF200-7

CF200-8

CF200-9

CF200-10

CF300-1

CF300-2

CF300-3

CF300-4

CF300-5

CF300-6

CF300-7

CF300-8

CF300-9

CF300-10

CF400-1

CF400-2

CF400-3

CF400-4

CF400-5

CF400-6

CF400-7

CF400-8

CF400-9

CF400-10

• turnover edge is sliced for easy ferrule removal

• large offering of ID sizes to match your hose OD

• streamlined and safe nal assembly

• Do NOT interchange with other products.

150-E-AL

200-E-AL

300-E-AL

400-E-AL

150-C-AL

200-C-AL

300-C-AL

400-C-AL

interlocking crimp ferrule

type E Dixon cam & groove

type C Dixon cam & groove

A

Cam &

Groove

23877.963.4966 • www.dixonvalve.com

Page 24

Cam & Groove

Crimped Interlocking Cam & Groove Recommendation Guide

See page 23 for Interlocking Cam & Groove products.

1½" Interlocking Style Cam and Groove

Cam &

Groove

Hose ID Ferrule Part #

1½" CF150-1

A

CF150-2

CF150-3

CF150-4

CF150-5

CF150-6

CF150-7

CF150-8

CF150-9

CF150-10

Hose OD

Fractional Decimal

1-49/64

1-50/64

1-51/64

1-52/64

1-53/64

1-54/64

1-55/64

1-56/64

1-57/64

1-58/64

1-59/64

1-60/64

1-61/64

1-62/64

1-63/64

2

2-1/64

2-2/64

2-3/64

2-4/64

2-5/64

2-6/64

2-7/64

2-8/64

2-9/64

2-10/64

2-11/64

2-12/64

2-13/64

2-14/64

2-15/64

2-16/64

2-17/64

2-18/64

2-19/64

2-20/64

2-21/64

2-22/64

2-23/64

2-24/64

1.766

1.781

1.797

1.813

1.828

1.844

1.859

1.875

1.891

1.906

1.922

1.938

1.953

1.969

1.984

2.000

2.016

2.031

2.047

2.063

2.078

2.094

2.109

2.125

2.141

2.156

2.172

2.188

2.203

2.219

2.234

2.250

2.266

2.281

2.297

2.313

2.328

2.344

2.359

2.375

Crimp Diameter

(±0.005)

1.845

1.857

1.870

1.882

1.895

1.907

1.920

1.932

1.945

1.957

1.970

1.982

1.995

2.007

2.020

2.032

2.045

2.057

2.070

2.082

2.095

2.107

2.120

2.132

2.145

2.157

2.170

2.182

2.195

2.207

2.220

2.232

2.245

2.257

2.270

2.282

2.295

2.307

2.320

2.332

% Reduction Crimp Die # Offset

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

45

45

45

45

45

45

45

45

45

45

45

45

45

45

51

51

51

51

51

51

51

51

51

51

51

51

51

51

51

51

51

51

57

57

57

57

57

57

57

57

0.072

0.085

0.097

0.110

0.123

0.135

0.148

0.160

0.173

0.185

0.198

0.210

0.223

0.235

0.011

0.024

0.036

0.049

0.061

0.074

0.087

0.099

0.112

0.124

0.137

0.149

0.162

0.174

0.187

0.199

0.212

0.224

0.000

0.013

0.025

0.038

0.050

0.063

0.075

0.088

2" Interlocking Style Cam and Groove

2-21/64

2-22/64

2-23/64

2-24/64

2-25/64

2-26/64

2-27/64

2-28/64

2-29/64

2-30/64

2-31/64

2-32/64

2-33/64

2-34/64

2-35/64

2-36/64

2-37/64

2-38/64

2-39/64

2-40/64

Hose OD

2.328

2.344

2.359

2.375

2.391

2.406

2.422

2.438

2.453

2.469

2.484

2.500

2.516

2.531

2.547

2.563

2.578

2.594

2.609

2.625

Hose ID Ferrule Part #

2" CF200-1

CF200-2

CF200-3

CF200-4

CF200-5

24 877.963.4966 • www.dixonvalve.com

Fractional Decimal

Crimp Diameter

(±0.005)

2.388

2.400

2.413

2.425

2.438

2.450

2.463

2.475

2.488

2.500

2.513

2.525

2.538

2.550

2.563

2.575

2.588

2.600

2.613

2.625

% Reduction Crimp Die # Offset

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

57

57

57

57

57

57

57

57

63

63

63

63

63

63

63

63

63

63

63

63

0.144

0.156

0.169

0.181

0.194

0.206

0.219

0.231

0.007

0.020

0.033

0.045

0.058

0.070

0.083

0.095

0.108

0.120

0.133

0.145

Page 25

Cam & Groove

Crimped Interlocking Cam & Groove Recommendation Guide

See page 23 for Interlocking Cam & Groove products.

2" Interlocking Style Cam and Groove

Hose ID Ferrule Part #

2" CF200-6

CF200-7

CF200-8

CF200-9

CF200-10

Hose ID Ferrule Part #

3" CF300-1

CF300-2

CF300-3

CF300-4

CF300-5

CF300-6

CF300-7

CF300-8

CF300-9

CF300-10

Hose OD

Fractional Decimal

2-41/64

2-42/64

2-43/64

2-44/64

2-45/64

2-46/64

2-47/64

2-48/64

2-49/64

2-50/64

2-51/64

2-52/64

2-53/64

2-54/64

2-55/64

2-56/64

2-57/64

2-58/64

2-59/64

2-60/64

2.641

2.656

2.672

2.688

2.703

2.719

2.734

2.750

2.766

2.781

2.797

2.813

2.828

2.844

2.859

2.875

2.891

2.906

2.922

2.938

Crimp Diameter

(±0.005)

2.638

2.650

2.663

2.675

2.688

2.700

2.713

2.725

2.738

2.750

2.763

2.775

2.788

2.800

2.813

2.825

2.838

2.850

2.863

2.875

3" Interlocking Style Cam and Groove

Hose OD

Fractional Decimal

3-23/64

3-24/64

3-25/64

3-26/64

3-27/64

3-28/64

3-29/64

3-30/64

3-31/64

3-32/64

3-33/64

3-34/64

3-35/64

3-36/64

3-37/64

3-38/64

3-39/64

3-40/64

3-41/64

3-42/64

3-43/64

3-44/64

3-45/64

3-46/64

3-47/64

3-48/64

3-49/64

3-50/64

3-51/64

3-52/64

3-53/64

3-54/64

3-55/64

3-56/64

3-57/64

3-58/64

3-59/64

3-60/64

3-61/64

3-62/64

3.359

3.375

3.391

3.406

3.422

3.438

3.453

3.469

3.484

3.500

3.516

3.531

3.547

3.563

3.578

3.594

3.609

3.625

3.641

3.656

3.672

3.688

3.703

3.719

3.734

3.750

3.766

3.781

3.797

3.813

3.828

3.844

3.859

3.875

3.891

3.906

3.922

3.938

3.953

3.969

Crimp Diameter

(±0.005)

3.553

3.565

3.578

3.590

3.603

3.615

3.628

3.640

3.653

3.665

3.678

3.690

3.703

3.715

3.728

3.740

3.753

3.765

3.778

3.790

3.803

3.815

3.828

3.840

3.853

3.865

3.878

3.890

3.903

3.915

3.928

3.940

3.953

3.965

3.978

3.990

4.003

4.015

4.028

4.040

% Reduction Crimp Die # Offset

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

% Reduction Crimp Die # Offset

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

63

63

63

63

63

63

63

69

69

69

69

69

69

69

69

69

69

69

69

69

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

96

96

96

96

96

96

96

96

96

96

96

96

96

96

96

96

96

96

96

102

102

0.158

0.170

0.183

0.195

0.208

0.220

0.233

0.008

0.020

0.033

0.046

0.058

0.071

0.083

0.095

0.108

0.121

0.133

0.146

0.158

0.010

0.022

0.035

0.047

0.059

0.072

0.084

0.097

0.110

0.122

0.135

0.147

0.160

0.172

0.185

0.197

0.210

0.222

0.235

0.010

0.023

0.035

0.048

0.060

0.073

0.085

0.098

0.110

0.123

0.135

0.148

0.160

0.173

0.185

0.198

0.210

0.223

0.235

0.011

0.024

A

Cam &

Groove

25877.963.4966 • www.dixonvalve.com

Page 26

Cam & Groove

Crimped Interlocking Cam & Groove Recommendation Guide

See page 23 for Interlocking Cam & Groove products.

4" Interlocking Style Cam and Groove

Cam &

Groove

Hose ID Ferrule Part #